CN111393882A - Ultraviolet radiation resistant low-absorptivity inorganic white thermal control coating and preparation method thereof - Google Patents

Ultraviolet radiation resistant low-absorptivity inorganic white thermal control coating and preparation method thereofDownload PDFInfo

- Publication number

- CN111393882A CN111393882ACN202010212002.2ACN202010212002ACN111393882ACN 111393882 ACN111393882 ACN 111393882ACN 202010212002 ACN202010212002 ACN 202010212002ACN 111393882 ACN111393882 ACN 111393882A

- Authority

- CN

- China

- Prior art keywords

- thermal control

- control coating

- inorganic white

- ultraviolet radiation

- coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000576coating methodMethods0.000titleclaimsabstractdescription66

- 239000011248coating agentSubstances0.000titleclaimsabstractdescription58

- 230000005855radiationEffects0.000titleclaimsabstractdescription18

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription8

- NTHWMYGWWRZVTN-UHFFFAOYSA-Nsodium silicateChemical compound[Na+].[Na+].[O-][Si]([O-])=ONTHWMYGWWRZVTN-UHFFFAOYSA-N0.000claimsabstractdescription15

- 239000002562thickening agentSubstances0.000claimsabstractdescription14

- 235000019353potassium silicateNutrition0.000claimsabstractdescription12

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription12

- 239000000203mixtureSubstances0.000claimsabstractdescription10

- 239000000758substrateSubstances0.000claimsabstractdescription9

- 239000002270dispersing agentSubstances0.000claimsabstractdescription7

- 239000000080wetting agentSubstances0.000claimsabstractdescription7

- 239000012463white pigmentSubstances0.000claimsabstractdescription4

- 230000001680brushing effectEffects0.000claimsabstractdescription3

- 238000005507sprayingMethods0.000claimsabstractdescription3

- 239000013530defoamerSubstances0.000claimsdescription12

- -1polyoxypropylene glyceryl etherPolymers0.000claimsdescription12

- 229910001868waterInorganic materials0.000claimsdescription11

- XLOMVQKBTHCTTD-UHFFFAOYSA-NZinc monoxideChemical compound[Zn]=OXLOMVQKBTHCTTD-UHFFFAOYSA-N0.000claimsdescription10

- KWYUFKZDYYNOTN-UHFFFAOYSA-MPotassium hydroxideChemical compound[OH-].[K+]KWYUFKZDYYNOTN-UHFFFAOYSA-M0.000claimsdescription9

- 239000004721Polyphenylene oxideSubstances0.000claimsdescription8

- 229920000570polyetherPolymers0.000claimsdescription8

- 238000003756stirringMethods0.000claimsdescription8

- RLQWHDODQVOVKU-UHFFFAOYSA-Ntetrapotassium;silicateChemical compound[K+].[K+].[K+].[K+].[O-][Si]([O-])([O-])[O-]RLQWHDODQVOVKU-UHFFFAOYSA-N0.000claimsdescription7

- WMFOQBRAJBCJND-UHFFFAOYSA-MLithium hydroxideChemical compound[Li+].[OH-]WMFOQBRAJBCJND-UHFFFAOYSA-M0.000claimsdescription6

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000claimsdescription6

- 229920001451polypropylene glycolPolymers0.000claimsdescription5

- 229920002635polyurethanePolymers0.000claimsdescription5

- 239000004814polyurethaneSubstances0.000claimsdescription5

- 239000011787zinc oxideSubstances0.000claimsdescription5

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription4

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000claimsdescription4

- GWEVSGVZZGPLCZ-UHFFFAOYSA-NTitan oxideChemical compoundO=[Ti]=OGWEVSGVZZGPLCZ-UHFFFAOYSA-N0.000claimsdescription4

- 125000002877alkyl aryl groupChemical group0.000claimsdescription4

- 229910052744lithiumInorganic materials0.000claimsdescription4

- 239000000049pigmentSubstances0.000claimsdescription4

- 229910000838Al alloyInorganic materials0.000claimsdescription3

- 239000004111Potassium silicateSubstances0.000claimsdescription3

- 239000004744fabricSubstances0.000claimsdescription3

- 239000000463materialSubstances0.000claimsdescription3

- NNHHDJVEYQHLHG-UHFFFAOYSA-Npotassium silicateChemical compound[K+].[K+].[O-][Si]([O-])=ONNHHDJVEYQHLHG-UHFFFAOYSA-N0.000claimsdescription3

- 229910052913potassium silicateInorganic materials0.000claimsdescription3

- 239000002994raw materialSubstances0.000claimsdescription3

- 229920000049Carbon (fiber)Polymers0.000claimsdescription2

- 229910000733Li alloyInorganic materials0.000claimsdescription2

- 239000004115Sodium SilicateSubstances0.000claimsdescription2

- MCMNRKCIXSYSNV-UHFFFAOYSA-NZrO2Inorganic materialsO=[Zr]=OMCMNRKCIXSYSNV-UHFFFAOYSA-N0.000claimsdescription2

- 239000000440bentoniteSubstances0.000claimsdescription2

- 229910000278bentoniteInorganic materials0.000claimsdescription2

- SVPXDRXYRYOSEX-UHFFFAOYSA-NbentoquatamChemical compoundO.O=[Si]=O.O=[Al]O[Al]=OSVPXDRXYRYOSEX-UHFFFAOYSA-N0.000claimsdescription2

- 239000004917carbon fiberSubstances0.000claimsdescription2

- 239000002131composite materialSubstances0.000claimsdescription2

- 239000001989lithium alloySubstances0.000claimsdescription2

- GCICAPWZNUIIDV-UHFFFAOYSA-Nlithium magnesiumChemical compound[Li].[Mg]GCICAPWZNUIIDV-UHFFFAOYSA-N0.000claimsdescription2

- PAZHGORSDKKUPI-UHFFFAOYSA-Nlithium metasilicateChemical compound[Li+].[Li+].[O-][Si]([O-])=OPAZHGORSDKKUPI-UHFFFAOYSA-N0.000claimsdescription2

- 229910052912lithium silicateInorganic materials0.000claimsdescription2

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneChemical compoundCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000claimsdescription2

- RVTZCBVAJQQJTK-UHFFFAOYSA-Noxygen(2-);zirconium(4+)Chemical compound[O-2].[O-2].[Zr+4]RVTZCBVAJQQJTK-UHFFFAOYSA-N0.000claimsdescription2

- 238000005498polishingMethods0.000claimsdescription2

- 239000004576sandSubstances0.000claimsdescription2

- 238000007790scrapingMethods0.000claimsdescription2

- 229910052911sodium silicateInorganic materials0.000claimsdescription2

- 239000004408titanium dioxideSubstances0.000claimsdescription2

- 239000011521glassSubstances0.000claims1

- 238000010521absorption reactionMethods0.000abstractdescription13

- 239000002518antifoaming agentSubstances0.000abstractdescription2

- 239000008367deionised waterSubstances0.000abstract1

- 229910021641deionized waterInorganic materials0.000abstract1

- 239000003973paintSubstances0.000abstract1

- 238000000034methodMethods0.000description4

- RBNPOMFGQQGHHO-UHFFFAOYSA-Nglyceric acidChemical compoundOCC(O)C(O)=ORBNPOMFGQQGHHO-UHFFFAOYSA-N0.000description3

- 230000003287optical effectEffects0.000description3

- 239000002585baseSubstances0.000description2

- 238000001914filtrationMethods0.000description2

- 238000002156mixingMethods0.000description2

- 229920001296polysiloxanePolymers0.000description2

- 230000003595spectral effectEffects0.000description2

- 238000009281ultraviolet germicidal irradiationMethods0.000description2

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000description1

- JJWKPURADFRFRB-UHFFFAOYSA-Ncarbonyl sulfideChemical compoundO=C=SJJWKPURADFRFRB-UHFFFAOYSA-N0.000description1

- 238000006243chemical reactionMethods0.000description1

- 230000007423decreaseEffects0.000description1

- 230000000694effectsEffects0.000description1

- 230000003628erosive effectEffects0.000description1

- RTZKZFJDLAIYFH-UHFFFAOYSA-NetherSubstancesCCOCCRTZKZFJDLAIYFH-UHFFFAOYSA-N0.000description1

- 239000002245particleSubstances0.000description1

- 229920000642polymerPolymers0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D1/00—Coating compositions, e.g. paints, varnishes or lacquers, based on inorganic substances

- C09D1/02—Coating compositions, e.g. paints, varnishes or lacquers, based on inorganic substances alkali metal silicates

- C09D1/04—Coating compositions, e.g. paints, varnishes or lacquers, based on inorganic substances alkali metal silicates with organic additives

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/60—Additives non-macromolecular

- C09D7/61—Additives non-macromolecular inorganic

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/65—Additives macromolecular

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Wood Science & Technology (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Paints Or Removers (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于功能涂层技术领域,具体涉及一种耐紫外辐照低吸收率无机白色热控涂层及其制备方法。The invention belongs to the technical field of functional coatings, in particular to an inorganic white thermal control coating with ultraviolet radiation resistance and low absorption rate and a preparation method thereof.

背景技术Background technique

宇宙空间是高真空环境,航天器与外部空间的热交换主要以热辐射的形式进行。在空间环境中运行的航天器,因受到太阳辐射而易产生高温影响航天器内部各元器件和设备的运行,所以,航天器的结构部件或设备表面的热物理性质对辐射换热状态起着决定性的作用。热控制设计的功能就是合理地选择涂层,组织航天器内外表面的热交换路径、过程与换热量,从而使得设备和结构达到一个平衡的温度,保证各设备所处的环境温度在其操作温度工作区间内,以便各设备正常运行。Cosmic space is a high vacuum environment, and the heat exchange between spacecraft and outer space is mainly carried out in the form of thermal radiation. The spacecraft operating in the space environment is prone to high temperature due to solar radiation, which affects the operation of various components and equipment inside the spacecraft. Therefore, the thermophysical properties of the structural components of the spacecraft or the surface of the equipment play an important role in the radiation heat exchange state. decisive role. The function of thermal control design is to select the coating reasonably, organize the heat exchange path, process and heat exchange on the inner and outer surfaces of the spacecraft, so as to make the equipment and structure reach a balanced temperature and ensure that the ambient temperature of each equipment is within its operation. within the temperature working range, so that the equipment can operate normally.

涂装热控涂层是航天器领域热控制系统中应用最广泛、经济、简便的一种措施,热控涂层主要是起被动温控作用,实现航天器与空间环境间的热交换。热控涂层的光热性能主要由其本身的太阳吸收比(αs)和红外发射率(ε)特性来调节航天器表面的温度。通常太阳吸收比越小,红外发射率越大则其温控性能越好。空间环境中运行的航天器易受到高真空、带电粒子辐照、紫外辐照、原子氧侵蚀和高低温差变化等影响,这些环境都会影响航天器表面涂层的光学和热学性能。然而,空间环境中太阳紫外光虽占比少,但其辐照具有较高的能量,对涂层具有较强的辐照损伤效应,造成白色热控涂层光学性能变化较大。在目前的研究中,无机热控涂层仍然存在附着力较差且涂层的太阳吸收较高,尤其是经紫外辐照后,涂层的光热性能下降较多。The application of thermal control coating is the most widely used, economical and simple measure in the thermal control system in the spacecraft field. The thermal control coating mainly plays the role of passive temperature control and realizes the heat exchange between the spacecraft and the space environment. The photothermal performance of the thermal control coating is mainly adjusted by its own solar absorption ratio (αs ) and infrared emissivity (ε) characteristics to adjust the temperature of the spacecraft surface. Generally, the smaller the solar absorption ratio and the larger the infrared emissivity, the better the temperature control performance. Spacecraft operating in the space environment are susceptible to high vacuum, charged particle irradiation, ultraviolet irradiation, atomic oxygen erosion, and changes in high and low temperature differences, all of which affect the optical and thermal properties of spacecraft surface coatings. However, although the proportion of solar ultraviolet light in the space environment is small, its irradiation has high energy, which has a strong radiation damage effect on the coating, resulting in a large change in the optical properties of the white thermal control coating. In the current study, the inorganic thermal control coating still has poor adhesion and high solar absorption of the coating, especially after UV irradiation, the photothermal performance of the coating decreases more.

发明内容SUMMARY OF THE INVENTION

本发明目的是提供一种光热性能优异的耐紫外无机白色热控涂层;主要是解决现有的无机白色热控涂层的在空间紫外辐照作用下对光热转换性能下降较多的问题,提出一种具有耐紫外辐照性能优异的低太阳吸收比无机白色热控涂层制备方法。The purpose of the invention is to provide a UV-resistant inorganic white thermal control coating with excellent photothermal performance; it mainly solves the problem that the photothermal conversion performance of the existing inorganic white thermal control coating is greatly reduced under the action of space ultraviolet radiation. Therefore, a method for preparing a low solar absorption ratio inorganic white thermal control coating with excellent UV radiation resistance was proposed.

为解决上述技术问题,本发明中耐紫外辐照低吸收率无机白色热控涂层是由下述原料制成的:In order to solve the above-mentioned technical problems, in the present invention, the inorganic white thermal control coating of ultraviolet radiation resistance and low absorption rate is made of the following raw materials:

一种耐紫外辐照低吸收率无机白色热控涂层的制备方法是按下述步骤进行的:A preparation method of UV-resistant and low-absorptive inorganic white thermal control coating is carried out according to the following steps:

步骤一、取占增稠剂总质量42wt%~46wt%的增稠剂和占消泡剂总质量的42wt%~46wt%的消泡剂,然后与水玻璃、消泡剂、分散剂和基材润湿剂混合后,以500rpm~800rpm速率搅拌10min~30min,加入白颜料,以1200rpm~1800rpm的速率砂磨分散2h~6h;

步骤二、然后在500~800rpm低速搅拌条件下,加入剩余的增稠剂和消泡剂,搅拌分散10min~30min;Step 2: Then, under the condition of low-speed stirring at 500-800 rpm, add the remaining thickener and defoamer, and stir and disperse for 10-30 minutes;

步骤三、然后用200~300目滤网或者滤布过滤后便可制得无机热控涂料。In step 3, the inorganic thermal control coating can be obtained after filtering with a 200-300 mesh filter screen or filter cloth.

步骤四、然后在用砂纸打磨后的基材表面涂覆步骤三获得的无机热控涂料,最后固化,即得到所述无机白色热控涂层。Step 4. Then, coat the inorganic thermal control coating obtained in Step 3 on the surface of the substrate after polishing with sandpaper, and finally cure, to obtain the inorganic white thermal control coating.

进一步地限定,所述水玻璃为钾水玻璃、钠水玻璃与锂水玻璃中的一种或其中几种按任意比的混合。To be further limited, the water glass is one of potassium water glass, sodium water glass and lithium water glass, or a mixture of several of them in any ratio.

进一步地限定,所述钾水玻璃是由硅酸钾、氢氧化钾和水按照(5~10):(0.2~1):20的质量比配制得到;所述钠水玻璃是由硅酸钠、氢氧化钠和水按照(5~10):(0.2~1):20的质量比配制得到;所述锂水玻璃是由硅酸锂、氢氧化锂和水按照(5~10):(0.2~1):20的质量比配制得到。Further limited, the potassium water glass is prepared from potassium silicate, potassium hydroxide and water according to the mass ratio of (5-10):(0.2-1):20; the sodium water glass is made of sodium silicate , sodium hydroxide and water are prepared according to the mass ratio of (5~10):(0.2~1):20; the lithium water glass is made of lithium silicate, lithium hydroxide and water according to (5~10):( The mass ratio of 0.2~1):20 is prepared.

进一步地限定,所述颜料为氧化锌、二氧化钛与二氧化锆中的一种或其中几种按任意比的混合。Further limited, the pigment is one of zinc oxide, titanium dioxide and zirconium dioxide, or a mixture of several of them in any ratio.

进一步地限定,所述消泡剂为聚氧丙烯甘油醚和/或聚氧丙烯聚氧乙烯甘油醚,两种混合时,聚氧丙烯甘油醚与聚氧丙烯聚氧乙烯甘油醚按任意比的混合。Further limited, the defoaming agent is polyoxypropylene glycerol ether and/or polyoxypropylene polyoxyethylene glycerol ether. mix.

进一步地限定,所述分散剂为烷芳基聚醚醇。To be further limited, the dispersant is an alkaryl polyether alcohol.

进一步地限定,所述基材润湿剂为有机硅聚醚。In a further limitation, the substrate wetting agent is an organosilicon polyether.

进一步地限定,所述增稠剂为膨润土、非离子型聚氨酯增稠剂中的一种。To be further limited, the thickener is one of bentonite and non-ionic polyurethane thickener.

进一步地限定,步骤四中所述的基材为铝合金、镁锂合金或碳纤维复合材料。Further limited, the base material in step 4 is aluminum alloy, magnesium-lithium alloy or carbon fiber composite material.

进一步地限定,步骤四中采用空气喷涂、刮涂或刷涂涂装工艺涂覆步骤三获得的无机热控涂料。To be further limited, in step 4, the inorganic thermal control coating obtained in step 3 is applied by air spraying, scraping or brushing coating process.

进一步地限定,步骤四中在室温下固化7天~10天。Further limited, in step 4, curing is performed at room temperature for 7 days to 10 days.

本发明提供了简便,易于生产的耐紫外辐照、低挥发的无机白色热控涂层,利用本方法制备的热控涂层,涂装厚度(干膜)为80~150μm时,具有较低的太阳吸收比(0.11~0.20),附着力为0~1级,经5000ESH紫外辐照后,涂层的太阳吸收比变化值不大于0.05,满足高性能、高可靠性航天器对热控涂层的性能需求。The invention provides a simple and easy-to-produce inorganic white thermal control coating with ultraviolet radiation resistance and low volatility. The thermal control coating prepared by the method has a low coating thickness (dry film) of 80-150 μm. The solar absorption ratio of the coating is 0.11~0.20, and the adhesion is grade 0~1. After 5000ESH ultraviolet irradiation, the change value of the solar absorption ratio of the coating is not more than 0.05, which meets the requirements of high-performance and high-reliability spacecraft for thermal control coatings. layer performance requirements.

附图说明Description of drawings

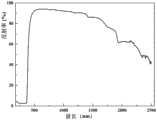

图1为无机白色热控涂层的太阳光谱反射率;Figure 1 shows the solar spectral reflectance of the inorganic white thermal control coating;

图2为无机白色热控涂层的附着力测试光学照片;Figure 2 is an optical photo of the adhesion test of the inorganic white thermal control coating;

图3为无机白色热控涂层经5000ESH紫外辐照后太阳光谱反射率。Figure 3 shows the solar spectral reflectance of the inorganic white thermal control coating after 5000ESH ultraviolet irradiation.

具体实施方式Detailed ways

实施例1:本实施例按质量百分比计,所述无机热控涂层组成是由下述原料制成的:20.8wt%钾水玻璃、28.9wt%氧化锌颜料、0.9wt%聚氧丙烯聚氧乙烯甘油醚、5.7wt%烷芳基聚醚醇、0.3wt%有机硅聚醚、3.6wt%非离子型聚氨酯和余量的水。其中所述钾水玻璃为硅酸钾、氢氧化钾和水按照8:0.5g:20的质量比混合得到。Example 1: In this example, in terms of mass percentage, the inorganic thermal control coating is made of the following raw materials: 20.8wt% potassium water glass, 28.9wt% zinc oxide pigment, 0.9wt% polyoxypropylene polymer Oxyethylene glycerol ether, 5.7 wt% alkaryl polyether alcohol, 0.3 wt% silicone polyether, 3.6 wt% nonionic polyurethane and balance water. Wherein the potassium water glass is obtained by mixing potassium silicate, potassium hydroxide and water according to the mass ratio of 8:0.5g:20.

以氧化锌颜料为例的无机热控涂层的制备方法,按以下具体步骤进行:The preparation method of inorganic thermal control coating with zinc oxide pigment as an example is carried out according to the following specific steps:

首先将20.8wt%钾水玻璃、0.4wt%消泡剂聚氧丙烯聚氧乙烯甘油醚(武汉能仁医药化工有限公司)、5.7wt%分散剂烷芳基聚醚醇(广州市德松化工有限公司,型号405)、0.3wt%基材润湿剂有机硅聚醚(晗泰化工有限公司,型号298)和1.6wt%非离子型聚氨酯增稠剂(晗泰化工有限公司,型号TT935)和水混合后,以500rpm低速搅拌20min,随后加入28.9wt%的氧化锌(阿拉丁试剂有限公司),并以1400rpm高速砂磨分散4h。First, 20.8wt% potassium water glass, 0.4wt% defoamer polyoxypropylene polyoxyethylene glycerol ether (Wuhan Nengren Pharmaceutical Chemical Co., Ltd.), 5.7wt% dispersant alkylaryl polyether alcohol (Guangzhou Desong Chemical Co., Ltd.) company, model 405), 0.3 wt% substrate wetting agent silicone polyether (Hantai Chemical Co., Ltd., model 298) and 1.6 wt% nonionic polyurethane thickener (Hantai Chemical Co., Ltd., model TT935) and After the water was mixed, the mixture was stirred at a low speed of 500 rpm for 20 min, and then 28.9 wt % of zinc oxide (Aladdin Reagent Co., Ltd.) was added, and the mixture was sanded and dispersed at a high speed of 1400 rpm for 4 h.

接着在500rpm低速搅拌下,滴加2.0wt%非离子型聚氨酯增稠剂和0.5wt%聚氧丙烯聚氧乙烯甘油醚消泡剂,搅拌分散20min后,用300目滤布过滤便可得到涂料。在刚刚用砂纸打磨好的铝合金基材表面,采用刮涂涂装工艺制备涂层,室温固化10天后,即制得无机热控涂层。测得无机热控涂层的厚度为100±5μm,涂层的太阳吸收比为0.14,如图1所示,附着力为1级,如图2所示;经5000ESH紫外辐照后,涂层的太阳吸收比为0.17,如图3所示,满足高性能、高可靠性航天器对热控涂层的性能需求。Then, under low-speed stirring at 500rpm, 2.0wt% non-ionic polyurethane thickener and 0.5wt% polyoxypropylene polyoxyethylene glyceryl ether defoamer were added dropwise, and after stirring and dispersing for 20min, the coating was obtained by filtering with a 300-mesh filter cloth. . On the surface of the aluminum alloy substrate that has just been polished with sandpaper, a coating is prepared by a blade coating process, and after curing at room temperature for 10 days, an inorganic thermal control coating is obtained. The thickness of the inorganic thermal control coating was measured to be 100±5μm, the solar absorption ratio of the coating was 0.14, as shown in Figure 1, and the adhesion was

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010212002.2ACN111393882B (en) | 2020-03-24 | 2020-03-24 | Ultraviolet radiation resistant low-absorptivity inorganic white thermal control coating and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010212002.2ACN111393882B (en) | 2020-03-24 | 2020-03-24 | Ultraviolet radiation resistant low-absorptivity inorganic white thermal control coating and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111393882Atrue CN111393882A (en) | 2020-07-10 |

| CN111393882B CN111393882B (en) | 2021-09-28 |

Family

ID=71427447

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010212002.2AActiveCN111393882B (en) | 2020-03-24 | 2020-03-24 | Ultraviolet radiation resistant low-absorptivity inorganic white thermal control coating and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111393882B (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111893451A (en)* | 2020-08-13 | 2020-11-06 | 上海卫星工程研究所 | High-performance wave-transparent nano thermal control film for satellite, preparation method and application thereof |

| CN112480727A (en)* | 2020-11-26 | 2021-03-12 | 哈尔滨工业大学 | Preparation method of white molecular adsorption coating with thermal control function |

| CN114192363A (en)* | 2021-12-23 | 2022-03-18 | 上海卫星装备研究所 | Preparation method and system of solar absorption ratio adjustable thermal control coating and heat insulation assembly |

| US11407684B1 (en)* | 2021-04-06 | 2022-08-09 | Guangzhou University | Water-resistant long-acting inorganic zinc oxide super-hydrophilic paint, preparation method and application thereof |

| CN116082877A (en)* | 2022-12-29 | 2023-05-09 | 上海卫星装备研究所 | High-reflectivity filler and inorganic thermal control coating thereof and preparation method thereof |

| CN118460049A (en)* | 2024-05-30 | 2024-08-09 | 哈尔滨工业大学 | ALD modified ultraviolet radiation resistant organic white thermal control coating and preparation method thereof |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5310422A (en)* | 1992-12-01 | 1994-05-10 | General Electric Co. | High temperature inorganic paint |

| US5885658A (en)* | 1992-08-10 | 1999-03-23 | Mcdonnell Douglas Technologies, Inc. | Process for protecting optical properties of a thermal control |

| US6176453B1 (en)* | 1997-03-18 | 2001-01-23 | Hughes Electronics Corporation | Radiator using thermal control coating |

| CN1474790A (en)* | 2000-09-20 | 2004-02-11 | Inorganic matrix compositions and composite material incorporating matrix composite material | |

| US6921431B2 (en)* | 2003-09-09 | 2005-07-26 | Wessex Incorporated | Thermal protective coating for ceramic surfaces |

| CN106661345A (en)* | 2014-07-07 | 2017-05-10 | 爱尔兰国立大学都柏林大学学院 | Thermal control coatings |

| CN106675391A (en)* | 2015-11-11 | 2017-05-17 | 北京卫星环境工程研究所 | Anti-radiation thermal control coating and manufacturing method thereof |

| CN108950549A (en)* | 2018-07-05 | 2018-12-07 | 哈尔滨工业大学 | A kind of preparation method of aluminum alloy surface low sunlight absorptivity high emissivity conduction thermal control coating |

| CN110330822A (en)* | 2019-07-29 | 2019-10-15 | 四川瑞珂新材料科技有限公司 | A kind of inorganic coating and its preparation method and application |

- 2020

- 2020-03-24CNCN202010212002.2Apatent/CN111393882B/enactiveActive

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5885658A (en)* | 1992-08-10 | 1999-03-23 | Mcdonnell Douglas Technologies, Inc. | Process for protecting optical properties of a thermal control |

| US5310422A (en)* | 1992-12-01 | 1994-05-10 | General Electric Co. | High temperature inorganic paint |

| US6176453B1 (en)* | 1997-03-18 | 2001-01-23 | Hughes Electronics Corporation | Radiator using thermal control coating |

| CN1474790A (en)* | 2000-09-20 | 2004-02-11 | Inorganic matrix compositions and composite material incorporating matrix composite material | |

| US6921431B2 (en)* | 2003-09-09 | 2005-07-26 | Wessex Incorporated | Thermal protective coating for ceramic surfaces |

| CN106661345A (en)* | 2014-07-07 | 2017-05-10 | 爱尔兰国立大学都柏林大学学院 | Thermal control coatings |

| CN106675391A (en)* | 2015-11-11 | 2017-05-17 | 北京卫星环境工程研究所 | Anti-radiation thermal control coating and manufacturing method thereof |

| CN108950549A (en)* | 2018-07-05 | 2018-12-07 | 哈尔滨工业大学 | A kind of preparation method of aluminum alloy surface low sunlight absorptivity high emissivity conduction thermal control coating |

| CN110330822A (en)* | 2019-07-29 | 2019-10-15 | 四川瑞珂新材料科技有限公司 | A kind of inorganic coating and its preparation method and application |

Non-Patent Citations (1)

| Title |

|---|

| 俞善庆: ""航天器热控涂料"", 《涂料工业》* |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111893451A (en)* | 2020-08-13 | 2020-11-06 | 上海卫星工程研究所 | High-performance wave-transparent nano thermal control film for satellite, preparation method and application thereof |

| CN112480727A (en)* | 2020-11-26 | 2021-03-12 | 哈尔滨工业大学 | Preparation method of white molecular adsorption coating with thermal control function |

| US11407684B1 (en)* | 2021-04-06 | 2022-08-09 | Guangzhou University | Water-resistant long-acting inorganic zinc oxide super-hydrophilic paint, preparation method and application thereof |

| CN114192363A (en)* | 2021-12-23 | 2022-03-18 | 上海卫星装备研究所 | Preparation method and system of solar absorption ratio adjustable thermal control coating and heat insulation assembly |

| CN116082877A (en)* | 2022-12-29 | 2023-05-09 | 上海卫星装备研究所 | High-reflectivity filler and inorganic thermal control coating thereof and preparation method thereof |

| CN116082877B (en)* | 2022-12-29 | 2024-04-09 | 上海卫星装备研究所 | High-reflectivity filler and inorganic thermal control coating thereof and preparation method thereof |

| CN118460049A (en)* | 2024-05-30 | 2024-08-09 | 哈尔滨工业大学 | ALD modified ultraviolet radiation resistant organic white thermal control coating and preparation method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111393882B (en) | 2021-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111393882A (en) | Ultraviolet radiation resistant low-absorptivity inorganic white thermal control coating and preparation method thereof | |

| CN108531083B (en) | Preparation method of silica aerogel reflective insulation exterior wall coating | |

| CN102190448B (en) | Composite broadband antireflecting film and preparation method thereof | |

| CN101649147B (en) | Water transparent heat insulation paint and preparation method thereof | |

| CN106752237B (en) | Water-borne heat-insulating slurry and preparation method thereof and water-borne heat-insulating glass coating and preparation method thereof | |

| CN109321050A (en) | A kind of weather-proof masking liquid, weatherability vehicle glass and its manufacturing method | |

| CN101781483A (en) | Environmental protection type high-temperature resistant nano paint and preparation method thereof | |

| CN116102928B (en) | Preparation method of radiation refrigeration coating with superhydrophobic properties | |

| CN110003779A (en) | A kind of super hardened resin lens Coating Materials and preparation method thereof | |

| CN118496731B (en) | A kind of reflective heat-insulating aerogel coating and preparation method thereof | |

| CN115232341B (en) | Light flexible heat insulation material with low absorption ratio and high emissivity and preparation method thereof | |

| CN105948533B (en) | A kind of preparation method of high-intensity broadband antireflective film | |

| CN112937048B (en) | Ablation-resistant gradient-distribution heat-proof composite material with surface coated with high-temperature infrared stealth coating and preparation method thereof | |

| CN107603102B (en) | Plexiglass and its preparation method | |

| CN101709189B (en) | High-weatherability anti-staining elastic fluorocarbon galling paint and manufacturing method thereof | |

| CN112521822B (en) | Polyacrylate composition, water-based paint and preparation method thereof | |

| CN119039842A (en) | Super-hydrophobic self-cleaning radiation cooling composite coating and preparation method and application thereof | |

| CN109052981A (en) | A kind of hydrophobicity automatically cleaning anti-reflection membrane preparation method of high rigidity super abrasive | |

| CN109385163B (en) | A PEEK modified acrylic full shielding infrared and ultraviolet water-based transparent thermal insulation coating | |

| CN106810975A (en) | For the light absorption paint and preparation method of planar vacuum glass solar water heater | |

| CN118064013A (en) | A low infrared emissivity coating and preparation method thereof | |

| CN103897577A (en) | Glass paint and preparation method thereof | |

| CN117070093A (en) | Radiation cooling topcoat and preparation method thereof | |

| CN110342832A (en) | A kind of preparation method of wear-resisting anti-reflection film coating solution | |

| CN110133764B (en) | Preparation method of zinc selenide nano hollow sphere double-layer graded-refractive-index antireflection film |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |