CN111516633A - Pyrotechnic gas generator for safety air bag - Google Patents

Pyrotechnic gas generator for safety air bagDownload PDFInfo

- Publication number

- CN111516633A CN111516633ACN202010414328.3ACN202010414328ACN111516633ACN 111516633 ACN111516633 ACN 111516633ACN 202010414328 ACN202010414328 ACN 202010414328ACN 111516633 ACN111516633 ACN 111516633A

- Authority

- CN

- China

- Prior art keywords

- gas generator

- filter

- cup body

- casing

- pyrotechnic gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/16—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags

- B60R21/26—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow

- B60R21/264—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow using instantaneous generation of gas, e.g. pyrotechnic

- B60R21/2644—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow using instantaneous generation of gas, e.g. pyrotechnic using only solid reacting substances, e.g. pellets, powder

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/16—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags

- B60R21/26—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/16—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags

- B60R21/26—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow

- B60R2021/26011—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow using a filter through which the inflation gas passes

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/16—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags

- B60R21/26—Inflatable occupant restraints or confinements designed to inflate upon impact or impending impact, e.g. air bags characterised by the inflation fluid source or means to control inflation fluid flow

- B60R2021/26029—Ignitors

Landscapes

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Air Bags (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及气体发生器技术领域,具体地说是一种安全气囊用烟火式气体发生器。The invention relates to the technical field of gas generators, in particular to a pyrotechnic gas generator for airbags.

背景技术Background technique

气体发生器是汽车被动安全领域中的一个关键部件。传统气体发生器结构一般采用杯状下壳体内置一过滤器,该过滤器采用低碳钢丝模压而成,下壳体嵌设有点火器座,点火器座上嵌设有点火器和点火壳体,点火壳体、点火器座、上壳体、下壳体、过滤器构成产气药室,产气药室内一般装有圆柱状产气药,如图2所示。Gas generators are a key component in the field of automotive passive safety. The traditional gas generator structure generally adopts a cup-shaped lower casing with a built-in filter. The filter is molded with low carbon steel wire. The lower casing is embedded with an igniter seat, and the igniter seat is embedded with an igniter and an ignition shell. The ignition housing, the igniter seat, the upper housing, the lower housing and the filter constitute a gas producing chamber, and the gas producing chamber is generally equipped with a cylindrical gas producing charge, as shown in Figure 2.

这种采用杯状下壳体的烟火式气体发生器,由于气体气流有趋向排气口的流动特性,传统结构气体发生器的过滤网与发生器高度近似相等,传统结构发生器排气孔设计在上壳体上,由于气体流动性的上述特性,仅仅与上壳体高度重合的过滤器部分起到过滤产气药燃烧产生残渣的作用,因而过滤器损失一部分功率,不利于气体发生器小型化轻量化。This kind of pyrotechnic gas generator using a cup-shaped lower shell has a flow characteristic of gas flow towards the exhaust port. The filter screen of the traditional structure gas generator is approximately equal to the height of the generator. The traditional structure generator exhaust hole design On the upper casing, due to the above-mentioned characteristics of gas fluidity, only the part of the filter that is highly overlapped with the upper casing plays the role of filtering the residue generated by the combustion of the gas-producing chemical, so the filter loses a part of the power, which is not conducive to the small size of the gas generator. Lightweight.

因为过滤器利用率不高,如果提高气体纯净度则需增加过滤器重量,导致整个气体发生器尺寸和重量大而笨重。另外,现有的烟火式气体发生器的产气药室装填圆柱状产气药,当点火药作用于产气药时,一次性点燃所有产气药,产气药燃烧不分阶段,导致烟火式气体发生器初期斜率输出过高,初期斜率过高,对于烟火式气体发生器冲击很大,容易造成气体发生器失效。为实现气体发生器的初期斜率较低避免对气体发生器的较大冲击和失效,设计一种新型产气药结构来实现分阶段燃烧特性。Because the utilization rate of the filter is not high, if the gas purity is improved, the weight of the filter needs to be increased, resulting in the large size and weight of the entire gas generator and heavy weight. In addition, the gas-generating medicine chamber of the existing pyrotechnic gas generator is filled with cylindrical gas-generating powder. When the ignition powder acts on the gas-generating powder, all the gas-generating powders will be ignited at one time, and the gas-generating powder will not burn in stages, resulting in pyrotechnics. The initial slope output of the type gas generator is too high, and the initial slope is too high, which has a great impact on the pyrotechnic gas generator, which is easy to cause the gas generator to fail. In order to realize the low initial slope of the gas generator and avoid the large impact and failure of the gas generator, a new type of gas-producing drug structure was designed to realize the staged combustion characteristics.

发明内容SUMMARY OF THE INVENTION

本发明的目的是克服现有技术的不足,通过改变过滤器的结构和布局以及产气药的形状结构实现分阶段燃烧来设计一款全新的烟火式气体发生器,从而提高过滤器的过滤效率,降低气体发生器初期的输出斜率,实现气体发生器的尺寸小、重量轻、工作可靠。The purpose of the present invention is to overcome the deficiencies of the prior art, and design a brand-new pyrotechnic gas generator by changing the structure and layout of the filter and the shape and structure of the gas-producing drug to achieve staged combustion, thereby improving the filtering efficiency of the filter. , reduce the initial output slope of the gas generator, and realize the small size, light weight and reliable operation of the gas generator.

为实现上述目的,设计一种安全气囊用烟火式气体发生器,包括上壳体、过滤器、下壳体、点火器座、点火器、点火壳体、产气药、点火药,其中点火器座嵌设于下壳体内,所述的下壳体为双杯体结构由内径不同的第一杯体和第二杯体组成,所述第一杯体的内径大于第二杯体内径;所述上壳体连接在第一杯体的开口处;第一杯体底面、上壳体底部内表面压紧过滤器的上下端面;由上壳体的底部内表面、第二杯体、点火器座外表面、点火壳体外表面、过滤器内表面构成产气药室。In order to achieve the above purpose, a pyrotechnic gas generator for an airbag is designed, which includes an upper casing, a filter, a lower casing, an igniter seat, an igniter, an ignition casing, a gas producing powder, and an ignition powder, wherein the igniter The seat is embedded in the lower casing, and the lower casing is a double-cup structure composed of a first cup body and a second cup body with different inner diameters, and the inner diameter of the first cup body is larger than the inner diameter of the second cup body; The upper shell is connected to the opening of the first cup body; the bottom surface of the first cup body and the inner surface of the bottom of the upper shell press the upper and lower end surfaces of the filter; The outer surface of the seat, the outer surface of the ignition casing, and the inner surface of the filter constitute a gas producing chamber.

本发明技术方案二:一种安全气囊用烟火式气体发生器,包括上壳体、过滤器、下壳体、点火器座、点火器、点火壳体、产气药、点火药,其中点火器座嵌设于下壳体内,所述的下壳体为开口向外翻边的杯体结构,所述上壳体与所述的翻边结构外端面固连;上壳体底部内表面与所述的翻边结构压紧过滤器的上下端面;由上壳体的底部内表面、下壳体侧壁、点火器座外表面、点火壳体外表面、过滤器内表面构成产气药室。

优选的,内置于产气药室的产气药的形状为中孔柱状且柱状横截面长轴、短轴半径比大于1。Preferably, the shape of the gas-generating drug built in the gas-generating drug chamber is a mesoporous column, and the ratio of the long axis and the short axis radius of the cylindrical cross section is greater than 1.

优选的,所述中孔内径大于等于1mm小于等于3mm,长轴短轴半径比大于等于1.5小于等于4。Preferably, the inner diameter of the middle hole is greater than or equal to 1 mm and less than or equal to 3 mm, and the ratio of the major axis to the minor axis radius is greater than or equal to 1.5 and less than or equal to 4.

优选的,所述的过滤器与第一杯体同轴心。Preferably, the filter is concentric with the first cup body.

优选的,所述过滤器采用一层以上金属材料板材卷制而成,每层金属材料板材厚度为0.1mm~1.0mm。Preferably, the filter is rolled by more than one layer of metal material sheets, and the thickness of each metal material sheet is 0.1 mm to 1.0 mm.

优选的,所述过滤器的每层金属材料板材均匀设置通气孔,通气孔直径不大于0.5mm。Preferably, each layer of metal material plate of the filter is evenly provided with ventilation holes, and the diameter of the ventilation holes is not greater than 0.5 mm.

优选的,所述过滤器的高度与所述第一杯体的高度之比大于10。Preferably, the ratio of the height of the filter to the height of the first cup is greater than 10.

优选的,所述的上壳体相对下壳体为倒扣的杯体,杯体的侧壁上均匀置有一个以上排气孔,杯体的侧壁内表面粘贴有密封箔,密封箔覆盖排气孔。Preferably, the upper shell is an inverted cup body relative to the lower shell, more than one vent hole is evenly arranged on the side wall of the cup body, the inner surface of the side wall of the cup body is pasted with sealing foil, and the sealing foil covers Vent.

优选的,所述密封箔采用铜箔、铝箔、铅箔或非金属材料。Preferably, the sealing foil is made of copper foil, aluminum foil, lead foil or non-metallic material.

优选的,所述的上壳体的内径与第一杯体的开口处外径之间通过过盈配合并焊接为一体。Preferably, the inner diameter of the upper casing and the outer diameter of the opening of the first cup body are integrated by interference fit and welding.

优选的,所述的上壳体、下壳体的厚度为1.0mm~2.0mm,材料使用抗拉强度大于300MPa的冷轧钢板。Preferably, the thickness of the upper casing and the lower casing is 1.0mm-2.0mm, and the material is a cold-rolled steel sheet with a tensile strength greater than 300MPa.

优选的,所述点火壳体采用长筒状结构,长筒状结构的侧壁上均匀置有一个以上传火孔。Preferably, the ignition housing adopts a long cylindrical structure, and the side wall of the long cylindrical structure is uniformly provided with more than one fire-up hole.

优选的,所述点火壳体的厚度为0.5mm~1.5mm,材料使用抗拉强度大于300MPa的冷轧钢板。Preferably, the thickness of the ignition casing is 0.5mm-1.5mm, and the material is a cold-rolled steel plate with a tensile strength greater than 300MPa.

优选的,所述的下壳体与点火器座采用尼龙注塑方式形成一个整体。Preferably, the lower casing and the igniter seat are formed as a whole by nylon injection molding.

优选的,所述的点火器座插入下壳体,两者相结合的部分采用过盈配合并通过焊接方式连接成为一体。Preferably, the igniter seat is inserted into the lower casing, and the combined part adopts an interference fit and is connected into one body by welding.

优选的,点火壳体通过点火器座的金属变形方式将两者连接成为一体。Preferably, the ignition housing connects the two into one body through metal deformation of the igniter seat.

本发明与现有技术相比的有益效果是:The beneficial effects of the present invention compared with the prior art are:

现有技术的烟火式发生器的过滤器与下壳体高度之比一般不大于3,只有高出下壳体,与上壳体高度重合的过滤器部分起到过滤产气药燃烧产生残渣的作用,故过滤器过滤效率一般不大于60%;本发明通过将下壳体采用双杯体设计,设有第一杯体和第二杯体,过滤器与第一杯体高度之比可以大于10,因而过滤器的过滤效率大于90%。The ratio of the height of the filter to the lower shell of the pyrotechnic generator in the prior art is generally not greater than 3, and only the part of the filter that is higher than the lower shell and overlaps with the height of the upper shell plays the role of filtering the residues produced by the combustion of the gas-producing agent. Therefore, the filtration efficiency of the filter is generally not greater than 60%; in the present invention, the lower casing is designed with a double cup body, with a first cup body and a second cup body, and the ratio of the height of the filter to the first cup body can be greater than 10, so the filtration efficiency of the filter is greater than 90%.

另外,采用形状为中孔柱状且长轴短轴半径比大于1的产气药,实现了药型的分阶段燃烧,降低了气体发生器初期的输出斜率,避免了对气体发生器的冲击和失效。In addition, the use of gas-generating drugs with a cylindrical shape with a long axis and a short axis radius ratio greater than 1 realizes the staged combustion of the drug type, reduces the output slope of the gas generator at the initial stage, and avoids the impact and damage to the gas generator. invalid.

附图说明Description of drawings

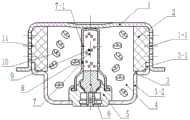

图1为本发明的结构示意图;Fig. 1 is the structural representation of the present invention;

图2为原有烟火式气体发生器产气药形状;Figure 2 is the shape of the gas-producing medicine of the original pyrotechnic gas generator;

图3为本发明气体发生器产气药形状;Fig. 3 is the shape of gas generator gas producing medicine of the present invention;

图4为本发明产气药燃烧过程示意图;Fig. 4 is the schematic diagram of the combustion process of the gas producing agent of the present invention;

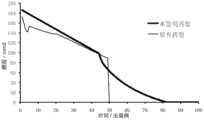

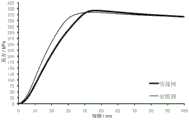

图5为本发明产气药型与原有产气药型燃面曲线示意图;Fig. 5 is a schematic diagram of the combustion surface curve of the gas-producing medicine type of the present invention and the original gas-producing medicine type;

图6为本发明实施例与对照例中烟火式气体发生器的输出斜率曲线图;Fig. 6 is the output slope curve diagram of the pyrotechnic gas generator in the embodiment of the present invention and the comparative example;

图7和图8和图9分别显示本发明的变型方案结构示意图。Figure 7, Figure 8 and Figure 9 respectively show the structural schematic diagram of the modification scheme of the present invention.

具体实施方式Detailed ways

现结合附图对本发明作进一步的说明。The present invention will now be further described with reference to the accompanying drawings.

实施例1:Example 1:

参见图1、图3、图4,本发明包括上壳体、下壳体、点火器座、点火器、点火壳体、过滤器、点火药、产气药,其中,点火器座嵌设于下壳体内,点火器座上连接点火器和点火壳体,下壳体3采用双杯体设计,设有第一杯体3-1和第二杯体3-2,上壳体1连接在所述第一杯体3-1开口处,所述第一杯体内置有过滤器2,所述上壳体1的底部内表面、第二杯体3-2、点火器座5外表面、点火壳体7外表面、过滤器2内表面构成产气药室4,产气药室4内置有产气药10,所述点火壳体内置有点火药9。1, 3, and 4, the present invention includes an upper casing, a lower casing, an igniter seat, an igniter, an ignition casing, a filter, an ignition powder, and a gas producing powder, wherein the igniter seat is embedded in the In the lower casing, the igniter seat is connected to the igniter and the ignition casing. The

本发明一优选实施例中上壳体1采用倒杯形,杯体的侧壁上均匀置有一个以上排气孔1-1,杯体的侧壁内表面粘贴有密封箔11,所述密封箔覆盖排气孔1-1。所述点火壳体7采用长筒状结构,长筒状结构的侧壁上均匀置有一个以上传火孔7-1。In a preferred embodiment of the present invention, the

本发明中烟火式气体发生器金属组件:上壳体1、下壳体3、点火壳体7均采用低碳钢拉伸而成,上壳体、下壳体的厚度通常为1.0mm~2.0mm,材料使用抗拉强度大于300MPa的冷轧钢板,含碳量要求小于0.2%。点火壳体7的厚度一般为0.5mm~1.5mm,材料使用抗拉强度大于300MPa的冷轧钢板,含碳量要求小于0.2%。过滤器2采用一层以上金属材料板材卷制而成,每层金属材料板材均匀置有一定数量一定形状的通气孔,通气孔直径一般不大于0.5mm,每层金属材料板材厚度为0.1mm~1.0mm,本例中过滤器2外表面如图1所示与上壳体1侧壁之间留有间隙。密封箔11采用铜箔、铝箔、铅箔或非金属材料。点火器座5部分可以采用低碳钢按要求进行机械加工而成,采用机加方式而成,点火器座5插入下壳体4,两者相结合的部分采用过盈配合,装配好的点火器座、下壳体采用激光焊接方式将两者连接成为一体;也可以采用尼龙注塑而成,采用尼龙注塑方式的时候,下壳体3和点火器座5可通过注塑形成一个整体,这样既保证了密封的可靠性也省去了点火器座的机械加工成本。In the present invention, the metal components of the pyrotechnic gas generator: the

本发明的烟火式气体发生器的点火壳体7通过点火器座5的金属变形的方式将两者连接成为一体。过滤器2放置在下壳体3的第一杯体3-1内,过滤器2与第一杯体3-1同轴心,过滤器2与第一杯体3-1底面、上壳体1底面紧密贴合。上壳体1、下壳体3之间采用激光焊接的方式来连接,上壳体1的内径与下壳体3的第一杯体3-1的开口处外径相匹配,两者采用过盈配合,装配好的上、下壳体采用激光焊接的方式将两者连接为一体。The

为了降低气体发生器初期的输出斜率,避免了对气体发生器的冲击和失效。本发明在下壳体设计为双杯体结构基础上,在不限制产气药配方的前提下,对产气药形状进行大量设计,研究发现,若产气药片的燃烧能够分为两个阶段,第一阶段为近似为等面燃烧,第二阶段为减面燃烧,则能够非常好的达到上述目的。经过大量研究发现,产气药的形状为截面为椭圆形的中孔柱状且柱状横截面内的长轴短轴半径比大于1(参见图3和图4),能够燃烧分为上述两个阶段(例如横截面为椭圆形,或者具有长轴和短轴的其他形状)。如图4和图5所示为产气药长轴短轴半径比1.6时的燃烧过程及燃面曲线,从图中可以看到,本发明所使用的药型实现了分阶段燃烧,传统的药型燃烧只有一个阶段,传统药型50时间单位之后燃烧结束,本发明产气药药型在50时间单位之后有第二阶段燃烧,分阶段燃烧降低了发生器的初期的输出斜率。In order to reduce the initial output slope of the gas generator, the impact and failure of the gas generator are avoided. Based on the design of the lower shell as a double-cup structure, the invention designs a large number of shapes of the gas-producing medicine without restricting the formula of the gas-producing medicine. The research finds that if the combustion of the gas-producing medicine tablet can be divided into two stages, The first stage is approximately isoplane combustion, and the second stage is reduced surface combustion, which can achieve the above goals very well. After a lot of research, it was found that the shape of the gas-generating drug is a mesoporous column with an oval cross-section and the ratio of the major axis to the minor axis radius in the cylindrical cross section is greater than 1 (see Figure 3 and Figure 4), which can be divided into the above two stages of combustion. (eg oval in cross-section, or other shapes with major and minor axes). As shown in Figure 4 and Figure 5, the combustion process and the combustion surface curve of the gas-producing drug when the ratio of the major axis to the minor axis radius is 1.6 is shown. It can be seen from the figures that the drug type used in the present invention realizes staged combustion. There is only one stage of combustion of the medicine form. The traditional medicine form burns after 50 time units. The gas-producing medicine form of the present invention has a second stage of combustion after 50 time units. The staged combustion reduces the initial output slope of the generator.

此处给出结论性的建议,长轴短轴半径比的具体数值根据系统对烟火式气体发生器输出的要求和产气药的装药量来计算,产气药的厚度也可以可根据系统对烟火式气体发生器的输出要求加以调节。当烟火式气体发生器工作时,点火器6点燃点火药9,点火药9迅速燃烧,通过传火孔7-1点燃燃烧室4内的产气药10,产气药10经历两个燃烧阶段,第一燃烧阶段和第二燃烧阶段,调节两个燃烧阶段的比例,从而有效降低了烟火式气体发生器的初期输出斜率。产气药形状中中孔大小优先选定中孔内径大于等于1mm小于等于3mm的范围,在中孔内径一定的情况下,长轴短轴比越大,第二燃烧阶段占比越长,初期输出斜率越低。长轴短轴半径比根据发生器装药率要求优先选择大于等于1.5小于等于4的范围,发生器的充气效果良好且对发生器冲击较小。Conclusive suggestions are given here. The specific value of the ratio of the radius of the major axis to the minor axis is calculated according to the system's requirements for the output of the pyrotechnic gas generator and the charge of the gas-producing agent. The thickness of the gas-producing agent can also be calculated according to the system. Adjust the output requirements of the pyrotechnic gas generator. When the pyrotechnic gas generator works, the

在本例中采用上述结构的烟火式气体发生器,在产气药配方和过滤器重量不变的情况下,可以提高烟火式气体发生器过滤器的过滤效率,同时降低气体发生器的初期输出斜率。如,在本发明的烟火式气体发生器中,装配硝酸胍类产气药90克,产气药长轴短轴半径比为1.5;过滤器的重量为120克,过滤器的高度与下壳体的第一杯体的高度比为10,在23℃下,该烟火式气体发生器在60L密闭容器测出的曲线参见图6。过滤器的过滤效率为90%。In this example, the pyrotechnic gas generator with the above structure can improve the filtration efficiency of the pyrotechnic gas generator filter and reduce the initial output of the gas generator under the condition that the formula of the gas producing agent and the weight of the filter remain unchanged. slope. For example, in the pyrotechnic gas generator of the present invention, 90 grams of guanidine nitrate gas-generating drug is assembled, and the ratio of the long-axis and short-axis radius of the gas-generating drug is 1.5; the weight of the filter is 120 grams, and the height of the filter is the same as the lower shell. The height ratio of the first cup body of the body is 10. At 23° C., the curve measured by the pyrotechnic gas generator in a 60L airtight container is shown in FIG. 6 . The filter has a filtration efficiency of 90%.

对照例Control example

采用原有结构的烟火式气体发生器,在产气药室内装有同等重量的圆片状产气药90克,采用相同重量过滤器120克,过滤器的高度与下壳体的高度比为2,同样在23℃下,该原有结构的烟火式气体发生器在60L密闭容器测出的曲线参见图6。过滤器的过滤效率为40%~50%。The pyrotechnic gas generator with the original structure is used, and the same weight of disc-shaped gas-generating medicine is 90 grams in the gas-producing medicine chamber. The same weight filter is 120 grams. The height ratio of the filter to the height of the lower shell is 2. Also at 23°C, the curve measured by the original structure of the pyrotechnic gas generator in a 60L airtight container is shown in Figure 6. The filtration efficiency of the filter is 40% to 50%.

从图6所示的两根曲线可以看出,在装有相同重量的产气药的条件下,实施例的烟火式气体发生器作用的前20ms压力升高的斜率明显低于对照例。实施例的烟火式气体发生器的过滤器的过滤效率高于对照例。It can be seen from the two curves shown in FIG. 6 that under the condition that the gas generating agent of the same weight is loaded, the slope of the pressure increase in the first 20 ms of the action of the pyrotechnic gas generator of the embodiment is significantly lower than that of the control example. The filter efficiency of the filter of the pyrotechnic gas generator of the example is higher than that of the control example.

实施例2Example 2

图7为本发明的扩展实例,该实例在实施例1基础上,过滤器2外表面与上壳体1侧壁无间隙。FIG. 7 is an expanded example of the present invention. In this example, based on

实施例3Example 3

一种安全气囊用烟火式气体发生器,包括上壳体、过滤器、下壳体、点火器座、点火器、点火壳体、产气药、点火药,其中点火器座嵌设于下壳体内,所述的下壳体为开口向外翻边的杯体结构(为了表述方便,本例中沿用之前标号,3-2为下壳体主体杯体结构相当于前述实施例的第二杯体,翻边结构相当于无侧壁的第一杯体3-1),所述上壳体与所述的翻边结构外端面固连;上壳体底部内表面与所述的翻边结构压紧过滤器的上下端面;由上壳体的底部内表面、下壳体侧壁、点火器座外表面、点火壳体外表面、过滤器内表面构成产气药室。本例中过滤器2外表面与上壳体1侧壁无间隙。A pyrotechnic gas generator for an airbag, comprising an upper shell, a filter, a lower shell, an igniter seat, an igniter, an ignition shell, a gas producing powder, and an ignition powder, wherein the igniter seat is embedded in the lower shell In the body, the lower shell is a cup body structure with an opening and turned outwards (for the convenience of description, the previous label is used in this example, 3-2 is the main body cup body structure of the lower shell, which is equivalent to the second cup in the previous embodiment. body, the flanging structure is equivalent to the first cup body without side walls 3-1), the upper shell is fixedly connected with the outer end face of the flanging structure; the inner surface of the bottom of the upper shell is connected to the flanging structure The upper and lower end faces of the filter are compressed; the gas producing chamber is composed of the bottom inner surface of the upper shell, the side wall of the lower shell, the outer surface of the igniter seat, the outer surface of the ignition shell and the inner surface of the filter. In this example, there is no gap between the outer surface of the

实施例4Example 4

该实例如图9所示,在实施例3基础上,过滤器2外表面与上壳体1侧壁之间有间隙。In this example, as shown in FIG. 9 , on the basis of

本发明未详细说明部分属于本领域技术人员的公知常识。The parts not described in detail in the present invention belong to the common knowledge of those skilled in the art.

Claims (17)

Translated fromChinesePriority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010414328.3ACN111516633A (en) | 2020-05-15 | 2020-05-15 | Pyrotechnic gas generator for safety air bag |

| PCT/CN2021/075532WO2021227576A1 (en) | 2020-05-15 | 2021-02-05 | Pyrotechnic gas generator for safety airbag |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010414328.3ACN111516633A (en) | 2020-05-15 | 2020-05-15 | Pyrotechnic gas generator for safety air bag |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111516633Atrue CN111516633A (en) | 2020-08-11 |

Family

ID=71907639

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010414328.3APendingCN111516633A (en) | 2020-05-15 | 2020-05-15 | Pyrotechnic gas generator for safety air bag |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN111516633A (en) |

| WO (1) | WO2021227576A1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021227576A1 (en)* | 2020-05-15 | 2021-11-18 | 湖北航鹏化学动力科技有限责任公司 | Pyrotechnic gas generator for safety airbag |

| WO2021227578A1 (en)* | 2020-05-15 | 2021-11-18 | 湖北航鹏化学动力科技有限责任公司 | Gas generator |

| CN114251981A (en)* | 2022-01-07 | 2022-03-29 | 湖南洪源远大科技有限公司 | Anti-UAV Swarm Munitions |

| JP7449432B2 (en) | 2019-08-09 | 2024-03-13 | 株式会社ダイセル | gas generator |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5682013A (en)* | 1992-08-24 | 1997-10-28 | Morton International, Inc. | Gas generant body having pressed-on burn inhibitor layer |

| CN1234776A (en)* | 1996-10-29 | 1999-11-10 | 大赛璐化学工业株式会社 | air bag gas generator |

| CN1461271A (en)* | 2001-04-10 | 2003-12-10 | 日本化药株式会社 | Gas generator |

| CN101062675A (en)* | 2006-04-26 | 2007-10-31 | 比亚迪股份有限公司 | Igniting means and gas generator having the same |

| CN105835827A (en)* | 2015-01-13 | 2016-08-10 | 湖北航天化学技术研究所 | Small gas generator |

| CN213920948U (en)* | 2020-05-15 | 2021-08-10 | 湖北航鹏化学动力科技有限责任公司 | Pyrotechnic gas generator for safety air bag |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5345873A (en)* | 1992-08-24 | 1994-09-13 | Morton International, Inc. | Gas bag inflator containing inhibited generant |

| US20040061319A1 (en)* | 2000-12-26 | 2004-04-01 | Takashi Saso | Gas generator |

| EP1473202A1 (en)* | 2002-02-06 | 2004-11-03 | Nippon Kayaku Kabushiki Kaisha | Gas generator |

| JP2006027291A (en)* | 2004-07-12 | 2006-02-02 | Daicel Chem Ind Ltd | Gas generator for airbag |

| JP4970813B2 (en)* | 2006-03-22 | 2012-07-11 | 株式会社ダイセル | Gas generator for vehicle restraint system |

| JP5016620B2 (en)* | 2009-01-15 | 2012-09-05 | 株式会社ダイセル | Gas generator for vehicle restraint system |

| CN103124658B (en)* | 2011-05-12 | 2017-02-22 | 丰田自动车株式会社 | Inflator and airbag device |

| CN109131198A (en)* | 2018-10-29 | 2019-01-04 | 湖北航天化学技术研究所 | A kind of gas generant for air cell tablet and its preparation process and gasifier system |

| CN209037528U (en)* | 2018-10-29 | 2019-06-28 | 湖北航天化学技术研究所 | A kind of gas generant for air cell tablet and gasifier system |

| CN111516633A (en)* | 2020-05-15 | 2020-08-11 | 湖北航鹏化学动力科技有限责任公司 | Pyrotechnic gas generator for safety air bag |

- 2020

- 2020-05-15CNCN202010414328.3Apatent/CN111516633A/enactivePending

- 2021

- 2021-02-05WOPCT/CN2021/075532patent/WO2021227576A1/ennot_activeCeased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5682013A (en)* | 1992-08-24 | 1997-10-28 | Morton International, Inc. | Gas generant body having pressed-on burn inhibitor layer |

| CN1234776A (en)* | 1996-10-29 | 1999-11-10 | 大赛璐化学工业株式会社 | air bag gas generator |

| CN1461271A (en)* | 2001-04-10 | 2003-12-10 | 日本化药株式会社 | Gas generator |

| CN101062675A (en)* | 2006-04-26 | 2007-10-31 | 比亚迪股份有限公司 | Igniting means and gas generator having the same |

| CN105835827A (en)* | 2015-01-13 | 2016-08-10 | 湖北航天化学技术研究所 | Small gas generator |

| CN213920948U (en)* | 2020-05-15 | 2021-08-10 | 湖北航鹏化学动力科技有限责任公司 | Pyrotechnic gas generator for safety air bag |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7449432B2 (en) | 2019-08-09 | 2024-03-13 | 株式会社ダイセル | gas generator |

| WO2021227576A1 (en)* | 2020-05-15 | 2021-11-18 | 湖北航鹏化学动力科技有限责任公司 | Pyrotechnic gas generator for safety airbag |

| WO2021227578A1 (en)* | 2020-05-15 | 2021-11-18 | 湖北航鹏化学动力科技有限责任公司 | Gas generator |

| CN114251981A (en)* | 2022-01-07 | 2022-03-29 | 湖南洪源远大科技有限公司 | Anti-UAV Swarm Munitions |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2021227576A1 (en) | 2021-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111516633A (en) | Pyrotechnic gas generator for safety air bag | |

| CN2234384Y (en) | Combined reaction tank and inflator with gas producing agent obtained by extrusion | |

| CN105835827B (en) | One kind miniaturization gas generator | |

| CN102271973A (en) | Gas generator | |

| WO2021227578A1 (en) | Gas generator | |

| CN105292045B (en) | A kind of gas generator | |

| CN105644491B (en) | Inflatable gas generator is ignited in a kind of secondary delay | |

| CN114523932B (en) | Integral ignition structure and compressed gas type gas generator | |

| CN100497048C (en) | Gas generator | |

| KR20140052919A (en) | Solid fuel body, gas generator, module having a gas generator, and pyrotechnic drive unit | |

| CN112061072A (en) | Gas generator capable of reducing influence of ambient temperature on performance | |

| CN100379610C (en) | Air generator for principal driver | |

| CN207274623U (en) | A kind of gas generator for safety air sac voltage stabilizing exports vent structure | |

| CN114030440A (en) | Gas generator | |

| CN213920948U (en) | Pyrotechnic gas generator for safety air bag | |

| CN112109657A (en) | Low-cost high-output columnar pyrotechnic safety airbag gas generator | |

| CN2900259Y (en) | Mixed gas generator for safety air sac | |

| JPH11105661A (en) | Gas generator for air bag and air bag device | |

| CN1989030B (en) | air bag gas generator | |

| CN109131198A (en) | A kind of gas generant for air cell tablet and its preparation process and gasifier system | |

| CN101746344A (en) | Twin-stage type gas generator | |

| CN207274622U (en) | A kind of gas generator for safety air sac throttle-valve structure | |

| CN201161579Y (en) | The gas generator | |

| CN203391722U (en) | Gas generator with variable combustion chamber | |

| WO2024108832A1 (en) | Gas generator having automatic pressure adjustment function |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |