CN111328245B - Return type jet microchannel radiator and heat dissipation method - Google Patents

Return type jet microchannel radiator and heat dissipation methodDownload PDFInfo

- Publication number

- CN111328245B CN111328245BCN202010094902.1ACN202010094902ACN111328245BCN 111328245 BCN111328245 BCN 111328245BCN 202010094902 ACN202010094902 ACN 202010094902ACN 111328245 BCN111328245 BCN 111328245B

- Authority

- CN

- China

- Prior art keywords

- jet

- microchannel

- return

- cavity

- working medium

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription13

- 230000017525heat dissipationEffects0.000titleclaimsabstractdescription10

- 238000009826distributionMethods0.000claimsabstractdescription63

- 239000007788liquidSubstances0.000claimsabstractdescription62

- 239000000758substrateSubstances0.000claimsabstractdescription28

- 239000000463materialSubstances0.000claimsdescription7

- 238000003754machiningMethods0.000claimsdescription6

- 229910000838Al alloyInorganic materials0.000claimsdescription5

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000claimsdescription5

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000claimsdescription5

- 238000003486chemical etchingMethods0.000claimsdescription5

- 229910052802copperInorganic materials0.000claimsdescription5

- 239000010949copperSubstances0.000claimsdescription5

- 229910052710siliconInorganic materials0.000claimsdescription5

- 239000010703siliconSubstances0.000claimsdescription5

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription4

- 239000008367deionised waterSubstances0.000claimsdescription3

- 229910021641deionized waterInorganic materials0.000claimsdescription3

- 238000001816coolingMethods0.000description12

- 238000005086pumpingMethods0.000description10

- 238000012546transferMethods0.000description8

- 230000001965increasing effectEffects0.000description7

- 230000004907fluxEffects0.000description6

- 230000008901benefitEffects0.000description5

- 239000012530fluidSubstances0.000description5

- 238000010586diagramMethods0.000description4

- 230000000694effectsEffects0.000description4

- 230000003116impacting effectEffects0.000description4

- 239000011148porous materialSubstances0.000description4

- 238000007789sealingMethods0.000description4

- 2380000101463D printingMethods0.000description3

- 238000013461designMethods0.000description3

- 230000009286beneficial effectEffects0.000description2

- 230000006866deteriorationEffects0.000description2

- 238000009792diffusion processMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 239000002861polymer materialSubstances0.000description2

- 230000008569processEffects0.000description2

- 238000011160researchMethods0.000description2

- 238000012795verificationMethods0.000description2

- 238000003466weldingMethods0.000description2

- 238000007792additionMethods0.000description1

- 230000004075alterationEffects0.000description1

- 238000003491arrayMethods0.000description1

- 230000008859changeEffects0.000description1

- 238000011161developmentMethods0.000description1

- 238000005516engineering processMethods0.000description1

- 230000002708enhancing effectEffects0.000description1

- 230000010354integrationEffects0.000description1

- 230000003137locomotive effectEffects0.000description1

- 229910052751metalInorganic materials0.000description1

- 239000002184metalSubstances0.000description1

- 239000007769metal materialSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000009467reductionEffects0.000description1

- 238000010992refluxMethods0.000description1

- 238000010200validation analysisMethods0.000description1

Images

Classifications

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K7/00—Constructional details common to different types of electric apparatus

- H05K7/20—Modifications to facilitate cooling, ventilating, or heating

- H05K7/20845—Modifications to facilitate cooling, ventilating, or heating for automotive electronic casings

- H05K7/20872—Liquid coolant without phase change

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K7/00—Constructional details common to different types of electric apparatus

- H05K7/20—Modifications to facilitate cooling, ventilating, or heating

- H05K7/20218—Modifications to facilitate cooling, ventilating, or heating using a liquid coolant without phase change in electronic enclosures

- H05K7/20281—Thermal management, e.g. liquid flow control

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Cooling Or The Like Of Semiconductors Or Solid State Devices (AREA)

Abstract

Translated fromChineseDescription

Technical Field

The invention relates to the technical field of cooling of electronic devices, in particular to a turn-back type jet flow micro-channel radiator and a radiating method.

Background

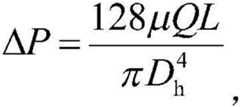

With the increasing integration density, the heat flux density of chip-scale devices, such as high-power laser diodes and high-power electronic components, is increased to 100W/cm2Even higher; core element IGBT chip level heat flux density in high-speed train and the new energy automobile can reach kW level. The performance of the components is sensitive to the increase of the temperature, and the reliability of the components is reduced due to high temperature, even the components are failed. The accelerated increase in component heat flux density presents a significant technical challenge to the thermal management of electronic devices. Aiming at the problem of high heat flux density, the conventional air cooling technology cannot meet the requirement. Tukerman and Pease in 1981 propose a micro-channel heat sink concept aiming at the problem of high heat flux density cooling, and realize 790W/cm2The heat dissipation of the heat flux density is realized, and simultaneously the temperature rise of the heat sink bottom wall surface and the inlet water temperature is 71 ℃, so that the high-efficiency and excellent cooling performance of the micro-channel heat transmitter is shown. After the micro-channel cooling concept is provided, a large number of students develop researches on the influence of the channel shape, the channel size and the heat radiating material on the performance of the micro-channel heat exchanger, and obtain general conclusions that the micro-channel with a rectangular section has better heat exchange performance, the comprehensive heat exchange performance of the heat exchanger can be improved by properly increasing the depth-to-width ratio of the rectangular channel, and the like. At present, the micro-channel heat exchanger is widely applied to the engineering fields of electronics, aerospace, locomotives and the like. But the conventional microchannel heat sink still has two prominent disadvantagesPoint: the problems of high temperature gradients in the flow direction due to the deterioration of heat exchange in the flow direction due to the development of thermal boundary layers, and the problems of high pressure drop due to the reduction of channel dimensions, both of which make the application of microchannels slower than their laboratory research. In addition, in various cooling means, due to the strong jet impact effect, the speed and the temperature gradient are good in cooperativity, the heat dissipation heat flow density achieved by jet cooling is higher than that of the traditional microchannel, and the heat dissipation performance is better, but the jet cooling has the problem that the heat transfer coefficient of the surface outside a stagnation area is sharply reduced. If the advantages of jet flow cooling and micro-channel cooling are combined, the comprehensive performance of the heat exchanger is greatly improved.

The above information disclosed in this background section is only for enhancement of understanding of the background of the invention and therefore it may contain information that does not form the prior art that is well known to those of ordinary skill in the art.

Disclosure of Invention

In order to solve the problems, the invention provides a turn-back type jet flow micro-channel radiator and a heat dissipation method, through the arrangement of an inlet distributor and an outlet distributor, the uniformity of flow distribution is improved, and the pump work required by a heat exchanger is reduced.

The purpose of the invention is realized by the following technical scheme.

A reentrant fluidic microchannel heat sink includes a heat sink,

a microchannel substrate provided with microchannels;

a jet orifice plate laminated on the microchannel substrate and hermetically connected between layers, the jet orifice plate including a plurality of jet inlet holes and a plurality of return outlet holes;

a distributor stacked on the jet orifice plate and hermetically connected between layers, the distributor comprising,

a liquid inlet pipe for pumping working medium,

a first distribution cavity communicated with the liquid inlet pipe,

a plurality of second distribution cavities respectively communicated with the first distribution cavities and the jet inlet holes, wherein the working medium is horizontally and fluidly introduced into the second distribution cavities through the first distribution cavities and then vertically enters the jet inlet holes to impact the bottom wall surfaces of the micro-channels,

a plurality of second liquid return cavities which are respectively communicated with the return outlet holes and the first liquid return cavities, and the working medium impacting the bottom wall surface of the microchannel returns back to enter the return outlet holes,

the working medium entering the backflow outlet hole enters the first liquid return cavity through the second liquid return cavity,

and the liquid return pipe is communicated with the first liquid return cavity, and the working medium entering the first liquid return cavity is discharged through the liquid return pipe.

In the reentrant jet flow microchannel radiator, the first distribution cavity and/or the second distribution cavity are/is of a wedge-shaped tapered structure along the flow direction, and the second liquid return cavity and/or the first liquid return cavity are/is of a wedge-shaped tapered structure.

In the turn-back type jet flow micro-channel radiator, a plurality of jet flow inlet holes and a plurality of return flow outlet holes are alternately arranged.

In the reentrant jet micro-channel radiator, a plurality of jet inlet holes and a plurality of backflow outlet holes are in a jet array with alternating incidence and backflow.

In the turn-back type jet flow micro-channel radiator, the micro-channel is machined on a micro-channel substrate through machining or chemical etching, the micro-channel is a rectangular channel, the depth-to-width ratio of the micro-channel is 1-10, and the ratio of the rib width of the micro-channel to the width of the micro-channel is 0.25-2.

In the turn-back type jet flow micro-channel radiator, the micro-channel is made of copper, silicon, aluminum alloy or other materials with high heat conductivity coefficient, and the micro-channel is arranged on the micro-channel substrate in parallel at equal intervals.

In the turn-back type jet flow micro-channel radiator, the distributor is of a U-shaped structure, and the working medium comprises deionized water.

In the turn-back type jet flow micro-channel radiator, a plurality of second distribution cavities and a plurality of second liquid return cavities are arranged in a staggered mode and are high at two sides and low in the middle.

In the turn-back type jet flow micro-channel radiator, the aperture of the jet flow inlet hole is smaller than that of the backflow outlet hole.

According to another aspect of the invention, a heat dissipation method of the turn-back type jet flow micro-channel heat sink comprises the following steps,

the working medium is pumped into the first distribution cavity through the liquid inlet pipe,

the working medium is horizontally guided into the second distribution cavity through the first distribution cavity and then vertically enters the jet inlet hole to impact the bottom wall surface of the micro-channel, the working medium impacting the bottom wall surface of the micro-channel is folded back to enter the backflow outlet hole,

and the working medium entering the backflow outlet hole enters the first liquid return cavity through the second liquid return cavity and then is discharged through the liquid return pipe.

Compared with the prior art, the invention has the beneficial effects that:

after the working medium passes through the inlet hole of the porous plate, the working medium generates higher kinetic energy to impact the bottom surface of the microchannel, and because of better temperature gradient and speed cooperativity, the heat on the wall surface of the bottom of the microchannel is taken away by strong impact convection heat exchange, and after the impact, the fluid flows to the outlet hole of the adjacent porous plate layer in the microchannel, so that the heat exchange area per unit volume provided by the microchannel is larger, the heat exchange coefficient is stronger when the fluid flows in a transverse flow manner, and the overall heat exchange performance is improved. The invention adopts the jet flow inlets and the jet flow outlets which are alternately arranged on the micro-channel, so that a single long micro-channel is divided into a plurality of short flow units, the flow of the working medium flowing in the micro-channel is greatly reduced, and compared with a straight channel, the flow distributed on a single jet flow inlet is also greatly reduced, so that the flow on each section of flow unit is also reduced,the pressure drop of the whole radiator is greatly reduced, and the pumping work required by pumping the working medium can be reduced under the same flow.

The invention divides a single longer microchannel into a plurality of shorter flow units by adopting the jet inlet holes and the reflux holes which are alternately arranged on the microchannel, the temperature rise of the working medium on the smaller flow is smaller, the temperature of the bottom wall surface of the heat exchanger is more uniform, and in addition, the jet impact heat transfer coefficient attenuation is smaller because the flow is shorter, and the surface temperature uniformity of the electronic device is also improved. The jet flow pore plate and the distributor of the microchannel heat exchanger are formed by 3D printing of high polymer materials or metal materials, and the distributor and the microchannel substrate are connected in a flexible sealing manner or formed by vacuum diffusion welding, so that the reliability of the whole device can be ensured.

The above description is only an overview of the technical solutions of the present invention, and in order to make the technical means of the present invention more clearly apparent, and to make the implementation of the content of the description possible for those skilled in the art, and to make the above and other objects, features and advantages of the present invention more obvious, the following description is given by way of example of the specific embodiments of the present invention.

Drawings

Various other advantages and benefits of the present invention will become apparent to those of ordinary skill in the art upon reading the following detailed description of the preferred embodiments. The drawings are only for purposes of illustrating the preferred embodiments and are not to be construed as limiting the invention. It is obvious that the drawings described below are only some embodiments of the invention, and that for a person skilled in the art, other drawings can be derived from them without inventive effort. Also, like parts are designated by like reference numerals throughout the drawings.

In the drawings:

FIG. 1 is an exploded view of a folded microchannel heat exchanger according to the present invention;

FIG. 2 is a schematic view of the dispenser of the present invention;

FIG. 3 is a schematic structural view of a jet orifice layer of the present invention;

FIG. 4 is a schematic structural diagram of a microchannel substrate according to the present invention;

FIG. 5 validation of the improved flow uniformity of a converging-diverging distribution chamber;

FIG. 6 is a schematic diagram of the flow process of the reentrant microchannel working medium of the present invention;

fig. 7 is a comparison of the flow heat exchange performance of the turn-back microchannel heat sink of the present invention and a conventional straight channel heat sink.

The invention is further explained below with reference to the figures and examples.

Detailed Description

Specific embodiments of the present invention will be described in more detail below with reference to fig. 1 to 7. While specific embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

It should be noted that certain terms are used throughout the description and claims to refer to particular components. As one skilled in the art will appreciate, various names may be used to refer to a component. This specification and claims do not intend to distinguish between components that differ in name but not function. In the following description and in the claims, the terms "include" and "comprise" are used in an open-ended fashion, and thus should be interpreted to mean "include, but not limited to. The description which follows is a preferred embodiment of the invention, but is made for the purpose of illustrating the general principles of the invention and not for the purpose of limiting the scope of the invention. The scope of the present invention is defined by the appended claims.

For the purpose of facilitating understanding of the embodiments of the present invention, the following description will be made by taking specific embodiments as examples with reference to the accompanying drawings, and the drawings are not to be construed as limiting the embodiments of the present invention.

For better understanding, as shown in fig. 1, a folded jet microchannel heat sink is included,

amicrochannel substrate 5 provided withmicrochannels 17;

thejet orifice plate 4 is laminated on themicro-channel substrate 5 and is connected in a sealing mode among layers, and thejet orifice plate 4 comprises a plurality of jet inlet holes 10-12 and a plurality of backflow outlet holes 13-16;

a distributor 1 which is laminated on thejet orifice plate 4 and is connected with the jet orifice plate in a sealing way, wherein the distributor 1 comprises,

aliquid inlet pipe 2 for pumping working medium,

afirst distribution chamber 6 which is communicated with theliquid inlet pipe 2,

a plurality ofsecond distribution chambers 7 respectively communicating with thefirst distribution chamber 6 and the jet inlet holes 10-12, wherein the working medium is horizontally introduced into thesecond distribution chambers 7 through thefirst distribution chamber 6 and then vertically enters the jet inlet holes 10-12 to impact the bottom wall surface of themicrochannel 17,

a plurality of second liquid returningcavities 8 which are respectively communicated with the backflow outlet holes 13-16 and the first liquid returningcavity 9, the working medium impacting the bottom wall surface of themicro channel 17 is folded back to enter the backflow outlet holes 13-16,

the working medium entering the return outlet holes 13-16 enters the firstliquid return cavity 9 through the secondliquid return cavity 8,

and theliquid return pipe 3 is communicated with the firstliquid return cavity 9, and the working medium entering the firstliquid return cavity 9 is discharged through theliquid return pipe 3.

In the preferred embodiment of the turn-back type jet flow microchannel heat sink, thefirst distribution cavity 6 and/or thesecond distribution cavity 7 are/is of a tapered structure along the flow direction in a wedge shape, and the secondliquid return cavity 8 and/or the firstliquid return cavity 9 are/is of a tapered structure in a wedge shape.

In the preferred embodiment of the described reentrant fluidic microchannel heat sink, a plurality of fluidic inlet holes 10-12 and a plurality of return outlet holes 13-16 are arranged alternately.

In the preferred embodiment of the described reentrant fluidic microchannel heat sink, the plurality of fluidic inlet orifices 10-12 and the plurality of return outlet orifices 13-16 are in an array of alternating incident and return jets.

In the preferred embodiment of the turn-back type jet flow micro-channel heat sink, the micro-channel 17 is machined on themicro-channel substrate 5 by machining or chemical etching, the micro-channel 17 is a rectangular channel, the depth-to-width ratio of the micro-channel 17 is 1-10, and the ratio of the rib width of the micro-channel 17 to the channel width is 0.25-2.

In the preferred embodiment of the turn-back type jet flow micro-channel radiator, the micro-channel 17 is made of copper, silicon, aluminum alloy or other materials with high thermal conductivity coefficient, and the micro-channel 17 is arranged on themicro-channel substrate 5 in parallel and at equal intervals.

In the preferred embodiment of the turn-back type jet flow microchannel radiator, the distributor 1 is in a U-shaped structure, and the working medium comprises deionized water.

In the preferred embodiment of the turn-back type jet micro-channel radiator, a plurality ofsecond distribution cavities 7 and a plurality of secondliquid return cavities 8 are arranged in a staggered mode and are high at two sides and low at the middle.

In the preferred embodiment of the described reentrant fluidic microchannel heat sink, the aperture of the fluidic inlet orifices 10-12 is smaller than the aperture of the return outlet orifices 13-16.

In one embodiment, the reentrant jet micro-channel heat sink comprises amicro-channel substrate 5 etched with micro-channels 17, ajet orifice plate 4 with low thermal conductivity and a distributor 1 are further configured above themicro-channel substrate 5, thejet orifice plate 4 is provided with jet inlet holes 10-12 and return outlet holes 13-16 which are alternately arranged, and the distributor 1 is composed of aliquid inlet pipe 2, afirst distribution chamber 6, asecond distribution chamber 7, asecond return chamber 8, afirst return chamber 9 and aliquid return pipe 3.

In one embodiment, the area of the microchannel 17 region is equivalent to the surface area of the cooled device, and the base of themicrochannel 17 is closely attached to the surface of the cooled device.

In one embodiment, themicrochannels 17 are machined on themicrochannel substrate 5 by a machining or chemical etching technique, and are rectangular channels arranged in parallel and equally spaced on themicrochannel substrate 5.

In one embodiment, the micro-channels 17 are made of copper, silicon, aluminum alloy or other high thermal conductivity material, the aspect ratio of the micro-channels 17 is 1-10, and the ratio of the rib width of the micro-channels 17 to the channel width is 0.25-2.

In one embodiment, thejet orifice plate 4 and the distributor 1 may be formed by 3D printing with a polymer material with low thermal conductivity and high mechanical strength, or by machining or 3D printing with a metal selected from the same material as themicrochannel substrate 5, and hermetically connected to themicrochannel substrate 5 by diffusion welding.

In one embodiment, theliquid inlet pipe 2 is respectively communicated with thefirst distribution chamber 6 and thesecond distribution chamber 7, thesecond distribution chamber 7 is communicated with the jet inlet holes 10-12 arranged on thejet orifice plate 4, the working medium is fed into the micro-channel 17 in a jet mode, the working medium impacts the bottom surface of the micro-channel 17 to absorb heat of the bottom wall surface in a convection heat transfer mode, the heat is carried out and flows out from the adjacent return outlet holes 13-16, the working medium is converged into thesecond return chamber 8, and the working medium flows out from thereturn pipe 3 through the first return chamber communicated with the second return chamber.

In one embodiment, thefirst distribution chamber 6, thesecond distribution chamber 7, thesecond return chamber 8, and thefirst return chamber 9 are of tapered wedge design in the flow direction, which is effective to improve the distribution characteristics of the flow at the jet inlet openings 10-12.

In one embodiment, the number of thesecond distribution chamber 7 and the second recirculation chamber depends on the precision of the manufacturing process, and the number of thesecond distribution chamber 7 and the second recirculation chamber can be increased appropriately as the manufacturing process allows, and the number of the arrays of the jet inlet holes 10-12 and the return outlet holes 13-16 and the number of the micro-channels 17 on thejet orifice plate 4 can be increased accordingly, so as to increase the number of jet cores, enhance heat transfer and reduce the pump work consumption.

In one embodiment, thejet orifice plate 4 is arranged above thestraight microchannels 17, the alternating jet inlet openings 10-12 and return outlet openings 13-16 of thejet orifice plate 4 are arranged in a direction perpendicular to the direction of themicrochannels 17 in themicrochannel plate 5, and the jet inlet openings 10-12 and the return outlet openings 13-16 communicate with themicrochannels 17.

In order to further understand the invention, in one embodiment, the turn-back type microchannel jet heat exchanger is formed by stacking amicrochannel substrate 5, ajet orifice plate 4 with low heat conductivity coefficient, which is further sequentially arranged above themicrochannel substrate 5, and a distributor 1, wherein the layers are connected in a sealing manner, and the distributor 1 is further provided with aliquid inlet pipe 2 and aliquid return pipe 3 which are used for being connected with an external working medium circulation system.

As shown in fig. 2, the distributor 1 is composed of aninlet pipe 2, afirst distribution chamber 6, asecond distribution chamber 7, a secondliquid return chamber 8, a firstliquid return chamber 9 and aliquid return pipe 3. The distributor 1 is used for pumping working medium through theliquid inlet pipe 2, the working medium flows in through thefirst distribution cavity 6 and thesecond distribution cavity 7 and flows horizontally in thesecond distribution cavity 7, thesecond distribution cavity 7 is communicated with the jet inlet holes 10-12 on thejet pore plate 4, the working medium enters themicro-channel substrate layer 5 through the vertical jetpore plate layer 4 and impacts the bottom wall surface of the micro-channel 17, one part of fluid entering from one jet inlet hole is two and flows in the micro-channel 17 in the opposite direction, heat introduced from the bottom wall surface of the micro-channel 17 through heat conduction is absorbed, the fluid flows out from the verticaljet pore plate 4 in the adjacent return outlet holes 13-16, flows into thesecond return cavity 8 and is collected into thereturn pipe 3 through thefirst return cavity 9 and is discharged. Thefirst distribution cavity 6 and thesecond distribution cavity 7 are designed in a tapered wedge shape, thesecond return cavity 8 and thefirst return cavity 9 are designed in a tapered wedge shape, the design is mainly used for improving the uniformity of the working medium entering each jet inlet hole, the verification of the structural effectiveness is shown in fig. 5, the verification structure is a two-dimensional micro-channel with a U-shaped distributor structure, the number of the channels is 7, and it can be seen from fig. 5 that in the arrangement form of the U-shaped distributor, the uniformity of the flow in the micro-channel configured with the tapered-tapered distribution cavity is remarkably improved, and the distribution effect of the flow distributed in the 7 micro-channels is better than that of a straight distribution cavity.

Fig. 3 shows a jet-perforatedplate 4, on which jet-perforatedplate 4 there are alternately arranged jet inlet openings 10-12 and return outlet openings 13-16, the jet inlet openings 10-12 and the return outlet openings 13-16 being arranged in parallel to form an alternating jet array. The jet inlet holes 10-12 have a small hole size, and the fluid entering from thesecond distribution chamber 7 obtains a high kinetic energy through the narrow jet inlet holes 10-12, and the high flow velocity enhances the impingement heat exchange performance. The return outlet holes 13-16 can be increased in size within an allowable design range (the size of the hole is smaller than the width of the second distribution chamber 7), and the increased size of the hole can effectively reduce the overall pumping power consumption of the reentrant jet micro-channel radiator.

Fig. 4 shows amicrochannel substrate 5, wherein themicrochannel substrate 5 is made of copper, silicon, aluminum alloy or other high thermal conductivity material, and themicrochannels 17 are machined on themicrochannel substrate 5 by a machining or chemical etching technique and are parallel rectangular channels with equal spacing, for enhancing heat transfer, the aspect ratio of themicrochannels 17 is 1-10, and the ratio of the rib width of the microchannels to the channel width is 0.25-2. The arrangement of therectangular micro-channels 17 can effectively guide the flow to flow along the bottom wall surface and the side wall surface of the micro-channels 17, and theadjacent micro-channels 17 are separated by the ribs, so that the influence of adjacent jet flows is weakened, and the impact cooling effect is not influenced because the jet flows are mutually interfered.

Fig. 6 shows a schematic diagram of the flow process of the reentrant fluidic microchannel working medium, and it can be seen from the diagram that the fluidic inlet holes 10-12 and the return outlet holes 13-16 alternately appear on asingle microchannel 17, and the flow path of the working medium traveling in themicrochannel 17 is shortened to the distance between the adjacent fluidic inlet holes and the return outlet holes, such as the distance between thefluidic inlet hole 10 and thereturn outlet hole 13. The arrangement mode can effectively reduce the pump power consumption of the whole radiator system, and plays the roles of saving energy and being beneficial to the miniaturization of the pump

FIG. 7 is a graph showing the comparison of the flow heat transfer performance of a turn-back fluidic microchannel heat sink with that of a conventional straight microchannel to verify the excellent performance of the turn-back fluidic microchannel heat sink, where the aspect ratio of the microchannel is 2, and in the graph of the change of the thermal resistance with the pumping function, the positive direction along the X axis is the direction of exchanging the high heat transfer performance with the high pumping function, the positive direction along the Y axis is the heat transfer deterioration direction with the low pumping function consumption, and the position near the intersection of the coordinate axes is the region where the low pumping function consumption is used to realize the low thermal resistance.

The heat dissipation method of the turn-back type jet flow micro-channel heat sink comprises the following steps,

working medium is pumped into thefirst distribution chamber 6 through theliquid inlet pipe 2,

the working medium is horizontally guided into thesecond distribution chamber 7 through thefirst distribution chamber 6 and then vertically enters the jet inlet holes 10-12 to impact the bottom wall surface of the micro-channel 17, the working medium impacting the bottom wall surface of the micro-channel 17 is folded back to enter the return outlet holes 13-16,

the working medium entering the return outlet holes 13-16 enters the firstliquid return cavity 9 through the secondliquid return cavity 8 and then is discharged through theliquid return pipe 3.

Industrial applicability

The turn-back type jet flow micro-channel radiator and the heat dissipation method can be manufactured and used in the field of cooling of electronic devices.

The foregoing describes the general principles of the present application in conjunction with specific embodiments, however, it is noted that the advantages, effects, etc. mentioned in the present application are merely examples and are not limiting, and they should not be considered essential to the various embodiments of the present application. Furthermore, the foregoing disclosure of specific details is for the purpose of illustration and description and is not intended to be limiting, since the foregoing disclosure is not intended to be exhaustive or to limit the disclosure to the precise details disclosed.

The foregoing description has been presented for purposes of illustration and description. Furthermore, the description is not intended to limit embodiments of the application to the form disclosed herein. While a number of example aspects and embodiments have been discussed above, those of skill in the art will recognize certain variations, modifications, alterations, additions and sub-combinations thereof.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010094902.1ACN111328245B (en) | 2020-02-14 | 2020-02-14 | Return type jet microchannel radiator and heat dissipation method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010094902.1ACN111328245B (en) | 2020-02-14 | 2020-02-14 | Return type jet microchannel radiator and heat dissipation method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111328245A CN111328245A (en) | 2020-06-23 |

| CN111328245Btrue CN111328245B (en) | 2021-07-06 |

Family

ID=71165239

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010094902.1AActiveCN111328245B (en) | 2020-02-14 | 2020-02-14 | Return type jet microchannel radiator and heat dissipation method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111328245B (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111900143A (en)* | 2020-07-31 | 2020-11-06 | 上海交通大学 | A manifold type high aspect ratio microchannel heat exchanger |

| CN112260648B (en)* | 2020-12-22 | 2021-03-26 | 四川大学 | High-power light-gathering intensive array photovoltaic cell microchannel liquid cooling module and heat dissipation structure |

| CN113960103A (en)* | 2021-07-30 | 2022-01-21 | 西安交通大学 | A microchannel phase change heat transfer test device and microchannel heat exchanger |

| CN113937615A (en)* | 2021-09-07 | 2022-01-14 | 中国电子科技集团公司第十一研究所 | Cooling assembly and cooling method for laser |

| CN114111099B (en)* | 2021-11-29 | 2023-06-06 | 上海交通大学 | Countercurrent communication microchannel evaporator device |

| CN116013886A (en)* | 2023-01-06 | 2023-04-25 | 成都万应微电子有限公司 | Radiator |

| CN117263507A (en)* | 2023-10-07 | 2023-12-22 | 江苏大学 | High-efficiency heat transfer impact jet array structure for physical tempering of ultrathin glass |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109524376B (en)* | 2018-09-18 | 2020-07-10 | 华中科技大学 | A liquid cooling device for a multi-distributed jet microchannel chip |

| CN109755199B (en)* | 2019-02-20 | 2020-11-06 | 合肥工业大学 | Micro-channel jet radiator |

- 2020

- 2020-02-14CNCN202010094902.1Apatent/CN111328245B/enactiveActive

Also Published As

| Publication number | Publication date |

|---|---|

| CN111328245A (en) | 2020-06-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111328245B (en) | Return type jet microchannel radiator and heat dissipation method | |

| CN109524376B (en) | A liquid cooling device for a multi-distributed jet microchannel chip | |

| US12100643B2 (en) | Thermal management of electronics using co-located microjet nozzles and electronic elements | |

| CN100565856C (en) | Microstructured cooler and use thereof | |

| US7017655B2 (en) | Forced fluid heat sink | |

| US8427832B2 (en) | Cold plate assemblies and power electronics modules | |

| CN108712852B (en) | A kind of microchannel heat sink of gas-liquid two-phase mixing jetting | |

| US7156159B2 (en) | Multi-level microchannel heat exchangers | |

| CN111052360A (en) | heat sink | |

| CN212695142U (en) | Microchannel heat sink with interrupted inclined rib structure | |

| WO2007145352A1 (en) | Heat sink and cooler | |

| US20080179046A1 (en) | Water cooling apparatus | |

| KR20190016945A (en) | Micro-channel evaporator with reduced pressure drop | |

| EP1810557A2 (en) | Liquid cold plate heat exchanger | |

| KR20040050910A (en) | High heat flux single-phase heat exchanger | |

| JP4619387B2 (en) | Semiconductor device cooling device | |

| CN114649284B (en) | A rib-row bionic structure microchannel radiator | |

| JP4041437B2 (en) | Semiconductor device cooling device | |

| CN113543600A (en) | An incompletely filled staggered microchannel heat exchanger | |

| CN113286497A (en) | Jet flow micro-channel radiator with surface micro-grooves | |

| CN212810289U (en) | Micro-channel heat sink with special rib structure | |

| CN113675160B (en) | An impact flow double-layer diversion microchannel heat sink suitable for high heat flux density devices | |

| CN115910953A (en) | Packaging-level microfluidic heat sink and chip with same | |

| CN111386011A (en) | A lateral flow impingement microchannel cold plate and electronic equipment | |

| CN116847628A (en) | A jet microchannel heat sink |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |