CN111423976A - Aseptic inoculation device of microorganism - Google Patents

Aseptic inoculation device of microorganismDownload PDFInfo

- Publication number

- CN111423976A CN111423976ACN202010276751.1ACN202010276751ACN111423976ACN 111423976 ACN111423976 ACN 111423976ACN 202010276751 ACN202010276751 ACN 202010276751ACN 111423976 ACN111423976 ACN 111423976A

- Authority

- CN

- China

- Prior art keywords

- plate

- assembly

- telescopic

- outer cover

- test tube

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M23/00—Constructional details, e.g. recesses, hinges

- C12M23/02—Form or structure of the vessel

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M33/00—Means for introduction, transport, positioning, extraction, harvesting, peeling or sampling of biological material in or from the apparatus

- C12M33/04—Means for introduction, transport, positioning, extraction, harvesting, peeling or sampling of biological material in or from the apparatus by injection or suction, e.g. using pipettes, syringes, needles

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M37/00—Means for sterilizing, maintaining sterile conditions or avoiding chemical or biological contamination

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Chemical & Material Sciences (AREA)

- Zoology (AREA)

- Wood Science & Technology (AREA)

- Sustainable Development (AREA)

- Microbiology (AREA)

- Biotechnology (AREA)

- Biomedical Technology (AREA)

- Biochemistry (AREA)

- General Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Molecular Biology (AREA)

- Clinical Laboratory Science (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及微生物接种相关技术领域,尤其涉及一种微生物无菌接种装置。The invention relates to the related technical field of microbial inoculation, in particular to a microbial aseptic inoculation device.

背景技术Background technique

微生物研究中,在实验阶段为了避免其它类别的微生物对目标菌种的研究产生影响,因此在接种的过程中,需要确保接种过程为无菌操作,现有地,采用各种方式来降低其它类别的微生物对目标菌种的影响,如在微生物接种过程中,采用高温灭菌的方式,放置常温菌种对目标菌种的影响,即在菌种接种过程中,放置一盏酒精灯在操作过程中,各种接种工具在接种前通过酒精灯进行灼烧,从而达到灭菌的效果,同时在接种的过程中,需要将接种的容器具放置在酒精灯周围,从而通过酒精灯灼烧消灭空气中的其他菌种。In microbiological research, in order to avoid the influence of other types of microorganisms on the research of target strains in the experimental stage, it is necessary to ensure that the inoculation process is aseptic during the inoculation process. Currently, various methods are used to reduce other types of bacteria. For example, in the process of microbial inoculation, high temperature sterilization is used to place the influence of normal temperature bacteria on the target bacteria, that is, during the inoculation process of bacteria, an alcohol lamp is placed in the operation process. In the process of inoculation, various inoculation tools are burned by alcohol lamp before inoculation, so as to achieve the effect of sterilization. At the same time, in the process of inoculation, the inoculated container needs to be placed around the alcohol lamp, so as to eliminate the air by burning the alcohol lamp other species of bacteria.

现有技术虽然能够做到无菌操作,但是对操作人员的熟练程度要求较高,并且这种接种方式均在进行过灭菌的环境内进行,但是,由于操作人员本身携带较多的其他菌种,增大了接种过程中目标菌种被污染的可能,同时这种接种方式效率较低,甚至由于操作人员操作不当使目标菌种扩散,可能对操作人员的身体产生影响。Although the prior art can achieve aseptic operation, it requires higher proficiency of operators, and this inoculation method is carried out in a sterilized environment. However, because the operators themselves carry a lot of other bacteria. It increases the possibility of contamination of the target bacterial species during the inoculation process. At the same time, this inoculation method is inefficient, and even the spread of the target bacterial species due to improper operation by the operator may have an impact on the operator's body.

发明内容SUMMARY OF THE INVENTION

本发明提供一种微生物无菌接种装置,以解决上述现有技术的不足,提高微生物接种的效率,能够有效地防止其他微生物对目标菌种产生影响,操作简单,能够有效地降低目标菌种对操作人员造成感染的可能,具有较强的实用性。The present invention provides a microbial aseptic inoculation device to solve the above-mentioned deficiencies of the prior art, improve the efficiency of microbial inoculation, can effectively prevent other microorganisms from affecting the target bacterial species, is simple to operate, and can effectively reduce the impact of the target bacterial species on the The possibility of infection caused by the operator has strong practicability.

为了实现本发明的目的,拟采用以下技术:In order to realize the purpose of the present invention, the following technologies are planned to be adopted:

一种微生物无菌接种装置,包括:A microbial aseptic inoculation device, comprising:

外罩,cover,

置管机构,设于外罩内,用于微生物试管的放置以及驱动微生物试管转动,以使微生物试管倾斜,包括设于外罩底板的基板;The tube placement mechanism, which is arranged in the outer cover, is used for placing the microorganism test tube and driving the microorganism test tube to rotate, so as to make the microorganism test tube incline, including a base plate arranged on the bottom plate of the outer cover;

拔塞机构,设于外罩内,用于拔出微生物试管的试管塞;A plug-pulling mechanism, located in the outer cover, is used to pull out the test tube plug of the microorganism test tube;

灭菌机构,设于外罩内,用于微生物试管管口灭菌;The sterilization mechanism is set in the outer cover and used for sterilizing the mouth of the microbial test tube;

接种机构,设于外罩上端,将微生物试管中的菌种转移至培养皿中;The inoculation mechanism is located at the upper end of the outer cover, and transfers the bacteria in the microbial test tube to the petri dish;

置皿单元,设于外罩内的基板上,用于放置培养皿;The dish setting unit, which is arranged on the base plate in the outer cover, is used to place the culture dish;

灭菌机构与置皿单元分别位于外罩两端,置管机构位于灭菌机构与置皿单元之间,拔塞机构位于置管机构的上方,接种机构沿着外罩的长度方向运动,用于微生物的接种。The sterilization mechanism and the dish-setting unit are respectively located at both ends of the outer cover, the tube-setting mechanism is located between the sterilization mechanism and the dish-setting unit, the plugging mechanism is located above the tube-setting mechanism, and the inoculation mechanism moves along the length direction of the outer cover for microorganisms. of vaccination.

进一步地,置管机构包括呈等间隔阵列地安装于基板一端的支撑件,支撑件上端均成形有凹形槽,凹形槽内均装配有连接件,连接件一端均安装有转杆,转杆装配于支撑件上端,转杆的一端连接有转动气缸,转动气缸安装于外罩,连接件另一端均安装有夹管组件,夹管组件用于夹持固定微生物试管,连接件均向下延伸地安装有下延杆,下延杆下端安装有下顶帽,微生物试管下端置于下顶帽内。Further, the tube placement mechanism includes a support member installed on one end of the base plate in an array at equal intervals, the upper end of the support member is formed with a concave groove, the concave groove is equipped with a connecting piece, and one end of the connecting piece is equipped with a rotating rod, and the rotating rod is installed at one end of the connecting piece. The rod is assembled on the upper end of the support, one end of the rotating rod is connected with a rotating cylinder, the rotating cylinder is installed on the outer cover, and the other end of the connecting piece is installed with a pinch assembly. The pinch assembly is used to clamp and fix the microorganism test tube, and the connecting pieces extend downward. A downward extension rod is installed on the ground, a lower top cap is installed at the lower end of the downward extension rod, and the lower end of the microorganism test tube is placed in the lower head cap.

进一步地,连接件包括装配于凹形槽处的转动块,转动块另一端安装有固连板。Further, the connecting piece includes a rotating block assembled at the concave groove, and the other end of the rotating block is mounted with a fixing plate.

进一步地,夹管组件包括安装于固连板另一端的第一夹管弧板,第一夹管弧板两端成形有第一凸耳,第一凸耳均穿有伸缩杆,伸缩杆一端成形有端堵,伸缩杆另一端均装配有转轴,转轴均装配有转动件,转动件外弧壁均成形有卡块,转动件外弧壁还成形有按压板,按压板与卡块相互垂直;Further, the pinch assembly includes a first pinch arc plate mounted on the other end of the fixing plate, and first lugs are formed at both ends of the first pinch arc plate, the first lugs are all pierced with a telescopic rod, and one end of the telescopic rod is formed. An end plug is formed, the other end of the telescopic rod is equipped with a rotating shaft, the rotating shaft is equipped with a rotating part, the outer arc wall of the rotating part is formed with a clamping block, and the outer arc wall of the rotating part is also formed with a pressing plate, and the pressing plate and the clamping block are perpendicular to each other ;

夹管组件还包括第二夹管弧板,第二夹管弧板两端均成形有第二凸耳,第二凸耳均穿于伸缩杆;The pinch assembly further includes a second pinch arc plate, both ends of the second pinch arc plate are formed with second lugs, and the second lugs are all passed through the telescopic rod;

当夹管组件夹持固定微生物试管时,转动件在按压板的作用下转动,以使卡块另一端作用于第二凸耳;When the tube clamp assembly clamps and fixes the microorganism test tube, the rotating member rotates under the action of the pressing plate, so that the other end of the clamping block acts on the second lug;

第一夹管弧板与第二夹管弧板内壁均安装有橡胶垫凸起。Rubber pad protrusions are installed on the inner walls of the first pinch arc plate and the second pinch arc plate.

进一步地,拔塞机构包括安装于外罩上顶的升降气缸,升降气缸的活动端安装有升降板,升降板两侧安装有安装延板若干,安装延板另一端均向下延伸地安装有固定杆,位于同侧的固定杆均安装有夹持装配板,夹持装配板均对称地成形有装配孔,装配孔均装配有夹持板,夹持板呈L形结构,夹持板均安装有夹持气缸,夹持气缸另一端安装有气缸安装板,气缸安装板均安装于夹持装配板。Further, the plug-pulling mechanism includes a lifting cylinder installed on the top of the outer cover, a lifting plate is installed at the movable end of the lifting cylinder, a number of installation extension plates are installed on both sides of the lifting plate, and the other end of the installation extension plate is installed with a fixed extension plate extending downward. The rods and the fixed rods on the same side are equipped with clamping and assembling plates. The clamping and assembling plates are symmetrically formed with assembly holes, and the assembly holes are equipped with clamping plates. The clamping plates have an L-shaped structure and the clamping plates are installed There is a clamping cylinder, the other end of the clamping cylinder is installed with a cylinder mounting plate, and the cylinder mounting plate is installed on the clamping assembly plate.

进一步地,灭菌机构包括设于基板另一端的升降组件若干,升降组件均装配有伸缩组件,伸缩组件另一端均安装有灭菌组件;Further, the sterilization mechanism includes a number of lifting components arranged at the other end of the base plate, the lifting components are all equipped with telescopic components, and the other end of the telescopic components are equipped with sterilization components;

升降组件包括安装于基板一端的延长安装板若干,延长安装板另一端均向上延伸地安装有升降丝杠;The lifting assembly includes several extension mounting plates installed on one end of the base plate, and the other ends of the extension mounting plates are all installed with lifting screws extending upward;

外罩内部设有隔板,隔板成形有穿孔若干,伸缩组件穿于穿孔。A partition plate is arranged inside the outer cover, the partition plate is formed with a plurality of perforations, and the expansion and contraction components pass through the perforations.

进一步地,伸缩组件包括装配于升降丝杠的升降装配板,升降装配板一端安装有安装固定板,安装固定板安装有伸缩气缸,安装固定板的上下两端安装有导向杆一对,伸缩气缸活动端安装有伸缩板,导向杆均穿于伸缩板,伸缩板安装有前延板,前延板上下两侧安装有导向筒,导向杆均穿于导向筒。Further, the telescopic assembly includes a lifting assembly plate assembled on the lifting screw, one end of the lifting assembly plate is installed with an installation fixing plate, the installation fixing plate is installed with a telescopic cylinder, the upper and lower ends of the installation fixing plate are installed with a pair of guide rods, and the telescopic cylinder is installed. A telescopic plate is installed at the movable end, the guide rods are all passed through the telescopic plate, the telescopic plate is installed with a front extension plate, and guide cylinders are installed on the upper and lower sides of the front extension plate, and the guide rods are all passed through the guide cylinder.

进一步地,灭菌组件包括安装于前延板的环形凹形件,环形凹形件上端装配有环形盖,环形凹形件内壁设有灯芯,环形凹形件内设有酒精。Further, the sterilization assembly includes an annular concave piece mounted on the front extension plate, an annular cover is assembled on the upper end of the annular concave piece, the inner wall of the annular concave piece is provided with a lamp wick, and the annular concave piece is provided with alcohol.

进一步地,接种机构包括成对地安装于外罩上顶的进给丝杠,进给丝杠均装配有运动板,运动板两端均安装有运动座,运动座上端均倾斜地安装有倾斜筒,倾斜筒外壁均安装有伸缩丝杠,伸缩丝杠均装配有伸缩运动板,伸缩运动板安装均有接种杆,接种杆另一端均成形有接种环;Further, the inoculation mechanism comprises a pair of feed screws installed on the top of the outer cover, the feed screws are all equipped with moving plates, both ends of the moving plates are installed with moving seats, and the upper ends of the moving seats are installed with inclined cylinders obliquely. , The outer wall of the inclined cylinder is equipped with a telescopic screw, the telescopic screw is equipped with a telescopic motion plate, the telescopic motion board is installed with an inoculation rod, and the other end of the inoculation rod is formed with an inoculation ring;

外罩上顶成形有运动孔若干,接种杆均穿于运动孔;There are several movement holes formed on the top of the outer cover, and the inoculation rods are all passed through the movement holes;

运动孔一处均成形有圆孔。A circular hole is formed in one place of the moving hole.

进一步地,基板一端成形有装配槽若干;Further, one end of the base plate is formed with several assembly grooves;

置皿单元包括设于基板的放置台,放置台下端成形有限位块,限位块均装配于装配槽,放置台上端呈等间隔阵列地安装有装配框,装配框两侧均成形有长条孔,装配框内均安装有限位杆,限位杆一端均穿有弹簧,每对限位杆之间均装配有活动夹件,每对装配框之间均安装有固定夹件,放置台一端安装有键形板,键形板另一端安装有盖板,盖板上端安装有密封凸起若干,当培养皿置于外罩内时,盖板盖合于外罩的一端下方;The dish setting unit includes a placing table set on the base plate, the lower end of the placing table is formed with a limit block, the limit blocks are all assembled in the assembly groove, the upper end of the placing table is installed with an assembly frame in an array of equal intervals, and long strips are formed on both sides of the assembly frame. A limit rod is installed in the assembly frame, a spring is pierced at one end of the limit rod, a movable clamp is installed between each pair of limit rods, a fixed clamp is installed between each pair of assembly frames, and one end of the placing table is installed A key-shaped plate is installed, a cover plate is installed at the other end of the key-shaped plate, and a number of sealing protrusions are installed at the upper end of the cover plate. When the culture dish is placed in the outer cover, the cover plate is covered under one end of the outer cover;

活动夹件包括培养皿夹持弧板,培养皿夹持弧板两端成形有装配凸板,装配凸板均装配于限位杆,装配凸板均穿于长条孔;The movable clip includes a culture dish clamping arc plate, and two ends of the culture dish clamping arc plate are formed with assembly convex plates, the assembly convex plates are all assembled on the limit rods, and the assembly convex plates are all passed through the elongated holes;

固定夹件包括均安装于固定凸板若干,固定凸板之间安装有固定弧板。The fixing clip includes a plurality of fixed convex plates, and a fixed arc plate is installed between the fixed convex plates.

上述技术方案的优点在于:The advantages of the above technical solutions are:

1.外罩,主要为微生物的接种提供一个无菌的环境,从而避免菌种扩散,降低菌种被其他菌种污染的概率,其中为了提供一个相对无菌的环境,因此在外罩内设置紫外灯,在不进行接种时对外罩内部进行灭菌操作,同时,为了进一步地提高这种效果,在运动孔的外侧均设置紫外灯,从而防止其他菌种进入外罩内部,其中为了避免灭菌机构对外罩内的无菌环境产生影响,因此在外罩内部一端设置了相应的隔板。1. The outer cover mainly provides a sterile environment for the inoculation of microorganisms, so as to avoid the spread of the bacteria and reduce the probability of the bacteria being contaminated by other bacteria. In order to provide a relatively sterile environment, an ultraviolet lamp is set in the outer cover. , sterilize the inside of the cover when inoculation is not carried out. At the same time, in order to further improve this effect, ultraviolet lamps are set on the outside of the movement hole to prevent other bacteria from entering the inside of the cover. In order to prevent the sterilization mechanism from external The sterile environment inside the hood is affected, so a corresponding baffle is provided at one end of the inner hood.

2.置管机构,设于外罩内部,用于微生物试管的放置以及驱动微生物试管转动,从而使微生物试管倾斜,从而方便接种机构进行接种作业。其中,置管机构通过夹管组件和下顶帽对微生物试管进行固定,从而方便进行微生物试管的转动,微生物试管的夹持固定操作简单,方便易行,在微生物试管夹持固定时,只需要通过转动按压板即可实现卡块的转动,最终使,卡块的一端作用于第二凸耳的外壁,从而缩短伸缩杆的长度,从而第一夹管弧板和第二夹管弧板彼此相向运动,并最终将微生物试管夹持在第一夹管弧板和第二夹管弧板之间,在夹持时,为了防止第一夹管弧板和第二夹管弧板夹持力度过大造成微生物试管的破裂,因此在第一夹管弧板和第二夹管弧板内壁设置了相应的橡胶垫凸起,一方面提高了摩擦力,另一方面提高避免微生物试管的破裂,而置管机构又能够在转动气缸的作用下发生转动,从而使微生物试管倾斜,从而方便接种机构进行接种操作。2. The tube placement mechanism, which is installed inside the outer cover, is used for placing the microorganism test tube and driving the microorganism test tube to rotate, so that the microorganism test tube is inclined, so as to facilitate the inoculation operation of the inoculation mechanism. Among them, the tube placement mechanism fixes the microbial test tube through the clamping tube assembly and the lower top cap, so as to facilitate the rotation of the microbial test tube. The clamping and fixing operation of the microbial test tube is simple and convenient. When the microbial test tube is clamped and fixed, only The clamping block can be rotated by rotating the pressing plate, and finally, one end of the clamping block acts on the outer wall of the second lug, thereby shortening the length of the telescopic rod, so that the first pinch arc plate and the second pinch arc plate are mutually Move towards each other, and finally clamp the microbial test tube between the first pinch arc plate and the second pinch arc plate. During clamping, in order to prevent the first pinch arc plate and the second pinch arc plate from clamping force Excessive size causes the rupture of the microbial test tube, so corresponding rubber pad protrusions are arranged on the inner wall of the first pinch arc plate and the second pinch arc plate, which improves the friction force on the one hand, and avoids the rupture of the microbial test tube on the other hand. And the tube placement mechanism can rotate under the action of the rotating cylinder, so that the microbial test tube is inclined, thereby facilitating the inoculation operation of the inoculation mechanism.

3.拔塞机构,用于拔出微生物试管的试管塞,其中为了方便实现试管塞的拔出,因此设置了专用的试管塞,该试管塞由设于微生物试管管口处的胶塞以及设置在胶塞的T形拉拔件组成,而针对性地,拔塞机构在拔塞操作过程中,在夹持气缸的作用下向内运动,并将T形拉拔件夹持住,而后启动升降气缸,升降气缸向上拉拔试管塞直至将试管塞拔出为止,同时,拔塞机构还方便将试管塞塞在微生物试管的管口上,从而降低被污染的风险。3. The plug-pulling mechanism is used to pull out the test-tube plug of the microorganism test tube. In order to facilitate the pull-out of the test-tube plug, a special test-tube plug is provided. It is composed of the T-shaped pulling piece of the rubber plug, and the plugging mechanism moves inwardly under the action of the clamping cylinder during the plugging operation, and clamps the T-shaped pulling piece, and then starts. The lifting cylinder pulls the test tube plug upwards until the test tube plug is pulled out. At the same time, the plugging mechanism also facilitates plugging the test tube plug on the nozzle of the microbial test tube, thereby reducing the risk of contamination.

4.灭菌机构,用于微生物试管管口的灭菌操作,当然该灭菌操作应该在拔塞机构将试管塞拔出后进行,其中,升降组件能够使灭菌组件进行升降运动,从而通过灭菌组件对微生物试管的管口的一段长度进行灭菌操作,并且方便在灭菌完成后将灭菌组件移出,其中,伸缩组件能够使灭菌组件进行水平方向的移动,当微生物试管需要灭菌时,在伸缩气缸的带动下灭菌组件向前运动至微生物试管的管口处,并且为了提高运动的稳定性,因此设置了相应的导向杆,导向杆还穿于伸缩板,同时穿于设置在前延板的导向筒中,通过上述两个部件提高了前延板前伸运动的稳定性,防止前延板向前运动时出现小幅度的震动,从而影响控制效果,灭菌组件采用环形火焰的方式对微生物试管的管口进行灭菌操作。4. The sterilization mechanism is used for the sterilization operation of the mouth of the microbial test tube. Of course, the sterilization operation should be carried out after the plug of the test tube is pulled out by the plugging mechanism. The sterilization assembly sterilizes a length of the mouth of the microbial test tube, and it is convenient to remove the sterilization assembly after the sterilization is completed. The telescopic assembly can make the sterilization assembly move in the horizontal direction. When sterilizing bacteria, the sterilization assembly moves forward to the mouth of the microbial test tube under the drive of the telescopic cylinder, and in order to improve the stability of the movement, a corresponding guide rod is set up. It is arranged in the guide cylinder of the front extension plate, and the stability of the forward extension movement of the front extension plate is improved through the above two components, so as to prevent the small vibration when the front extension plate moves forward, which will affect the control effect. The sterilization component adopts an annular flame. sterilize the mouth of the microbial test tube.

5.接种机构,将微生物试管中的菌种转移至培养皿中,在转移过程中,通过进给丝杠带动下带动接种环进行运动,其中,设置在进给丝杠的倾斜筒在接种杆伸缩运动时,对接种杆起着导向的作用,同时倾斜设置的方式,方便接种环进行接种作业,其中接种环在伸缩丝杠的带动下进行伸缩运动,从而提高运动的稳定性。5. The inoculation mechanism transfers the bacteria in the microbial test tube to the petri dish. During the transfer process, the inoculation ring is driven by the feeding screw to move. During the telescopic movement, the inoculation rod plays a guiding role, and the inclined arrangement is convenient for the inoculation operation of the inoculation ring.

6.置皿单元,能够通过固定夹件和活动夹件将培养皿夹持固定在放置台上,其中活动夹件在弹簧的作用下,朝向固定夹件侧运动,从而将培养皿夹持在固定夹件和活动夹件之间,其中为了方便将夹持完成后的培养皿推到外罩内部,因此将放置台装配在基板上,为了防止外界的菌种进入外罩内部,因此在放置台上设置了相应的键形板,同时在键形板的另一端设置了相应的盖板,当在实施接种时,盖板盖合在外罩的一侧,从而使外罩形成一个较为密闭的无菌环境。6. The dish setting unit can clamp and fix the culture dish on the placing table through the fixed clip and the movable clip, wherein the movable clip moves towards the side of the fixed clip under the action of the spring, so as to clamp the culture dish on the table. Between the fixed clip and the movable clip, in order to facilitate the push of the culture dish after clamping to the inside of the housing, the placing table is assembled on the base plate. A corresponding key-shaped plate is provided, and a corresponding cover plate is set at the other end of the key-shaped plate. When inoculation is performed, the cover plate is closed on one side of the outer cover, so that the outer cover forms a relatively closed sterile environment. .

7.本发明提高微生物接种的效率,能够有效地防止其他微生物对目标菌种产生影响,操作简单,能够有效地降低目标菌种对操作人员造成感染的可能,具有较强的实用性。7. The present invention improves the efficiency of microbial inoculation, can effectively prevent other microorganisms from affecting the target bacterial species, is simple to operate, can effectively reduce the possibility of the target bacterial species infecting operators, and has strong practicability.

附图说明Description of drawings

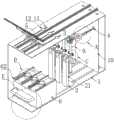

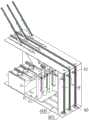

图1示出了本发明立体结构图一。Fig. 1 shows a three-dimensional structure diagram 1 of the present invention.

图2示出了本发明立体结构图二。FIG. 2 shows a second perspective structure diagram of the present invention.

图3示出了局部剖面图一。Figure 3 shows a partial sectional view one.

图4示出了局部剖面图二。Figure 4 shows a partial cross-sectional view II.

图5示出了局部剖面图三。Figure 5 shows a partial cross-section of Figure III.

图6示出了局部剖面图四。Figure 6 shows a partial cross-sectional view IV.

图7示出了A处局部放大图。FIG. 7 shows a partial enlarged view of A.

图8示出了B处局部放大图。FIG. 8 shows a partial enlarged view of B.

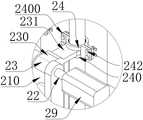

图9示出了C处局部放大图。FIG. 9 shows a partial enlarged view at C.

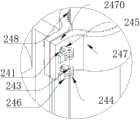

图10示出了D处局部放大图。FIG. 10 shows a partial enlarged view at D.

图11示出了E处局部放大图。FIG. 11 shows a partial enlarged view at E.

图12示出了F处局部放大图。FIG. 12 shows an enlarged view of the part at F. FIG.

图13示出了G处局部放大图。FIG. 13 shows a partial enlarged view of G.

图14示出了H处局部放大图。FIG. 14 shows a partial enlarged view at H.

图15示出了M处局部放大图。FIG. 15 shows a partial enlarged view of M.

具体实施方式Detailed ways

为使本发明实施例的目的、技术方案和优点更加清楚,下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例是本发明一部分实施例,而不是全部的实施例。通常在此处附图中描述和示出的本发明实施例的组件可以以各种不同的配置来布置和设计。In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments These are some embodiments of the present invention, but not all embodiments. The components of the embodiments of the invention generally described and illustrated in the drawings herein may be arranged and designed in a variety of different configurations.

因此,以下对在附图中提供的本发明的实施例的详细描述并非旨在限制要求保护的本发明的范围,而是仅仅表示本发明的选定实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。Thus, the following detailed description of the embodiments of the invention provided in the accompanying drawings is not intended to limit the scope of the invention as claimed, but is merely representative of selected embodiments of the invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

应注意到:相似的标号和字母在下面的附图中表示类似项,因此,一旦某一项在一个附图中被定义,则在随后的附图中不需要对其进行进一步定义和解释。It should be noted that like numerals and letters refer to like items in the following figures, so once an item is defined in one figure, it does not require further definition and explanation in subsequent figures.

在本发明的描述中,需要说明的是,术语“中心”、“上”、“下”、“左”、“右”、“竖直”、“水平”、“内”、“外”等指示的方位或位置关系为基于附图所示的方位或位置关系,或者是该发明产品使用时惯常摆放的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。In the description of the present invention, it should be noted that the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer", etc. The indicated orientation or positional relationship is based on the orientation or positional relationship shown in the accompanying drawings, or the orientation or positional relationship that the product of the invention is usually placed in use, only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying The device or element referred to must have a particular orientation, be constructed and operate in a particular orientation, and therefore should not be construed as limiting the invention.

术语“第一”、“第二”等仅用于区分描述,而不能理解为指示或暗示相对重要性。The terms "first", "second", etc. are only used to differentiate the description and should not be construed to indicate or imply relative importance.

术语“平行”、“垂直”等并不表示要求部件绝对平行或垂直,而是可以稍微倾斜。如“平行”仅仅是指其方向相对“垂直”而言更加平行,并不是表示该结构一定要完全平行,而是可以稍微倾斜。The terms "parallel," "perpendicular," etc. do not imply that components are required to be absolutely parallel or perpendicular, but rather may be slightly inclined. For example, "parallel" only means that its direction is more parallel than "perpendicular", it does not mean that the structure must be completely parallel, but can be slightly inclined.

此外,“大致”、“基本”等用语旨在说明相关内容并不是要求绝对的精确,而是可以有一定的偏差。例如:“大致等于”并不仅仅表示绝对的等于,由于实际生产、操作过程中,难以做到绝对的“相等”,一般都存在一定的偏差。因此,除了绝对相等之外,“大致等于”还包括上述的存在一定偏差的情况。以此为例,其他情况下,除非有特别说明,“大致”、“基本”等用语均为与上述类似的含义。In addition, terms such as "substantially" and "basically" are intended to indicate that the relevant content does not require absolute precision, but may have certain deviations. For example, "roughly equal" does not only mean absolute equality, because it is difficult to achieve absolute "equal" in the actual production and operation process, and there are generally certain deviations. Therefore, in addition to being absolutely equal, "substantially equal" also includes the above-mentioned circumstances with certain deviations. Taking this as an example, in other cases, unless otherwise specified, terms such as "substantially" and "basically" have similar meanings to those described above.

在本发明的描述中,还需要说明的是,除非另有明确的规定和限定,术语“设置”、“安装”、“相连”、“连接”应做广义理解,例如,可以是固定连接,也可以是可拆卸连接,或一体地连接;可以是直接相连,也可以通过中间媒介间接相连,可以是两个元件内部的连通。对于本领域的普通技术人员而言,可以具体情况理解上述术语在本发明中的具体含义。In the description of the present invention, it should also be noted that, unless otherwise expressly specified and limited, the terms "arranged", "installed", "connected" and "connected" should be understood in a broad sense, for example, it may be a fixed connection, It can also be a detachable connection, or an integral connection; it can be directly connected, or indirectly connected through an intermediate medium, and it can be internal communication between two components. For those of ordinary skill in the art, the specific meanings of the above terms in the present invention can be understood in specific situations.

如图1-图15所示,一种微生物无菌接种装置,包括:外罩1,置管机构2,设于外罩1内,用于微生物试管27的放置以及驱动微生物试管27转动,以使微生物试管27倾斜,包括设于外罩1底板的基板20, 基板20一端成形有装配槽200若干。拔塞机构3,设于外罩1内,用于拔出微生物试管27的试管塞28。灭菌机构4,设于外罩1内,用于微生物试管27管口灭菌。接种机构5,设于外罩1上端,将微生物试管27中的菌种转移至培养皿中。置皿单元6,设于外罩1内的基板20上,用于放置培养皿。灭菌机构4与置皿单元6分别位于外罩1两端,置管机构2位于灭菌机构4与置皿单元6之间,拔塞机构3位于置管机构2的上方,接种机构5沿着外罩1的长度方向运动,用于微生物的接种。As shown in FIGS. 1-15 , an aseptic inoculation device for microorganisms includes: an

外罩1,主要为微生物的接种提供一个无菌的环境,从而避免菌种扩散,降低菌种被其他菌种污染的概率,其中为了提供一个相对无菌的环境,因此在外罩1内设置紫外灯,在不进行接种时对外罩1内部进行灭菌操作,同时,为了进一步地提高这种效果,在运动孔11的外侧均设置紫外灯,从而防止其他菌种进入外罩1内部,其中为了避免灭菌机构4对外罩1内的无菌环境产生影响,因此在外罩1内部一端设置了相应的隔板10。The

置管机构2包括呈等间隔阵列地安装于基板20一端的支撑件21,支撑件21上端均成形有凹形槽210,凹形槽210内均装配有连接件23,连接件23一端均安装有转杆22,转杆22装配于支撑件21上端,转杆22的一端连接有转动气缸29,转动气缸29安装于外罩1,连接件23另一端均安装有夹管组件24,夹管组件24用于夹持固定微生物试管27,连接件23均向下延伸地安装有下延杆25,下延杆25下端安装有下顶帽26,微生物试管27下端置于下顶帽26内。连接件23包括装配于凹形槽210处的转动块230,转动块230另一端安装有固连板231。夹管组件24包括安装于固连板231另一端的第一夹管弧板240,第一夹管弧板240两端成形有第一凸耳2400,第一凸耳2400均穿有伸缩杆241,伸缩杆241一端成形有端堵242,伸缩杆241另一端均装配有转轴243,转轴243均装配有转动件244,转动件244外弧壁均成形有卡块245,转动件244外弧壁还成形有按压板246,按压板246与卡块245相互垂直。夹管组件24还包括第二夹管弧板247,第二夹管弧板247两端均成形有第二凸耳2470,第二凸耳2470均穿于伸缩杆241。当夹管组件24夹持固定微生物试管27时,转动件244在按压板246的作用下转动,以使卡块245另一端作用于第二凸耳2470。第一夹管弧板240与第二夹管弧板247内壁均安装有橡胶垫凸起248。The

置管机构2,设于外罩1内部,用于微生物试管27的放置以及驱动微生物试管27转动,从而使微生物试管27倾斜,从而方便接种机构5进行接种作业。其中,置管机构2通过夹管组件24和下顶帽26对微生物试管27进行固定,从而方便进行微生物试管27的转动,微生物试管27的夹持固定操作简单,方便易行,在微生物试管夹持固定时,只需要通过转动按压板246即可实现卡块245的转动,最终使,卡块245的一端作用于第二凸耳2470的外壁,从而缩短伸缩杆241的长度,从而第一夹管弧板240和第二夹管弧板247彼此相向运动,并最终将微生物试管27夹持在第一夹管弧板240和第二夹管弧板247之间,在夹持时,为了防止第一夹管弧板240和第二夹管弧板247夹持力度过大造成微生物试管27的破裂,因此在第一夹管弧板240和第二夹管弧板247内壁设置了相应的橡胶垫凸起248,一方面提高了摩擦力,另一方面提高避免微生物试管27的破裂,而置管机构2又能够在转动气缸29的作用下发生转动,从而使微生物试管27倾斜,从而方便接种机构5进行接种操作。The

拔塞机构3包括安装于外罩1上顶的升降气缸36,升降气缸36的活动端安装有升降板35,升降板35两侧安装有安装延板37若干,安装延板37另一端均向下延伸地安装有固定杆34,位于同侧的固定杆34均安装有夹持装配板30,夹持装配板30均对称地成形有装配孔300,装配孔300均装配有夹持板31,夹持板31呈L形结构,夹持板31均安装有夹持气缸32,夹持气缸32另一端安装有气缸安装板33,气缸安装板33均安装于夹持装配板30。The plug-pulling

拔塞机构3,用于拔出微生物试管27的试管塞28,其中为了方便实现试管塞28的拔出,因此设置了专用的试管塞28,该试管塞28由设于微生物试管27管口处的胶塞以及设置在胶塞280的T形拉拔件281组成,而针对性地,拔塞机构3在拔塞操作过程中,在夹持气缸32的作用下向内运动,并将T形拉拔件281夹持住,而后启动升降气缸36,升降气缸36向上拉拔试管塞28直至将试管塞28拔出为止,同时,拔塞机构3还方便将试管塞28塞在微生物试管27的管口上,从而降低被污染的风险。The plugging

灭菌机构4包括设于基板20另一端的升降组件40若干,升降组件40均装配有伸缩组件41,伸缩组件41另一端均安装有灭菌组件42。升降组件40包括安装于基板20一端的延长安装板400若干,延长安装板400另一端均向上延伸地安装有升降丝杠401。外罩1内部设有隔板10,隔板10成形有穿孔100若干,伸缩组件41穿于穿孔100。伸缩组件41包括装配于升降丝杠401的升降装配板403,升降装配板403一端安装有安装固定板410,安装固定板410安装有伸缩气缸411,安装固定板410的上下两端安装有导向杆412一对,伸缩气缸411活动端安装有伸缩板413,导向杆412均穿于伸缩板413,伸缩板413安装有前延板414,前延板414上下两侧安装有导向筒415,导向杆412均穿于导向筒415。灭菌组件42包括安装于前延板414的环形凹形件420,环形凹形件420上端装配有环形盖421,环形凹形件420内壁设有灯芯422,环形凹形件420内设有酒精。The

灭菌机构4,用于微生物试管27管口的灭菌操作,当然该灭菌操作应该在拔塞机构3将试管塞28拔出后进行,其中,升降组件40能够使灭菌组件42进行升降运动,从而通过灭菌组件42对微生物试管27的管口的一段长度进行灭菌操作,并且方便在灭菌完成后将灭菌组件42移出,其中,伸缩组件41能够使灭菌组件42进行水平方向的移动,当微生物试管27需要灭菌时,在伸缩气缸411的带动下灭菌组件42向前运动至微生物试管27的管口处,并且为了提高运动的稳定性,因此设置了相应的导向杆412,导向杆412还穿于伸缩板413,同时穿于设置在前延板414的导向筒415中,通过上述两个部件提高了前延板414前伸运动的稳定性,防止前延板414向前运动时出现小幅度的震动,从而影响控制效果,灭菌组件42采用环形火焰的方式对微生物试管27的管口进行灭菌操作。The

接种机构5包括成对地安装于外罩1上顶的进给丝杠50,进给丝杠50均装配有运动板51,运动板51两端均安装有运动座52,运动座52上端均倾斜地安装有倾斜筒53,倾斜筒53外壁均安装有伸缩丝杠54,伸缩丝杠54均装配有伸缩运动板55,伸缩运动板55安装均有接种杆56,接种杆56另一端均成形有接种环57,外罩1上顶成形有运动孔11若干,接种杆56均穿于运动孔11,运动孔11一处均成形有圆孔12。The

接种机构5,将微生物试管27中的菌种转移至培养皿中,在转移过程中,通过进给丝杠50带动下带动接种环57进行运动,其中,设置在进给丝杠50的倾斜筒53在接种杆56伸缩运动时,对接种杆56起着导向的作用,同时倾斜设置的方式,方便接种环57进行接种作业,其中接种环57在伸缩丝杠54的带动下进行伸缩运动,从而提高运动的稳定性。The

置皿单元6包括设于基板20的放置台60,放置台60下端成形有限位块600,限位块600均装配于装配槽200,放置台60上端呈等间隔阵列地安装有装配框62,装配框62两侧均成形有长条孔620,装配框62内均安装有限位杆,限位杆一端均穿有弹簧63,每对限位杆之间均装配有活动夹件64,每对装配框62之间均安装有固定夹件65,放置台60一端安装有键形板61,键形板61另一端安装有盖板66,盖板66上端安装有密封凸起660若干,当培养皿置于外罩1内时,盖板66盖合于外罩1的一端下方。活动夹件64包括培养皿夹持弧板641,培养皿夹持弧板641两端成形有装配凸板640,装配凸板640均装配于限位杆,装配凸板640均穿于长条孔620。固定夹件65包括均安装于固定凸板651若干,固定凸板651之间安装有固定弧板650。The

置皿单元6,能够通过固定夹件65和活动夹件64将培养皿夹持固定在放置台60上,其中活动夹件64在弹簧63的作用下,朝向固定夹件65侧运动,从而将培养皿夹持在固定夹件65和活动夹件64之间,其中为了方便将夹持完成后的培养皿推到外罩1内部,因此将放置台60装配在基板20上,为了防止外界的菌种进入外罩1内部,因此在放置台60上设置了相应的键形板61,同时在键形板61的另一端设置了相应的盖板66,当在实施接种时,盖板66盖合在外罩1的一侧,从而使外罩1形成一个较为密闭的无菌环境。The

具体地实施方式如下所述:The specific implementation is as follows:

在具体实施过程中,首先需要向各个紫外灯进行通电,对外罩1内进行灭菌,在灭菌完成后,开始实施接种过程。In the specific implementation process, each ultraviolet lamp needs to be energized first to sterilize the inside of the

在接种过程前,首先将三根目标微生物试管27固定在置管机构2的夹管组件24上,同时微生物试管27下端置于下顶帽26上,并通过转动夹管组件24的按压板246,使得卡块245作用于第二凸耳2470,从而使得夹管组件24对微生物试管27进行有效地夹持,夹持完成后,启动拔塞机构3的升降气缸36,使夹持板31向下运动,直至夹持板31运动至T形拉拔件281处,而后启动夹持气缸32,使得夹持板31夹持住T形拉拔件281处,之后,升降气缸36向上运动,将试管塞28从微生物试管27上拔出,完成后,启动伸缩气缸411将点燃的灭菌组件42向微生物试管27处推进,直至灭菌组件42套在微生物试管27的管口处,而后,启动升降丝杠401使灭菌组件42高温灭菌,灭菌完成后,通过升降丝杠401以及伸缩气缸411使灭菌组件42移出微生物试管27,而后将外罩1的侧盖进行盖合,盖合后,开始实施接种操作,接种前,需要通过转动气缸29使微生物试管27进行转动,转动角度一般为45°,倾斜完成后,通过进给丝杠50将接种环57移动至微生物试管27管口处,而后,启动伸缩丝杠54使接种环57运动至微生物试管27的菌液中,完成后,伸缩丝杠54启动,接种环57运动出微生物试管27,而后启动进给丝杠50,使接种环57运动至培养皿出,并在培养皿中滑动一定的距离,直至完成接种。在接种前,需要将培养皿置于活动夹件64和固定夹件65之间,完成培养皿的夹持,完成后,并向内推动放置台60,使放置台60位于内罩1内部,接种完成后,可以根据需要向不同的培养皿中进行多次接种。Before the inoculation process, three target

以上所述仅为本发明的优选实施例,并不用于限制本发明,显然,本领域的技术人员可以对本发明进行各种改动和变型而不脱离本发明的精神和范围。这样,倘若本发明的这些修改和变型属于本发明权利要求及其等同技术的范围之内,则本发明也意图包含这些改动和变型在内。The above descriptions are only preferred embodiments of the present invention and are not intended to limit the present invention. Obviously, those skilled in the art can make various changes and modifications to the present invention without departing from the spirit and scope of the present invention. Thus, provided that these modifications and variations of the present invention fall within the scope of the claims of the present invention and their equivalents, the present invention is also intended to include these modifications and variations.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010276751.1ACN111423976B (en) | 2020-04-10 | 2020-04-10 | Aseptic inoculation device of microorganism |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010276751.1ACN111423976B (en) | 2020-04-10 | 2020-04-10 | Aseptic inoculation device of microorganism |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111423976Atrue CN111423976A (en) | 2020-07-17 |

| CN111423976B CN111423976B (en) | 2023-03-21 |

Family

ID=71557761

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010276751.1AExpired - Fee RelatedCN111423976B (en) | 2020-04-10 | 2020-04-10 | Aseptic inoculation device of microorganism |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111423976B (en) |

Citations (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0119573A1 (en)* | 1983-03-21 | 1984-09-26 | Miles Laboratories, Inc. | Microdroplet dispensing apparatus and method |

| CN87104015A (en)* | 1986-04-30 | 1988-03-09 | 伊藤照明 | Automatic device for pulling out test tube stopper |

| US20070202564A1 (en)* | 2004-01-22 | 2007-08-30 | Medvet Science Pty Ltd. | Microbial streaking device |

| US20100330654A1 (en)* | 2007-11-05 | 2010-12-30 | Van Der Kaap Trienko Marten | Methods and apparatus for handling microbial samples |

| CN102166366A (en)* | 2011-02-21 | 2011-08-31 | 天津开发区合普工贸有限公司 | Temperature control inoculation sterilization apparatus for beaker and test tube mouth |

| CN202478966U (en)* | 2011-12-27 | 2012-10-10 | 于桐凤 | Novel special test tube cover |

| CN104403938A (en)* | 2014-12-04 | 2015-03-11 | 威海世利电子科技有限公司 | Intelligent microbial sample processing robot |

| CN205163694U (en)* | 2015-11-10 | 2016-04-20 | 镇江市环境监测中心站 | Portable cyclic annular flame sterilization ware |

| CN206127319U (en)* | 2016-10-25 | 2017-04-26 | 深圳市依波特科技有限公司 | Automatic appearance of vaccinating of microorganism |

| CN106916738A (en)* | 2017-04-10 | 2017-07-04 | 林春芳 | An auxiliary experimental device for ultra-clean workbench |

| CN107118950A (en)* | 2017-05-06 | 2017-09-01 | 尹康康 | A kind of bacterium automatic vaccination instrument |

| CN108285865A (en)* | 2018-04-24 | 2018-07-17 | 河南科技大学 | A kind of use for laboratory microbe inoculating device |

| CN207872234U (en)* | 2017-12-23 | 2018-09-18 | 天津一瑞生物科技股份有限公司 | A kind of electronic clamping device of test tube with elevating function |

| CN108753614A (en)* | 2018-06-22 | 2018-11-06 | 太原师范学院 | Anti-tumor experiment tumor cell culture device |

| CN208995497U (en)* | 2018-10-17 | 2019-06-18 | 宁波卫生职业技术学院 | An inoculation device that can automatically partition and scribe a petri dish |

| CN110577887A (en)* | 2019-09-26 | 2019-12-17 | 山东省农业科学院农业质量标准与检测技术研究所 | Microorganism inclined plane inoculation device |

| CN210243254U (en)* | 2019-05-18 | 2020-04-03 | 杭州龙鑫科技有限公司 | Urine sampling tube combination for urine sampling tube cap removing machine |

| CN111218394A (en)* | 2020-03-27 | 2020-06-02 | 广州中安基因科技有限公司 | Reduce bacterial solution inoculation device that other bacterial sneaked into |

- 2020

- 2020-04-10CNCN202010276751.1Apatent/CN111423976B/ennot_activeExpired - Fee Related

Patent Citations (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0119573A1 (en)* | 1983-03-21 | 1984-09-26 | Miles Laboratories, Inc. | Microdroplet dispensing apparatus and method |

| CN87104015A (en)* | 1986-04-30 | 1988-03-09 | 伊藤照明 | Automatic device for pulling out test tube stopper |

| US20070202564A1 (en)* | 2004-01-22 | 2007-08-30 | Medvet Science Pty Ltd. | Microbial streaking device |

| US20100330654A1 (en)* | 2007-11-05 | 2010-12-30 | Van Der Kaap Trienko Marten | Methods and apparatus for handling microbial samples |

| CN102166366A (en)* | 2011-02-21 | 2011-08-31 | 天津开发区合普工贸有限公司 | Temperature control inoculation sterilization apparatus for beaker and test tube mouth |

| CN202478966U (en)* | 2011-12-27 | 2012-10-10 | 于桐凤 | Novel special test tube cover |

| CN104403938A (en)* | 2014-12-04 | 2015-03-11 | 威海世利电子科技有限公司 | Intelligent microbial sample processing robot |

| CN205163694U (en)* | 2015-11-10 | 2016-04-20 | 镇江市环境监测中心站 | Portable cyclic annular flame sterilization ware |

| CN206127319U (en)* | 2016-10-25 | 2017-04-26 | 深圳市依波特科技有限公司 | Automatic appearance of vaccinating of microorganism |

| CN106916738A (en)* | 2017-04-10 | 2017-07-04 | 林春芳 | An auxiliary experimental device for ultra-clean workbench |

| CN107118950A (en)* | 2017-05-06 | 2017-09-01 | 尹康康 | A kind of bacterium automatic vaccination instrument |

| CN207872234U (en)* | 2017-12-23 | 2018-09-18 | 天津一瑞生物科技股份有限公司 | A kind of electronic clamping device of test tube with elevating function |

| CN108285865A (en)* | 2018-04-24 | 2018-07-17 | 河南科技大学 | A kind of use for laboratory microbe inoculating device |

| CN108753614A (en)* | 2018-06-22 | 2018-11-06 | 太原师范学院 | Anti-tumor experiment tumor cell culture device |

| CN208995497U (en)* | 2018-10-17 | 2019-06-18 | 宁波卫生职业技术学院 | An inoculation device that can automatically partition and scribe a petri dish |

| CN210243254U (en)* | 2019-05-18 | 2020-04-03 | 杭州龙鑫科技有限公司 | Urine sampling tube combination for urine sampling tube cap removing machine |

| CN110577887A (en)* | 2019-09-26 | 2019-12-17 | 山东省农业科学院农业质量标准与检测技术研究所 | Microorganism inclined plane inoculation device |

| CN111218394A (en)* | 2020-03-27 | 2020-06-02 | 广州中安基因科技有限公司 | Reduce bacterial solution inoculation device that other bacterial sneaked into |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111423976B (en) | 2023-03-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113927294B (en) | Overturning positioning device | |

| CN117551531A (en) | A kind of medical examination microorganism culture device | |

| CN111423976A (en) | Aseptic inoculation device of microorganism | |

| CN111635857B (en) | Integrated equipment for avoiding bacteria contamination based on microbial cultivation | |

| CN205731341U (en) | A kind of agar slant connects bacterium test tube rack special | |

| CN108277146A (en) | A kind of bioengineering installation for fermenting being convenient to clean | |

| CN117844617A (en) | Biological raw material fermentation equipment | |

| CN218584730U (en) | Gas automatic sample injector | |

| CN216337579U (en) | Pathogenic microorganism culture apparatus | |

| CN215799499U (en) | A Novel Pipette for Anti-pollution Stem Cell Culture | |

| CN217324106U (en) | Constant temperature culture shaking table | |

| CN211814406U (en) | Isolation equipment for strain culture | |

| CN210765277U (en) | A kind of food-borne pathogenic bacteria experimental culture device | |

| CN204529876U (en) | Liquid cell cultivates special inoculation frame | |

| CN112899118A (en) | A shaking table for microbial cultivation | |

| CN223102983U (en) | A fermentation tank for microbial fermentation convenient for inoculation | |

| CN217052246U (en) | Culture apparatus of microbial inoculum | |

| CN214830384U (en) | Microalgae high-flux culture equipment | |

| CN214937448U (en) | A new type of bacterial inoculator | |

| CN220684964U (en) | Mouth burning equipment | |

| CN218710396U (en) | Microbial strain incubator | |

| CN210711565U (en) | Constant-temperature incubator for bacterial culture | |

| CN204276000U (en) | With the clean bench device of sucked type ultraviolet lamp device | |

| CN217605446U (en) | Nitrogen blowing instrument capable of adjusting needle position | |

| CN206143179U (en) | Conical bottle holder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20230321 |