CN110853203A - An intelligent management unmanned tool room based on RFID technology - Google Patents

An intelligent management unmanned tool room based on RFID technologyDownload PDFInfo

- Publication number

- CN110853203A CN110853203ACN201911083124.XACN201911083124ACN110853203ACN 110853203 ACN110853203 ACN 110853203ACN 201911083124 ACN201911083124 ACN 201911083124ACN 110853203 ACN110853203 ACN 110853203A

- Authority

- CN

- China

- Prior art keywords

- tool

- information

- rfid

- intelligent management

- unmanned

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06K—GRAPHICAL DATA READING; PRESENTATION OF DATA; RECORD CARRIERS; HANDLING RECORD CARRIERS

- G06K17/00—Methods or arrangements for effecting co-operative working between equipments covered by two or more of main groups G06K1/00 - G06K15/00, e.g. automatic card files incorporating conveying and reading operations

- G06K17/0022—Methods or arrangements for effecting co-operative working between equipments covered by two or more of main groups G06K1/00 - G06K15/00, e.g. automatic card files incorporating conveying and reading operations arrangements or provisions for transferring data to distant stations, e.g. from a sensing device

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07G—REGISTERING THE RECEIPT OF CASH, VALUABLES, OR TOKENS

- G07G1/00—Cash registers

- G07G1/0036—Checkout procedures

- G07G1/0045—Checkout procedures with a code reader for reading of an identifying code of the article to be registered, e.g. barcode reader or radio-frequency identity [RFID] reader

- G07G1/009—Checkout procedures with a code reader for reading of an identifying code of the article to be registered, e.g. barcode reader or radio-frequency identity [RFID] reader the reader being an RFID reader

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于铁路部门工具管理技术领域,更具体地,涉及一种基于RFID技术智能管理无人工具间装置。The invention belongs to the technical field of tool management in railway departments, and more particularly relates to a device for intelligent management of unmanned tool room based on RFID technology.

背景技术Background technique

铁路工务部门均配备有工具间,工具间的存在为职工提供了种类丰富的辅助设备,这些设备的合理使用直接提高各铁路线路生产维护的效率,也关系到列车的安全状况。随着铁路各部门自动化水平的提升,线路与列车的维护频次逐渐增多,职工对工具间的使用愈加频繁,这就对现有的工具间提出更高的要求。Railway public works departments are equipped with tool rooms. The existence of tool rooms provides employees with a variety of auxiliary equipment. The rational use of these equipment directly improves the efficiency of production and maintenance of various railway lines, and is also related to the safety of trains. With the improvement of the automation level of various railway departments, the maintenance frequency of lines and trains has gradually increased, and employees have used the tool room more frequently, which puts forward higher requirements for the existing tool room.

目前我国铁路工务部门对工具间的生产方式、管理模式、检测手段等已经远不能满足铁路运输发展的需要,人员外出进行检修作业时浪费大量时间进行工具清点,在作业完成时同样花费大量时间来防止工具散落在铁路沿线上,这不仅造成工作效率低下并且还有较大的安全隐患。在工具间的管理方面,工务部门对工具间的管理也大都采用传统方式,即职工自己到工具间领用登记或者由专人配送,也有个别路局采用了智能化程度较低的“微库管理”,但没有从根本上解决手续复杂、操作繁琐等问题。At present, the production methods, management modes, and detection methods of the tool rooms in my country's railway works departments are far from meeting the needs of railway transportation development. When personnel go out for maintenance operations, a lot of time is wasted for tool inventory, and a lot of time is also spent when the work is completed. Prevent tools from being scattered along the railway line, which not only causes low work efficiency but also a greater safety hazard. In terms of tool room management, most of the public works departments use traditional methods to manage the tool room, that is, the employees themselves go to the tool room for registration or delivery by a special person, and some road bureaus have adopted the less intelligent "micro-warehouse management". ”, but did not fundamentally solve the problems of complicated procedures and complicated operations.

科技的快速发展提供了新的发向,大数据与物联网已经深入到各行各业,利用并结合RFID技术与云端技术设计一种新型工具间。该工具间能够确保工具是由内部职工借出,所借出的工具能够进行物品追踪从而保证员工不会发生遗落并且按期归还。员工可以“无障碍”的取用与存放工具,省去工具间的登记手续提高工具使用效率。提供更智能化、高效的管理系统,开发手机APP平台方便职工使用工具间,并将工具间的管理连接到工务部门的管理系统中进行统一管理。The rapid development of science and technology has provided a new direction. Big data and the Internet of Things have penetrated into all walks of life, using and combining RFID technology and cloud technology to design a new type of tool room. The tool room can ensure that tools are lent by internal employees, and the loaned tools can be tracked to ensure that employees will not be left behind and returned on time. Employees can access and store tools "barrier-free", eliminating the need for registration procedures between tools and improving the efficiency of tool use. Provide a more intelligent and efficient management system, develop a mobile APP platform to facilitate employees to use the tool room, and connect the management of the tool room to the management system of the public works department for unified management.

发明内容SUMMARY OF THE INVENTION

针对现有技术的以上缺陷或改进需求,本发明提供一种基于RFID技术智能管理无人工具间,采用Java开发管理平台,方便管理员使用各种终端设备登入平台。采用MySQL数据库,将云端服务器和数据库联结,优点是数据信息不易丢失且易于二次开发。采用android语言开发手机APP,职工可以通过该APP使用工具间。Aiming at the above defects or improvement requirements of the prior art, the present invention provides an intelligent management unmanned tool room based on RFID technology, and a Java development management platform is adopted to facilitate administrators to log in to the platform using various terminal devices. The MySQL database is used to connect the cloud server and the database. The advantage is that the data information is not easily lost and it is easy for secondary development. Using android language to develop mobile APP, employees can use the tool room through the APP.

为了实现上述目的,本发明提供一种基于RFID技术智能管理无人工具间,包括工具储存机构、门禁信息采集装置和云端服务器;其中,In order to achieve the above purpose, the present invention provides an unmanned tool room for intelligent management based on RFID technology, including a tool storage mechanism, an access control information collection device and a cloud server; wherein,

所述工具储存机构包括工具墙体和工具箱,所述工具墙体的一端面上设有工具,所述工具箱为内部设有小件工具的长方体盒,所述工具墙体和工具箱将工件存储与对应位置,所述工具与工具箱均设有相对应的RFID标签;The tool storage mechanism includes a tool wall and a tool box, one end surface of the tool wall is provided with tools, the tool box is a cuboid box with small tools inside, and the tool wall and the tool box store tools. Workpiece storage and corresponding positions, the tools and toolboxes are provided with corresponding RFID tags;

所述门禁信息采集装置包括通道门和闸机部分,所述通道门竖直设于所述闸机部分的一侧,所述通道门上设有检测记录人员的传感器,所述闸机部分包括两台“凸”字形的闸机,所述闸机之间设有起阻隔作用的闸机门,且所述闸机的两侧均设有用于验证身份信息的刷卡台;The access control information collection device includes a passage door and a gate part, the access door is vertically arranged on one side of the gate part, the access door is provided with a sensor for detecting and recording personnel, and the gate part includes Two "convex"-shaped gates, between the gates there are gates that act as barriers, and both sides of the gates are provided with card swiping desks for verifying identity information;

所述云端服务器收集由所述工具储存机构和门禁信息采集装置产生的数据信息,所述数据信息由处理器进行集中处理,处理完毕将所述数据信息传输于Web服务器,且由所述云端服务器进行存储。The cloud server collects data information generated by the tool storage mechanism and the access control information collection device, the data information is centrally processed by the processor, and the data information is transmitted to the web server after processing, and the cloud server to store.

进一步的,所述基于RFID技术智能管理无人工具间还包括远程终端,所述远程终端包括手机APP和工务部门管理平台的PC机。Further, the unmanned tool room for intelligent management based on RFID technology further includes a remote terminal, and the remote terminal includes a mobile phone APP and a PC of the public works department management platform.

进一步的,所述手机APP与刷卡台均能进行所述闸机部分的人员信息的认证。Further, both the mobile phone APP and the card swiping station can authenticate the personnel information of the gate part.

进一步的,所述闸机部分还包括设于所述闸机侧板上的信息提示灯和设于其“凸”字形顶端面上的摄像头。Further, the gate part also includes an information prompt light arranged on the side plate of the gate and a camera arranged on the top surface of the "convex" shape.

进一步的,所述信息提示灯对在进行验证后对人员进行提示,所述摄像头对人员脸部信息进行收集,由所述云端服务器人员信息进行比对,确认人员信息。Further, the information prompt light prompts the personnel after verification, the camera collects the facial information of the personnel, and the cloud server personnel information is compared to confirm the personnel information.

进一步的,所述通道门还设置有RFID阅读器和信息采集模块,所述RFID阅读器读取所述RFID标签的相关信息。Further, the access door is also provided with an RFID reader and an information collection module, and the RFID reader reads the relevant information of the RFID tag.

进一步的,所述RFID阅读器读取所述RFID标签的相关信息,经过RFID识别模块进行识别处理,存储于所述云端服务器内部。Further, the RFID reader reads the relevant information of the RFID tag, performs identification processing through the RFID identification module, and stores it in the cloud server.

进一步的,所述手机APP能够对所述工具和工具箱的位置信息进行直观显示。Further, the mobile phone APP can visually display the location information of the tools and toolboxes.

总体而言,通过本发明所构思的以上技术方案与现有技术相比,能够取得下列有益效果:In general, compared with the prior art, the above technical solutions conceived by the present invention can achieve the following beneficial effects:

(1)本发明的一种基于RFID技术智能管理无人工具间,采用Java开发管理平台,方便管理员使用各种终端设备登入平台。采用MySQL数据库,将云端服务器和数据库联结,优点是数据信息不易丢失且易于二次开发。采用android语言开发手机APP,职工可以通过该APP使用工具间。(1) An unmanned tool room for intelligent management based on RFID technology of the present invention adopts a Java development management platform, which is convenient for administrators to log in to the platform using various terminal devices. The MySQL database is used to connect the cloud server and the database. The advantage is that the data information is not easily lost and it is easy for secondary development. Using android language to develop mobile APP, employees can use the tool room through the APP.

(2)本发明的一种基于RFID技术智能管理无人工具间,闸机处有RFID身份牌刷卡、摄像头和通道门。RFID身份牌存入员工信息,员工只需身份牌就可随意出入工具间。摄像头连有面部识别模块,通过扫描职工脸部信息确定职工身份。通道口简化了数据采集的具体方式,只需职工通过通道口就能获得职工与工具的关联信息。(2) An unmanned tool room of the present invention is intelligently managed based on RFID technology, and there are RFID identity card swiping cards, cameras and access doors at the gate. The RFID ID card stores employee information, and employees can enter and leave the tool room at will with only the ID card. The camera is connected to a facial recognition module, which determines the identity of the employee by scanning the employee's face information. The channel port simplifies the specific method of data collection, and only the employee can obtain the related information between the employee and the tool through the channel port.

(3)本发明的一种基于RFID技术智能管理无人工具间,采用大数据与物联网技术,简化工具间使用工具流程、提高工具间的安全性、提升工具间的使用效率、降低工具的遗失事故。(3) An unmanned tool room of the present invention is intelligently managed based on RFID technology, adopts big data and Internet of Things technology, simplifies the process of using tools between tools, improves the security between tools, improves the use efficiency of tools, and reduces the cost of tools. Loss accident.

附图说明Description of drawings

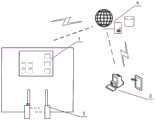

图1为本发明实施例一种基于RFID技术智能管理无人工具间的工具间整体空间布置图;1 is an overall spatial layout diagram of a tool room for intelligently managing an unmanned tool room based on RFID technology according to an embodiment of the present invention;

图2为本发明实施例一种基于RFID技术智能管理无人工具间的工具摆放存储处示意图;2 is a schematic diagram of a tool placement storage place for intelligently managing an unmanned tool room based on RFID technology according to an embodiment of the present invention;

图3为本发明实施例一种基于RFID技术智能管理无人工具间的闸机与信息采集处示意图;3 is a schematic diagram of a gate and an information collection place for intelligently managing an unmanned tool room based on RFID technology according to an embodiment of the present invention;

图4为本发明实施例一种基于RFID技术智能管理无人工具间的刷卡台32示意图;4 is a schematic diagram of a

图5为本发明实施例一种基于RFID技术智能管理无人工具间的工具间装置示意图;5 is a schematic diagram of a tool room device for intelligently managing an unmanned tool room based on RFID technology according to an embodiment of the present invention;

图6为本发明实施例一种基于RFID技术智能管理无人工具间的职工存/取工具流程图。FIG. 6 is a flowchart of an employee access/retrieval tool for intelligently managing an unmanned tool room based on RFID technology according to an embodiment of the present invention.

在所有附图中,同样的附图标记表示相同的技术特征,具体为:1-工具储存机构、2-门禁信息采集装置、3-远程终端、4-云端服务器、21-工具墙体、22-RFID标签、23-工具、24-工具箱、31-摄像头、32-刷卡台、33-通道门、34-闸机门、35-信息提示灯、51-处理器、52-Web服务器、53-手机APP、54-RFID识别模块。In all the drawings, the same reference numerals represent the same technical features, specifically: 1-tool storage mechanism, 2-access control information collection device, 3-remote terminal, 4-cloud server, 21-tool wall, 22 -RFID tag, 23-tool, 24-toolbox, 31-camera, 32-card swipe station, 33-passage door, 34-gateway, 35-information light, 51-processor, 52-web server, 53 -Mobile APP, 54-RFID identification module.

具体实施方式Detailed ways

为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例,对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅用以解释本发明,并不用于限定本发明。此外,下面所描述的本发明各个实施方式中所涉及到的技术特征只要彼此之间未构成冲突就可以相互组合。In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

如图1所示,一种基于RFID技术智能管理无人工具间包括工具储存机构1、门禁信息采集装置2、远程终端3和云端服务器4。其中,工具储存机构1用于提供职工所需要的检修工具和辅助设备,工具设备在不借出使用时均收放在工具储存机构1中,而且工具储存机构1中的工具类型、数量等数据都要记录在案。门禁与信息采集处2的主要任务是检测是否是有内部职工借出工具,并对借出的工具进行信息收集。远程终端3的主要是指工务部门管理平台的PC机和职工使用的手机,远程终端3可以通过互联网接收数据并发出操作指令。同时,云端服务器4有很大的弹性计算优势、强大的计算力、企业负担小的优点,可以寄存数据,将采集装置收集到的信息进行整理打包存储在虚拟数据库中进行备份。As shown in FIG. 1 , an unmanned tool room for intelligent management based on RFID technology includes a tool storage mechanism 1 , an access control

如图2所示,工具储存机构1包括用于摆放大型工具的工具墙体21和用于存放小零件的工具箱24。工具墙体21是一个矩形墙体,墙体设计整洁方便,职工一眼确定所需工具摆放位置,并且工具墙21上可以设置挂钩用来摆放、固定工具,方便职工取出。工具储存机构1中的所有工具都需要张贴有RFID标签22,RFID标签22的内部信号包括工具编号、工具类型、工具型号、工具功能等重要信息。工具23是指工具间内的所有具体应用设备,这些设备包括钳子、螺丝刀、锤子、尺规等。工具箱外形24是一个长方体的盒子,考虑到工具间中除工具墙外还有一些零碎件或是小型设备需要存放到工具箱中,内部的主要设备和零件需要张贴RFID标签22,工具箱体也张贴有RFID标签22。As shown in FIG. 2 , the tool storage mechanism 1 includes a

如图3所示,门禁与信息采集模块包括闸机部分和通道门33。通道门33呈倒“T”形,主体结构上设置有长方形和两个三角形区域而且上端倒有圆角。通道门33两侧均装有红外感知模块、RFID阅读器和信息采集模块,通过红外感知确定人员进出顺序,通过RFID阅读器读取工具上的RFID标签信息,通过信息采集模块将本次人员信息和工具信息进行收集整理并发送至处理器。闸机部分主要由摄像头31、刷卡台32、闸机门34和信息提示灯35组成,闸机呈“凸”字形。摄像头31为USB连接摄像头,位于闸机最上方,通过USB接口连接闸机来获得电量维持运作,同时,摄像头31还会收集脸部信息,比对后台数据库中已录入信息从而判定是否为内部职工。As shown in FIG. 3 , the access control and information collection module includes a gate part and an

此外,如图4所示,刷卡台32呈长方体中间设置有一个圆形的刷卡感应图标,顶角为圆角。闸机的最前端和最后端的上方都设置有刷卡台32,刷卡台内有RFID阅读器,刷卡台的作用是给职工刷卡进出工具间,当刷卡通过后,脸部识别功能将会开启,增加刷卡这一步骤是防止有人冒用身份牌。除刷卡外还可以通过手机APP指纹方式申请进行面部识别来防止身份牌丢失。闸机门34由两个扇形结构的伸缩门组成,位于闸机中间位置,闸机门34是对经过验证后的人员做出一个判定,对通过验证的人员允许放行,对未通过验证的人员进行阻止。信息提示灯35位于闸机前后段的正方形区域,信息显示在正方形中的圆形区域内,信息正确则会出现向前箭头,错误组会出现错误提示。信息提示灯的作用是对刷卡和脸部识别情况进行一个反馈,可以起到提示职工是否取错身份牌或未将脸部对准摄像头,同时也可以起到警示周边人的作用。In addition, as shown in FIG. 4 , the card swiping table 32 is in the form of a cuboid and is provided with a circular card swiping induction icon in the middle, and the top corner is a rounded corner. The front end and the top of the gate are provided with a card swiping table 32, and there is an RFID reader in the card swiping table. The function of the card swiping table is to swipe the card into and out of the tool room for the employees. The step of swiping the card is to prevent someone from using the ID card fraudulently. In addition to swiping the card, you can also apply for facial recognition through the fingerprint method of the mobile phone APP to prevent the loss of the identity card. The

如图5所示,该工具间的装置所获取的信息均要通过云端服务器4进行整理打包存储在虚拟数据库中进行备份。其工具间之间的各个装置之间都是通过处理器51进行控制,处理器51的主要功能有信息处理、身份认证、触发报警以及与Web服务器52连接。Web服务器52为铁路工务平台和手机APP53提供网络服务,且所述Web平台采用了功能全面、结构严谨、安全可靠、可以运行在不同的操作系统和硬件上的Java语言开发。同时,所述手机APP53采用了用户量最多的移动操作系统Android开发,还添加了指纹识别功能。因此,能够使用所述Web的PC机和能使用所述APP的职工手机共同组成了远程终端模块,对工具间进行一定程度上的远程操控。信息处理包括RFID技术采集信息,RFID识别模块54采集工具使用信息和身份牌信息,每一个工具均张贴有RFID标签22并将工具的编号、类型、型号、功能等信息提前存入数据库中。身份认证包括人脸识别和身份牌验证,人脸识别信息库中已存入内部职工的脸部信息,在进行判定时将根据特征点进行扫描比对。身份牌内含有RFID标签22,标签内有职工所在部门、岗位、职务等信息。以上信息均要通过云端服务器4进行整理打包存储在虚拟数据库中进行备份。As shown in FIG. 5 , the information obtained by the devices between the tools should be sorted, packaged and stored in the virtual database by the cloud server 4 for backup. The various devices between the tools are controlled by the

如图6所示,当职工需要进入工具间时,首先要使用自己的RFID身份牌在刷卡台32刷卡进行身份判定,若所述身份牌遗失,也可通过手机APP上53的指纹识别功能进行身份判定。之后,通过摄像头31的面部采集并与数据库中资料对比来确定是否是职工本人,防止有人冒用身份牌,从而给职工造成未进入工具间却出现显示已借出工具的困扰。职工通过判定后即可进入工具储存机构1选择归还或是取用工具,工具摆放的位置一目了然。最后,职工可以刷卡或手机APP53直接离开工具间。职工在工具间的领用情况将通过RFID技术自动传入处理器中,处理器将借用时间、归还时间、人员、工具信息等情况上传至云端服务器4中,服务器可以通过Web直接发至工务平台和手机上。As shown in Figure 6, when an employee needs to enter the tool room, they must first use their own RFID identification card to swipe the card at the

本领域的技术人员容易理解,以上所述仅为本发明的较佳实施例而已,并不用于限制本发明,凡在本发明的精神和原则之内所作的任何修改、等同替换和改进等,均应包含在本发明的保护范围之内。Those skilled in the art can easily understand that the above are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention, etc., All should be included within the protection scope of the present invention.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911083124.XACN110853203A (en) | 2019-11-07 | 2019-11-07 | An intelligent management unmanned tool room based on RFID technology |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911083124.XACN110853203A (en) | 2019-11-07 | 2019-11-07 | An intelligent management unmanned tool room based on RFID technology |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110853203Atrue CN110853203A (en) | 2020-02-28 |

Family

ID=69599651

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911083124.XAPendingCN110853203A (en) | 2019-11-07 | 2019-11-07 | An intelligent management unmanned tool room based on RFID technology |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110853203A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113763062A (en)* | 2020-06-02 | 2021-12-07 | 济南济公信息科技有限公司 | Tool management system for borrowing and returning registration based on intelligent terminal code scanning |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101174337A (en)* | 2006-11-03 | 2008-05-07 | 上海银晨智能识别科技有限公司 | Monitoring apparatus based on face recognition and built-in type door control monitoring system |

| CN202854920U (en)* | 2012-07-03 | 2013-04-03 | 北京盛世光明软件股份有限公司 | Access control system based on active RFID (radio frequency identification device) technology and face recognition technology |

| CN105488644A (en)* | 2014-09-03 | 2016-04-13 | 无锡优赛科技有限公司 | Intelligent warehouse management system method |

| CN105931342A (en)* | 2016-06-08 | 2016-09-07 | 胡昔兵 | Access control device |

| CN206058328U (en)* | 2016-08-26 | 2017-03-29 | 四川谛达诺科技有限公司 | A kind of new entrance guard device |

| CN107016765A (en)* | 2017-05-24 | 2017-08-04 | 六安维奥智能科技有限公司 | A kind of entrance guard device |

| CN206684814U (en)* | 2017-04-14 | 2017-11-28 | 昆山优自在智能科技有限公司 | A kind of RFID face recognition systems based on high in the clouds data exchange |

| CN208110703U (en)* | 2018-04-27 | 2018-11-16 | 桂林电子科技大学 | Guest room smart door lock device |

| CN208225160U (en)* | 2018-06-07 | 2018-12-11 | 贵州维迪话科技有限公司 | A kind of video monitoring remote unlocking system |

| CN109146041A (en)* | 2018-11-15 | 2019-01-04 | 云南电网有限责任公司红河供电局 | Unmanned plane storehouse intelligent management system based on RFID technique |

| CN109448262A (en)* | 2018-12-26 | 2019-03-08 | 四川四原科技有限公司 | Channel type intelligent article borrowing and returning management system |

| CN109559081A (en)* | 2019-02-01 | 2019-04-02 | 沈阳宝通门业有限公司 | A kind of storehouse tool management system and control method based on RFID label tag |

| CN110111469A (en)* | 2019-05-15 | 2019-08-09 | 云南电网有限责任公司带电作业分公司 | One kind being based on the unattended treasury management system of RFID and method |

| CN110135536A (en)* | 2019-04-29 | 2019-08-16 | Izure国际集团有限公司 | An intelligent warehouse management system and management method |

| CN211015674U (en)* | 2019-11-07 | 2020-07-14 | 中铁第四勘察设计院集团有限公司 | Intelligent management unmanned tool room based on RFID technology |

- 2019

- 2019-11-07CNCN201911083124.XApatent/CN110853203A/enactivePending

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101174337A (en)* | 2006-11-03 | 2008-05-07 | 上海银晨智能识别科技有限公司 | Monitoring apparatus based on face recognition and built-in type door control monitoring system |

| CN202854920U (en)* | 2012-07-03 | 2013-04-03 | 北京盛世光明软件股份有限公司 | Access control system based on active RFID (radio frequency identification device) technology and face recognition technology |

| CN105488644A (en)* | 2014-09-03 | 2016-04-13 | 无锡优赛科技有限公司 | Intelligent warehouse management system method |

| CN105931342A (en)* | 2016-06-08 | 2016-09-07 | 胡昔兵 | Access control device |

| CN206058328U (en)* | 2016-08-26 | 2017-03-29 | 四川谛达诺科技有限公司 | A kind of new entrance guard device |

| CN206684814U (en)* | 2017-04-14 | 2017-11-28 | 昆山优自在智能科技有限公司 | A kind of RFID face recognition systems based on high in the clouds data exchange |

| CN107016765A (en)* | 2017-05-24 | 2017-08-04 | 六安维奥智能科技有限公司 | A kind of entrance guard device |

| CN208110703U (en)* | 2018-04-27 | 2018-11-16 | 桂林电子科技大学 | Guest room smart door lock device |

| CN208225160U (en)* | 2018-06-07 | 2018-12-11 | 贵州维迪话科技有限公司 | A kind of video monitoring remote unlocking system |

| CN109146041A (en)* | 2018-11-15 | 2019-01-04 | 云南电网有限责任公司红河供电局 | Unmanned plane storehouse intelligent management system based on RFID technique |

| CN109448262A (en)* | 2018-12-26 | 2019-03-08 | 四川四原科技有限公司 | Channel type intelligent article borrowing and returning management system |

| CN109559081A (en)* | 2019-02-01 | 2019-04-02 | 沈阳宝通门业有限公司 | A kind of storehouse tool management system and control method based on RFID label tag |

| CN110135536A (en)* | 2019-04-29 | 2019-08-16 | Izure国际集团有限公司 | An intelligent warehouse management system and management method |

| CN110111469A (en)* | 2019-05-15 | 2019-08-09 | 云南电网有限责任公司带电作业分公司 | One kind being based on the unattended treasury management system of RFID and method |

| CN211015674U (en)* | 2019-11-07 | 2020-07-14 | 中铁第四勘察设计院集团有限公司 | Intelligent management unmanned tool room based on RFID technology |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113763062A (en)* | 2020-06-02 | 2021-12-07 | 济南济公信息科技有限公司 | Tool management system for borrowing and returning registration based on intelligent terminal code scanning |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN106960405B (en) | Intelligent file big data platform system | |

| CN204719878U (en) | Intelligent article management cabinet | |

| CN104240409A (en) | Intelligent tool cabinet | |

| CN105160748A (en) | Intelligent power supply station storeroom management system and method based on internet of things | |

| CN104331790A (en) | Intelligent management system for tool based on radio frequency technology | |

| CN203616829U (en) | Intelligent tool cabinet | |

| CN104504782A (en) | Intelligent door lock system of hydropower station | |

| CN110555657A (en) | material management system, warehousing method, ex-warehouse method and ex-warehouse method | |

| CN204120554U (en) | A kind of vehicle reservation and car key access terminal device | |

| CN109465798B (en) | Intelligent tool cabinet system of Internet of things | |

| CN110853203A (en) | An intelligent management unmanned tool room based on RFID technology | |

| CN210563879U (en) | Finger vein identification stamp checking cabinet | |

| CN211015674U (en) | Intelligent management unmanned tool room based on RFID technology | |

| CN111369153A (en) | Railway maintenance tool management system | |

| CN213264096U (en) | Measurement turnover cabinet | |

| CN211787188U (en) | Safety tool management system | |

| CN103295293B (en) | A kind of neck volume and backrush automated management system | |

| CN202495101U (en) | Vein recognition secure channel system | |

| CN202126701U (en) | Intelligent management system of key storeroom | |

| CN217238843U (en) | Self-service distribution equipment of thermoluminescence dosimeter for radioactive unit | |

| CN216748880U (en) | Intelligent recognition distribution network construction tool's strorage device | |

| CN214704837U (en) | Torque wrench management cabinet | |

| CN212123219U (en) | Intelligent tool cabinet based on RFID technology and intelligent tool management system | |

| CN211992879U (en) | Intelligent management equipment for tool cabinet | |

| CN205827471U (en) | Wheelchair Accessible machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200228 |