CN111091244B - A method for predicting the oil change interval of engine lubricating oil - Google Patents

A method for predicting the oil change interval of engine lubricating oilDownload PDFInfo

- Publication number

- CN111091244B CN111091244BCN201911291211.4ACN201911291211ACN111091244BCN 111091244 BCN111091244 BCN 111091244BCN 201911291211 ACN201911291211 ACN 201911291211ACN 111091244 BCN111091244 BCN 111091244B

- Authority

- CN

- China

- Prior art keywords

- lubricating oil

- oil

- mileage

- oxidation temperature

- initial oxidation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/04—Forecasting or optimisation specially adapted for administrative or management purposes, e.g. linear programming or "cutting stock problem"

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/06—Resources, workflows, human or project management; Enterprise or organisation planning; Enterprise or organisation modelling

- G06Q10/067—Enterprise or organisation modelling

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/30—Computing systems specially adapted for manufacturing

Landscapes

- Business, Economics & Management (AREA)

- Engineering & Computer Science (AREA)

- Strategic Management (AREA)

- Human Resources & Organizations (AREA)

- Economics (AREA)

- Entrepreneurship & Innovation (AREA)

- Marketing (AREA)

- Game Theory and Decision Science (AREA)

- Development Economics (AREA)

- Operations Research (AREA)

- Quality & Reliability (AREA)

- Tourism & Hospitality (AREA)

- Physics & Mathematics (AREA)

- General Business, Economics & Management (AREA)

- General Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- Educational Administration (AREA)

- Lubrication Details And Ventilation Of Internal Combustion Engines (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于润滑油技术领域,涉及一种发动机油换油周期判断技术,具体涉及一种发动机润滑油换油周期预测方法。The invention belongs to the technical field of lubricating oil, and relates to a technology for judging the oil change period of engine oil, in particular to a method for predicting the oil change period of engine lubricating oil.

背景技术Background technique

车用润滑油主要指发动机润滑油,是保持发动机可靠行驶、减小发动机摩擦能量损耗、防止发动机部件早期磨损的关键。润滑油更换也是汽车保养中最频繁的项目。按照4S店和汽车销售商的要求,目前我国民用轿车常用的换油周期基本是行车5000km或者6个月。对目前国内市场上278款不同品牌的民用轿车的推荐换油周期进行统计,约有56.1%的民用汽车推荐5000km进行发动机油更换,109款不同品牌民用轿车中,有78款车型推荐换油时间为6个月,6款车型推荐以3个月,约77%民用轿车要求在6个月以内进行润滑油更换。由于汽车保有量巨大,车用润滑油的大量使用与更换,导致车用润滑油消耗量已经占据我国润滑油年消耗总量的一半以上。车用润滑油的过度使用不仅造成石油资源的浪费,而且废油回收困难,容易造成环境污染。因此,合理科学的更换车用润滑油已经受到相关人士与广大车主关注。国外已经提倡将换油周期提高到1万公里以上。日本日石三菱润滑油研究所提出以硝酸酯为主要劣化指标,推测行车15000km后润滑油才完全失效;通用汽车公司的专利表明,美国本土通用品牌车辆可以每12000km(根据运行条件,可延长至16000km)或12个月进行发动机油更换。我国的路况和空气质量等因素与国外有差别,因此,尽管我国采用的汽车发动机及其润滑油与国外基本相同,延长换油周期依然存在疑虑,进展较缓慢。针对我国典型城市工况条件下运行的民用轿车进行了多组长时间的行车监测实验表明,当运行时长达到6个月时,各组润滑油的理化指标均远未达到国家现行换油标准(GB/T 8028-2010),试验用油仍然具有良好的润滑分散能力。因此,我国现行换油周期可以延长是肯定的。Automotive lubricating oil mainly refers to engine lubricating oil, which is the key to keep the engine running reliably, reduce the frictional energy loss of the engine, and prevent early wear and tear of engine components. Lubricating oil replacement is also the most frequent item in car maintenance. According to the requirements of 4S stores and car dealers, the oil change interval commonly used for civilian cars in my country is basically 5000km or 6 months. According to statistics on the recommended oil change intervals of 278 civilian cars of different brands in the domestic market, about 56.1% of civilian cars recommend 5000km for engine oil replacement. Among the 109 civilian cars of different brands, 78 models recommend

目前评估换油周期的方法主要是基于对润滑油的测试,有润滑油斑点试验法、红外光谱法以及传感器在线监控等。美国学者S.Jagammathan运用微传感器技术和神经网络算法,提出了一种通过监测发动机与润滑油运行状况以预测发动机油使用寿命的方法;R.E.Kauffman利用循环伏安方法测定润滑油中抗氧剂含量随时间的消耗量,来判断润滑油的换油周期。我国学者也对发动机油寿命评估进行了研究,通过测定车用发动机油介电常数表征其理化性能,红外光的透射值及散射值表征润滑油劣化程度等。但是,这些评估方法都要求对车用润滑油进行检测,相对复杂,成本较高,同时仅仅能够预测被测试润滑油的换油周期,没有给出简洁明了、直接可用的通用预测模型,不便于一般车主参考。At present, the methods for evaluating the oil change interval are mainly based on the test of lubricating oil, including lubricating oil spot test method, infrared spectroscopy and online sensor monitoring. American scholar S.Jagammathan used micro-sensor technology and neural network algorithm to propose a method to predict the service life of engine oil by monitoring the operating conditions of the engine and lubricating oil; R.E.Kauffman used cyclic voltammetry to determine the content of antioxidants in lubricating oil The consumption over time is used to judge the oil change interval of lubricating oil. Scholars in my country have also conducted research on the life evaluation of engine oil, by measuring the dielectric constant of vehicle engine oil to characterize its physical and chemical properties, and the transmission value and scattering value of infrared light to characterize the degree of deterioration of lubricating oil. However, these evaluation methods all require the detection of automotive lubricants, which are relatively complicated and costly. At the same time, they can only predict the oil change interval of the tested lubricants, and they do not provide a concise and directly available general prediction model, which is inconvenient. General car owner reference.

发明内容Contents of the invention

本发明根据获得的大量润滑油样品理化性能及其对应的运行工况数据,通过多重线性回归分析方法,研究三类车用润滑油的起始氧化温度变化与运行里程、运行时间之间的关系,尝试建立基于起始氧化温度的车用润滑油换油周期数学模型,便于用户直接在决定换油时参考与借鉴。According to the physical and chemical properties of a large number of lubricating oil samples obtained and the corresponding operating condition data, the present invention studies the relationship between the initial oxidation temperature change of the three types of lubricating oils for vehicles and the running mileage and running time through the multiple linear regression analysis method , trying to establish a mathematical model of the oil change cycle of automotive lubricants based on the initial oxidation temperature, which is convenient for users to directly refer to and learn from when deciding to change oil.

鉴于以上思路,本发明的目的在于提供一种发动机润滑油换油周期预测方法,解决现有技术中机动车发动机润滑油浪费严重的问题。In view of the above ideas, the purpose of the present invention is to provide a method for predicting the oil change interval of engine lubricating oil, which solves the problem of serious waste of motor vehicle engine lubricating oil in the prior art.

本发明为实现上述目的所采用的技术方案为:The technical scheme that the present invention adopts for realizing the above object is:

一种发动机润滑油换油周期预测方法,其特征在于,包括以下步骤:A method for predicting engine lubricating oil change intervals, comprising the following steps:

步骤1、参数选取,选取起始氧化温度为润滑油质量参考指标,即润滑油的起始氧化温度达到一定阈值,即需要更换,选取运行里程和运行时间作为发动机换油的直观参考指标;

步骤2、以起始氧化温度为因变量,机动车的运行里程和运行时间为自变量,建立润滑油质量的多重线性回归模型;

步骤3、根据多重线性回归模型计算换油周期,即在给定时间内,机动车可以运行的最大里程数或者给定的运行里程内最长的运行时间。Step 3. Calculate the oil change interval according to the multiple linear regression model, that is, within a given time, the maximum mileage that the motor vehicle can run or the longest running time within a given mileage.

优选地,所述多重线性回归模型如下:Preferably, the multiple linear regression model is as follows:

其中,y为起始氧化温度,x1为运行里程,单位百公里;x2为运行时间,单位为月;y0为润滑油对发动机起到保护作用的临界起始氧化温度,C为常数项,B1为运行里程的偏回归系数,B2为运行时间的偏回归系数。Among them, y is the initial oxidation temperature, x1 is the running mileage, the unit is hundreds of kilometers; x2 is the running time, the unit is month; y0 is the critical initial oxidation temperature for the lubricating oil to protect the engine, and C is a constant Item, B1 is the partial regression coefficient of running mileage, B2 is the partial regression coefficient of running time.

优选地,所述多重线性回归模型中,常数项C、偏回归系数B1、B2与润滑油种类有关;Preferably, in the multiple linear regression model, the constant term C, partial regression coefficients B1 and B2 are related to the type of lubricating oil;

当润滑油种类为矿物油时:C=3.685,B1=-0.013,B2=-0.104;When the lubricating oil is mineral oil: C=3.685, B1 =-0.013, B2 =-0.104;

当润滑油种类为半合成油润滑油时:C=3.803,B1=-0.014,B2=-0.056;When the type of lubricating oil is semi-synthetic lubricating oil: C=3.803, B1 =-0.014, B2 =-0.056;

当润滑油种类为全合成油润滑油时:C=3.971,B1=-0.012,B2=-0.031。When the type of lubricating oil is fully synthetic lubricating oil: C=3.971, B1 =-0.012, B2 =-0.031.

优选地,在步骤3计算换油周期过程中,对起始氧化温度y设定一定保证车辆运行的缓冲余量,即3<y-y0≤8。Preferably, during the calculation of the oil change interval in step 3, a certain buffer margin is set for the initial oxidation temperature y to ensure vehicle operation, that is, 3<yy0 ≤8.

本发明的有益效果:Beneficial effects of the present invention:

(1)本发明运用多重线性回归分析方法,在7台车312组实车润滑油测试数据的基础上分别建立了针对矿物油、半合成油、全合成油以及混合用油条件的润滑油起始氧化温度与行车里程和运行时间回归分析模型。拟合模型精度高,公式简洁,能够较好的反应车辆运行里程、运行时间对起始氧化温度的影响,便于用户在确定更换车用润滑油时参考和借鉴,为科学评估换油周期提供一定的依据。(1) The present invention utilizes the multiple linear regression analysis method, and on the basis of the test data of 312 groups of actual vehicle lubricating oils in 7 vehicles, respectively establishes the lubricating oil starting point for mineral oil, semi-synthetic oil, fully synthetic oil and mixed oil conditions. Regression analysis model of initial oxidation temperature and driving mileage and running time. The fitting model has high precision and simple formula, which can better reflect the impact of the vehicle's operating mileage and operating time on the initial oxidation temperature. basis.

(2)本发明将拟合模型用于现行民用轿车典型的换油周期(5000km、6个月)校核,得到的起始氧化温度预测值均远远高于添加剂完全消耗时的临界值,说明此时换油是一种浪费;根据模型推算,在12个月内,矿物油可运行6366km,而半合成油及全合成油在18个月内分别可运行约8468km及15030km,在实际应用中适当的延长换油周期是有试验依据的。(2) The present invention applies the fitting model to the typical oil change interval (5000km, 6 months) check of the existing civilian car, and the initial oxidation temperature prediction value obtained is all far higher than the critical value when the additive is completely consumed, It shows that oil change at this time is a waste; according to the model calculation, within 12 months, mineral oil can run 6366km, while semi-synthetic oil and fully synthetic oil can run about 8468km and 15030km respectively within 18 months. Properly extending the oil change interval is based on experiments.

附图说明Description of drawings

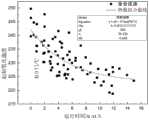

图1为矿物油起始氧化温度与运行里程的关系。Figure 1 shows the relationship between the initial oxidation temperature of mineral oil and the running mileage.

图2为矿物油起始氧化温度与运行时间的关系。Figure 2 is the relationship between the initial oxidation temperature of mineral oil and the running time.

图3为半合成油起始氧化温度与运行里程的关系。Figure 3 shows the relationship between the initial oxidation temperature of semi-synthetic oil and the running mileage.

图4为半合成油起始氧化温度与运行时间的关系Figure 4 is the relationship between the initial oxidation temperature of semi-synthetic oil and the running time

图5为合成油起始氧化温度与运行里程的关系。Figure 5 shows the relationship between the initial oxidation temperature of synthetic oil and the running mileage.

图6为合成油起始氧化温度与运行时间的关系。Figure 6 shows the relationship between the initial oxidation temperature of synthetic oil and the running time.

具体实施方式Detailed ways

下面结合附图对本发明进行举例说明。The present invention is illustrated below in conjunction with the accompanying drawings.

本发明提供了一种发动机润滑油换油周期预测方法,具体方法如下:The invention provides a method for predicting the oil change interval of engine lubricating oil, the specific method is as follows:

1、试验对象选取,本发明选取常规城市工况下运行的7台民用轿车为测试对象,进行长时间运行状况和润滑油性能跟踪监测。试验车辆基本信息、所用润滑油品牌及种类、总运行里程以及总运行时间如表1所示。试验车辆完全按照车主的意愿使用,无任何附加要求。根据车辆具体的运行状况定期(约一个月取一次)从试验车辆曲轴箱中采取试验油样,直至测试结束。利用NETZSCH HP204高压差式扫描量热仪(PDSC)测定试验油样的起始氧化温度(升温速率为10℃/min,氧气流量为100mL/min,氧气压力3.5MPa),分析润滑油氧化安定性随服役时间延长的变化特征。试验时间跨度为:2015年-2018年,总数据样本为312组。1. Test object selection. The present invention selects 7 civil cars operated under conventional urban working conditions as test objects, and carries out long-term operation status and lubricating oil performance tracking and monitoring. The basic information of the test vehicle, the brand and type of lubricating oil used, the total running mileage and the total running time are shown in Table 1. The test vehicle is used completely according to the wishes of the owner without any additional requirements. Take test oil samples from the crankcase of the test vehicle at regular intervals (about once a month) according to the specific operating conditions of the vehicle until the end of the test. Use NETZSCH HP204 high pressure differential scanning calorimeter (PDSC) to measure the initial oxidation temperature of the test oil sample (heating rate is 10°C/min, oxygen flow rate is 100mL/min, oxygen pressure is 3.5MPa), and the oxidation stability of lubricating oil is analyzed Changing characteristics with prolonged service time. The time span of the experiment is: 2015-2018, and the total data samples are 312 groups.

表1试验车辆及试验润滑油类型Table 1 Test vehicle and test lubricant type

2、数据分析方法,现有技术表明,在众多的润滑油理化指标中,润滑油的起始氧化温度变化最能够表征车用润滑油性能的衰退规律,根据润滑油的起始氧化温度来确定是否必须更换车用润滑油是比较科学的,其他指标如酸性物质生成,不溶混合物累积或抗磨性能的下降均与润滑油抗氧能力下降密切相关。对于车主而言,润滑油的运行里程(俗称公里数)与润滑油使用时间是最直接和最直观的决定换油周期的参数。因此,以起始氧化温度为指标,在大量试验数据基础上,建立我国典型运行工况下润滑油起始氧化温度与运行里程、运行时间关系模型,最容易被车主采用。2. Data analysis method. The existing technology shows that among many physical and chemical indicators of lubricating oil, the change of initial oxidation temperature of lubricating oil can best characterize the decline law of the performance of automotive lubricating oil. It is determined according to the initial oxidation temperature of lubricating oil Whether it is necessary to replace the lubricating oil for vehicles is relatively scientific. Other indicators such as the formation of acidic substances, the accumulation of insoluble mixtures or the decline in anti-wear performance are closely related to the decline in the anti-oxidation ability of lubricating oil. For car owners, the operating mileage (commonly known as the number of kilometers) of lubricating oil and the use time of lubricating oil are the most direct and intuitive parameters to determine the oil change interval. Therefore, using the initial oxidation temperature as an index and based on a large number of test data, the model of the relationship between the initial oxidation temperature of lubricating oil and the operating mileage and operating time under typical operating conditions in my country is established, which is most likely to be adopted by vehicle owners.

本发明分别针对采用单一矿物油、半合成油以及全合成油的车辆,以起始氧化温度为被解释变量,以运行里程及运行时间为解释变量(表2),建立多重线性回归模型,并通过岭回归分析得出更加符合实际的方程,分析车用润滑油氧化安定性随运行里程以及运行时间的变化特征。The present invention aims at adopting the vehicle of single mineral oil, semi-synthetic oil and fully synthetic oil respectively, with initial oxidation temperature as explained variable, with running mileage and running time as explanatory variable (Table 2), multiple linear regression model is established, and Through the ridge regression analysis, a more realistic equation is obtained, and the variation characteristics of the oxidation stability of the vehicle lubricating oil with the running mileage and running time are analyzed.

表2分析模型变量表Table 2 Analysis model variable table

第一步:选取起始氧化温度为因变量,运行里程与运行时间为自变量,模型选取为多重线性回归模型,如表1所示;多重线性回归分析的一般模型形式为:Step 1: Select the initial oxidation temperature as the dependent variable, and the operating mileage and operating time as the independent variables. The model is selected as a multiple linear regression model, as shown in Table 1; the general model form of multiple linear regression analysis is:

上式中,Y为被解释变量;表示给定自变量取值时因变量y的估计值;μ为随机误差,表示具体取值与平均取值间的差异,也称为残差;α为常量,表示当所有自变量(即解释变量)取值均为0时因变量的估计值;xi为解释变量;γi为偏回归系数,表示当其他自变量取值固定值,自变量xi每改变一个单位时的变化量。In the above formula, Y is the explained variable; Indicates the estimated value of the dependent variable y when the value of the independent variable is given; μ is a random error, indicating the difference between the specific value and the average value, also known as the residual; α is a constant, indicating that when all independent variables (that is, explained variable) is theestimated value of the dependent variable when the value is 0; xi is the explanatory variable; amount of change.

第二步:对试验车辆润滑油的起始氧化温度随运行里程与运行时间分别做散点图观察分布趋势(以矿物油油为例),如图1、2所示;Step 2: Make a scatter plot of the initial oxidation temperature of the lubricating oil of the test vehicle along with the running mileage and running time to observe the distribution trend (taking mineral oil as an example), as shown in Figures 1 and 2;

第三步:根据多重线性回归模型要求选取指数函数进行变量变换使自变量与因变量之间满足线性关系(以矿物油为例),对原始数据进行变量变换的方法如下。首先对原始变量(运行里程、时间)和起始氧化温度数据分别进行非线性拟合,拟合模型选取指数函数,模型形式如式1所示The third step: According to the requirements of the multiple linear regression model, an exponential function is selected for variable transformation to satisfy the linear relationship between the independent variable and the dependent variable (taking mineral oil as an example). The method of variable transformation for the original data is as follows. Firstly, the original variables (mileage, time) and initial oxidation temperature data are nonlinearly fitted, and the fitting model is an exponential function, and the model form is shown in

式中y0、A、R0均为常数。在拟合过程中,y0的拟合值均处于200附近(近似等于基础油的起始氧化温度),因此固定y0为200。In the formula, y0 , A and R0 are all constants. During the fitting process, the fitted values of y0 are all around 200 (approximately equal to the initial oxidation temperature of base oil), so y0 is fixed at 200.

拟合结果如下:The fitting results are as follows:

其中x1、x2分别代表运行里程/100km(百公里数)和运行时间/month(运行月数),y1表示单独以运行里程x1作为自变量的因变量,y2表示单独以运行时间x2作为自变量的因变量,经过线性变换可得(如图3、4所示):Among them, x1 and x2 represent running mileage/100km (hundred kilometers) and running time/month (running months), y1 represents the dependent variable with running mileage x1 as independent variable, and y2 represents running alone Time x2 is used as the dependent variable of the independent variable, and it can be obtained through linear transformation (as shown in Figures 3 and 4):

ln(y1-200)=ln43.101-0.034x1ln(y1 -200)=ln43.101-0.034x1

ln(y2-200)=ln40.233-0.237x2ln(y2 -200)=ln40.233-0.237x2

令Y*=ln(y-200)并替换上式:Let Y* =ln(y-200) and replace the above formula:

Y*=ln43.101–0.034x1 式2Y* =ln43.101–0.034x1 formula 2

Y*=ln40.233–0.237x2 式3Y* =ln40.233–0.237x2 Equation 3

第四步:此时过渡变量Y*与x1、x2为线性关系。同理可将半合成油以及全合成油进行变量变换,将过度变量Y*与x1、x2数据导入数据分析软件进行多重线性回归分析,得到Y*=C+B1x1+B2x2,将计算结果进行变量置换,即可实现车用润滑油起始氧化温度随运行里程以及运行时间变化特征的回归分析,如式3、表2所示;Step 4: At this time, the transition variable Y* has a linear relationship with x1 and x2 . In the same way, semi-synthetic oil and fully synthetic oil can be transformed into variables, and the excessive variable Y* and x1 , x2 data can be imported into the data analysis software for multiple linear regression analysis, and Y* = C + B1 x1 + B2 can be obtained x2 , by performing variable substitution on the calculation results, the regression analysis of the characteristics of the initial oxidation temperature of the vehicle lubricating oil with the operating mileage and operating time can be realized, as shown in Equation 3 and Table 2;

其中,y为起始氧化温度,x1为运行里程,单位百公里;x2为运行时间,单位为月;y0为润滑油对发动机起到保护作用的临界起始氧化温度,y0=200;C为常数项,B1为运行里程的偏回归系数,B2为运行时间的偏回归系数。Among them, y is the initial oxidation temperature, x1 is the running mileage, the unit is hundreds of kilometers; x2 is the running time, the unit is month; y0 is the critical initial oxidation temperature at which the lubricating oil plays a protective role on the engine, y0 = 200; C is a constant term, B1 is the partial regression coefficient of running mileage, and B2 is the partial regression coefficient of running time.

表3分析模型参数Table 3 Analysis model parameters

第五步:根据实验模型与原始数据比较推算,在城市工况下,矿物润滑油可在12个月内运行6366km;半合成润滑油在18个月内可运行8468km,而全合成油在18个月内可运行15030km,如表4所示。Step 5: According to the comparison between the experimental model and the original data, under urban conditions, mineral lubricating oil can run 6366km within 12 months; semi-synthetic lubricating oil can run 8468km within 18 months; It can run 15030km within a month, as shown in Table 4.

表4模型换油周期预测表Table 4 Model oil change interval prediction table

总结:Summarize:

(1)本发明运用多重线性回归分析方法,在7台车312组实车润滑油测试数据的基础上分别建立了针对矿物油、半合成油、全合成油以及混合用油条件的润滑油起始氧化温度与行车里程和运行时间回归分析模型。拟合模型精度高,公式简洁,能够较好的反应车辆运行里程、运行时间对起始氧化温度的影响,便于用户在确定更换车用润滑油时参考和借鉴,为科学评估换油周期提供一定的依据。(1) The present invention utilizes the multiple linear regression analysis method, and on the basis of the test data of 312 groups of actual vehicle lubricating oils in 7 vehicles, respectively establishes the lubricating oil starting point for mineral oil, semi-synthetic oil, fully synthetic oil and mixed oil conditions. Regression analysis model of initial oxidation temperature and driving mileage and running time. The fitting model has high precision and simple formula, which can better reflect the impact of the vehicle's operating mileage and operating time on the initial oxidation temperature. basis.

(2)本发明将拟合模型用于现行民用轿车典型的换油周期(5000km、6个月)校核,得到的起始氧化温度预测值均远远高于添加剂完全消耗时的临界值,说明此时换油是一种浪费;根据模型推算,在12个月内,矿物油可运行6366km,而半合成油及全合成油在18个月内分别可运行约8468km及15030km,在实际应用中适当的延长换油周期是有试验依据的。(2) The present invention applies the fitting model to the typical oil change interval (5000km, 6 months) check of the existing civilian car, and the initial oxidation temperature prediction value obtained is all far higher than the critical value when the additive is completely consumed, It shows that oil change at this time is a waste; according to the model calculation, within 12 months, mineral oil can run 6366km, while semi-synthetic oil and fully synthetic oil can run about 8468km and 15030km respectively within 18 months. Properly extending the oil change interval is based on experiments.

Claims (3)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911291211.4ACN111091244B (en) | 2019-12-16 | 2019-12-16 | A method for predicting the oil change interval of engine lubricating oil |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911291211.4ACN111091244B (en) | 2019-12-16 | 2019-12-16 | A method for predicting the oil change interval of engine lubricating oil |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111091244A CN111091244A (en) | 2020-05-01 |

| CN111091244Btrue CN111091244B (en) | 2023-02-03 |

Family

ID=70396490

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911291211.4AActiveCN111091244B (en) | 2019-12-16 | 2019-12-16 | A method for predicting the oil change interval of engine lubricating oil |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111091244B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4530449A1 (en)* | 2023-09-26 | 2025-04-02 | GEOTAB Inc. | Systems and methods for estimating a remaining useful life of vehicle engine oil |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112232530B (en)* | 2020-09-11 | 2021-09-21 | 上海远度汽车科技有限公司 | Automobile maintenance cycle operation method and vehicle-mounted intelligent operation system |

| CN113012763B (en)* | 2021-02-24 | 2022-02-11 | 西南石油大学 | Crude oil oxidation reaction kinetic model building method based on four-group components |

| CN113343411A (en)* | 2021-04-20 | 2021-09-03 | 北京新联铁集团股份有限公司 | Method and device for determining gear box lubricating oil replacement time and electronic equipment |

| CN114778553A (en)* | 2022-04-18 | 2022-07-22 | 中汽研汽车检验中心(天津)有限公司 | An oil spot detection system for rapid identification of lubricating oil quality |

| CN115424368A (en)* | 2022-08-25 | 2022-12-02 | 武汉迪昌科技有限公司 | Method and device for testing unpowered marshalling of EMUs |

| CN116227727A (en)* | 2023-03-20 | 2023-06-06 | 一汽解放汽车有限公司 | Method and device for evaluating grease replacement cycle and computer equipment |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105205565A (en)* | 2015-09-30 | 2015-12-30 | 成都民航空管科技发展有限公司 | Controller workload prediction method and system based on multiple regression model |

| CN109164249A (en)* | 2018-10-09 | 2019-01-08 | 武汉材料保护研究所有限公司 | A kind of petrol engine lubricants performance appraisal procedure based on onboard diagnostic system |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010016110A1 (en)* | 2008-08-05 | 2010-02-11 | 富士通株式会社 | Method of creating estimation model by means of multiple regression analysis, creation system and creation program |

- 2019

- 2019-12-16CNCN201911291211.4Apatent/CN111091244B/enactiveActive

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105205565A (en)* | 2015-09-30 | 2015-12-30 | 成都民航空管科技发展有限公司 | Controller workload prediction method and system based on multiple regression model |

| CN109164249A (en)* | 2018-10-09 | 2019-01-08 | 武汉材料保护研究所有限公司 | A kind of petrol engine lubricants performance appraisal procedure based on onboard diagnostic system |

Non-Patent Citations (3)

| Title |

|---|

| 城市道路交通拥堵预测及持续时间研究;熊励等;《公路》;20171125(第11期);全文* |

| 基于SPSS湿法烟气脱硫系统的优化;刘延泉等;《电力科学与工程》;20121028(第10期);全文* |

| 福州水泥路面的温度预测及气象要素分析;曾惠珍等;《四川理工学院学报(自然科学版)》;20131029(第05期);全文* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4530449A1 (en)* | 2023-09-26 | 2025-04-02 | GEOTAB Inc. | Systems and methods for estimating a remaining useful life of vehicle engine oil |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111091244A (en) | 2020-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111091244B (en) | A method for predicting the oil change interval of engine lubricating oil | |

| CN111126685B (en) | Method for establishing engine lubricating oil quality prediction model | |

| Kral Jr et al. | Degradation and chemical change of longlife oils following intensive use in automobile engines | |

| US10458830B2 (en) | Method for improving fuel economy test precision in on-road vehicles | |

| CN110988311B (en) | Vehicle oil life diagnosis method and device, vehicle and storage medium | |

| De Carvalho et al. | Lubricant viscosity and viscosity improver additive effects on diesel fuel economy | |

| Wolak | TBN performance study on a test fleet in real-world driving conditions using present-day engine oils | |

| CN109164249B (en) | A method for evaluating the performance of gasoline engine lubricating oil based on on-board diagnostic system | |

| CN112232530B (en) | Automobile maintenance cycle operation method and vehicle-mounted intelligent operation system | |

| Styer et al. | Fuel economy beyond ILSAC GF-5: correlation of modern engine oil tests to real world performance | |

| Wei et al. | Motor oil condition evaluation based on on-board diagnostic system | |

| CN111311783A (en) | Vehicle-mounted oil consumption data analysis method and system | |

| Loman et al. | Comparison of fuel consumption of a passenger car depending on the driving style of the driver | |

| CN103471963A (en) | Performance analysis experiment of internal combustion engine oil | |

| Alimov et al. | Choosing of rational periodicity of engine crankcase oil changing taking into account energy-saving properties of oils | |

| Youngk | Automobile engine reliability, maintainability and oil maintenance | |

| Ha et al. | Development of driver fuel economy index for real road fuel economy | |

| RU2129711C1 (en) | Method checking reliability indices of motor vehicle | |

| WolAk et al. | Evaluation of engine oil foaming tendency under urban driving conditions | |

| Van Rensselar | PC-11 and GF-6: New engines drive change in oil specs. | |

| Zöldy | Engine oil test method development | |

| Kwak et al. | Continuously Variable Transmission (CVT) Fuel Economy | |

| Wierzbicka et al. | Evaluation of deterioration of engine oil properties in the function of mileage | |

| Kollmann et al. | Extended Oil Drain Intervals-Conservation of Resources or Reduction of Engine Life (Part II | |

| Idros et al. | Optical behavior of transmission oil lubricant for degradation monitoring |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |