CN110874055A - Prediction and control method for hypersonic aircraft separation process under action of two-phase flow field - Google Patents

Prediction and control method for hypersonic aircraft separation process under action of two-phase flow fieldDownload PDFInfo

- Publication number

- CN110874055A CN110874055ACN201811014136.2ACN201811014136ACN110874055ACN 110874055 ACN110874055 ACN 110874055ACN 201811014136 ACN201811014136 ACN 201811014136ACN 110874055 ACN110874055 ACN 110874055A

- Authority

- CN

- China

- Prior art keywords

- flow field

- separation

- angle

- angular velocity

- equation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000926separation methodMethods0.000titleclaimsabstractdescription81

- 238000000034methodMethods0.000titleclaimsabstractdescription45

- 230000005514two-phase flowEffects0.000titleclaimsabstractdescription11

- 230000009471actionEffects0.000titleclaimsabstractdescription7

- 238000004364calculation methodMethods0.000claimsabstractdescription32

- 239000012530fluidSubstances0.000claimsabstractdescription17

- 239000002243precursorSubstances0.000claimsabstractdescription4

- 238000004088simulationMethods0.000claimsdescription14

- 230000008878couplingEffects0.000claimsdescription10

- 238000010168coupling processMethods0.000claimsdescription10

- 238000005859coupling reactionMethods0.000claimsdescription10

- 206010034719Personality changeDiseases0.000claimsdescription4

- 238000006073displacement reactionMethods0.000claimsdescription4

- 230000000704physical effectEffects0.000claimsdescription3

- 239000006185dispersionSubstances0.000claimsdescription2

- 238000012937correctionMethods0.000abstractdescription2

- 238000013461designMethods0.000description9

- 230000008569processEffects0.000description8

- 230000008859changeEffects0.000description3

- 238000010586diagramMethods0.000description3

- 238000004458analytical methodMethods0.000description2

- 238000011438discrete methodMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 230000036544postureEffects0.000description2

- 238000012360testing methodMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 238000012805post-processingMethods0.000description1

- 238000007781pre-processingMethods0.000description1

- 238000012545processingMethods0.000description1

- 238000011160researchMethods0.000description1

- 238000012795verificationMethods0.000description1

Images

Classifications

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B11/00—Automatic controllers

- G05B11/01—Automatic controllers electric

- G05B11/36—Automatic controllers electric with provision for obtaining particular characteristics, e.g. proportional, integral, differential

- G05B11/42—Automatic controllers electric with provision for obtaining particular characteristics, e.g. proportional, integral, differential for obtaining a characteristic which is both proportional and time-dependent, e.g. P. I., P. I. D.

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Automation & Control Theory (AREA)

- Aerodynamic Tests, Hydrodynamic Tests, Wind Tunnels, And Water Tanks (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于飞行器分离设计领域,是大气层内高超声速飞行器分离过程的一种高精度仿真分析方法。The invention belongs to the field of aircraft separation design, and is a high-precision simulation analysis method for the separation process of a hypersonic aircraft in the atmosphere.

背景技术Background technique

高超声速飞行器凭借其独特的优势正逐渐成为航天运输、军事攻防博弈等领域的研究热点。由于其在大气层内高超声速飞行,其分离过程面临着极其严酷的环境,大动压及喷流干扰等因素影响,使其分离流场极为复杂,且与分离运动相耦合,分离过程预示困难。传统分离设计方法,采用定常气动数据插值表作为分离仿真计算的依据,已经不能满足该类飞行其分离可靠设计的需求。With its unique advantages, hypersonic vehicles are gradually becoming a research hotspot in the fields of space transportation and military offensive and defensive games. Due to its hypersonic flight in the atmosphere, its separation process is faced with extremely harsh environment, high dynamic pressure and jet interference and other factors, which make the separation flow field extremely complex and coupled with the separation movement. The separation process indicates difficulties. The traditional separation design method, which uses the steady aerodynamic data interpolation table as the basis for separation simulation calculation, can no longer meet the requirements of reliable separation design for this type of flight.

发明内容SUMMARY OF THE INVENTION

本发明的技术解决问题是:本发明提出了两相流场作用下高超声速静不稳定飞行器分离过程精确预示与主动控制方法,目的在于解决大气层内高超声速飞行器复杂气动干扰作用下的分离设计难题。The technical problem solved by the present invention is: the present invention proposes a method for accurate prediction and active control of the separation process of a hypersonic statically unstable aircraft under the action of a two-phase flow field, and the purpose is to solve the separation design problem under the complex aerodynamic interference of the hypersonic aircraft in the atmosphere .

本发明的技术解决方案是:两相流场作用下高超声速飞行器分离过程预示方法,通过下述方式实现:The technical solution of the present invention is: the prediction method of the separation process of the hypersonic aircraft under the action of the two-phase flow field is realized by the following methods:

采用重叠网格方法对高超声速飞行器的流场进行离散;Using the overlapping grid method to discretize the flow field of the hypersonic vehicle;

将反推火箭内流体等效为空气,对流体的动能和动量开展等效修正,建立等效后流场的N-S方程;The fluid in the reverse thrust rocket is equivalent to air, and the kinetic energy and momentum of the fluid are equivalently corrected, and the N-S equation of the equivalent flow field is established;

根据上述建立的等效后流场的N-S方程进行流场CFD计算,得到分离过程中分离体受到的气动力及力矩;According to the N-S equation of the equivalent flow field established above, the flow field CFD calculation is carried out, and the aerodynamic force and moment of the separation body during the separation process are obtained;

利用上述得到的分离体受到的气动力及力矩,求解不同工况下的分离运动,得到分离体的质心运动及姿态运动参数;Using the above-obtained aerodynamic force and moment of the separation body, the separation motion under different working conditions is solved, and the centroid motion and attitude motion parameters of the separation body are obtained;

所述的分离体包括前体和后体。The separated body includes a precursor and a rear body.

进一步的,建立等效后流场的N-S方程通过下述方式实现:Further, the N-S equation of the equivalent flow field is established by the following methods:

第一步,采用多组分N-S方程模拟喷管内部的流场,获得喷管出口处多组分流体的动量及动能;In the first step, the multi-component N-S equation is used to simulate the flow field inside the nozzle, and the momentum and kinetic energy of the multi-component fluid at the nozzle outlet are obtained;

第二步,根据流体动量动能表达式及第一步中获得的喷管出口处多组分流体的动量及动能,采用空气的物理属性,获得喷管出口处的空气流动参数;In the second step, according to the fluid momentum kinetic energy expression and the momentum and kinetic energy of the multi-component fluid at the nozzle outlet obtained in the first step, the physical properties of the air are used to obtain the air flow parameters at the nozzle outlet;

第三步,根据一维等熵关系式,获得简化后的喷管喉部外形及喉部的流动参数;In the third step, according to the one-dimensional isentropic relationship, the simplified shape of the nozzle throat and the flow parameters of the throat are obtained;

第四步,根据普朗特迈耶尔膨胀关系式进行喉部扩张角修型,使简化后的气体膨胀角与多组分流动一致;The fourth step is to modify the expansion angle of the throat according to the Prandt-Meyer expansion relationship, so that the simplified gas expansion angle is consistent with the multi-component flow;

第五步,采用简化后的喉部外形及修型后的喷管扩张角及喉部的流动参数,建立等效后流场的N-S方程。The fifth step is to establish the N-S equation of the equivalent flow field by using the simplified throat shape and the modified nozzle expansion angle and the flow parameters of the throat.

进一步的,求解不同工况下的分离运动,得到分离体的质心运动及姿态运动参数,通过采用流场CFD与六自由度运动耦合计算的方法进行分离仿真预示。Further, the separation motion under different working conditions is solved, and the centroid motion and attitude motion parameters of the separation body are obtained, and the separation simulation prediction is carried out by using the method of coupling calculation of flow field CFD and six-degree-of-freedom motion.

进一步的,所述的耦合计算将整个分离过程离散成若干的时间步,具体步骤如下:Further, the coupling calculation discretizes the entire separation process into several time steps, and the specific steps are as follows:

(1)在当前时间步上利用等效后流场的N-S方程求解流场,得到作用在前体和后体上的气动力和力矩;(1) Use the N-S equation of the equivalent rear flow field to solve the flow field at the current time step, and obtain the aerodynamic forces and moments acting on the front and rear bodies;

(2)将当前时间步得到的前体和后体上的气动力和力矩连同其它外力一齐代入六自由度刚体运动方程,求得时间步长Δt内前体和后体的位移和姿态变化,得到下一个时间步前体和后体的位置和姿态;(2) Substitute the aerodynamic forces and moments on the front and rear bodies obtained at the current time step together with other external forces into the six-degree-of-freedom rigid body motion equation, and obtain the displacement and attitude changes of the front and rear bodies in the time step Δt, Get the position and pose of the front and rear bodies in the next time step;

(3)针对上述得到前体和后体的新位置、姿态,利用重叠网格得到新的流场离散,并转步骤(1),如此循环,直到分离结束。(3) For the new positions and attitudes of the front and rear bodies obtained above, use the overlapping grid to obtain a new flow field dispersion, and go to step (1), and so on until the separation ends.

进一步的,在步骤(2)计算得到前体和后体的位置和姿态后,进行是否安全分离判断,若前体和后体发生碰撞或者干涉,则结束当前仿真;否则执行步骤(3)。Further, after calculating the positions and postures of the front body and the rear body in step (2), it is judged whether it is safe to separate. If the front body and the rear body collide or interfere, the current simulation is ended; otherwise, step (3) is performed.

进一步的,所述的时间步长Δt<5ms。Further, the time step Δt<5ms.

两相流场作用下高超声速飞行器分离过程控制方法,在分离过程中,根据实时计算的分离体的质心运动及姿态运动参数对俯仰角、偏航角和滚转角分别采用比例反馈控制律进行分离过程主动控制。The separation process control method of hypersonic aircraft under the action of two-phase flow field. In the separation process, the pitch angle, yaw angle and roll angle are separated by proportional feedback control law according to the real-time calculation of the center of mass motion and attitude motion parameters of the separation body. Process active control.

进一步的,采用比例反馈控制律确定的控制舵偏角为:Further, the control rudder deflection angle determined by the proportional feedback control law is:

其中:Dψ、Dγ分别为俯仰、偏航和滚转控制舵偏角;为当前俯仰角和角速度,为期望的俯仰角和角速度,为俯仰角反馈系数和角速度反馈系数;ψu,为当前偏航角和角速度,ψq,为期望的偏航角和角速度,Kψ,Cψ为偏航角反馈系数和角速度反馈系数;γu,为当前滚转角和角速度,γq,为期望的滚转角和角速度,Kγ,Cγ为滚转角反馈系数和角速度反馈系数。in: Dψ , Dγ are the pitch, yaw and roll control rudder deflection angles, respectively; is the current pitch angle and angular velocity, are the desired pitch angle and angular velocity, are pitch angle feedback coefficient and angular velocity feedback coefficient; ψu , is the current yaw angle and angular velocity, ψq , are the desired yaw angle and angular velocity, Kψ , Cψ are the yaw angle feedback coefficient and angular velocity feedback coefficient; γu , is the current roll angle and angular velocity, γq , are the desired roll angle and angular velocity, Kγ , Cγ are the roll angle feedback coefficient and the angular velocity feedback coefficient.

进一步的,Kψ、Kγ的取值范围为2~4。further, The value range of Kψ and Kγ is 2-4.

进一步的,Cψ、Cγ的取值范围为0.2~0.5。further, The values of Cψ and Cγ range from 0.2 to 0.5.

本发明与现有技术相比有益效果为:Compared with the prior art, the present invention has the following beneficial effects:

高超声速飞行器在大气层内进行分离时,面临着极其严酷的环境,大动压及喷流干扰等因素影响,使其分离流场极为复杂,一方面,复杂的流场造成作用在飞行器上的气动力和力矩变化规律复杂,采用传统的定常状态气动数据插值表不能很精确地得到作用在飞行器上真实气动力和力矩;另一方面,飞行器受到分离过程中气动力和力矩影响,姿态变化剧烈,而姿态的变化又会引起作用在飞行器上力和力矩的变化,分离过程中飞行器的姿态运动与流场之间存在强耦合关系,传统计算方法不能精确预示出分离运动过程。为此,本发明提出两相流场等效方法,解决了分离过程中气动力和力矩精确预示问题,提出了基于重叠网格的流场CFD与六自由度运动耦合计算方法,解决了分离过程中飞行器的姿态运动与流场之间强耦合问题,计算精度较传统设计方法大幅提高,同时针对该类飞行器分离过程中姿态变化剧烈的特点,基于前述方法得到的结果,提出基于比例反馈控制律的分离过程主动控制方法,解决了该类飞行器可靠分离设计难题。When a hypersonic vehicle is separated in the atmosphere, it is faced with an extremely harsh environment. Factors such as large dynamic pressure and jet interference make the separation flow field extremely complicated. The changing laws of power and torque are complex, and the real aerodynamic force and torque acting on the aircraft cannot be accurately obtained by using the traditional steady state aerodynamic data interpolation table; The change of attitude will cause the change of force and moment acting on the aircraft. During the separation process, there is a strong coupling relationship between the aircraft's attitude movement and the flow field. Traditional calculation methods cannot accurately predict the separation movement process. Therefore, the present invention proposes an equivalent method of two-phase flow field, which solves the problem of accurate prediction of aerodynamic force and torque in the separation process, and proposes a coupling calculation method of flow field CFD and six-degree-of-freedom motion based on overlapping grids, which solves the problem of separation process. In the problem of strong coupling between the attitude motion and the flow field of the aircraft in the mid-aircraft, the calculation accuracy is greatly improved compared with the traditional design method. At the same time, in view of the characteristics of severe attitude changes during the separation process of this type of aircraft, based on the results obtained by the above methods, a proportional feedback control law is proposed. The active control method of the separation process solves the problem of reliable separation design of this type of aircraft.

本发明已成功应用于我国第一型全程飞行的1:1面对称助推滑翔导弹方案验证飞行试验,飞行试验取得了圆满成功,有效验证了方法准确性。The present invention has been successfully applied to the verification flight test of my country's first full-flying 1:1 plane symmetric boost gliding missile scheme, and the flight test has been a complete success, effectively verifying the accuracy of the method.

附图说明Description of drawings

图1为本发明重叠网格示例示意图;1 is a schematic diagram of an example of an overlapping grid of the present invention;

图2为本发明等效后流场的N-S方程流程;Fig. 2 is the N-S equation flow process of the flow field after the equivalent of the present invention;

图3为本发明整个分离求解的推进过程与传统计算方法对比示意图;3 is a schematic diagram of the comparison between the propulsion process of the entire separation solution of the present invention and the traditional calculation method;

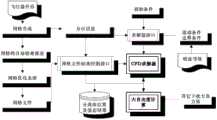

图4为本发明方法框架示意图。FIG. 4 is a schematic diagram of the method framework of the present invention.

具体实施方式Detailed ways

下面结合附图及实例对本发明作详细说明。The present invention will be described in detail below with reference to the accompanying drawings and examples.

1、网格建立1. Grid establishment

根据飞行器及分离体几何信息建立分离气动CFD计算所需的分区重叠网格。According to the geometric information of the aircraft and the separation body, the partitioned overlapping meshes required for the separation aerodynamic CFD calculation are established.

分区重叠网格方法是一种结构空间的离散方法。它将复杂的流动区域分成几何边界比较简单的子区域,各子区域中的计算网格独立生成,彼此存在着重叠或嵌套关系,流场信息通过插值在重叠区边界进行匹配和耦合。重叠网格方法能很方便的处理各种复杂的流场结构,特别适合于复杂外形绕流和物体存在相对运动的流场计算,各子网格生成完毕后,网格随着物体一起运动,不再需要人工干预。The partitioned overlapping grid method is a discrete method of structure space. It divides the complex flow region into sub-regions with relatively simple geometric boundaries. The computational grids in each sub-region are generated independently, and there is an overlapping or nested relationship with each other. The flow field information is matched and coupled at the boundary of the overlapping region through interpolation. The overlapping grid method can easily deal with various complex flow field structures, and is especially suitable for flow field calculations with complex shapes around the flow and objects with relative motion. After each sub-grid is generated, the grid moves with the object. Human intervention is no longer required.

本发明采用重叠网格方法,作为高超声速飞行器分离体气动特性CFD计算的流场离散方法,重叠网格示例如图1所示。The present invention adopts the overlapping grid method as the flow field discrete method for CFD calculation of the aerodynamic characteristics of the separated body of the hypersonic aircraft. An example of the overlapping grid is shown in FIG. 1 .

2、两相流场等效2. Two-phase flow field is equivalent

分离过程中飞行器受到的气动力及力矩,可以通过求解N-S方程得到。而N-S方程具有强非线性,目前尚无解析解,利用计算机则可以通过数值计算的方法来解出N-S方程在初始条件和边界条件下的数值解。即通过用有限差分来近似代替微分,从而使N-S方程转化为代数方程,编制程序进行数值求解。The aerodynamic force and torque received by the aircraft during the separation process can be obtained by solving the N-S equation. The N-S equation has strong nonlinearity, and there is no analytical solution at present. Using a computer, the numerical solution of the N-S equation under the initial conditions and boundary conditions can be solved by numerical calculation. That is, by using finite difference to approximate instead of differential, the N-S equation is transformed into an algebraic equation, and a program is programmed to solve it numerically.

流场计算采用高精度数值离散格式和湍流模型,求解了的三维NS控制方程组。其守恒形式的方程组如下:The flow field calculation adopts a high-precision numerical discrete format and a turbulent flow model, and the three-dimensional NS governing equations are solved. The system of equations in its conserved form is as follows:

其中U为守恒变量,E、F和G分别为x、y和z方向上的对流项,Ev、Fv和Gv分别为x、y和z方向上的粘性项。where U is a conserved variable, E, F and G are the convection terms in the x, y and z directions, respectively, and Ev , Fv and Gv are the viscous terms in the x, y and z directions, respectively.

由于高超声速飞行器在分离过程中通常会借助分离火箭来产生所需的分离主动冲量,而分离火箭喷流通常为高温两相流,且喷流方向一般与飞行器来流方向相反,这就导致了飞行器流场极为复杂。而反推喷管的流场仿真的精确度是保证整个分离仿真的关键,我们有必要对其进行模拟。为简化计算的复杂程度,屏蔽因两相流计算偏差带来气动特性仿真更大的误差,本发明将反推火箭内流体等效为空气,对流体的动能和动量开展等效修正,实现单一组分的CFD仿真计算,具体方法如下:Because the hypersonic vehicle usually uses the separation rocket to generate the required separation active impulse during the separation process, and the separation rocket jet is usually a high-temperature two-phase flow, and the direction of the jet is generally opposite to the direction of the incoming flow of the aircraft, which leads to The aircraft flow field is extremely complex. The accuracy of the flow field simulation of the reverse thrust nozzle is the key to ensure the entire separation simulation, and it is necessary for us to simulate it. In order to simplify the complexity of the calculation and shield the larger errors in the simulation of aerodynamic characteristics caused by the deviation of the two-phase flow calculation, the present invention converts the fluid in the reverse thrust rocket into air, and performs equivalent corrections on the kinetic energy and momentum of the fluid to achieve a single The CFD simulation calculation of the components is as follows:

喷管喉道处赋予发动机喉部参数,通过全流场赋反推火箭出口的γ,以此γ数计算得到的结果作为标准值,计算得到了喷管的喷口参数(有量纲量,同时进行了面积加权平均),并与实际入口条件计算得到的喉道参数进行比较。通过三方面对此喷管进行修正:扩张角修形、喉道修形、喉道入口条件变换,得到一种合理的喷流模拟方案。计算流程如图2所示,具体可以概括为如下步骤:The engine throat parameters are assigned to the nozzle throat, and the γ of the reverse thrust rocket outlet is assigned through the full flow field, and the calculated result of this γ number is used as the standard value, and the nozzle parameters of the nozzle (dimensioned, while Area-weighted averages were performed) and compared with throat parameters calculated from actual inlet conditions. The nozzle is modified through three aspects: expansion angle modification, throat modification, and throat inlet condition change, and a reasonable jet flow simulation scheme is obtained. The calculation process is shown in Figure 2, which can be summarized as the following steps:

第一步,采用多组分N-S方程模拟喷管内部的流场,获得喷管出口处多组分流体的动量及动能;In the first step, the multi-component N-S equation is used to simulate the flow field inside the nozzle, and the momentum and kinetic energy of the multi-component fluid at the nozzle outlet are obtained;

第二步,根据流体动量动能表达式及第一步中获得的喷管出口处多组分流体的动量及动能,采用空气的物理属性,获得喷管出口处的空气流动参数;In the second step, according to the fluid momentum kinetic energy expression and the momentum and kinetic energy of the multi-component fluid at the nozzle outlet obtained in the first step, the physical properties of the air are used to obtain the air flow parameters at the nozzle outlet;

第三步,根据一维等熵关系式,获得简化后的喷管喉部外形及喉部的流动参数;In the third step, according to the one-dimensional isentropic relationship, the simplified shape of the nozzle throat and the flow parameters of the throat are obtained;

第四步,根据普朗特迈耶尔膨胀关系式进行喉部扩张角修型,使简化后的气体膨胀角与多组分流动一致;The fourth step is to modify the expansion angle of the throat according to the Prandt-Meyer expansion relationship, so that the simplified gas expansion angle is consistent with the multi-component flow;

第五步,采用简化后的喉部外形及修型后的喷管扩张角及喉部的流动参数,建立等效后流场的N-S方程。The fifth step is to establish the N-S equation of the equivalent flow field by using the simplified throat shape and the modified nozzle expansion angle and the flow parameters of the throat.

3、流场CFD与六自由度运动耦合计算3. Coupling calculation of flow field CFD and 6-DOF motion

a、分离运动刚体动力学计算a, separate motion rigid body dynamics calculation

(1)分离体质心的运动(1) Movement to separate the center of mass of the body

分离坐标系下分离体质心动力学方程可表示为The dynamic equation of the centroid of the separated body in the separated coordinate system can be expressed as

其中,Ω,V分别表示分离坐标系相对分离体的位移运动速度矢量和转动角速度矢量。Among them, Ω and V respectively represent the displacement motion velocity vector and the rotational angular velocity vector of the separation coordinate system relative to the separation body.

(2)分离体绕质心的转动(2) Rotation of the separation body around the center of mass

在分离坐标系下描述分离体绕质心的转动运动动力学方程可表示为:In the separation coordinate system, the dynamic equation describing the rotational motion of the separation body around the center of mass can be expressed as:

其中,Iij,i,j=x,y,z分别表示分离体绕其弹体坐标系各轴的转动惯量;ωx,ωy,ωz分别表示分离体绕其弹体坐标系各轴的转动角速度分量。Among them, Iij , i, j=x, y, z respectively represent the moment of inertia of the separating body around each axis of its missile coordinate system; ωx, ωy, ωz respectively represent the rotational angular velocity of the separating body around each axis of its missile coordinate system weight.

(3)分离体姿态角的确定(3) Determination of the attitude angle of the separated body

分离体姿态角γ与分离体在其弹体坐标系下的转动角速度存在如下关系:Split body attitude angle There is the following relationship between γ and the rotational angular velocity of the separating body in its projectile coordinate system:

其中,是俯仰角,是偏航角,γ是滚转角。in, is the pitch angle, is the yaw angle and γ is the roll angle.

根据以上动力学模型,可以求解不同工况下的分离运动,得到分离体的质心运动及姿态运动参数。According to the above dynamic model, the separation motion under different working conditions can be solved, and the centroid motion and attitude motion parameters of the separated body can be obtained.

b、流场CFD与六自由度运动耦合计算的分离仿真方法b. Separate simulation method for coupled calculation of flow field CFD and six-degree-of-freedom motion

对于高超声速飞行器分离而言,流场与飞行器运动状态(分离距离、速度等)相关,而飞行器运动状态又与流程的气动力和力矩相关,两者是紧密耦合的,因此本发明采用流场CFD与六自由度运动耦合计算的方法进行分离仿真分析,提高预示精度。For the separation of hypersonic aircraft, the flow field is related to the motion state of the aircraft (separation distance, speed, etc.), and the motion state of the aircraft is related to the aerodynamic force and torque of the process, and the two are closely coupled, so the present invention adopts the flow field CFD and 6-DOF motion coupling calculation method is used for separate simulation analysis to improve prediction accuracy.

整个分离求解的推进过程与传统计算方法对比如图3所示。Figure 3 shows the comparison between the whole separation solution and the traditional calculation method.

本发明求解中,将整个分离过程划分成若干个时间段,首先在每个时间步上精细求解流场,得到作用在前体和后体上的气动力和力矩;进一步,连同其它外力一齐代入六自由度刚体运动方程,求得时间步长Δt(一般小于5ms)内前体和后体的位移和姿态变化,得到下一个时刻的位置和姿态;然后针对新位置、新姿态下的前体和后体外形生成新网格进行流场计算;如此循环,直到分离结束。该方法考虑了喷流、分离流场及两体运动的耦合关系,可以更精确地预示起控姿态边界。In the solution of the present invention, the entire separation process is divided into several time periods. First, the flow field is solved finely at each time step to obtain the aerodynamic force and torque acting on the precursor and the rear body; further, together with other external forces, substitute them into The six-degree-of-freedom rigid body motion equation is used to obtain the displacement and attitude changes of the front and rear bodies within the time step Δt (generally less than 5ms), and the position and attitude of the next moment are obtained; Generate a new mesh with the shape of the rear body for flow field calculation; this cycle is repeated until the end of separation. The method takes into account the coupling relationship between the jet flow, the separation flow field and the motion of the two bodies, and can predict the start-control attitude boundary more accurately.

当然为了提高方法的可靠性,在计算得到前体和后体的位置和姿态后,进行是否安全分离判断,若前体和后体发生碰撞或者干涉,则结束当前仿真,否则继续执行。Of course, in order to improve the reliability of the method, after calculating the positions and postures of the front body and the rear body, it is determined whether it is safe to separate. If the front body and the rear body collide or interfere, the current simulation is ended, otherwise the execution continues.

4、分离干扰主动控制4. Active control of separation interference

高超声速飞行器在大气层内分离通常由于高动压及喷流干扰影响,气动干扰对飞行器姿态影响较大,对分离后飞行器的起控不利,为此,本发明进一步提出了一种分离干扰主动控制方法。The separation of the hypersonic aircraft in the atmosphere is usually due to the influence of high dynamic pressure and jet flow interference. The aerodynamic interference has a great influence on the attitude of the aircraft, which is unfavorable for the start and control of the aircraft after separation. Therefore, the present invention further proposes a separation interference active control method.

对俯仰角、偏航角和滚转角分别采用比例反馈控制律,即控制舵偏角为:The proportional feedback control law is used for the pitch angle, yaw angle and roll angle respectively, that is, the control rudder declination angle is:

其中:Dψ、Dγ分别为俯仰、偏航和滚转控制舵偏角;为当前俯仰角和角速度,为期望的俯仰角和角速度,为俯仰角反馈系数和角速度反馈系数;ψu,为当前偏航角和角速度,ψq,为期望的偏航角和角速度,Kψ,Cψ为偏航角反馈系数和角速度反馈系数;γu,为当前滚转角和角速度,γq,为期望的滚转角和角速度,Kγ,Cγ为滚转角反馈系数和角速度反馈系数。Kψ、Kγ的取值范围为2~4,Cψ、Cγ的取值范围为0.2~0.5。in: Dψ , Dγ are the pitch, yaw and roll control rudder deflection angles, respectively; is the current pitch angle and angular velocity, are the desired pitch angle and angular velocity, are pitch angle feedback coefficient and angular velocity feedback coefficient; ψu , is the current yaw angle and angular velocity, ψq , are the desired yaw angle and angular velocity, Kψ , Cψ are the yaw angle feedback coefficient and angular velocity feedback coefficient; γu , is the current roll angle and angular velocity, γq , are the desired roll angle and angular velocity, Kγ , Cγ are the roll angle feedback coefficient and the angular velocity feedback coefficient. The value range of Kψ and Kγ is 2~4, The values of Cψ and Cγ range from 0.2 to 0.5.

根据分离过程姿态干扰计算结果,进行起控舵偏的反馈控制,如无法满足设计要求,调整分离设计参数(如时序、判据等)重新进行上述过程,直到满足设计要求。According to the calculation results of attitude interference in the separation process, the feedback control of the starting and control rudder bias is carried out. If the design requirements cannot be met, adjust the separation design parameters (such as timing, criteria, etc.) and repeat the above process until the design requirements are met.

上述过程在工程实现在可以采用图4所示的框架进行实现,飞行器外形模块和喷流等效模块为原始输入;网格文件标准控制接口和求解器接口为接口模块,用于将上述输入信息处理为求解器可以识别的标准接口格式文件;CFD求解器和六自由度计算模块为求解器模块,进行CFD求解和六自由度计算;分离体位置及姿态结果模块为输出和后处理模块,输出计算结果以及进行干涉、碰撞检查等工作;其余为前处理模块,用于将原始输入的物理条件转化为相应的计算输入条件。The above process can be implemented by the framework shown in Figure 4 in the engineering implementation. The aircraft shape module and the jet equivalent module are the original inputs; the grid file standard control interface and the solver interface are the interface modules, which are used to convert the above input information. The processing is a standard interface format file that can be recognized by the solver; the CFD solver and the six-degree-of-freedom calculation module are the solver modules, which perform CFD solutions and six-degree-of-freedom calculations; the separated body position and attitude result module is the output and post-processing module, output Calculate the results and perform interference and collision checks; the rest are pre-processing modules, which are used to convert the physical conditions of the original input into the corresponding calculation input conditions.

本发明未详细说明部分属于本领域技术人员公知常识。The parts of the present invention that are not described in detail belong to the common knowledge of those skilled in the art.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811014136.2ACN110874055B (en) | 2018-08-31 | 2018-08-31 | Prediction and control method of hypersonic vehicle separation process under the action of two-phase flow field |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811014136.2ACN110874055B (en) | 2018-08-31 | 2018-08-31 | Prediction and control method of hypersonic vehicle separation process under the action of two-phase flow field |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110874055Atrue CN110874055A (en) | 2020-03-10 |

| CN110874055B CN110874055B (en) | 2023-04-14 |

Family

ID=69715348

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811014136.2AActiveCN110874055B (en) | 2018-08-31 | 2018-08-31 | Prediction and control method of hypersonic vehicle separation process under the action of two-phase flow field |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110874055B (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112068581A (en)* | 2020-09-11 | 2020-12-11 | 中国运载火箭技术研究院 | Aircraft composite control method, control device and storage medium |

| CN112182771A (en)* | 2020-10-11 | 2021-01-05 | 中国运载火箭技术研究院 | Numerical simulation-based data processing method, storage medium, and electronic device |

| CN112528420A (en)* | 2020-12-25 | 2021-03-19 | 中国空气动力研究与发展中心计算空气动力研究所 | Dynamic boundary condition switching method for jet flow time sequence control simulation |

| CN113867381A (en)* | 2021-12-02 | 2021-12-31 | 中国空气动力研究与发展中心计算空气动力研究所 | Aircraft attitude control method |

| CN113886942A (en)* | 2021-09-01 | 2022-01-04 | 北京机电工程研究所 | Numerical simulation method of aircraft hood hinge-constrained ejection separation |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100251692A1 (en)* | 2006-10-27 | 2010-10-07 | Kinde Sr Ronald August | Methods of combining a series of more efficient aircraft engines into a unit, or modular units |

| US20130060538A1 (en)* | 2011-09-06 | 2013-03-07 | Airbus Operations S.L. | Method for predicting the impact on an aircraft of debris shed off from it |

| CN106712833A (en)* | 2016-12-14 | 2017-05-24 | 中国运载火箭技术研究院 | Aircraft integrated information processing subsystem and spaceflight measurement and control system |

| CN107977494A (en)* | 2017-11-20 | 2018-05-01 | 中国运载火箭技术研究院 | Gas handling system characteristic predicting method and system under hypersonic aircraft back-pressure |

- 2018

- 2018-08-31CNCN201811014136.2Apatent/CN110874055B/enactiveActive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100251692A1 (en)* | 2006-10-27 | 2010-10-07 | Kinde Sr Ronald August | Methods of combining a series of more efficient aircraft engines into a unit, or modular units |

| US20130060538A1 (en)* | 2011-09-06 | 2013-03-07 | Airbus Operations S.L. | Method for predicting the impact on an aircraft of debris shed off from it |

| CN106712833A (en)* | 2016-12-14 | 2017-05-24 | 中国运载火箭技术研究院 | Aircraft integrated information processing subsystem and spaceflight measurement and control system |

| CN107977494A (en)* | 2017-11-20 | 2018-05-01 | 中国运载火箭技术研究院 | Gas handling system characteristic predicting method and system under hypersonic aircraft back-pressure |

Non-Patent Citations (2)

| Title |

|---|

| 周铸等: "CFD技术在航空工程领域的应用、挑战与发展", 《航空学报》* |

| 孙学功等: "高超声速飞行器并行仿真方法研究", 《系统仿真学报》* |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112068581A (en)* | 2020-09-11 | 2020-12-11 | 中国运载火箭技术研究院 | Aircraft composite control method, control device and storage medium |

| CN112068581B (en)* | 2020-09-11 | 2023-11-17 | 中国运载火箭技术研究院 | Aircraft composite control method, control device and storage medium |

| CN112182771A (en)* | 2020-10-11 | 2021-01-05 | 中国运载火箭技术研究院 | Numerical simulation-based data processing method, storage medium, and electronic device |

| CN112182771B (en)* | 2020-10-11 | 2022-08-05 | 中国运载火箭技术研究院 | Data processing method based on numerical simulation, storage medium and electronic device |

| CN112528420A (en)* | 2020-12-25 | 2021-03-19 | 中国空气动力研究与发展中心计算空气动力研究所 | Dynamic boundary condition switching method for jet flow time sequence control simulation |

| CN113886942A (en)* | 2021-09-01 | 2022-01-04 | 北京机电工程研究所 | Numerical simulation method of aircraft hood hinge-constrained ejection separation |

| CN113867381A (en)* | 2021-12-02 | 2021-12-31 | 中国空气动力研究与发展中心计算空气动力研究所 | Aircraft attitude control method |

| CN113867381B (en)* | 2021-12-02 | 2022-02-22 | 中国空气动力研究与发展中心计算空气动力研究所 | Aircraft attitude control method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110874055B (en) | 2023-04-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110874055B (en) | Prediction and control method of hypersonic vehicle separation process under the action of two-phase flow field | |

| CN111339681B (en) | Nozzle outlet parameter matching method for simulating engine gas medium jet flow aerodynamic interference effect by adopting air medium | |

| CN109709978B (en) | Hypersonic aircraft guidance control integrated design method | |

| CN108052008B (en) | Geometric optimal controller design method for transition state switching process of tilt rotor aircraft | |

| CN111591470B (en) | Aircraft precise soft landing closed-loop guidance method adapting to thrust adjustable mode | |

| CN112346359B (en) | Direct force-aerodynamic force composite control numerical simulation method based on CFD and RBD coupling | |

| CN108595755A (en) | A kind of fast modeling method of new mars exploration aircraft Control-oriented | |

| CN110320927A (en) | Flight control method and system of intelligent deformable aircraft | |

| CN106570242B (en) | The big dynamic pressure monoblock type radome fairing high-speed separation fluid structurecoupling emulation mode in low latitude | |

| Hua et al. | Effect of elastic deformation on flight dynamics of projectiles with large slenderness ratio | |

| CN109446582A (en) | A kind of high-precision depression of order considering earth rotation steadily glides dynamic modeling method | |

| CN109918808B (en) | Three-field coupling simulation analysis method for gas-thermal bomb | |

| Kier et al. | Integrated flexible dynamic loads models based on aerodynamic influence coefficients of a 3d panel method | |

| Vallespin et al. | Computational fluid dynamics framework for aerodynamic model assessment | |

| CN104019701A (en) | Direct force and aerodynamic force composite control method and forward-direction interception guidance method | |

| CN113094807A (en) | Deformation track optimization method for variable-profile aircraft | |

| CN113221237B (en) | A high angle of attack flutter analysis method based on reduced-order modeling | |

| CN106125571B (en) | A Modeling Method for Speed Control of Cruise Missile | |

| CN107894775B (en) | Under-actuated unmanned underwater vehicle track generation and control method | |

| Waite et al. | Active Flutter Suppression Controllers Derived from Linear and Nonlinear Aerodynamics: Application to a Transport Aircraft Model | |

| CN113467498B (en) | A Bezier-convex optimization-based trajectory planning method for the ascent segment of a launch vehicle | |

| Li et al. | Trajectory optimization method of interceptor for high-speed gliding target via Hp-adaptive Radau pseudo-spectral method | |

| Xuefei et al. | Applications of overset grid technique to CFD simulation of high Mach number multi-body interaction/separation flow | |

| CN211685678U (en) | Simulation analysis system of real-time trail of multi-rotor unmanned aerial vehicle | |

| CN116401852A (en) | Kinetic modeling and attitude control method for rapid rocket |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |