CN111409415A - Fuel cell stack thermal management apparatus, method and system - Google Patents

Fuel cell stack thermal management apparatus, method and systemDownload PDFInfo

- Publication number

- CN111409415A CN111409415ACN202010247383.8ACN202010247383ACN111409415ACN 111409415 ACN111409415 ACN 111409415ACN 202010247383 ACN202010247383 ACN 202010247383ACN 111409415 ACN111409415 ACN 111409415A

- Authority

- CN

- China

- Prior art keywords

- fuel cell

- cell stack

- accumulator

- way valve

- circuit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00321—Heat exchangers for air-conditioning devices

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00357—Air-conditioning arrangements specially adapted for particular vehicles

- B60H1/00385—Air-conditioning arrangements specially adapted for particular vehicles for vehicles having an electrical drive, e.g. hybrid or fuel cell

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00485—Valves for air-conditioning devices, e.g. thermostatic valves

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00507—Details, e.g. mounting arrangements, desaeration devices

- B60H1/00585—Means for monitoring, testing or servicing the air-conditioning

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/30—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling fuel cells

- B60L58/31—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling fuel cells for starting of fuel cells

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/30—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling fuel cells

- B60L58/32—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling fuel cells for controlling the temperature of fuel cells, e.g. by controlling the electric load

- B60L58/33—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling fuel cells for controlling the temperature of fuel cells, e.g. by controlling the electric load by cooling

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B13/00—Compression machines, plants or systems, with reversible cycle

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B41/00—Fluid-circulation arrangements

- F25B41/30—Expansion means; Dispositions thereof

- F25B41/31—Expansion valves

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/24—Storage receiver heat

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02T90/40—Application of hydrogen technology to transportation, e.g. using fuel cells

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- General Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Transportation (AREA)

- Fuel Cell (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明实施例涉及燃料电池堆技术领域,尤其涉及一种燃料电池堆热管理设备、方法及系统。Embodiments of the present invention relate to the technical field of fuel cell stacks, and in particular, to a fuel cell stack thermal management device, method, and system.

背景技术Background technique

燃料电池发动机作为一种新型的绿色动力能源,因其零污染、高效率、续航里程长等优点被广泛以用于汽车领域。燃料电池堆在运行过程中会产生大量的余热,如何对燃料电池堆的余热进行再利用,是当前研究的一个热点。As a new type of green power energy, fuel cell engines are widely used in the automotive field due to their advantages of zero pollution, high efficiency, and long cruising range. A large amount of waste heat will be generated during the operation of the fuel cell stack. How to reuse the waste heat of the fuel cell stack is a hot research topic at present.

在现有技术中,通过将燃料电池堆冷却液与空调的空气循环系统进行热交换,利用燃料电池堆冷却液对吹过空调散热器表面的空气进行加热,实现冬季对乘客舱进行加热。In the prior art, by exchanging heat between the fuel cell stack coolant and the air circulation system of the air conditioner, the fuel cell stack coolant is used to heat the air blowing over the surface of the air conditioner radiator, so as to heat the passenger compartment in winter.

然而,发明人发现,这种方式仅仅是冬季利用燃料电池堆余热加热乘客舱,且是通过燃料电池堆余热与空气进行热交换,热交换效率低,并未充分利用燃料电池堆余热,燃料电池堆余热利用率较低。However, the inventor found that this method only uses the waste heat of the fuel cell stack to heat the passenger compartment in winter, and exchanges heat with the air through the waste heat of the fuel cell stack. The heat exchange efficiency is low, and the waste heat of the fuel cell stack is not fully utilized. The utilization rate of the residual heat of the stack is low.

发明内容SUMMARY OF THE INVENTION

本发明实施例提供一种燃料电池堆热管理设备、方法及系统,以提高燃料电池堆余热的利用率。Embodiments of the present invention provide a fuel cell stack thermal management device, method and system, so as to improve the utilization rate of the waste heat of the fuel cell stack.

第一方面,本发明实施例提供一种燃料电池堆热管理设备,包括:In a first aspect, an embodiment of the present invention provides a fuel cell stack thermal management device, including:

燃料电池堆、蓄能器、压缩机、室外换热器、室内换热器和散热器总成;Fuel cell stacks, accumulators, compressors, outdoor heat exchangers, indoor heat exchangers and radiator assemblies;

所述燃料电池堆和所述蓄能器通过冷却液管路形成蓄能器回路;The fuel cell stack and the accumulator form an accumulator circuit through a coolant pipeline;

所述燃料电池堆和所述室外换热器通过冷却液管路形成耦合空调回路;The fuel cell stack and the outdoor heat exchanger form a coupled air conditioning circuit through a cooling liquid pipeline;

所述室外换热器、所述压缩机和所述室内换热器通过冷却液管路形成车载空调回路;The outdoor heat exchanger, the compressor and the indoor heat exchanger form a vehicle air conditioning circuit through a cooling liquid pipeline;

所述燃料电池堆和所述散热器总成通过冷却液管路形成系统散热回路。The fuel cell stack and the radiator assembly form a system heat dissipation circuit through a coolant pipeline.

作为本发明的一个实施例,所述蓄能器的入口端设有第一温度传感器,所述蓄能器的出口端设有第二温度传感器。As an embodiment of the present invention, the inlet end of the accumulator is provided with a first temperature sensor, and the outlet end of the accumulator is provided with a second temperature sensor.

作为本发明的一个实施例,还包括:电动水泵、第一三通阀和第二三通阀;As an embodiment of the present invention, it further includes: an electric water pump, a first three-way valve and a second three-way valve;

所述电动水泵的入口端与所述燃料电池堆的第一端连接;The inlet end of the electric water pump is connected with the first end of the fuel cell stack;

所述第一三通阀的第一端与所述电动水泵的出口端连接,所述第一三通阀的第二端与所述蓄能器的入口端连接,所述第一三通阀的第三端与所述室外换热器的第一端连接;The first end of the first three-way valve is connected to the outlet end of the electric water pump, the second end of the first three-way valve is connected to the inlet end of the accumulator, and the first three-way valve is connected to the inlet end of the accumulator. The third end of the heat exchanger is connected to the first end of the outdoor heat exchanger;

所述第二三通阀的第一端与所述蓄能器的出口端连接,所述第二三通阀的第二端与所述燃料电池堆的第二端连接,所述第二三通阀的第三端与所述室外换热器的第二端连接。The first end of the second three-way valve is connected to the outlet end of the accumulator, the second end of the second three-way valve is connected to the second end of the fuel cell stack, and the second three-way valve is connected to the second end of the fuel cell stack. The third end of the through valve is connected to the second end of the outdoor heat exchanger.

作为本发明的一个实施例,还包括:第三三通阀;As an embodiment of the present invention, it further includes: a third three-way valve;

所述第三三通阀设于所述第一三通阀与所述室外换热器的第一端之间;所述第三三通阀的第一端与所述第一三通阀的第三端连接,所述第三三通阀的第二端与所述室外换热器的第一端连接,所述第三三通阀的第三端与所述散热器总成的第一端连接。The third three-way valve is arranged between the first three-way valve and the first end of the outdoor heat exchanger; the first end of the third three-way valve and the first three-way valve are The third end is connected, the second end of the third three-way valve is connected with the first end of the outdoor heat exchanger, the third end of the third three-way valve is connected with the first end of the radiator assembly end connection.

作为本发明的一个实施例,还包括:第四三通阀;As an embodiment of the present invention, it further includes: a fourth three-way valve;

所述第四三通阀设于所述第二三通阀与所述室外换热器的第二端之间;所述第四三通阀的第一端与所述第二三通阀的第三端连接,所述第四三通阀的第二端与所述室外换热器的第二端连接,所述第四三通阀的第三端与所述散热器总成的第二端连接。The fourth three-way valve is arranged between the second three-way valve and the second end of the outdoor heat exchanger; the first end of the fourth three-way valve is connected to the second three-way valve. The third end is connected, the second end of the fourth three-way valve is connected with the second end of the outdoor heat exchanger, the third end of the fourth three-way valve is connected with the second end of the radiator assembly end connection.

作为本发明的一个实施例,还包括:四通换向阀和膨胀阀;As an embodiment of the present invention, it further includes: a four-way reversing valve and an expansion valve;

所述四通换向阀的第一端与所述压缩机的第一端连接,所述四通换向阀的第二端与所述压缩机的第二端连接,所述四通换向阀的第三端与所述室外换热器的第三端连接,所述四通换向阀的第四端与所述室内换热器的第一端连接;The first end of the four-way reversing valve is connected to the first end of the compressor, the second end of the four-way reversing valve is connected to the second end of the compressor, and the four-way reversing valve is connected to the second end of the compressor. The third end of the valve is connected to the third end of the outdoor heat exchanger, and the fourth end of the four-way reversing valve is connected to the first end of the indoor heat exchanger;

所述膨胀阀的第一端与所述室内换热器的第二端连接,所述膨胀阀的第二端与所述室外换热器的第四端连接。The first end of the expansion valve is connected to the second end of the indoor heat exchanger, and the second end of the expansion valve is connected to the fourth end of the outdoor heat exchanger.

第二方面,本发明实施例提供一种燃料电池堆热管理方法,应用于第一方面以及任一种可能的实现方式所述的燃料电池堆热管理设备,包括:In a second aspect, an embodiment of the present invention provides a fuel cell stack thermal management method, which is applied to the fuel cell stack thermal management device described in the first aspect and any possible implementation manner, including:

若检测到燃料电池堆启动指令,则开启蓄能器回路,并在所述燃料电池堆启动后,关闭所述蓄能器回路;If a fuel cell stack start-up instruction is detected, the accumulator circuit is opened, and after the fuel cell stack is started, the accumulator circuit is closed;

若检测到所述燃料电池堆处于开启状态,则检测所述燃料电池堆的温度;If it is detected that the fuel cell stack is in an open state, detecting the temperature of the fuel cell stack;

若检测到所述燃料电池堆的温度大于第一预设温度阈值,则再次开启所述蓄能器回路,并检测车载空调的工作模式;If it is detected that the temperature of the fuel cell stack is greater than the first preset temperature threshold, the accumulator circuit is opened again, and the working mode of the vehicle air conditioner is detected;

若检测到所述车载空调处于制热工作模式,则开启耦合空调回路和车载空调回路,并将所述车载空调回路切换至制热模式。If it is detected that the vehicle air conditioner is in the heating mode, the coupled air conditioner circuit and the vehicle air conditioner circuit are turned on, and the vehicle air conditioner circuit is switched to the heating mode.

作为本发明的一个实施例,所述若检测到所述燃料电池堆的温度大于第一预设温度阈值,则再次开启所述蓄能器回路之后,还包括:As an embodiment of the present invention, if it is detected that the temperature of the fuel cell stack is greater than a first preset temperature threshold, after opening the accumulator circuit again, the method further includes:

若检测到所述蓄能器的入口端温度与所述蓄能器的出口端温度相同,则再次关闭所述蓄能器回路。If it is detected that the temperature of the inlet end of the accumulator is the same as the temperature of the outlet end of the accumulator, the accumulator circuit is closed again.

作为本发明的一个实施例,若检测到所述车载空调处于制热工作模式,则开启耦合空调回路和车载空调回路,并将所述车载空调回路切换至制热模式之后,还包括:As an embodiment of the present invention, if it is detected that the on-board air conditioner is in the heating working mode, the coupled air-conditioning circuit and the on-board air-conditioning circuit are turned on, and after the on-board air-conditioning circuit is switched to the heating mode, the method further includes:

若检测到所述燃料电池堆的温度大于第二预设阈值,则开启系统散热回路,其中,所述第二预设阈值大于所述第一预设阈值。If it is detected that the temperature of the fuel cell stack is greater than a second preset threshold, the system heat dissipation circuit is opened, wherein the second preset threshold is greater than the first preset threshold.

作为本发明的一个实施例,所述检测车载空调的工作模式之后,还包括:As an embodiment of the present invention, after the detection of the working mode of the vehicle air conditioner, the method further includes:

若检测到所述车载空调处于制冷模式,则开启耦合空调回路和车载空调回路,并将所述车载空调回路切换至制冷模式。If it is detected that the vehicle air conditioner is in the cooling mode, the coupled air conditioner circuit and the vehicle air conditioner circuit are turned on, and the vehicle air conditioner circuit is switched to the cooling mode.

作为本发明的一个实施例,所述若检测到燃料电池堆启动指令,则开启蓄能器回路,包括:As an embodiment of the present invention, if the fuel cell stack startup instruction is detected, the accumulator circuit is opened, including:

若检测到燃料电池堆启动指令,且所述燃料电池堆的温度小于第三预设阈值,则开启蓄能器回路。If a fuel cell stack start-up command is detected and the temperature of the fuel cell stack is less than a third preset threshold, the accumulator circuit is opened.

第三方面,本发明实施例提供一种燃料电池堆热管理装置,应用于第一方面以及任一种可能的实现方式所述的燃料电池堆热管理设备,包括:In a third aspect, embodiments of the present invention provide a fuel cell stack thermal management device, which is applied to the fuel cell stack thermal management device described in the first aspect and any possible implementation manner, including:

第一开启模块,用于若检测到燃料电池堆启动指令,则开启蓄能器回路,并在所述燃料电池堆启动后,关闭所述蓄能器回路;a first opening module, configured to open an accumulator circuit if a fuel cell stack start-up instruction is detected, and close the accumulator circuit after the fuel cell stack is started;

检测模块,用于若检测到所述燃料电池堆处于开启状态,则检测所述燃料电池堆的温度;a detection module, configured to detect the temperature of the fuel cell stack if it is detected that the fuel cell stack is in an open state;

第二开启模块,用于若检测到所述燃料电池堆的温度大于第一预设温度阈值,则再次开启所述蓄能器回路,并检测车载空调的工作模式;a second opening module, configured to open the accumulator circuit again if it is detected that the temperature of the fuel cell stack is greater than the first preset temperature threshold, and detect the working mode of the vehicle air conditioner;

第三开启模块,用于若检测到所述车载空调处于制热工作模式,则开启耦合空调回路和车载空调回路,并将所述车载空调回路切换至制热模式。The third opening module is configured to open the coupling air conditioner circuit and the vehicle air conditioner circuit if it is detected that the vehicle air conditioner is in the heating mode, and switch the vehicle air conditioner circuit to the heating mode.

第四方面,本发明实施例提供一种燃料电池堆热管理系统,包括:本发明实施例第一方面以及任一种可能的实现方式所述的燃料电池堆热管理设备和控制器;In a fourth aspect, an embodiment of the present invention provides a fuel cell stack thermal management system, including: the fuel cell stack thermal management device and controller described in the first aspect and any possible implementation manner of the embodiment of the present invention;

所述控制器包括至少一个存储器和处理器;所述存储器存储计算机执行指令;所述至少一个处理器执行所述存储器存储的计算机执行指令,使得所述至少一个处理器执行如本发明实施例第二方面以及任一种可能的实现方式所述的燃料电池堆热管理方法。The controller includes at least one memory and a processor; the memory stores computer-executable instructions; the at least one processor executes the computer-executable instructions stored in the memory, so that the at least one processor executes the computer-executable instructions according to the first embodiment of the present invention. The fuel cell stack thermal management method described in the second aspect and any possible implementation manner.

第五方面,本发明实施例提供一种车辆,包括:本发明实施例第三方面所述的燃料电池堆热管理系统。In a fifth aspect, an embodiment of the present invention provides a vehicle, including: the fuel cell stack thermal management system described in the third aspect of the embodiment of the present invention.

第六方面,本发明实施例提供一种计算机可读存储介质,所述计算机可读存储介质中存储有计算机执行指令,当处理器执行所述计算机执行指令时,实现本发明实施例第二方面以及任一种可能的实现方式所述的燃料电池堆热管理方法。In a sixth aspect, an embodiment of the present invention provides a computer-readable storage medium, where computer-executable instructions are stored in the computer-readable storage medium, and when a processor executes the computer-executable instructions, the second aspect of the embodiment of the present invention is implemented and the fuel cell stack thermal management method described in any possible implementation manner.

本发明实施例提供的燃料电池堆热管理设备、方法及系统,燃料电池堆热管理设备包括:燃料电池堆、蓄能器、室外换热器、压缩机、室内换热器和散热器总成。燃料电池堆和蓄能器通过冷却液管路形成蓄能器回路。燃料电池堆和室外换热器通过冷却液管路形成耦合空调回路。室外换热器、压缩机和室内换热器通过冷却液管路形成车载空调回路。燃料电池堆和散热器总成通过冷却液管路形成系统散热回路。通过蓄能器回路实现燃料电池堆的冷启动和余热存储,通过耦合空调回路和车载空调回路实现燃料电池堆余热与车载空调的热交换,通过系统散热回路实现燃料电池堆的散热。本发明实施例能够提高燃料电池堆余热的利用效率,并能保证燃料电池堆处于合适的工作温度。The fuel cell stack thermal management device, method, and system provided by the embodiments of the present invention, the fuel cell stack thermal management device includes: a fuel cell stack, an accumulator, an outdoor heat exchanger, a compressor, an indoor heat exchanger, and a radiator assembly . The fuel cell stack and the accumulator form an accumulator circuit through the coolant line. The fuel cell stack and the outdoor heat exchanger form a coupled air conditioning circuit through the coolant pipeline. The outdoor heat exchanger, compressor and indoor heat exchanger form the vehicle air conditioning circuit through the coolant pipeline. The fuel cell stack and the radiator assembly form a system heat dissipation circuit through the coolant pipeline. The cold start and waste heat storage of the fuel cell stack are realized through the accumulator circuit, the heat exchange between the fuel cell stack waste heat and the vehicle air conditioner is realized by coupling the air conditioning circuit and the vehicle air conditioning circuit, and the heat dissipation of the fuel cell stack is realized through the system heat dissipation circuit. The embodiments of the present invention can improve the utilization efficiency of the waste heat of the fuel cell stack, and can ensure that the fuel cell stack is at a suitable working temperature.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作一简单地介绍,显而易见地,下面描述中的附图是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动性的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description These are some embodiments of the present invention, and for those of ordinary skill in the art, other drawings can also be obtained from these drawings without any creative effort.

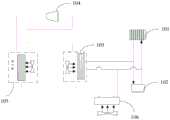

图1为本发明实施例提供的燃料电池堆热管理设备的结构示意图一;FIG. 1 is a schematic structural diagram 1 of a fuel cell stack thermal management device provided by an embodiment of the present invention;

图2为本发明实施例提供的燃料电池堆热管理设备的结构示意图二;FIG. 2 is a second schematic structural diagram of a fuel cell stack thermal management device provided by an embodiment of the present invention;

图3为本发明实施例提供的燃料电池堆热管理设备的结构示意图三;FIG. 3 is a third structural schematic diagram of a fuel cell stack thermal management device provided by an embodiment of the present invention;

图4为本发明实施例提供的燃料电池堆热管理方法的流程示意图;4 is a schematic flowchart of a method for thermal management of a fuel cell stack provided by an embodiment of the present invention;

图5为本发明实施例提供的燃料电池堆热管理装置的结构示意图一;5 is a schematic structural diagram 1 of a fuel cell stack thermal management device provided by an embodiment of the present invention;

图6为本发明实施例提供的燃料电池堆热管理装置的结构示意图二;FIG. 6 is a second structural schematic diagram of a fuel cell stack thermal management device provided by an embodiment of the present invention;

图7为本发明实施例提供的燃料电池堆热管理系统的硬件结构示意图。FIG. 7 is a schematic diagram of a hardware structure of a fuel cell stack thermal management system according to an embodiment of the present invention.

具体实施方式Detailed ways

为使本发明实施例的目的、技术方案和优点更加清楚,下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments These are some embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

现有技术中,对燃料电池堆的余热进行再利用时,主要是利用燃料电池堆的余热对乘客舱进行供暖,例如,将燃料电池堆冷却液与空调的空气循环系统进行热交换,利用燃料电池堆冷却液对吹过空调散热器表面的空气进行加热,实现冬季对乘客舱进行加热。然而,这种方式是通过燃料电池堆余热与空气进行热交换,热交换效率低,并未充分利用燃料电池堆的余热,且未考虑燃料燃料电池堆冷启动的问题。In the prior art, when the waste heat of the fuel cell stack is reused, the waste heat of the fuel cell stack is mainly used to heat the passenger compartment. The battery stack coolant heats the air blowing over the surface of the air conditioner radiator, enabling heating of the passenger compartment in winter. However, this method uses the waste heat of the fuel cell stack to exchange heat with the air, and the heat exchange efficiency is low, the waste heat of the fuel cell stack is not fully utilized, and the problem of cold start of the fuel cell stack is not considered.

在低温环境下,燃料电池堆内部的冷却液会结冰,造成启动过程中气体扩散受阻,甚至启动失败。因此,在燃料电池堆冷启动前,需要对燃料电池堆进行预热融冰处理,提升燃料电池堆内部的温度,从而保证燃料电池堆成功启动。在燃料电池堆启动后,燃料电池堆在运行过程中会产生大量的余热,需要实现对燃料电池堆余热的高效利用和散热,保证燃料电池堆处于合适的工作温度。In a low temperature environment, the coolant inside the fuel cell stack will freeze, which will hinder the gas diffusion during the start-up process, or even fail to start. Therefore, before the cold start of the fuel cell stack, the fuel cell stack needs to be preheated and ice-melted to increase the temperature inside the fuel cell stack, so as to ensure the successful start of the fuel cell stack. After the fuel cell stack is started, a large amount of waste heat will be generated during the operation of the fuel cell stack. It is necessary to efficiently utilize and dissipate the waste heat of the fuel cell stack to ensure that the fuel cell stack is at a suitable working temperature.

基于此,本发明实施例提供一种燃料电池堆热管理设备,在低温环境下,先对燃料电池堆进行升温再启动,燃料电池堆成功启动后,能够实现对燃料电池堆余热的高效利用以及散热,保证燃料电池堆处于合适的工作温度。Based on this, the embodiments of the present invention provide a thermal management device for a fuel cell stack. In a low temperature environment, the fuel cell stack is first heated up and then started. After the fuel cell stack is successfully started, the efficient utilization of the fuel cell stack waste heat and Dissipate heat to ensure that the fuel cell stack is at a suitable operating temperature.

图1为本发明实施例提供的燃料电池堆热管理设备的结构示意图一,如图1所示,本实施例的燃料电池堆热管理设备包括:燃料电池堆101、蓄能器102、室外换热器103、压缩机104、室内换热器105和散热器总成106。FIG. 1 is a schematic structural diagram 1 of a fuel cell stack thermal management device provided by an embodiment of the present invention. As shown in FIG. 1 , the fuel cell stack thermal management device in this embodiment includes: a

燃料电池堆101和蓄能器102通过冷却液管路形成蓄能器回路。The

燃料电池堆101和室外换热器103通过冷却液管路形成耦合空调回路。The

室外换热器103、压缩机104和室内换热器105通过冷却液管路形成车载空调回路。The

燃料电池堆101和散热器总成106通过冷却液管路形成系统散热回路。The

在本发明实施例中,燃料电池堆101是由多片燃料电池单体叠加后经密封、压紧等流程制作而成,包括单体、密封件、端板、捆扎带、集流板等组件。In the embodiment of the present invention, the

蓄能器102是一种能量储存与利用装置。蓄能器102内填充相变材料,外部热量通过流体介质带入蓄能器实现能量的储存,同时通过流体介质的流动实现对能量的提取。The

在燃料电池堆101低温启动前,冷却液流经蓄能器回路,通过蓄能器102存储的能量对燃料电池堆101进行预热处理,提升燃料电池堆101内部的温度,保证燃料电池堆的成功启动。Before the

在燃料电池堆101启动后,冷却液流经蓄能器回路,将燃料电池堆的余热储存在蓄能器102中,以备冷启动时使用。After the

耦合空调回路和车载空调回路实现燃料电池堆101的余热与车载空调进行热交换。The coupling of the air conditioning circuit and the vehicle air conditioning circuit realizes heat exchange between the waste heat of the

在环境温度低于车载空调的制冷剂蒸发温度时,制冷剂吸热蒸发的难度大幅增加,车载空调的制热能力大幅下降,甚至出现车载空调处于过冷保护停机状态,通过将燃料电池堆的余热与车载空调蒸发器进行热交换,不仅能够实现燃料电池堆的余热再利用,而且能够保证车载空调稳定而高效的工作。When the ambient temperature is lower than the refrigerant evaporation temperature of the vehicle air conditioner, the difficulty of absorbing heat and evaporating the refrigerant is greatly increased, the heating capacity of the vehicle air conditioner is greatly reduced, and even the vehicle air conditioner is in the state of overcooling protection shutdown. The heat exchange between the waste heat and the evaporator of the vehicle air conditioner can not only realize the reuse of the waste heat of the fuel cell stack, but also ensure the stable and efficient operation of the vehicle air conditioner.

在高温环境下,燃料电池堆处于大功率运行工况时,单独依靠系统散热回路难以得到理想的散热效果,通过将燃料电池堆的余热与车载空调冷凝器进行热交换,联合散热回路和车载空调回路散热,实现燃料电池堆余热的高效排出。In a high temperature environment, when the fuel cell stack is in high-power operation, it is difficult to obtain the ideal heat dissipation effect by relying on the system heat dissipation circuit alone. The circuit dissipates heat and realizes the efficient discharge of the waste heat of the fuel cell stack.

系统散热回路实现燃料电池堆101的散热,使燃料电池堆101工作在合适的温度范围,避免处于低效工作区。The system heat dissipation circuit realizes the heat dissipation of the

本发明实施例提供的燃料电池堆热管理设备100包括:燃料电池堆101、蓄能器102、室外换热器103、压缩机104、室内换热器105和散热器总成106。燃料电池堆101和蓄能器102通过冷却液管路形成蓄能器回路。燃料电池堆101和室外换热器103通过冷却液管路形成耦合空调回路。室外换热器103、压缩机104和室内换热器105通过冷却液管路形成车载空调回路。燃料电池堆101和散热器总成106通过冷却液管路形成系统散热回路。通过蓄能器回路实现燃料电池堆的冷启动和余热存储,通过耦合空调回路和车载空调回路实现燃料电池堆余热与车载空调的热交换,通过系统散热回路实现燃料电池堆的散热。本发明实施例能够提高燃料电池堆101余热的利用效率,并能保证燃料电池堆101处于合适的工作温度。The fuel cell stack thermal management device 100 provided by the embodiment of the present invention includes: a

图2为本发明实施例提供的燃料电池堆热管理设备的结构示意图二,如图2所示,本实施例的燃料电池堆热管理设备还包括:第一温度传感器107和第二温度传感器108。FIG. 2 is a second schematic structural diagram of a fuel cell stack thermal management device provided by an embodiment of the present invention. As shown in FIG. 2 , the fuel cell stack thermal management device in this embodiment further includes: a

第一温度传感器107设于蓄能器102的入口端,用于检测蓄能器102入口端的温度。The

第二温度传感器108设于蓄能器102的出口端,用于检测蓄能器102出口端的温度。The

若第一温度传感器107检测得到的蓄能器102入口端的温度与第二温度传感器108检测到的蓄能器102出口端的温度相同,则指示蓄能器102存储的能量达到上限,需要停止将燃料电池堆101的余热继续存储在蓄能器102中,从而防止蓄能器102被损坏。If the temperature at the inlet end of the

图3为本发明实施例提供的燃料电池堆热管理设备的结构示意图三,如图3所示,本实施例的燃料电池堆热管理设备100还包括:电动水泵109、第一三通阀110、第二三通阀111、第三三通阀112、第四三通阀113、四通换向阀114和膨胀阀115。FIG. 3 is a schematic structural diagram 3 of a fuel cell stack thermal management device provided by an embodiment of the present invention. As shown in FIG. 3 , the fuel cell stack thermal management device 100 in this embodiment further includes: an

电动水泵109的入口端与燃料电池堆101的第一端连接。The inlet end of the

第一三通阀110的第一端与电动水泵109的出口端连接,第一三通阀110的第二端与蓄能器102的入口端连接,第一三通阀110的第三端与室外换热器103的第一端连接。The first end of the first three-

第二三通阀111的第一端与蓄能器102的出口端连接,第二三通阀111的第二端与燃料电池堆101的第二端连接,第二三通阀111的第三端与室外换热器103的第二端连接。The first end of the second three-

第三三通阀112设于第一三通阀110与室外换热器103的第一端之间。第三三通阀112的第一端与第一三通阀110的第三端连接,第三三通阀112的第二端与室外换热器103的第一端连接,第三三通阀112的第三端与散热器总成106的第一端连接。The third three-

第四三通阀113设于第二三通阀111与室外换热器103的第二端之间。第四三通阀113的第一端与第二三通阀111的第三端连接,第四三通阀113的第二端与室外换热器103的第二端连接,第四三通阀113的第三端与散热器总成106的第二端连接。The fourth three-

四通换向阀114的第一端与压缩机104的第一端连接,四通换向阀114的第二端与压缩机104的第二端连接,四通换向阀114的第三端与室外换热器103的第三端连接,四通换向阀114的第四端与室内换热器105的第一端连接。The first end of the four-

膨胀阀115的第一端与室内换热器105的第二端连接,膨胀阀115的第二端与室外换热器103的第四端连接。The first end of the

在本发明实施例中,燃料电池堆101、电动水泵109、第一三通阀110、蓄能器102、第二三通阀111通过冷却液管路构成蓄能器回路。In the embodiment of the present invention, the

燃料电池堆在低温冷启动前,开启第一三通阀110的第一端和第二端,以及第二三通阀111的第一端和第二端,即开启蓄能器回路,冷却液流经蓄能器回路,通过蓄能器102中的能量对燃料电池堆101进行预热处理。燃料电池堆101启动后,关闭第一三通阀110的第一端和第二端,以及第二三通阀111的第一端和第二端,即关闭蓄能器回路。若检测到燃料电池堆101的温度大于第一预设温度,再次开启第一三通阀110的第一端和第二端,以及第二三通阀111的第一端和第二端,即再次开启蓄能器回路,冷却液流经蓄能器回路,将燃料电池堆101的余热存储在蓄能器102中。Before the low-temperature cold start of the fuel cell stack, the first and second ends of the first three-

燃料电池堆101、电动水泵109、第一三通阀110、第三三通阀112、燃散热器总成106、第四三通阀113和第二三通阀111通过冷却液管路构成系统散热回路。The

通过开启第一三通阀110的第一端、第二端和第三端、第三三通阀112的第一端和第三端、第四三通阀113的第一端和第三端,以及第二三通阀111的第一端、第二端和第三端,开启系统散热路径,冷却液流经系统散热回路,将燃料电池堆101的余热通过散热器总成106散出。By opening the first, second and third ends of the first three-

燃料电池堆101、电动水泵109、第一三通阀110、第三三通阀112、室外换热器103、第四三通阀113和第二三通阀111通过冷却液管路构成耦合空调回路。The

通过开启第一三通阀110的第一端、第二端和第三端,第三三通阀112的第一端和第二端,第四三通阀113的第一端和第二端,以及第二三通阀111的第一端、第二端和第三端,开启耦合空调回路,冷却液流经耦合空调回路,将燃料电池堆101的余热耦合进入车载空调中。By opening the first, second and third ends of the first three-

压缩机104、四通换向阀114、室内换热器105、膨胀阀115和室外换热器103通过冷却液管路形成车载空调回路。The

通过依次开启四通换向阀114的第一端、第四端,膨胀阀115的第一端和第二端,以及通阀114的第三端和第二端,冷却液依次流经压缩机104、室内换热器105、室外换热器103和压缩机104,实现车载空调的制热工作模式,此时,室内散热器105相当于冷凝器,室外散热器103相当于蒸发器,实现对乘客舱加热。By sequentially opening the first and fourth ends of the four-

通过依次开启四通换向阀114的第二端和第三端,膨胀阀115的第一端和第二端,以及四通换向阀114的第四端和第一端,冷却液依次流经压缩机104、室外换热器103、室内换热器105和压缩机104,实现车载空调的制冷工作模式,此时,室内散热器105相当于蒸发器,室外散热器103相当于冷凝器。通过车载空调实现对燃料电池堆101余热的散出。By sequentially opening the second and third ends of the four-

图4为本发明实施例提供的燃料电池堆热管理方法的流程示意图,本实施例的方法应用于图1至图3所示的燃料电池堆热管理设备。如图4所示,本实施例的燃料电池堆热管理设方法包括:FIG. 4 is a schematic flowchart of a fuel cell stack thermal management method provided by an embodiment of the present invention. The method of this embodiment is applied to the fuel cell stack thermal management apparatus shown in FIGS. 1 to 3 . As shown in FIG. 4 , the fuel cell stack thermal management design method of this embodiment includes:

步骤S101,若检测到燃料电池堆启动指令,则开启蓄能器回路,并在燃料电池堆启动后,关闭蓄能器回路。In step S101, if a fuel cell stack start-up instruction is detected, the accumulator circuit is opened, and after the fuel cell stack is started, the accumulator circuit is closed.

在本发明实施例中,通过检测燃料电池发动机启动指令,判断是否检测到燃料电池堆启动指令。若检测到燃料电池堆启动指令,则开启蓄能器回路,通过蓄能器对燃料电池堆进行预热处理。在检测到燃料电池堆的温度升高至预设温度阈值时,启动燃料电池堆,并关闭蓄能器回路。其中,预设温度阈值指示燃料电池堆的温度处于可以启动的状态。In the embodiment of the present invention, it is determined whether the fuel cell stack startup instruction is detected by detecting the fuel cell engine startup instruction. If the fuel cell stack start command is detected, the accumulator circuit is opened, and the fuel cell stack is preheated through the accumulator. When it is detected that the temperature of the fuel cell stack rises to a preset temperature threshold, the fuel cell stack is activated, and the accumulator circuit is closed. Wherein, the preset temperature threshold value indicates that the temperature of the fuel cell stack is in a startable state.

通过开启图3所示实施例中的第一三通阀的第一端和第二端以及第二三通阀的第一端和第二端开启蓄能器回路。冷却液管路中的冷却液依次流经电动水泵、蓄能器、燃料电池堆和电动水泵,通过蓄能器中的能量对燃料电池堆进行预热处理。燃料电池堆成功启动后,关闭第一三通阀的第一端和第二端,以及第二三通阀的第一端和第二端,停止蓄能器向燃料电池堆供热,燃料电池堆处于正常运行状态。The accumulator circuit is opened by opening the first and second ends of the first three-way valve and the first and second ends of the second three-way valve in the embodiment shown in FIG. 3 . The cooling liquid in the cooling liquid pipeline flows through the electric water pump, the accumulator, the fuel cell stack and the electric water pump in sequence, and the fuel cell stack is preheated by the energy in the accumulator. After the fuel cell stack is successfully started, close the first and second ends of the first three-way valve, and the first and second ends of the second three-way valve, stop the accumulator supplying heat to the fuel cell stack, and the fuel cell The heap is in a healthy state.

步骤S102,若检测到燃料电池堆处于开启状态,则检测燃料电池堆的温度。Step S102, if it is detected that the fuel cell stack is in an on state, the temperature of the fuel cell stack is detected.

在本发明实施例中,燃料电池堆成功启动后,检测燃料电池堆的温度以及车载空调的工作模式。车载空调的模式分为工作模式和非工作模式,工作模式又分为制冷模式、制热模式和换气模式等。In the embodiment of the present invention, after the fuel cell stack is successfully started, the temperature of the fuel cell stack and the working mode of the vehicle air conditioner are detected. The modes of the vehicle air conditioner are divided into working mode and non-working mode, and the working mode is further divided into cooling mode, heating mode and ventilation mode.

步骤S103,若检测到燃料电池堆的温度大于第一预设温度阈值,则再次开启蓄能器回路,并检测车载空调的工作模式。Step S103, if it is detected that the temperature of the fuel cell stack is greater than the first preset temperature threshold, the accumulator circuit is turned on again, and the working mode of the vehicle air conditioner is detected.

燃料电池堆的温度大于第一温度阈值指示燃料电池堆处于需要散热的工况,此时,开启蓄能器回路。通过开启图3所示实施例中的第一三通阀的第一端和第二端以及第二三通阀的第一端和第二端开启蓄能器回路。冷却液管路中的冷却液依次流经电动水泵、蓄能器、燃料电池堆和电动水泵,将燃料电池堆的余热存储在蓄能器路径中,以备冷启动时使用。The temperature of the fuel cell stack being greater than the first temperature threshold indicates that the fuel cell stack is in a working condition requiring heat dissipation, and at this time, the accumulator circuit is opened. The accumulator circuit is opened by opening the first and second ends of the first three-way valve and the first and second ends of the second three-way valve in the embodiment shown in FIG. 3 . The cooling liquid in the cooling liquid pipeline flows through the electric water pump, the accumulator, the fuel cell stack and the electric water pump in sequence, and the waste heat of the fuel cell stack is stored in the accumulator path for use during cold start.

步骤S104,若检测到车载空调处于制热工作模式,则开启耦合空调回路和车载空调回路,并将车载空调回路切换至制热模式。Step S104, if it is detected that the vehicle air conditioner is in the heating mode, the coupled air conditioner circuit and the vehicle air conditioner circuit are turned on, and the vehicle air conditioner circuit is switched to the heating mode.

在低温环境下,通过耦合空调回路和车载空调回路实现利用燃料电池堆余热为乘客舱加热。In a low temperature environment, the passenger compartment can be heated by using the waste heat of the fuel cell stack by coupling the air conditioning circuit and the vehicle air conditioning circuit.

通过开启图3所示实施例中的第一三通阀的第一端、第二端和第三端,第三三通阀的第一端和第二端,第四三通阀的第一端和第二端,以及第二三通阀的第一端、第二端和第三端,开启耦合空调路径,将燃料电池堆的余热耦合进入车载空调中。By opening the first end, the second end and the third end of the first three-way valve in the embodiment shown in FIG. 3 , the first end and the second end of the third three-way valve, and the first end of the fourth three-way valve The end and the second end, as well as the first end, the second end and the third end of the second three-way valve, open the coupling air conditioner path, and couple the waste heat of the fuel cell stack into the vehicle air conditioner.

通过依次开启四通换向阀的第一端、第四端,膨胀阀的第一端和第二端,以及通阀的第三端和第二端,冷却液依次流经压缩机、室内换热器、室外换热器和压缩机,实现车载空调的制热工作模式,此时,室内散热器相当于冷凝器,室外散热器相当于蒸发器,实现对乘客舱加热。By sequentially opening the first and fourth ends of the four-way reversing valve, the first and second ends of the expansion valve, and the third and second ends of the through valve, the coolant flows through the compressor, the indoor switching valve in sequence, and the Heater, outdoor heat exchanger and compressor to realize the heating mode of vehicle air conditioner. At this time, the indoor radiator is equivalent to the condenser, and the outdoor radiator is equivalent to the evaporator to achieve heating of the passenger compartment.

本发明实施例通过在燃料电池堆启动前,通过蓄能器回路对燃料电池堆进行预热,能够避免在低温环境下,由于燃料电池内部结冰,导致启动失败。并且在燃料电池启动后,通过蓄能器回路将燃料电池堆的余热存储在蓄能器中,通过耦合空调回路和车载空调回路利用燃料电池堆的余热对乘客舱进行加热,实现燃料电池堆余热的高效利用。In the embodiment of the present invention, by preheating the fuel cell stack through the accumulator circuit before starting the fuel cell stack, it is possible to avoid starting failure due to ice formation inside the fuel cell in a low temperature environment. And after the fuel cell is started, the waste heat of the fuel cell stack is stored in the accumulator through the accumulator circuit, and the passenger cabin is heated by the waste heat of the fuel cell stack by coupling the air conditioning circuit and the vehicle air conditioning circuit to realize the waste heat of the fuel cell stack. efficient use.

作为本发明的一个实施例,在上述图4所示实施例的基础上,步骤S103之后,本发明的实施例还可以包括:As an embodiment of the present invention, on the basis of the embodiment shown in FIG. 4 above, after step S103, the embodiment of the present invention may further include:

若检测到蓄能器的入口端温度与蓄能器的出口端温度相同,则再次关闭蓄能器回路。If it is detected that the temperature at the inlet end of the accumulator is the same as the temperature at the outlet end of the accumulator, the circuit of the accumulator is closed again.

在本发明实施例中,通过图2所示实施例的第一温度传感器和第二温度传感器分别检测蓄能器的入口温度和蓄能器的出口温度,蓄能器的入口端温度与蓄能器的出口端温度相同指示蓄能器存储的能量达到上限,需要停止将燃料电池堆的余热继续存储在蓄能器中,从而防止蓄能器被损坏。In the embodiment of the present invention, the inlet temperature of the accumulator and the outlet temperature of the accumulator are respectively detected by the first temperature sensor and the second temperature sensor of the embodiment shown in FIG. The same temperature at the outlet of the accumulator indicates that the energy stored in the accumulator has reached the upper limit, and it is necessary to stop storing the waste heat of the fuel cell stack in the accumulator to prevent the accumulator from being damaged.

作为本发明的一个实施例,在上述图4所示实施例的基础上,步骤S104之后,本发明的实施例还可以包括:As an embodiment of the present invention, on the basis of the embodiment shown in FIG. 4 above, after step S104, the embodiment of the present invention may further include:

若检测燃料电池堆的温度大于第二预设阈值,则开启系统散热回路,其中,第二预设阈值大于第一预设阈值。If it is detected that the temperature of the fuel cell stack is greater than the second preset threshold, the system heat dissipation circuit is opened, wherein the second preset threshold is greater than the first preset threshold.

在本发明实施例中,燃料电池堆的温度大于第二预设阈值指示依靠蓄能器回路、耦合空调回路以及车载空调回路难以满足散热的需求,此时,开启系统散热回路,实现对燃料电池堆的有效散热,使燃料电池堆工作在合适的温度范围,避免处于低效工作区。In the embodiment of the present invention, if the temperature of the fuel cell stack is greater than the second preset threshold, it indicates that the accumulator circuit, the coupled air conditioner circuit and the vehicle air conditioner circuit cannot meet the heat dissipation requirement. The effective heat dissipation of the stack enables the fuel cell stack to work in a suitable temperature range and avoid being in an inefficient working area.

通过开启图3所示实施例中的第一三通阀的第一端、第二端和第三端、第三三通阀的第一端和第三端,第四三通阀的第一端和第三端,以及第二三通阀的第一端、第二端和第三端,开启系统散热路径,冷却液流经系统散热回路,将燃料电池堆的余热通过散热器总成散出。By opening the first end, the second end and the third end of the first three-way valve, the first end and the third end of the third three-way valve in the embodiment shown in FIG. The end and the third end, and the first end, the second end and the third end of the second three-way valve, open the system heat dissipation path, the cooling liquid flows through the system heat dissipation circuit, and the waste heat of the fuel cell stack is dissipated through the radiator assembly. out.

作为本发明的一个实施例,在上述图4所示实施例的基础上,步骤S103之后,本发明的实施例还可以包括:As an embodiment of the present invention, on the basis of the embodiment shown in FIG. 4 above, after step S103, the embodiment of the present invention may further include:

若检测到车载空调处于制冷模式,则开启耦合空调回路和车载空调回路,并将车载空调回路切换至制冷模式。If it is detected that the vehicle air conditioner is in the cooling mode, the coupled air conditioner circuit and the vehicle air conditioner circuit are turned on, and the vehicle air conditioner circuit is switched to the cooling mode.

在本发明实施例中,在高温环境下,燃料电池运行过程中,大量的余热如果不能及时排出,将造成燃料电池堆内部过热导致输出性能下降,系统甚至处于过热保护而停机。高温环境下,利用车载空调的散热系统散热。In the embodiment of the present invention, in the high temperature environment, during the operation of the fuel cell, if a large amount of waste heat cannot be discharged in time, the internal overheating of the fuel cell stack will cause the output performance to decrease, and the system may even shut down due to overheat protection. In a high temperature environment, the cooling system of the vehicle air conditioner is used to dissipate heat.

在本发明实施例中,通过开启如图3所示的实施例中第一三通阀的第一端、第二端和第三端,第三三通阀的第一端和第二端,第四三通阀的第一端和第二端,以及第二三通阀的第一端、第二端和第三端,开启耦合空调路径,将燃料电池堆的余热耦合进入车载空调中。In the embodiment of the present invention, by opening the first end, the second end and the third end of the first three-way valve and the first end and the second end of the third three-way valve in the embodiment shown in FIG. 3 , The first end and the second end of the fourth three-way valve, and the first end, the second end and the third end of the second three-way valve, open the coupling air conditioner path, and couple the waste heat of the fuel cell stack into the vehicle air conditioner.

通过依次开启四通换向阀的第二端和第三端,膨胀阀的第一端和第二端,以及四通换向阀的第四端和第一端,冷却液依次流经压缩机、室外换热器、室内换热器和压缩机,实现车载空调的制冷工作模式,此时,室内散热器相当于蒸发器,室外散热器相当于冷凝器。通过车载空调实现对燃料电池堆余热的散出。By sequentially opening the second and third ends of the four-way reversing valve, the first and second ends of the expansion valve, and the fourth and first ends of the four-way reversing valve, the coolant flows through the compressor in sequence , outdoor heat exchanger, indoor heat exchanger and compressor to realize the refrigeration working mode of the vehicle air conditioner. At this time, the indoor radiator is equivalent to the evaporator, and the outdoor radiator is equivalent to the condenser. The waste heat of the fuel cell stack is dissipated through the on-board air conditioner.

作为本发明的一个实施例,在上述图4所示实施例的基础上,步骤S101若检测到燃料电池堆启动指令,则开启蓄能器回路,包括:As an embodiment of the present invention, on the basis of the above-mentioned embodiment shown in FIG. 4 , if a fuel cell stack startup instruction is detected in step S101, the accumulator circuit is opened, including:

若检测到燃料电池堆启动指令,且燃料电池堆的温度小于第三预设阈值,则开启蓄能器回路。If the fuel cell stack start command is detected and the temperature of the fuel cell stack is lower than the third preset threshold, the accumulator circuit is opened.

在本发明实施例中,通过温度传感器检测燃料电池堆的温度。燃料电池堆的温度小于第三预设阈值指示燃料电池堆的温度较低,不能正常启动,此时,需要开启蓄能器回路,利用蓄能器对燃料电池堆进行预热。燃料电池堆的温度大于或等于第三预设阈值指示燃料电池堆可以正常启动,不需要开启蓄能器回路。In the embodiment of the present invention, the temperature of the fuel cell stack is detected by a temperature sensor. If the temperature of the fuel cell stack is lower than the third preset threshold, it indicates that the temperature of the fuel cell stack is low and cannot be started normally. In this case, the accumulator circuit needs to be opened, and the accumulator is used to preheat the fuel cell stack. The temperature of the fuel cell stack is greater than or equal to the third preset threshold value, indicating that the fuel cell stack can be started normally without opening the accumulator circuit.

本发明实施例只有在燃料电池堆温度较低时才利用蓄能器对燃料电池堆进行预热后再启动,而在燃料电池堆温度较高时不经过对燃料电池堆预热,直接启动,从而节省蓄能器中的能量。In the embodiment of the present invention, the accumulator is used to preheat the fuel cell stack before starting only when the temperature of the fuel cell stack is low. This saves the energy in the accumulator.

图5为本发明实施例提供的燃料电池堆热管理装置的结构示意图一。如图5所示,该燃料电池的热管理装置50应用于上述图1至图3所示的燃料电池堆热管理设备。包括:第一开启模块501、检测模块502、第二开启模块503和第三开启模块504。各模块的具体功能如下。FIG. 5 is a first structural schematic diagram of a fuel cell stack thermal management device provided by an embodiment of the present invention. As shown in FIG. 5 , the thermal management device 50 of the fuel cell is applied to the fuel cell stack thermal management apparatus shown in FIGS. 1 to 3 . It includes: a

第一开启模块501,用于若检测到燃料电池堆启动指令,则开启蓄能器回路,并在燃料电池堆启动后,关闭蓄能器回路。The

检测模块502,用于若检测到燃料电池堆处于开启状态,则检测燃料电池堆的温度。The

第二开启模块503,用于若检测到燃料电池堆的温度大于第一预设温度阈值,则再次开启蓄能器回路,并检测车载空调的工作模式。The

第三开启模块504,用于若检测到车载空调处于制热工作模式,则开启耦合空调回路和车载空调回路,并将车载空调回路切换至制热模式。The

作为本发明的一个实施例,第二开启模块503,还用于若检测到蓄能器的入口端温度与蓄能器的出口端温度相同,则再次关闭蓄能器回路。As an embodiment of the present invention, the

图6为本发明实施例提供的燃料电池堆热管理装置的结构示意图二。如图6所示,本发明实施例提供的燃料电池的热管理装置500还包括:第四开启模块505,用于若检测到燃料电池堆的温度大于第二预设阈值,则开启系统散热回路,其中,第二预设阈值大于第一预设阈值。FIG. 6 is a second structural schematic diagram of a fuel cell stack thermal management device provided by an embodiment of the present invention. As shown in FIG. 6 , the thermal management device 500 for the fuel cell provided by the embodiment of the present invention further includes: a

作为本发明的一个实施例,第三开启模块504,还用于若检测到车载空调处于制冷模式,则开启耦合空调回路和车载空调回路,并将车载空调回路切换至制冷模式。As an embodiment of the present invention, the

作为本发明的一个实施例,第一开启模块501,具体用于若检测到燃料电池堆启动指令,且燃料电池堆的温度小于第三预设阈值,则开启蓄能器回路。As an embodiment of the present invention, the

本发明实施例提供的燃料电池堆热管理装置,可用于执行上述的方法实施例,其实现原理和技术效果类似,本实施例此处不再赘述。The fuel cell stack thermal management device provided in the embodiment of the present invention can be used to execute the above-mentioned method embodiments, and its implementation principle and technical effect are similar, and details are not described herein again in this embodiment.

图7为本发明实施例提供的燃料电池堆热管理系统的硬件结构示意图。如图7所示,本实施例提供的燃料电池堆热管理系统70包括:上述图1至图3任一个实施例所示的燃料电池堆热管理设备701,以及至少一个处理器702和存储器703。该燃料电池堆热管理设备70还包括通信部件704。其中,燃料电池堆热管理设备701、处理器702、存储器703以及通信部件704通过总线705连接。FIG. 7 is a schematic diagram of a hardware structure of a fuel cell stack thermal management system according to an embodiment of the present invention. As shown in FIG. 7 , the fuel cell stack thermal management system 70 provided in this embodiment includes: the fuel cell stack thermal management device 701 shown in any one of the above embodiments in FIGS. 1 to 3 , and at least one

在具体实现过程中,至少一个处理器702执行存储器703存储的计算机执行指令,使得至少一个处理器702执行如上燃料电池堆热管理系统70所执行的燃料电池堆热管理方法。In a specific implementation process, the at least one

处理器702的具体实现过程可参见上述方法实施例,其实现原理和技术效果类似,本实施例此处不再赘述。For the specific implementation process of the

在上述的图7所示的实施例中,应理解,处理器可以是中央处理单元(英文:Central Processing Unit,简称:CPU),还可以是其他通用处理器、数字信号处理器(英文:Digital Signal Processor,简称:DSP)、专用集成电路(英文:Application SpecificIntegrated Circuit,简称:ASIC)等。通用处理器可以是微处理器或者该处理器也可以是任何常规的处理器等。结合发明所公开的方法的步骤可以直接体现为硬件处理器执行完成,或者用处理器中的硬件及软件模块组合执行完成。In the above-mentioned embodiment shown in FIG. 7 , it should be understood that the processor may be a central processing unit (English: Central Processing Unit, CPU for short), or other general-purpose processors, digital signal processors (English: Digital Signal Processor) Signal Processor, referred to as DSP), application specific integrated circuit (English: Application Specific Integrated Circuit, referred to as: ASIC) and the like. A general purpose processor may be a microprocessor or the processor may be any conventional processor or the like. The steps of the method disclosed in conjunction with the invention can be directly embodied as executed by a hardware processor, or executed by a combination of hardware and software modules in the processor.

存储器可能包含高速RAM存储器,也可能还包括非易失性存储NVM,例如至少一个磁盘存储器。The memory may include high-speed RAM memory, and may also include non-volatile storage NVM, such as at least one disk memory.

总线可以是工业标准体系结构(Industry Standard Architecture,ISA)总线、外部设备互连(Peripheral Component,PCI)总线或扩展工业标准体系结构(ExtendedIndustry Standard Architecture,EISA)总线等。总线可以分为地址总线、数据总线、控制总线等。为便于表示,本申请附图中的总线并不限定仅有一根总线或一种类型的总线。The bus may be an industry standard architecture (Industry Standard Architecture, ISA) bus, a Peripheral Component (Peripheral Component, PCI) bus, or an extended industry standard architecture (Extended Industry Standard Architecture, EISA) bus, or the like. The bus can be divided into address bus, data bus, control bus and so on. For convenience of representation, the buses in the drawings of the present application are not limited to only one bus or one type of bus.

本申请还提供一种计算机可读存储介质,计算机可读存储介质中存储有计算机执行指令,当处理器执行计算机执行指令时,实现如上燃料电池堆热管理设备执行的燃料电池堆热管理方法。The present application also provides a computer-readable storage medium, where computer-executable instructions are stored in the computer-readable storage medium, and when the processor executes the computer-executable instructions, the fuel cell stack thermal management method performed by the fuel cell stack thermal management device as described above is implemented.

上述的计算机可读存储介质,上述可读存储介质可以是由任何类型的易失性或非易失性存储设备或者它们的组合实现,如静态随机存取存储器(SRAM),电可擦除可编程只读存储器(EEPROM),可擦除可编程只读存储器(EPROM),可编程只读存储器(PROM),只读存储器(ROM),磁存储器,快闪存储器,磁盘或光盘。可读存储介质可以是通用或专用计算机能够存取的任何可用介质。The above-mentioned computer-readable storage medium, the above-mentioned readable storage medium can be realized by any type of volatile or non-volatile storage device or their combination, such as static random access memory (SRAM), electrically erasable Programmable Read Only Memory (EEPROM), Erasable Programmable Read Only Memory (EPROM), Programmable Read Only Memory (PROM), Read Only Memory (ROM), Magnetic Memory, Flash Memory, Magnetic or Optical Disk. A readable storage medium can be any available medium that can be accessed by a general purpose or special purpose computer.

一种示例性的可读存储介质耦合至处理器,从而使处理器能够从该可读存储介质读取信息,且可向该可读存储介质写入信息。当然,可读存储介质也可以是处理器的组成部分。处理器和可读存储介质可以位于专用集成电路(Application Specific IntegratedCircuits,简称:ASIC)中。当然,处理器和可读存储介质也可以作为分立组件存在于设备中。An exemplary readable storage medium is coupled to the processor such that the processor can read information from, and write information to, the readable storage medium. Of course, the readable storage medium can also be an integral part of the processor. The processor and the readable storage medium may be located in application specific integrated circuits (Application Specific Integrated Circuits, ASIC for short). Of course, the processor and the readable storage medium may also exist in the device as discrete components.

本领域普通技术人员可以理解:实现上述各方法实施例的全部或部分步骤可以通过程序指令相关的硬件来完成。前述的程序可以存储于一计算机可读取存储介质中。该程序在执行时,执行包括上述各方法实施例的步骤;而前述的存储介质包括:ROM、RAM、磁碟或者光盘等各种可以存储程序代码的介质。Those of ordinary skill in the art can understand that all or part of the steps of implementing the above method embodiments may be completed by program instructions related to hardware. The aforementioned program can be stored in a computer-readable storage medium. When the program is executed, the steps including the above method embodiments are executed; and the foregoing storage medium includes: ROM, RAM, magnetic disk or optical disk and other media that can store program codes.

最后应说明的是:以上各实施例仅用以说明本发明的技术方案,而非对其限制;尽管参照前述各实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分或者全部技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的范围。Finally, it should be noted that the above embodiments are only used to illustrate the technical solutions of the present invention, but not to limit them; although the present invention has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand that: The technical solutions described in the foregoing embodiments can still be modified, or some or all of the technical features thereof can be equivalently replaced; and these modifications or replacements do not make the essence of the corresponding technical solutions deviate from the technical solutions of the embodiments of the present invention. scope.

Claims (15)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010247383.8ACN111409415B (en) | 2020-03-31 | 2020-03-31 | Fuel cell stack thermal management apparatus, method and system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010247383.8ACN111409415B (en) | 2020-03-31 | 2020-03-31 | Fuel cell stack thermal management apparatus, method and system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111409415Atrue CN111409415A (en) | 2020-07-14 |

| CN111409415B CN111409415B (en) | 2021-12-21 |

Family

ID=71488059

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010247383.8AActiveCN111409415B (en) | 2020-03-31 | 2020-03-31 | Fuel cell stack thermal management apparatus, method and system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111409415B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106642803A (en)* | 2017-01-24 | 2017-05-10 | 武汉地质资源环境工业技术研究院有限公司 | High-temperature heat supply system for proton exchange membrane fuel cell |

| CN106642802A (en)* | 2017-01-24 | 2017-05-10 | 武汉地质资源环境工业技术研究院有限公司 | High-temperature heat pump hot water system driven by proton exchange membrane fuel cell |

| CN113071287A (en)* | 2021-04-21 | 2021-07-06 | 吉林大学 | Fuel cell thermal management mode switching and control method |

| CN113580882A (en)* | 2021-09-08 | 2021-11-02 | 华为技术有限公司 | Thermal management system and vehicle |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050178523A1 (en)* | 2004-02-18 | 2005-08-18 | Satoshi Itoh | Automotive air conditioning system |

| CN204118213U (en)* | 2014-02-19 | 2015-01-21 | 广州汽车集团股份有限公司 | A kind of for regulating device and the automobile of temperature of powered cell |

| CN105522888A (en)* | 2014-10-21 | 2016-04-27 | 源捷公司 | EV Multi-Mode Thermal Management System |

| CN205351796U (en)* | 2016-01-21 | 2016-06-29 | 成都理工大学 | Remote control shower water economizer |

| CN208164796U (en)* | 2018-05-07 | 2018-11-30 | 杭州三花研究院有限公司 | The heat management system and fuel cell car of fuel cell car |

| CN109367352A (en)* | 2018-10-15 | 2019-02-22 | 武汉格罗夫氢能汽车有限公司 | Fuel cell motive force passenger car cooling system |

| CN110217070A (en)* | 2019-06-13 | 2019-09-10 | 深圳创维空调科技有限公司 | A kind of new-energy automobile heat management air-conditioning system |

| CN110641248A (en)* | 2019-10-28 | 2020-01-03 | 湖北文理学院 | Fuel cell vehicle heat pump air conditioning system, control method and air conditioner |

| US20200047583A1 (en)* | 2017-04-26 | 2020-02-13 | Sanden Automotive Climate Systems Corporation | Air conditioner for vehicle |

- 2020

- 2020-03-31CNCN202010247383.8Apatent/CN111409415B/enactiveActive

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050178523A1 (en)* | 2004-02-18 | 2005-08-18 | Satoshi Itoh | Automotive air conditioning system |

| CN204118213U (en)* | 2014-02-19 | 2015-01-21 | 广州汽车集团股份有限公司 | A kind of for regulating device and the automobile of temperature of powered cell |

| CN105522888A (en)* | 2014-10-21 | 2016-04-27 | 源捷公司 | EV Multi-Mode Thermal Management System |

| CN205351796U (en)* | 2016-01-21 | 2016-06-29 | 成都理工大学 | Remote control shower water economizer |

| US20200047583A1 (en)* | 2017-04-26 | 2020-02-13 | Sanden Automotive Climate Systems Corporation | Air conditioner for vehicle |

| CN208164796U (en)* | 2018-05-07 | 2018-11-30 | 杭州三花研究院有限公司 | The heat management system and fuel cell car of fuel cell car |

| CN109367352A (en)* | 2018-10-15 | 2019-02-22 | 武汉格罗夫氢能汽车有限公司 | Fuel cell motive force passenger car cooling system |

| CN110217070A (en)* | 2019-06-13 | 2019-09-10 | 深圳创维空调科技有限公司 | A kind of new-energy automobile heat management air-conditioning system |

| CN110641248A (en)* | 2019-10-28 | 2020-01-03 | 湖北文理学院 | Fuel cell vehicle heat pump air conditioning system, control method and air conditioner |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106642803A (en)* | 2017-01-24 | 2017-05-10 | 武汉地质资源环境工业技术研究院有限公司 | High-temperature heat supply system for proton exchange membrane fuel cell |

| CN106642802A (en)* | 2017-01-24 | 2017-05-10 | 武汉地质资源环境工业技术研究院有限公司 | High-temperature heat pump hot water system driven by proton exchange membrane fuel cell |

| CN113071287A (en)* | 2021-04-21 | 2021-07-06 | 吉林大学 | Fuel cell thermal management mode switching and control method |

| CN113580882A (en)* | 2021-09-08 | 2021-11-02 | 华为技术有限公司 | Thermal management system and vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111409415B (en) | 2021-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111409415B (en) | Fuel cell stack thermal management apparatus, method and system | |

| CN105026193B (en) | Air conditioner for vehicles | |

| CN115465089B (en) | Thermal management system control method for hybrid vehicle and hybrid vehicle | |

| CN115320321A (en) | Control method of thermal management system, vehicle and related equipment | |

| US20180272840A1 (en) | Vehicle-mounted heat utilization device | |

| CN114312471B (en) | Method, system and storage medium for thermal management of power battery of range-extended vehicle | |

| KR20220085886A (en) | Thermal management system for fuel cell electric vehicle | |

| CN220923754U (en) | Heat management system of extended range type new energy automobile | |

| CN115431839A (en) | Whole vehicle thermal management system of fuel cell vehicle and control method | |

| CN116039457A (en) | Range-extended fuel cell thermal management system and control method thereof, automobile | |

| WO2024222122A1 (en) | Temperature control method, apparatus and device for battery pack, and new energy vehicle | |

| WO2024074064A1 (en) | Indirect multi-level waste heat recovery heat pump air-conditioning system, and control method therefor | |

| CN116710299A (en) | Thermal management system, heating method, heating device, vehicle and storage medium | |

| CN116923047A (en) | Vehicle thermal management system and control method thereof | |

| US11760161B2 (en) | Heat pump system for vehicle and control method thereof | |

| CN110182018A (en) | A kind of thermal management system of whole | |

| CN118810342A (en) | A thermal management system and method for electric vehicles based on R290 air supplement and enthalpy increase | |

| CN110385963B (en) | Electric automobile air conditioning system and control method thereof | |

| US12424643B2 (en) | Thermal management system for a fuel cell electric vehicle and a method for controlling same | |

| JP7574296B2 (en) | Thermal management system, thermal management method and power consuming device | |

| CN116749711A (en) | Vehicle control method and device, vehicle and storage medium | |

| CN111284364A (en) | Thermal management system for a vehicle | |

| CN118269541A (en) | Vehicle thermal management system, control method and control device thereof, and vehicle | |

| CN115848098A (en) | Pure electric drive excavator and whole vehicle thermal management system thereof | |

| CN205033902U (en) | Electricelectric moves air conditioning system for vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |