CN111216498B - A kind of deformable multi-habitable robot and its control method - Google Patents

A kind of deformable multi-habitable robot and its control methodDownload PDFInfo

- Publication number

- CN111216498B CN111216498BCN202010180964.4ACN202010180964ACN111216498BCN 111216498 BCN111216498 BCN 111216498BCN 202010180964 ACN202010180964 ACN 202010180964ACN 111216498 BCN111216498 BCN 111216498B

- Authority

- CN

- China

- Prior art keywords

- wheel

- attitude

- robot

- front wheel

- angle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription28

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription182

- 238000007667floatingMethods0.000claimsabstractdescription13

- 230000005484gravityEffects0.000claimsdescription72

- 230000007246mechanismEffects0.000claimsdescription49

- 230000001131transforming effectEffects0.000claimsdescription22

- 230000008569processEffects0.000claimsdescription18

- 238000012546transferMethods0.000claimsdescription13

- 230000009189divingEffects0.000claimsdescription12

- 238000007789sealingMethods0.000claimsdescription12

- 230000001105regulatory effectEffects0.000claimsdescription11

- 238000005192partitionMethods0.000claimsdescription9

- 239000000446fuelSubstances0.000claimsdescription7

- 230000033001locomotionEffects0.000claimsdescription7

- 230000009471actionEffects0.000claimsdescription5

- 230000004888barrier functionEffects0.000claimsdescription4

- 238000005096rolling processMethods0.000claimsdescription3

- 238000004891communicationMethods0.000claimsdescription2

- 239000012528membraneSubstances0.000claims1

- 230000036544postureEffects0.000abstractdescription26

- 238000006243chemical reactionMethods0.000abstract1

- 238000010586diagramMethods0.000description14

- 230000007704transitionEffects0.000description8

- 230000008859changeEffects0.000description2

- 230000001360synchronised effectEffects0.000description2

- 208000028804PERCHING syndromeDiseases0.000description1

- 230000009286beneficial effectEffects0.000description1

- 238000005516engineering processMethods0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 238000011160researchMethods0.000description1

- 238000004804windingMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60F—VEHICLES FOR USE BOTH ON RAIL AND ON ROAD; AMPHIBIOUS OR LIKE VEHICLES; CONVERTIBLE VEHICLES

- B60F5/00—Other convertible vehicles, i.e. vehicles capable of travelling in or on different media

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B19/00—Wheels not otherwise provided for or having characteristics specified in one of the subgroups of this group

- B60B19/02—Wheels not otherwise provided for or having characteristics specified in one of the subgroups of this group convertible, e.g. from road wheel to rail wheel; Wheels specially designed for alternative use on road and rail

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60F—VEHICLES FOR USE BOTH ON RAIL AND ON ROAD; AMPHIBIOUS OR LIKE VEHICLES; CONVERTIBLE VEHICLES

- B60F5/00—Other convertible vehicles, i.e. vehicles capable of travelling in or on different media

- B60F5/02—Other convertible vehicles, i.e. vehicles capable of travelling in or on different media convertible into aircraft

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L50/00—Electric propulsion with power supplied within the vehicle

- B60L50/50—Electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells

- B60L50/75—Electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells using propulsion power supplied by both fuel cells and batteries

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C27/00—Rotorcraft; Rotors peculiar thereto

- B64C27/22—Compound rotorcraft, i.e. aircraft using in flight the features of both aeroplane and rotorcraft

- B64C27/26—Compound rotorcraft, i.e. aircraft using in flight the features of both aeroplane and rotorcraft characterised by provision of fixed wings

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C29/00—Aircraft capable of landing or taking-off vertically, e.g. vertical take-off and landing [VTOL] aircraft

- B64C29/0008—Aircraft capable of landing or taking-off vertically, e.g. vertical take-off and landing [VTOL] aircraft having its flight directional axis horizontal when grounded

- B64C29/0016—Aircraft capable of landing or taking-off vertically, e.g. vertical take-off and landing [VTOL] aircraft having its flight directional axis horizontal when grounded the lift during taking-off being created by free or ducted propellers or by blowers

- B64C29/0033—Aircraft capable of landing or taking-off vertically, e.g. vertical take-off and landing [VTOL] aircraft having its flight directional axis horizontal when grounded the lift during taking-off being created by free or ducted propellers or by blowers the propellers being tiltable relative to the fuselage

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C35/00—Flying-boats; Seaplanes

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64D—EQUIPMENT FOR FITTING IN OR TO AIRCRAFT; FLIGHT SUITS; PARACHUTES; ARRANGEMENT OR MOUNTING OF POWER PLANTS OR PROPULSION TRANSMISSIONS IN AIRCRAFT

- B64D27/00—Arrangement or mounting of power plants in aircraft; Aircraft characterised by the type or position of power plants

- B64D27/02—Aircraft characterised by the type or position of power plants

- B64D27/24—Aircraft characterised by the type or position of power plants using steam or spring force

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64U—UNMANNED AERIAL VEHICLES [UAV]; EQUIPMENT THEREFOR

- B64U10/00—Type of UAV

- B64U10/10—Rotorcrafts

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64U—UNMANNED AERIAL VEHICLES [UAV]; EQUIPMENT THEREFOR

- B64U30/00—Means for producing lift; Empennages; Arrangements thereof

- B64U30/20—Rotors; Rotor supports

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64U—UNMANNED AERIAL VEHICLES [UAV]; EQUIPMENT THEREFOR

- B64U50/00—Propulsion; Power supply

- B64U50/10—Propulsion

- B64U50/13—Propulsion using external fans or propellers

- B64U50/14—Propulsion using external fans or propellers ducted or shrouded

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64U—UNMANNED AERIAL VEHICLES [UAV]; EQUIPMENT THEREFOR

- B64U50/00—Propulsion; Power supply

- B64U50/10—Propulsion

- B64U50/19—Propulsion using electrically powered motors

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02T90/40—Application of hydrogen technology to transportation, e.g. using fuel cells

Landscapes

- Engineering & Computer Science (AREA)

- Aviation & Aerospace Engineering (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Remote Sensing (AREA)

- Power Engineering (AREA)

- Toys (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于机器人技术领域,特别是涉及一种变形多栖机器人及控制方法。The invention belongs to the technical field of robots, and in particular relates to a deformable multi-robot and a control method.

背景技术Background technique

根据工作环境的不同,机器人可分为空中飞行类机器人、陆地航行类机器人和水中航行类机器人。空中方面,最有代表的便是无人机,而无人机目前已经广泛的应用到诸多领域和行业中。陆地方面,轮式、履带式、肢节式机器人都在快速发展,技术也越发成熟,同样也已经广泛的应用到诸多领域和行业中。水中方面,无论是水面航行器,还是潜航器,在水文科研、资源勘探等领域的地位已经越来越重要。According to the different working environments, robots can be divided into air-flying robots, land-navigating robots and underwater-navigating robots. In the air, the most representative is the UAV, and UAV has been widely used in many fields and industries. In terms of land, wheeled, crawler, and segmented robots are developing rapidly, and the technology is becoming more and more mature, and they have also been widely used in many fields and industries. In terms of water, whether it is a surface vehicle or a submersible, its status has become more and more important in the fields of hydrological scientific research and resource exploration.

目前,种类繁多的机器人主要以单栖机器人为主,但面对复杂的工作环境,单栖单栖机器人越来越难以完成任务,为此越来越多的两栖机器人逐渐被研发和制造,虽然两栖机器人能够在一定程度上弥补单栖机器人的弱点,但在复杂的工作环境下仍然存在很大的局限性,特殊情况下两栖机器人仍然不能很好的完成任务目标。At present, a wide variety of robots are mainly mono-habitable robots, but in the face of complex working environments, it is more and more difficult for mono- and mono-habitable robots to complete tasks. For this reason, more and more amphibious robots are gradually developed and manufactured. Although Amphibious robots can make up for the weaknesses of single-sided robots to a certain extent, but they still have great limitations in complex working environments.

发明内容SUMMARY OF THE INVENTION

针对现有技术存在的问题,本发明提供一种变形多栖机器人及控制方法,能够实现水陆空三栖作业,能够在复杂工作环境下无间隙的进行不同工作模式下的转换,为完成特殊情况下的任务目标提供了可行性方案。Aiming at the problems existing in the prior art, the present invention provides a deformable multi-habitable robot and a control method, which can realize amphibious operations, and can switch between different working modes without gaps in a complex working environment. The mission objectives provide a feasible solution.

为了实现上述目的,本发明采用如下技术方案:一种变形多栖机器人,包括机身、机翼、多功能车轮及车轮姿态调整组件,所述机翼数量为两个,两个机翼对称安装在机身顶部左右两侧;所述多功能车轮数量为四个,四个多功能车轮在机身四周均布设置,机身与每个多功能车轮之间均通过车轮姿态调整组件相连。In order to achieve the above purpose, the present invention adopts the following technical solutions: a deformable multi-robot, including a fuselage, wings, multi-functional wheels and wheel attitude adjustment components, the number of the wings is two, and the two wings are installed symmetrically On the left and right sides of the top of the fuselage; the number of the multifunctional wheels is four, and the four multifunctional wheels are evenly arranged around the fuselage, and the fuselage and each multifunctional wheel are connected by a wheel attitude adjustment component.

所述机身内部分别设有前货仓、中部货仓、后货仓、左货仓及右货仓;所述中部货仓分为上下两层,两层之间由密封隔板进行分隔,上层空间用于储物,在下层空间分别安装有主控制器、重心调节器、通讯器、压力调节器、电源管理器及卫星导航器;在所述机身前端安装有图像识别相机、激光雷达及空速管;所述左货仓分为上下两层,两层之间由密封隔板进行分隔,上层空间用于储物,下层空间包括第一机身重心调节室和第一蓄水舱,在第一机身重心调节室内安装有第一机身重心调节机构,在第一机身重心调节机构上设置有蓄水舱调压组件;所述右货仓分为上下两层,两层之间由密封隔板进行分隔,上层空间用于储物,下层空间包括第二机身重心调节室和第二蓄水舱,在第二机身重心调节室内安装有第二机身重心调节机构,在第二机身重心调节机构上设置有中枢供能组件;在所述第一蓄水舱和第二蓄水舱内均设置有水压传感器;所述第一机身重心调节室与第二机身重心调节室左右对称分布,所述第一蓄水舱与第二蓄水舱左右对称分布。The interior of the fuselage is respectively provided with a front warehouse, a middle warehouse, a rear warehouse, a left warehouse and a right warehouse; the middle warehouse is divided into upper and lower layers, and the two layers are separated by a sealing partition. The upper space is used for storage, and the main controller, the center of gravity regulator, the communication device, the pressure regulator, the power manager and the satellite navigator are respectively installed in the lower space; the front of the fuselage is installed with an image recognition camera and a laser radar. and pitot; the left cargo compartment is divided into upper and lower layers, the two layers are separated by a sealed partition, the upper space is used for storage, and the lower space includes the first fuselage center of gravity adjustment room and the first water storage tank , a first fuselage center of gravity adjustment mechanism is installed in the first fuselage center of gravity adjustment chamber, and a water storage tank pressure regulating assembly is installed on the first fuselage center of gravity adjustment mechanism; the right cargo compartment is divided into upper and lower layers, two layers They are separated by sealed partitions, the upper space is used for storage, the lower space includes the second fuselage center of gravity adjustment chamber and the second water storage tank, and the second fuselage center of gravity adjustment mechanism is installed in the second fuselage center of gravity adjustment chamber , a central energy supply assembly is arranged on the second fuselage center of gravity adjustment mechanism; a water pressure sensor is arranged in both the first water storage tank and the second water storage tank; the first fuselage center of gravity adjustment chamber and the The center of gravity adjustment chambers of the two fuselage are symmetrically distributed on the left and right, and the first water storage tank and the second water storage tank are symmetrically distributed on the left and right.

所述第一机身重心调节机构和第二机身重心调节机构结构相同,均包括矢量电机、主动带轮、从动带轮、皮带、导向滑轨、滑块及滑台板;所述导向滑轨采用平行双轨结构,所述皮带传动连接在主动带轮与从动带轮之间,皮带位于两根导向滑轨中间,皮带与导向滑轨相平行,所述主动带轮固装在矢量电机的电机轴上;所述滑块安装在导向滑轨上,所述滑台板水平固装在滑块上,滑台板通过滑块可沿导向滑轨直线移动,滑台板下表面与皮带相固连;所述蓄水舱调压组件安装在第一机身重心调节机构的滑台板上,所述中枢供能组件安装在第二机身重心调节机构的滑台板上。The first fuselage center of gravity adjustment mechanism and the second fuselage center of gravity adjustment mechanism have the same structure, including a vector motor, a driving pulley, a driven pulley, a belt, a guide rail, a slider and a sliding table; the guide The slide rail adopts a parallel double rail structure, the belt drive is connected between the driving pulley and the driven pulley, the belt is located between the two guide slide rails, the belt is parallel to the guide slide rail, and the driving pulley is fixed on the vector On the motor shaft of the motor; the slider is installed on the guide rail, the slider plate is horizontally fixed on the slider, the slider plate can move linearly along the guide rail through the slider, and the lower surface of the slider plate is in line with the guide rail. The belts are fixedly connected to each other; the water storage tank pressure regulating component is installed on the sliding platform of the first fuselage center of gravity adjustment mechanism, and the central energy supply component is installed on the sliding platform of the second fuselage center of gravity adjustment mechanism.

所述第一蓄水舱和第二蓄水舱结构相同,均分为上下两层,两层之间由隔水膜进行分隔,上层空间作为气体仓,下层空间作为水仓,所述水仓的仓底板上开设有通水孔,水仓通过通水孔与机身外部连通,在通水孔处设置有电动密封盖;所述蓄水舱调压组件包括空压机及高压气瓶,空压机的吸气口通过管路与气体仓相连通,空压机的排气口与高压气瓶的进气口相连通,高压气瓶的出气口通过管路与气体仓相连通。The first water storage tank and the second water storage tank have the same structure and are divided into upper and lower layers. The two layers are separated by a water barrier film. The upper space is used as a gas silo, and the lower space is used as a water silo. The bottom of the silo is provided with a water hole, the water silo is communicated with the outside of the fuselage through the water hole, and an electric sealing cover is arranged at the water hole; the pressure regulating component of the water storage tank includes an air compressor and a high-pressure gas cylinder, The suction port of the air compressor is communicated with the gas silo through the pipeline, the exhaust port of the air compressor is communicated with the air inlet of the high-pressure gas cylinder, and the air outlet of the high-pressure gas cylinder is communicated with the gas silo through the pipeline.

所述中枢供能组件包括燃料电池、蓄电池及电源转换器,所述燃料电池和蓄电池通过电源线与电源转换器的电力输入端口相连,电源转换器的电力输出端口通过电源线为机器人的全部用电部件进行供电。The central energy supply assembly includes a fuel cell, a battery and a power converter. The fuel cell and the battery are connected to the power input port of the power converter through a power cord, and the power output port of the power converter is used for all the functions of the robot through the power cord. Electrical components are powered.

所述机翼上表面安装有太阳能电池,在机翼的翼根处连接有机翼收展驱动电机,机翼收展驱动电机嵌装在机身上。A solar cell is installed on the upper surface of the wing, a wing extension drive motor is connected to the wing root of the wing, and the wing extension drive motor is embedded on the fuselage.

所述车轮姿态调整组件包括第一调姿电机、第一支臂、第二调姿电机及第二支臂,所述第一调姿电机嵌装在机身上,所述第一支臂一端固连在第一调姿电机的电机轴上,第一支臂另一端与第二支臂一端相铰接,所述多功能车轮连接在第二支臂另一端;所述第二调姿电机安装在第一支臂与第二支臂的铰接处,第二调姿电机用于驱动第二支臂做摆转运动,所述第一调姿电机用于驱动第一支臂做回转运动。The wheel attitude adjustment assembly includes a first attitude adjustment motor, a first support arm, a second attitude adjustment motor and a second support arm, the first attitude adjustment motor is embedded on the fuselage, and one end of the first support arm is It is fixedly connected to the motor shaft of the first attitude adjustment motor, the other end of the first support arm is hinged with one end of the second support arm, and the multifunctional wheel is connected to the other end of the second support arm; the second attitude adjustment motor is installed At the hinge joint between the first support arm and the second support arm, the second attitude adjustment motor is used to drive the second support arm to perform a swing motion, and the first attitude adjustment motor is used to drive the first support arm to perform a rotary motion.

所述多功能车轮包括橡胶轮胎、原磁体轮毂、电磁套筒、转接轴及涵道动力机构;所述橡胶轮胎固定套装在原磁体轮毂上,原磁体轮毂套装在电磁套筒上,原磁体轮毂内表面与电磁套筒外表面滑动接触配合;所述涵道动力机构位于电磁套筒内侧,所述转接轴穿过原磁体轮毂的中心孔,转接轴一端与第二支臂相固连,所述涵道动力机构连接在转接轴的另一端。The multifunctional wheel includes a rubber tire, an original magnet hub, an electromagnetic sleeve, an adapter shaft and a duct power mechanism; the rubber tire is fixedly sleeved on the original magnet hub, the original magnet hub is sleeved on the electromagnetic sleeve, and the original magnet hub is sleeved. The inner surface is in sliding contact with the outer surface of the electromagnetic sleeve; the duct power mechanism is located inside the electromagnetic sleeve, the transfer shaft passes through the central hole of the original magnet hub, and one end of the transfer shaft is fixedly connected with the second arm , the duct power mechanism is connected to the other end of the transfer shaft.

所述涵道动力机构包括叶片、外转子电机及整流罩;所述外转子电机的内定子轴与转接轴相固连,外转子电机的转子外套上均布有若干叶片安装座,叶片安装座采用直杆形结构,每个叶片安装座上均固装有一个叶片,叶片的根部固连在叶片安装座上,在叶片的顶部中心固设有销柱,在所述电磁套筒的内表面开设有销孔,销柱位于销孔内,销柱可在销孔内自由转动;在所述外转子电机的转子外套表面开设有滑槽,叶片安装座滑动连接在滑槽内,所述整流罩扣装在外转子电机顶部,在整流罩内部的外转子电机上设置有叶片转角调整电机,在叶片转角调整电机的电机轴上串联固装有第一卷线轮和第二卷线轮,在所述外转子电机上分别设置有第一导向器、第二导向器、第一分向柱及第二分向柱,所述第一卷线轮与线索一端缠绕连接,线索另一端首先穿过第一导向器,再绕过第一分向柱,然后依次固定穿过所有叶片安装座端部穿线孔,之后再绕过第二分向柱,最后穿过第二导向器后缠绕连接在第二卷线轮上,且线索在第一卷线轮和第二卷线轮上的缠绕方向相反。The ducted power mechanism includes blades, an outer rotor motor and a fairing; the inner stator shaft of the outer rotor motor is fixedly connected with the transfer shaft, and a plurality of blade mounting seats are evenly distributed on the rotor jacket of the outer rotor motor. The seat adopts a straight rod-shaped structure, each blade mounting seat is fixed with a blade, the root of the blade is fixed on the blade mounting seat, a pin is fixed at the top center of the blade, and the inner part of the electromagnetic sleeve is fixed. A pin hole is opened on the surface, the pin is located in the pin hole, and the pin can rotate freely in the pin hole; a chute is opened on the surface of the outer casing of the rotor of the outer rotor motor, and the blade mounting seat is slidably connected in the chute, the The fairing is fastened on the top of the outer rotor motor, a blade angle adjustment motor is arranged on the outer rotor motor inside the fairing, and a first reel and a second reel are fixed in series on the motor shaft of the blade angle adjustment motor. A first guide, a second guide, a first diverting column and a second diverting column are respectively arranged on the outer rotor motor, the first reel is wound and connected to one end of the thread, and the other end of the thread is first threaded Pass through the first guide, then bypass the first shunt column, and then fix it through the thread holes at the end of all blade mounts in turn, then bypass the second shunt column, and finally pass through the second guide and then wrap around and connect it in on the second reel, and the thread is wound in opposite directions on the first reel and the second reel.

所述的变形多栖机器人的控制方法,包括如下步骤:The control method of the deformable multi-habitable robot includes the following steps:

步骤一:设定变形多栖机器人的工作模式,分别为地面工作模式、空中工作模式、水面工作模式及水下工作模式;Step 1: Set the working modes of the deformable multi-robot, which are ground working mode, aerial working mode, surface working mode and underwater working mode;

步骤二:设定叶片转角,分别为第一档叶片转角、第二档叶片转角及第三档叶片转角;当叶片处于第一档叶片转角时,涵道动力机构不产生推力;当叶片处于第二档叶片转角时,涵道动力机构在空中产生最大推力;当叶片处于第三档叶片转角时,涵道动力机构在水中产生最大推力;Step 2: Set the blade rotation angle, which are the first-speed blade rotation angle, the second-speed blade rotation angle and the third-speed blade rotation angle; when the blade is at the first-speed blade rotation angle, the duct power mechanism does not generate thrust; When the second-gear blade angle, the duct power mechanism generates the maximum thrust in the air; when the blade is at the third-gear blade angle, the duct power mechanism generates the maximum thrust in the water;

步骤三:设定机翼展角,分别为第一档机翼展角、第二档机翼展角及第三档机翼展角;当机翼处于第一档机翼展角时,机翼在空中不产生升力;当机翼处于第二档机翼展角时,机翼在空中产生中等升力;当机翼处于第三档机翼展角时,机翼在空中产生最大升力;Step 3: Set the wing span angle, which are the first gear span angle, the second gear span angle and the third gear span angle; when the wing is in the first gear span angle, the The wing does not produce lift in the air; when the wing is in the second gear span, the wing produces moderate lift in the air; when the wing is in the third gear, the wing produces the maximum lift in the air;

步骤四:设定车轮姿态,分别为地面行驶姿态、空中垂直飞行姿态、空中水平飞行姿态、水面滑行姿态、水中水平航行姿态、水中下潜姿态及水中上浮姿态;当车轮姿态处于地面行驶姿态时,四个车轮的姿态相同,四个车轮姿态调整组件中的第一支臂与第二支臂的夹角均为90°,左前车轮和左后车轮均水平朝向机身左侧,右前车轮和右后车轮均水平朝向机身右侧;当车轮姿态处于空中垂直飞行姿态时,四个车轮的姿态相同,四个车轮姿态调整组件中的第一支臂与第二支臂的夹角均为90°,四个车轮均竖直朝向机身正上方;当车轮姿态处于空中水平飞行姿态或水中水平航行姿态时,四个车轮的姿态相同,车轮姿态调整组件中的第一支臂与第二支臂的夹角均为180°,左前车轮和右前车轮均水平朝向机身正前方,左后车轮和右后车轮均水平朝向机身正后方;当车轮姿态处于水面滑行姿态时,左前车轮和右前车轮的姿态相同,左后车轮和右后车轮的姿态相同,左前车轮和右前车轮的车轮姿态调整组件中的第一支臂与第二支臂的夹角均为120°,左前车轮和右前车轮均倾斜朝向机身斜上方,左后车轮和右后车轮的车轮姿态调整组件中的第一支臂与第二支臂的夹角均为180°,左后车轮和右后车轮均水平朝向机身正后方;当车轮姿态处于水中下潜姿态时,左前车轮和右前车轮的姿态相同,左后车轮和右后车轮的姿态相同,左前车轮和右前车轮的车轮姿态调整组件中的第一支臂与第二支臂的夹角均为90°~120°,左前车轮和右前车轮均倾斜朝向机身斜下方,下潜过程中左前车轮和右前车轮相对于水体始终保持竖直朝下,左后车轮和右后车轮的车轮姿态调整组件中的第一支臂与第二支臂的夹角均为180°,左后车轮和右后车轮均水平朝向机身正后方;当车轮姿态处于水中上浮姿态时,左前车轮和右前车轮的姿态相同,左后车轮和右后车轮的姿态相同,左前车轮和右前车轮的车轮姿态调整组件中的第一支臂与第二支臂的夹角均为90°~120°,左前车轮和右前车轮均倾斜朝向机身斜上方,上浮过程中左前车轮和右前车轮相对于水体始终保持竖直朝上,左后车轮和右后车轮的车轮姿态调整组件中的第一支臂与第二支臂的夹角均为180°,左后车轮和右后车轮均水平朝向机身正后方;Step 4: Set the wheel attitudes, which are ground driving attitude, vertical flight attitude in air, horizontal flight attitude in air, surface taxi attitude, horizontal sailing attitude in water, underwater diving attitude and water floating attitude; when the wheel attitude is in the ground driving attitude , the posture of the four wheels is the same, the angle between the first arm and the second arm in the four wheel posture adjustment components is 90°, the left front wheel and the left rear wheel are horizontally facing the left side of the fuselage, the right front wheel and the The right rear wheels are horizontally facing the right side of the fuselage; when the wheel attitude is in the vertical flight attitude in the air, the attitudes of the four wheels are the same, and the angle between the first arm and the second arm in the four wheel attitude adjustment components is the same. 90°, the four wheels are vertically facing the top of the fuselage; when the wheel attitude is in the horizontal flight attitude in the air or the horizontal sailing attitude in the water, the attitude of the four wheels is the same, and the first arm and the second arm in the wheel attitude adjustment assembly are in the same position. The included angles of the arms are all 180°, the left front wheel and the right front wheel are horizontally facing the front of the fuselage, and the left rear wheel and the right rear wheel are horizontally facing the rear of the fuselage; The posture of the right front wheel is the same, the posture of the left rear wheel and the right rear wheel is the same, the angle between the first arm and the second arm in the wheel posture adjustment assembly of the left front wheel and the right front wheel is 120°, The wheels are inclined towards the top of the fuselage, the angle between the first arm and the second arm in the wheel attitude adjustment components of the left rear wheel and the right rear wheel are both 180°, and the left rear wheel and the right rear wheel are horizontally oriented. Right behind the fuselage; when the wheel attitude is in the underwater diving attitude, the attitude of the left front wheel and the right front wheel are the same, the attitude of the left rear wheel and the right rear wheel are the same, the first one in the wheel attitude adjustment assembly of the left front wheel and the right front wheel The included angle between the arm and the second arm is 90°~120°, the left front wheel and the right front wheel are inclined towards the downward direction of the fuselage. The angle between the first arm and the second arm in the wheel attitude adjustment assembly of the rear wheel and the right rear wheel is both 180°, and the left rear wheel and the right rear wheel are horizontally facing the rear of the fuselage; when the wheel attitude is in the water In the floating attitude, the left front wheel and the right front wheel have the same attitude, the left rear wheel and the right rear wheel have the same attitude, and the angle between the first arm and the second arm in the wheel attitude adjustment assembly of the left front wheel and the right front wheel is the same. 90°~120°, the left front wheel and the right front wheel are inclined towards the fuselage diagonally upward, and the left front wheel and the right front wheel are always kept vertically upward relative to the water body during the floating process. The angle between the first arm and the second arm is 180°, and the left and right rear wheels are horizontally facing the rear of the fuselage;

步骤五:执行地面工作模式、空中工作模式、水面工作模式或水下工作模式,以及在不同工作模式间转换;Step 5: Execute ground work mode, aerial work mode, surface work mode or underwater work mode, and switch between different work modes;

一、地面工作模式1. Ground working mode

叶片转角调整到第一档叶片转角,机翼展角调整到第一档机翼展角,车轮姿态调整到地面行驶姿态,电磁套筒通电,使电磁套筒与原磁体轮毂吸附在一起,外转子电机启动,依次带动叶片、电磁套筒、原磁体轮毂及橡胶轮胎转动,使变形多栖机器人行驶在地面上;The blade rotation angle is adjusted to the first gear blade rotation angle, the wing span angle is adjusted to the first gear wingspan angle, the wheel attitude is adjusted to the ground driving attitude, the electromagnetic sleeve is energized, so that the electromagnetic sleeve and the original magnet hub are adsorbed together. The rotor motor is started, which in turn drives the blades, the electromagnetic sleeve, the original magnet hub and the rubber tires to rotate, so that the deformed multi-robot drives on the ground;

二、地面工作模式转换到空中工作模式2. Convert the ground working mode to the air working mode

①、垂直起飞①、Vertical take-off

首先使变形多栖机器人静止在地面上,叶片转角调整到第二档叶片转角,机翼展角调整到第二档机翼展角,车轮姿态调整到空中垂直飞行姿态,电磁套筒断电,电磁套筒与原磁体轮毂脱离吸附,外转子电机启动,依次带动叶片及电磁套筒转动,此时叶片产生向下的推力,使变形多栖机器人垂直升空;Firstly, make the deformable multi-robot stationary on the ground, adjust the blade rotation angle to the second gear blade rotation angle, adjust the wing span angle to the second gear wingspan angle, adjust the wheel attitude to the vertical flight attitude in the air, the electromagnetic sleeve is powered off, The electromagnetic sleeve is de-adsorbed from the original magnet hub, and the outer rotor motor starts, which drives the blades and the electromagnetic sleeve to rotate in turn. At this time, the blades generate downward thrust, which makes the deformed multi-robot lift vertically;

②、慢速行驶起飞②, take off at a slow speed

变形多栖机器人保持地面慢速行驶状态,机翼展角调整到第二档机翼展角,右前车轮和左后车轮翻转到竖直朝上状态,电磁套筒断电,然后将右前车轮和左后车轮内的叶片转角调整到第二档叶片转角,使右前车轮和左后车轮内的叶片产生向下的推力,变形多栖机器人在叶片推力作用下初步离开地面,同时完成变形多栖机器人的重心调整,然后关闭左前车轮和右后车轮内的外转子电机,再将左前车轮翻转到水平朝前状态,将右后车轮翻转到水平朝后状态,电磁套筒断电,然后将左前车轮和右后车轮内的叶片转角调整到第二档叶片转角,之后重新启动左前车轮和右后车轮内的外转子电机,使左前车轮和右后车轮内的叶片产生向后的推力,当变形多栖机器人完全离开地面后,先关闭右前车轮和左后车轮内的外转子电机,再将右前车轮翻转到水平朝前状态,将左后车轮翻转到水平朝后状态,同时将机翼展角调整到第三档机翼展角,然后重新启动右前车轮和左后车轮内的外转子电机,使右前车轮和左后车轮内的叶片产生向后的推力,此时变形多栖机器人的车轮姿态完全调整到空中水平飞行姿态,变形多栖机器人在空中水平飞行姿态下实现高速飞行;The transforming multi-robot keeps running at a slow speed on the ground, the wingspan is adjusted to the second wing span, the right front wheel and the left rear wheel are turned upright, the electromagnetic sleeve is powered off, and then the right front wheel and the left rear wheel are turned upright. The blade rotation angle in the left rear wheel is adjusted to the second gear blade rotation angle, so that the blades in the right front wheel and the left rear wheel generate downward thrust. Adjust the center of gravity, then turn off the outer rotor motors in the left front wheel and the right rear wheel, then turn the left front wheel to a horizontal forward state, turn the right rear wheel to a horizontal rearward state, power off the electromagnetic sleeve, and then turn the left front wheel And the blade angle in the right rear wheel is adjusted to the second gear blade angle, and then the outer rotor motor in the left front wheel and the right rear wheel is restarted, so that the blades in the left front wheel and the right rear wheel generate backward thrust. After the robo-robot completely leaves the ground, first turn off the outer rotor motors in the right front wheel and the left rear wheel, then turn the right front wheel to a horizontal forward state, turn the left rear wheel to a horizontal rearward state, and adjust the wingspan angle at the same time. To the third gear span angle, and then restart the outer rotor motors in the right front wheel and the left rear wheel, so that the blades in the right front wheel and the left rear wheel generate backward thrust, at this time, the wheel posture of the deformed multi-robot is completely Adjust to the horizontal flight attitude in the air, and the deformable multi-robot can achieve high-speed flight in the horizontal flight attitude in the air;

③、高速滑跑起飞③, high-speed rolling takeoff

变形多栖机器人保持地面高速行驶状态,机翼展角调整到第三档机翼展角,变形多栖机器人在机翼升力作用下初步离开地面,同时完成变形多栖机器人的重心调整,先关闭右前车轮和左后车轮内的外转子电机,然后将右前车轮翻转到水平朝前状态,将左后车轮翻转到水平朝后状态,电磁套筒断电,再将右前车轮和左后车轮内的叶片转角调整到第二档叶片转角,然后重新启动右前车轮和左后车轮内的外转子电机,使右前车轮和左后车轮内的叶片产生向后的推力,当变形多栖机器人完全离开地面后,先关闭左前车轮和右后车轮内的外转子电机,然后将左前车轮翻转到水平朝前状态,将右后车轮翻转到水平朝后状态,电磁套筒断电,再将左前车轮和右后车轮内的叶片转角调整到第二档叶片转角,然后重新启动左前车轮和右后车轮内的外转子电机,使左前车轮和右后车轮内的叶片产生向后的推力,此时变形多栖机器人的车轮姿态完全调整到空中水平飞行姿态,变形多栖机器人在空中水平飞行姿态下实现高速飞行;The transforming multi-robot keeps the ground running at a high speed, and the wing span is adjusted to the third gear. The outer rotor motor in the right front wheel and the left rear wheel, then turn the right front wheel to the horizontal forward state, turn the left rear wheel to the horizontal rearward state, power off the electromagnetic sleeve, and then turn the right front wheel and the left rear wheel. The blade rotation angle is adjusted to the second gear blade rotation angle, and then the outer rotor motors in the right front wheel and the left rear wheel are restarted, so that the blades in the right front wheel and the left rear wheel generate a backward thrust. When the deformed multi-robot completely leaves the ground , first turn off the outer rotor motors in the left front wheel and the right rear wheel, then turn the left front wheel to the horizontal forward state, turn the right rear wheel to the horizontal rearward state, power off the electromagnetic sleeve, and then turn the left front wheel and the right rear wheel. The blade rotation angle in the wheel is adjusted to the second gear blade rotation angle, and then the outer rotor motors in the left front wheel and the right rear wheel are restarted, so that the blades in the left front wheel and the right rear wheel generate backward thrust, and the deformed multi-robot is at this time. The wheel attitude of the robot is completely adjusted to the horizontal flight attitude in the air, and the deformable multi-robot can achieve high-speed flight in the horizontal flight attitude in the air;

三、空中工作模式3. Air work mode

①、多旋翼飞行①、Multi-rotor flight

在变形多栖机器人垂直升空后,四个车轮内的叶片均产生向下的推力,此过程中只需改变车轮的倾斜角度,就可以实现多旋翼飞行转向;After the transforming multi-robot takes off vertically, the blades in the four wheels all generate downward thrust. In this process, the multi-rotor flight steering can be realized only by changing the inclination angle of the wheels;

②、固定翼飞行②, fixed wing flight

在变形多栖机器人慢速行驶起飞或高速滑跑起飞后,四个车轮内的叶片均产生向后的推力,此过程中只需改变车轮的倾斜角度,就可以实现固定翼飞行转向;After the transforming multi-robot takes off at a slow speed or rolls off at a high speed, the blades in the four wheels all generate backward thrust. In this process, the fixed-wing flight steering can be realized only by changing the inclination angle of the wheels;

③、多旋翼飞行转换为固定翼飞行3. Convert multi-rotor flight to fixed-wing flight

变形多栖机器人进行多旋翼飞行时,先关闭左前车轮和右后车轮内的外转子电机,同时完成变形多栖机器人的重心调整,然后将左前车轮翻转到水平朝前状态,将右后车轮翻转到水平朝后状态,再重新启动左前车轮和右后车轮内的外转子电机,使左前车轮和右后车轮内的叶片产生向后的推力,同时将机翼展角调整到第三档机翼展角,之后关闭右前车轮和左后车轮内的外转子电机,然后将右前车轮翻转到水平朝前状态,将左后车轮翻转到水平朝后状态,最后重新启动右前车轮和左后车轮内的外转子电机,使右前车轮和左后车轮内的叶片产生向后的推力,此时变形多栖机器人的车轮姿态完全调整到空中水平飞行姿态,变形多栖机器人在空中水平飞行姿态下实现高速飞行;When the transforming multi-robot is flying with multi-rotors, first turn off the outer rotor motors in the left front wheel and the right rear wheel, and at the same time complete the center of gravity adjustment of the transforming multi-robot, then turn the left front wheel to a horizontal forward state, and turn the right rear wheel over. To the horizontal rearward state, restart the outer rotor motors in the left front wheel and the right rear wheel, so that the blades in the left front wheel and the right rear wheel generate backward thrust, and at the same time adjust the wing span angle to the third gear. Expand the angle, then turn off the outer rotor motors in the right front wheel and the left rear wheel, then flip the right front wheel to the horizontal forward state, flip the left rear wheel to the horizontal rearward state, and finally restart the right front wheel and the left rear wheel. The outer rotor motor makes the blades in the right front wheel and the left rear wheel generate backward thrust. At this time, the wheel attitude of the deformable multi-robot is completely adjusted to the horizontal flight attitude in the air, and the deformable multi-robot achieves high-speed flight in the horizontal flight attitude in the air. ;

④、固定翼飞行转换为多旋翼飞行④. Convert fixed-wing flight to multi-rotor flight

变形多栖机器人进行固定翼飞行时,先关闭左前车轮和右后车轮内的外转子电机,同时完成变形多栖机器人的重心调整,然后将左前车轮和右后车轮均调整到竖直朝上状态,再重新启动左前车轮和右后车轮内的外转子电机,使左前车轮和右后车轮内的叶片产生向下的推力,同时将机翼展角调整到第二档机翼展角,之后关闭右前车轮和左后车轮内的外转子电机,然后将右前车轮和左后车轮均调整到竖直朝上状态,最后重新启动右前车轮和左后车轮内的外转子电机,使右前车轮和左后车轮内的叶片产生向下的推力,此时变形多栖机器人的车轮姿态完全调整到空中垂直飞行姿态;When the shape-changing robot is flying with fixed wings, first turn off the outer rotor motors in the left front wheel and the right rear wheel, and at the same time complete the center of gravity adjustment of the shape-changing robot, and then adjust both the left front wheel and the right rear wheel to be vertically upward. , and then restart the outer rotor motors in the left front wheel and the right rear wheel, so that the blades in the left front wheel and the right rear wheel generate downward thrust, and at the same time adjust the wing span angle to the second gear span angle, and then turn off The outer rotor motor in the right front wheel and the left rear wheel, then adjust the right front wheel and the left rear wheel to be vertically upward, and finally restart the outer rotor motor in the right front wheel and the left rear wheel, so that the right front wheel and the left rear wheel are turned on. The blades in the wheel generate downward thrust, and the wheel attitude of the deformable multi-robot is completely adjusted to the vertical flight attitude in the air;

四、空中工作模式转换到水面工作模式4. Convert from aerial working mode to surface working mode

①、垂直降落①, vertical landing

变形多栖机器人进行多旋翼飞行时,逐渐降低四个车轮内的叶片产生的向下推力,直到变形多栖机器人的机身降落到水面,然后将机翼展角调整到第一档机翼展角;When the multi-rotor flight is performed by the multi-rotor, the downward thrust generated by the blades in the four wheels is gradually reduced until the fuselage of the multi-robot lands on the water surface, and then the wingspan is adjusted to the first gear span. horn;

②、滑翔降落②, gliding and landing

变形多栖机器人进行固定翼飞行时,逐渐降低四个车轮内的叶片产生的向后推力,直到变形多栖机器人的机身滑行降落到水面,然后将机翼展角调整到第一档机翼展角;When the shape-changing robot is flying with fixed wings, gradually reduce the backward thrust generated by the blades in the four wheels until the body of the shape-changing robot slides down to the water surface, and then adjusts the wingspan to the first wing. spread angle;

五、水面工作模式5. Surface working mode

①、水面缓慢移动① The water surface moves slowly

变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水中水平航行姿态,机翼展角调整到第一档机翼展角,启动四个车轮内的外转子电机,使四个车轮内的叶片产生向后的推力,此时变形多栖机器人可实现水面缓慢移动;The deformed multi-robot floats on the water by buoyancy, the wheel attitude is adjusted to the horizontal sailing attitude in the water, the wingspan angle is adjusted to the first gear wingspan angle, and the outer rotor motors in the four wheels are activated, so that the The blades generate backward thrust, and the deformable multi-robot can move slowly on the water surface;

②、水面慢速滑翔②, gliding slowly on the water surface

变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水面滑行姿态,机翼展角调整到第一档机翼展角,启动四个车轮内的外转子电机,使左前车轮和右前车轮内的叶片产生斜向下的推力,使左后车轮和右后车轮内的叶片产生向后的推力,此时变形多栖机器人可实现水面慢速滑翔;The deformed multi-robot floats on the water surface by buoyancy, the wheel attitude is adjusted to the water surface sliding attitude, the wingspan angle is adjusted to the first gear wingspan angle, and the outer rotor motors in the four wheels are activated to make the left front wheel and the right front wheel inside. The blades of the robot generate oblique downward thrust, so that the blades in the left rear wheel and the right rear wheel generate backward thrust. At this time, the deformed multi-robot can glide slowly on the water surface;

③、水面高速滑翔③、High-speed gliding on the water surface

变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水面滑行姿态,机翼展角调整到第三档机翼展角,启动四个车轮内的外转子电机,使左前车轮和右前车轮内的叶片产生斜向下的推力,使左后车轮和右后车轮内的叶片产生向后的推力,此时变形多栖机器人可实现水面高速滑翔;The deformed multi-robot floats on the water by buoyancy, the wheel attitude is adjusted to the water surface sliding attitude, the wing span angle is adjusted to the third gear wing span angle, and the outer rotor motors in the four wheels are activated, so that the left front wheel and the right front wheel are inside. The blades of the robot generate oblique downward thrust, so that the blades in the left rear wheel and the right rear wheel generate backward thrust. At this time, the deformable multi-robot can glide at high speed on the water surface;

六、水面工作模式转换到水下工作模式6. Switch from surface working mode to underwater working mode

变形多栖机器人依靠浮力漂浮在水面上,当需要进行下潜时,车轮姿态调整到水中下潜姿态,机翼展角调整到第一档机翼展角,叶片转角调整到第三档叶片转角,蓄水舱进行排气注水,启动四个车轮内的外转子电机,使左前车轮和右前车轮内的叶片产生向上的推力,使左后车轮和右后车轮内的叶片产生向后的推力,当达到设定下潜深度后,蓄水舱停止排气注水,变形多栖机器人姿态调整到水中水平航行姿态;The deformable multi-robot relies on buoyancy to float on the water. When it needs to dive, the wheel attitude is adjusted to the underwater diving attitude, the wing span angle is adjusted to the first gear span angle, and the blade angle is adjusted to the third gear blade angle. , the water storage tank is exhausted and water injected, and the outer rotor motors in the four wheels are activated, so that the blades in the left front wheel and the right front wheel generate upward thrust, and the blades in the left rear wheel and the right rear wheel generate backward thrust, When the set diving depth is reached, the water storage tank stops exhausting and filling water, and the posture of the deformable multi-robot is adjusted to the horizontal navigation posture in the water;

七、水下工作模式7. Underwater working mode

当变形多栖机器人下潜到设定深度后处于水中水平航行姿态时,四个车轮内的叶片均产生向后的推力,此过程中只需改变车轮的倾斜角度,就可以实现水平航行转向;When the deformable multi-robot dives to the set depth and is in a horizontal sailing attitude in the water, the blades in the four wheels all generate backward thrust. In this process, only the inclination angle of the wheels can be changed to achieve horizontal sailing steering;

八、水下工作模式转换到水面工作模式8. Switch from underwater working mode to surface working mode

当变形多栖机器人需要从水下上浮到水面时,车轮姿态调整到水中上浮姿态,机翼展角调整到第一档机翼展角,叶片转角调整到第三档叶片转角,蓄水舱进行充气排水,启动四个车轮内的外转子电机,使左前车轮和右前车轮内的叶片产生向下的推力,使左后车轮和右后车轮内的叶片产生向后的推力,当上浮到水面后,蓄水舱停止充气排水,变形多栖机器人依靠浮力漂浮在水面上;When the deformable multi-robot needs to float from the water to the surface, the wheel attitude is adjusted to the water-floating attitude, the wing span angle is adjusted to the first-speed wing span angle, the blade angle is adjusted to the third-speed blade angle, and the water storage tank is carried out. Inflated and drained, the outer rotor motors in the four wheels are activated, so that the blades in the left front wheel and the right front wheel generate downward thrust, and the blades in the left rear wheel and the right rear wheel generate backward thrust. , the water storage tank stops inflating and draining, and the deformable multi-robot floats on the water surface by buoyancy;

九、水面工作模式转换到空中工作模式9. Switch from surface working mode to aerial working mode

①、垂直起飞①、Vertical take-off

变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到空中垂直飞行姿态,叶片转角调整到第二档叶片转角,机翼展角调整到第二档机翼展角,启动四个车轮内的外转子电机,使四个车轮内的叶片均产生向下的推力,使变形多栖机器人垂直升空;The deformable multi-robot floats on the water by buoyancy, the wheel attitude is adjusted to the vertical flight attitude in the air, the blade rotation angle is adjusted to the second gear blade rotation angle, the wingspan angle is adjusted to the second gear wingspan angle, and the four wheels are activated. The outer rotor motor makes the blades in the four wheels generate downward thrust, so that the deformable multi-robot can be lifted vertically;

②、滑翔起飞②, gliding take off

变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水面滑行姿态,叶片转角调整到第二档叶片转角,机翼展角调整到第三档机翼展角,启动四个车轮内的外转子电机,使左前车轮和右前车轮内的叶片产生斜向下的推力,使左后车轮和右后车轮内的叶片产生向后的推力,变形多栖机器人在机翼升力作用下离开水面,然后将车轮姿态调整到空中水平飞行姿态,此时四个车轮内的叶片均产生向后的推力;The deformed multi-robot floats on the water by buoyancy, the wheel attitude is adjusted to the water surface sliding attitude, the blade rotation angle is adjusted to the second gear blade rotation angle, the wing span angle is adjusted to the third gear wingspan angle, and the four wheels inside and outside are activated. The rotor motor makes the blades in the left front wheel and the right front wheel generate oblique downward thrust, and the blades in the left rear wheel and the right rear wheel generate backward thrust, and the deformed multi-robot leaves the water surface under the action of wing lift, and then Adjust the wheel attitude to the horizontal flight attitude in the air, at this time, the blades in the four wheels all generate backward thrust;

十、空中工作模式转换到地面工作模式10. Convert from aerial working mode to ground working mode

①、垂直降落①, vertical landing

变形多栖机器人进行多旋翼飞行时,机翼展角调整到第二档机翼展角,先关闭左前车轮和右后车轮内的外转子电机,然后将左前车轮和右后车轮内的叶片转角调整到第一档叶片转角,同时完成变形多栖机器人的重心调整,再将左前车轮翻转到水平朝左状态,将右后车轮翻转到水平朝右状态,然后逐渐降低右前车轮和左后车轮内的叶片产生的向下推力,使变形多栖机器人缓慢下落,直到左前车轮和右后车轮接触地面,之后关闭右前车轮和左后车轮内的外转子电机,再将右前车轮和左后车轮内的叶片转角调整到第一档叶片转角,再将右前车轮翻转到水平朝右状态,将左后车轮翻转到水平朝左状态,最后将机翼展角调整到第一档机翼展角,使变形多栖机器人姿态变为地面行驶姿态,然后将四个车轮内的电磁套筒全部通电,再启动四个车轮内的外转子电机,带动四个车轮转动,最终使变形多栖机器人行驶在地面上;When the multi-rotor flight is performed by the transforming multi-robot, the wingspan angle is adjusted to the second-gear wingspan angle, and the outer rotor motors in the left front wheel and the right rear wheel are turned off first, and then the blades in the left front wheel and the right rear wheel are turned. Adjust to the first gear blade angle, and at the same time complete the adjustment of the center of gravity of the deformed multi-robot, then turn the left front wheel to the horizontal to the left, turn the right rear wheel to the horizontal to the right, and then gradually lower the right front wheel and the left rear wheel. The downward thrust generated by the blades makes the deformable multi-robot slowly fall until the left front wheel and the right rear wheel touch the ground, then turn off the outer rotor motors in the right front wheel and the left rear wheel, and then connect the right front wheel and the left rear wheel. Adjust the blade turning angle to the first gear blade turning angle, then turn the right front wheel to the horizontal to the right state, turn the left rear wheel to the horizontal to the left state, and finally adjust the wing span angle to the first gear wing span angle to make the deformation The posture of the multi-habitat robot changes to the ground driving posture, and then all the electromagnetic sleeves in the four wheels are energized, and then the outer rotor motors in the four wheels are activated to drive the four wheels to rotate, and finally the deformed multi-habitat robot drives on the ground. ;

②、滑翔降落②, gliding and landing

变形多栖机器人进行固定翼飞行时,首先关闭四个车轮内的外转子电机,然后将四个车轮内的叶片转角调整到第一档叶片转角,同时完成变形多栖机器人的重心调整,再将车轮姿态调整到地面行驶姿态,直到变形多栖机器人通过机翼滑翔降落至地面,当四个车轮全部接触地面后,将机翼展角调整到第一档机翼展角,再将四个车轮内的电磁套筒全部通电,然后启动四个车轮内的外转子电机,带动四个车轮转动,最终使变形多栖机器人行驶在地面上。When the transforming multi-robot performs fixed-wing flight, firstly turn off the outer rotor motors in the four wheels, then adjust the blade corners in the four wheels to the first-speed blade angle, and at the same time complete the center of gravity adjustment of the transforming multi-robot. Adjust the wheel attitude to the ground driving attitude until the deformed multi-robot glides to the ground through the wings. When all four wheels touch the ground, adjust the wingspan angle to the first gear wingspan angle, and then move the four wheels to the ground. All the inner electromagnetic sleeves are energized, and then the outer rotor motors in the four wheels are activated, which drives the four wheels to rotate, and finally makes the deformed multi-robot drive on the ground.

本发明的有益效果:Beneficial effects of the present invention:

本发明的变形多栖机器人及控制方法,能够实现水陆空三栖作业,能够在复杂工作环境下无间隙的进行不同工作模式下的转换,为完成特殊情况下的任务目标提供了可行性方案。The deformable multi-habitable robot and the control method of the invention can realize the amphibious operation of water, land and air, and can switch between different working modes without gaps in a complex working environment, which provides a feasible solution for accomplishing the task objectives under special circumstances.

附图说明Description of drawings

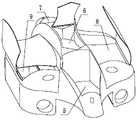

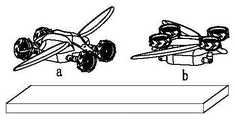

图1为本发明的一种变形多栖机器人的结构示意图;Fig. 1 is the structural representation of a kind of deformable multi-habitable robot of the present invention;

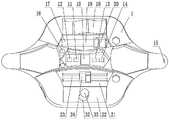

图2为本发明变形多栖机器人的机身立体图;Fig. 2 is the fuselage perspective view of the deformable multi-habitable robot of the present invention;

图3为本发明变形多栖机器人的机身俯视图;Fig. 3 is the top view of the fuselage of the deformable multi-habitable robot of the present invention;

图4为本发明变形多栖机器人的机翼结构示意图;4 is a schematic diagram of the wing structure of the deformable multi-habitable robot of the present invention;

图5为本发明变形多栖机器人的车轮姿态调整组件爆炸示意图;Fig. 5 is the exploded schematic diagram of the wheel attitude adjustment assembly of the deformable multi-habitable robot of the present invention;

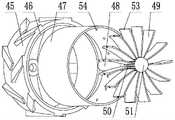

图6为本发明变形多栖机器人的多功能车轮爆炸示意图;Fig. 6 is the exploded schematic diagram of the multifunctional wheel of the deformable multi-habitable robot of the present invention;

图7为本发明变形多栖机器人的外转子电机结构示意图;FIG. 7 is a schematic structural diagram of the outer rotor motor of the deformable multi-habitable robot of the present invention;

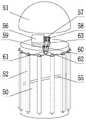

图8为本发明变形多栖机器人的第一机身重心调节机构与蓄水舱调压组件的装配结构示意图;8 is a schematic diagram of the assembly structure of the first body center of gravity adjustment mechanism and the water storage tank pressure regulating assembly of the deformable multi-habitable robot of the present invention;

图9为本发明变形多栖机器人的第二机身重心调节机构与中枢供能组件的装配结构示意图;9 is a schematic diagram of the assembly structure of the second body center of gravity adjustment mechanism and the central energy supply assembly of the deformable multi-robot according to the present invention;

图10为本发明变形多栖机器人在水面缓慢移动、水面慢速滑翔及水面高速滑翔之间的状态转换示意图;10 is a schematic diagram of state transition of the deformable multi-habitable robot of the present invention between slow movement on the water surface, slow gliding on the water surface, and high-speed gliding on the water surface;

图11为本发明变形多栖机器人在固定翼飞行和多旋翼飞行之间的状态转换示意图;11 is a schematic diagram of the state transition between the fixed-wing flight and the multi-rotor flight of the deformable multi-robot of the present invention;

图12为本发明变形多栖机器人在不同工作模式间的状态转换示意图(一);12 is a schematic diagram (1) of the state transition of the deformable multi-habitable robot of the present invention between different working modes;

图13为本发明变形多栖机器人在不同工作模式间的状态转换示意图(二);13 is a schematic diagram (2) of the state transition of the deformable multi-habitable robot of the present invention between different working modes;

图14为本发明变形多栖机器人在不同工作模式间的状态转换示意图(三);Fig. 14 is a schematic diagram (3) of the state transition of the deformable multi-habitable robot of the present invention between different working modes;

图15为本发明变形多栖机器人在不同工作模式间的状态转换示意图(四);Fig. 15 is a schematic diagram (4) of the state transition of the deformable multi-habitable robot of the present invention between different working modes;

图16为本发明变形多栖机器人在不同工作模式间的状态转换示意图(五);16 is a schematic diagram (5) of the state transition of the deformable multi-habitable robot of the present invention between different working modes;

图17为本发明变形多栖机器人在不同工作模式间的状态转换示意图(六);17 is a schematic diagram (6) of the state transition of the deformable multi-habitable robot of the present invention between different working modes;

图中,1—机身,2—机翼,3—多功能车轮,4—车轮姿态调整组件,5—前货仓,6—中部货仓,7—后货仓,8—左货仓,9—右货仓,10—主控制器,11—重心调节器,12—通讯器,13—压力调节器,14—电源管理器,15—空速管,16—卫星导航器,17—第一机身重心调节室,18—第一蓄水舱,19—第一机身重心调节机构,20—蓄水舱调压组件,21—第二机身重心调节室,22—第二蓄水舱,23—第二机身重心调节机构,24—中枢供能组件,25—矢量电机,26—主动带轮,27—从动带轮,28—皮带,29—导向滑轨,30—滑块,31—滑台板,32—通水孔,33—电动密封盖,34—空压机,35—高压气瓶,36—燃料电池,37—蓄电池,38—电源转换器,39—太阳能电池,40—机翼收展驱动电机,41—第一调姿电机,42—第一支臂,43—第二调姿电机,44—第二支臂,45—橡胶轮胎,46—原磁体轮毂,47—电磁套筒,48—转接轴,49—叶片,50—外转子电机,51—整流罩,52—叶片安装座,53—销柱,54—销孔,55—滑槽,56—叶片转角调整电机,57—第一卷线轮,58—第二卷线轮,59—第一导向器,60—第二导向器,61—第一分向柱,62—第二分向柱,63—线索。In the figure, 1—fuselage, 2—wings, 3—multi-purpose wheels, 4—wheel attitude adjustment components, 5—front cargo compartment, 6 — middle cargo compartment, 7 — rear cargo compartment, 8 — left cargo compartment, 9—right cargo compartment, 10—main controller, 11—gravity regulator, 12—communicator, 13—pressure regulator, 14—power manager, 15—pitot, 16—satellite navigator, 17—paragraph A fuselage center of gravity adjustment chamber, 18—the first water storage tank, 19—the first airframe center of gravity adjustment mechanism, 20—the water storage tank pressure regulating assembly, 21—the second airframe center of gravity adjustment chamber, 22—the second water storage Cabin, 23—the center of gravity adjustment mechanism of the second fuselage, 24—central energy supply assembly, 25—vector motor, 26—driving pulley, 27—driven pulley, 28—belt, 29—guide rail, 30—slider Block, 31—slide plate, 32—water hole, 33—electric sealing cover, 34—air compressor, 35—high pressure gas cylinder, 36—fuel cell, 37—battery, 38—power converter, 39—solar energy Battery, 40—wing extension drive motor, 41—first attitude adjustment motor, 42—first arm, 43—second attitude adjustment motor, 44—second arm, 45—rubber tire, 46—original magnet Hub, 47—Electromagnetic Sleeve, 48—Transfer Shaft, 49—Blade, 50—Outer Rotor Motor, 51—Fairing, 52—Blade Mounting Seat, 53—Pin, 54—Pin Hole, 55—Chute, 56—Blade angle adjustment motor, 57—First reel, 58—Second reel, 59—First guide, 60—Second guide, 61—First diverter column, 62—Second divider Xiangzhu, 63 - Clue.

具体实施方式Detailed ways

下面结合附图和具体实施例对本发明做进一步的详细说明。The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

如图1~9所示,一种变形多栖机器人,包括机身1、机翼2、多功能车轮3及车轮姿态调整组件4,所述机翼2数量为两个,两个机翼2对称安装在机身1顶部左右两侧;所述多功能车轮3数量为四个,四个多功能车轮3在机身1四周均布设置,机身1与每个多功能车轮3之间均通过车轮姿态调整组件4相连。As shown in Figures 1-9, a deformable multi-robot includes a fuselage 1, a

所述机身1内部分别设有前货仓5、中部货仓6、后货仓7、左货仓8及右货仓9;所述中部货仓6分为上下两层,两层之间由密封隔板进行分隔,上层空间用于储物,在下层空间分别安装有主控制器10、重心调节器11、通讯器12、压力调节器13、电源管理器14及卫星导航器16;在所述机身1前端安装有图像识别相机、激光雷达及空速管15;所述左货仓8分为上下两层,两层之间由密封隔板进行分隔,上层空间用于储物,下层空间包括第一机身重心调节室17和第一蓄水舱18,在第一机身重心调节室17内安装有第一机身重心调节机构19,在第一机身重心调节机构19上设置有蓄水舱调压组件20;所述右货仓9分为上下两层,两层之间由密封隔板进行分隔,上层空间用于储物,下层空间包括第二机身重心调节室21和第二蓄水舱22,在第二机身重心调节室21内安装有第二机身重心调节机构23,在第二机身重心调节机构23上设置有中枢供能组件24;在所述第一蓄水舱18和第二蓄水舱22内均设置有水压传感器;所述第一机身重心调节室17与第二机身重心调节室21左右对称分布,所述第一蓄水舱18与第二蓄水舱22左右对称分布。The interior of the fuselage 1 is respectively provided with a

所述第一机身重心调节机构19和第二机身重心调节机构23结构相同,均包括矢量电机25、主动带轮26、从动带轮27、皮带28、导向滑轨29、滑块30及滑台板31;所述导向滑轨29采用平行双轨结构,所述皮带28传动连接在主动带轮26与从动带轮27之间,皮带28位于两根导向滑轨29中间,皮带28与导向滑轨29相平行,所述主动带轮26固装在矢量电机25的电机轴上;所述滑块30安装在导向滑轨29上,所述滑台板31水平固装在滑块30上,滑台板31通过滑块31可沿导向滑轨29直线移动,滑台板31下表面与皮带28相固连;所述蓄水舱调压组件20安装在第一机身重心调节机构19的滑台板31上,所述中枢供能组件24安装在第二机身重心调节机构23的滑台板31上。The first fuselage center of

机身重心调节过程为:主控制器10首先将控制指令传输给重心调节器11,重心调节器11进而控制矢量电机25转动,在矢量电机25的驱动下,将依次带动主动带轮26、皮带28及从动带轮27转动,随着皮带28的转动,将带动滑台板31沿着导向滑轨29移动,此时蓄水舱调压组件20或中枢供能组件24同步随着滑台板31移动,实现机身重心的改变,直到主控制器10检测到重心调整满足要求后,重心调节器11控制矢量电机25停机。The adjustment process of the center of gravity of the fuselage is as follows: the

所述第一蓄水舱18和第二蓄水舱22结构相同,均分为上下两层,两层之间由隔水膜进行分隔,上层空间作为气体仓,下层空间作为水仓,所述水仓的仓底板上开设有通水孔32,水仓通过通水孔32与机身1外部连通,在通水孔32处设置有电动密封盖33;所述蓄水舱调压组件20包括空压机34及高压气瓶35,空压机34的吸气口通过管路与与气体仓相连通,空压机34的排气口通过管路与高压气瓶35的进气口相连通,高压气瓶35的出气口通过管路与气体仓相连通。The first

蓄水舱调压过程为:当机器人需要下潜时,蓄水舱则需要进行排气注水,主控制器10首先将控制指令传输给压力调节器13,压力调节器13进而控制空压机34启动,空压机34开始将气体仓内的空气抽出并返回到高压气瓶35中,同时控制电动密封盖33开启,随着抽气的进行,气体仓内压力逐渐降低,隔水膜逐渐向上回缩,在机身外部的水压作用下,水会通过通水孔32进入水仓中,直到气体仓内的压力降低到设定压力为止,机器人开始匀速下潜,此时空压机34停机,电动密封盖33关闭,通过电动密封盖33将通水孔32封堵住。当机器人需要上浮时,蓄水舱则需要进行充气排水,主控制器10首先将控制指令传输给压力调节器13,压力调节器13进而控制高压气瓶35开启,高压气瓶35开始向气体仓内充入空气,同时控制电动密封盖33开启,随着充气的进行,隔水膜逐渐向下膨胀,而膨胀的隔水膜逐渐将水仓中的水通过通水孔32排挤出机身,直到气体仓内的压力达到设定压力为止,此时高压气瓶35关闭,同时电动密封盖33关闭,通过电动密封盖33将通水孔32封堵住。The pressure regulation process of the water storage tank is as follows: when the robot needs to dive, the water storage tank needs to be exhausted and watered. The

所述中枢供能组件24包括燃料电池36、蓄电池37及电源转换器38,所述燃料电池36和蓄电池37通过电源线与电源转换器38的电力输入端口相连,电源转换器38的电力输出端口通过电源线为机器人的全部用电部件进行供电。The central

所述机翼2上表面安装有太阳能电池39,在机翼2的翼根处连接有机翼收展驱动电机40,机翼收展驱动电机40嵌装在机身1上。A

所述车轮姿态调整组件4包括第一调姿电机41、第一支臂42、第二调姿电机43及第二支臂44,所述第一调姿电机41嵌装在机身1上,所述第一支臂42一端固连在第一调姿电机41的电机轴上,第一支臂42另一端与第二支臂44一端相铰接,所述多功能车轮3连接在第二支臂44另一端;所述第二调姿电机43安装在第一支臂42与第二支臂44的铰接处,第二调姿电机43用于驱动第二支臂44做摆转运动,所述第一调姿电机41用于驱动第一支臂42做回转运动。The wheel

车轮姿态调整过程为:当第一调姿电机41启动时,可以控制第一支臂42绕其中轴线旋转,如果此时第一支臂42与第二支臂44具有夹角,则在第一支臂42旋转过程中,可以实现多功能车轮3在竖直平面内位置的回转调整。当第二调姿电机43启动时,可以控制第二支臂44相对于第一支臂42的夹角,在第一支臂42的回转角度固定后,通过第二支臂44的摆转过程,可以实现多功能车轮3在同一平面内的朝向调整。The wheel attitude adjustment process is as follows: when the first

所述多功能车轮3包括橡胶轮胎45、原磁体轮毂46、电磁套筒47、转接轴48及涵道动力机构;所述橡胶轮胎45固定套装在原磁体轮毂46上,原磁体轮毂46套装在电磁套筒47上,原磁体轮毂46内表面与电磁套筒47外表面滑动接触配合;所述涵道动力机构位于电磁套筒47内侧,所述转接轴48穿过原磁体轮毂46的中心孔,转接轴48一端与第二支臂44相固连,所述涵道动力机构连接在转接轴48的另一端。The

所述涵道动力机构包括叶片49、外转子电机50及整流罩51;所述外转子电机50的内定子轴与转接轴48相固连,外转子电机50的转子外套上均布有若干叶片安装座52,叶片安装座52采用直杆形结构,每个叶片安装座52上均固装有一个叶片49,叶片49的根部固连在叶片安装座52上,在叶片49的顶部中心固设有销柱53,在所述电磁套筒47的内表面开设有销孔54,销柱53位于销孔54内,销柱53可在销孔54内自由转动;在所述外转子电机50的转子外套表面开设有滑槽55,叶片安装座52滑动连接在滑槽55内,所述整流罩51扣装在外转子电机50顶部,在整流罩51内部的外转子电机50上设置有叶片转角调整电机56,在叶片转角调整电机56的电机轴上串联固装有第一卷线轮57和第二卷线轮58,在所述外转子电机50上分别设置有第一导向器59、第二导向器60、第一分向柱61及第二分向柱62,所述第一卷线轮57与线索63一端缠绕连接,线索63另一端首先穿过第一导向器59,再绕过第一分向柱61,然后依次固定穿过所有叶片安装座52端部穿线孔,之后再绕过第二分向柱62,最后穿过第二导向器60后缠绕连接在第二卷线轮58上,且线索63在第一卷线轮57和第二卷线轮58上的缠绕方向相反。The ducted power mechanism includes

叶片转角调整过程为:首先启动叶片转角调整电机56,带动第一卷线轮57和第二卷线轮58同步转动,以第一卷线轮57进行收线为例,则第二卷线轮58进行同步放线,在此过程中,线索63会相对于外转子电机50圆周方向移动,并带动叶片安装座52在滑槽55内移动,进而带动叶片49顶部中心的销柱53在电磁套筒47内表面的销孔54内转动,最终实现叶片49转角的调整。The blade rotation angle adjustment process is as follows: firstly, start the blade rotation

所述的变形多栖机器人的控制方法,包括如下步骤:The control method of the deformable multi-habitable robot includes the following steps:

步骤一:设定变形多栖机器人的工作模式,分别为地面工作模式、空中工作模式、水面工作模式及水下工作模式;Step 1: Set the working modes of the deformable multi-robot, which are ground working mode, aerial working mode, surface working mode and underwater working mode;

步骤二:设定叶片转角,分别为第一档叶片转角、第二档叶片转角及第三档叶片转角;当叶片处于第一档叶片转角时,涵道动力机构不产生推力;当叶片处于第二档叶片转角时,涵道动力机构在空中产生最大推力;当叶片处于第三档叶片转角时,涵道动力机构在水中产生最大推力;Step 2: Set the blade rotation angle, which are the first-speed blade rotation angle, the second-speed blade rotation angle and the third-speed blade rotation angle; when the blade is at the first-speed blade rotation angle, the duct power mechanism does not generate thrust; When the second-gear blade angle, the duct power mechanism generates the maximum thrust in the air; when the blade is at the third-gear blade angle, the duct power mechanism generates the maximum thrust in the water;

步骤三:设定机翼展角,分别为第一档机翼展角(0°)、第二档机翼展角(25°)及第三档机翼展角(75°);当机翼处于第一档机翼展角时,机翼在空中不产生升力;当机翼处于第二档机翼展角时,机翼在空中产生中等升力;当机翼处于第三档机翼展角时,机翼在空中产生最大升力;Step 3: Set the wingspan angle of the first gear (0°), the second gear (25°) and the third gear (75°); When the wing is in the first gear span, the wing does not produce lift in the air; when the wing is in the second gear, the wing produces moderate lift in the air; when the wing is in the third gear span At the angle, the wing produces maximum lift in the air;

步骤四:设定车轮姿态,分别为地面行驶姿态、空中垂直飞行姿态、空中水平飞行姿态、水面滑行姿态、水中水平航行姿态、水中下潜姿态及水中上浮姿态;当车轮姿态处于地面行驶姿态时,四个车轮的姿态相同,四个车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为90°,左前车轮和左后车轮均水平朝向机身1左侧,右前车轮和右后车轮均水平朝向机身1右侧;当车轮姿态处于空中垂直飞行姿态时,四个车轮的姿态相同,四个车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为90°,四个车轮均竖直朝向机身1正上方;当车轮姿态处于空中水平飞行姿态或水中水平航行姿态时,四个车轮的姿态相同,车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为180°,左前车轮和右前车轮均水平朝向机身1正前方,左后车轮和右后车轮均水平朝向机身1正后方;当车轮姿态处于水面滑行姿态时,左前车轮和右前车轮的姿态相同,左后车轮和右后车轮的姿态相同,左前车轮和右前车轮的车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为120°,左前车轮和右前车轮均倾斜朝向机身1斜上方,左后车轮和右后车轮的车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为180°,左后车轮和右后车轮均水平朝向机身1正后方;当车轮姿态处于水中下潜姿态时,左前车轮和右前车轮的姿态相同,左后车轮和右后车轮的姿态相同,左前车轮和右前车轮的车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为90°~120°,左前车轮和右前车轮均倾斜朝向机身1斜下方,下潜过程中左前车轮和右前车轮相对于水体始终保持竖直朝下,左后车轮和右后车轮的车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为180°,左后车轮和右后车轮均水平朝向机身1正后方;当车轮姿态处于水中上浮姿态时,左前车轮和右前车轮的姿态相同,左后车轮和右后车轮的姿态相同,左前车轮和右前车轮的车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为90°~120°,左前车轮和右前车轮均倾斜朝向机身1斜上方,上浮过程中左前车轮和右前车轮相对于水体始终保持竖直朝上,左后车轮和右后车轮的车轮姿态调整组件4中的第一支臂42与第二支臂44的夹角均为180°,左后车轮和右后车轮均水平朝向机身1正后方;Step 4: Set the wheel attitudes, which are ground driving attitude, vertical flight attitude in air, horizontal flight attitude in air, surface taxi attitude, horizontal sailing attitude in water, underwater diving attitude and water floating attitude; when the wheel attitude is in the ground driving attitude , the postures of the four wheels are the same, the angle between the first arm 42 and the second arm 44 in the four wheel posture adjustment components 4 are both 90°, the left front wheel and the left rear wheel are horizontally facing the left side of the fuselage 1 , the right front wheel and the right rear wheel are horizontally facing the right side of the fuselage 1; when the wheel attitude is in the vertical flight attitude in the air, the attitudes of the four wheels are the same, the first arm 42 in the four wheel attitude adjustment assembly 4 and the second The included angles of the arms 44 are all 90°, and the four wheels are vertically facing the top of the fuselage 1; when the wheel attitude is in the horizontal flight attitude in the air or the horizontal sailing attitude in the water, the attitude of the four wheels is the same, and the wheel attitude adjustment component The angle between the first arm 42 and the second arm 44 in 4 is 180°, the left front wheel and the right front wheel are horizontally facing the front of the fuselage 1, and the left rear wheel and the right rear wheel are horizontally facing the front of the fuselage 1. Rear; when the wheel attitude is in the water surface sliding attitude, the attitude of the left front wheel and the right front wheel are the same, the attitude of the left rear wheel and the right rear wheel are the same, the first arm 42 in the wheel attitude adjustment assembly 4 of the left front wheel and the right front wheel is the same as The included angles of the second arms 44 are both 120°, the left front wheel and the right front wheel are inclined towards the upper side of the fuselage 1, the first arm 42 and the second arm 42 in the wheel attitude adjustment assembly 4 of the left rear wheel and the right rear wheel The included angles of the arms 44 are all 180°, and the left rear wheel and the right rear wheel are horizontally facing the rear of the fuselage 1; when the wheel attitude is in the underwater diving attitude, the attitude of the left front wheel and the right front wheel The attitude of the right rear wheel is the same, the angle between the first arm 42 and the second arm 44 in the wheel attitude adjustment assembly 4 of the left front wheel and the right front wheel are both 90°~120°, and the left front wheel and the right front wheel are inclined towards The fuselage 1 is inclined downward, the left front wheel and the right front wheel are always kept vertically downward relative to the water body during the dive, and the first arm 42 and the second arm in the wheel attitude adjustment assembly 4 of the left rear wheel and the right rear wheel are The included angle of 44 is 180°, and the left rear wheel and right rear wheel are horizontally facing the rear of fuselage 1; when the wheel attitude is in the water-floating attitude, the attitude of the left front wheel and the right front wheel is the same, the left rear wheel and the right rear wheel are the same. The attitude of the front left wheel and the front right wheel is the same, the angle between the

步骤五:执行地面工作模式、空中工作模式、水面工作模式或水下工作模式,以及在不同工作模式间转换;Step 5: Execute ground work mode, aerial work mode, surface work mode or underwater work mode, and switch between different work modes;

一、地面工作模式1. Ground working mode

叶片转角调整到第一档叶片转角,机翼展角调整到第一档机翼展角,车轮姿态调整到地面行驶姿态,电磁套筒47通电,使电磁套筒47与原磁体轮毂46吸附在一起,外转子电机50启动,依次带动叶片49、电磁套筒47、原磁体轮毂46及橡胶轮胎45转动,使变形多栖机器人行驶在地面上;The blade rotation angle is adjusted to the first gear blade rotation angle, the wing span angle is adjusted to the first gear wingspan angle, the wheel attitude is adjusted to the ground driving attitude, the

二、地面工作模式转换到空中工作模式2. Convert the ground working mode to the air working mode

①、垂直起飞①、Vertical take-off

如图12a~12c所示,首先使变形多栖机器人静止在地面上,叶片转角调整到第二档叶片转角,机翼展角调整到第二档机翼展角,车轮姿态调整到空中垂直飞行姿态,电磁套筒47断电,电磁套筒47与原磁体轮毂46脱离吸附,外转子电机50启动,依次带动叶片49及电磁套筒47转动,此时叶片49产生向下的推力,使变形多栖机器人垂直升空;As shown in Figures 12a to 12c, first make the deformable multi-robot stationary on the ground, adjust the blade rotation angle to the second gear blade rotation angle, adjust the wing span angle to the second gear wingspan angle, and adjust the wheel attitude to fly vertically in the air Attitude, the

②、慢速行驶起飞②, take off at a slow speed

如图13a~13d所示,变形多栖机器人保持地面慢速行驶状态,机翼展角调整到第二档机翼展角,右前车轮和左后车轮翻转到竖直朝上状态,电磁套筒47断电,然后将右前车轮和左后车轮内的叶片转角调整到第二档叶片转角,使右前车轮和左后车轮内的叶片49产生向下的推力,变形多栖机器人在叶片推力作用下初步离开地面,同时完成变形多栖机器人的重心调整,然后关闭左前车轮和右后车轮内的外转子电机50,再将左前车轮翻转到水平朝前状态,将右后车轮翻转到水平朝后状态,电磁套筒47断电,然后将左前车轮和右后车轮内的叶片转角调整到第二档叶片转角,之后重新启动左前车轮和右后车轮内的外转子电机50,使左前车轮和右后车轮内的叶片49产生向后的推力,当变形多栖机器人完全离开地面后,先关闭右前车轮和左后车轮内的外转子电机50,再将右前车轮翻转到水平朝前状态,将左后车轮翻转到水平朝后状态,同时将机翼展角调整到第三档机翼展角,然后重新启动右前车轮和左后车轮内的外转子电机50,使右前车轮和左后车轮内的叶片49产生向后的推力,此时变形多栖机器人的车轮姿态完全调整到空中水平飞行姿态,变形多栖机器人在空中水平飞行姿态下实现高速飞行;As shown in Figures 13a to 13d, the deformable multi-robot keeps running at a slow speed on the ground, the wing span is adjusted to the second gear span, the right front wheel and the left rear wheel are turned to the vertical upward state, and the

③、高速滑跑起飞③, high-speed rolling takeoff

如图14a~14c所示,变形多栖机器人保持地面高速行驶状态,机翼展角调整到第三档机翼展角,变形多栖机器人在机翼升力作用下初步离开地面,同时完成变形多栖机器人的重心调整,先关闭右前车轮和左后车轮内的外转子电机50,然后将右前车轮翻转到水平朝前状态,将左后车轮翻转到水平朝后状态,电磁套筒47断电,再将右前车轮和左后车轮内的叶片转角调整到第二档叶片转角,然后重新启动右前车轮和左后车轮内的外转子电机50,使右前车轮和左后车轮内的叶片49产生向后的推力,当变形多栖机器人完全离开地面后,先关闭左前车轮和右后车轮内的外转子电机50,然后将左前车轮翻转到水平朝前状态,将右后车轮翻转到水平朝后状态,电磁套筒47断电,再将左前车轮和右后车轮内的叶片转角调整到第二档叶片转角,然后重新启动左前车轮和右后车轮内的外转子电机50,使左前车轮和右后车轮内的叶片49产生向后的推力,此时变形多栖机器人的车轮姿态完全调整到空中水平飞行姿态,变形多栖机器人在空中水平飞行姿态下实现高速飞行;As shown in Figures 14a to 14c, the deformable multi-robot keeps the ground running at high speed, and the wingspan angle is adjusted to the third gear. To adjust the center of gravity of the robot, first turn off the

三、空中工作模式3. Air work mode

①、多旋翼飞行①、Multi-rotor flight

如图11b所示,在变形多栖机器人垂直升空后,四个车轮内的叶片49均产生向下的推力,此过程中只需改变车轮的倾斜角度,就可以实现多旋翼飞行转向;As shown in Fig. 11b, after the transforming multi-robot is lifted vertically, the

②、固定翼飞行②, fixed wing flight

如图11a所示,在变形多栖机器人慢速行驶起飞或高速滑跑起飞后,四个车轮内的叶片49均产生向后的推力,此过程中只需改变车轮的倾斜角度,就可以实现固定翼飞行转向;As shown in Figure 11a, after the transforming multi-robot takes off at a slow speed or rolls out at a high speed, the

③、多旋翼飞行转换为固定翼飞行3. Convert multi-rotor flight to fixed-wing flight

如图12c~12e所示,变形多栖机器人进行多旋翼飞行时,先关闭左前车轮和右后车轮内的外转子电机50,同时完成变形多栖机器人的重心调整,然后将左前车轮翻转到水平朝前状态,将右后车轮翻转到水平朝后状态,再重新启动左前车轮和右后车轮内的外转子电机50,使左前车轮和右后车轮内的叶片49产生向后的推力,同时将机翼展角调整到第三档机翼展角,之后关闭右前车轮和左后车轮内的外转子电机50,然后将右前车轮翻转到水平朝前状态,将左后车轮翻转到水平朝后状态,最后重新启动右前车轮和左后车轮内的外转子电机50,使右前车轮和左后车轮内的叶片49产生向后的推力,此时变形多栖机器人的车轮姿态完全调整到空中水平飞行姿态,变形多栖机器人在空中水平飞行姿态下实现高速飞行;As shown in Figures 12c to 12e, when the multi-rotor flight is performed by the transforming multi-robot, the

④、固定翼飞行转换为多旋翼飞行④. Convert fixed-wing flight to multi-rotor flight

如图12e~12g所示,变形多栖机器人进行固定翼飞行时,先关闭左前车轮和右后车轮内的外转子电机50,同时完成变形多栖机器人的重心调整,然后将左前车轮和右后车轮均调整到竖直朝上状态,再重新启动左前车轮和右后车轮内的外转子电机50,使左前车轮和右后车轮内的叶片49产生向下的推力,同时将机翼展角调整到第二档机翼展角,之后关闭右前车轮和左后车轮内的外转子电机50,然后将右前车轮和左后车轮均调整到竖直朝上状态,最后重新启动右前车轮和左后车轮内的外转子电机50,使右前车轮和左后车轮内的叶片49产生向下的推力,此时变形多栖机器人的车轮姿态完全调整到空中垂直飞行姿态;As shown in Figs. 12e to 12g, when the shape-changing robot performs fixed-wing flight, the

四、空中工作模式转换到水面工作模式4. Convert from aerial working mode to surface working mode

①、垂直降落①, vertical landing

如图15a~15b所示,变形多栖机器人进行多旋翼飞行时,逐渐降低四个车轮内的叶片49产生的向下推力,直到变形多栖机器人的机身1降落到水面,然后将机翼展角调整到第一档机翼展角;As shown in Figures 15a-15b, when the multi-rotor flight is performed by the multi-rotor, the downward thrust generated by the

②、滑翔降落②, gliding and landing

如图16a~16b所示,变形多栖机器人进行固定翼飞行时,逐渐降低四个车轮内的叶片49产生的向后推力,直到变形多栖机器人的机身1滑行降落到水面,然后将机翼展角调整到第一档机翼展角;As shown in Figures 16a to 16b, when the shape-changing robot performs fixed-wing flight, the backward thrust generated by the

五、水面工作模式5. Surface working mode

①、水面缓慢移动① The water surface moves slowly

如图10a所示,变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水中水平航行姿态,机翼展角调整到第一档机翼展角,启动四个车轮内的外转子电机50,使四个车轮内的叶片49产生向后的推力,此时变形多栖机器人可实现水面缓慢移动;As shown in Figure 10a, the deformable multi-robot floats on the water by buoyancy, the wheel attitude is adjusted to the horizontal sailing attitude in the water, the wingspan angle is adjusted to the first gear wingspan angle, and the

②、水面慢速滑翔②, gliding slowly on the water surface

如图10b所示,变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水面滑行姿态,机翼展角调整到第一档机翼展角,启动四个车轮内的外转子电机50,使左前车轮和右前车轮内的叶片49产生斜向下的推力,使左后车轮和右后车轮内的叶片49产生向后的推力,此时变形多栖机器人可实现水面慢速滑翔;As shown in Figure 10b, the deformable multi-robot floats on the water surface by buoyancy, the wheel attitude is adjusted to the water surface sliding attitude, the wing span angle is adjusted to the first-gear wing span angle, and the

③、水面高速滑翔③、High-speed gliding on the water surface

如图10c所示,变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水面滑行姿态,机翼展角调整到第三档机翼展角,启动四个车轮内的外转子电机50,使左前车轮和右前车轮内的叶片49产生斜向下的推力,使左后车轮和右后车轮内的叶片49产生向后的推力,此时变形多栖机器人可实现水面高速滑翔;As shown in Figure 10c, the deformable multi-robot floats on the water surface by buoyancy, the wheel attitude is adjusted to the water surface sliding attitude, the wing span is adjusted to the third-gear span angle, and the

六、水面工作模式转换到水下工作模式6. Switch from surface working mode to underwater working mode

如图16a~16d所示,变形多栖机器人依靠浮力漂浮在水面上,当需要进行下潜时,车轮姿态调整到水中下潜姿态,机翼展角调整到第一档机翼展角,叶片转角调整到第三档叶片转角,蓄水舱进行排气注水,启动四个车轮内的外转子电机50,使左前车轮和右前车轮内的叶片49产生向上的推力,使左后车轮和右后车轮内的叶片49产生向后的推力,当达到设定下潜深度后,蓄水舱停止排气注水,变形多栖机器人姿态调整到水中水平航行姿态;As shown in Figures 16a~16d, the deformable multi-robot floats on the water surface by buoyancy. When it needs to dive, the wheel attitude is adjusted to the underwater diving attitude, the wingspan angle is adjusted to the first gear wingspan angle, and the blades The turning angle is adjusted to the third gear blade turning angle, the water storage tank is exhausted and water is injected, and the

七、水下工作模式7. Underwater working mode

如图16d所示,当变形多栖机器人下潜到设定深度后处于水中水平航行姿态时,四个车轮内的叶片49均产生向后的推力,此过程中只需改变车轮的倾斜角度,就可以实现水平航行转向;As shown in Fig. 16d, when the deformable multi-robot dives to the set depth and is in a horizontal sailing attitude in the water, the

八、水下工作模式转换到水面工作模式8. Switch from underwater working mode to surface working mode

如图16d~16f所示,当变形多栖机器人需要从水下上浮到水面时,车轮姿态调整到水中上浮姿态,机翼展角调整到第一档机翼展角,叶片转角调整到第三档叶片转角,蓄水舱进行充气排水,启动四个车轮内的外转子电机50,使左前车轮和右前车轮内的叶片49产生向下的推力,使左后车轮和右后车轮内的叶片49产生向后的推力,当上浮到水面后,蓄水舱停止充气排水,变形多栖机器人依靠浮力漂浮在水面上;As shown in Figures 16d-16f, when the deformable multi-robot needs to float from the water to the surface, the wheel attitude is adjusted to the water-floating attitude, the wing span angle is adjusted to the first gear span angle, and the blade rotation angle is adjusted to the third When the angle of the blades stops, the water storage tank is inflated and drained, and the

九、水面工作模式转换到空中工作模式9. Switch from surface working mode to aerial working mode

①、垂直起飞①、Vertical take-off

如图17a~17c所示,变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到空中垂直飞行姿态,叶片转角调整到第二档叶片转角,机翼展角调整到第二档机翼展角,启动四个车轮内的外转子电机50,使四个车轮内的叶片49均产生向下的推力,使变形多栖机器人垂直升空;As shown in Figures 17a-17c, the deformable multi-robot relies on buoyancy to float on the water, the wheel attitude is adjusted to the vertical flight attitude in the air, the blade angle is adjusted to the second blade angle, and the wingspan angle is adjusted to the second wing span angle, start the

②、滑翔起飞②, gliding take off

如图17c~17f所示,变形多栖机器人依靠浮力漂浮在水面上,车轮姿态调整到水面滑行姿态,叶片转角调整到第二档叶片转角,机翼展角调整到第三档机翼展角,启动四个车轮内的外转子电机50,使左前车轮和右前车轮内的叶片49产生斜向下的推力,使左后车轮和右后车轮内的叶片49产生向后的推力,变形多栖机器人在机翼升力作用下离开水面,然后将车轮姿态调整到空中水平飞行姿态,此时四个车轮内的叶片49均产生向后的推力;As shown in Figures 17c to 17f, the deformable multi-robot floats on the water by buoyancy, the wheel attitude is adjusted to the water surface sliding attitude, the blade angle is adjusted to the second blade angle, and the wing span angle is adjusted to the third wing span angle. , start the

十、空中工作模式转换到地面工作模式10. Convert from aerial working mode to ground working mode

①、垂直降落①, vertical landing

如图12g~12i所示,变形多栖机器人进行多旋翼飞行时,机翼展角调整到第二档机翼展角,先关闭左前车轮和右后车轮内的外转子电机50,然后将左前车轮和右后车轮内的叶片转角调整到第一档叶片转角,同时完成变形多栖机器人的重心调整,再将左前车轮翻转到水平朝左状态,将右后车轮翻转到水平朝右状态,然后逐渐降低右前车轮和左后车轮内的叶片49产生的向下推力,使变形多栖机器人缓慢下落,直到左前车轮和右后车轮接触地面,之后关闭右前车轮和左后车轮内的外转子电机50,再将右前车轮和左后车轮内的叶片转角调整到第一档叶片转角,再将右前车轮翻转到水平朝右状态,将左后车轮翻转到水平朝左状态,最后将机翼展角调整到第一档机翼展角,使变形多栖机器人姿态变为地面行驶姿态,然后将四个车轮内的电磁套筒47全部通电,再启动四个车轮内的外转子电机50,带动四个车轮转动,最终使变形多栖机器人行驶在地面上;As shown in Figures 12g to 12i, when the multi-rotor flight is performed by the deformable multi-robot, the wingspan angle is adjusted to the second gear wingspan angle, and the

②、滑翔降落②, gliding and landing

如图13d~13f所示,变形多栖机器人进行固定翼飞行时,首先关闭四个车轮内的外转子电机50,然后将四个车轮内的叶片转角调整到第一档叶片转角,同时完成变形多栖机器人的重心调整,再将车轮姿态调整到地面行驶姿态,直到变形多栖机器人通过机翼滑翔降落至地面,当四个车轮全部接触地面后,将机翼展角调整到第一档机翼展角,再将四个车轮内的电磁套筒47全部通电,然后启动四个车轮内的外转子电机50,带动四个车轮转动,最终使变形多栖机器人行驶在地面上。As shown in Figures 13d to 13f, when the deformable multi-robot performs fixed-wing flight, it first turns off the

实施例中的方案并非用以限制本发明的专利保护范围,凡未脱离本发明所为的等效实施或变更,均包含于本案的专利范围中。The solutions in the embodiments are not intended to limit the scope of the patent protection of the present invention, and all equivalent implementations or modifications that do not depart from the present invention are included in the scope of the patent of this case.

Claims (7)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010180964.4ACN111216498B (en) | 2020-03-16 | 2020-03-16 | A kind of deformable multi-habitable robot and its control method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010180964.4ACN111216498B (en) | 2020-03-16 | 2020-03-16 | A kind of deformable multi-habitable robot and its control method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111216498A CN111216498A (en) | 2020-06-02 |

| CN111216498Btrue CN111216498B (en) | 2022-07-12 |

Family

ID=70808012

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010180964.4AActiveCN111216498B (en) | 2020-03-16 | 2020-03-16 | A kind of deformable multi-habitable robot and its control method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111216498B (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11772440B2 (en)* | 2018-06-04 | 2023-10-03 | Ali Salem | Multi-purpose wheels for use in multi-purpose vehicles |

| CN111645860B (en)* | 2020-06-18 | 2023-09-05 | 航大汉来(天津)航空技术有限公司 | Air-ground amphibious unmanned aerial vehicle with three-axis tilting rotor wings and folding wings |

| CN112622547B (en)* | 2020-12-24 | 2023-02-24 | 中国直升机设计研究所 | Rotor wheel and hovercar |

| CN112923790A (en)* | 2021-01-19 | 2021-06-08 | 安徽芯感微电子科技有限公司 | Intelligent mobile target shooting electromagnetic device based on computer vision and control method |

| CN114019993B (en)* | 2021-10-26 | 2023-09-12 | 江汉大学 | A control method for portable multi-terrain drones |

| CN114013649A (en)* | 2021-11-10 | 2022-02-08 | 沈阳航空航天大学 | Triphibian cross-medium transverse tilting dual-rotor aircraft |

| CN117228004A (en)* | 2023-10-30 | 2023-12-15 | 北京理工大学 | A ground-air amphibious Mars exploration platform |

| CN119098931B (en)* | 2024-08-16 | 2025-09-16 | 南方科技大学 | Three-dimensional metamorphic robot |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4534455A (en)* | 1982-08-26 | 1985-08-13 | Aisin Seiki Kabushiki Kaisha | Wheel hub clutch assembly |

| GB9318739D0 (en)* | 1992-09-29 | 1993-10-27 | Borg Warner Automotive | Power transmitting assembly |

| CN106427435A (en)* | 2015-08-07 | 2017-02-22 | 刘新广 | Triphibian flying vehicle |

| CN106564349A (en)* | 2016-10-31 | 2017-04-19 | 广东工业大学 | Triphibian unmanned aerial vehicle |

| CN107758334A (en)* | 2017-11-09 | 2018-03-06 | 深圳市系存通信技术有限公司 | A kind of transfer robot |

| CN110182008A (en)* | 2019-05-31 | 2019-08-30 | 北京无线电测量研究所 | A kind of variable unmanned motor platform of appearance of two-stage type |

| CN110588263A (en)* | 2019-09-26 | 2019-12-20 | 沈阳航空航天大学 | A multi-dwelling unmanned mobile platform system and its control method |

| CN209972084U (en)* | 2019-06-06 | 2020-01-21 | 贵州师范大学 | Foldable amphibious quadrotor aircraft |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9016565B2 (en)* | 2011-07-18 | 2015-04-28 | Dylan T X Zhou | Wearable personal digital device for facilitating mobile device payments and personal use |

- 2020

- 2020-03-16CNCN202010180964.4Apatent/CN111216498B/enactiveActive

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4534455A (en)* | 1982-08-26 | 1985-08-13 | Aisin Seiki Kabushiki Kaisha | Wheel hub clutch assembly |

| GB9318739D0 (en)* | 1992-09-29 | 1993-10-27 | Borg Warner Automotive | Power transmitting assembly |

| CN106427435A (en)* | 2015-08-07 | 2017-02-22 | 刘新广 | Triphibian flying vehicle |

| CN106564349A (en)* | 2016-10-31 | 2017-04-19 | 广东工业大学 | Triphibian unmanned aerial vehicle |

| CN107758334A (en)* | 2017-11-09 | 2018-03-06 | 深圳市系存通信技术有限公司 | A kind of transfer robot |

| CN110182008A (en)* | 2019-05-31 | 2019-08-30 | 北京无线电测量研究所 | A kind of variable unmanned motor platform of appearance of two-stage type |

| CN209972084U (en)* | 2019-06-06 | 2020-01-21 | 贵州师范大学 | Foldable amphibious quadrotor aircraft |

| CN110588263A (en)* | 2019-09-26 | 2019-12-20 | 沈阳航空航天大学 | A multi-dwelling unmanned mobile platform system and its control method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111216498A (en) | 2020-06-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111216498B (en) | A kind of deformable multi-habitable robot and its control method | |

| EP3224140B1 (en) | High speed multi-rotor vertical takeoff and landing aircraft | |

| WO2019119556A1 (en) | Fixed-wing sea-air amphibious aircraft and control method | |

| US20120091257A1 (en) | Air vehicle | |