CN111519894A - Concrete placement encloses fender support steel form - Google Patents

Concrete placement encloses fender support steel formDownload PDFInfo

- Publication number

- CN111519894A CN111519894ACN202010372170.8ACN202010372170ACN111519894ACN 111519894 ACN111519894 ACN 111519894ACN 202010372170 ACN202010372170 ACN 202010372170ACN 111519894 ACN111519894 ACN 111519894A

- Authority

- CN

- China

- Prior art keywords

- corner plate

- support

- baffle

- plate

- stabilizing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G9/00—Forming or shuttering elements for general use

- E04G9/02—Forming boards or similar elements

- E04G9/06—Forming boards or similar elements the form surface being of metal

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G11/00—Forms, shutterings, or falsework for making walls, floors, ceilings, or roofs

- E04G11/06—Forms, shutterings, or falsework for making walls, floors, ceilings, or roofs for walls, e.g. curved end panels for wall shutterings; filler elements for wall shutterings; shutterings for vertical ducts

- E04G11/08—Forms, which are completely dismantled after setting of the concrete and re-built for next pouring

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G17/00—Connecting or other auxiliary members for forms, falsework structures, or shutterings

- E04G17/14—Bracing or strutting arrangements for formwalls; Devices for aligning forms

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Forms Removed On Construction Sites Or Auxiliary Members Thereof (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及建筑施工技术领域,特别涉及一种混凝土浇筑围挡支护钢模板。The invention relates to the technical field of building construction, in particular to a concrete casting enclosure supporting steel formwork.

背景技术Background technique

在现代建筑中建筑的支撑柱一般通过混凝土浇筑的方式进行施工,混凝土浇筑前需要在支撑柱的位置处搭建钢结构支架,然后通过钢模板将搭建的钢结构支架进行围挡支撑,之后在刚摸板组成的结构内浇筑混凝土,使得支撑柱能够以刚摸板组成的结构进行成型,支撑柱成型后将钢模板进行拆除。In modern buildings, the support columns of buildings are generally constructed by concrete pouring. Before the concrete is poured, a steel structure bracket needs to be built at the position of the support column, and then the built steel structure bracket is fenced and supported by a steel formwork. Concrete is poured into the structure composed of the formwork, so that the support column can be formed with the structure composed of the formwork, and the steel formwork is removed after the support column is formed.

钢模板的边角的接合处一般通过钢筋柱进行围挡支护,之后通过卡夹将钢筋柱围挡进行锁定,现有钢模板接合处的围挡支撑存在的问题如下:The joints of the corners of the steel formwork are generally fenced and supported by reinforced columns, and then the reinforced column fences are locked by clips. The existing problems of the fence support at the joints of the steel formwork are as follows:

1.钢模板的接合处无法进行锁定成一个整体,使得钢模板内浇筑混凝土时钢模板会发生倾斜或者偏斜,造成钢模板的稳定性较差;1. The joints of the steel formwork cannot be locked into a whole, so that the steel formwork will be inclined or skewed when concrete is poured into the steel formwork, resulting in poor stability of the steel formwork;

2.钢结构围挡支撑安装步骤较为繁琐,且钢模板的接合位置会发生一定程度的位移,导致建筑的支撑柱成型效果差。2. The installation steps of the steel structure enclosure support are cumbersome, and the joint position of the steel formwork will be displaced to a certain extent, resulting in the poor forming effect of the support column of the building.

发明内容SUMMARY OF THE INVENTION

为了解决上述问题,本发明提供了一种混凝土浇筑围挡支护钢模板,包括横挡板、纵挡板、转角板、支护平台、斜支杆和侧支机构,所述的横挡板横向竖直布置,纵挡板纵向竖直布置,横挡板的外侧面为空心结构,横挡板的空心结构内从上到下设置有支撑筋,支撑筋上均匀设置有圆孔,横挡板与纵挡板的结构相同,且横挡板的右端与纵挡板的前端相叠合,所述的转角板为L型结构,转角板位于横挡板与纵挡板叠合位置的外侧,转角板的右端前侧与斜支杆的上端相连接,斜支杆的下端通过铰链安装在支护平台上,支护平台通过膨胀螺栓安装在地面上,转角板的左端与后端均分布有一个侧支机构,侧支机构安装在转角板与支护平台之间,本发明能够对横挡板与纵挡板的交接处进行支护,并与横挡板与纵挡板形成一体结构,增加横挡板与纵挡板之间的稳定性,提高模板的支护效果,斜支杆能够对转角板进行支撑,增加转角板与横挡板、纵挡板连接的紧密度。In order to solve the above problems, the present invention provides a concrete casting enclosure support steel formwork, which includes a transverse baffle, a longitudinal baffle, a corner plate, a supporting platform, an oblique support rod and a side support mechanism. Horizontal and vertical arrangement, vertical vertical arrangement of vertical baffle, the outer side of the horizontal baffle is a hollow structure, the hollow structure of the horizontal baffle is provided with support ribs from top to bottom, the support ribs are evenly provided with circular holes, the horizontal baffle The structure of the plate is the same as that of the vertical baffle, and the right end of the horizontal baffle is superimposed with the front end of the vertical baffle. The corner plate is an L-shaped structure, and the corner plate is located outside the overlapping position of the horizontal baffle and the vertical baffle , the front side of the right end of the corner plate is connected with the upper end of the diagonal support rod, the lower end of the diagonal support rod is installed on the support platform through hinges, the support platform is installed on the ground through expansion bolts, and the left and rear ends of the corner plate are distributed. There is a side support mechanism, the side support mechanism is installed between the corner plate and the support platform, the present invention can support the junction of the horizontal baffle and the vertical baffle, and form an integrated structure with the horizontal baffle and the vertical baffle , Increase the stability between the horizontal baffle and the vertical baffle, improve the support effect of the formwork, the diagonal strut can support the corner plate, and increase the tightness of the connection between the corner plate and the horizontal baffle and the vertical baffle.

所述的侧支机构包括定位块、螺柱、定位螺栓、侧支板、侧支杆和锁定螺帽,定位块的数量为二,转角板的左端的两个定位块分别分布在横挡板上端相邻的两个支撑筋之间与横挡板下端相邻的两个支撑筋之间,转角板的后端的两个定位块分别分布在纵挡板上端相邻的两个支撑筋之间与纵挡板下端相邻的两个支撑筋之间,定位块的中部设置有插孔;The side support mechanism includes a positioning block, a stud, a positioning bolt, a side support plate, a side support rod and a locking nut. The number of positioning blocks is two, and the two positioning blocks at the left end of the corner plate are respectively distributed on the horizontal baffle. Between the two supporting ribs adjacent to the upper end and between the two supporting ribs adjacent to the lower end of the transverse baffle, the two positioning blocks at the rear end of the corner plate are respectively distributed between the two supporting ribs adjacent to the upper end of the longitudinal baffle Between the two supporting ribs adjacent to the lower end of the longitudinal baffle, the middle part of the positioning block is provided with an insertion hole;

定位螺栓穿过支撑筋上的圆孔与定位块上的插孔,定位螺栓的下端通过螺母进行锁定,转角板的左端与后端对应每个定位块的位置处均设置有方槽,定位块的前侧面上安装有螺柱,螺柱的外端穿过方槽,侧支板套设在螺柱的外侧,螺柱的外端通过锁定螺帽锁定在侧支板的外侧面上;The positioning bolts pass through the round holes on the support ribs and the jacks on the positioning blocks. The lower ends of the positioning bolts are locked by nuts. The left and rear ends of the corner plate are provided with square slots corresponding to the positions of each positioning block. A stud is installed on the front side of the stud, the outer end of the stud passes through the square groove, the side support plate is sleeved on the outer side of the stud, and the outer end of the stud is locked on the outer side of the side support plate by a locking nut;

每个侧支板的外侧面上均通过铰链与一个侧支杆的上端相连接,侧支杆的下端与支护平台相连接,具体工作时,侧支机构能够将横挡板、纵挡板与转角板进行紧密连接,并通过侧支杆对横挡板、纵挡板的侧面进行支撑,增加模板的支护时的稳定性,定位块通过定位螺栓安装在支撑筋之间,使得定位块的位置得到限定,通过锁定螺帽能够将定位块前端的螺柱锁定在侧支板上,从而增加横挡板或纵挡板与转角板之间的一体化效果,侧支杆能够对转角板的上下两端分别进行支撑。The outer surface of each side support plate is connected with the upper end of a side support rod through a hinge, and the lower end of the side support rod is connected with the support platform. It is closely connected with the corner plate, and supports the sides of the transverse baffle and the longitudinal baffle through the side struts to increase the stability of the formwork during support. The positioning block is installed between the supporting ribs through the positioning bolts, so that the positioning block The position of the bracket is limited, and the stud at the front end of the positioning block can be locked on the side support plate by the locking nut, so as to increase the integration effect between the horizontal baffle or the vertical baffle and the corner plate, and the side support rod can be opposite to the corner plate. The upper and lower ends are supported respectively.

作为本发明的一种优选技术方案,所述的转角板的右端前侧设置有斜支槽,斜支槽所在的平面与转角板的前侧面之间的夹角为四十五度,斜支槽上安装有斜支连架,斜支连架为π型结构,斜支连架的中部外侧面与斜支杆的上端通过铰链相连接,且斜支杆轴心线所在的竖直平面垂直于斜支槽所在的平面,且两个侧支机构以斜支杆轴心线所在的竖直平面为对称面对称布置,这种设置使得两个侧支机构能够对转角板施加对称的支撑力,增加转角板的稳定性,斜支杆通过斜支连架将支撑力均匀作用在转角板设置的斜支槽上。As a preferred technical solution of the present invention, the front side of the right end of the corner plate is provided with an inclined support groove, and the angle between the plane where the inclined support groove is located and the front side of the corner plate is 45 degrees, and the inclined support groove is 45 degrees. There is an inclined support connecting frame installed on the groove, and the inclined support connecting frame is a π-shaped structure. In the plane where the inclined support groove is located, and the two side support mechanisms are symmetrically arranged on the vertical plane where the axis line of the inclined support rod is located, this arrangement enables the two side support mechanisms to apply symmetrical support to the corner plate It increases the stability of the corner plate, and the oblique support rod evenly acts on the oblique support groove set on the corner plate through the oblique support connecting frame.

作为本发明的一种优选技术方案,所述的支护平台的右端前侧设置有三角形凸起,斜支杆的底部通过铰链与三角形凸起相连接,三角形凸起能够增加斜支杆对转角板的支撑效果。As a preferred technical solution of the present invention, the front side of the right end of the support platform is provided with a triangular protrusion, the bottom of the oblique support rod is connected with the triangular protrusion through a hinge, and the triangular protrusion can increase the angle of rotation of the diagonal support rod. plate support.

作为本发明的一种优选技术方案,所述的转角板的右端后侧面上设置有稳固槽,稳固槽内通过滑动配合的方式连接有稳固块,稳固块的前侧面通过轴承与稳固螺栓的后端相连接,稳固螺栓穿过转角板,且稳固螺栓的中部通过螺纹配合的方式与转角板相连接,通过转动稳固螺栓能够带动稳固块在稳固槽内滑动,使得稳固槽的后侧面与左侧面能够分别撑在纵挡板与横挡板上,防止混凝土浇筑时纵挡板与横挡板的交接位置发生位移。As a preferred technical solution of the present invention, a stabilization groove is provided on the rear side of the right end of the corner plate, and a stabilization block is connected in the stabilization groove by sliding fit. The ends are connected, the stabilizing bolt passes through the corner plate, and the middle part of the stabilizing bolt is connected with the corner plate by means of threaded fitting. By rotating the stabilizing bolt, the stabilizing block can be driven to slide in the stabilizing groove, so that the rear side of the stabilizing groove is connected to the left side of the stabilizing groove. The surface can be supported on the vertical baffle and the horizontal baffle respectively to prevent the displacement of the junction position of the vertical baffle and the horizontal baffle when the concrete is poured.

作为本发明的一种优选技术方案,所述的稳固块的后侧面与后端左侧面上均设置有橡胶垫,稳固块的前侧面设置有稳固杆,稳固杆穿过转角板,稳固块设置的橡胶垫能够增加稳固块与纵挡板、横挡板的贴合效果,稳固杆在稳固块进行前后位置调节时增加其稳定性。As a preferred technical solution of the present invention, rubber pads are provided on the rear side and the left side of the rear end of the stabilizer block, and a stabilizer rod is provided on the front side of the stabilizer block. The stabilizer rod passes through the corner plate, and the stabilizer block The rubber pad provided can increase the fitting effect of the stabilizing block with the vertical baffle and the horizontal baffle, and the stabilizing rod increases the stability of the stabilizing block when the front and rear positions of the stabilizing block are adjusted.

作为本发明的一种优选技术方案,位于转角板上端的所述侧支杆的底部通过铰链安装在支护平台的顶部上,位于转角板下端的侧支杆的底部通过铰链安装在支护平台的内侧面上,且转角板上端侧支杆的尺寸大于转角板下端侧支杆的尺寸,侧支杆这种安装方式使得侧支杆能够以不同的方向对转角板进行支撑。As a preferred technical solution of the present invention, the bottom of the side strut located at the upper end of the corner plate is mounted on the top of the support platform through a hinge, and the bottom of the side strut located at the lower end of the corner plate is mounted on the support platform through a hinge. On the inner side of the corner board, and the size of the upper-side support rod on the corner board is larger than the size of the lower-end side support rod of the corner board, the installation method of the side support rod enables the side support rod to support the corner board in different directions.

作为本发明的一种优选技术方案,所述的斜支杆与侧支杆均为可伸缩结构,斜支杆与侧支杆的可伸缩结构能够使其具有一定力度的进行支撑动作。As a preferred technical solution of the present invention, the diagonal struts and the side struts are both retractable structures, and the retractable structures of the oblique struts and the side struts enable them to perform supporting actions with a certain strength.

本发明的有益效果在于:The beneficial effects of the present invention are:

一、本发明能够对横挡板、纵挡板的交接位置处通过L型的转角板进行支护,通过将转角板与横挡板、纵挡板进行一体化锁定连接能够增加模板之间的稳定性,增加模板在混凝土浇筑时的支护效果,本发明还能够将横挡板、纵挡板交接位置进行支撑,防止横挡板、纵挡板交接位置发生位移;1. The present invention can support the intersection of the horizontal baffle and the vertical baffle through the L-shaped corner plate, and can increase the distance between the templates by integrally locking the corner plate with the horizontal baffle and the vertical baffle. stability, increasing the support effect of the formwork during concrete pouring, and the present invention can also support the cross-over position of the horizontal baffle and the vertical baffle to prevent displacement of the cross-over position of the horizontal baffle and the vertical baffle;

二、本发明侧支机构对称布置使得两个侧支机构能够对转角板施加对称的支撑力,增加转角板的稳定性;2. The symmetrical arrangement of the side support mechanisms of the present invention enables the two side support mechanisms to apply symmetrical supporting force to the corner plate, thereby increasing the stability of the corner plate;

三、本发明侧支机构能够将横挡板、纵挡板与转角板进行紧密连接,并将横挡板、纵挡板与转角板连接形成一个整体;3. The side support mechanism of the present invention can tightly connect the horizontal baffle, the vertical baffle and the corner plate, and connect the horizontal baffle, the vertical baffle and the corner plate to form a whole;

四、本发明稳固螺栓能够带动稳固块在稳固槽内滑动,使得稳固槽的后侧面与左侧面能够分别撑在纵挡板与横挡板上,防止混凝土浇筑时纵挡板与横挡板的交接位置发生位移。Fourth, the stabilizing bolt of the present invention can drive the stabilizing block to slide in the stabilizing groove, so that the rear side and the left side of the stabilizing groove can be supported on the vertical baffle and the horizontal baffle respectively, so as to prevent the vertical baffle and the horizontal baffle during concrete pouring The transfer position is shifted.

附图说明Description of drawings

下面接合附图和实施例对本发明进一步说明。The present invention will be further described below with reference to the accompanying drawings and embodiments.

图1是本发明的第一结构示意图;Fig. 1 is the first structural representation of the present invention;

图2是本发明的第二结构示意图;Fig. 2 is the second structural representation of the present invention;

图3是本发明的第三结构示意图;Fig. 3 is the third structural representation of the present invention;

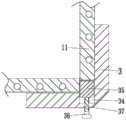

图4是本发明横挡板、纵挡板与转角板之间的剖视图;Fig. 4 is the cross-sectional view between the horizontal baffle plate, the vertical baffle plate and the corner plate of the present invention;

图5是本发明转角板、支护平台与侧支机之间的结构示意图。5 is a schematic diagram of the structure between the corner plate, the support platform and the side supporter of the present invention.

具体实施方式Detailed ways

为了使本发明实现的技术手段、创作特征、达成目的与功效易于明白了解,下面接合具体图示,进一步阐述本发明。需要说明的是,在不冲突的情况下,本申请中的实施例及实施例中的特征可以相互接合。In order to make it easy to understand the technical means, creative features, goals and effects realized by the present invention, the present invention will be further described below in conjunction with specific illustrations. It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other without conflict.

如图1至图5所示,一种混凝土浇筑围挡支护钢模板,包括横挡板1、纵挡板2、转角板3、支护平台4、斜支杆5和侧支机构6,所述的横挡板1横向竖直布置,纵挡板2纵向竖直布置,横挡板1的外侧面为空心结构,横挡板1的空心结构内从上到下设置有支撑筋11,支撑筋11上均匀设置有圆孔,横挡板1与纵挡板2的结构相同,且横挡板1的右端与纵挡板2的前端相叠合,所述的转角板3为L型结构,转角板3位于横挡板1与纵挡板2叠合位置的外侧,转角板3的右端前侧与斜支杆5的上端相连接,斜支杆5的下端通过铰链安装在支护平台4上,支护平台4通过膨胀螺栓安装在地面上,转角板3的左端与后端均分布有一个侧支机构6,侧支机构6安装在转角板3与支护平台4之间,本发明能够对横挡板1与纵挡板2的交接处进行支护,并与横挡板1与纵挡板2形成一体结构,增加横挡板1与纵挡板2之间的稳定性,提高模板的支护效果,斜支杆5能够对转角板3进行支撑,增加转角板3与横挡板1、纵挡板2连接的紧密度。As shown in Figures 1 to 5, a concrete casting enclosure support steel formwork includes a

所述的转角板3的右端前侧设置有斜支槽31,斜支槽31所在的平面与转角板3的前侧面之间的夹角为四十五度,斜支槽31上安装有斜支连架32,斜支连架32为π型结构,斜支连架32的中部外侧面与斜支杆5的上端通过铰链相连接,且斜支杆5轴心线所在的竖直平面垂直于斜支槽31所在的平面,且两个侧支机构6以斜支杆5轴心线所在的竖直平面为对称面对称布置,这种设置使得两个侧支机构6能够对转角板3施加对称的支撑力,增加转角板3的稳定性,斜支杆5通过斜支连架32将支撑力均匀作用在转角板3设置的斜支槽31上。The front side of the right end of the

所述的支护平台4的右端前侧设置有三角形凸起41,斜支杆5的底部通过铰链与三角形凸起41相连接,三角形凸起41能够增加斜支杆5对转角板3的支撑效果。The front side of the right end of the

所述的转角板3的右端后侧面上设置有稳固槽34,稳固槽34内通过滑动配合的方式连接有稳固块35,稳固块35的前侧面通过轴承与稳固螺栓36的后端相连接,稳固螺栓36穿过转角板3,且稳固螺栓36的中部通过螺纹配合的方式与转角板3相连接,通过转动稳固螺栓36能够带动稳固块35在稳固槽34内滑动,使得稳固槽34的后侧面与左侧面能够分别撑在纵挡板2与横挡板1上,防止混凝土浇筑时纵挡板2与横挡板1的交接位置发生位移。The rear side of the right end of the

所述的稳固块35的后侧面与后端左侧面上均设置有橡胶垫,稳固块35的前侧面设置有稳固杆37,稳固杆37穿过转角板3,稳固块35设置的橡胶垫能够增加稳固块35与纵挡板2、横挡板1的贴合效果,稳固杆37在稳固块35进行前后位置调节时增加其稳定性。The rear side and the left side of the rear end are provided with rubber pads. The front side of the stabilizing

所述的侧支机构6包括定位块61、螺柱62、定位螺栓63、侧支板64、侧支杆65和锁定螺帽66,定位块61的数量为二,转角板3的左端的两个定位块61分别分布在横挡板1上端相邻的两个支撑筋11之间与横挡板1下端相邻的两个支撑筋11之间,转角板3的后端的两个定位块61分别分布在纵挡板2上端相邻的两个支撑筋11之间与纵挡板2下端相邻的两个支撑筋11之间,定位块61的中部设置有插孔;The

定位螺栓63穿过支撑筋11上的圆孔与定位块61上的插孔,定位螺栓63的下端通过螺母进行锁定,转角板3的左端与后端对应每个定位块61的位置处均设置有方槽33,定位块61的前侧面上安装有螺柱62,螺柱62的外端穿过方槽33,侧支板64套设在螺柱62的外侧,螺柱62的外端通过锁定螺帽66锁定在侧支板64的外侧面上;The

每个侧支板64的外侧面上均通过铰链与一个侧支杆65的上端相连接,侧支杆65的下端与支护平台4相连接,具体工作时,侧支机构6能够将横挡板1、纵挡板2与转角板3进行紧密连接,并通过侧支杆65对横挡板1、纵挡板2的侧面进行支撑,增加模板的支护时的稳定性,定位块61通过定位螺栓63安装在支撑筋11之间,使得定位块61的位置得到限定,通过锁定螺帽66能够将定位块61前端的螺柱62锁定在侧支板64上,从而增加横挡板1或纵挡板2与转角板3之间的一体化效果,侧支杆65能够对转角板3的上下两端分别进行支撑。The outer side of each

位于转角板3上端的所述侧支杆65的底部通过铰链安装在支护平台4的顶部上,位于转角板3下端的侧支杆65的底部通过铰链安装在支护平台4的内侧面上,且转角板3上端侧支杆65的尺寸大于转角板3下端侧支杆65的尺寸,侧支杆65这种安装方式使得侧支杆65能够以不同的方向对转角板3进行支撑。The bottom of the

所述的斜支杆5与侧支杆65均为可伸缩结构,斜支杆5与侧支杆65的可伸缩结构能够使其具有一定力度的进行支撑动作。The oblique struts 5 and the side struts 65 are both telescopic structures, and the telescopic structures of the oblique struts 5 and the side struts 65 can enable them to perform a supporting action with a certain strength.

工作时,首先在搭接好的横挡板1、纵挡板2上合适的位置安装定位块61,定位块61通过定位螺栓63安装在支撑筋11之间,使得定位块61的位置得到限定,然后支护平台4通过膨胀螺栓安装在地面上,使得转角板3能够贴在横挡板1、纵挡板2的交接位置,此时斜支杆5能够对转角板3进行支撑,增加转角板3与横挡板1、纵挡板2连接的紧密度;When working, firstly install the

支护平台4安装完毕后,螺柱62的外端能够穿过方槽33,然后将侧支板64套设在螺柱62的外侧,通过锁定螺帽66将螺柱62的外端锁定在侧支板64的外侧面上,侧支杆65能够对转角板3的上下两端分别进行支撑,侧支机构6能够将横挡板1、纵挡板2与转角板3进行紧密连接,并通过侧支杆65对横挡板1、纵挡板2的侧面进行支撑,侧支机构6对称布置使得两个侧支机构6能够对转角板3施加对称的支撑力,增加转角板3的稳定性,斜支杆5通过斜支连架32将支撑力均匀作用在转角板3设置的斜支槽31上,最后通过转动稳固螺栓36能够带动稳固块35在稳固槽34内滑动,使得稳固槽34的后侧面与左侧面能够分别撑在纵挡板2与横挡板1上,防止混凝土浇筑时纵挡板2与横挡板1的交接位置发生位移。After the

本发明能够对横挡板、纵挡板的交接位置处通过L型的转角板进行支护,通过将转角板与横挡板、纵挡板进行一体化锁定连接能够增加模板之间的稳定性,增加模板在混凝土浇筑时的支护效果,本发明还能够将横挡板、纵挡板交接位置进行支撑,防止横挡板、纵挡板交接位置发生位移。The invention can support the intersection position of the horizontal baffle and the vertical baffle by the L-shaped corner plate, and can increase the stability between the templates by integrally locking the corner plate with the horizontal baffle and the vertical baffle. , the support effect of the formwork during concrete pouring is increased, and the present invention can also support the cross-over position of the horizontal baffle and the vertical baffle to prevent displacement of the cross-over position of the horizontal baffle and the vertical baffle.

以上显示和描述了本发明的基本原理、主要特征和优点。本行业的技术人员应该了解,本发明不受上述实施例的限制,上述实施例和说明书中的描述的只是说明本发明的原理,在不脱离本发明精神和范围的前提下,本发明还会有各种变化和改进,这些变化和改进都落入要求保护的本发明范围内。本发明要求保护范围由所附的权利要求书及其等效物界定。The foregoing has shown and described the basic principles, main features and advantages of the present invention. Those skilled in the art should understand that the present invention is not limited by the above-mentioned embodiments, and the descriptions in the above-mentioned embodiments and the description are only to illustrate the principle of the present invention, without departing from the spirit and scope of the present invention, the present invention will also There are various changes and modifications which fall within the scope of the claimed invention. The claimed scope of the present invention is defined by the appended claims and their equivalents.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010372170.8ACN111519894B (en) | 2020-05-06 | 2020-05-06 | Concrete placement encloses fender support steel form |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010372170.8ACN111519894B (en) | 2020-05-06 | 2020-05-06 | Concrete placement encloses fender support steel form |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111519894Atrue CN111519894A (en) | 2020-08-11 |

| CN111519894B CN111519894B (en) | 2021-09-10 |

Family

ID=71907061

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010372170.8AExpired - Fee RelatedCN111519894B (en) | 2020-05-06 | 2020-05-06 | Concrete placement encloses fender support steel form |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111519894B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112962623A (en)* | 2021-03-11 | 2021-06-15 | 南京登革自动化技术有限公司 | Constructional engineering excavation supporting steel form |

| CN115898055A (en)* | 2022-12-20 | 2023-04-04 | 中建三局绿色产业投资有限公司 | A temporary protection device for cast-in-place column corners on construction sites |

| CN116122593A (en)* | 2022-11-23 | 2023-05-16 | 国网安徽省电力有限公司经济技术研究院 | Substation construction device based on assembled building |

| CN119352751A (en)* | 2024-12-05 | 2025-01-24 | 广西路建集团建筑工程有限公司 | A formwork structure and construction method for shear wall in narrow space |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2257757A1 (en)* | 1974-09-02 | 1975-08-08 | Samep Sa | Shuttering for concrete walls - prop adjustable for length and vertically |

| JPH10159338A (en)* | 1996-11-27 | 1998-06-16 | Takeshi Okuya | Vertical adjuster for formwork, patch for formwork, patch holder for formwork, and corner part holder for formwork |

| CN201125529Y (en)* | 2007-11-16 | 2008-10-01 | 浙江省建工集团有限责任公司 | Large template corner chucking appliance for building |

| KR20100134225A (en)* | 2009-06-15 | 2010-12-23 | (주)블루폼 | Corner blocking unit for column-beam separation |

| CN104453224A (en)* | 2014-10-24 | 2015-03-25 | 中国建筑第四工程局有限公司 | Formwork support structure of basement exterior wall and construction method of formwork support structure |

| CN206267521U (en)* | 2016-10-27 | 2017-06-20 | 合迪科技江苏有限公司 | Precast concrete installs node with cast-in-place structural mortar leakage prevention |

| CN206591827U (en)* | 2017-03-20 | 2017-10-27 | 中冶建工集团有限公司 | A kind of shear wall aluminum alloy mould plate inclined support structure |

| CN207296409U (en)* | 2017-07-15 | 2018-05-01 | 云南乾园建筑工程有限公司 | Build aluminum alloy pattern plate external corner connecting piece |

| CN207332319U (en)* | 2017-10-19 | 2018-05-08 | 凯里学院 | A kind of assembled architecture plate device |

| CN108532949A (en)* | 2018-05-30 | 2018-09-14 | 广东建星建造集团有限公司 | Mortar leakage prevention sizing module |

| CN207934438U (en)* | 2018-02-09 | 2018-10-02 | 中交第四公路工程局有限公司 | Bracing members formwork reinforcement structure |

| CN208668930U (en)* | 2018-08-01 | 2019-03-29 | 中建科技长春有限公司 | Fabricated construction turning is installed by bracing means |

| CN209114864U (en)* | 2018-11-05 | 2019-07-16 | 河北晶达建筑科技股份有限公司 | Scalable angle mould support |

| CN110091421A (en)* | 2019-05-08 | 2019-08-06 | 苏州良浦住宅工业有限公司 | A kind of prefabricated overlapping board mold of the building PC of corner leak stopping |

| CN209976024U (en)* | 2019-05-24 | 2020-01-21 | 董永新 | A building bearing diagonal structure for construction |

- 2020

- 2020-05-06CNCN202010372170.8Apatent/CN111519894B/ennot_activeExpired - Fee Related

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2257757A1 (en)* | 1974-09-02 | 1975-08-08 | Samep Sa | Shuttering for concrete walls - prop adjustable for length and vertically |

| JPH10159338A (en)* | 1996-11-27 | 1998-06-16 | Takeshi Okuya | Vertical adjuster for formwork, patch for formwork, patch holder for formwork, and corner part holder for formwork |

| CN201125529Y (en)* | 2007-11-16 | 2008-10-01 | 浙江省建工集团有限责任公司 | Large template corner chucking appliance for building |

| KR20100134225A (en)* | 2009-06-15 | 2010-12-23 | (주)블루폼 | Corner blocking unit for column-beam separation |

| CN104453224A (en)* | 2014-10-24 | 2015-03-25 | 中国建筑第四工程局有限公司 | Formwork support structure of basement exterior wall and construction method of formwork support structure |

| CN206267521U (en)* | 2016-10-27 | 2017-06-20 | 合迪科技江苏有限公司 | Precast concrete installs node with cast-in-place structural mortar leakage prevention |

| CN206591827U (en)* | 2017-03-20 | 2017-10-27 | 中冶建工集团有限公司 | A kind of shear wall aluminum alloy mould plate inclined support structure |

| CN207296409U (en)* | 2017-07-15 | 2018-05-01 | 云南乾园建筑工程有限公司 | Build aluminum alloy pattern plate external corner connecting piece |

| CN207332319U (en)* | 2017-10-19 | 2018-05-08 | 凯里学院 | A kind of assembled architecture plate device |

| CN207934438U (en)* | 2018-02-09 | 2018-10-02 | 中交第四公路工程局有限公司 | Bracing members formwork reinforcement structure |

| CN108532949A (en)* | 2018-05-30 | 2018-09-14 | 广东建星建造集团有限公司 | Mortar leakage prevention sizing module |

| CN208668930U (en)* | 2018-08-01 | 2019-03-29 | 中建科技长春有限公司 | Fabricated construction turning is installed by bracing means |

| CN209114864U (en)* | 2018-11-05 | 2019-07-16 | 河北晶达建筑科技股份有限公司 | Scalable angle mould support |

| CN110091421A (en)* | 2019-05-08 | 2019-08-06 | 苏州良浦住宅工业有限公司 | A kind of prefabricated overlapping board mold of the building PC of corner leak stopping |

| CN209976024U (en)* | 2019-05-24 | 2020-01-21 | 董永新 | A building bearing diagonal structure for construction |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112962623A (en)* | 2021-03-11 | 2021-06-15 | 南京登革自动化技术有限公司 | Constructional engineering excavation supporting steel form |

| CN112962623B (en)* | 2021-03-11 | 2022-10-25 | 上海林伟建筑工程有限公司 | Constructional engineering excavation supporting steel form |

| CN116122593A (en)* | 2022-11-23 | 2023-05-16 | 国网安徽省电力有限公司经济技术研究院 | Substation construction device based on assembled building |

| CN116122593B (en)* | 2022-11-23 | 2024-11-05 | 国网安徽省电力有限公司经济技术研究院 | Substation construction device based on assembled building |

| CN115898055A (en)* | 2022-12-20 | 2023-04-04 | 中建三局绿色产业投资有限公司 | A temporary protection device for cast-in-place column corners on construction sites |

| CN119352751A (en)* | 2024-12-05 | 2025-01-24 | 广西路建集团建筑工程有限公司 | A formwork structure and construction method for shear wall in narrow space |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111519894B (en) | 2021-09-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111519894A (en) | Concrete placement encloses fender support steel form | |

| CN111749457A (en) | A kind of formwork system and construction method for first support and then assembly and early dismantling | |

| CN206360402U (en) | Basement roof ruggedized construction | |

| CN113482333A (en) | Construction method for polygonal concrete frame column formwork support | |

| CN112696012A (en) | Wall column template device capable of being spliced | |

| CN216587710U (en) | Modular anti-bank reinforced structure of aluminum alloy template | |

| CN205742998U (en) | Straight cutting dish pin falsework side bar formwork system | |

| CN212200084U (en) | Cast-in-place beam support with longitudinal slope | |

| CN210177807U (en) | A corner structural column reinforcement device | |

| CN218264577U (en) | A prefabricated building structure | |

| CN106284669B (en) | A column for quickly building a steel structure house | |

| CN104831919A (en) | Support system for prefabricating and integral casting crosswise floor structure | |

| CN107476200B (en) | Full-hall support staggered overlapping structure and method | |

| CN111719882A (en) | A wall reinforcement structure and method for strengthening the integrity of ancient buildings | |

| CN111719428A (en) | A bridge tower beam assembled construction support and its installation method | |

| CN104947836B (en) | Construction method of cast-in-place floor slab without support in high-rise steel structure residence | |

| CN205224579U (en) | Steel framework template and self -supporting truss board combination concrete quick detach system | |

| CN212200085U (en) | Cast-in-place beam support with uniform section | |

| CN222207264U (en) | Reverse support system for beam structure construction | |

| CN222456792U (en) | Concrete placement turn-ups auxiliary device | |

| CN222066141U (en) | A cast-in-place formwork support device with haunch plate | |

| CN222991162U (en) | Aluminum template reinforced structure | |

| CN217840857U (en) | Top mold shrink wall conversion device | |

| CN220747653U (en) | Building outer facade line and bay window template supporting device | |

| CN220014370U (en) | Full scaffold using bailey frame as supporting platform |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| CB03 | Change of inventor or designer information | ||

| CB03 | Change of inventor or designer information | Inventor after:Liu Zhanlei Inventor after:Zhang Sai Inventor after:Li Shenghu Inventor before:Zhang Sai Inventor before:Li Shenghu | |

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right | Effective date of registration:20210819 Address after:251700 No.1 Qingzi Road, Xindian Town, Huimin County, Binzhou City, Shandong Province (Huimin Economic Development Zone (Xindian) Intelligent Manufacturing Industrial Park) Applicant after:Shandong Haide Heavy Industry Co.,Ltd. Address before:246001, the first floor of Yang Jiashan C building, Yingjiang District, Anqing, Anhui, from west to East. Applicant before:ANQING MIRUI INTELLIGENT TECHNOLOGY Co.,Ltd. | |

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20210910 |