CN111376032A - Moving tool and moving method of generator - Google Patents

Moving tool and moving method of generatorDownload PDFInfo

- Publication number

- CN111376032A CN111376032ACN201811624779.9ACN201811624779ACN111376032ACN 111376032 ACN111376032 ACN 111376032ACN 201811624779 ACN201811624779 ACN 201811624779ACN 111376032 ACN111376032 ACN 111376032A

- Authority

- CN

- China

- Prior art keywords

- generator

- guide rail

- lifting

- moving

- mobile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription25

- 230000007246mechanismEffects0.000claimsabstractdescription41

- 238000004904shorteningMethods0.000claimsdescription3

- 238000012423maintenanceMethods0.000abstractdescription11

- 230000001174ascending effectEffects0.000abstract1

- 238000009434installationMethods0.000description37

- 230000003028elevating effectEffects0.000description14

- 238000010586diagramMethods0.000description5

- 230000008602contractionEffects0.000description2

- 230000005484gravityEffects0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 229910000831SteelInorganic materials0.000description1

- 230000007547defectEffects0.000description1

- 230000005611electricityEffects0.000description1

- 238000004519manufacturing processMethods0.000description1

- 238000010248power generationMethods0.000description1

- 230000000750progressive effectEffects0.000description1

- 239000010959steelSubstances0.000description1

- 238000009423ventilationMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P19/00—Machines for simply fitting together or separating metal parts or objects, or metal and non-metal parts, whether or not involving some deformation; Tools or devices therefor so far as not provided for in other classes

- B23P19/04—Machines for simply fitting together or separating metal parts or objects, or metal and non-metal parts, whether or not involving some deformation; Tools or devices therefor so far as not provided for in other classes for assembling or disassembling parts

- B23P19/042—Machines for simply fitting together or separating metal parts or objects, or metal and non-metal parts, whether or not involving some deformation; Tools or devices therefor so far as not provided for in other classes for assembling or disassembling parts specially adapted for combustion engines

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Manufacture Of Motors, Generators (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及燃气发电领域,特别涉及一种移动工装及发电机的移动方法。The invention relates to the field of gas-fired power generation, in particular to a moving tool and a method for moving a generator.

背景技术Background technique

在发电机组中的发电机是安装于静音箱内部的,且由于静音箱体内的通风需要,消声元件及过滤模块都安装在静音箱的上部。The generator in the generator set is installed inside the mute box, and due to the ventilation requirements in the mute box, the muffler element and the filter module are installed on the upper part of the mute box.

在现有技术中,当发电机组内部的发电机出现故障或需要进行定期维修时,要将位于发电机上部的静音箱的顶部框架拆除,再通过外部的吊装设备将发电机从发电机组中吊出,这种将顶部框架拆除的维护方式会产生大量的拆除和安装时间,使得发电机组的工作时间被大幅缩减,影响发电机组的经济性。In the prior art, when the generator inside the generator set fails or needs regular maintenance, the top frame of the mute box located on the upper part of the generator should be removed, and then the generator should be hoisted from the generator set by external hoisting equipment. However, this maintenance method of dismantling the top frame will generate a lot of time for dismantling and installation, which greatly reduces the working time of the generator set and affects the economy of the generator set.

发明内容SUMMARY OF THE INVENTION

本发明要解决的技术问题是为了克服现有技术中对发电机组中的发电机进行维护需要耗费大量时间,而影响发电机组的经济性的缺陷,提供一种移动工装及发电机的移动方法。The technical problem to be solved by the present invention is to provide a mobile tool and a method for moving the generator in order to overcome the defect that maintenance of the generator in the generator set takes a lot of time and affects the economy of the generator set in the prior art.

本发明是通过下述技术方案来解决上述技术问题:The present invention solves the above-mentioned technical problems through the following technical solutions:

一种移动工装,其用于将发电机从发电机组中移出,所述移动工装包括:A mobile tooling for removing a generator from a generator set, the mobile tooling comprising:

升降机构,所述升降机构用于驱动所述发电机上升或下降;a lifting mechanism, the lifting mechanism is used to drive the generator to rise or fall;

导轨,所述导轨水平设置并向外延伸;a guide rail, the guide rail is arranged horizontally and extends outward;

滑块,所述滑块沿所述导轨的延伸方向滑设于所述导轨,所述滑块用于承载所述发电机并带动所述发电机沿所述延伸方向移动。The sliding block is slidably arranged on the guide rail along the extending direction of the guide rail, and the sliding block is used to carry the generator and drive the generator to move along the extending direction.

该移动工装通过升降机构将发电机相对于发电机安装板抬起,并通过将导轨及滑块设置在被抬起的发电机底部,使滑块能够承载该发电机并带动发电机沿着导轨的延伸方向移动,从而实现从发电机组内部水平移出的功能。通过使用该移动工装,使得在对发电机进行维护时,无需再将发电机组的顶部框架拆除,从而可有效减少发电机的维护所产生的工作量和时间,进而大幅提升发电机组的运行时间,提高了发电机组的经济性。The mobile tool lifts the generator relative to the generator mounting plate through the lifting mechanism, and by arranging the guide rail and the slider at the bottom of the lifted generator, the slider can carry the generator and drive the generator along the guide rail. It moves in the extension direction of the generator set, so as to realize the function of horizontally moving out from the inside of the generator set. By using the mobile tooling, it is unnecessary to remove the top frame of the generator set when maintaining the generator, thereby effectively reducing the workload and time generated by the maintenance of the generator, thereby greatly improving the running time of the generator set. The economy of the generator set is improved.

较佳地,所述移动工装还包括:Preferably, the mobile tooling also includes:

支撑座,所述支撑座连接于所述导轨,所述支撑座用于支撑所述导轨。a support base, the support base is connected to the guide rail, and the support base is used for supporting the guide rail.

除导轨能够固定于发电机组上之外,还可通过在导轨伸出于发电机组外的部分上设置支撑座,以使滑块在承载发电机沿导轨移出于发电机组时,通过支撑座对导轨进行良好的支撑,保证导轨的结构稳定。In addition to the guide rail can be fixed on the generator set, a support seat can also be provided on the part of the guide rail that protrudes out of the generator set, so that when the sliding block carries the generator and moves out of the generator set along the guide rail, the guide rail can be connected to the guide rail through the support seat. Provide good support to ensure the structural stability of the guide rail.

较佳地,所述支撑座沿高度方向的长度可调节,以使导轨在固定于不同规格型号的发电机组时,可通过调节支撑座的长度,使之适配于导轨距离地面的高度。Preferably, the length of the support base along the height direction is adjustable, so that when the guide rail is fixed to generator sets of different specifications, the length of the support base can be adjusted to fit the height of the guide rail from the ground.

较佳地,所述移动工装还包括:Preferably, the mobile tooling also includes:

牵引机构,所述牵引机构设置于所述导轨的端部,并用于牵引所述滑块沿所述延伸方向移动。A traction mechanism, which is arranged on the end of the guide rail and is used for pulling the sliding block to move along the extending direction.

通过在导轨上设置用于牵引滑块移动的牵引机构,以替代例如人工直接推拉等使滑块移动的方式,使移动工装能够移动重量较重的发电机,并可有效避免工人的手在发电机平移时过于接近滑块而产生安全隐患。By arranging a traction mechanism on the guide rail for pulling the slider to move, instead of manually pushing and pulling the slider, the mobile tool can move the heavier generator, and can effectively prevent the worker's hands from generating electricity. When the machine pans too close to the slider, it will cause a safety hazard.

较佳地,所述牵引机构为手动葫芦或电动葫芦。Preferably, the traction mechanism is a manual hoist or an electric hoist.

较佳地,所述移动工装包括两根所述导轨和多个所述滑块,两根所述导轨相对平行设置,多个所述滑块均滑设于任一所述导轨。Preferably, the mobile tooling includes two of the guide rails and a plurality of the sliding blocks, the two guide rails are arranged in parallel with each other, and the plurality of the sliding blocks are all slidably arranged on any one of the guide rails.

通过上述的设置方式,可提高移动工装承载发电机时的稳固程度,有效避免发电机在移动过程中因重心不稳而导致倾覆。Through the above arrangement, the stability of the mobile tooling when it carries the generator can be improved, and the overturning of the generator due to the unstable center of gravity during the moving process can be effectively avoided.

较佳地,所述移动工装还包括横梁,所述横梁设置于两根所述导轨之间,且所述横梁的两端分别固接于两根所述导轨。Preferably, the mobile tooling further includes a cross beam, the cross beam is arranged between the two guide rails, and both ends of the cross beam are respectively fixed to the two guide rails.

通过设置横梁可加强并限定两根导轨的间距,同时也方便在固定于发电机安装板时能够整体安装。By arranging a beam, the distance between the two guide rails can be strengthened and limited, and at the same time, it is also convenient for the integral installation when fixed on the generator mounting plate.

较佳地,所述升降机构包括若干升降单元,所述升降单元均布于所述发电机的底部,每个所述升降单元均为可伸缩结构。Preferably, the elevating mechanism includes a plurality of elevating units, the elevating units are evenly distributed at the bottom of the generator, and each elevating unit is a retractable structure.

通过设置这些可伸缩的升降单元,使这些升降单元能够对发电机进行多点支撑并使其升降。另外,由于是使用多个升降单元同时对发电机进行抬升,因此单个升降单元的体积和功率也无需很大,便于在发电机组内部进行布设安装。By arranging these retractable lifting units, these lifting units can support the generator at multiple points and lift it up and down. In addition, since multiple lifting units are used to lift the generator at the same time, the volume and power of a single lifting unit do not need to be large, which is convenient for layout and installation inside the generator set.

较佳地,所述升降单元包括:Preferably, the lifting unit includes:

底座,所述底座的顶面具有一螺纹孔,a base, the top surface of the base has a threaded hole,

升降杆,所述升降杆的表面具有螺纹,所述升降杆通过所述螺纹孔螺纹连接于所述底座,所述升降杆顶部用于抵靠所述发电机的底部。A lift rod, the surface of the lift rod is threaded, the lift rod is threadedly connected to the base through the threaded hole, and the top of the lift rod is used to abut against the bottom of the generator.

通过旋转该升降杆,使升降杆通过螺纹与底座产生相对运动,实现对发电机的顶升功能,该升降单元的结构简单,成本低廉且便于维护更换,是一种使升降单元实现带动发电机升降的较佳实现方式。By rotating the lifting rod, the lifting rod can move relative to the base through the thread to realize the lifting function of the generator. The lifting unit has a simple structure, low cost and easy maintenance and replacement. The best way to achieve lift.

较佳地,所述升降单元为油缸,所述油缸的油缸杆用于抵靠所述发电机的底部,以通过油缸杆的伸缩实现对发电机的顶升,并经由对多个油缸的同步控制,提高移动工装的自动化水平。Preferably, the lifting unit is an oil cylinder, and the oil cylinder rod of the oil cylinder is used to abut the bottom of the generator, so as to realize the lifting of the generator through the expansion and contraction of the oil cylinder rod, and to synchronize the plurality of oil cylinders. Control, improve the automation level of mobile tooling.

较佳地,所述升降机构包括多组所述升降单元,每一组所述升降单元均包括若干所述升降单元,多组所述升降单元之间的可伸缩高度均不同。Preferably, the elevating mechanism includes a plurality of groups of the elevating units, each group of the elevating units includes a plurality of the elevating units, and the retractable heights of the plural groups of the elevating units are different.

通过设置多组具有不同伸缩高度的升降单元,使升降机构满足对发电机不同伸缩高度的需要。By setting up multiple groups of lifting units with different telescopic heights, the lifting mechanism can meet the needs of different telescopic heights of the generator.

较佳地,所述导轨具有第一安装接口,所述第一安装接口用于与所述发电机组的发电机安装板连接所述发电机的接口连接,使得导轨在设置于发电机和发电机安装板之间时,可通过与发电机安装板上的现成接口相固定,使导轨在供滑块及发电机滑动时保持稳固状态,提高该移动工装的使用安全性。Preferably, the guide rail has a first installation interface, and the first installation interface is used to connect with the generator installation plate of the generator set to connect the interface of the generator, so that the guide rail is arranged on the generator and the generator. When between the installation plates, it can be fixed with the ready-made interface on the generator installation plate, so that the guide rail can be kept in a stable state when the slider and the generator slide, and the use safety of the mobile tooling can be improved.

较佳地,所述滑块具有第二安装接口,所述第二安装接口用于与所述发电机连接所述发电机组的发电机安装板的接口连接,得滑块在承载发电机时能够与发电机连接牢固,避免在沿导轨滑动时产生相对滑脱的情况,提高该移动工装的使用安全性。Preferably, the slider has a second installation interface, and the second installation interface is used for connecting the generator to the interface of the generator installation plate of the generator set, so that the slider can carry the generator. The connection with the generator is firm, so as to avoid relative slippage when sliding along the guide rail, and improve the use safety of the mobile tooling.

较佳地,所述滑块滑设于所述导轨的上表面,所述滑块具有向下延伸的限位部,所述限位部位于所述导轨的左右两侧,以在滑块滑动时进行限位,避免滑块从导轨表面意外滑落。Preferably, the slider is slidably arranged on the upper surface of the guide rail, and the slider has a limit portion extending downward, and the limit portion is located on the left and right sides of the guide rail to slide on the slider. To limit the position at the time, to prevent the slider from accidentally slipping off the surface of the guide rail.

一种发电机的移动方法,其用于将所述发电机从所述发电机组中移出,所述发电机的移动方法利用如上所述的移动工装,所述发电机的移动方法包含以下步骤:A moving method of a generator, which is used to remove the generator from the generator set, the moving method of the generator utilizes the above-mentioned moving tool, and the moving method of the generator comprises the following steps:

S1、拆除所述发电机与所述发电机组的发电机安装板之间的连接;S1, remove the connection between the generator and the generator mounting plate of the generator set;

S2、通过所述升降机构抬升所述发电机,使所述发电机离开所述发电机安装板;S2. Lift the generator through the lifting mechanism, so that the generator leaves the generator mounting plate;

S3、将所述导轨水平设置在所述发电机和所述发电机安装板之间,使所述滑块位于所述发电机的底部;S3. The guide rail is horizontally arranged between the generator and the generator mounting plate, so that the slider is located at the bottom of the generator;

S4、通过所述升降机构下降所述发电机,使所述滑块承载所述发电机;S4, lowering the generator through the lifting mechanism, so that the slider can carry the generator;

S5、移动所述滑块,使所述发电机随所述滑块沿所述延伸方向移出所述发电机组。S5. Move the slider so that the generator moves out of the generator set along the extension direction along with the slider.

该发电机的移动方法通过使用移动工装,使发电机能够随滑块一起沿着导轨从发电机组中水平移出,从而有效避免了发电机在移出过程中必须将发电机组的顶部框架拆除,有效减少了安装和拆除所耗费的时间,以通过降低发电机的维护时间来提升发电机组的工作时间,进而提高了发电机组的经济性。The moving method of the generator enables the generator to be horizontally moved out of the generator set along the guide rail together with the slider by using a mobile tool, thereby effectively avoiding the need to remove the top frame of the generator set during the process of removing the generator, effectively reducing the need for The time spent on installation and removal is reduced to increase the working time of the generator set by reducing the maintenance time of the generator, thereby improving the economy of the generator set.

较佳地,所述升降机构包括若干升降单元,每个所述升降单元均为可伸缩结构;Preferably, the lifting mechanism includes a plurality of lifting units, each of which is a retractable structure;

在所述步骤S1和步骤S2之间还包括步骤S11:将若干所述升降单元设置在所述发电机和所述发电机组的发电机安装板之间;Between the step S1 and the step S2, there is also a step S11: disposing a plurality of the lifting units between the generator and the generator mounting plate of the generator set;

在所述步骤S2中:通过伸长所述升降单元,使所述发电机离开所述发电机安装板;In the step S2: by extending the lifting unit, the generator is separated from the generator mounting plate;

在所述步骤S4中:通过缩短所述升降单元,使所述滑块承载所述发电机。In the step S4: by shortening the lifting unit, the slider is made to carry the generator.

通过同时设置这些可伸缩的升降单元,使升降单元能够对发电机进行多点支撑并使其升降,并通过多个升降单元分担对发电机的抬升,降低每个升降单元的体积和功率,以便于在发电机组内部进行布设安装。By arranging these retractable lifting units at the same time, the lifting unit can support the generator at multiple points and lift it, and share the lifting of the generator through multiple lifting units, reducing the volume and power of each lifting unit, so that For layout and installation inside the generator set.

较佳地,所述导轨具有第一安装接口;Preferably, the guide rail has a first installation interface;

在所述步骤S3和步骤S4之间还包括步骤S31:将所述发电机安装板用于连接所述发电机的接口与所述导轨的第一安装接口连接,以利用发电机安装板上现成的安装结构来固定导轨,使导轨在供滑块及发电机滑动时保持稳固状态,提高该移动工装的使用安全性。Between the step S3 and the step S4, there is also a step S31: connecting the interface of the generator mounting plate for connecting the generator to the first installation interface of the guide rail, so as to use the generator mounting plate ready-made The installation structure is used to fix the guide rail, so that the guide rail maintains a stable state when the slider and the generator slide, and the use safety of the mobile tooling is improved.

较佳地,所述滑块具有第二安装接口;Preferably, the slider has a second installation interface;

在所述步骤S4和步骤S5之间还包括步骤S41:将所述发电机用于连接所述发电机安装板的接口与所述滑块的第二安装接口连接,以利用发电机上现成的安装接口来与滑块相连,避免发电机和滑块在沿导轨滑动时产生相对滑脱的情况,提高该移动工装的使用安全性。Between the step S4 and the step S5, there is also a step S41: connecting the interface of the generator for connecting the generator mounting plate to the second installation interface of the slider, so as to utilize the ready-made installation on the generator The interface is connected with the sliding block, so as to avoid the relative slippage of the generator and the sliding block when sliding along the guide rail, and improve the use safety of the mobile tooling.

本发明的积极进步效果在于:The positive progressive effect of the present invention is:

该移动工装及发电机的移动方法中,通过使用移动工装的升降机构将发电机相对于发电机安装板抬起,再通过将导轨及滑块设置在被抬起的发电机底部,使滑块能够承载该发电机并带动发电机沿着导轨的延伸方向移动,从而实现从发电机组内部水平移出的功能。In the moving method of the mobile tool and the generator, the generator is lifted relative to the generator mounting plate by using the lifting mechanism of the mobile tool, and then the guide rail and the slider are arranged at the bottom of the lifted generator to make the slider It can carry the generator and drive the generator to move along the extension direction of the guide rail, so as to realize the function of horizontally moving out from the inside of the generator set.

通过使用该移动工装,可在对发电机进行维护时,无需再将发电机组的顶部框架拆除,从而可有效减少发电机的维护所产生的工作量和时间,进而大幅提升发电机组的运行时间,提高了发电机组的经济性。By using the mobile tooling, it is unnecessary to remove the top frame of the generator set when maintaining the generator, which can effectively reduce the workload and time generated by the maintenance of the generator, thereby greatly improving the running time of the generator set. The economy of the generator set is improved.

附图说明Description of drawings

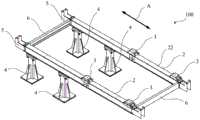

图1为本发明的一实施例的移动工装的立体结构示意图,其中升降机构被隐藏。FIG. 1 is a schematic three-dimensional structural diagram of a mobile tooling according to an embodiment of the present invention, wherein the lifting mechanism is hidden.

图2为本发明的一实施例的移动工装的使用状态示意图。FIG. 2 is a schematic diagram of a use state of a mobile tool according to an embodiment of the present invention.

图3为本发明的一实施例的移动工装的局部结构示意图。FIG. 3 is a schematic diagram of a partial structure of a mobile tool according to an embodiment of the present invention.

图4为本发明的一实施例的升降机构的使用状态示意图。FIG. 4 is a schematic diagram of a use state of the lifting mechanism according to an embodiment of the present invention.

图5为本发明的一实施例的升降单元的立体结构示意图。FIG. 5 is a schematic three-dimensional structural diagram of a lifting unit according to an embodiment of the present invention.

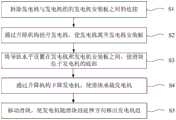

图6为本发明的一实施例的发电机的移动方法的流程示意图。6 is a schematic flowchart of a method for moving a generator according to an embodiment of the present invention.

附图标记说明:Description of reference numbers:

移动工装100

升降机构1Lifting mechanism 1

升降单元11Lifting

底座111,螺纹孔1111,底面1112

升降杆112Lifting

导轨2,上表面22,延伸方向A

滑块3,第二安装接口31,限位部32

支撑座4

牵引机构5

横梁6

发电机组101Generator Set 101

发电机102

发电机安装板103

步骤S1~S5Steps S1 to S5

具体实施方式Detailed ways

下面通过实施例的方式进一步说明本发明,但并不因此将本发明限制在所述的实施例范围之中。The present invention is further described below by way of examples, but the present invention is not limited to the scope of the described examples.

如图1和图2所示,本发明提供一种移动工装100,其用于将发电机102从发电机组101中移出,该移动工装100包括有升降机构1、导轨2和滑块3。其中,升降机构1用于驱动发电机102相对于发电机组101的发电机安装板103上升或下降,导轨2水平设置并向外延伸,而滑块3则沿着导轨2的延伸方向A在该导轨2上滑动,该滑块3用于承载发电机102并带动发电机102沿着导轨2的延伸方向A移动。As shown in FIG. 1 and FIG. 2 , the present invention provides a

该移动工装100通过升降机构1将发电机102相对于发电机安装板103抬起,并通过将导轨2及滑块3设置在被抬起的发电机102底部,使滑块3能够承载该发电机102并带动发电机102沿着导轨2的延伸方向A移动,从而实现从发电机组101内部水平移出的功能。The

通过使用该移动工装100,使得在对发电机102进行维护时,无需再将发电机组101的顶部框架拆除,从而可有效减少发电机102的维护所产生的工作量和时间,进而大幅提升发电机组101的运行时间,提高了发电机组101的经济性。By using the

该导轨2具有第一安装接口(图中未示出),第一安装接口可用于与发电机安装板103连接于发电机102的接口连接,使得导轨2在设置于发电机102和发电机安装板103之间时,通过与发电机安装板103上的现成接口相固定,使导轨2在供滑块3及发电机102滑动时保持稳固状态,提高该移动工装100的使用安全性。The

另外,图3所示,该滑块3同样可具有第二安装接口31,第二安装接口31可用于与发电机102连接于发电机安装板103的接口连接,使得滑块3在承载发电机102时能够与发电机102连接牢固,避免在沿导轨2滑动时产生相对滑脱的情况,进而进一步提高该移动工装100的使用安全性。同时,为了避免滑块3在导轨2的上表面22滑动时,因缺乏限位而从导轨2表面滑落,在滑块3上设置有具有向下延伸的限位部32,该限位部32位于导轨2的左右两侧,以在滑块3滑动时进行限位。其中,在本实施例中,该滑块3采用搬运小坦克来实现对发电机102的承载及沿导轨2滑动的功能,搬运小坦克(或又称钢辊地牛)的承载量较大,且能够市购获得,为本移动工装100的滑块3的一种较佳实现方案。In addition, as shown in FIG. 3 , the

该移动工装100还包括有支撑座4,支撑座4连接在导轨2上,以用于对该导轨2进行支撑,使导轨2除能够固定于发电机组101上之外,还可通过在导轨2伸出于发电机组101外的部分上设置支撑座4,以使得滑块3在承载发电机102沿导轨2移出于发电机组101时,通过支撑座4对导轨2进行良好的支撑,保证导轨2的结构稳定。The

其中,该支撑座4沿着高度方向的长度能够调节,以使导轨2在固定于不同规格型号的发电机组101时,可通过调节支撑座4的长度,使之适配于导轨2距离地面的高度,以适用多种工况,并能够更好地为导轨2提供支撑。其中,调节支撑座4长度的具体结构与原理均为现有技术,因此在此不再赘述。The length of the

该移动工装100还包括有牵引机构5,该牵引机构5设置在导轨2的端部上,以用于牵引滑块3沿着导轨2的延伸方向A移动。通过在导轨2上设置用于牵引滑块3移动的牵引机构5,以替代例如人工直接推拉等使滑块3移动的方式,使移动工装100能够移动重量较重的发电机102,并可有效避免工人的手在发电机102平移时过于接近滑块3而产生安全隐患。优选地,因手动葫芦及电动葫芦的制造成本及维护成本均较低,该牵引机构5可以采用上述两种机构来实现对滑块3的牵引,在本实施例中,该牵引机构5即为手动葫芦,通过将手动葫芦的链条连接于滑块3,使工人使用较小的力量即可使较重的发电机102实现水平移动的效果。The moving

在本实施例中,该移动工装100包括两根导轨2及四个滑块3,两根导轨2相对平行设置并同时固定在发电机组101上,四个滑块3分为两组分别设置在两根导轨2上,并均用于承载发电机组101。通过上述的设置方式,可提高移动工装100承载发电机102时的稳固程度,有效避免发电机102在移动过程中因重心不稳而导致倾覆。其中,本实施例中设置四个滑块3是由于对应的发电机102底部具有四个对应的安装接口所致,因此在移动其他规格型号的发电机102时,可采用不同数量的滑块3来实现。In this embodiment, the

该移动工装100还包括有横梁6,横梁6设置在两根导轨2之间,且横梁6的两端分别固定连接在两根导轨2上。通过设置横梁6以加强并限定两根导轨2的间距,同时,也方便在固定于发电机安装板103时能够整体安装,提高该移动工装100的使用效率。The

如图4所示,在本实施例中,该升降机构1包括有若干个升降单元11,这些升降单元11均布于发电机102的底部,且每一个升降单元11均为可伸缩结构,从而实现向上抬升发电机102的功能。As shown in FIG. 4 , in this embodiment, the lifting mechanism 1 includes a plurality of lifting

通过设置这些可伸缩的升降单元11,使这些升降单元11能够对发电机102进行多点支撑并使其升降。另外,由于是使用多个升降单元11同时对发电机102进行抬升,因此单个升降单元11的体积和功率也无需很大,便于在发电机组101内部进行布设安装。By arranging these

如图5所示,该升降单元11可包括有底座111和升降杆112,其中,底座111的顶面具有一螺纹孔1111,而升降杆112的表面则具有螺纹,该升降杆112通过螺纹孔1111与底座111保持螺纹连接,且升降杆112的顶部用于抵靠发电机102的底部。通过旋转该升降杆112,使升降杆112通过螺纹与底座111产生相对运动,即沿着图5中箭头所示的方向,实现对发电机102的顶升功能。该升降单元11的结构简单,成本低廉且便于维护更换,是一种使升降单元11实现带动发电机102升降的较佳实现方式。As shown in FIG. 5 , the lifting

该升降单元11也可以为油缸,该油缸的油缸杆抵靠于发电机102的底部,以通过油缸杆的伸缩实现对发电机102的顶升。该方案相较于上述的方案,可通过对布设的多个油缸进行同步控制,提高移动工装100的自动化水平。The lifting

此外,升降机构1可包括有多组升降单元11,每一组升降单元11均包括有若干个同时使用的升降单元11,且每组升降单元11的可伸缩高度均不同。通过设置多组不同伸缩高度的升降单元11,使升降机构1满足对发电机102不同伸缩高度的需要。In addition, the elevating mechanism 1 may include multiple groups of elevating

例如,当某一台发电机组101中的发电机102与位于发电机102下方的发电机安装板103之间仅仅具有很小的间距,那么,在需要使用升降机构1对该发电机102抬升较高高度时,可以先使用高度尺寸较小的升降单元11设置在发电机102和发电机安装板103之间,使之先将发电机102抬升一定的高度,再使用高度较高的另一组升降单元11,通过交替抬升的方式不断将发电机102最终抬升至所需的指定高度。For example, when there is only a small distance between the

如图1和图6所示,本发明还提供一种发电机的移动方法,其用于将发电机102从发电机组101中移出,该发电机的移动方法利用如上所述的移动工装100,且该方法包含以下步骤:As shown in FIG. 1 and FIG. 6 , the present invention also provides a method for moving the generator, which is used to remove the

S1、拆除发电机102与发电机组101的发电机安装板103之间的连接;S1, remove the connection between the

S2、通过升降机构1抬升发电机102,使发电机102离开发电机安装板103;S2, lift the

S3、将导轨2水平设置在发电机102和发电机安装板103之间,使滑块3位于发电机102的底部;S3, set the

S4、通过升降机构1下降发电机102,使滑块3承载发电机102;S4, lowering the

S5、移动滑块3,使发电机102随滑块3沿延伸方向A移出发电机组101。S5 , move the

该发电机的移动方法通过使用移动工装100,使发电机102能够随滑块3一起沿着导轨2从发电机组101中水平移出,从而有效避免了发电机102在移出过程中必须将发电机组101的顶部框架拆除,有效减少了安装和拆除所耗费的时间,以通过降低发电机102的维护时间来提升发电机组101的工作时间,进而提高了发电机组101的经济性。By using the moving

由于该升降机构1包括有多个升降单元11,因此在步骤S1和步骤S2之间还包括步骤S11:将若干升降单元11设置在发电机102和发电机组101的发电机安装板103之间。且在步骤S2中:通过伸长升降单元11,使发电机102离开发电机安装板103。同时,在步骤S4中:通过缩短升降单元11,使滑块3承载发电机102。Since the lifting mechanism 1 includes a plurality of lifting

通过同时设置这些可伸缩的升降单元11,使升降单元11能够对发电机102进行多点支撑并使其升降,并通过多个升降单元11分担对发电机102的抬升,降低每个升降单元11的体积和功率,以便于在发电机组101内部进行布设安装。By arranging these

另外,由于导轨2具有第一安装接口,在步骤S3和步骤S4之间还包括步骤S31:将发电机安装板103用于连接发电机102的接口与导轨2的第一安装接口连接,以利用发电机安装板103上现成的安装接口来固定导轨2,使导轨2在供滑块3及发电机102滑动时保持稳固状态,提高该移动工装100的使用安全性。In addition, since the

同时,由于滑块3具有第二安装接口31,在步骤S4和步骤S5之间还包括步骤S41:将发电机102用于连接发电机安装板103的接口与滑块3的第二安装接口31连接,以利用发电机102上现成的安装接口来与滑块3相连,避免发电机102和滑块3在沿导轨2滑动时产生相对滑脱的情况,提高该移动工装100的使用安全性。At the same time, since the

在本发明的描述中,需要理解的是,术语“上”、“下”、“前”、“后”、“左”、“右”、“竖直”、“水平”、“顶”、“底”、“内”、“外”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或组件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。In the description of the present invention, it should be understood that the terms "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", The orientation or positional relationship indicated by "bottom", "inner", "outer", etc. is based on the orientation or positional relationship shown in the accompanying drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying the indicated device. Or the components must have a specific orientation, be constructed and operated in a specific orientation, and therefore should not be construed as a limitation of the present invention.

虽然以上描述了本发明的具体实施方式,但是本领域的技术人员应当理解,这仅是举例说明,本发明的保护范围是由所附权利要求书限定的。本领域的技术人员在不背离本发明的原理和实质的前提下,可以对这些实施方式做出多种变更或修改,但这些变更和修改均落入本发明的保护范围。Although the specific embodiments of the present invention are described above, those skilled in the art should understand that this is only an illustration, and the protection scope of the present invention is defined by the appended claims. Those skilled in the art can make various changes or modifications to these embodiments without departing from the principle and essence of the present invention, but these changes and modifications all fall within the protection scope of the present invention.

Claims (18)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811624779.9ACN111376032A (en) | 2018-12-28 | 2018-12-28 | Moving tool and moving method of generator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811624779.9ACN111376032A (en) | 2018-12-28 | 2018-12-28 | Moving tool and moving method of generator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111376032Atrue CN111376032A (en) | 2020-07-07 |

Family

ID=71220548

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811624779.9AWithdrawnCN111376032A (en) | 2018-12-28 | 2018-12-28 | Moving tool and moving method of generator |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111376032A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112253960A (en)* | 2020-11-17 | 2021-01-22 | 江西清华泰豪三波电机有限公司 | Slide rail device and generating set |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE8304520D0 (en)* | 1983-08-19 | 1983-08-19 | Ibm Svenska Ab | DOCKING AND FIXING DEVICE FOR A PALLET IN A ROBOT OR LIKE SYSTEM |

| JPH09295230A (en)* | 1996-04-26 | 1997-11-18 | Tokyo Denki Komusho:Kk | Large nut attachment / detachment device |

| EP1366836A1 (en)* | 2002-05-31 | 2003-12-03 | Newfrey LLC | Self-piercing rivet setting apparatus |

| CN102030076A (en)* | 2010-12-14 | 2011-04-27 | 广州中船黄埔造船有限公司 | Cabin entry process for main diesel generating set of 50,000-ton semi-submerged ship |

| CN102651588A (en)* | 2011-02-25 | 2012-08-29 | 上海宝钢设备检修有限公司 | Drawing method of gas turbine generator rotor in overhauling operation |

| CN202600359U (en)* | 2012-03-05 | 2012-12-12 | 上海微电子装备有限公司 | Dual-functional bottom device for reticle stage |

| CN203345653U (en)* | 2012-09-13 | 2013-12-18 | 润弘精密工程事业股份有限公司 | Carrying implement |

| CN203956854U (en)* | 2014-06-19 | 2014-11-26 | 西安盾安电气有限公司 | A kind of motor bearings provision for disengagement |

| CN205739208U (en)* | 2016-05-18 | 2016-11-30 | 上海泰胜风能装备股份有限公司 | The tower transfer system of wind turbine power generation unit |

| CN106586387A (en)* | 2016-12-16 | 2017-04-26 | 昆明理工大学 | Lifting and moving device |

| CN206280194U (en)* | 2016-12-08 | 2017-06-27 | 北京三一电机系统有限责任公司 | Wind-driven generator mobile device and the mobile system using the device |

| CN207726439U (en)* | 2017-10-25 | 2018-08-14 | 中国原子能科学研究院 | A kind of single motor driving two-way tape mechanism moving up and down |

| CN207986617U (en)* | 2018-01-22 | 2018-10-19 | 上海船厂船舶有限公司 | Support base mobile device |

| CN109067104A (en)* | 2018-08-24 | 2018-12-21 | 浙江农林大学 | A kind of hub motor permanent magnet automatic dismantling equipment |

| CN209288691U (en)* | 2018-12-28 | 2019-08-23 | 利星行能源(昆山)有限公司 | Mobile tool |

- 2018

- 2018-12-28CNCN201811624779.9Apatent/CN111376032A/ennot_activeWithdrawn

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE8304520D0 (en)* | 1983-08-19 | 1983-08-19 | Ibm Svenska Ab | DOCKING AND FIXING DEVICE FOR A PALLET IN A ROBOT OR LIKE SYSTEM |

| JPH09295230A (en)* | 1996-04-26 | 1997-11-18 | Tokyo Denki Komusho:Kk | Large nut attachment / detachment device |

| EP1366836A1 (en)* | 2002-05-31 | 2003-12-03 | Newfrey LLC | Self-piercing rivet setting apparatus |

| CN102030076A (en)* | 2010-12-14 | 2011-04-27 | 广州中船黄埔造船有限公司 | Cabin entry process for main diesel generating set of 50,000-ton semi-submerged ship |

| CN102651588A (en)* | 2011-02-25 | 2012-08-29 | 上海宝钢设备检修有限公司 | Drawing method of gas turbine generator rotor in overhauling operation |

| CN202600359U (en)* | 2012-03-05 | 2012-12-12 | 上海微电子装备有限公司 | Dual-functional bottom device for reticle stage |

| CN203345653U (en)* | 2012-09-13 | 2013-12-18 | 润弘精密工程事业股份有限公司 | Carrying implement |

| CN203956854U (en)* | 2014-06-19 | 2014-11-26 | 西安盾安电气有限公司 | A kind of motor bearings provision for disengagement |

| CN205739208U (en)* | 2016-05-18 | 2016-11-30 | 上海泰胜风能装备股份有限公司 | The tower transfer system of wind turbine power generation unit |

| CN206280194U (en)* | 2016-12-08 | 2017-06-27 | 北京三一电机系统有限责任公司 | Wind-driven generator mobile device and the mobile system using the device |

| CN106586387A (en)* | 2016-12-16 | 2017-04-26 | 昆明理工大学 | Lifting and moving device |

| CN207726439U (en)* | 2017-10-25 | 2018-08-14 | 中国原子能科学研究院 | A kind of single motor driving two-way tape mechanism moving up and down |

| CN207986617U (en)* | 2018-01-22 | 2018-10-19 | 上海船厂船舶有限公司 | Support base mobile device |

| CN109067104A (en)* | 2018-08-24 | 2018-12-21 | 浙江农林大学 | A kind of hub motor permanent magnet automatic dismantling equipment |

| CN209288691U (en)* | 2018-12-28 | 2019-08-23 | 利星行能源(昆山)有限公司 | Mobile tool |

Non-Patent Citations (2)

| Title |

|---|

| 彭锦涛;: "一种用于空调压缩机生产线的壳体热套装置", 机电工程技术, no. 07, 23 July 2018 (2018-07-23), pages 36 - 37* |

| 闵道广;: "一种可抽拉式移动电源的结构设计", 科技视界, no. 34, 5 December 2013 (2013-12-05), pages 112* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112253960A (en)* | 2020-11-17 | 2021-01-22 | 江西清华泰豪三波电机有限公司 | Slide rail device and generating set |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201882859U (en) | Automatic elevator | |

| CN114152828B (en) | Flexible direct-current transmission converter valve submodule power overhaul test device and test method | |

| CN111377362A (en) | Lifting tooling and lifting method of gas turbine | |

| CN111376032A (en) | Moving tool and moving method of generator | |

| CN105502213A (en) | Power transformation equipment jacking device and adjusting mechanism thereof | |

| CN209288691U (en) | Mobile tool | |

| CN209868507U (en) | Automatic change maintenance platform device | |

| CN108974390A (en) | A kind of aircraft horizontal wings test bracket | |

| CN221174728U (en) | Conductive immunity test platform | |

| CN205527546U (en) | Jacking mechanism | |

| CN210825200U (en) | Lifting device for large-scale power equipment installation | |

| CN209853572U (en) | Boiler installation overhead hoist | |

| CN205091131U (en) | Diesel engine water resistance experimental apparatus | |

| CN111228755A (en) | High-altitude operation device for electric power construction and use method thereof | |

| CN216556155U (en) | Liftable 3D camera stand | |

| CN214496489U (en) | Compact etching machine of small-size metal convenient to height-adjusting | |

| CN213171283U (en) | Digit control machine tool maintenance experiment platform | |

| CN202012187U (en) | Lifting scaffold | |

| CN212356304U (en) | Vertical hanging beam capable of being provided with clamps of various specifications | |

| CN205091998U (en) | Water resistance case plate electrode elevating gear | |

| CN219751637U (en) | Part hoisting jig convenient to install | |

| CN219837450U (en) | Workbench convenient to fix | |

| CN222082230U (en) | A mobile and adjustable lifting platform for a ditch photovoltaic power generation system | |

| CN216667050U (en) | Suspension device for mounting power equipment in power engineering | |

| CN219343878U (en) | Door installation auxiliary device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication | ||

| WW01 | Invention patent application withdrawn after publication | Application publication date:20200707 |