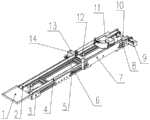

CN111180185A - Automatic output mechanism of transformer - Google Patents

Automatic output mechanism of transformerDownload PDFInfo

- Publication number

- CN111180185A CN111180185ACN202010055971.1ACN202010055971ACN111180185ACN 111180185 ACN111180185 ACN 111180185ACN 202010055971 ACN202010055971 ACN 202010055971ACN 111180185 ACN111180185 ACN 111180185A

- Authority

- CN

- China

- Prior art keywords

- transformer

- frame body

- profile frame

- plate

- fixed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/74—Feeding, transfer, or discharging devices of particular kinds or types

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Control Of Conveyors (AREA)

Abstract

Translated fromChineseDescription

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010055971.1ACN111180185B (en) | 2020-01-18 | 2020-01-18 | Automatic output mechanism of transformer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010055971.1ACN111180185B (en) | 2020-01-18 | 2020-01-18 | Automatic output mechanism of transformer |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111180185Atrue CN111180185A (en) | 2020-05-19 |

| CN111180185B CN111180185B (en) | 2025-07-29 |

Family

ID=70654792

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010055971.1AActiveCN111180185B (en) | 2020-01-18 | 2020-01-18 | Automatic output mechanism of transformer |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111180185B (en) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20090012675U (en)* | 2008-06-09 | 2009-12-14 | 세크론 주식회사 | Substrate material feeder for semiconductor device molding system |

| CN104931744A (en)* | 2015-05-27 | 2015-09-23 | 广东电网有限责任公司江门供电局 | Automatic sealing device for electric meter programming door switch |

| CN104959818A (en)* | 2015-06-30 | 2015-10-07 | 佛山隆深机器人有限公司 | Robot automatic assembling line for air conditioner base plates |

| CN205972710U (en)* | 2016-07-28 | 2017-02-22 | 昆山苏创达自动化有限公司 | Hold -in range assembly line |

| CN208358196U (en)* | 2018-06-21 | 2019-01-11 | 苏州德尔富自动化科技有限公司 | The feeding transplantation device of elastic slice |

| CN209396607U (en)* | 2019-01-02 | 2019-09-17 | 杭州君辰机器人有限公司 | Conveying mechanism and its truck-loading facilities |

| CN110294250A (en)* | 2019-07-01 | 2019-10-01 | 冯志高 | A kind of automatic transport pallet of miniature cold storage cargo |

| CN209614762U (en)* | 2019-04-11 | 2019-11-12 | 秦皇岛丰泰自动化设备制造有限公司 | Product conveying mechanism for a screw workstation |

| CN211016752U (en)* | 2020-01-18 | 2020-07-14 | 秦皇岛丰泰自动化设备制造有限公司 | Automatic output mechanism of transformer |

- 2020

- 2020-01-18CNCN202010055971.1Apatent/CN111180185B/enactiveActive

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20090012675U (en)* | 2008-06-09 | 2009-12-14 | 세크론 주식회사 | Substrate material feeder for semiconductor device molding system |

| CN104931744A (en)* | 2015-05-27 | 2015-09-23 | 广东电网有限责任公司江门供电局 | Automatic sealing device for electric meter programming door switch |

| CN104959818A (en)* | 2015-06-30 | 2015-10-07 | 佛山隆深机器人有限公司 | Robot automatic assembling line for air conditioner base plates |

| CN205972710U (en)* | 2016-07-28 | 2017-02-22 | 昆山苏创达自动化有限公司 | Hold -in range assembly line |

| CN208358196U (en)* | 2018-06-21 | 2019-01-11 | 苏州德尔富自动化科技有限公司 | The feeding transplantation device of elastic slice |

| CN209396607U (en)* | 2019-01-02 | 2019-09-17 | 杭州君辰机器人有限公司 | Conveying mechanism and its truck-loading facilities |

| CN209614762U (en)* | 2019-04-11 | 2019-11-12 | 秦皇岛丰泰自动化设备制造有限公司 | Product conveying mechanism for a screw workstation |

| CN110294250A (en)* | 2019-07-01 | 2019-10-01 | 冯志高 | A kind of automatic transport pallet of miniature cold storage cargo |

| CN211016752U (en)* | 2020-01-18 | 2020-07-14 | 秦皇岛丰泰自动化设备制造有限公司 | Automatic output mechanism of transformer |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111180185B (en) | 2025-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205387346U (en) | Assembly line module | |

| CN210149686U (en) | Self-adaptive box sealing system | |

| CN205274540U (en) | a product conveyor line | |

| CN212953014U (en) | Material grabbing and distance changing structure | |

| CN204489880U (en) | With the conveyer of panel height automatic lifting | |

| CN211016752U (en) | Automatic output mechanism of transformer | |

| CN111180185A (en) | Automatic output mechanism of transformer | |

| CN207792592U (en) | Lift and conveyer | |

| CN208783107U (en) | A kind of loudspeaker automatic assembly line | |

| CN217433579U (en) | Condensing tube and inner container assembling and pressing machine | |

| CN214289181U (en) | Vertical carbon dispensing mechanism | |

| CN202742014U (en) | Full-automatic shell buckling machine | |

| CN209554324U (en) | A sheet-fed standard matching machine | |

| CN108340630A (en) | A kind of high efficiency high-reliability two ply board automatic joint device | |

| CN113370314A (en) | Cutting saw, cutting production line and cutting method | |

| CN102700986B (en) | Crawler automatic air leakage paper receiving machine | |

| CN108116931B (en) | Automatic film sticking machine for index card | |

| CN220663072U (en) | Bag feeding centering mechanism | |

| CN205555439U (en) | Storage conveyer | |

| CN220536709U (en) | Dismounting-free jacking transfer machine | |

| CN218859513U (en) | Automatic balance device | |

| CN112440007A (en) | Modular cutting apparatus | |

| CN206437604U (en) | A kind of solar energy frame production robot automatic charging machine | |

| CN102951831B (en) | Glass toughening unit | |

| CN211638066U (en) | Stamping flow conveyor line |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | Effective date of registration:20250122 Address after:350000 Building 10, Zhonghai Huanyu Tianxia, Shangjie Town, Minhou County, Fuzhou City, Fujian Province Applicant after:Huang Jingwen Country or region after:China Address before:066000 Room 305, 3/F, No. 7, Wushan Road, Qinhuangdao Economic and Technological Development Zone, Hebei Province Applicant before:QINHUANGDAO FENGTAI AUTOMATION EQUIPMENT MANUFACTURING Co.,Ltd. Country or region before:China | |

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right | Effective date of registration:20250701 Address after:271100 Shandong Province, Jinan City, Laiwu High-tech Development Zone, Xiangshan Road No. 9 Applicant after:Shandong Ruihan Electric Power Engineering Co.,Ltd. Country or region after:China Address before:350000 Building 10, Zhonghai Huanyu Tianxia, Shangjie Town, Minhou County, Fuzhou City, Fujian Province Applicant before:Huang Jingwen Country or region before:China | |

| TA01 | Transfer of patent application right | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |