CN111286693A - Microporous anode for cluster plasma spray gun and cluster plasma spraying method - Google Patents

Microporous anode for cluster plasma spray gun and cluster plasma spraying methodDownload PDFInfo

- Publication number

- CN111286693A CN111286693ACN202010225525.0ACN202010225525ACN111286693ACN 111286693 ACN111286693 ACN 111286693ACN 202010225525 ACN202010225525 ACN 202010225525ACN 111286693 ACN111286693 ACN 111286693A

- Authority

- CN

- China

- Prior art keywords

- anode

- plasma

- powder

- microporous

- spray gun

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000007921spraySubstances0.000titleclaimsabstractdescription73

- 238000000034methodMethods0.000titleclaimsabstractdescription17

- 238000007750plasma sprayingMethods0.000titleclaimsdescription40

- 239000000843powderSubstances0.000claimsabstractdescription94

- 230000001681protective effectEffects0.000claimsabstractdescription28

- 238000001816coolingMethods0.000claimsdescription7

- 238000012546transferMethods0.000claimsdescription6

- 238000007789sealingMethods0.000claimsdescription5

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription5

- 230000008602contractionEffects0.000claims1

- 238000000576coating methodMethods0.000abstractdescription31

- 239000011248coating agentSubstances0.000abstractdescription27

- 239000000758substrateSubstances0.000abstractdescription19

- 238000005507sprayingMethods0.000abstractdescription13

- 230000000694effectsEffects0.000abstractdescription8

- 239000000203mixtureSubstances0.000abstractdescription7

- 239000000126substanceSubstances0.000abstractdescription7

- 230000006835compressionEffects0.000abstractdescription6

- 238000007906compressionMethods0.000abstractdescription6

- 239000000155meltSubstances0.000abstractdescription3

- 239000007789gasSubstances0.000description24

- 238000010438heat treatmentMethods0.000description19

- 238000005516engineering processMethods0.000description7

- 238000010586diagramMethods0.000description6

- 238000004519manufacturing processMethods0.000description6

- 229910052751metalInorganic materials0.000description6

- 239000002184metalSubstances0.000description6

- 230000008569processEffects0.000description6

- 238000011160researchMethods0.000description5

- 230000001133accelerationEffects0.000description4

- 239000000463materialSubstances0.000description4

- 238000011017operating methodMethods0.000description4

- 239000002245particleSubstances0.000description4

- 238000002360preparation methodMethods0.000description4

- 239000000956alloySubstances0.000description3

- 229910045601alloyInorganic materials0.000description3

- 238000007689inspectionMethods0.000description3

- 238000009434installationMethods0.000description3

- 238000013021overheatingMethods0.000description3

- 238000012545processingMethods0.000description3

- 238000003892spreadingMethods0.000description3

- 230000007480spreadingEffects0.000description3

- XKRFYHLGVUSROY-UHFFFAOYSA-NArgonChemical compound[Ar]XKRFYHLGVUSROY-UHFFFAOYSA-N0.000description2

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000description2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-NTitan oxideChemical compoundO=[Ti]=OGWEVSGVZZGPLCZ-UHFFFAOYSA-N0.000description2

- 238000004458analytical methodMethods0.000description2

- 230000009286beneficial effectEffects0.000description2

- 239000002131composite materialSubstances0.000description2

- 230000007613environmental effectEffects0.000description2

- 230000008020evaporationEffects0.000description2

- 238000001704evaporationMethods0.000description2

- 230000036541healthEffects0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 230000009467reductionEffects0.000description2

- 230000000630rising effectEffects0.000description2

- 238000004088simulationMethods0.000description2

- 238000009827uniform distributionMethods0.000description2

- 229910018072Al 2 O 3Inorganic materials0.000description1

- 229910017945Cu—TiInorganic materials0.000description1

- 229910052786argonInorganic materials0.000description1

- 230000007812deficiencyEffects0.000description1

- 230000008021depositionEffects0.000description1

- 238000013461designMethods0.000description1

- 238000004141dimensional analysisMethods0.000description1

- 239000006185dispersionSubstances0.000description1

- 238000009826distributionMethods0.000description1

- 239000001307heliumSubstances0.000description1

- 229910052734heliumInorganic materials0.000description1

- SWQJXJOGLNCZEY-UHFFFAOYSA-Nhelium atomChemical compound[He]SWQJXJOGLNCZEY-UHFFFAOYSA-N0.000description1

- 239000001257hydrogenSubstances0.000description1

- 229910052739hydrogenInorganic materials0.000description1

- 125000004435hydrogen atomChemical class[H]*0.000description1

- 150000001247metal acetylidesChemical class0.000description1

- 229910044991metal oxideInorganic materials0.000description1

- 150000004706metal oxidesChemical class0.000description1

- 150000002739metalsChemical class0.000description1

- 229910052757nitrogenInorganic materials0.000description1

- 230000002093peripheral effectEffects0.000description1

- 230000005855radiationEffects0.000description1

- 230000008439repair processEffects0.000description1

- 239000007787solidSubstances0.000description1

- 238000007711solidificationMethods0.000description1

- 230000008023solidificationEffects0.000description1

- 238000005728strengtheningMethods0.000description1

- 238000006467substitution reactionMethods0.000description1

- 238000004804windingMethods0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/12—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the method of spraying

- C23C4/134—Plasma spraying

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/06—Metallic material

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Coating By Spraying Or Casting (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及等离子喷涂、再制造和修复领域,具体涉及一种用于集束等离子喷枪的微孔阳极及集束等离子喷涂方法,通过将阳极出口内径限制在0.5-3毫米的范围内,利用微孔阳极压缩效应获得能量密度集中、发散性小的等离子微射流,等离子微射流的斑点小,适合用于精密零件、微小零件、薄壁零件的表面涂层加工,同时可以把射流加热工件的位置集中在微小的射流斑点区域内,在避免工件整体温度上升的同时,瞬间熔化待喷涂工件表面的局部区域,使得涂层与基体产生冶金结合;利用周向环形分布的粉末输送通道将粉末形成具有预先设计夹角、发散性小的锥形粉末流,使其在等离子微射流中的加热、加速更加均匀,从而获得化学成分均匀、微观结构致密、形成冶金结合的喷涂涂层。The invention relates to the fields of plasma spraying, remanufacturing and repair, in particular to a microporous anode for a cluster plasma spray gun and a cluster plasma spraying method. The compression effect obtains the plasma microjet with concentrated energy density and small divergence. The spot of the plasma microjet is small, which is suitable for surface coating processing of precision parts, tiny parts and thin-walled parts. In the tiny jet spot area, while avoiding the overall temperature rise of the workpiece, the local area of the surface of the workpiece to be sprayed is instantly melted, so that the coating and the substrate are metallurgically bonded; the powder is formed with a pre-designed powder conveying channel with a circumferential annular distribution. The conical powder flow with small included angle and divergence makes the heating and acceleration in the plasma microjet more uniform, so as to obtain a spray coating with uniform chemical composition, dense microstructure and metallurgical bonding.

背景技术Background technique

等离子喷涂是一种材料表面强化和表面改性的技术,如图1所示,其利用电能将氩气、氮气、氢气、或氦气等混合气体在等离子喷枪的阴极与阳极之间发生电离,转变为高温等离子体并形成高温等离子射流(一般10000摄氏度以上),利用其高温、高速等离子射流将通过送粉装置送入的金属、合金、金属氧化物、金属碳化物等粉末材料迅速加热、加速后,撞击工件基体后经过扁平化并急速冷却形成涂层的工艺方法。Plasma spraying is a technology for surface strengthening and surface modification of materials. As shown in Figure 1, it uses electric energy to ionize mixed gases such as argon, nitrogen, hydrogen, or helium between the cathode and anode of the plasma spray gun. Transform into high-temperature plasma and form high-temperature plasma jet (generally above 10,000 degrees Celsius), and use its high-temperature, high-speed plasma jet to rapidly heat and accelerate powder materials such as metals, alloys, metal oxides, and metal carbides sent through the powder feeding device Then, after hitting the workpiece substrate, it is flattened and rapidly cooled to form a coating.

等离子喷涂过程中,基体的温度一般被控制在300-400摄氏度以下,基体表面不发生熔化,等离子喷涂涂层与工件基体的结合方式为机械结合(杨焜等,大气等离子喷涂TiO2涂层性能及厚涂层制备工艺,中国表面工程,第27卷第4期(2014),P12-18;杨卓,哈尔滨工业大学学位位论文,离子喷涂法制备Al2O3/Ag-Cu-Ti复合涂层工艺研究,2012年7月)。During the plasma spraying process, the temperature of the substrate is generally controlled below 300-400 degrees Celsius, the surface of the substrate does not melt, and the combination of the plasma sprayed coating and the workpiece substrate is mechanical bonding (Yang Kun et al., Atmospheric plasma sprayingTiO2 coating performance. and Thick Coating Preparation Process, China Surface Engineering, Vol. 27, No. 4 (2014), P12-18; Yang Zhuo, Dissertation of Harbin Institute of Technology, Preparation of Al2 O3 /Ag-Cu-Ti Composite by Ion Spraying Coating Process Research, July 2012).

如图1所示,现有等离子喷涂技术通过单根送粉管或两根送粉管送粉,通常选用送粉管置于阳极前部的外送粉方式,与等离子射流成直角将粉末送入等离子射流中,粉末发散严重,在等离子射流受热中受热不均匀,位于等离子射流中心的粉末过度熔化而发生破碎和蒸发,而位于等离子射流边缘的粉末多处于固态或半熔化状态,所制备的涂层中容易夹杂未熔化的粉末颗粒。As shown in Figure 1, in the existing plasma spraying technology, powder is fed through a single powder feeding tube or two powder feeding tubes. Usually, the powder feeding tube is placed in the front of the anode, and the powder is sent at a right angle to the plasma jet. In the plasma jet, the powder is seriously scattered, and the heating is uneven in the heating of the plasma jet. The powder located in the center of the plasma jet is excessively melted and broken and evaporated, while the powder located at the edge of the plasma jet is mostly in a solid or semi-melted state. Unmelted powder particles are easily included in the coating.

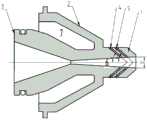

如图1所示,阳极位于等离子喷枪的前部。图2为现有等离子喷枪的阳极的剖面结构示意图,阳极作为等离子喷枪的电极和等离子体的流通通道,是等离子喷枪的一个关键零部件。为了提高等离子喷涂设备的功率,提高等离子气体的流量,获得大的粉末的送粉速度和高的喷涂生产效率,国内主要开展等离子喷涂研究和应用的单位所采用的等离子喷枪其阳极出口内径较大,通常为5-20毫米,具体情况详述如下:As shown in Figure 1, the anode is located at the front of the plasma torch. FIG. 2 is a schematic cross-sectional structure diagram of an anode of a conventional plasma spray gun. The anode serves as an electrode of the plasma spray gun and a circulation channel for plasma, and is a key component of the plasma spray gun. In order to improve the power of plasma spraying equipment, increase the flow rate of plasma gas, and obtain large powder feeding speed and high spraying production efficiency, the plasma spray gun used by the domestic main research and application units of plasma spraying has a larger inner diameter of the anode outlet. , usually 5-20 mm, as detailed below:

(1)水利部杭州机械设计研究所公布的等离子喷枪,其阳极出口内径为6-13毫米(发明专利,申请公布号CN 108165923 A,陈小明,一种新型超高音速高焓值等离子喷枪及WC基复合涂层的制备工艺)。(1) The plasma spray gun announced by the Hangzhou Machinery Design and Research Institute of the Ministry of Water Resources has an anode outlet inner diameter of 6-13 mm (invention patent, application publication number CN 108165923 A, Chen Xiaoming, a new type of supersonic high-enthalpy plasma spray gun and WC Preparation process of base composite coating).

(2)大连海事大学公布的低压等离子喷枪的阳极出口内径为8-20毫米(发明专利,授权公告号CN 101954324B,高阳,一种低压等离子喷涂用等离子喷枪)。大连海事大学自行开发的最大功率为5千瓦的小功率等离子喷枪的阳极出口内径为5毫米,并没有因为功率低些而大大减小阳极出口内径(高阳等,小功率等离子体射流的流特性,第24卷第2期(2003),P147-151)。(2) The inner diameter of the anode outlet of the low-pressure plasma spray gun announced by Dalian Maritime University is 8-20 mm (invention patent, authorized announcement number CN 101954324B, Gaoyang, a plasma spray gun for low-pressure plasma spraying). The inner diameter of the anode outlet of the low-power plasma spray gun with a maximum power of 5 kW developed by Dalian Maritime University is 5 mm, and the inner diameter of the anode outlet has not been greatly reduced due to the lower power (Gao Yang et al., Flow characteristics of low-power plasma jets, Vol. 24, No. 2 (2003), P147-151).

(3)广东新材料研究所使用的等离子喷涂系统的喷枪为德国GTV GmbH的F6喷枪,其阳极出口内径为6毫米(Kui Wen等,Numerical simulation and experimental studyof Ar-H2 DC atmospheric plasma spraying,Surface&Coatings Technology,371(2019),P312-321)。(3) The spray gun of the plasma spraying system used by the Guangdong New Materials Research Institute is the F6 spray gun of GTV GmbH, Germany, and the inner diameter of the anode outlet is 6 mm (Kui Wen et al., Numerical simulation and experimental study of Ar-H2 DC atmospheric plasma spraying, Surface & Coatings Technology, 371(2019), P312-321).

(4)装甲兵工程学院和西安交通大学联合开发的超音速等离子喷涂系统,其喷枪的阳极出口内径为5.6毫米(谭超等,内送粉超声速等离子喷涂流场特性分析,推进技术,第36卷第1期(2015),P30-36)。(4) The supersonic plasma spraying system jointly developed by the Armored Forces Engineering College and Xi'an Jiaotong University, the inner diameter of the anode outlet of the spray gun is 5.6 mm (Tan Chao et al., Analysis of the Flow Field Characteristics of Supersonic Plasma Spraying with Internal Powder Feeding, Propulsion Technology, Vol. 36 Issue 1 (2015), P30-36).

(5)福州大学使用的等离子喷涂系统的喷枪为北京航空制造工艺研究所生产的PQ-1S喷枪,其阳极出口内径为7.8毫米(叶向艺,硕士毕业论文,直流等离子喷枪内电弧和射流行为的三维非稳态模拟,2013年1月)。(5) The spray gun of the plasma spraying system used by Fuzhou University is the PQ-1S spray gun produced by the Beijing Institute of Aeronautical Manufacturing Technology, and the inner diameter of the anode outlet is 7.8 mm (Ye Xiangyi, Master's Thesis, Three-dimensional analysis of the arc and jet behavior in the DC plasma spray gun Unsteady Simulation, January 2013).

(6)天津大学和西安交通大学使用的等离子喷涂系统的喷枪为APS-2000型9M喷枪,其阳极出口内径为7.8毫米。(6) The spray gun of the plasma spraying system used by Tianjin University and Xi'an Jiaotong University is APS-2000 type 9M spray gun, and the inner diameter of the anode outlet is 7.8 mm.

(7)西南石油大学使用的超音速等离子喷涂系统,其喷枪的阳极出口内径为5.5毫米(张勇,博士毕业论文,等离子喷涂射流特性及熔滴铺展凝固行为研究,2015年9月)。(7) The supersonic plasma spraying system used by Southwest Petroleum University, the inner diameter of the anode outlet of the spray gun is 5.5 mm (Zhang Yong, Ph.D. dissertation, Research on the characteristics of plasma spraying jet and the spreading and solidification behavior of molten droplets, September 2015).

由上述分析可知,现有的等离子喷涂技术有如下四点不足:It can be seen from the above analysis that the existing plasma spraying technology has the following four deficiencies:

(1)目前,市场对精密、小型零部件的表面喷涂需求急剧增加。由于现有等离子喷枪的阳极出口内径较大,因此等离子射流的直径大,对于精密、小型零部件的表面制备涂层时,为了防止不需要喷涂的周边位置附上涂层,通常采用遮挡的方法进行防护(比如缠绕高温胶带、金属片等),这不仅增加了生产前期准备工作量,而且由于等离子射流的温度高,高温胶带、金属片等容易烧损脱落,其防护效果很差。因此,为了满足精细零件的等离子喷涂需求,急需开发阳极出口内径小、等离子射流更加集中的等离子喷涂设备。(1) At present, the market demand for surface coating of precision and small parts has increased sharply. Due to the large inner diameter of the anode outlet of the existing plasma spray gun, the diameter of the plasma jet is large. When preparing coatings on the surface of precision and small parts, in order to prevent the coating from attaching to the peripheral positions that do not need to be sprayed, the method of shielding is usually used. For protection (such as winding high-temperature tapes, metal sheets, etc.), this not only increases the workload of pre-production preparations, but also due to the high temperature of the plasma jet, high-temperature tapes, metal sheets, etc. are easy to burn and fall off, and their protective effect is very poor. Therefore, in order to meet the demand for plasma spraying of fine parts, it is urgent to develop plasma spraying equipment with a small anode outlet inner diameter and a more concentrated plasma jet.

(2)由于阳极出口内径通常为5-20毫米,尺寸较大,必然导致等离子射流的斑点大。喷涂过程中,大斑点、炽热的等离子射流对工件进行大面积的加热,工件的温度整体升高,将劣化工件的微观组织和力学性能。为了避免工件受到等离子射流加热的影响,在等离子喷涂生产过程中,喷涂距离(喷涂工件表面到喷枪阳极出口的距离)设定较远,通常为80-150毫米。然而,喷涂距离越远,等离子射流的集中性越差,所制备涂层的致密性就越低。(2) Since the inner diameter of the anode outlet is usually 5-20 mm, the size is large, which will inevitably lead to large spots of the plasma jet. During the spraying process, the large spot and hot plasma jet heats the workpiece in a large area, and the temperature of the workpiece increases as a whole, which will deteriorate the microstructure and mechanical properties of the workpiece. In order to avoid the workpiece being affected by the plasma jet heating, in the plasma spraying production process, the spraying distance (the distance from the surface of the sprayed workpiece to the anode outlet of the spray gun) is set far, usually 80-150 mm. However, the longer the spray distance, the less concentrated the plasma jet, and the less dense the prepared coating.

(3)现有等离子喷涂过程中,基体的温度一般被控制在300-400摄氏度以下,基体表面不发生熔化,制备的涂层与基体的结合方式为机械结合,结合力通常低于40MPa,与冶金结合相比,涂层与基体的结合强度较低,导致在涂层服役过程中,涂层容易发生局部脱落,甚至整体剥落,涂层的工作寿命短。(3) In the existing plasma spraying process, the temperature of the substrate is generally controlled below 300-400 degrees Celsius, and the surface of the substrate does not melt. The combination of the prepared coating and the substrate is mechanical bonding, and the bonding force is usually lower than 40MPa. Compared with metallurgical bonding, the bonding strength between the coating and the substrate is lower, which leads to the local peeling off of the coating during the service process of the coating, or even the overall peeling off, and the working life of the coating is short.

(4)现有等离子喷涂的等离子射流的集中性差;单根送粉管或两根送粉管送粉的均匀性也差。导致经过等离子射流加热、加速后的粉末颗粒的速度和温度各不相同,均匀性差,所制备的涂层中容易夹杂未熔化的粉末颗粒,同时未沉积为涂层的粉末颗粒飞向周边环境中,粉末材料的沉积效率低。不仅污染环境,而且提高了制备单位面积涂层的粉末的消耗量,从而降低了生产效率,提高了生产成本。(4) The concentration of the plasma jet of the existing plasma spraying is poor; the uniformity of powder feeding by a single powder feeding tube or two powder feeding tubes is also poor. As a result, the speed and temperature of the powder particles heated and accelerated by the plasma jet are different, and the uniformity is poor. The prepared coating is easily mixed with unmelted powder particles, and the powder particles that are not deposited as coatings fly into the surrounding environment. , the deposition efficiency of powder materials is low. It not only pollutes the environment, but also increases the consumption of powder for preparing the coating per unit area, thereby reducing the production efficiency and increasing the production cost.

发明内容SUMMARY OF THE INVENTION

针对上述现有技术的不足之处,本发明提供了一种用于集束等离子喷枪的微孔阳极及集束等离子喷涂方法,将阳极出口内径限制在0.5-3毫米的范围内,等离子微射流的斑点小,能使涂层与基体产生冶金结合,粉末加热、加速更加均匀,从而获得化学成分均匀、微观结构致密、形成冶金结合的喷涂涂层。本发明结构简单,无需另外增加冷却循环装置,安装、拆卸、检查方便。In view of the above-mentioned shortcomings of the prior art, the present invention provides a microporous anode for a cluster plasma spray gun and a cluster plasma spray method, which limits the inner diameter of the anode outlet within the range of 0.5-3 mm, and the spots of the plasma micro-jet are limited. Small, can make the coating and the substrate metallurgical bonding, powder heating and acceleration more uniform, so as to obtain a spray coating with uniform chemical composition, dense microstructure and metallurgical bonding. The invention has a simple structure, does not need to add a cooling circulation device, and is convenient for installation, disassembly and inspection.

本发明的技术方案如下:The technical scheme of the present invention is as follows:

本发明公开了一种用于集束等离子喷枪的微孔阳极;包括阳极前部、阳极中部和阳极后部,并与等离子喷枪进行同轴连接。阳极前部有粉末输送通道和保护气体输送通道;微孔阳极的内通道自行围合形成喷管,微孔阳极的出口内径为0.5-3毫米;微孔阳极内有冷却循环水空间。The invention discloses a microporous anode used for a cluster plasma spray gun; it comprises an anode front part, an anode middle part and an anode rear part, and is coaxially connected with the plasma spray gun. There are powder conveying channels and protective gas conveying channels at the front of the anode; the inner channel of the microporous anode is self-enclosed to form a nozzle, and the inner diameter of the outlet of the microporous anode is 0.5-3 mm; there is a cooling circulating water space in the microporous anode.

所述的阳极前部有粉末输送通道,其数量为3-6个,在阳极前部的外圆周面上均匀分布;所述的粉末输送通道与喷管相通,其与中心线的夹角A为10-85度。The front part of the anode has powder conveying channels, the number of which is 3-6, and is evenly distributed on the outer circumference of the front part of the anode; the powder conveying channel is communicated with the nozzle, and the angle A between it and the center line is 10-85 degrees.

所述的粉末输送通道将粉末高速、均匀地送至等离子射流中,形成具有预先设计夹角A的锥形粉末射流,并最终聚焦于中心轴某一点上,从而获得高速、均匀分布、发散性小的粉末射流。由于粉末输送通道有3-6个,粉末从四周环形送粉,与现有的单送粉管或双送粉管相比,单位时间内送粉量可以大大提高,从而获得高浓度的锥形粉末射流;特别地,利用高浓度粉末射流挡住等离子射流对工件基体的辐射加热,可降低等离子射流对工件基体的热作用,从而即使在短的喷涂距离内,也能大幅度缓解工件整体由于过度受热引起的整体力学性能降低,也提高了等离子喷涂热源用于加热粉末的热效率。另外,粉末在等离子射流中加热均匀性好,避免了粉末合金元素由于过热发生蒸发和烧损,喷涂涂层的化学成分与原始粉末更近似一致,不向环境中释放有害的金属蒸气,有利于保护操作工人的身体健康和满足环保要求。The powder conveying channel sends the powder into the plasma jet at a high speed and uniformly, forming a conical powder jet with a pre-designed angle A, and finally focuses on a certain point of the central axis, so as to obtain high speed, uniform distribution and divergence. Small powder jet. Since there are 3-6 powder conveying channels, the powder is fed from all sides in a ring shape. Compared with the existing single powder feeding tube or double powder feeding tube, the powder feeding amount per unit time can be greatly increased, so as to obtain a high-concentration cone. Powder jet; in particular, the use of high-concentration powder jet to block the radiative heating of the plasma jet to the workpiece substrate can reduce the thermal effect of the plasma jet on the workpiece substrate, so that even in a short spraying distance, it can also greatly alleviate the overall overheating of the workpiece. The reduction in overall mechanical properties caused by heating also improves the thermal efficiency of the plasma spray heat source for heating powders. In addition, the powder has good heating uniformity in the plasma jet, which avoids the evaporation and burning of powder alloy elements due to overheating. The chemical composition of the spray coating is more similar to the original powder, and no harmful metal vapor is released into the environment, which is beneficial to Protect the health of operators and meet environmental protection requirements.

所述的阳极前部有保护气体输送通道,其数量为3-6个,在阳极前部的外圆周面上均匀分布。所述的保护气体输送通道与喷管相通,其与中心线的夹角B为10-85度。所述保护气体输送通道与所述的粉末输送通道相比,更靠近喷管出口方向。所述的保护气体输送通道将保护气体高速、均匀地送至等离子射流中,形成具有预先设计夹角B的锥形保护气流,并最终聚焦于中心轴上,在防止外界空气卷入等离子射流中的同时,进一步约束粉末,防止粉末发生发散,促进粉末聚焦在一起。The front part of the anode is provided with protective gas conveying channels, the number of which is 3-6, which are evenly distributed on the outer circumference of the front part of the anode. The protective gas conveying channel communicates with the nozzle, and the included angle B between it and the center line is 10-85 degrees. Compared with the powder conveying passage, the protective gas conveying passage is closer to the outlet direction of the nozzle. The protective gas delivery channel sends the protective gas into the plasma jet at a high speed and uniformity, forming a conical protective air flow with a pre-designed included angle B, and finally focuses on the central axis to prevent the outside air from being involved in the plasma jet. At the same time, it further constrains the powder, prevents the powder from spreading, and promotes the powder to focus together.

所述微孔阳极的喷管为等离子体的流通通道,其出口内径D非常小,仅为0.5-3毫米。利用微孔阳极压缩效应获得能量密度集中、发散性小的等离子微射流,等离子微射流的斑点小,可以把射流加热工件的位置集中在微小的射流斑点区域内,在避免工件整体温度上升的同时,瞬间熔化待喷涂工件表面的局部区域,使得涂层与基体产生冶金结合。The nozzle of the microporous anode is the flow channel of the plasma, and the inner diameter D of the outlet is very small, only 0.5-3 mm. The plasma microjet with concentrated energy density and small divergence is obtained by using the compression effect of the microporous anode. The spot of the plasma microjet is small, and the position of the jet heating the workpiece can be concentrated in the tiny jet spot area, while avoiding the overall temperature rise of the workpiece. , which instantly melts the local area of the surface of the workpiece to be sprayed, so that the coating and the substrate produce metallurgical bonding.

所述的喷管沿出口方向其内径呈现收缩形式;或沿出口方向上其内径保持不变;或沿出口方向上其内径呈现扩张形式;或是上述形式的组合方式。The inner diameter of the nozzle exhibits a shrinking form along the outlet direction; or the inner diameter remains unchanged along the outlet direction; or the inner diameter exhibits an expanding form along the outlet direction; or a combination of the above forms.

所述的阳极前部与阳极中部分开为两个单独的零件,二者通过螺纹固定连接,并采用密封圈进行密封。The front part of the anode and the middle part of the anode are separated into two separate parts, which are fixedly connected by threads and sealed by a sealing ring.

为了简化微孔阳极的结构,所述保护气体输送通道可以安装在阳极的前部,或省略不要。In order to simplify the structure of the microporous anode, the protective gas delivery channel can be installed at the front of the anode, or omitted.

所述的等离子喷枪为大气等离子喷枪、真空等离子喷枪、超音速等离子喷枪、微束等离子喷枪;等离子喷枪的等离子弧可为非转移型等离子弧,也可以为转移型等离子弧。The plasma spray guns are atmospheric plasma spray guns, vacuum plasma spray guns, supersonic plasma spray guns, and microbeam plasma spray guns; the plasma arc of the plasma spray gun can be a non-transfer plasma arc or a transfer plasma arc.

采用本发明的一种用于集束等离子喷枪的微孔阳极,与现有等离子喷枪相配合,获得集束等离子射流,从而形成集束等离子喷涂方法,其具体的操作步骤如下:A microporous anode for a cluster plasma spray gun of the present invention is adopted, and the existing plasma spray gun is matched to obtain a cluster plasma jet, thereby forming a cluster plasma spray method. The specific operation steps are as follows:

(a)将本发明的用于集束等离子喷枪的微孔阳极替换现有等离子喷枪的阳极,并做好固定和密封,获得集束等离子射流;(a) replace the anode of the existing plasma spray gun with the microporous anode of the present invention for the cluster plasma spray gun, and do a good job of fixing and sealing to obtain the cluster plasma jet;

(b)通过粉末输送通道(4)送入粉末和送粉气,通过保护气体输送通道(5)通入保护气;(b) feeding powder and powder feeding gas through the powder conveying passage (4), and feeding the shielding gas through the shielding gas conveying passage (5);

(c)按照等离子喷涂系统的操作程序开机,设置集束等离子喷涂的工艺参数,进行集束等离子喷涂;(c) Start the machine according to the operating procedure of the plasma spraying system, set the process parameters of the cluster plasma spraying, and carry out the cluster plasma spraying;

(d)集束等离子喷涂作业完成后按照设备操作程序关机。(d) After the cluster plasma spraying operation is completed, shut down the equipment according to the equipment operating procedures.

本发明的一种用于集束等离子喷枪的微孔阳极及集束等离子喷涂方法,将阳极出口内径限制在0.5-3毫米的范围内,利用微孔阳极压缩效应获得能量密度集中、发散性小的等离子微射流,等离子微射流的斑点小,适合用于精密零件、微小零件、薄壁零件的表面涂层加工,同时可以把射流加热工件的位置集中在微小的射流斑点区域内,在避免工件整体温度上升的同时,瞬间熔化待喷涂工件表面的局部区域,使得涂层与基体产生冶金结合;利用周向环形分布的粉末输送通道将粉末形成具有预先设计夹角、发散性小的锥形粉末流,使其在等离子微射流中的加热、加速更加均匀,从而获得化学成分均匀、微观结构致密、形成冶金结合的喷涂涂层。本发明结构简单,无需另外增加冷却循环装置,安装、拆卸、检查方便,工程应用广泛。The invention provides a microporous anode for a cluster plasma spray gun and a cluster plasma spraying method. The inner diameter of the anode outlet is limited within the range of 0.5-3 mm, and the microporous anode compression effect is used to obtain plasma with concentrated energy density and small divergence. Micro-jet, plasma micro-jet has small spots, suitable for surface coating processing of precision parts, tiny parts, and thin-walled parts. At the same time, the position of the jet heating workpiece can be concentrated in the tiny jet spot area, so as to avoid the overall temperature of the workpiece. At the same time of rising, the local area of the surface of the workpiece to be sprayed is instantly melted, so that the coating and the substrate are metallurgically combined; the powder is formed into a conical powder flow with a pre-designed angle and small divergence by using the powder conveying channel distributed in a circumferential ring. The heating and acceleration in the plasma microjet are more uniform, so as to obtain a spray coating with uniform chemical composition, dense microstructure and metallurgical bonding. The invention has a simple structure, does not need to add a cooling circulation device, is convenient for installation, disassembly and inspection, and is widely used in engineering.

附图说明Description of drawings

图1为现有等离子喷涂技术原理图;Fig. 1 is the schematic diagram of the existing plasma spraying technology;

图2为现有等离子喷枪的阳极的剖面结构示意图;Fig. 2 is the cross-sectional structure schematic diagram of the anode of the existing plasma spray gun;

图3为本发明提供的一种用于集束等离子喷枪的微孔阳极的剖面结构正视图;3 is a front view of a cross-sectional structure of a microporous anode for a cluster plasma torch provided by the present invention;

图4为本发明提供的一种用于集束等离子喷枪的微孔阳极的前部的左视图;4 is a left side view of the front of a microporous anode for a cluster plasma torch provided by the present invention;

图5为沿出口方向上其内径保持不变的喷管的剖面结构示意图;5 is a schematic cross-sectional structure diagram of a nozzle whose inner diameter remains unchanged along the outlet direction;

图6为沿出口方向上其内径呈现扩张形式的喷管的剖面结构示意图;6 is a schematic cross-sectional structure diagram of a nozzle whose inner diameter presents an expanded form along the outlet direction;

图7为与阳极中部分离的阳极前部的剖面结构示意图;Fig. 7 is the cross-sectional structure schematic diagram of the anode front part separated from the anode middle part;

图8为保护气体输送通道安装在阳极的前部的剖面结构示意图。FIG. 8 is a schematic cross-sectional view of the protective gas delivery channel installed at the front of the anode.

附图标记说明:Description of reference numbers:

1、阳极前部;2、阳极中部;3、阳极后部;4、粉末输送通道;5、保护气体输送通道;6、喷管;7、冷却循环水空间。1. Front part of anode; 2. Middle part of anode; 3. Rear part of anode; 4. Powder conveying channel; 5. Protective gas conveying channel; 6. Nozzle; 7. Cooling circulating water space.

具体实施方式Detailed ways

通过以下参照附图对本发明实施例的描述,本发明的上述以及其它目的、特征和优点将更为清楚。以下基于实施例对本发明进行描述,本领域普通技术人员应当理解,在此提供的附图都是为了说明目的,并且附图不一定是按比例绘制的。The above and other objects, features and advantages of the present invention will become more apparent from the following description of embodiments of the present invention with reference to the accompanying drawings. The present invention is described below based on the embodiments, and those of ordinary skill in the art should understand that the drawings provided herein are for illustrative purposes and are not necessarily drawn to scale.

除非上下文明确要求,否则整个说明书和权利要求书中的“包括”、“包含”等类似词语应当解释为包含的含义而不是排他或穷举的含义;也就是说,是“包括但不限于”的含义。Unless clearly required by the context, words such as "including", "comprising" and the like throughout the specification and claims should be construed in an inclusive rather than an exclusive or exhaustive sense; that is, "including but not limited to" meaning.

如图3和图4所示,本发明公开了一种用于集束等离子喷枪的微孔阳极,包括阳极前部(1)、阳极中部(2)和阳极后部(3),并与等离子喷枪进行同轴连接。阳极前部(1)有粉末输送通道(4)和保护气体输送通道(5)。微孔阳极的内通道自行围合形成喷管(6),微孔阳极出口内径为0.5-3毫米;微孔阳极内有冷却循环水空间(7)。As shown in Figures 3 and 4, the present invention discloses a microporous anode for a cluster plasma spray gun, comprising an anode front part (1), an anode middle part (2) and an anode rear part (3), and is integrated with the plasma spray gun Make a coaxial connection. The front part (1) of the anode is provided with a powder conveying channel (4) and a protective gas conveying channel (5). The inner channel of the microporous anode is self-enclosed to form a nozzle (6), and the inner diameter of the outlet of the microporous anode is 0.5-3 mm; a cooling circulating water space (7) is arranged in the microporous anode.

优选地,如图3和图4所示,所述的阳极前部(1)有粉末输送通道(4),其数量为3-6个,在阳极前部(1)的外圆周面上均匀分布。所述的粉末输送通道(4)与喷管(6)相通,其与中心线的夹角A为10-85度。Preferably, as shown in Figures 3 and 4, the anode front (1) is provided with powder conveying channels (4), the number of which is 3-6, which are uniform on the outer circumferential surface of the anode front (1). distributed. The powder conveying channel (4) communicates with the nozzle (6), and the included angle A between it and the center line is 10-85 degrees.

所述的粉末输送通道(4)将粉末高速、均匀地送至等离子射流中,形成具有预先设计夹角A的锥形粉末射流,并最终聚焦于中心轴某一点上,从而获得高速、均匀分布、发散性小的粉末射流。由于粉末输送通道(4)有3-6个,粉末从四周环形送粉,与现有的单送粉管或双送粉管相比,单位时间内送粉量可以大大提高,从而获得高浓度的锥形粉末射流;特别地,利用高浓度粉末射流挡住等离子射流对工件基体的辐射加热,可降低等离子射流对工件基体的热作用,从而即使在短的喷涂距离内,也能大幅度缓解工件整体由于过度受热引起的整体力学性能降低,也提高了等离子喷涂热源用于加热粉末的热效率。另外,粉末在等离子射流中加热均匀性好,避免了粉末合金元素由于过热发生蒸发和烧损,喷涂涂层的化学成分与原始粉末更近似一致,不向环境中释放有害的金属蒸气,有利于保护操作工人的身体健康和满足环保要求。The powder conveying channel (4) sends the powder into the plasma jet at a high speed and uniformly to form a conical powder jet with a pre-designed included angle A, and finally focuses on a certain point of the central axis, so as to obtain a high-speed and uniform distribution , Powder jet with small dispersion. Since there are 3-6 powder conveying channels (4), the powder is fed in a ring shape from all sides. Compared with the existing single powder feeding tube or double powder feeding tube, the powder feeding amount per unit time can be greatly increased, so that high concentration can be obtained. In particular, the use of high-concentration powder jet to block the radiation heating of the plasma jet to the workpiece substrate can reduce the thermal effect of the plasma jet on the workpiece substrate, so that even in a short spraying distance, the workpiece can be greatly relieved. The overall reduction in overall mechanical properties due to excessive heating also improves the thermal efficiency of the plasma spray heat source for heating powders. In addition, the powder has good heating uniformity in the plasma jet, which avoids the evaporation and burning of powder alloy elements due to overheating. The chemical composition of the spray coating is more similar to the original powder, and no harmful metal vapor is released into the environment, which is beneficial to Protect the health of operators and meet environmental protection requirements.

优选地,如图3所示,所述的阳极前部(1)有保护气体输送通道(5),其数量为3-6个,在阳极前部(1)的外圆周面上均匀分布。所述的保护气体输送通道(5)与喷管(6)相通,其与中心线的夹角B为10-85度。所述保护气体输送通道(5)与所述的粉末输送通道(4)相比,更靠近喷管(6)出口方向。所述的保护气体输送通道(5)将保护气体高速、均匀地送至等离子射流中,形成具有预先设计夹角B的锥形保护气流,并最终聚焦于中心轴上,在防止外界空气卷入等离子射流中的同时,进一步约束粉末,防止粉末发生发散,促进粉末聚焦在一起。Preferably, as shown in FIG. 3 , the anode front (1) has protective gas delivery channels (5), the number of which is 3-6, which are evenly distributed on the outer circumference of the anode front (1). The protective gas conveying channel (5) communicates with the nozzle (6), and the included angle B between it and the center line is 10-85 degrees. The protective gas conveying channel (5) is closer to the outlet direction of the nozzle (6) than the powder conveying channel (4). The protective gas delivery channel (5) sends the protective gas into the plasma jet at a high speed and evenly, forming a conical protective air flow with a pre-designed included angle B, and finally focuses on the central axis to prevent the outside air from being involved. While in the plasma jet, it further confines the powder, prevents the powder from spreading, and promotes the powder to focus together.

优选地,如图3所示,所述微孔阳极的喷管(6)为等离子体的流通通道,其出口内径D非常小,仅为0.5-3毫米。利用微孔阳极压缩效应获得能量密度集中、发散性小的等离子微射流,等离子微射流的斑点小,可以把射流加热工件的位置集中在微小的射流斑点区域内,在避免工件整体温度上升的同时,瞬间熔化待喷涂工件表面的局部区域,使得涂层与基体产生冶金结合。Preferably, as shown in FIG. 3 , the nozzle (6) of the microporous anode is a plasma circulation channel, and the inner diameter D of the outlet is very small, only 0.5-3 mm. The plasma microjet with concentrated energy density and small divergence is obtained by using the compression effect of the microporous anode. The spot of the plasma microjet is small, and the position of the jet heating the workpiece can be concentrated in the tiny jet spot area, while avoiding the overall temperature rise of the workpiece. , which instantly melts the local area of the surface of the workpiece to be sprayed, so that the coating and the substrate produce metallurgical bonding.

优选地,如图3所示,所述的喷管(6)沿出口方向其内径呈现收缩形式;或如图5所示,所述的喷管(6)沿出口方向上其内径保持不变;或如图6所示,所述的喷管(6)沿出口方向上其内径呈现扩张形式;或是上述形式的组合方式。Preferably, as shown in Fig. 3, the inner diameter of the nozzle (6) along the outlet direction is in a shrinking form; or as shown in Fig. 5, the inner diameter of the nozzle (6) along the outlet direction remains unchanged ; Or as shown in FIG. 6 , the inner diameter of the nozzle (6) along the outlet direction presents an expansion form; or a combination of the above forms.

优选地,如图7所示,所述的阳极前部(1)与阳极中部(2)分开为两个单独的零件,二者通过螺纹固定连接,并采用密封圈进行密封。Preferably, as shown in FIG. 7 , the anode front part (1) and the anode middle part (2) are separated into two separate parts, which are fixedly connected by screws and sealed with a sealing ring.

优选地,如图8所示,为了简化微孔阳极的结构,所述保护气体输送通道(6)可以安装在阳极的前部,或省略不要。Preferably, as shown in Fig. 8, in order to simplify the structure of the microporous anode, the protective gas delivery channel (6) can be installed at the front of the anode, or omitted.

所述的等离子喷枪为大气等离子喷枪、真空等离子喷枪、超音速等离子喷枪、微束等离子喷枪;等离子喷枪的等离子弧可为非转移型等离子弧,也可以为转移型等离子弧。The plasma spray guns are atmospheric plasma spray guns, vacuum plasma spray guns, supersonic plasma spray guns, and microbeam plasma spray guns; the plasma arc of the plasma spray gun can be a non-transfer plasma arc or a transfer plasma arc.

采用本发明的一种用于集束等离子喷枪的微孔阳极,与现有等离子喷枪相配合,获得集束等离子射流,从而形成集束等离子喷涂方法,其具体的操作步骤如下:A microporous anode for a cluster plasma spray gun of the present invention is adopted, and the existing plasma spray gun is matched to obtain a cluster plasma jet, thereby forming a cluster plasma spray method. The specific operation steps are as follows:

(a)将权利要求1所述的用于集束等离子喷枪的微孔阳极替换现有等离子喷枪的阳极,并做好固定和密封,获得集束等离子射流;(a) replace the anode of the existing plasma spray gun with the microporous anode of

(b)通过粉末输送通道(4)送入粉末和送粉气,通过保护气体输送通道(5)通入保护气;(b) feeding powder and powder feeding gas through the powder conveying passage (4), and feeding the shielding gas through the shielding gas conveying passage (5);

(c)按照等离子喷涂系统的操作程序开机,设置集束等离子喷涂的工艺参数,进行集束等离子喷涂;(c) Start the machine according to the operating procedure of the plasma spraying system, set the process parameters of the cluster plasma spraying, and carry out the cluster plasma spraying;

(d)集束等离子喷涂作业完成后按照设备操作程序关机。(d) After the cluster plasma spraying operation is completed, shut down the equipment according to the equipment operating procedures.

本发明的一种用于集束等离子喷枪的微孔阳极及集束等离子喷涂方法,将阳极出口内径限制在0.5-3毫米的范围内,利用微孔阳极压缩效应获得能量密度集中、发散性小的等离子微射流,等离子微射流的斑点小,适合用于精密零件、微小零件、薄壁零件的表面涂层加工,同时可以把射流加热工件的位置集中在微小的射流斑点区域内,在避免工件整体温度上升的同时,瞬间熔化待喷涂工件表面的局部区域,使得涂层与基体产生冶金结合;利用周向环形分布的粉末输送通道将粉末形成具有预先设计夹角、发散性小的锥形粉末流,使其在等离子微射流中的加热、加速更加均匀,从而获得化学成分均匀、微观结构致密、形成冶金结合的喷涂涂层。本发明结构简单,无需另外增加冷却循环装置,安装、拆卸、检查方便,工程应用广泛。The invention provides a microporous anode for a cluster plasma spray gun and a cluster plasma spraying method. The inner diameter of the anode outlet is limited within the range of 0.5-3 mm, and the microporous anode compression effect is used to obtain plasma with concentrated energy density and small divergence. Micro-jet, plasma micro-jet has small spots, suitable for surface coating processing of precision parts, tiny parts, and thin-walled parts. At the same time, the position of the jet heating workpiece can be concentrated in the tiny jet spot area, so as to avoid the overall temperature of the workpiece. At the same time of rising, the local area of the surface of the workpiece to be sprayed is instantly melted, so that the coating and the substrate are metallurgically combined; the powder is formed into a conical powder flow with a pre-designed angle and small divergence by using the powder conveying channel distributed in a circumferential ring. The heating and acceleration in the plasma microjet are more uniform, so as to obtain a spray coating with uniform chemical composition, dense microstructure and metallurgical bonding. The invention has a simple structure, does not need to add a cooling circulation device, is convenient for installation, disassembly and inspection, and is widely used in engineering.

本领域的技术人员容易理解的是,在不冲突的前提下,上述各优选方案自由地组合、叠加。Those skilled in the art can easily understand that, under the premise of no conflict, the above preferred solutions can be freely combined and superimposed.

以上所述仅为本发明的优选实施例,但本发明的实施方式并不受上述实施例的限制,其他的任何未背离本发明的精神实质与原理下所作的改变、修饰、替代、组合、简化,均应为等效的置换方式,都包含在本发明的保护范围之内。The above are only the preferred embodiments of the present invention, but the embodiments of the present invention are not limited by the above-mentioned embodiments, and any other changes, modifications, substitutions, combinations, The simplification should be equivalent replacement manners, which are all included in the protection scope of the present invention.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010225525.0ACN111286693A (en) | 2020-03-26 | 2020-03-26 | Microporous anode for cluster plasma spray gun and cluster plasma spraying method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010225525.0ACN111286693A (en) | 2020-03-26 | 2020-03-26 | Microporous anode for cluster plasma spray gun and cluster plasma spraying method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111286693Atrue CN111286693A (en) | 2020-06-16 |

Family

ID=71025994

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010225525.0APendingCN111286693A (en) | 2020-03-26 | 2020-03-26 | Microporous anode for cluster plasma spray gun and cluster plasma spraying method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111286693A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111885808A (en)* | 2020-07-22 | 2020-11-03 | 安徽工业大学 | An atmospheric pressure-cooled plasma jet flow-assisted focusing device |

| CN112647037A (en)* | 2020-12-17 | 2021-04-13 | 青岛科技大学 | Four-cathode plasma spraying spray gun device |

| CN112695268A (en)* | 2021-01-14 | 2021-04-23 | 四川大学 | Annular powder feeding and gas focusing device for supersonic plasma spraying |

| CN113913725A (en)* | 2021-09-02 | 2022-01-11 | 四川大学 | A gas-liquid phase separation nozzle device for plasma spraying physical vapor deposition |

| CN117282991A (en)* | 2023-09-25 | 2023-12-26 | 中国海洋大学 | Plasma spraying device for additive manufacturing |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07139424A (en)* | 1993-03-05 | 1995-05-30 | Nittan Valve Kk | Piston crown strengthening method |

| JPH09310134A (en)* | 1996-05-21 | 1997-12-02 | Ishikawajima Harima Heavy Ind Co Ltd | Ceramics dispersion strengthened Ti-Al based composite material using plasma arc and method for producing the same |

| RU2225084C1 (en)* | 2003-04-25 | 2004-02-27 | Суслов Виктор Иванович | Plasmatron |

| JP2011225959A (en)* | 2010-04-23 | 2011-11-10 | Tocalo Co Ltd | Method for strengthening surface layer of light metal or alloy thereof |

| CN213013056U (en)* | 2020-03-26 | 2021-04-20 | 天津大学 | A microporous anode for cluster plasma torch |

- 2020

- 2020-03-26CNCN202010225525.0Apatent/CN111286693A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07139424A (en)* | 1993-03-05 | 1995-05-30 | Nittan Valve Kk | Piston crown strengthening method |

| JPH09310134A (en)* | 1996-05-21 | 1997-12-02 | Ishikawajima Harima Heavy Ind Co Ltd | Ceramics dispersion strengthened Ti-Al based composite material using plasma arc and method for producing the same |

| RU2225084C1 (en)* | 2003-04-25 | 2004-02-27 | Суслов Виктор Иванович | Plasmatron |

| JP2011225959A (en)* | 2010-04-23 | 2011-11-10 | Tocalo Co Ltd | Method for strengthening surface layer of light metal or alloy thereof |

| CN213013056U (en)* | 2020-03-26 | 2021-04-20 | 天津大学 | A microporous anode for cluster plasma torch |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111885808A (en)* | 2020-07-22 | 2020-11-03 | 安徽工业大学 | An atmospheric pressure-cooled plasma jet flow-assisted focusing device |

| CN112647037A (en)* | 2020-12-17 | 2021-04-13 | 青岛科技大学 | Four-cathode plasma spraying spray gun device |

| CN112695268A (en)* | 2021-01-14 | 2021-04-23 | 四川大学 | Annular powder feeding and gas focusing device for supersonic plasma spraying |

| CN113913725A (en)* | 2021-09-02 | 2022-01-11 | 四川大学 | A gas-liquid phase separation nozzle device for plasma spraying physical vapor deposition |

| CN117282991A (en)* | 2023-09-25 | 2023-12-26 | 中国海洋大学 | Plasma spraying device for additive manufacturing |

| CN117282991B (en)* | 2023-09-25 | 2025-01-28 | 中国海洋大学 | Plasma spraying device for additive manufacturing |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111286693A (en) | Microporous anode for cluster plasma spray gun and cluster plasma spraying method | |

| CN104902666B (en) | A dual-flow supersonic plasma spray gun | |

| CN110302909B (en) | High-power hot cathode supersonic plasma spraying gun | |

| CN105132908A (en) | Gas turbine blade thermal barrier coating bonding layer and preparation method thereof | |

| JP2009001891A (en) | Nozzle for cold spray, and cold spray device using nozzle for cold spray | |

| CN101954324B (en) | Plasma spray gun for low-pressure plasma spraying | |

| CN110055484B (en) | Supersonic laser deposition spray gun, laser deposition device and laser deposition method | |

| CN107124814A (en) | A kind of many negative electrode laminar flow plasma powder spheroidization devices | |

| CN101162125A (en) | Split graphite crucible and method for preparing carbon coating inside the crucible | |

| CN103276394A (en) | Laser remelting one-step reinforcing processing method and device thereof for plasma sprayed thermal barrier coating with double-layer structure | |

| CN1281102C (en) | Double anode heat plasma generator | |

| CN213013056U (en) | A microporous anode for cluster plasma torch | |

| CN204244556U (en) | A laminar flow plasma gun body used for the treatment of the inner wall of the tunnel | |

| CN113529065A (en) | Method and device for preparing iridium metal coating based on cold spraying high-speed deposition additive manufacturing technology | |

| CN101289744A (en) | Supersonic reaction plasma spray gun | |

| CN104284503A (en) | A laminar flow plasma gun body used for the treatment of the inner wall of the tunnel | |

| CN210093634U (en) | Transfer arc plasma gun for producing metal nano powder | |

| CN108165923B (en) | Novel superhigh-speed high-enthalpy-value plasma spray gun and preparation process of WC-based composite coating | |

| CN210474360U (en) | A high-power hot cathode supersonic plasma spray gun | |

| CN114059024A (en) | Spray gun for plasma physical vapor deposition and thermal barrier coating preparation method | |

| CN110035596A (en) | Transferred arc plasma torch is used in a kind of production of metal nano powder | |

| CN112647037A (en) | Four-cathode plasma spraying spray gun device | |

| CN104302086A (en) | Plasma generator intake structure with gas compression effect | |

| CN115679240B (en) | High-energy plasma spray gun device and method for in-situ atomization of metal or ceramic powder | |

| CN109695013B (en) | Transferred arc supersonic speed plasma silk material spraying device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200616 |