CN111307358A - High-strength bolt pre-tightening force control device and method - Google Patents

High-strength bolt pre-tightening force control device and methodDownload PDFInfo

- Publication number

- CN111307358A CN111307358ACN202010297640.9ACN202010297640ACN111307358ACN 111307358 ACN111307358 ACN 111307358ACN 202010297640 ACN202010297640 ACN 202010297640ACN 111307358 ACN111307358 ACN 111307358A

- Authority

- CN

- China

- Prior art keywords

- strength bolt

- tightening force

- torque

- control unit

- tightening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription48

- 230000008569processEffects0.000claimsabstractdescription28

- 230000036316preloadEffects0.000claimsdescription47

- 230000005540biological transmissionEffects0.000claimsdescription26

- 238000005259measurementMethods0.000claimsdescription20

- 230000009467reductionEffects0.000claimsdescription18

- 238000006243chemical reactionMethods0.000claimsdescription10

- 238000004891communicationMethods0.000claimsdescription8

- 238000001514detection methodMethods0.000claimsdescription7

- 238000012360testing methodMethods0.000claimsdescription2

- 238000010276constructionMethods0.000abstractdescription15

- 239000000523sampleSubstances0.000description14

- 238000013461designMethods0.000description5

- 238000002474experimental methodMethods0.000description5

- 230000008859changeEffects0.000description4

- 238000010586diagramMethods0.000description3

- 238000012986modificationMethods0.000description3

- 230000004048modificationEffects0.000description3

- 238000011217control strategyMethods0.000description2

- 238000005516engineering processMethods0.000description2

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000description1

- 238000013459approachMethods0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000000694effectsEffects0.000description1

- 230000006872improvementEffects0.000description1

- 229910052744lithiumInorganic materials0.000description1

- 238000007639printingMethods0.000description1

- 238000009864tensile testMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01L—MEASURING FORCE, STRESS, TORQUE, WORK, MECHANICAL POWER, MECHANICAL EFFICIENCY, OR FLUID PRESSURE

- G01L5/00—Apparatus for, or methods of, measuring force, work, mechanical power, or torque, specially adapted for specific purposes

- G01L5/24—Apparatus for, or methods of, measuring force, work, mechanical power, or torque, specially adapted for specific purposes for determining value of torque or twisting moment for tightening a nut or other member which is similarly stressed

- G01L5/246—Apparatus for, or methods of, measuring force, work, mechanical power, or torque, specially adapted for specific purposes for determining value of torque or twisting moment for tightening a nut or other member which is similarly stressed using acoustic waves

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05D—SYSTEMS FOR CONTROLLING OR REGULATING NON-ELECTRIC VARIABLES

- G05D15/00—Control of mechanical force or stress; Control of mechanical pressure

- G05D15/01—Control of mechanical force or stress; Control of mechanical pressure characterised by the use of electric means

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Automation & Control Theory (AREA)

- Acoustics & Sound (AREA)

- Details Of Spanners, Wrenches, And Screw Drivers And Accessories (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及高强度螺栓施工技术领域,尤其涉及高强度螺栓预紧力控制装置及方法。The invention relates to the technical field of high-strength bolt construction, in particular to a high-strength bolt pre-tightening force control device and method.

背景技术Background technique

螺栓作为一种结构简单的标准件,在工业上有广泛的应用,为确保设备安全可靠的运行,则高强度螺栓在拧紧完成后能否达到设计预紧力显得尤为重要。As a standard part with a simple structure, the bolt is widely used in the industry. In order to ensure the safe and reliable operation of the equipment, it is particularly important whether the high-strength bolt can reach the design pre-tightening force after the tightening is completed.

目前高强度螺栓预紧力施工多数是基于扭矩控制,也有扭矩-转角控制,张拉法等。这些施工方式都不能得知施工后高强度螺栓的预紧力,更不能测量出高强度螺栓施工后的预紧力。使用基于扭矩控制的预紧力施工方式,使得高强度螺栓获得的预紧力与扭矩系数关系密切,而扭矩系数并非是一个常数;扭矩-转角控制法,其第一步中扭矩控制值也存在同样的问题,扭矩系数并非一个常数;张拉法施工速度较慢,同时夹紧长度等因素对高强度螺栓预紧力影响也较大。At present, most of the high-strength bolt pre-tightening construction is based on torque control, but also torque-angle control, tension method, etc. None of these construction methods can know the pre-tightening force of the high-strength bolts after construction, let alone measure the pre-tightening force of the high-strength bolts after construction. Using the pre-tightening construction method based on torque control, the pre-tightening force obtained by the high-strength bolts is closely related to the torque coefficient, and the torque coefficient is not a constant; the torque-angle control method, the torque control value also exists in the first step. For the same problem, the torque coefficient is not a constant; the construction speed of the tensioning method is slow, and factors such as the clamping length also have a great influence on the pre-tightening force of the high-strength bolts.

因此,保证高强度螺栓在拧紧完成后达到设计预紧力,显得尤为重要。Therefore, it is particularly important to ensure that the high-strength bolts reach the design preload after tightening.

发明内容SUMMARY OF THE INVENTION

本发明提供的高强度螺栓预紧力控制装置及方法,其能够在高强度螺栓1施工的过程中达到高强度螺栓精确控制的目的。The high-strength bolt pre-tightening force control device and method provided by the present invention can achieve the purpose of precise control of the high-strength bolt during the construction of the high-

一方面,本发明提供的高强度螺栓预紧力控制装置,包括:On the one hand, the high-strength bolt pre-tightening force control device provided by the present invention includes:

预紧力测量单元,用于在拧紧高强度螺栓1过程中采用超声波检测得螺栓的预紧力;The pre-tightening force measuring unit is used to detect the pre-tightening force of the bolt by ultrasonic detection during the process of tightening the high-

伺服电机,用于拧紧高强度螺栓提供动力;Servo motor for tightening high-strength bolts to provide power;

扭矩控制单元,用于根据输入数据和预紧力测量单元输出的预紧力,生成控制信号控制伺服电机的转速;The torque control unit is used to generate a control signal to control the speed of the servo motor according to the input data and the preload force output by the preload force measurement unit;

所述扭矩控制单元分别与预紧力测量单元和伺服电机电性相连。The torque control unit is electrically connected with the preload force measurement unit and the servo motor, respectively.

进一步地,所述扭矩控制单元与伺服电机之间连接有电机驱动器;Further, a motor driver is connected between the torque control unit and the servo motor;

所述电机驱动器,用于接收扭矩控制单元输出的控制信号,根据控制信号驱动伺服电机的运转。The motor driver is used for receiving the control signal output by the torque control unit, and driving the operation of the servo motor according to the control signal.

更近一步地,所述电机驱动器,还用于接收伺服电机反馈的位置信号,并将位置信号反馈至扭矩控制单元;Further, the motor driver is also used for receiving the position signal fed back by the servo motor, and feeding the position signal back to the torque control unit;

所述扭矩控制单元,用于根据输入数据、位置信号和预紧力,生成控制信号。The torque control unit is used for generating a control signal according to the input data, the position signal and the preload force.

再进一步地,所述装置还包括:Still further, the device also includes:

高传动比减速箱,用于为高强度螺栓匹配转速和传递扭矩;High transmission ratio gearbox for matching speed and transmitting torque for high-strength bolts;

所述高传动比减速箱分别连接高强度螺栓和伺服电机的输出端。The high transmission ratio reduction box is respectively connected with the high strength bolt and the output end of the servo motor.

还进一步地,所述装置还包括:Still further, the device also includes:

扭矩测量单元,用于测量高传动比减速箱的输出扭矩值,并将输出扭矩值反馈至扭矩控制单元;Torque measurement unit, used to measure the output torque value of the high transmission ratio gearbox, and feed back the output torque value to the torque control unit;

所述扭矩测量单元分别与高传动比减速箱和扭矩控制单元连接;The torque measuring unit is respectively connected with the high transmission ratio reduction box and the torque control unit;

所述扭矩控制单元,用于根据输入数据、输出扭矩值、位置信号和预紧力,生成控制信号。The torque control unit is configured to generate a control signal according to the input data, the output torque value, the position signal and the preload.

又进一步地,所述高传动比减速箱和高强度螺栓之间连接有辅助装置;Still further, an auxiliary device is connected between the high transmission ratio reduction box and the high strength bolt;

当高强度螺栓在拧紧的过程中,尾部露出连接件外时,所述辅助装置为套筒;When the tail of the high-strength bolt is exposed outside the connector during the tightening process, the auxiliary device is a sleeve;

当高强度螺栓在拧紧的过程中,尾部埋于连接件内时,所述辅助装置为方形中空驱动转换装置;When the tail of the high-strength bolt is buried in the connecting piece during the tightening process, the auxiliary device is a square hollow drive conversion device;

所述高传动比减速箱通过辅助装置带动高强度螺栓1转动,从而拧紧高强度螺栓。The high transmission ratio reduction box drives the high-

优选地,所述扭矩控制单元和预紧力测量单元之间通过接口单元电性连接;Preferably, the torque control unit and the preload force measurement unit are electrically connected through an interface unit;

所述装置还包括:动力电源和精密电源;The device also includes: a power source and a precision power source;

所述动力电源分别与电机驱动器和扭矩控制单元相连;the power source is respectively connected with the motor driver and the torque control unit;

所述精密电源与预紧力测量单元相连;The precision power supply is connected with the pre-tightening force measuring unit;

所述装置还包括:The device also includes:

外接数据接口,用于连接外接设备,从而与外接设备进行数据通信;The external data interface is used to connect the external device, so as to carry out data communication with the external device;

无线通信模块,用于与终端设备相连,并实时与终端设备进行通信。The wireless communication module is used to connect with the terminal equipment and communicate with the terminal equipment in real time.

另一方面,本发明提供的高强度螺栓预紧力控制方法,包括:On the other hand, the high-strength bolt pre-tightening force control method provided by the present invention includes:

预紧力测量单元在拧紧高强度螺栓过程中采用超声波检测得螺栓的预紧力;The pre-tightening force measuring unit adopts ultrasonic detection to obtain the pre-tightening force of the bolts in the process of tightening the high-strength bolts;

伺服电机拧紧高强度螺栓提供动力;Servo motor tightens high-strength bolts to provide power;

扭矩控制单元根据输入数据、预紧力测量单元输出的预紧力,生成控制信号控制伺服电机的转速。The torque control unit generates a control signal to control the speed of the servo motor according to the input data and the preload force output by the preload force measurement unit.

更进一步地,所述预紧力测量单元在拧紧高强度螺栓过程中测得螺栓的预紧力,之前还包括:Further, the pre-tightening force measuring unit measures the pre-tightening force of the bolts during the process of tightening the high-strength bolts, which further includes:

针对待拧紧的高强度螺栓进行标定,计算得到待拧紧的高强度螺栓的预紧力系数;Calibrate the high-strength bolts to be tightened, and calculate the pre-tightening force coefficient of the high-strength bolts to be tightened;

将预紧力系数和待拧紧的高强度螺栓的属性参数作为输入数据,输入至扭矩控制单元。The pre-tightening force coefficient and the property parameters of the high-strength bolt to be tightened are input to the torque control unit as input data.

在上述技术方案中,还包括:In the above technical solution, it also includes:

电机驱动器接收伺服电机反馈的位置信号,并将位置信号反馈至扭矩控制单元;The motor driver receives the position signal fed back by the servo motor, and feeds back the position signal to the torque control unit;

扭矩测量单元测量高传动比减速箱的输出扭矩值,并将输出扭矩值反馈至扭矩控制单元;The torque measurement unit measures the output torque value of the high transmission ratio gearbox, and feeds back the output torque value to the torque control unit;

所述扭矩控制单元根据输入数据、预紧力测量单元输出的预紧力,生成控制信号控制伺服电机的转速,具体包括:The torque control unit generates a control signal to control the rotational speed of the servo motor according to the input data and the preload force output by the preload force measurement unit, which specifically includes:

所述扭矩控制单元根据输入数据、预紧力、位置信号和输出扭矩值,生成控制信号控制伺服电机的转速。The torque control unit generates a control signal to control the rotation speed of the servo motor according to the input data, the preload, the position signal and the output torque value.

本发明能够在高强度螺栓施工的过程中,检测螺栓的预紧力;然后扭矩控制单元根据该预紧力控制伺服电机;伺服电机根据扭矩控制单元的控制信号,为拧紧高强度螺栓提供动力。从而在拧紧高强度螺栓的全过程中,通过对预紧力的全程检测,达到对高强度螺栓预紧力实时控制的效果。The invention can detect the pre-tightening force of the bolts during the construction of the high-strength bolts; then the torque control unit controls the servo motor according to the pre-tightening force; the servo motor provides power for tightening the high-strength bolts according to the control signal of the torque control unit. Therefore, in the whole process of tightening the high-strength bolts, through the whole-process detection of the pre-tightening force, the effect of real-time control of the pre-tightening force of the high-strength bolts is achieved.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

图1为本发明实施例的装置结构示意图;1 is a schematic structural diagram of an apparatus according to an embodiment of the present invention;

图2为本发明实施例的方法流程示意图;2 is a schematic flowchart of a method according to an embodiment of the present invention;

图3为本发明实施例中待拧紧的高强度螺栓的排列示意图;3 is a schematic diagram of the arrangement of high-strength bolts to be tightened in an embodiment of the present invention;

图4为本发明实施例中伺服电机的转速控制曲线示意图;4 is a schematic diagram of a rotational speed control curve of a servo motor in an embodiment of the present invention;

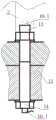

图5为本发明实施例中高强度螺栓尾部露出连接件外的剖面示意图;5 is a schematic cross-sectional view of the tail of the high-strength bolt exposed to the outside of the connector according to the embodiment of the present invention;

图6为本发明实施例中高强度螺栓尾部埋于连接件内的剖面示意图。6 is a schematic cross-sectional view of the tail of the high-strength bolt buried in the connector according to the embodiment of the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

实施例一Example 1

如图1所示,本发明提供的高强度螺栓预紧力控制装置,包括:As shown in Figure 1, the high-strength bolt pre-tightening force control device provided by the present invention includes:

预紧力测量单元10,用于在拧紧高强度螺栓1过程中采用超声波检测得螺栓1的预紧力;The pre-tightening

伺服电机4,用于拧紧高强度螺栓1提供动力;

扭矩控制单元7,用于根据输入数据和预紧力测量单元10输出的预紧力,生成控制信号控制伺服电机4的转速;The

所述扭矩控制单元7分别与预紧力测量单元10和伺服电机4电性相连。The

在本实施例中,预紧力测量单元10利用超声波技术,根据应力应变原理,声弹性理论,通过回波声时变化与应力变化的关系,测量高强度螺栓1轴向预紧力。超声波可以采用压电超声波,也可以采用电磁超声波。预紧力测量单元10包括传感器,传感器探头10.1 可以放置在高强度螺栓1的顶部端面或者尾部端面。利用电磁超声技术,传感器探头10.1 的放置无需耦合剂,对螺栓1端面要求低,无需打磨,测试效率高。预紧力测量单元10 采用电磁超声检测应力的原理,不需要耦合剂,不需要打磨螺栓表面,可以实时跟踪螺栓轴力并且反馈给高强螺栓预紧力控制装置。In this embodiment, the pretightening

所述预紧力的计算公式为:The calculation formula of the preload is:

式中,k为超声波预紧力系数,是比例常数,S是螺栓1平均截面积,T是螺栓1未加载力时的超声波声时,ΔT是加载力后螺栓1中超声波声时的变化时间。In the formula, k is the ultrasonic pre-tightening force coefficient, which is a proportional constant, S is the average cross-sectional area of

所述输入数据包括:预紧力系数和待拧紧的高强度螺栓1的属性参数。The input data includes: the pre-tightening force coefficient and the attribute parameters of the high-

所述扭矩控制单元7与伺服电机4之间连接有电机驱动器5;A

所述电机驱动器5,用于接收扭矩控制单元7输出的控制信号,根据控制信号驱动伺服电机4的运转。The

所述电机驱动器5,还用于接收伺服电机4反馈的位置信号,并将位置信号反馈至扭矩控制单元7;The

所述扭矩控制单元7,用于根据输入数据、位置信号和预紧力,生成控制信号。The

在本发明中,伺服电机4带角度反馈功能,能将位置信号反馈至电机驱动器5;然后电机驱动器5再将改位置信号反馈至扭矩控制单元7。In the present invention, the

所述装置还包括:The device also includes:

高传动比减速箱3,用于为高强度螺栓1匹配转速和传递扭矩;The high transmission

所述高传动比减速箱3分别连接高强度螺栓1和伺服电机4的输出端。The high transmission

所述装置还包括:The device also includes:

扭矩测量单元8,用于测量高传动比减速箱3的输出扭矩值,并将输出扭矩值反馈至扭矩控制单元7;a

所述扭矩测量单元8分别与高传动比减速箱3和扭矩控制单元7连接;The

所述扭矩控制单元7,用于根据输入数据、输出扭矩值、位置信号和预紧力,生成控制信号。The

在本实施例中,预紧力测量单元10反馈的预紧力为第一反馈量;伺服电机4反馈的位置信号为第二反馈量;扭矩测量单元8反馈的输出扭矩值为第三反馈量。由此,扭矩控制单元7可以实时跟进三个反馈量针对伺服电机4电机进行精准控制。上述三个反馈量进一步的保证了对高强度螺栓1预紧力的控制质量。In this embodiment, the preload force fed back by the preload

伺服电机4和电机驱动器5的连接,功能上分为两部分:一部分是驱动器5驱动伺服电机4的转动;另一部分是安装在伺服电机4轴上的旋转编码器提供给驱动器5的位置信号(即伺服电机4的角度反馈功能)。The connection between the

所述高传动比减速箱3和高强度螺栓1之间连接有辅助装置2;An

当高强度螺栓1在拧紧的过程中,尾部露出连接件外时,所述辅助装置2为套筒;When the tail of the high-

当高强度螺栓1在拧紧的过程中,尾部埋于连接件内时,所述辅助装置2为方形中空驱动转换装置;When the tail of the high-

所述高传动比减速箱3通过辅助装置2带动高强度螺栓1转动,从而拧紧高强度螺栓 1。The high transmission

在本实施例中,辅助装置2为套筒。套筒连接高传动比减速箱3输出轴和螺栓1顶部。如图5所示,由于高强度螺栓1在拧紧的过程中,尾部露出连接件外,所以可以与传感器探头10.1连接。In this embodiment, the

所述传感器探头10.1采用压电超声探头或者电磁超声探头。这两种探头都带有永磁体方便探头与高强度螺栓1的均匀接触。The sensor probe 10.1 is a piezoelectric ultrasonic probe or an electromagnetic ultrasonic probe. Both probes are equipped with permanent magnets to facilitate uniform contact between the probe and the high-

在本实施例中,传感器探头10.1采用定位器进行定位,定位器定位有尾部定位和六角头边(顶部)定位两种。当高强度螺栓1在拧紧的过程中,尾部露出连接件外时,使用套筒,采用尾部定位;当高强度螺栓1在拧紧的过程中,尾部埋于连接件内时,采用方形中空驱动转换装置,采用顶部定位。在本实施例中,辅助装置2为套筒。定位器的目的是方便放置预紧力测量单元10中的传感器探头10.1并且具有放置位置的可重复性。In this embodiment, the sensor probe 10.1 is positioned using a locator, and the locator has two types of positioning: tail positioning and hexagonal head edge (top) positioning. When the tail of the high-

所述扭矩控制单元7和预紧力测量单元10之间通过接口单元9电性连接;The

所述装置还包括:动力电源6和精密电源11;The device also includes: a

所述动力电源6分别与电机驱动器5和扭矩控制单元7相连;The

所述精密电源11与预紧力测量单元10相连;The

所述装置还包括:The device also includes:

外接数据接口,用于连接外接设备,从而与外接设备进行数据通信;The external data interface is used to connect the external device, so as to carry out data communication with the external device;

无线通信模块,用于与终端设备相连,并实时与终端设备进行通信。The wireless communication module is used to connect with the terminal equipment and communicate with the terminal equipment in real time.

在本实施例中,接口单元9作用是连接扭矩控制单元7和预紧力测量单元10的通讯。扭矩控制单元7具有485信号输入接口、脉冲信号输入接口,开关量信号输入接口,预紧力测量单元10具有485信号输出接口、脉冲信号输出接口,开关量信号输出接口,0-10V 模拟量信号输出接口。动力电源6,可以是220V交流电,也可以是锂电池组。无线通信模块可以实时传递数据至终端这边,并支持打印功能。所述控制装置还能够自动生成预紧力 -时间图、角度-时间图、扭矩-时间图、角度-预紧力图,以及扭矩-预紧力图。In this embodiment, the function of the

如图2所示,本发明提供的高强度螺栓预紧力控制方法,包括:As shown in Figure 2, the method for controlling the pre-tightening force of high-strength bolts provided by the present invention includes:

101、预紧力测量单元10在拧紧高强度螺栓1过程中采用超声波检测得螺栓1的预紧力;101. The pre-tightening

102、伺服电机4拧紧高强度螺栓1提供动力;102.

103、扭矩控制单元7根据输入数据、预紧力测量单元10输出的预紧力,生成控制信号控制伺服电机4的转速。103 . The

所述预紧力测量单元10在拧紧高强度螺栓1过程中测得螺栓1的预紧力,之前还包括:The pre-tightening

104、针对待拧紧的高强度螺栓1进行标定,计算得到待拧紧的高强度螺栓1的预紧力系数;104. Perform calibration on the high-

105、将预紧力系数和待拧紧的高强度螺栓1的属性参数作为输入数据,输入至扭矩控制单元7。105. Input the pre-tightening force coefficient and the attribute parameters of the high-

所述方法还包括:The method also includes:

106、电机驱动器5接收伺服电机4反馈的位置信号,并将位置信号反馈至扭矩控制单元7;106. The

107、扭矩测量单元8测量高传动比减速箱3的输出扭矩值,并将输出扭矩值反馈至扭矩控制单元7;107. The

所述扭矩控制单元7根据输入数据、预紧力测量单元10输出的预紧力,生成控制信号控制伺服电机4的转速,具体包括:The

1031、所述扭矩控制单元7根据输入数据、预紧力、位置信号和输出扭矩值,生成控制信号控制伺服电机4的转速。1031. The

所述扭矩控制单元7除生成控制伺服电机4转速的控制信号外,还能够生成高强度螺栓1的拧紧顺序和控制策略。The

在本实施例中,可以先选择高强度螺栓组中若干螺栓1使用50%的预紧力设置值进行拧紧,然后拧紧其他螺栓1。具体地:In this embodiment,

当高强度螺栓组中螺栓1数量小于20颗,选取4颗位置等分的螺栓1在首先拧紧;When the number of

当高强度螺栓组中螺栓1数量大于等于20颗,选取8颗位置等分的螺栓1在首先拧紧;When the number of

首先拧紧的4颗螺栓1或8颗螺栓1之后会先松退,然后再一次紧固。The 4

如图3所示,以16个高强度螺栓组为例,假设螺栓组分度圆800,六角头螺栓1M30X320-10.9级,夹持长度为270mm,法兰面另一侧有螺母连接。As shown in Figure 3, taking 16 high-strength bolt groups as an example, assume that the bolt group has a circle of 800, hexagon head bolts of 1M30X320-10.9 grade, a clamping length of 270mm, and a nut connection on the other side of the flange surface.

首先,需要对该批次高强度螺栓1,按照夹紧长度270mm,进行标定,采用超声波预紧力系数标定实验的方式。实验前,准备6颗该该批次的高强度螺栓1、垫片及螺母,并对螺栓1编号。实验可采用100吨拉伸实验机进行轴力加载,实验环境应能对环境温度进行监测和控制,实验过程要求环境温度变化小于3摄氏度。First, the batch of high-

对于M30标准螺纹螺栓1,查标准可知,其有效横截面积为561mm^2,10.9级高强度螺栓1,抗拉强度约为1000Mpa,屈服强度约为900Mpa,如果取设计预紧力的拉应力为屈服强度的0.78倍,则设计预紧力可计算为393kN。分别按总加载量的40%,60%,80%, 100%进行加载,则分别为157KN,235KN,314KN,393KN。For M30 standard threaded

选取编号为1号到编号为6号螺栓1进行上述标定实验,可获得对应的超声波预紧力系数k。对上述6颗螺栓1的超声波预紧力系数取平均,得该批次螺栓1该夹紧长度下的超声波预紧力系数。Select the No. 1 to No. 6

所述输入数据包括:预紧力系数和待拧紧的高强度螺栓1的属性参数;The input data includes: the pre-tightening force coefficient and the attribute parameters of the high-

所述属性参数包括:待拧紧的高强度螺栓1的螺栓1规格、批次号、螺栓1数量、螺栓1夹持长度和所在环境的温度。The attribute parameters include: bolt 1 specification, batch number, quantity of

然后,在标定实验后,将输入参数输入至扭矩控制单元7;然后扭矩控制单元7根据输入参数,生成待拧紧螺栓组的拧紧先后顺序。当然,此拧紧先后顺序可根据不同的工艺要求进行调整。Then, after the calibration experiment, the input parameters are input to the

如图4所示,同时扭矩控制单元7还能够生成对高强度螺栓1预紧力加载的控制策略。其中,曲线1(OA)的斜率大于曲线2(AB)的斜率。即,扭矩控制单元7在开始的一段时间内控制伺服电机4快速运转;然后在之后的时间段内,使伺服电机4转速降低。As shown in FIG. 4 , at the same time, the

在高强度螺栓组拧紧过程中,将传感器探头10.1放置在螺纹端的尾端上,先在自由无预紧力状态下,先测得被测螺栓1的回波时间T0。然后,分别拧紧1号~4号高强度螺栓1,预紧力测量单元10在拧紧过程中实时反馈螺栓1的预紧力。During the tightening process of the high-strength bolt group, place the sensor probe 10.1 on the tail end of the threaded end, and first measure the echo time T0 of the tested

所述控制装置还包括:指示灯。当预紧力达到196KN(计算得到预紧力393KN的50%) 时,有指示灯显示绿色,表示施工完成并合格。每施工一颗高强度螺栓1,都需要移动测量单元10中的传感器。根据扭矩控制单元7生成待拧紧螺栓组的拧紧先后顺序,移动移动测量单元10中的传感器的位置。The control device further includes: an indicator light. When the preload reaches 196KN (50% of the calculated preload of 393KN), an indicator light will show green, indicating that the construction is completed and qualified. Each time a high-

然后移动测量单元10中的传感器到9号螺栓1;当预紧力达到393KN时,指示灯显示绿色,表示施工完成并合格。以顺时针方向紧固剩余未拧紧的螺栓1;然后将1号~4号螺栓1螺栓1松退;移动测量单元10中的传感器到1号螺栓1,使用该装置拧紧该螺栓1,当预紧力达到393KN时,有指示灯显示绿色,表示施工完成并合格。并以相同的方式拧紧剩下的3颗螺栓1。Then move the sensor in the measuring

此时,上述高强度螺栓组施工完成,本装置有指示灯显示绿色,需人工确认。当确认后,本装置自动生成报告。At this time, the construction of the above-mentioned high-strength bolt group is completed, and the device has an indicator light showing green, which needs to be confirmed manually. When confirmed, the unit automatically generates a report.

在本实施例中,指示灯的开启是根据扭矩控制单元7判断而来,判断过程为:In this embodiment, the turning on of the indicator light is judged according to the

设第一反馈量为F(单位KN),第三反馈量为扭矩值Tq(单位Nm)。设螺栓1的直径为D,设置的预紧力为Fa:Let the first feedback amount be F (unit KN), and the third feedback amount be the torque value Tq (unit Nm). Let the diameter of

1、当F在(a*Fa,b*Fa)区间时,预紧力合格,a和b为经验值,可取a=0.95,b=1.05;1. When F is in the (a*Fa, b*Fa) interval, the preload force is qualified, a and b are empirical values, and a=0.95, b=1.05;

计算螺栓1扭矩系数Kb=Tq/F/D,,当Kb在(Kbmin,Kbmax)区间时,扭矩系数正常,Kbmin,Kbmax为经验值为用户设置值,一般取(0.9~0.15);超出范围,可进一步提示小于扭矩系数范围或大于扭矩系数范围;Calculate the torque coefficient of

2、当F不在(a*Fa,b*Fa)区间时,则提示大于或小于合格范围。2. When F is not in the (a*Fa, b*Fa) interval, it will prompt that it is greater than or less than the qualified range.

实施例二

如图6所示,本实施例中,辅助装置2为方形中空驱动转换装置。由于待拧紧的高强度螺栓1尾部埋于连接件内,所以采用方形中空驱动转换装置,采用顶部定位。由于方形中空驱动转换装置内部中空,在传递高传动比减速箱3的力矩时,可以使高强度螺顶部露出,方便将传感器探头10.1放置在上面。As shown in FIG. 6 , in this embodiment, the

方形中空驱动转换装置的传动方式为齿轮传动,选择减速功能,相当于一级平行传动。方形中空驱动转换装置具有扭矩扳手中的反作用力臂的功能。The transmission mode of the square hollow drive conversion device is gear transmission, and the deceleration function is selected, which is equivalent to a first-level parallel transmission. The square hollow drive conversion unit functions as a reaction arm in a torque wrench.

本实施例其余结构及功能均与实施例相同,在此就不再赘述。The remaining structures and functions of this embodiment are the same as those of the embodiment, and are not repeated here.

应该明白,公开的过程中的步骤的特定顺序或层次是示例性方法的实例。基于设计偏好,应该理解,过程中的步骤的特定顺序或层次可以在不脱离本公开的保护范围的情况下得到重新安排。所附的方法权利要求以示例性的顺序给出了各种步骤的要素,并且不是要限于所述的特定顺序或层次。It is understood that the specific order or hierarchy of steps in the disclosed processes is an example of a sample approach. Based upon design preferences, it is understood that the specific order or hierarchy of steps in the processes may be rearranged without departing from the scope of the present disclosure. The accompanying method claims present elements of the various steps in a sample order, and are not meant to be limited to the specific order or hierarchy presented.

在上述的详细描述中,各种特征一起组合在单个的实施方案中,以简化本公开。不应该将这种公开方法解释为反映了这样的意图,即,所要求保护的主题的实施方案需要比清楚地在每个权利要求中所陈述的特征更多的特征。相反,如所附的权利要求书所反映的那样,本发明处于比所公开的单个实施方案的全部特征少的状态。因此,所附的权利要求书特此清楚地被并入详细描述中,其中每项权利要求独自作为本发明单独的优选实施方案。In the foregoing Detailed Description, various features are grouped together in a single embodiment for the purpose of simplifying the disclosure. This method of disclosure should not be construed as reflecting an intention that embodiments of the claimed subject matter require more features than are expressly recited in each claim. Rather, as the following claims reflect, present invention lies in less than all features of a single disclosed embodiment. Thus, the following claims are hereby expressly incorporated into the Detailed Description, with each claim standing on its own as a separate preferred embodiment of this invention.

为使本领域内的任何技术人员能够实现或者使用本发明,上面对所公开实施例进行了描述。对于本领域技术人员来说;这些实施例的各种修改方式都是显而易见的,并且本文定义的一般原理也可以在不脱离本公开的精神和保护范围的基础上适用于其它实施例。因此,本公开并不限于本文给出的实施例,而是与本申请公开的原理和新颖性特征的最广范围相一致。The disclosed embodiments are described above to enable any person skilled in the art to make or use the present invention. Various modifications to these embodiments will be readily apparent to those skilled in the art, and the generic principles defined herein may be applied to other embodiments without departing from the spirit and scope of this disclosure. Thus, the present disclosure is not intended to be limited to the embodiments set forth herein but is to be accorded the widest scope consistent with the principles and novel features disclosed herein.

上文的描述包括一个或多个实施例的举例。当然,为了描述上述实施例而描述部件或方法的所有可能的结合是不可能的,但是本领域普通技术人员应该认识到,各个实施例可以做进一步的组合和排列。因此,本文中描述的实施例旨在涵盖落入所附权利要求书的保护范围内的所有这样的改变、修改和变型。此外,就说明书或权利要求书中使用的术语“包含”,该词的涵盖方式类似于术语“包括”,就如同“包括,”在权利要求中用作衔接词所解释的那样。此外,使用在权利要求书的说明书中的任何一个术语“或者”是要表示“非排它性的或者”。The above description includes examples of one or more embodiments. Of course, it is not possible to describe all possible combinations of components or methods in order to describe the above embodiments, but one of ordinary skill in the art will recognize that further combinations and permutations of the various embodiments are possible. Accordingly, the embodiments described herein are intended to cover all such changes, modifications and variations that fall within the scope of the appended claims. Furthermore, with respect to the term "comprising," as used in the specification or claims, the word is encompassed in a manner similar to the term "comprising," as if "comprising," were interpreted as a conjunction in the claims. Furthermore, any use of the term "or" in the specification of the claims is intended to mean a "non-exclusive or."

以上所述的具体实施方式,对本发明的目的、技术方案和有益效果进行了进一步详细说明,所应理解的是,以上所述仅为本发明的具体实施方式而已,并不用于限定本发明的保护范围,凡在本发明的精神和原则之内,所做的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。The specific embodiments described above further describe the objectives, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the scope of the present invention. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present invention shall be included within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010297640.9ACN111307358A (en) | 2020-04-16 | 2020-04-16 | High-strength bolt pre-tightening force control device and method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010297640.9ACN111307358A (en) | 2020-04-16 | 2020-04-16 | High-strength bolt pre-tightening force control device and method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111307358Atrue CN111307358A (en) | 2020-06-19 |

Family

ID=71146305

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010297640.9APendingCN111307358A (en) | 2020-04-16 | 2020-04-16 | High-strength bolt pre-tightening force control device and method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111307358A (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112747856A (en)* | 2020-12-29 | 2021-05-04 | 湘潭大学 | Method for detecting pretightening force of high-strength bolt |

| CN113358266A (en)* | 2021-06-29 | 2021-09-07 | 神龙汽车有限公司 | Bolt assembling tension force testing method |

| CN114179020A (en)* | 2021-12-10 | 2022-03-15 | 航天精工股份有限公司 | An automatic installation tool that can measure the preload of smart fasteners |

| CN114577394A (en)* | 2022-03-04 | 2022-06-03 | 北京理工大学 | Bolt fastening axial tensile stress detection calibration method and device |

| CN117124059A (en)* | 2023-09-04 | 2023-11-28 | 中国航发贵阳发动机设计研究所 | Method for controlling uniformity of bolt connection rigidity between aero-engine rotors |

| CN118682456A (en)* | 2024-08-22 | 2024-09-24 | 大连理工大学 | A method for controlling the tightening of an aircraft engine rotor based on bolt preload force feedback and an automated tightening equipment |

| EP4206636A4 (en)* | 2020-08-25 | 2024-10-09 | Suzhou Phaserise Technology Co., Ltd. | Method for quick calibration and measurement of axial forces of high-strength bolts by transverse and longitudinal ultrasonic waves |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1999039879A1 (en)* | 1998-02-05 | 1999-08-12 | Robert Bosch Gmbh | Process for prestressing a screw connection to the desired level |

| CN101354299A (en)* | 2008-08-29 | 2009-01-28 | 奇瑞汽车股份有限公司 | Bolt torque test stand |

| JP2010117334A (en)* | 2008-11-11 | 2010-05-27 | Hiroshi Taniguchi | Method and instrument for measuring bolt axial force |

| CN201645425U (en)* | 2010-03-17 | 2010-11-24 | 银川西部大森数控技术有限公司 | Intelligent bolt tightening machine |

| CN102759940A (en)* | 2012-05-21 | 2012-10-31 | 大连嘉禾自控技术有限公司 | Full-function type bolt screwing shaft controller |

| CN104149062A (en)* | 2014-06-30 | 2014-11-19 | 山东中兴电动工具有限公司 | Controllable pre-tightening force electric wrench |

| CN104236465A (en)* | 2014-09-15 | 2014-12-24 | 成都嘉陵华西光学精密机械有限公司 | Machine for detecting tightening degree and center height of screw |

| CN105014366A (en)* | 2015-07-10 | 2015-11-04 | 成都力鑫科技有限公司 | High-safety assembling tool based on torque feedback |

| CN105606289A (en)* | 2016-03-17 | 2016-05-25 | 西北工业大学 | Bolt tightening torque coefficient measuring device |

| CN107186469A (en)* | 2017-06-20 | 2017-09-22 | 东北大学 | Aero-engine disk rouses structural member bolt automatic screwing-down tool arm and its method of work |

| KR20170129396A (en)* | 2016-05-17 | 2017-11-27 | 금오공과대학교 산학협력단 | Nut runner system capable of Automatic torque control by wired - wireless communication |

| CN108015530A (en)* | 2017-12-14 | 2018-05-11 | 哈尔滨零声科技有限公司 | A kind of bolt pretightening loads automatically and control device |

| CN108068043A (en)* | 2016-11-18 | 2018-05-25 | 中国铁道科学研究院 | Torque intelligent electric wrench is determined in a kind of numerical control |

| CN109781332A (en)* | 2019-01-08 | 2019-05-21 | 中国大唐集团新能源科学技术研究院有限公司 | Method based on axle power and elongation control bolt pretightening |

| CN211504497U (en)* | 2020-04-16 | 2020-09-15 | 律音科技(武汉)有限公司 | High-strength bolt pretightening force control device |

- 2020

- 2020-04-16CNCN202010297640.9Apatent/CN111307358A/enactivePending

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1999039879A1 (en)* | 1998-02-05 | 1999-08-12 | Robert Bosch Gmbh | Process for prestressing a screw connection to the desired level |

| CN101354299A (en)* | 2008-08-29 | 2009-01-28 | 奇瑞汽车股份有限公司 | Bolt torque test stand |

| JP2010117334A (en)* | 2008-11-11 | 2010-05-27 | Hiroshi Taniguchi | Method and instrument for measuring bolt axial force |

| CN201645425U (en)* | 2010-03-17 | 2010-11-24 | 银川西部大森数控技术有限公司 | Intelligent bolt tightening machine |

| CN102759940A (en)* | 2012-05-21 | 2012-10-31 | 大连嘉禾自控技术有限公司 | Full-function type bolt screwing shaft controller |

| CN104149062A (en)* | 2014-06-30 | 2014-11-19 | 山东中兴电动工具有限公司 | Controllable pre-tightening force electric wrench |

| CN104236465A (en)* | 2014-09-15 | 2014-12-24 | 成都嘉陵华西光学精密机械有限公司 | Machine for detecting tightening degree and center height of screw |

| CN105014366A (en)* | 2015-07-10 | 2015-11-04 | 成都力鑫科技有限公司 | High-safety assembling tool based on torque feedback |

| CN105606289A (en)* | 2016-03-17 | 2016-05-25 | 西北工业大学 | Bolt tightening torque coefficient measuring device |

| KR20170129396A (en)* | 2016-05-17 | 2017-11-27 | 금오공과대학교 산학협력단 | Nut runner system capable of Automatic torque control by wired - wireless communication |

| CN108068043A (en)* | 2016-11-18 | 2018-05-25 | 中国铁道科学研究院 | Torque intelligent electric wrench is determined in a kind of numerical control |

| CN107186469A (en)* | 2017-06-20 | 2017-09-22 | 东北大学 | Aero-engine disk rouses structural member bolt automatic screwing-down tool arm and its method of work |

| CN108015530A (en)* | 2017-12-14 | 2018-05-11 | 哈尔滨零声科技有限公司 | A kind of bolt pretightening loads automatically and control device |

| CN109781332A (en)* | 2019-01-08 | 2019-05-21 | 中国大唐集团新能源科学技术研究院有限公司 | Method based on axle power and elongation control bolt pretightening |

| CN211504497U (en)* | 2020-04-16 | 2020-09-15 | 律音科技(武汉)有限公司 | High-strength bolt pretightening force control device |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4206636A4 (en)* | 2020-08-25 | 2024-10-09 | Suzhou Phaserise Technology Co., Ltd. | Method for quick calibration and measurement of axial forces of high-strength bolts by transverse and longitudinal ultrasonic waves |

| CN112747856A (en)* | 2020-12-29 | 2021-05-04 | 湘潭大学 | Method for detecting pretightening force of high-strength bolt |

| CN112747856B (en)* | 2020-12-29 | 2022-04-01 | 湘潭大学 | A kind of detection method of high-strength bolt pre-tightening force |

| CN113358266A (en)* | 2021-06-29 | 2021-09-07 | 神龙汽车有限公司 | Bolt assembling tension force testing method |

| CN114179020A (en)* | 2021-12-10 | 2022-03-15 | 航天精工股份有限公司 | An automatic installation tool that can measure the preload of smart fasteners |

| CN114577394A (en)* | 2022-03-04 | 2022-06-03 | 北京理工大学 | Bolt fastening axial tensile stress detection calibration method and device |

| CN117124059A (en)* | 2023-09-04 | 2023-11-28 | 中国航发贵阳发动机设计研究所 | Method for controlling uniformity of bolt connection rigidity between aero-engine rotors |

| CN118682456A (en)* | 2024-08-22 | 2024-09-24 | 大连理工大学 | A method for controlling the tightening of an aircraft engine rotor based on bolt preload force feedback and an automated tightening equipment |

| CN118682456B (en)* | 2024-08-22 | 2024-12-24 | 大连理工大学 | Aircraft engine rotor tightening control method based on bolt pretightening force feedback and automatic tightening equipment |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111307358A (en) | High-strength bolt pre-tightening force control device and method | |

| CN211504497U (en) | High-strength bolt pretightening force control device | |

| CN105784249B (en) | A kind of measuring device and measuring method that helicitic texture torsion is established unprincipled connection | |

| CN108466218A (en) | Numerical control electric formula torque detects the detection method of spanner and bolt tightening torque value | |

| CN105277302A (en) | Torque measuring shaft and measuring method | |

| US8590402B2 (en) | Assembly, intercalated between a torque tool and a fastening element, for measuring torques and tightening angles | |

| JP2008267939A (en) | Torsion testing device | |

| CN107186469A (en) | Aero-engine disk rouses structural member bolt automatic screwing-down tool arm and its method of work | |

| US7467669B2 (en) | Method for governing the operation of a pneumatic impulse wrench and a power screw joint tightening tool system | |

| CN107138848A (en) | Pressure and moment of torsion On-line sampling system device for agitating friction weldering | |

| CN113021243B (en) | Calibration method of fixed-torque impact wrench | |

| CN207942347U (en) | Numerical control electric formula torque detects spanner | |

| CN207534718U (en) | A kind of aeroengine rotor stay-bolt for monitoring pretightning force synchronizes device for screwing up | |

| TW202332545A (en) | Method and system of using usb user interface in electronic torque wrench | |

| CN109239201B (en) | Portable automatic clamping device for nonlinear ultrasonic detection | |

| JP2003014565A (en) | Calibration curve automatically preparing apparatus for bolt axial tension | |

| JPH10274609A (en) | Method and machine for torsion test | |

| JPH08267368A (en) | Torque control type pulse tool | |

| CN113021242B (en) | Constant torque output control method of constant torque impact wrench | |

| CN213874028U (en) | Portable internal thread detection device | |

| US11529719B2 (en) | Bolt clamping force transducer for bolt tightening operation | |

| JP3437052B2 (en) | Torsion testing machine | |

| JPH02262030A (en) | Ultrasonic load display member, apparatus and method | |

| CN223107124U (en) | A device for calibrating the torque setting value of a torque screwdriver by electric means | |

| CN112757205B (en) | Torque gun control method for avoiding beating hands |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |