CN111289575A - A method for detecting the quality of conductive pipe rods based on relative motion - Google Patents

A method for detecting the quality of conductive pipe rods based on relative motionDownload PDFInfo

- Publication number

- CN111289575A CN111289575ACN201811497427.1ACN201811497427ACN111289575ACN 111289575 ACN111289575 ACN 111289575ACN 201811497427 ACN201811497427 ACN 201811497427ACN 111289575 ACN111289575 ACN 111289575A

- Authority

- CN

- China

- Prior art keywords

- information

- conductive pipe

- quality

- standard

- relative motion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

- G01N27/02—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating impedance

- G01N27/04—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating impedance by investigating resistance

- G01N27/041—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating impedance by investigating resistance of a solid body

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Or Analyzing Materials By The Use Of Electric Means (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种基于相对运动检测导电管棒质量的方法,属于材料质量检测技术领域,具体属于材料质量连续检测技术领域。The invention relates to a method for detecting the quality of a conductive pipe rod based on relative motion, belonging to the technical field of material quality detection, in particular to the technical field of continuous material quality detection.

背景技术Background technique

随着国民经济的发展,我国导电管棒的生产能力不断扩大,生产门类不断拓宽。但是由于缺乏有效的在线检测和监控系统,造成生产的导电管棒质量没有保障,使得我国在导电管棒生产的高端领域缺乏竞争力。建立导电管棒生产过程中缺陷的在线检测系统,通过精确反馈和控制生产工艺来提高产品质量,一直是我国导电管棒生产单位非常关注的问题。目前使用最多的导电管棒缺陷在线检测方法有:涡流检测法以及基于图像的表面质量检测法,但均存在应用局限:前者对产品表面的裂纹、刮伤、夹杂物、凹坑等缺陷检测灵敏度高,但此方法必须有足够的时间加热才能充分暴露缺陷,响应速度慢,不适用于在高速生产线上应用;后者虽然能针对导电管棒表面缺陷进行精确检测,但对存在内部缺陷的导电管棒不能检出。以上方法均受限于各自的原理,并且生产过程中常常涉及退火等高温处理手段,上述检测设施无法在生产线全程安置,检测控制存在“盲点”。专利CN201310530795.2中公开了一种电阻测试装置,能够测量样品在变温环境下的电阻变化情况,但所述专利未涉及信息采集及分析,且所测区域固定不变。With the development of the national economy, the production capacity of my country's conductive rods has been continuously expanded, and the production categories have been continuously expanded. However, due to the lack of an effective online detection and monitoring system, the quality of the produced conductive pipes and rods is not guaranteed, which makes our country lack of competitiveness in the high-end field of conductive pipe and rod production. Establishing an on-line detection system for defects in the production process of conductive pipes and rods, and improving product quality through accurate feedback and control of the production process, has always been a problem of great concern to the production units of conductive pipes and rods in my country. At present, the most commonly used on-line detection methods for conductive pipe and rod defects are: eddy current detection method and image-based surface quality detection method, but both have application limitations: the former is sensitive to defects such as cracks, scratches, inclusions, and pits on the surface of products. High, but this method must have enough time to heat to fully expose the defects, and the response speed is slow, so it is not suitable for application in high-speed production lines; although the latter can accurately detect the surface defects of conductive pipes and rods, it is not suitable for conductive pipes with internal defects. Pipe rods cannot be detected. The above methods are all limited by their respective principles, and high-temperature treatment methods such as annealing are often involved in the production process. The above-mentioned detection facilities cannot be installed in the whole production line, and there are "blind spots" in detection and control. Patent CN201310530795.2 discloses a resistance testing device, which can measure the resistance change of a sample in a variable temperature environment, but the patent does not involve information collection and analysis, and the measured area is fixed.

本发明的检测装置和导电管棒之间可以相对运动,并且能够连续采集导电管棒质量信息,并基于采集到的连续信息进行系统计算和分析,进而实现缺陷判定和质量检测。本发明能对运动或静止的导电管棒进行检测,既可以实现导电管棒的连续检测,亦可实现离散检测,兼具现有离散检测技术的所有功能。The detection device of the present invention can move relative to the conductive pipe rod, and can continuously collect the quality information of the conductive pipe rod, and perform systematic calculation and analysis based on the collected continuous information, thereby realizing defect judgment and quality detection. The invention can detect the moving or static conductive pipe rods, can realize both continuous detection and discrete detection of the conductive pipe rods, and has all the functions of the existing discrete detection technology.

发明内容SUMMARY OF THE INVENTION

针对现有技术不足,本发明提出一种基于相对运动检测导电管棒质量的方法。Aiming at the deficiencies of the prior art, the present invention proposes a method for detecting the quality of a conductive pipe rod based on relative motion.

本发明一种基于相对运动检测导电管棒质量的方法;检测时,检测装置和导电管棒可以相对运动,通过连续采集信息和计算信息参数来判定导电管棒的质量;所述信息包括但不限于电压、电流、位置,所述信息是连续信息,所述连续信息是连续采集导电管棒不同位置的信息;所述信息参数选自电压、电阻、电阻率、导电率、电导率中的一种或多种;将实际信息参数与标准信息参数进行比对,当|实际信息参数-标准信息参数|/标准信息参数大于等于缺陷判断阈值时,判定所述实际信息参数对应区域存在缺陷,当|实际信息参数-标准信息参数|/标准信息参数小于缺陷判断阈值时,则判定所述实际信息参数对应区域质量合格。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; during detection, the detection device and the conductive pipe rod can move relatively, and the quality of the conductive pipe rod is determined by continuously collecting information and calculating information parameters; the information includes but does not include Limited to voltage, current, and position, the information is continuous information, and the continuous information is the information of continuously collecting different positions of the conductive pipe rod; the information parameters are selected from one of voltage, resistance, resistivity, conductivity, and conductivity. The actual information parameter is compared with the standard information parameter, and when |actual information parameter-standard information parameter|/standard information parameter is greater than or equal to the defect judgment threshold, it is determined that the area corresponding to the actual information parameter has defects, and when |Actual information parameter-standard information parameter|/When the standard information parameter is less than the defect judgment threshold, it is judged that the quality of the area corresponding to the actual information parameter is qualified.

本发明一种基于相对运动检测导电管棒质量的方法;所述检测装置和导电管棒的相对运动包括下述三种情况:检测装置静止,导电管棒运动,定义导电管棒运动方向的反方向为检测方向,多用于流程生产的导电管棒质量检测;检测装置运动,导电管棒静止,定义检测装置运动方向为检测方向,多用于难以移动导电管棒的检测;检测装置和导电管棒同时以不同速度运动,定义导电管棒相对于检测装置运动方向的反方向为检测方向,多用于辅助调节信息采集频率和对特定区域进行检测;所述相对运动优选为连续的相对运动。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; the relative motion of the detection device and the conductive pipe rod includes the following three situations: the detection device is stationary, the conductive pipe rod is moving, and the reverse direction that defines the movement direction of the conductive pipe rod The direction is the detection direction, which is mostly used for the quality inspection of the conductive pipe rods in process production; the detection device moves, the conductive pipe rods are stationary, and the moving direction of the detection device is defined as the detection direction, which is mostly used for the detection of the conductive pipe rods that are difficult to move; the detection device and the conductive pipe rods Simultaneously move at different speeds, and define the opposite direction of the conductive pipe rod relative to the movement direction of the detection device as the detection direction, which is mostly used to assist in adjusting the frequency of information collection and detecting specific areas; the relative movement is preferably continuous relative movement.

本发明一种基于相对运动检测导电管棒质量的方法;所述信息包括但不限于电压、电流、位置,所述电压、电流信息的采集方法包括但不限于直流四点法、单电桥法、双电桥法。优选为直流四点法。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; the information includes but is not limited to voltage, current, and position, and the collection methods of the voltage and current information include but are not limited to the DC four-point method and the single bridge method. , Double bridge method. The DC four-point method is preferred.

本发明一种基于相对运动检测导电管棒质量的方法;检测装置通过接触端与导电管棒接触,任意一个接触端与导电管棒的接触面积小于等于100mm2,优选为小于等于25mm2,进一步优选为小于等于1mm2,更进一步优选为小于等于0.25mm2,该参数的选择,关系到检测的精度,对于高端检测而言,其在保证物理性能的同时最好选用优选方案,当然,为了进一步提升信息的可靠性,用于信息采集的两个接触端与导电管棒的接触面积要相等。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; the detection device contacts the conductive pipe rod through a contact end, and the contact area between any contact end and the conductive pipe rod is less than or equal to 100mm2 , preferably less than or equal to 25mm2 , and further It is preferably less than or equal to 1 mm2 , and more preferably less than or equal to 0.25 mm2 . The selection of this parameter is related to the detection accuracy. For high-end detection, it is best to choose the preferred solution while ensuring physical performance. Of course, in order to To further improve the reliability of information, the contact areas of the two contact ends used for information collection and the conductive pipe rod should be equal.

本发明一种基于相对运动检测导电管棒质量的方法;有2个接触端用于信息采集,2个信息采集接触端的间距小于等于1500mm,优选为小于等于1000mm,进一步优选为小于等于500mm,更进一步优选为小于等于100mm。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; there are two contact ends for information collection, and the distance between the two information collection contact ends is less than or equal to 1500mm, preferably less than or equal to 1000mm, more preferably less than or equal to 500mm, and more More preferably, it is 100 mm or less.

本发明一种基于相对运动检测导电管棒质量的方法;2个信息采集接触端之间的材料区域为信息采集区域,定义检测方向上第1个信息采集接触端为定位接触端,定义采集到第1个信息的状态为起始状态,在起始状态,与定位接触端接触的导电管棒位置为信息采集起始点(坐标原点);该坐标原点也可以进行人为设置和更改;设置好坐标原点后,导电管棒上其他点的位置用其与坐标原点的距离表征。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; the material area between two information collecting contact ends is the information collecting area, the first information collecting contact end in the detection direction is defined as the positioning contact end, and the collecting The state of the first information is the initial state. In the initial state, the position of the conductive pipe rod in contact with the positioning contact end is the information collection starting point (coordinate origin); the coordinate origin can also be manually set and changed; set the coordinates After the origin, the positions of other points on the conductive rod are characterized by their distances from the origin of the coordinates.

本发明一种基于相对运动检测导电管棒质量的方法;检测装置在导电管棒进、出信息采集区域的过程中自动采集信息,并自动画出信息参数-距离曲线;所述信息参数-距离曲线横坐标为导电管棒和定位接触端接触的位置与信息采集起始点的距离;所述距离的获取方式包括但不限于直接测量得到、根据时间和速度参数计算得到。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; a detection device automatically collects information during the process of the conductive pipe rod entering and exiting an information collection area, and automatically draws an information parameter-distance curve; the information parameter-distance The abscissa of the curve is the distance between the contact position of the conductive pipe rod and the positioning contact end and the starting point of information collection; the acquisition methods of the distance include but are not limited to direct measurement and calculation based on time and speed parameters.

本发明一种基于相对运动检测导电管棒质量的方法;采集的信息还可以包括时间、温度信息,当所获信息中包括时间信息时,可以根据所获信息参数、位置信息、时间信息得到连续的信息参数-位置-时间曲线。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; the collected information can also include time and temperature information, and when the obtained information includes time information, continuous information can be obtained according to the obtained information parameters, position information and time information. The information parameter-location-time curve.

本领域技术人员根据本发明所获信息及所进行的数学处理、理论计算、物理意义的变换,其实质还属于本发明的范围。The information obtained by those skilled in the art and the mathematical processing, theoretical calculation, and transformation of physical meanings performed by those skilled in the art according to the present invention also belong to the scope of the present invention.

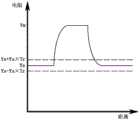

本发明一种基于相对运动检测导电管棒质量的方法;所述信息参数-距离曲线反映导电管棒的质量信息,信息参数-距离曲线出现异常和回归正常反映有缺陷进入和离开信息采集区域。图1为信息参数-距离曲线与导电管棒缺陷及所在位置对应的示意图,根据采集的第1个信息获得信息参数-距离曲线的起点(O点),O点在导电管棒上的对应位置与信息采集起始点的距离为0,其横坐标为0;A状态为有1个缺陷即将进入信息采集区域的状态,当导电管棒由起始状态运动到A状态时,信息采集区域内无缺陷存在,信息参数-距离曲线相应出现OA段,信息参数为正常状态,A点在导电管棒上的对应位置与信息采集起始点的距离为50mm,该点的横坐标为50mm;B状态为1个缺陷刚刚完全进入信息采集区域的状态,当导电管棒由A状态运动到B状态时,缺陷经历了开始进入和完全进入信息采集区域的过程,信息参数-距离曲线相应出现AB段,信息参数为异常信息参数,B点在导电管棒上的对应位置与信息采集起始点的距离为60mm,该点的横坐标为60mm;C状态为缺陷即将离开信息采集区域的状态,当导电管棒由B状态运动到C状态时,信息参数-距离曲线相应出现BC段,C点在导电管棒上的对应位置与信息采集起始点的距离为90mm,该点的横坐标为90mm;D状态为缺陷刚刚离开信息采集区域的状态,当导电管棒由C状态运动到D状态时,信息参数回归正常,D点在导电管棒上的对应位置与信息采集起始点的距离为100mm,该点的横坐标为100mm。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; the information parameter-distance curve reflects the quality information of the conductive pipe rods, and the abnormality and return to normal of the information parameter-distance curve reflect that defects enter and leave the information collection area. Figure 1 is a schematic diagram of the correspondence between the information parameter-distance curve and the defect and location of the conductive pipe rod. The starting point (point O) of the information parameter-distance curve is obtained according to the first information collected, and the corresponding position of point O on the conductive pipe rod The distance from the starting point of information collection is 0, and its abscissa is 0; state A is a state where there is 1 defect about to enter the information collection area. The defect exists, the information parameter-distance curve correspondingly appears in the OA segment, the information parameter is in the normal state, the distance between the corresponding position of point A on the conductive pipe rod and the starting point of information collection is 50mm, and the abscissa of this point is 50mm; the state of B is 1 defect has just completely entered the information collection area. When the conductive rod moves from the A state to the B state, the defect has experienced the process of entering and completely entering the information collection area. The information parameter-distance curve appears in the AB segment correspondingly, and the information The parameters are abnormal information parameters. The distance between the corresponding position of point B on the conductive pipe rod and the starting point of information collection is 60mm, and the abscissa of this point is 60mm; state C is the state where the defect is about to leave the information collection area. When moving from state B to state C, the information parameter-distance curve correspondingly appears in segment BC, the distance between the corresponding position of point C on the conductive pipe rod and the starting point of information collection is 90mm, and the abscissa of this point is 90mm; state D is The defect has just left the information collection area. When the conductive pipe rod moves from the C state to the D state, the information parameters return to normal. The distance between the corresponding position of the D point on the conductive pipe rod and the information collection starting point is 100mm. The abscissa is 100mm.

本发明一种基于相对运动检测导电管棒质量的方法;少部分情况下,在所测导电管棒的前端存在缺陷时,信息参数-距离曲线起始点的信息参数出现异常,或者在所测导电管棒的末端存在缺陷时,信息参数-距离曲线终止点的信息参数出现异常。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; in a small number of cases, when there is a defect in the front end of the tested conductive pipe rod, the information parameter of the starting point of the information parameter-distance curve is abnormal, or the measured conductive pipe rod is abnormal. When there is a defect at the end of the pipe rod, the information parameter - the information parameter of the end point of the distance curve is abnormal.

本发明一种基于相对运动检测导电管棒质量的方法;所述缺陷判断阈值用Tr表示,当所得信息参数为电压,且所用单位为V时,所述Tr的取值大于等于0.0001,优选为0.0001~0.1,进一步优选为0.0001~0.01,更进一步优选为0.0001~0.001;当信息参数之间进行切换时,所述Tr的取值进行相应换算。The present invention is a method for detecting the quality of conductive pipes and rods based on relative motion; the defect judgment threshold is represented by Tr , when the obtained information parameter is voltage and the used unit is V, the value of Tr is greater than or equal to 0.0001, It is preferably 0.0001-0.1, more preferably 0.0001-0.01, and still more preferably0.0001-0.001 ; when switching between information parameters, the value of Tr is converted accordingly.

本发明一种基于相对运动检测导电管棒质量的方法;可以根据信息参数-距离曲线进行质量分析,根据信息参数回归正常的起始点和终止点的横坐标,可以确定缺陷在导电管棒上的实际位置和缺陷长度,根据信息参数的最大值(或最小值)与标准信息参数的差值可以确定缺陷的显著程度;图2为信息参数-距离示意图,实际信息参数用Y表示,标准信息参数用Ys表示,Ys±(Tr×Ys)为正常信息参数范围,误差范围主要是考虑系统的测量误差。如图2所示,AB段和BC段的|Y-Ys|<Tr×Ys,表明对应的导电管棒区间无缺陷,C点处实际信息参数Y满足|Y-Ys|=Tr×Ys,Y=YC,实际信息参数处于临界值;CD段的实际信息参数超出了正常范围,|Y-Ys|≥Tr×Ys,对应缺陷逐渐进入信息采集区域;DF段的实际信息参数相对恒定,对应缺陷完全处于信息采集区域内,Ym为实际信息参数的最大值;FG段的实际信息参数开始回归,对应缺陷逐渐离开信息采集区域,F点在导电管棒上的位置为缺陷起始点,G点实际信息参数值Y满足|Y-Ys|=Tr×Ys,Y=YG,实际信息参数处于临界值,G点在导电管棒上的相应位置为缺陷终止点;GH段和HI段的实际信息参数满足|Y-Ys|<Tr×Ys,处于正常信息参数范围,表明对应的导电管棒区域无缺陷。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; the quality analysis can be carried out according to the information parameter-distance curve, and the abscissas of the normal starting point and the end point according to the information parameters can be used to determine the defect on the conductive pipe rod. The actual position and defect length can be determined according to the difference between the maximum value (or minimum value) of the information parameter and the standard information parameter; Figure 2 is a schematic diagram of the information parameter-distance, the actual information parameter is represented by Y, and the standard information parameter It is represented by Ys , Ys ±(Tr ×Ys ) is the normal information parameter range, and the error range mainly considers the measurement error of the system. As shown in Fig. 2, the |YYs |<Tr ×Ys of the AB and BC sections indicate that the corresponding conductive pipe rods are free of defects, and the actual information parameter Y at point C satisfies |YYs |=Tr ×Ys , Y=YC , the actual information parameter is at the critical value; the actual information parameter of the CD segment exceeds the normal range, |YYs |≥Tr ×Ys , the corresponding defect gradually enters the information collection area; the actual information parameter of the DF segment Relatively constant, the corresponding defect is completely in the information collection area, Ym is the maximum value of the actual information parameter; the actual information parameter of the FG segment begins to return, the corresponding defect gradually leaves the information collection area, and the position of point F on the conductive pipe rod is the defect The starting point, the actual information parameter value Y of point G satisfies |YYs |=Tr ×Ys , Y=YG , the actual information parameter is at the critical value, and the corresponding position of point G on the conductive pipe rod is the defect termination point; GH The actual information parameters of the segment and the HI segment satisfy |YYs |<Tr ×Ys , which are in the normal information parameter range, indicating that the corresponding conductive pipe rod area is free of defects.

本发明一种基于相对运动检测导电管棒质量的方法;当|实际信息参数-标准信息参数|/标准信息参数大于等于Tr时,判定所测区域至少包括1种或1个缺陷,计算Ty,所述Ty=(Ym-Ys)÷Ys,所述Ys是标准信息参数,所述Ym是实际信息参数的最大值或最小值,所述Ty为缺陷判定因子。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; when |actual information parameter-standard information parameter|/standard information parameter is greater than or equal to Tr , it is determined that the measured area includes at least one or one defect, and T is calculated.y , theTy = (Ym -Ys )÷Ys , the Ys is the standard information parameter, the Ym is the maximum or minimum value of the actual information parameter, and theTy is the defect determination factor .

本发明一种基于相对运动检测导电管棒质量的方法;导致材料电阻变化的缺陷均属本方法可检测的缺陷种类,所述导致电阻变化的因素包括但不限于材料电阻率变化、横截面积变化;当缺陷属于截面积变小的类型时,截面积变小导致电阻变大,对应电阻值增大,如图3所示,Ym是所获连续电阻的最大值,Ym>Ys,Ty>0;当缺陷属于截面积变大的类型时,截面积变大导致电阻变小,对应电阻值减小,如图4所示,Ym是所获连续电阻的最小值,Ym<Ys,Ty<0;Ym和Ys的差值反映缺陷的剧烈程度。The present invention is a method for detecting the quality of conductive pipes and rods based on relative motion; defects that cause material resistance changes are all types of defects that can be detected by this method, and the factors that cause resistance changes include but are not limited to material resistivity changes, cross-sectional area When the defect is of the type with a smaller cross-sectional area, the smaller cross-sectional area leads to a larger resistance, and the corresponding resistance value increases, as shown in Figure 3, Ym is the maximum value of the obtained continuous resistance, Ym > Ys ,Ty >0; when the defect belongs to the type with a larger cross-sectional area, the larger cross-sectional area leads to a smaller resistance, and the corresponding resistance value decreases, as shown in Figure 4, Ym is the minimum value of the obtained continuous resistance, Ym <Ys ,Ty <0; the difference between Ym and Ys reflects the severity of the defect.

本发明一种基于相对运动检测导电管棒质量的方法;当信息参数选用电压信息和/或电阻和/或电阻率时,Ty>0,缺陷种类包括但不限于划痕、凹陷、尺寸偏小、开裂、管壁过薄、腐蚀,Ty<0,缺陷种类包括但不限于内鼓包、内结疤、尺寸偏大、管壁过厚;当信息参数选用导电率和/或电导率时,Ty<0,缺陷种类包括但不限于划痕、凹陷、尺寸偏小、开裂、管壁过薄、腐蚀,Ty>0,缺陷种类包括但不限于内鼓包、内结疤、尺寸偏大、管壁过厚。The present invention is a method for detecting the quality of conductive pipes and rods based on relative motion; when voltage information and/or resistance and/or resistivity are selected as information parameters,Ty > 0, and the types of defects include but are not limited to scratches, dents, dimensional deviations Small, cracked, tube wall is too thin, corroded,Ty < 0, the types of defects include but are not limited to inner bulge, inner scar, large size, tube wall is too thick; when conductivity and/or conductivity are selected as information parameters ,Ty < 0, the types of defects include but are not limited to scratches, dents, undersized, cracked, thin wall, corrosion,Ty > 0, types of defects include but are not limited to inner bulges, inner scars, oversized dimensions Large, the pipe wall is too thick.

本发明一种基于相对运动检测导电管棒质量的方法;通过分析信息参数-距离曲线的变化情况,可以判定缺陷的个数;一般地,实际信息参数-距离曲线出现异常和回归正常1次,可以判定导电管棒对应区域至少存在1种或1个缺陷;少数情况下,信息参数-距离曲线反复出现异常和回归正常或变化率突然增大或变小,可以判定导电管棒对应区域至少存在2种或2个缺陷;极少数情况下,信息参数-距离曲线反复出现异常和回归正常,且最终无法回归正常参数范围,判定导电管棒对应区域存在大量缺陷或导电管棒对应区域为物理边界。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; by analyzing the change of the information parameter-distance curve, the number of defects can be determined; generally, when the actual information parameter-distance curve is abnormal and returns to normal once, It can be determined that there is at least one or one defect in the corresponding area of the conductive pipe rod; in a few cases, the information parameter-distance curve repeatedly appears abnormal and returns to normal or the rate of change suddenly increases or decreases, and it can be determined that there is at least one defect in the corresponding area of the

本发明一种基于相对运动检测导电管棒质量的方法;可检测多种缺陷连续出现的情况,信息参数-距离曲线出现异常且长时间不回归或直至检测完成其还未回归,则根据信息参数-距离曲线的斜率以及斜率的变化情况判定信息采集区域是否存在2种或2种以上缺陷。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; it can detect the continuous occurrence of various defects, and the information parameter-distance curve is abnormal and does not return for a long time or does not return until the detection is completed. - The slope of the distance curve and the change of the slope determine whether there are two or more defects in the information collection area.

本发明一种基于相对运动检测导电管棒质量的方法;缺陷判定方法还有很多种,应当认为,凡基于本发明的缺陷判定方法均属于本专利的保护范围。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; there are many methods for judging defects, and it should be considered that all methods for judging defects based on the present invention belong to the protection scope of this patent.

本发明一种基于相对运动检测导电管棒质量的方法;所述标准信息参数为标样的信息参数,所述标样可以根据标准确定,所述标准为国家标准、行业标准或企业标准。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; the standard information parameter is the information parameter of a standard sample, and the standard sample can be determined according to a standard, and the standard is a national standard, an industry standard or an enterprise standard.

本发明一种基于相对运动检测导电管棒质量的方法;所述标样信息参数还可以由用户确定,或根据用户确定的标样进行检测和/或计算获得。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; the standard sample information parameters can also be determined by the user, or obtained by detection and/or calculation according to the standard sample determined by the user.

本发明一种基于相对运动检测导电管棒质量的方法;获取标准信息参数时,检测环境与实际检测环境相同,所述检测环境包括但不限于温度、压强、湿度、噪音。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; when obtaining standard information parameters, the detection environment is the same as the actual detection environment, and the detection environment includes but is not limited to temperature, pressure, humidity, and noise.

本发明一种基于相对运动检测导电管棒质量的方法;所述导电管棒的横截面积小于等于2000mm2,优选为小于等于200mm2,进一步优选为小于等于20mm2,还可进一步优选为小于等于2mm2,更进一步优选为小于等于1mm2。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; the cross-sectional area of the conductive pipe rod is less than or equal to 2000 mm2 , preferably less than or equal to 200 mm2 , more preferably less than or equal to 20 mm2 , and still more preferably less than or equal to 200

本发明一种基于相对运动检测导电管棒质量的方法;其适用温度区域为10K~待测导电管棒材料的熔化温度或液化温度或气化温度。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; the applicable temperature range is from 10K to the melting temperature, liquefaction temperature or gasification temperature of the conductive pipe rod material to be measured.

本发明一种基于相对运动检测导电管棒质量的方法;检测时,信息采集频率、检测装置与导电管棒之间的相对运动速度、信息采集接触端间距三者间的关系为:相对运动速度÷信息采集频率<信息采集接触端间距,可保证检测样品所有区域均能被检测到,且采集的信息样本足够用于分析,相对运动速度越小、采集频率越大,采集的信息样本越多;所述信息采集频率大于等于1次/10秒,优选为大于等于1次/秒,更进一步优选为大于等于10次/秒。The present invention is a method for detecting the quality of a conductive pipe rod based on relative motion; during detection, the relationship among the information collection frequency, the relative motion speed between the detection device and the conductive pipe rod, and the distance between the contact ends of the information collection is: relative motion speed ÷Information collection frequency<spacing of information collection contacts, which can ensure that all areas of the test sample can be detected, and the collected information samples are sufficient for analysis. The smaller the relative movement speed and the higher the collection frequency, the more information samples are collected. ; The information collection frequency is greater than or equal to 1 time/10 seconds, preferably greater than or equal to 1 time/second, more preferably greater than or equal to 10 times/second.

本发明一种基于相对运动检测导电管棒质量的方法;也可根据信息采集区域长度设定信息采集频率,在10mm检测区间内,其信息采集数大于等于1次,优选为大于等于10次,更进一步优选为大于等于100次;还可根据导电管棒与检测装置的相对运动速度和信息采集装置的特性进行信息采集频率优化调整。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; the frequency of information collection can also be set according to the length of the information collection area. More preferably, it is greater than or equal to 100 times; the frequency of information collection can also be optimized and adjusted according to the relative movement speed of the conductive pipe rod and the detection device and the characteristics of the information collection device.

本发明一种基于相对运动检测导电管棒质量的方法;缺陷进入和离开信息采集区域时,对应的信息参数曲线存在一定映射关系,可根据映射关系对信息采集系统进行校核。图2中BD段对应缺陷进入信息采集区域,FH段对应缺陷离开信息采集区域,BD段和FH段的信息参数在理想情况下互为映射,即对于BD上任意一点(X,Y(X))和FH上映射点(X+l,Y(X+l)),存在关系Y(X)'=-Y(X+l)',其中l为信息采集区域的长度。The present invention is a method for detecting the quality of conductive pipe rods based on relative motion; when the defect enters and leaves the information collection area, the corresponding information parameter curve has a certain mapping relationship, and the information collection system can be checked according to the mapping relationship. In Figure 2, the BD segment corresponds to the defect and enters the information collection area, and the FH segment corresponds to the defect to leave the information collection area. The information parameters of the BD segment and the FH segment are ideally mapped to each other, that is, for any point on the BD (X, Y(X) ) and the mapping point (X+l, Y(X+l) ) on FH, there is a relationship Y(X) '=-Y(X+l) ', where l is the length of the information collection area.

本发明还专门设计了与上述检测方法相匹配的装置;所述装置包括P个独立的检测单元,检测时,P个单元可全部或部分与导电管棒接触;所述检测单元可以静止或按设计轨迹运动,所述导电管棒也可以静止或按设计轨迹运动;所述检测单元和导电管棒之间可以相对运动;所述P为大于等于1的整数。The present invention also specially designs a device matching the above-mentioned detection method; the device includes P independent detection units, and during detection, the P units can be in contact with the conductive pipe rods in whole or in part; the detection units can be static or pressed Design trajectory motion, the conductive pipe rod can also be static or move according to the designed trajectory; the detection unit and the conductive pipe rod can move relative to each other; the P is an integer greater than or equal to 1.

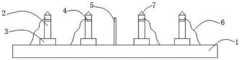

本发明一种基于相对运动检测导电管棒质量的装置;当采用直流四点法检测信息参数时,每个检测单元包括4根并排设置的接线柱、恒定电流提供模块、测温模块、信息采集模块;所述4根接线柱中,两端的两根接线柱通过导线与恒定电流提供模块连接,中间的两根接线柱通过导线与信息采集模块连接;所述测温模块与所述信息采集模块相连。The invention is a device for detecting the quality of conductive pipe rods based on relative motion; when the DC four-point method is used to detect information parameters, each detection unit includes 4 connecting posts arranged side by side, a constant current supply module, a temperature measurement module, and an information acquisition module. module; among the four terminals, the two terminals at both ends are connected to the constant current supply module through wires, and the two terminals in the middle are connected to the information collection module through wires; the temperature measurement module is connected to the information collection module connected.

本发明一种基于相对运动检测导电管棒质量的装置;所述接线柱与接触端连接,其导电率大于等于10%IACS,优选为大于等于50%IACS,进一步优选为大于等于80%IACS;所述接触端包括但不限于导电滚珠、探针,使用时,导电管棒与接触端相接触,且存在相对运动。The present invention is a device for detecting the quality of a conductive pipe rod based on relative motion; the terminal is connected to the contact end, and its conductivity is greater than or equal to 10% IACS, preferably greater than or equal to 50% IACS, more preferably greater than or equal to 80% IACS; The contact end includes, but is not limited to, conductive balls and probes. When in use, the conductive pipe rod is in contact with the contact end, and there is a relative movement.

本发明一种基于相对运动检测导电管棒质量的装置;在接线柱和接触端之间设有压力传感装置,用于调节与检测样品接触的压力大小,防止接触压力过大损坏检测样品或接触压力过小造成接触不良。The present invention is a device for detecting the quality of conductive pipe rods based on relative motion; a pressure sensing device is arranged between the terminal post and the contact end, which is used to adjust the pressure in contact with the detection sample, so as to prevent the detection sample from being damaged or damaged by excessive contact pressure. The contact pressure is too small to cause poor contact.

本发明的装置优化后,还可以检测管材的内壁质量。After the device of the present invention is optimized, the quality of the inner wall of the pipe can also be detected.

相对于现有技术,本发明提出一种基于相对运动检测导电管棒质量的方案,其技术优势为:Compared with the prior art, the present invention proposes a scheme for detecting the quality of the conductive pipe rod based on relative motion, and its technical advantages are:

1.本发明能够实现导电管棒的连续在线检测,检测装置与导电管棒可以有多种相对运动方式,此点对于连续的在线检测具有较大实用价值。1. The present invention can realize the continuous on-line detection of the conductive pipe rod, and the detection device and the conductive pipe rod can have various relative motion modes, which has great practical value for continuous on-line detection.

2.本发明可适用于不同检测场所,可检测的材料种类多,可实现不同温度环境下的在线检测,并可以进行不同温度下的连续信息参数的换算。2. The present invention can be applied to different detection places, can detect many kinds of materials, can realize on-line detection under different temperature environments, and can perform the conversion of continuous information parameters under different temperatures.

3.本发明可以检测导致电阻变化的缺陷并分析缺陷的种类,不仅能够检测表层质量问题,也可以检测内部缺陷,尤其是可以检测到2种及2种以上缺陷共存的情况,现有技术无法实现此功能。3. The present invention can detect defects that cause resistance changes and analyze the types of defects, not only can detect surface quality problems, but also can detect internal defects, especially can detect the coexistence of two or more kinds of defects, the existing technology can not be. implement this function.

附图说明Description of drawings

附图1为信息参数-距离曲线与导电管棒缺陷及所在位置对应的示意图;Accompanying drawing 1 is the schematic diagram corresponding to information parameter-distance curve and conductive pipe rod defect and position;

附图2为信息参数-距离示意图;Accompanying drawing 2 is information parameter-distance schematic diagram;

附图3为横截面变小缺陷的电阻-距离曲线示意图;Accompanying drawing 3 is the resistance-distance curve schematic diagram of the defect that the cross section becomes smaller;

附图4为横截面变大缺陷的电阻-距离曲线示意图;Accompanying drawing 4 is the resistance-distance curve schematic diagram of the defect that the cross section becomes enlarged;

附图5为本发明的检测装置示意图,1为信号采集模块;2为接线柱;3为接线柱升降装置;4为压力传感器;5为测温探头;6为信号引线;7为接触端;5 is a schematic diagram of the detection device of the present invention, 1 is a signal acquisition module; 2 is a terminal; 3 is a terminal lifting device; 4 is a pressure sensor; 5 is a temperature measuring probe; 6 is a signal lead; 7 is a contact end;

附图6为实施例1检测样品照片;Accompanying drawing 6 is

附图7为实施例1的导电率-距离曲线;Accompanying drawing 7 is the conductivity-distance curve of

附图8为实施例2检测样品照片;Accompanying drawing 8 is

附图9为实施例2的电导率-距离曲线;Accompanying drawing 9 is the conductivity-distance curve of

附图10为实施例2中的缺陷的照片;Figure 10 is a photograph of the defect in Example 2;

附图11为实施例3的电压-距离曲线;Accompanying drawing 11 is the voltage-distance curve of

附图12为实施例3中的缺陷的照片;Figure 12 is a photograph of the defect in Example 3;

附图13为对比例1的电压-距离曲线。FIG. 13 is a voltage-distance curve of Comparative Example 1. FIG.

具体实施方式Detailed ways

本发明的具体实施方式中,采用四点法检测。在下述实施例中,检测环境温度均为20±2℃,接触端和导电管棒的接触面积≤5mm2。检测系统在导电管棒与检测装置的相对运动中自动采集电压信息、位置信息、尺寸信息,自动计算信息参数,并画出信息参数-距离曲线。In the specific embodiment of the present invention, the four-point method is used for detection. In the following embodiments, the detection environment temperature is 20±2°C, and the contact area between the contact end and the conductive pipe rod is less than or equal to 5 mm2 . The detection system automatically collects voltage information, position information and size information in the relative movement of the conductive pipe rod and the detection device, automatically calculates the information parameters, and draws the information parameter-distance curve.

信息参数计算采用下述公式:The information parameter calculation adopts the following formula:

电阻(Ω)=电压(V)÷电流(A);Resistance (Ω) = voltage (V) ÷ current (A);

电阻率(Ω·m)=电阻(Ω)×截面积(m2)÷长度(m);Resistivity (Ω·m)=resistance (Ω)×cross-sectional area (m2 )÷length (m);

电导率(S/m)=1÷电阻率(Ω·m);Conductivity (S/m)=1÷Resistivity (Ω·m);

导电率(%IACS)=电导率(MS/m)÷0.58。Conductivity (% IACS) = Conductivity (MS/m) ÷ 0.58.

实施例1:Example 1:

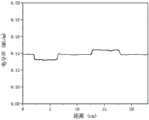

检测材料:T2紫铜棒,直径7.92mm,长度为305mm,图6为检测样品照片;Test material: T2 copper rod, diameter 7.92mm, length 305mm, Figure 6 is the photo of the test sample;

接线柱间隔/信息采集区域长度:30mm;Terminal interval / length of information collection area: 30mm;

输入恒定电流:1.3A;Input constant current: 1.3A;

运动方式:检测装置静止,样品运动;Movement mode: the detection device is stationary and the sample is moving;

样品运动速度:30mm/s;Sample movement speed: 30mm/s;

信号采集频率:20次/s;Signal acquisition frequency: 20 times/s;

标准导电率:99.8%IACS;Standard conductivity: 99.8% IACS;

图7为所获的导电率-距离曲线,Tr=0.003,根据|实际导电率-标准导电率|/标准导电率<Tr,判定不存在缺陷,样品合格。Fig. 7 is the obtained conductivity-distance curve,Tr =0.003, according to |actual conductivity-standard conductivity|/standard conductivity<Tr , it is judged that there is no defect, and the sample is qualified.

实施例2Example 2

检测材料:不锈钢管材,外径20mm,内径18mm,长度约23cm,图8为检测样品照片;Testing material: stainless steel pipe, the outer diameter is 20mm, the inner diameter is 18mm, and the length is about 23cm. Figure 8 is a photo of the test sample;

接线柱间隔/信息采集区域长度:50mm;Binding post interval / length of information collection area: 50mm;

输入恒定电流:2.3A;Input constant current: 2.3A;

运动方式:检测装置静止,样品运动;Movement mode: the detection device is stationary and the sample is moving;

样品运动速度:30mm/s;Sample movement speed: 30mm/s;

信号采集频率:30次/s;Signal acquisition frequency: 30 times/s;

标准电导率:0.139MS/m;Standard conductivity: 0.139MS/m;

图9为所获的电导率-距离曲线,Tr=0.0144,根据|实际电导率-标准电导率|/标准电导率≥Tr,判定存在2处缺陷。在19mm-20mm位置范围内的电导率异常下降,对应第1处缺陷进入信息采集区域,Ym1=0.132mMS/m,在69mm-70mm位置范围内的电导率回归正常,对应缺陷离开信息采集区域,缺陷的起始点和终止点位置与信息采集起始点的距离分别为69mm、70mm,确定缺陷区域的长度为1mm,缺陷判定因子Ty1=(0.132-0.139)÷0.139=-0.0504,由于Ty1<0,判定缺陷类型为尺寸偏小或凹坑;在125mm-127mm位置范围内的电导率异常上升,对应第2处缺陷进入信息采集区域,Ym2=0.144MS/m,在175mm-177mm位置范围内的电导率回归正常,对应缺陷离开信息采集区域,缺陷的起始点和终止点位置与信息采集起始点的距离分别为175mm、177mm,确定缺陷区域的长度为2mm,缺陷判定因子Ty2=(0.144-0.139)÷0.139=0.0360,由于Ty2>0,判定缺陷类型为尺寸偏大。Figure 9 is the obtained conductivity-distance curve,Tr =0.0144 , according to |actual conductivity-standard conductivity|/standard conductivity≥Tr, it is determined that there are two defects. The conductivity in the range of 19mm-20mm is abnormally decreased, corresponding to the first defect entering the information collection area, Ym1 = 0.132mMS/m, the conductivity within the range of 69mm-70mm returns to normal, and the corresponding defect leaves the information collection area , the distances between the starting point and ending point of the defect and the starting point of information collection are69mm and 70mm respectively, and the length of the defect area is determined to be1mm . <0, the defect type is judged to be small in size or pit; the electrical conductivity in the range of 125mm-127mm is abnormally increased, corresponding to the second defect entering the information collection area, Ym2 = 0.144MS/m, at the position of 175mm-177mm The electrical conductivity within the range returns to normal, and the corresponding defect leaves the information collection area. The distances between the starting point and the end point of the defect and the starting point of the information collection are 175mm and 177mm, respectively. The length of the defect area is determined to be 2mm, and the defect judgment factor Ty2 = (0.144-0.139)÷0.139=0.0360, since Ty2 >0, it is determined that the defect type is too large in size.

图10所示为样品孔内照片,对应位置处存在缺陷,凹坑处缺陷可能由腐蚀引起,另一处缺陷为厚度尺寸偏大。Figure 10 shows a photo of the inside of the sample hole. There are defects at the corresponding positions. The defects at the pits may be caused by corrosion. Another defect is that the thickness is too large.

实施例3Example 3

检测材料:铝合金棒材,直径5mm,长度800mm;Detection material: aluminum alloy bar, diameter 5mm, length 800mm;

接线柱间隔/信息采集区域长度:100mm;Terminal interval / length of information collection area: 100mm;

输入恒定电流:1.0A;Input constant current: 1.0A;

运动方式:检测装置静止,样品运动;Movement mode: the detection device is stationary and the sample is moving;

样品运动速度:30mm/s;Sample movement speed: 30mm/s;

信号采集频率:60次/s;Signal acquisition frequency: 60 times/s;

标准电压:0.14418mV;Standard voltage: 0.14418mV;

图11为所获的电压-距离曲线,Tr=0.001645,根据|实测电压信号-标准电压信号|/标准电压信号≥Tr,判定存在1处缺陷。在310mm-364mm位置范围内的电压异常上升,对应缺陷进入信息采集区域,Ym=0.14635mV,在410mm-464mm位置范围内的电压回归正常,对应缺陷离开信息采集区域,缺陷的起始点和终止点位置与信息采集起始点的距离分别为410mm、464mm,确定缺陷区域的长度为54mm;缺陷判定因子Ty=(0.14635-0.14418)÷0.14418=0.015051,由于判定因子大于零,且缺陷区域的长度较长,判定可能的缺陷类型是划痕。Fig. 11 is the obtained voltage-distance curve, Tr=0.001645 , according to |measured voltage signal-standard voltage signal|/standard voltagesignal≥Tr , it is determined that there is one defect. The voltage within the range of 310mm-364mm rises abnormally, corresponding to the defect entering the information collection area, Ym = 0.14635mV, the voltage within the range of 410mm-464mm returns to normal, the corresponding defect leaves the information collection area, the start point and end of the defect The distance between the point position and the starting point of information collection is 410mm and 464mm respectively, and the length of the defect area is determined to be 54mm; the defect judgment factorTy = (0.14635-0.14418)÷0.14418=0.015051, because the judgment factor is greater than zero, and the length of the defect area is If it is longer, it is judged that the possible defect type is scratches.

进一步发现,所测电压-距离曲线在异常上升和下降阶段的斜率发生明显改变,在310mm-334mm范围内,上升阶段斜率约为2.98×10-5mV/mm,在360mm-364mm范围内,上升阶段斜率约为0.00036mV/mm,在310mm-334mm范围内,下降阶段斜率约为-2.98×10-5mV/mm,在460mm-464mm范围内,下降阶段斜率约为-0.00036mV/mm,判断该处缺陷由两类缺陷构成,第一个缺陷斜率绝对值较小、长度较长,最有可能为划痕,第二个缺陷斜率绝对值较大、长度较短,最有可能是压痕。两斜率间中间平台长度26mm,说明两缺陷相距约26mm,图12所示照片显示缺陷为划痕和压痕。It was further found that the slope of the measured voltage-distance curve in the abnormal rising and falling stages changed significantly. In the range of 310mm-334mm, the slope of the rising stage was about 2.98×10-5 mV/mm, and in the range of 360mm-364mm, the rising The slope of the stage is about 0.00036mV/mm, in the range of 310mm-334mm, the slope of the descending stage is about -2.98×10-5 mV/mm, and in the range of 460mm-464mm, the slope of the descending stage is about -0.00036mV/mm, judge The defect here is composed of two types of defects. The first defect has a small absolute slope and a long length, and is most likely scratches. The second defect has a large absolute slope and a short length, and is most likely to be an indentation. . The length of the middle platform between the two slopes is 26mm, indicating that the two defects are about 26mm apart. The photo shown in Figure 12 shows that the defects are scratches and indentations.

对比例Comparative ratio

检测方式:分段离散检测;Detection method: segmented discrete detection;

检测材料:铝合金棒材,直径为5mm,长度为800mm,与实施例3为同一检测材料;Detection material: aluminum alloy bar, with a diameter of 5mm and a length of 800mm, which is the same detection material as Example 3;

接线柱间隔/信息采集区域长度:100mm;Terminal interval / length of information collection area: 100mm;

输入恒定电流:1.0A;Input constant current: 1.0A;

标准电压:0.14418mV;Standard voltage: 0.14418mV;

图13为所测电压-距离曲线,Tr=0.001645,由于中间2个接线柱相距100mm,需要测量8次,每次检测的结果是100mm段平均化的结果,根据|实测电压信号-标准电压信号|/标准电压信号≥Tr,判定400mm-500mm区域存在缺陷,由于只有8个离散数据点,无法确定其具体程度和长度,因而无法判断可能的缺陷种类;实施例3检测到410mm-464mm区域存在缺陷,并可以分析出两类缺陷,而本对比例无法检测到。Figure 13 is the measured voltage-distance curve, Tr =0.001645, because the distance between the two terminals in the middle is 100mm, it needs to be measured 8 times, the result of each test is the averaged result of the 100mm section, according to | measured voltage signal - standard voltage Signal|/Standard voltagesignal≥Tr , it is judged that there is a defect in the 400mm-500mm area. Since there are only 8 discrete data points, the specific degree and length cannot be determined, so the possible defect type cannot be judged; Example 3 detected 410mm-464mm There are defects in the area, and two types of defects can be analyzed, which cannot be detected in this comparative example.

对比例显示出离散检测的缺点:需要提前划分、检测次数多、检测速度慢、信号不明显、定位不要准确、无法进一步区分种类、无法检测缺陷极小的情况等。The comparative example shows the shortcomings of discrete detection: it needs to be divided in advance, the number of detections is large, the detection speed is slow, the signal is not obvious, the positioning is not accurate, the types cannot be further distinguished, and the detection of extremely small defects is impossible.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811497427.1ACN111289575A (en) | 2018-12-07 | 2018-12-07 | A method for detecting the quality of conductive pipe rods based on relative motion |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811497427.1ACN111289575A (en) | 2018-12-07 | 2018-12-07 | A method for detecting the quality of conductive pipe rods based on relative motion |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111289575Atrue CN111289575A (en) | 2020-06-16 |

Family

ID=71026399

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811497427.1AWithdrawnCN111289575A (en) | 2018-12-07 | 2018-12-07 | A method for detecting the quality of conductive pipe rods based on relative motion |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111289575A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114994139A (en)* | 2022-08-05 | 2022-09-02 | 国网天津市电力公司电力科学研究院 | Method, device, equipment and storage medium for defect detection of cable buffer layer |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20110121844A1 (en)* | 2009-11-24 | 2011-05-26 | Fluke Corporation | Method of measuring earth ground resistance of a pylon |

| CN102207413A (en)* | 2011-03-18 | 2011-10-05 | 上海贝洱热系统有限公司 | Detection circuit and method of temperature sensor |

| CN103675454A (en)* | 2013-10-31 | 2014-03-26 | 成都金采科技有限公司 | Resistor testing apparatus |

| WO2015087098A1 (en)* | 2013-12-13 | 2015-06-18 | Prause József | Method for measuring the insulation resistance of an ungrounded dc power network and for localizing the earth fault, and current injecting two-pole device |

| CN105202374A (en)* | 2015-10-14 | 2015-12-30 | 中国石油大学(华东) | Movable-electrode type pipe nondestructive detecting device applied to electric field fingerprint method |

| CN105259220A (en)* | 2015-10-29 | 2016-01-20 | 西安交通大学 | Crack conductivity determination method based on four-terminal direct-current potential detection signal |

| CN105723385A (en)* | 2013-10-30 | 2016-06-29 | 泰克托斯梦室私人有限公司 | Arrangement and method for inspecting an object, in particular a building |

| CN106093575A (en)* | 2016-06-01 | 2016-11-09 | 国网河北省电力公司电力科学研究院 | A kind of method measuring conductor resistivity at room temperature and temperature-coefficient of electrical resistance under alternating temperature |

| CN106645392A (en)* | 2016-11-28 | 2017-05-10 | 中国人民解放军装甲兵工程学院 | Nondestructive testing excitation device of eddy pulse infrared thermal imaging |

| CN106770502A (en)* | 2017-01-03 | 2017-05-31 | 航天科工防御技术研究试验中心 | A kind of position finding and detection method of capacitance short-circuit failure |

- 2018

- 2018-12-07CNCN201811497427.1Apatent/CN111289575A/ennot_activeWithdrawn

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20110121844A1 (en)* | 2009-11-24 | 2011-05-26 | Fluke Corporation | Method of measuring earth ground resistance of a pylon |

| CN102207413A (en)* | 2011-03-18 | 2011-10-05 | 上海贝洱热系统有限公司 | Detection circuit and method of temperature sensor |

| CN105723385A (en)* | 2013-10-30 | 2016-06-29 | 泰克托斯梦室私人有限公司 | Arrangement and method for inspecting an object, in particular a building |

| CN103675454A (en)* | 2013-10-31 | 2014-03-26 | 成都金采科技有限公司 | Resistor testing apparatus |

| WO2015087098A1 (en)* | 2013-12-13 | 2015-06-18 | Prause József | Method for measuring the insulation resistance of an ungrounded dc power network and for localizing the earth fault, and current injecting two-pole device |

| CN105202374A (en)* | 2015-10-14 | 2015-12-30 | 中国石油大学(华东) | Movable-electrode type pipe nondestructive detecting device applied to electric field fingerprint method |

| CN105259220A (en)* | 2015-10-29 | 2016-01-20 | 西安交通大学 | Crack conductivity determination method based on four-terminal direct-current potential detection signal |

| CN106093575A (en)* | 2016-06-01 | 2016-11-09 | 国网河北省电力公司电力科学研究院 | A kind of method measuring conductor resistivity at room temperature and temperature-coefficient of electrical resistance under alternating temperature |

| CN106645392A (en)* | 2016-11-28 | 2017-05-10 | 中国人民解放军装甲兵工程学院 | Nondestructive testing excitation device of eddy pulse infrared thermal imaging |

| CN106770502A (en)* | 2017-01-03 | 2017-05-31 | 航天科工防御技术研究试验中心 | A kind of position finding and detection method of capacitance short-circuit failure |

Non-Patent Citations (1)

| Title |

|---|

| 张龙赐: "磨削加工的面齿轮齿面传动最小油膜厚度研究", 《中国优秀硕士学位论文全文数据库 工程科技Ⅱ辑》* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114994139A (en)* | 2022-08-05 | 2022-09-02 | 国网天津市电力公司电力科学研究院 | Method, device, equipment and storage medium for defect detection of cable buffer layer |

| CN114994139B (en)* | 2022-08-05 | 2022-11-08 | 国网天津市电力公司电力科学研究院 | Defect detection method, device and equipment for cable buffer layer and storage medium |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111289572A (en) | Method and device for nondestructive testing of quality of conductive material based on resistance parameters | |

| CN100504368C (en) | System and method for monitoring defects in a structure | |

| CN105675657B (en) | Sample surface coating nondestructive testing method and system based on skin effect | |

| US20200018737A1 (en) | Method for detecting compromised zone in cleanroom | |

| CN105548348A (en) | An online detecting method for metal wire surface detects and a detecting device | |

| CN111289566A (en) | Method for efficiently detecting quality of conductive film | |

| CN1720458B (en) | Circuit pattern inspection device and circuit pattern inspection method | |

| CN111289811A (en) | A method for detecting the quality of conductive wire rods based on continuous information | |

| CN104748643A (en) | Metal surface liquid-state film layer measuring device and measuring method thereof | |

| CN114964389B (en) | System and method for evaluating running state of pantograph slide plate | |

| CN107748199B (en) | Power transformer coil material identification method | |

| CN111289575A (en) | A method for detecting the quality of conductive pipe rods based on relative motion | |

| CN207689414U (en) | It is a kind of to monitor H in pickle in real time+、Fe2+The device of ion concentration and acid liquor temperature | |

| CN111289574A (en) | Method and device for nondestructive testing of quality of conductive material based on conductive parameters | |

| CN111289565B (en) | A method and device for nondestructively detecting the quality of conductive materials based on continuously collected information | |

| CN118518590B (en) | Performance data tracking method and system for detection jig | |

| CN111289567A (en) | Method for detecting quality of metal foil on line | |

| WO2004057350A1 (en) | Circuit pattern inspection instrument and pattern inspecting method | |

| CN114406014A (en) | Online detection system and method for band steel edge crack defects | |

| CN118731119A (en) | A method for detecting water content in oil based on interdigital capacitance | |

| CN110231364B (en) | On-line detection dew point corrosion probe device | |

| CN104568629B (en) | A sample and method for on-line detection of metal thinning rate | |

| JP2002014132A (en) | Device for inspecting circuit board | |

| CN111289872A (en) | Method for rapidly detecting quality of conductive plate strip | |

| CN114705726B (en) | Method and device for rapidly detecting welding defects in metal spot welding joint |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication | Application publication date:20200616 | |

| WW01 | Invention patent application withdrawn after publication |