CN111486588A - Instant heating type nanometer boiler furnace - Google Patents

Instant heating type nanometer boiler furnaceDownload PDFInfo

- Publication number

- CN111486588A CN111486588ACN202010340769.3ACN202010340769ACN111486588ACN 111486588 ACN111486588 ACN 111486588ACN 202010340769 ACN202010340769 ACN 202010340769ACN 111486588 ACN111486588 ACN 111486588A

- Authority

- CN

- China

- Prior art keywords

- sleeve

- electric heating

- nano

- wall

- instant heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/18—Arrangement or mounting of grates or heating means

- F24H9/1809—Arrangement or mounting of grates or heating means for water heaters

- F24H9/1818—Arrangement or mounting of electric heating means

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H1/00—Water heaters, e.g. boilers, continuous-flow heaters or water-storage heaters

- F24H1/18—Water-storage heaters

- F24H1/185—Water-storage heaters using electric energy supply

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/0005—Details for water heaters

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/02—Details

- H05B3/04—Waterproof or air-tight seals for heaters

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/10—Heating elements characterised by the composition or nature of the materials or by the arrangement of the conductor

- H05B3/12—Heating elements characterised by the composition or nature of the materials or by the arrangement of the conductor characterised by the composition or nature of the conductive material

- H05B3/14—Heating elements characterised by the composition or nature of the materials or by the arrangement of the conductor characterised by the composition or nature of the conductive material the material being non-metallic

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/40—Heating elements having the shape of rods or tubes

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Instantaneous Water Boilers, Portable Hot-Water Supply Apparatuses, And Control Of Portable Hot-Water Supply Apparatuses (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及石英电热膜模组技术领域,具体为一种即热式纳米锅炉炉胆。The invention relates to the technical field of quartz electric heating film modules, in particular to an instant-heated nano-boiler furnace.

背景技术Background technique

石英电热膜模组具有加热速度快,不结水垢等优点,在使用过程中热能效率高,但纳米电锅炉具有体积大,安装维修复杂,制作成本高等问题,本发明主要实现了加热速度更快,安装维修更便捷,制作成本更低,并且可以实现组合安装。The quartz electric heating film module has the advantages of fast heating speed, no scale formation, etc., and high thermal energy efficiency during use, but the nano-electric boiler has the problems of large volume, complicated installation and maintenance, and high production cost. The present invention mainly realizes faster heating speed. , the installation and maintenance are more convenient, the production cost is lower, and the combined installation can be realized.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提供一种即热式纳米锅炉炉胆,具有加热速度更快,安装维修更便捷,制作成本更低,并且可以实现组合安装的优点,解决了现有技术中的问题。The purpose of the present invention is to provide an instant nano-boiler furnace, which has the advantages of faster heating speed, more convenient installation and maintenance, lower production cost, and can realize combined installation, thereby solving the problems in the prior art.

为实现上述目的,本发明提供如下技术方案:一种即热式纳米锅炉炉胆,包括套筒和纳米电加热管,所述套筒与纳米电加热管套接,套筒下端连接有进水环,进水环的一侧固定连接有进水管,套筒下端的外壁上开设有外螺纹,外螺纹上啮合有封盖,套筒的上端连接有出水管,套筒上端的内壁上对称连接有弧形支撑块,弧形支撑块的下表面与纳米电加热管的上端相接,所述封盖的中心开设有通孔,通孔的一周连接有挤压套,挤压套的一端延伸至套筒的内部,挤压套靠近套筒的一端设置有硅胶密封套,所述纳米电加热管的下端贯穿通孔,且纳米电加热管的下端与硅胶密封套套接。In order to achieve the above purpose, the present invention provides the following technical solutions: an instant-heated nano-boiler furnace, comprising a sleeve and a nano-electric heating tube, the sleeve is sleeved with the nano-electric heating tube, and the lower end of the sleeve is connected with a water inlet One side of the water inlet ring is fixedly connected with a water inlet pipe, the outer wall of the lower end of the sleeve is provided with an outer thread, the outer thread is engaged with a cover, the upper end of the sleeve is connected with a water outlet pipe, and the inner wall of the upper end of the sleeve is symmetrically connected There is an arc-shaped support block, the lower surface of the arc-shaped support block is connected with the upper end of the nano-electric heating tube, the center of the cover is provided with a through hole, the circumference of the through hole is connected with an extrusion sleeve, and one end of the extrusion sleeve extends To the inside of the sleeve, the end of the extrusion sleeve close to the sleeve is provided with a silicone sealing sleeve, the lower end of the nano electric heating tube penetrates the through hole, and the lower end of the nano electric heating tube is sleeved with the silicone sealing sleeve.

优选的,所述套筒靠近纳米电加热管下端的内壁设置有锥形面,锥形面与硅胶密封套贴合。Preferably, the inner wall of the sleeve close to the lower end of the nano-electric heating tube is provided with a tapered surface, and the tapered surface is fitted with the silicone sealing sleeve.

优选的,所述封盖的内壁上开设有内螺纹,内螺纹与外螺纹啮合。Preferably, an inner thread is provided on the inner wall of the cover, and the inner thread engages with the outer thread.

优选的,所述挤压套下端的内圈上连接有限位板,限位板上开设有安装孔。Preferably, a limiting plate is connected to the inner ring at the lower end of the extrusion sleeve, and a mounting hole is provided on the limiting plate.

优选的,所述挤压套与封盖的内壁围成环形容置槽。Preferably, the extrusion sleeve and the inner wall of the cover form an annular accommodating groove.

优选的,所述硅胶密封套的外壁为斜面结构。Preferably, the outer wall of the silicone sealing sleeve is an inclined surface structure.

与现有技术相比,本发明的有益效果如下:Compared with the prior art, the beneficial effects of the present invention are as follows:

本即热式纳米锅炉炉胆,由套筒、硅胶密封套、封盖、纳米电加热管组成,套筒用于固定纳米电加热管,硅胶密封套密封水路,封盖锁紧纳米电加热管,结构简单,实现了纳米电锅炉即热加热功能,组合排列实现大功率锅炉使用,通过进水管并联及出水管并联将套筒模块组合起来,套筒模块化设计使得制作以及组装维修等更加方便快捷,加热速度更快,制作成本更低,满足大功率锅炉即热功能要求。The instant heating nano boiler furnace is composed of a sleeve, a silicone sealing sleeve, a cover, and a nano electric heating tube. The sleeve is used to fix the nano electric heating tube, the silicone sealing sleeve seals the waterway, and the cover locks the nano electric heating tube , Simple structure, realizes the instant heating function of nano electric boiler, combined arrangement to realize the use of high-power boilers, and the sleeve modules are combined by parallel connection of water inlet pipes and water outlet pipes. The modular design of the sleeve makes the production, assembly and maintenance more convenient. Fast, faster heating, lower production cost, and meet the instant heating function requirements of high-power boilers.

附图说明Description of drawings

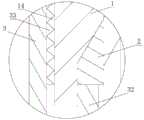

图1为本发明的实施例一结构图;1 is a structural diagram of an embodiment of the present invention;

图2为本发明的A放大图;Fig. 2 is the enlarged view of A of the present invention;

图3为本发明的实施例二结构图。FIG. 3 is a structural diagram of

图中:1、套筒;11、进水环;111、进水管;12、出水管;13、弧形支撑块;14、外螺纹;2、硅胶密封套;3、封盖;31、通孔;32、挤压套;321、限位板;322、安装孔;33、内螺纹;4、纳米电加热管。In the figure: 1. Sleeve; 11. Water inlet ring; 111. Water inlet pipe; 12. Water outlet pipe; 13. Arc support block; 14. External thread; 2. Silicone sealing sleeve; 3. Cover; 31. Passage hole; 32, extrusion sleeve; 321, limit plate; 322, mounting hole; 33, internal thread; 4, nano-electric heating tube.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

实施例一:Example 1:

请参阅图1-2,一种即热式纳米锅炉炉胆,包括套筒1和纳米电加热管4,套筒1与纳米电加热管4套接,套筒1下端连接有进水环11,进水环11的一侧固定连接有进水管111,套筒1下端的外壁上开设有外螺纹14,外螺纹14上啮合有封盖3,封盖3的内壁上开设有内螺纹33,内螺纹33与外螺纹14啮合,通过螺纹啮合的方式连接,方便安装拆卸,且能够调节硅胶密封套2的松紧,套筒1的上端连接有出水管12,套筒1上端的内壁上对称连接有弧形支撑块13,弧形支撑块13的下表面与纳米电加热管4的上端相接,弧形支撑块13起到固定纳米电加热管4的作用,提高结构的稳定性,封盖3的中心开设有通孔31,通孔31的一周连接有挤压套32,挤压套32下端的内圈上连接有限位板321,限位板321上开设有安装孔322,限位板321对纳米电加热管4起到限位作用,挤压套32的一端延伸至套筒1的内部,挤压套32靠近套筒1的一端设置有硅胶密封套2,挤压套32与封盖3的内壁围成环形容置槽,套筒1的下端置于容置槽内,且套筒1的内外壁分别与挤压套32的外壁和封盖3的内壁相接,结构牢固,密封效果好,纳米电加热管4的下端贯穿通孔31,且纳米电加热管4的下端与硅胶密封套2套接,套筒1靠近纳米电加热管4下端的内壁设置有锥形面,锥形面与硅胶密封套2贴合,挤压套32挤压硅胶密封套2的一侧,使得硅胶密封套2与锥形面紧密贴合,实现密封效果,硅胶密封套2的外壁为斜面结构,硅胶密封套2的斜面结构与锥形面贴合,密封效果好。Please refer to Figure 1-2, an instant-heated nano-boiler furnace includes a

工作过程:纳米电加热管4的下端套接硅胶密封套2,并将纳米电加热管4套入至套筒1内,弧形支撑块13与纳米电加热管4相接,起到固定纳米电加热管4的作用,封盖3旋紧在套筒1上将硅胶密封套2压紧,内螺纹33与外螺纹14啮合,从而保证炉胆水的密封以及固定纳米电加热管4,水从套筒1下面的进水管111进入到炉胆中,纳米电加热管4对炉胆中的水进行加热,由于炉胆体积小,存水少,所以纳米电加热管4可以实现将炉胆中的水立即加热到高温状态,再从套筒1上端的出水管12处出水。Working process: the lower end of the nano-

实施例二:Embodiment 2:

请参阅图3,本实施例中将不少于三个套筒1组合使用,每个套筒1内均设有纳米电加热管4,通过进水管111并联及出水管12并联将套筒1模块组合起来,满足大功率锅炉即热功能要求。Please refer to FIG. 3 , in this embodiment, no less than three

综上所述:本即热式纳米锅炉炉胆,由套筒1、硅胶密封套2、封盖3、纳米电加热管4组成,套筒1用于固定纳米电加热管4,硅胶密封套2密封水路,封盖3锁紧纳米电加热管4,结构简单,实现了纳米电锅炉即热加热功能,组合排列实现大功率锅炉使用,通过进水管111并联及出水管12并联将套筒1模块组合起来,套筒1模块化设计使得制作以及组装维修等更加方便快捷,加热速度更快,制作成本更低,满足大功率锅炉即热功能要求。To sum up: The instant heating nano boiler furnace is composed of a

需要说明的是,在本文中,诸如第一和第二等之类的关系术语仅仅用来将一个实体或者操作与另一个实体或操作区分开来,而不一定要求或者暗示这些实体或操作之间存在任何这种实际的关系或者顺序。而且,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的过程、方法、物品或者设备不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者设备所固有的要素。It should be noted that, in this document, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply any relationship between these entities or operations. any such actual relationship or sequence exists. Moreover, the terms "comprising", "comprising" or any other variation thereof are intended to encompass non-exclusive inclusion such that a process, method, article or device comprising a list of elements includes not only those elements, but also includes not explicitly listed or other elements inherent to such a process, method, article or apparatus.

尽管已经示出和描述了本发明的实施例,对于本领域的普通技术人员而言,可以理解在不脱离本发明的原理和精神的情况下可以对这些实施例进行多种变化、修改、替换和变型,本发明的范围由所附权利要求及其等同物限定。Although embodiments of the present invention have been shown and described, it will be understood by those skilled in the art that various changes, modifications, and substitutions can be made in these embodiments without departing from the principle and spirit of the invention and modifications, the scope of the present invention is defined by the appended claims and their equivalents.

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010340769.3ACN111486588B (en) | 2020-04-26 | 2020-04-26 | A kind of instant heating nano boiler furnace |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010340769.3ACN111486588B (en) | 2020-04-26 | 2020-04-26 | A kind of instant heating nano boiler furnace |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111486588Atrue CN111486588A (en) | 2020-08-04 |

| CN111486588B CN111486588B (en) | 2021-07-02 |

Family

ID=71813084

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010340769.3AActiveCN111486588B (en) | 2020-04-26 | 2020-04-26 | A kind of instant heating nano boiler furnace |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111486588B (en) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20090120739A (en)* | 2008-05-20 | 2009-11-25 | 김명구 | Fluid heater |

| CN202254229U (en)* | 2011-08-29 | 2012-05-30 | 廖世杰 | Infrared light wave fluid heating device |

| CN202432731U (en)* | 2011-12-21 | 2012-09-12 | 张文征 | Solar thermal collector |

| CN204335831U (en)* | 2014-08-14 | 2015-05-20 | 惠州市吉瑞科技有限公司 | A kind of atomizer and electronic cigarette |

| CN207763236U (en)* | 2018-01-25 | 2018-08-24 | 山东大学 | Circulating-heating single-ended electrode heating tube |

| CN208175011U (en)* | 2018-05-21 | 2018-11-30 | 广东汇晶新能源科技有限公司 | A kind of seal nipple and electrothermal film heating pipe |

| CN208635338U (en)* | 2018-05-16 | 2019-03-22 | 广西泰亿诺新能源有限公司 | A kind of heating water jacket for glass nano electrothermal tube |

| CN109691224A (en)* | 2017-02-22 | 2019-04-26 | 李宇宙 | Integrated light unit and the dual spot of liquid circulation type with it |

| CN209310253U (en)* | 2017-08-04 | 2019-08-27 | 淄博环能海臣环保技术服务有限公司 | Equipped with insulating sleeve diversion circulation electrical isolation heat delivery surface scale inhibition safety electric heater |

- 2020

- 2020-04-26CNCN202010340769.3Apatent/CN111486588B/enactiveActive

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20090120739A (en)* | 2008-05-20 | 2009-11-25 | 김명구 | Fluid heater |

| CN202254229U (en)* | 2011-08-29 | 2012-05-30 | 廖世杰 | Infrared light wave fluid heating device |

| CN202432731U (en)* | 2011-12-21 | 2012-09-12 | 张文征 | Solar thermal collector |

| CN204335831U (en)* | 2014-08-14 | 2015-05-20 | 惠州市吉瑞科技有限公司 | A kind of atomizer and electronic cigarette |

| CN109691224A (en)* | 2017-02-22 | 2019-04-26 | 李宇宙 | Integrated light unit and the dual spot of liquid circulation type with it |

| CN209310253U (en)* | 2017-08-04 | 2019-08-27 | 淄博环能海臣环保技术服务有限公司 | Equipped with insulating sleeve diversion circulation electrical isolation heat delivery surface scale inhibition safety electric heater |

| CN207763236U (en)* | 2018-01-25 | 2018-08-24 | 山东大学 | Circulating-heating single-ended electrode heating tube |

| CN208635338U (en)* | 2018-05-16 | 2019-03-22 | 广西泰亿诺新能源有限公司 | A kind of heating water jacket for glass nano electrothermal tube |

| CN208175011U (en)* | 2018-05-21 | 2018-11-30 | 广东汇晶新能源科技有限公司 | A kind of seal nipple and electrothermal film heating pipe |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111486588B (en) | 2021-07-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101408350A (en) | Coaxial sleeve tube U type thermal-collecting tube | |

| CN111486588A (en) | Instant heating type nanometer boiler furnace | |

| CN201344669Y (en) | Solar high-temperature vacuum heat-collecting tube | |

| CN201852334U (en) | Solar collector tube | |

| CN204874828U (en) | Double -deck thermal -insulated connection structure of quartz capsule | |

| CN104061694A (en) | Solar heat absorber with composite rib structure | |

| CN203940763U (en) | A kind of detachable combination heat pipe | |

| CN209558390U (en) | A waste heat recovery device for biogas power generation | |

| CN205534628U (en) | Combustion engine exhaust -heat boiler wall pipe high temperature expansion festival | |

| CN217662204U (en) | A flue gas purification device with waste heat recovery function in a thermal power plant | |

| CN206724465U (en) | A kind of Industrial Boiler | |

| CN207936091U (en) | The energy saving runner of infusibility garbage disposal special type incinerator fusant | |

| CN204558872U (en) | A shatterproof connection structure of laser return air pipe | |

| CN101403532A (en) | Solar vacuum heat collection pipe with pipe mouth having buckle and its connection device | |

| CN106123650A (en) | A kind of boiler wastewater TRT | |

| CN201145393Y (en) | A glass liner for an electric water heater | |

| CN101178258A (en) | Glass-to-metal seals for medium-temperature solar heat pipe receivers | |

| CN204005895U (en) | Nanometer physics and chemistry steam generator | |

| CN216592263U (en) | Graphene boiler with insulation construction | |

| CN203148050U (en) | Flat-plate solar thermal collector with vacuum heat insulating layer | |

| CN217031590U (en) | Photovoltaic ultra-pure water industrial water heater | |

| CN209840050U (en) | Electric heating vacuum boiler | |

| CN201476336U (en) | Straight through vacuum sleeve solar collector | |

| CN217423627U (en) | A heat exchange tube installation structure for a boiler | |

| CN103673351A (en) | U-shaped vacuum heat pipe type vacuum photo-thermal and photovoltaic conversion glass pipe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | Effective date of registration:20250609 Address after:224000 Jiangsu Province Yancheng City Yandu District Yandu Street Yandu Road 886 (B) Patentee after:Jiangsu Xingtai Energy Technology Co.,Ltd. Country or region after:China Address before:253 Ruihe Road, environmental protection technology city, Tinghu District, Yancheng City, Jiangsu Province (28) Patentee before:China Energy Huabang Environmental Protection Technology Co.,Ltd. Country or region before:China | |

| TR01 | Transfer of patent right |