CN110845523A - A kind of rare earth metal organic complex microsphere wave absorbing material and preparation method thereof - Google Patents

A kind of rare earth metal organic complex microsphere wave absorbing material and preparation method thereofDownload PDFInfo

- Publication number

- CN110845523A CN110845523ACN201911140534.3ACN201911140534ACN110845523ACN 110845523 ACN110845523 ACN 110845523ACN 201911140534 ACN201911140534 ACN 201911140534ACN 110845523 ACN110845523 ACN 110845523A

- Authority

- CN

- China

- Prior art keywords

- rare earth

- earth metal

- organic complex

- complex microsphere

- metal organic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 229910052761rare earth metalInorganic materials0.000titleclaimsabstractdescription147

- 239000004005microsphereSubstances0.000titleclaimsabstractdescription109

- 150000002910rare earth metalsChemical class0.000titleclaimsabstractdescription106

- 239000011358absorbing materialSubstances0.000titleclaimsabstractdescription65

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription23

- 239000000203mixtureSubstances0.000claimsabstractdescription27

- 238000005406washingMethods0.000claimsabstractdescription23

- 238000002791soakingMethods0.000claimsabstractdescription9

- ZMXDDKWLCZADIW-UHFFFAOYSA-NN,N-DimethylformamideChemical compoundCN(C)C=OZMXDDKWLCZADIW-UHFFFAOYSA-N0.000claimsdescription125

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000claimsdescription44

- 239000000843powderSubstances0.000claimsdescription43

- -1rare earth metal saltChemical class0.000claimsdescription43

- 238000006243chemical reactionMethods0.000claimsdescription36

- 239000002904solventSubstances0.000claimsdescription20

- LXXCECZPOWZKLC-UHFFFAOYSA-Npraseodymium(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[Pr+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OLXXCECZPOWZKLC-UHFFFAOYSA-N0.000claimsdescription19

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription16

- 238000000034methodMethods0.000claimsdescription16

- GJKFIJKSBFYMQK-UHFFFAOYSA-Nlanthanum(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[La+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OGJKFIJKSBFYMQK-UHFFFAOYSA-N0.000claimsdescription15

- 238000006555catalytic reactionMethods0.000claimsdescription13

- 230000004913activationEffects0.000claimsdescription12

- QQZMWMKOWKGPQY-UHFFFAOYSA-Ncerium(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[Ce+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OQQZMWMKOWKGPQY-UHFFFAOYSA-N0.000claimsdescription11

- 230000009471actionEffects0.000claimsdescription7

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription7

- XWFVFZQEDMDSET-UHFFFAOYSA-Ngadolinium(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[Gd+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OXWFVFZQEDMDSET-UHFFFAOYSA-N0.000claimsdescription6

- 239000000463materialSubstances0.000claimsdescription6

- VYLVYHXQOHJDJL-UHFFFAOYSA-Kcerium trichlorideChemical compoundCl[Ce](Cl)ClVYLVYHXQOHJDJL-UHFFFAOYSA-K0.000claimsdescription4

- 238000004090dissolutionMethods0.000claimsdescription4

- 238000001914filtrationMethods0.000claimsdescription4

- RHVPCSSKNPYQDU-UHFFFAOYSA-Hneodymium(3+);trisulfate;hydrateChemical compoundO.[Nd+3].[Nd+3].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=ORHVPCSSKNPYQDU-UHFFFAOYSA-H0.000claimsdescription4

- ATINCSYRHURBSP-UHFFFAOYSA-Kneodymium(iii) chlorideChemical compoundCl[Nd](Cl)ClATINCSYRHURBSP-UHFFFAOYSA-K0.000claimsdescription4

- OZECDDHOAMNMQI-UHFFFAOYSA-Hcerium(3+);trisulfateChemical compound[Ce+3].[Ce+3].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=OOZECDDHOAMNMQI-UHFFFAOYSA-H0.000claimsdescription3

- 150000001875compoundsChemical class0.000claimsdescription3

- VQEHIYWBGOJJDM-UHFFFAOYSA-Hlanthanum(3+);trisulfateChemical compound[La+3].[La+3].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=OVQEHIYWBGOJJDM-UHFFFAOYSA-H0.000claimsdescription3

- ICAKDTKJOYSXGC-UHFFFAOYSA-Klanthanum(iii) chlorideChemical compoundCl[La](Cl)ClICAKDTKJOYSXGC-UHFFFAOYSA-K0.000claimsdescription3

- 239000007788liquidSubstances0.000claimsdescription3

- VQVDTKCSDUNYBO-UHFFFAOYSA-Nneodymium(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[Nd+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OVQVDTKCSDUNYBO-UHFFFAOYSA-N0.000claimsdescription3

- HDCOFJGRHQAIPE-UHFFFAOYSA-Nsamarium(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[Sm+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OHDCOFJGRHQAIPE-UHFFFAOYSA-N0.000claimsdescription3

- DVMZCYSFPFUKKE-UHFFFAOYSA-Kscandium chlorideChemical compoundCl[Sc](Cl)ClDVMZCYSFPFUKKE-UHFFFAOYSA-K0.000claimsdescription3

- 229910000346scandium sulfateInorganic materials0.000claimsdescription3

- QHYMYKHVGWATOS-UHFFFAOYSA-Hscandium(3+);trisulfateChemical compound[Sc+3].[Sc+3].[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=O.[O-]S([O-])(=O)=OQHYMYKHVGWATOS-UHFFFAOYSA-H0.000claimsdescription3

- QBAZWXKSCUESGU-UHFFFAOYSA-Nyttrium(3+);trinitrate;hexahydrateChemical compoundO.O.O.O.O.O.[Y+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OQBAZWXKSCUESGU-UHFFFAOYSA-N0.000claimsdescription3

- 238000001816coolingMethods0.000claimsdescription2

- SNVRDQORMVVQBI-UPHRSURJSA-N(z)-but-2-enedihydrazideChemical compoundNNC(=O)\C=C/C(=O)NNSNVRDQORMVVQBI-UPHRSURJSA-N0.000claims2

- 230000003213activating effectEffects0.000claims1

- 239000003125aqueous solventSubstances0.000claims1

- 239000012295chemical reaction liquidSubstances0.000claims1

- FDPIMTJIUBPUKL-UHFFFAOYSA-NdimethylacetoneNatural productsCCC(=O)CCFDPIMTJIUBPUKL-UHFFFAOYSA-N0.000claims1

- 238000007669thermal treatmentMethods0.000claims1

- 238000010438heat treatmentMethods0.000abstractdescription8

- 238000003763carbonizationMethods0.000abstractdescription2

- 238000009776industrial productionMethods0.000abstractdescription2

- 238000007036catalytic synthesis reactionMethods0.000abstract1

- 230000002349favourable effectEffects0.000abstract1

- BGRDGMRNKXEXQD-UHFFFAOYSA-NMaleic hydrazideChemical compoundOC1=CC=C(O)N=N1BGRDGMRNKXEXQD-UHFFFAOYSA-N0.000description37

- 239000005983Maleic hydrazideSubstances0.000description37

- 239000000243solutionSubstances0.000description36

- 238000010521absorption reactionMethods0.000description15

- 238000009826distributionMethods0.000description14

- 238000010586diagramMethods0.000description9

- 239000000047productSubstances0.000description8

- 230000035484reaction timeEffects0.000description7

- 239000002994raw materialSubstances0.000description5

- 230000005540biological transmissionEffects0.000description4

- 238000001514detection methodMethods0.000description4

- 239000013110organic ligandSubstances0.000description4

- 238000001556precipitationMethods0.000description4

- 238000003786synthesis reactionMethods0.000description3

- 238000012360testing methodMethods0.000description3

- 239000002841Lewis acidSubstances0.000description2

- 238000005054agglomerationMethods0.000description2

- 230000002776aggregationEffects0.000description2

- 238000004458analytical methodMethods0.000description2

- 230000009286beneficial effectEffects0.000description2

- 239000000919ceramicSubstances0.000description2

- 230000007547defectEffects0.000description2

- 238000005516engineering processMethods0.000description2

- 229910052747lanthanoidInorganic materials0.000description2

- 150000007517lewis acidsChemical class0.000description2

- 238000004020luminiscence typeMethods0.000description2

- 230000005389magnetismEffects0.000description2

- 229910052751metalInorganic materials0.000description2

- 239000002184metalSubstances0.000description2

- 239000012621metal-organic frameworkSubstances0.000description2

- 239000011259mixed solutionSubstances0.000description2

- 238000005424photoluminescenceMethods0.000description2

- 230000008569processEffects0.000description2

- 239000000376reactantSubstances0.000description2

- 230000007704transitionEffects0.000description2

- 239000002699waste materialSubstances0.000description2

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical class[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description1

- 229910000858La alloyInorganic materials0.000description1

- 229910002148La0.6Sr0.4MnO3Inorganic materials0.000description1

- 229910052777PraseodymiumInorganic materials0.000description1

- 238000007171acid catalysisMethods0.000description1

- 230000015572biosynthetic processEffects0.000description1

- 229910052799carbonInorganic materials0.000description1

- 239000005539carbonized materialSubstances0.000description1

- 230000008859changeEffects0.000description1

- 239000007795chemical reaction productSubstances0.000description1

- 239000002131composite materialSubstances0.000description1

- 239000013078crystalSubstances0.000description1

- 239000003937drug carrierSubstances0.000description1

- 230000000694effectsEffects0.000description1

- 238000002474experimental methodMethods0.000description1

- 238000000605extractionMethods0.000description1

- MWFSXYMZCVAQCC-UHFFFAOYSA-Ngadolinium(iii) nitrateChemical class[Gd+3].[O-][N+]([O-])=O.[O-][N+]([O-])=O.[O-][N+]([O-])=OMWFSXYMZCVAQCC-UHFFFAOYSA-N0.000description1

- PCHJSUWPFVWCPO-UHFFFAOYSA-NgoldChemical compound[Au]PCHJSUWPFVWCPO-UHFFFAOYSA-N0.000description1

- 229910052737goldInorganic materials0.000description1

- 239000010931goldSubstances0.000description1

- 150000004687hexahydratesChemical class0.000description1

- 238000001027hydrothermal synthesisMethods0.000description1

- 150000002602lanthanoidsChemical class0.000description1

- 239000004973liquid crystal related substanceSubstances0.000description1

- 239000007791liquid phaseSubstances0.000description1

- 238000004519manufacturing processMethods0.000description1

- 238000005272metallurgyMethods0.000description1

- 150000002739metalsChemical class0.000description1

- 239000002105nanoparticleSubstances0.000description1

- 229910052757nitrogenInorganic materials0.000description1

- 229910052760oxygenInorganic materials0.000description1

- 239000003208petroleumSubstances0.000description1

- 229910052698phosphorusInorganic materials0.000description1

- 239000011148porous materialSubstances0.000description1

- 238000004886process controlMethods0.000description1

- 230000009467reductionEffects0.000description1

- 238000004626scanning electron microscopyMethods0.000description1

- 238000000926separation methodMethods0.000description1

- 150000003384small moleculesChemical class0.000description1

- 239000007787solidSubstances0.000description1

- 239000000126substanceSubstances0.000description1

- 229910052717sulfurInorganic materials0.000description1

- 238000001308synthesis methodMethods0.000description1

- 229910052723transition metalInorganic materials0.000description1

- 150000003624transition metalsChemical class0.000description1

- 238000004627transmission electron microscopyMethods0.000description1

- 229910000859α-FeInorganic materials0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07F—ACYCLIC, CARBOCYCLIC OR HETEROCYCLIC COMPOUNDS CONTAINING ELEMENTS OTHER THAN CARBON, HYDROGEN, HALOGEN, OXYGEN, NITROGEN, SULFUR, SELENIUM OR TELLURIUM

- C07F5/00—Compounds containing elements of Groups 3 or 13 of the Periodic Table

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Catalysts (AREA)

Abstract

Description

Translated fromChinese【技术领域】【Technical field】

本发明属于新型金属有机框架材料。更具体地,本发明涉及一种稀土金属有机配合物微球吸波材料,还涉及所述稀土金属有机配合物微球吸波材料的制备方法。The invention belongs to a novel metal organic framework material. More specifically, the present invention relates to a rare earth metal organic complex microsphere absorbing material, and also relates to a preparation method of the rare earth metal organic complex microsphere absorbing material.

【背景技术】【Background technique】

稀土金属在军事工业、冶金、石油化工、陶瓷、农业等方面的广泛应用,使其成为具有工业黄金的称谓。稀土金属具有独特的4f电子轨道,外层的S、P轨道电子对4f轨道具有极强的屏蔽作用,使稀土金属具有独特的磁性和配位性能。这些稀土金属离子半径大,配位数高,比过渡金属和主族金属更易活化有机配体。它们的路易斯酸特性使其具有亲氧、亲氮的特性,使其在有机配体反应过程中更加容易配位。The wide application of rare earth metals in military industry, metallurgy, petrochemical industry, ceramics, agriculture, etc. makes it the title of industrial gold. Rare earth metals have a unique 4f electron orbit, and the S and P orbital electrons in the outer layer have a strong shielding effect on the 4f orbit, which makes rare earth metals have unique magnetic and coordination properties. These rare earth metals have large ionic radii and high coordination numbers, making them easier to activate organic ligands than transition metals and main group metals. Their Lewis acid properties make them oxophilic and nitrophilic, making them easier to coordinate during the reaction of organic ligands.

稀土金属配合物具有广泛的应用,在发光、磁性、有机合成催化等方面尤其如此。在发光方面,单一的稀土金属较难发光,因为稀土离子的f-f跃迁属于禁戒跃迁,这使得稀土金属离子不论是在紫外区域还是在可见光区域都表现出很低的吸收,导致其光致发光性能很低。但是,当它与有机配体进行络合之后,则表现出优异的光致发光性能。在磁性方面,稀土金属的4f轨道电子具有较大的未淬灭的轨道角动量,因此稀土离子构筑的磁体具有较大的磁矩。在催化方面,1983年Bednarski等人(Aziz FihriA CLBR.Hydroxyapatite:Areview of syntheses,structure and applications in heterogeneouscatalysisq.Coordination Chemistry Reviews 2017:48-76)报道了第一例镧系元素络合物作为路易斯酸催化手性反应的实例。近年来,稀土金属催化有机合成实验取得了长足的发展。这可能与稀土金属的亲氧、亲氮等特性有关。Rare earth metal complexes have a wide range of applications, especially in luminescence, magnetism, and catalysis of organic synthesis. In terms of luminescence, it is difficult for a single rare earth metal to emit light, because the f-f transition of rare earth ions is a forbidden transition, which makes rare earth metal ions show very low absorption in both the ultraviolet region and the visible light region, resulting in its photoluminescence. Performance is low. However, when it is complexed with organic ligands, it exhibits excellent photoluminescence properties. In terms of magnetism, the 4f orbital electrons of rare earth metals have large unquenched orbital angular momentum, so the magnets constructed by rare earth ions have large magnetic moments. In catalysis, the first case of lanthanide complexes as Lewis acid catalysis was reported by Bednarski et al. Examples of chiral reactions. In recent years, rare earth metal-catalyzed organic synthesis experiments have made great progress. This may be related to the oxygen-philic and nitrogen-philic properties of rare earth metals.

传统的吸波材料,比如铁氧体、陶瓷类吸波材料,具有有效吸收频带窄、材料密度太大,吸收强度太低等缺点。而镧系金属配合物吸波材料具有“宽”、“薄”、“轻”、“强”等特点,有着广阔的应用前景。Yan等人(Yan J,Huang Y,Han X,Gao X,Liu P.Metal organicframework(ZIF-67)-derived hollow CoS2/N-doped carbon nanotube composites forextraordinary electromagnetic wave absorption.Composites Part B:Engineering2019;163:67-76)制备了配合物碳化材料,其吸收电磁波达到-65.1dB。Cheng等人(Cheng YL,Dai JM,Zhu XB,et al.Enhanced Microwave Absorption PropertiesofIntrinsically Core/shell Structured La0.6Sr0.4MnO3 Nanoparticles.NANOSCALERES LETT 2009;4:1153-1158)制备了金属镧合金,在高温碳化,其吸波性能达到了-41.1dB。然而,这些材料存在密度太大,无法实现工业化生产等缺陷。Traditional absorbing materials, such as ferrite and ceramic absorbing materials, have the disadvantages of narrow effective absorption frequency band, too high material density, and too low absorption intensity. The lanthanide metal complex absorbing materials have the characteristics of "wide", "thin", "light" and "strong", and have broad application prospects. Yan et al. (Yan J, Huang Y, Han X, Gao X, Liu P. Metal organicframework (ZIF-67)-derived hollow CoS2/N-doped carbon nanotube composites for extraordinary electromagnetic wave absorption. Composites Part B: Engineering 2019; 163: 67-76) prepared complex carbonized materials, which absorb electromagnetic waves up to -65.1dB. Cheng et al. (Cheng YL, Dai JM, Zhu XB, et al. Enhanced Microwave Absorption Properties of Intrinsically Core/shell Structured La0.6Sr0.4MnO3 Nanoparticles. NANOSCALERES LETT 2009; 4:1153-1158) prepared metallic lanthanum alloys, carbonized at high temperature , its absorbing performance reached -41.1dB. However, these materials have drawbacks such as being too dense to be industrially produced.

稀土配合物微球具有良好的分散性,同时保障了其配合物性能不变。它们的直径是纳米级,是当代工业,尤其是液晶、药物载体、荧光标记等高新技术产业的重要支持技术之一。其合成方法有水热法、沉淀法、微波法等。然而,这些微球制备技术还存在诸多技术缺陷,例如合成流程长、设备性能要求高、工艺过程难以控制等。Rare earth complex microspheres have good dispersibility, and at the same time ensure the constant performance of their complexes. Their diameters are nanometers, and they are one of the important supporting technologies for contemporary industries, especially high-tech industries such as liquid crystals, drug carriers, and fluorescent labels. The synthesis methods include hydrothermal method, precipitation method, microwave method and so on. However, these microsphere preparation technologies still have many technical defects, such as long synthesis process, high equipment performance requirements, and difficult process control.

因此,针对现有技术存在的技术缺陷,本发明人通过大量实验研究与分析总结,终于完成了本发明。Therefore, in view of the technical defects existing in the prior art, the present inventor finally completed the present invention through a large number of experimental studies and analysis and summary.

【发明内容】[Content of the invention]

[要解决的技术问题][Technical problem to be solved]

本发明的目的是提供一种稀土金属有机配合物微球吸波材料。The purpose of the present invention is to provide a rare earth metal organic complex microsphere wave absorbing material.

本发明的另一个目的是提供所述稀土金属有机配合物微球吸波材料的制备方法。Another object of the present invention is to provide a preparation method of the rare earth metal organic complex microsphere wave absorbing material.

[技术方案][Technical solutions]

本发明是通过下述技术方案实现的。The present invention is achieved through the following technical solutions.

本发明涉及一种稀土金属有机配合物微球吸波材料的制备方法。The invention relates to a preparation method of a rare earth metal organic complex microsphere wave absorbing material.

该稀土金属有机配合物微球吸波材料制备方法的步骤如下:The steps of the preparation method of the rare earth metal organic complex microsphere wave absorbing material are as follows:

A、制备混合物溶液A. Prepare the mixture solution

在超声波的作用下,稀土金属盐与顺丁烯二酰肼按照其摩尔比1:1~5溶于溶剂中,得到一种混合物溶液;Under the action of ultrasonic wave, the rare earth metal salt and maleic hydrazide are dissolved in the solvent according to the molar ratio of 1:1-5 to obtain a mixed solution;

B、微波催化反应B, microwave catalytic reaction

将步骤A得到的混合物溶液在微波反应釜中在微波功率40~150W、温度100~200℃与压力10~20bar的条件下进行反应5~120min;The mixture solution obtained in step A is reacted in a microwave reactor for 5-120min under the conditions of microwave power 40-150W, temperature 100-200°C and pressure 10-20bar;

C、洗涤C. to wash

让步骤B得到的反应液自然降温至室温,过滤,分离的滤渣用洗涤液洗涤,得到稀土金属有机配合物微球粉末;The reaction solution obtained in step B is naturally cooled to room temperature, filtered, and the separated filter residue is washed with washing solution to obtain rare earth metal organic complex microsphere powder;

D、浸泡D. to soak

按照稀土金属有机配合物微球粉末与DMF的体积比为1:3~8,将步骤C得到的稀土金属有机配合物微球粉末在室温下在DMF中重复浸泡,每次浸泡12h,接着按照同样的体积比在丙酮中重复浸泡,每次浸泡12h;According to the volume ratio of the rare earth metal organic complex microsphere powder to DMF is 1:3 to 8, the rare earth metal organic complex microsphere powder obtained in step C was repeatedly soaked in DMF at room temperature for 12 hours each time, and then according to the following steps: The same volume ratio was repeatedly soaked in acetone for 12h each time;

E、热处理E. Heat treatment

步骤D浸泡的稀土金属有机配合物微球粉末在温度120~200℃下进行活化处理,得到所述的吸波材料。The rare earth metal organic complex microsphere powder soaked in step D is activated at a temperature of 120-200° C. to obtain the wave absorbing material.

根据本发明的一种优选实施方式,在步骤A中,所述的稀土金属盐是一种或多种选自六水硝酸镨、六水硝酸钕、六水硝酸镧、六水硝酸钐、六水硝酸钆、六水硝酸钇、六水硝酸铈、氯化钪、氯化镧、氯化铈、氯化钕、硫酸钪、硫酸镧、硫酸铈或硫酸钕的稀土金属盐。According to a preferred embodiment of the present invention, in step A, the rare earth metal salt is one or more selected from the group consisting of praseodymium nitrate hexahydrate, neodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, samarium nitrate hexahydrate, hexahydrate Rare earth metal salts of gadolinium nitrate, yttrium nitrate hexahydrate, cerium nitrate hexahydrate, scandium chloride, lanthanum chloride, cerium chloride, neodymium chloride, scandium sulfate, lanthanum sulfate, cerium sulfate or neodymium sulfate.

根据本发明的另一种优选实施方式,在步骤A中,所述的溶剂是DMF、乙醇或水溶剂,以克计稀土金属盐与以毫升计溶剂的比1:4~8。According to another preferred embodiment of the present invention, in step A, the solvent is DMF, ethanol or water solvent, and the ratio of rare earth metal salt in grams to solvent in milliliters is 1:4-8.

根据本发明的另一种优选实施方式,在步骤A中,所述超声波的超声频率是20~40kHz,它的功率密度是0.3~0.35W/cm2,其溶解时间是25~35min。According to another preferred embodiment of the present invention, in step A, the ultrasonic frequency of the ultrasonic wave is 20-40 kHz, its power density is 0.3-0.35 W/cm2 , and its dissolving time is 25-35 min.

根据本发明的另一种优选实施方式,在步骤C中,所述的洗涤液是DMF、乙醇或水。According to another preferred embodiment of the present invention, in step C, the washing solution is DMF, ethanol or water.

根据本发明的另一种优选实施方式,在步骤C洗涤时,分离的滤渣与洗涤液按照体积比1:5~8洗涤3~5次。According to another preferred embodiment of the present invention, during the washing in step C, the separated filter residue and the washing solution are washed 3 to 5 times according to a volume ratio of 1:5 to 8.

根据本发明的另一种优选实施方式,在步骤D中,步骤C得到的稀土金属有机配合物微球粉末分别在DMF中与在丙酮中浸泡的总时间都是12~72h。According to another preferred embodiment of the present invention, in step D, the total time of soaking the rare earth metal organic complex microsphere powder obtained in step C in DMF and in acetone is 12-72 h respectively.

根据本发明的另一种优选实施方式,在步骤E中,步骤D浸泡的稀土金属有机配合物微球粉末进行活化处理的时间是1~12h。According to another preferred embodiment of the present invention, in step E, the time for the activation treatment of the rare earth metal organic complex microsphere powder soaked in step D is 1-12 hours.

本发明还涉及所述制备方法制备得到的稀土金属有机配合物微球吸波材料,它是由稀土金属离子与顺丁烯二酰肼配位化合物组成的直径为750~850nm的微球吸波材料。The invention also relates to the rare earth metal organic complex microsphere wave absorbing material prepared by the preparation method, which is a microsphere wave absorbing material with a diameter of 750-850 nm composed of a rare earth metal ion and a maleic hydrazide coordination compound Material.

根据本发明的一种优选实施方式,所述稀土金属有机配合物微球吸波材料具有下述吸波性能:According to a preferred embodiment of the present invention, the rare earth metal organic complex microsphere wave absorbing material has the following wave absorbing properties:

它的最大反射损耗是-12.118dB;Its maximum reflection loss is -12.118dB;

该吸波材料厚度为2mm时,它的反射损耗是-10dB以下。When the thickness of the absorbing material is 2mm, its reflection loss is below -10dB.

下面将更详细地描述本发明。The present invention will be described in more detail below.

本发明涉及一种稀土金属有机配合物微球吸波材料的制备方法。The invention relates to a preparation method of a rare earth metal organic complex microsphere wave absorbing material.

该稀土金属有机配合物微球吸波材料制备方法的步骤如下:The steps of the preparation method of the rare earth metal organic complex microsphere wave absorbing material are as follows:

A、制备混合物溶液A. Prepare the mixture solution

在超声波的作用下,稀土金属盐与顺丁烯二酰肼按照其摩尔比1:1~5溶于溶剂中,得到一种混合物溶液;Under the action of ultrasonic wave, the rare earth metal salt and maleic hydrazide are dissolved in the solvent according to the molar ratio of 1:1-5 to obtain a mixed solution;

在本发明稀土金属有机配合物微球吸波材料中,金属有机配合物微球是由稀土金属盐与顺丁烯二酰肼配位所生成的配合物组成的。In the rare earth metal organic complex microsphere wave absorbing material of the present invention, the metal organic complex microsphere is composed of a complex formed by the coordination of a rare earth metal salt and maleic hydrazide.

该金属有机配合物在本发明稀土金属有机配合物微球中是无序排布的。The metal-organic complexes are arranged disorderly in the rare earth metal-organic complex microspheres of the present invention.

根据本发明,稀土金属盐与顺丁烯二酰肼的摩尔比是1:1~5。如果稀土金属盐与顺丁烯二酰肼的摩尔比大于1:1,则不能形成顺丁烯二酰肼与稀土金属配合物微球;如果稀土金属盐与顺丁烯二酰肼的摩尔比小于1:5,则也不能形成顺丁烯二酰肼与稀土金属配位配合物微球;因此,稀土金属盐与顺丁烯二酰肼的摩尔比为1:1~5是合理的,优选地是1:1.5~4.5,更优选地是1:2.0~4.0。According to the present invention, the molar ratio of rare earth metal salt to maleic hydrazide is 1:1-5. If the molar ratio of rare earth metal salt to maleic hydrazide is greater than 1:1, the microspheres of maleic hydrazide and rare earth metal complex cannot be formed; if the molar ratio of rare earth metal salt to maleic hydrazide If the ratio is less than 1:5, the maleic hydrazide and rare earth metal coordination complex microspheres cannot be formed; therefore, the molar ratio of rare earth metal salt to maleic hydrazide is reasonable to be 1:1 to 5. It is preferably 1:1.5-4.5, more preferably 1:2.0-4.0.

本发明使用的稀土金属盐是一种或多种选自六水硝酸镨、六水硝酸钕、六水硝酸镧、六水硝酸钐、六水硝酸钆、六水硝酸钇、六水硝酸铈、氯化钪、氯化镧、氯化铈、氯化钕、硫酸钪、硫酸镧、硫酸铈或硫酸钕的稀土金属盐。它们都是目前市场上销售的产品,例如由阿拉丁公司销售的六水硝酸镨、国药公司销售的氯化铈、由sigma公司销售的硫酸钕。当然,除了所述的稀土金属外,其它稀土金属都可以用于本发明,只是它们对本发明吸波材料不会产生负面影响,因此,这些稀土金属也都在本发明保护范围之内。The rare earth metal salt used in the present invention is one or more selected from praseodymium nitrate hexahydrate, neodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, samarium nitrate hexahydrate, gadolinium nitrate hexahydrate, yttrium nitrate hexahydrate, cerium nitrate hexahydrate, Rare earth metal salts of scandium chloride, lanthanum chloride, cerium chloride, neodymium chloride, scandium sulfate, lanthanum sulfate, cerium sulfate or neodymium sulfate. They are all products currently on the market, such as praseodymium nitrate hexahydrate sold by Aladdin, cerium chloride sold by Sinopharm, and neodymium sulfate sold by Sigma. Of course, in addition to the rare earth metals, other rare earth metals can be used in the present invention, but they will not negatively affect the wave absorbing material of the present invention. Therefore, these rare earth metals are also within the protection scope of the present invention.

本发明使用的顺丁烯二酰肼是目前市场上销售的产品,例如由阿拉丁公司销售的分析纯顺丁烯二酰肼。The maleic hydrazide used in the present invention is a product currently on the market, such as analytically pure maleic hydrazide sold by Aladdin Company.

根据本发明,所述的溶剂是DMF、乙醇或水溶剂。它在这个步骤中的作用是加速溶解速率,促进催化反应。在这个步骤中,以克计稀土金属盐与以毫升计溶剂的比1:4~8。According to the present invention, the solvent is DMF, ethanol or water solvent. Its role in this step is to accelerate the dissolution rate and promote the catalytic reaction. In this step, the ratio of rare earth metal salt in grams to solvent in milliliters is 1:4-8.

在这个步骤中超声溶解的基本作用在于加速溶解速率,促进催化反应。The basic function of ultrasonic dissolution in this step is to accelerate the dissolution rate and promote the catalytic reaction.

本发明采用超声波的超声频率是20~40kHz,它的功率密度是0.3~0.35W/cm2,其超声溶解时间是25~35min。The ultrasonic frequency of the ultrasonic wave used in the present invention is 20-40 kHz, the power density thereof is 0.3-0.35 W/cm2 , and the ultrasonic dissolving time is 25-35 min.

在本发明中,如果超声频率、功率密度或超声时间超过所述的范围都是不可取的,因为超声功率过大,会导致反应物析出,没有参与反应,超声功率过低则会使原料部分溶解;如果超声时间过长,则会造成成本增加,超声时间过短,则反应原料部分不溶解;超声频率过高则会导致反应物析出,超声频率过低则不能完全实现催化反应。In the present invention, it is not advisable if the ultrasonic frequency, power density or ultrasonic time exceeds the stated range, because the ultrasonic power is too large, which will lead to the precipitation of the reactants and do not participate in the reaction, and the ultrasonic power is too low, which will cause the raw material part If the ultrasonic time is too long, the cost will increase; if the ultrasonic time is too short, the reaction raw materials will not be partially dissolved; if the ultrasonic frequency is too high, the reactants will be precipitated; if the ultrasonic frequency is too low, the catalytic reaction cannot be fully realized.

优选地,超声频率是26~35kHz,功率密度是0.32~0.34W/cm2,超声溶解时间是28~32min。Preferably, the ultrasonic frequency is 26-35 kHz, the power density is 0.32-0.34 W/cm2 , and the ultrasonic dissolving time is 28-32 min.

本发明使用的超声设备是目前市场上销售的产品,例如深圳市方奥微电子有限公司销售的语盟YM-040S产品。The ultrasonic equipment used in the present invention is a product currently on the market, such as the Yumeng YM-040S product sold by Shenzhen Fangao Microelectronics Co., Ltd.

B、微波催化反应B, microwave catalytic reaction

将步骤A得到的混合物溶液在微波反应釜中在微波功率40~150W、温度100~200℃与压力10~20bar的条件下进行反应5~120min;The mixture solution obtained in step A is reacted in a microwave reactor for 5-120min under the conditions of microwave power 40-150W, temperature 100-200°C and pressure 10-20bar;

在这个步骤中,稀土金属盐与顺丁烯二酰肼进行配位反应,得到所述的配合物。通常根据扫描电镜检测该微波催化反应产物,以此检测其反应进程情况。In this step, the rare earth metal salt is subjected to a coordination reaction with maleic hydrazide to obtain the complex. The microwave catalyzed reaction product is usually detected by scanning electron microscope to detect its reaction progress.

根据本发明,反应温度、反应时间与反应压力在所述的范围内时,如果微波功率低于40W,则出现反应体系透明、无沉淀现象,表明稀土金属盐与顺丁烯二酰肼没有完全配位形成配合物微球,如果微波功率高于150W,则出现小球团聚严重现象,表明反应过于剧烈,通过扫描电镜检测没有形成规则的配合物微球。因此,稀土金属盐与顺丁烯二酰肼的反应温度为40~150W是恰当的,优选地是60~130W,更优选地是80~120W。According to the present invention, when the reaction temperature, reaction time and reaction pressure are within the described ranges, if the microwave power is lower than 40W, the reaction system is transparent and has no precipitation, indicating that the rare earth metal salt and maleic hydrazide are not completely The complex microspheres are formed by coordination. If the microwave power is higher than 150W, serious agglomeration of small spheres occurs, indicating that the reaction is too violent, and no regular complex microspheres are formed by scanning electron microscopy. Therefore, it is appropriate that the reaction temperature of the rare earth metal salt and maleic hydrazide is 40-150W, preferably 60-130W, more preferably 80-120W.

同样地,微波功率、反应时间与反应压力在所述的范围内时,如果反应温度低于100℃,则出现反应体系透明、无沉淀现象,表明稀土金属盐与顺丁烯二酰肼没有完全配位形成配合物微球;如果反应温度高于200℃,则出现小球团聚严重现象,表明反应过于剧烈,不能形成规则的配合物微球。因此,稀土金属盐与顺丁烯二酰肼的反应温度为100~200℃是合理的,优选地是120~180℃,更优选的是132~175℃。Similarly, when the microwave power, reaction time and reaction pressure are within the stated ranges, if the reaction temperature is lower than 100°C, the reaction system will be transparent and there will be no precipitation, indicating that the rare earth metal salt and maleic hydrazide are not completely Coordination to form complex microspheres; if the reaction temperature is higher than 200 °C, serious agglomeration of small spheres occurs, indicating that the reaction is too violent to form regular complex microspheres. Therefore, it is reasonable that the reaction temperature of the rare earth metal salt and maleic hydrazide is 100-200°C, preferably 120-180°C, and more preferably 132-175°C.

微波功率、反应时间与反应温度在所述的范围内时,如果反应压力低于10bar,则该体系温度达不到所述的反应温度,不能使稀土金属盐与顺丁烯二酰肼配位形成配合物微球;如果反应压力高于20bar,则出现温度迅速升高、反应釜内压力远远未达到设定承受压力现象,表明会造成资源浪费。因此,稀土金属盐与顺丁烯二酰肼的反应压力为10~20bar是合适的,优选地是12~18bar,更优选地是14~16bar。When the microwave power, reaction time and reaction temperature are within the stated ranges, if the reaction pressure is lower than 10 bar, the temperature of the system cannot reach the stated reaction temperature, and the rare earth metal salt cannot be coordinated with maleic hydrazide. The complex microspheres are formed; if the reaction pressure is higher than 20 bar, the temperature rises rapidly, and the pressure in the reaction kettle is far from the set pressure, indicating that it will cause waste of resources. Therefore, it is suitable that the reaction pressure of the rare earth metal salt and maleic hydrazide is 10-20 bar, preferably 12-18 bar, more preferably 14-16 bar.

微波功率、反应压力与反应温度在所述的范围内时,如果反应时间短于5min,则反应时间过短而出现产率过少现象,表明稀土金属盐与顺丁烯二酰肼没完全有配位形成配合物微球;如果反应时间长于120min,则出现产率、形貌与用时少于120min没有差异现象,表明会造成设备资源浪费。因此,稀土金属盐与顺丁烯二酰肼的反应时间为5~120min是可取的,优选地是18~100min,更优选地是32~74min。When the microwave power, reaction pressure and reaction temperature are within the stated ranges, if the reaction time is shorter than 5min, the reaction time is too short and the yield is too low, indicating that the rare earth metal salt and maleic hydrazide are not completely compatible. Coordinate to form complex microspheres; if the reaction time is longer than 120min, there will be no difference in yield, morphology and time less than 120min, indicating that equipment resources will be wasted. Therefore, the reaction time between the rare earth metal salt and maleic hydrazide is preferably 5-120 min, preferably 18-100 min, more preferably 32-74 min.

微波反应釜是主要用于化工、医药、石油、染料、生化等工业生产过程中的化学反应和加热冷却,液体萃取,气体吸收等物理变化过程的反应釜。本发明使用的微波反应釜是目前市场上销售的产品,例如由美国CEM公司销售的产品。Microwave reactor is mainly used for chemical reaction and heating and cooling, liquid extraction, gas absorption and other physical change processes in chemical, pharmaceutical, petroleum, dye, biochemical and other industrial production processes. The microwave reactor used in the present invention is a product currently on the market, for example, a product sold by CEM Company in the United States.

C、洗涤C. to wash

让步骤B得到的反应液自然降温至室温,过滤,分离的滤渣用洗涤液洗涤,得到稀土金属有机配合物微球粉末;The reaction solution obtained in step B is naturally cooled to room temperature, filtered, and the separated filter residue is washed with washing solution to obtain rare earth metal organic complex microsphere powder;

在这个步骤中,将步骤B得到的反应液自然降至室温的基本目的是终止上述反应,便于反应体系进行后续处理。In this step, the basic purpose of naturally lowering the reaction solution obtained in step B to room temperature is to terminate the above reaction and facilitate the subsequent treatment of the reaction system.

本发明使用的过滤设备是目前市场上销售的过滤设备,例如精达牌滤网勺。这种滤网勺是一种具有网状结构的滤网勺,因此,它能够除去不规则形状的粉末固体,而保留完整的稀土金属有机配合物微球。The filtering equipment used in the present invention is the filtering equipment currently on the market, such as the Jingda brand filter mesh spoon. The mesh scoop is a mesh scoop with a mesh structure, so it can remove irregularly shaped powder solids while leaving intact rare earth metal organic complex microspheres.

在这个步骤中,过滤分离得到的滤渣用DMF(二甲基甲酰胺)、乙醇或水洗涤液按照滤渣与洗涤液的体积比为1:5~8洗涤3~5次。In this step, the filter residue obtained by filtration and separation is washed 3-5 times with DMF (dimethylformamide), ethanol or water washing solution according to the volume ratio of filter residue and washing solution being 1:5-8.

在洗涤时收集洗涤液,根据高效液相方法进行检查,确定其含有有机配体顺丁烯二酰肼的量低于10-5mg·mL就可以确定其洗涤过程结束,否则还需要继续进行洗涤。Collect the washing liquid during washing, check it according to the high performance liquid phase method, and confirm that the amount of the organic ligand maleic hydrazide is less than 10-5 mg·mL to determine that the washing process is over, otherwise it is necessary to continue. washing.

D、浸泡D. to soak

按照稀土金属有机配合物微球粉末与DMF的体积比为1:3~8,将步骤C得到的稀土金属有机配合物微球粉末在室温下在DMF中重复浸泡,每次浸泡12h,接着按照同样的体积比在丙酮中重复浸泡,每次浸泡12h;According to the volume ratio of the rare earth metal organic complex microsphere powder to DMF is 1:3 to 8, the rare earth metal organic complex microsphere powder obtained in step C was repeatedly soaked in DMF at room temperature for 12 hours each time, and then according to the following steps: The same volume ratio was repeatedly soaked in acetone for 12h each time;

根据本发明,步骤C得到的稀土金属有机配合物首先在DMF中浸泡,接着在丙酮中浸泡。According to the present invention, the rare earth metal organic complex obtained in step C is first soaked in DMF, and then soaked in acetone.

让稀土金属有机配合物在DMF中浸泡主要是为了出去未反应而吸附在晶体表面的原料。稀土金属有机配合物与DMF的体积比是1:2~5。如果稀土金属有机配合物与DMF的体积比大于1:2,则不易除去原料;如果稀土金属有机配合物与DMF的体积比小于1:5,则产物发生溶解;因此,稀土金属有机配合物与DMF的体积比为1:2~5是恰当的,优选地是1:3~4;Soaking rare earth metal organic complexes in DMF is mainly to remove unreacted raw materials adsorbed on the crystal surface. The volume ratio of rare earth metal organic complex to DMF is 1:2-5. If the volume ratio of rare earth metal organic complex to DMF is greater than 1:2, it is difficult to remove the raw materials; if the volume ratio of rare earth metal organic complex to DMF is less than 1:5, the product will dissolve; therefore, rare earth metal organic complex and It is appropriate that the volume ratio of DMF is 1:2-5, preferably 1:3-4;

如果稀土金属有机配合物在DMF中浸泡时间少于12h,则不能完全除去;如果稀土金属有机配合物在DMF中浸泡时间长于72h则产物坍塌或溶解;因此,稀土金属有机配合物在DMF中浸泡时间为12~72h是合适的,优选地是22~52h;If the rare earth metal organic complex is soaked in DMF for less than 12 hours, it cannot be completely removed; if the rare earth metal organic complex is soaked in DMF for longer than 72 hours, the product collapses or dissolves; therefore, the rare earth metal organic complex is soaked in DMF. The suitable time is 12-72h, preferably 22-52h;

让在DMF中浸泡的稀土金属有机配合物接着在丙酮中浸泡主要是为了交换框架孔中客体小分子。稀土金属有机配合物与丙酮的体积比是1:2~5。如果稀土金属有机配合物与丙酮的体积比大于1:2,则不易完全交换;如果稀土金属有机配合物与丙酮的体积比小于1:5,则丙酮浪费严重;因此,稀土金属有机配合物与丙酮的体积比为1:2~5是恰当的,优选地是1:3~4;The rare earth metal-organic complexes soaked in DMF and then soaked in acetone are mainly to exchange small guest molecules in the framework pores. The volume ratio of rare earth metal organic complex to acetone is 1:2-5. If the volume ratio of rare earth metal-organic complexes to acetone is greater than 1:2, complete exchange is not easy; if the volume ratio of rare earth metal-organic complexes to acetone is less than 1:5, acetone is wasted seriously; It is appropriate that the volume ratio of acetone is 1:2-5, preferably 1:3-4;

如果在DMF中浸泡的稀土金属有机配合物在丙酮中浸泡时间少于12h,则不能完全溶解原料或交换小分子;如果在DMF中浸泡的稀土金属有机配合物在丙酮中浸泡时间长于72h则发生坍塌溶解;因此,在DMF中浸泡的稀土金属有机配合物在丙酮中浸泡时间为12~72h是合适的,优选地是22~52h;If the rare earth metal organic complex soaked in DMF is soaked in acetone for less than 12 hours, the raw materials cannot be completely dissolved or exchanged for small molecules; if the rare earth metal organic complex soaked in DMF is soaked in acetone for longer than 72 hours, it will occur Collapse and dissolve; therefore, it is suitable for the rare earth metal organic complex soaked in DMF to soak in acetone for 12-72h, preferably 22-52h;

根据本发明,步骤C得到的稀土金属有机配合物微球粉末分别在DMF中与在丙酮中浸泡的总时间都是12~72h。According to the present invention, the total time of soaking the rare earth metal organic complex microsphere powder obtained in step C in DMF and in acetone respectively is 12-72 h.

E、热处理E. Heat treatment

步骤D浸泡的稀土金属有机配合物微球粉末在温度120~200℃下进行活化处理,得到所述的吸波材料。The rare earth metal organic complex microsphere powder soaked in step D is activated at a temperature of 120-200° C. to obtain the wave absorbing material.

在本发明中,这个活化处理的目的在于除去残留在微球中的丙酮。In the present invention, the purpose of this activation treatment is to remove acetone remaining in the microspheres.

根据本发明,所述的稀土金属有机配合物微球粉末进行活化处理的时间是1~12h。According to the present invention, the time for the activation treatment of the rare earth metal organic complex microsphere powder is 1-12 hours.

在本发明中,活化处理时间为1~12h时,如果活化处理的温度低于120℃,则不能完全除去丙酮;如果活化处理的温度高于200℃,则会破坏配合物微球框架结构;因此,活化处理的温度为120~200℃是合理的;优选地是140~180℃。In the present invention, when the activation treatment time is 1 to 12 hours, if the activation treatment temperature is lower than 120°C, the acetone cannot be completely removed; if the activation treatment temperature is higher than 200°C, the complex microsphere framework structure will be destroyed; Therefore, the temperature of the activation treatment is reasonable in the range of 120 to 200°C; preferably 140 to 180°C.

活化处理的温度为120~200℃时,如果活化处理时间短于1h,则不能完全除去表面附着的有机溶液;如果活化处理时间长于12h,则会超出除去溶剂所需要的时间,造成能源资源的浪费;因此,活化处理时间为1~12h是合理的;优选地是3.5~8.0h。When the activation treatment temperature is 120-200℃, if the activation treatment time is shorter than 1h, the organic solution attached to the surface cannot be completely removed; if the activation treatment time is longer than 12h, the time required to remove the solvent will be exceeded, resulting in the loss of energy resources. Waste; therefore, the activation treatment time is reasonable for 1-12h; preferably 3.5-8.0h.

本发明还涉及所述制备方法制备得到的稀土金属有机配合物微球吸波材料,它是由稀土金属离子与顺丁烯二酰肼配位化合物组成的直径为750~850nm的微球吸波材料,该微球吸波材料进行了常规透射电子显微镜观察,其观察结果分布列于附图1-4。附图1是顺丁烯二酰肼与六水硝酸镨金属有机配合物微球的元素分布图,其中C、N、O与Pr元素分布图;附图2是顺丁烯二酰肼与六水硝酸镨与六水硝酸镧混合物稀土金属有机配合物微球的元素分布图;附图3是顺丁烯二酰肼与六水硝酸镨、六水硝酸镧与六水硝酸铈混合物稀土金属有机配合物微球的元素分布图;附图4是顺丁烯二酰肼与六水硝酸镨、六水硝酸镧、六水硝酸铈与六水硝酸钆混合物稀土金属有机配合物微球的元素分布图。由附图1-4可知,它们是稀土金属均匀分布的直径为750~850nm的微球。The invention also relates to the rare earth metal organic complex microsphere wave absorbing material prepared by the preparation method, which is a microsphere wave absorbing material with a diameter of 750-850 nm composed of a rare earth metal ion and a maleic hydrazide coordination compound material, the microsphere absorbing material was observed by conventional transmission electron microscope, and the distribution of the observation results is listed in the accompanying drawings 1-4. Accompanying drawing 1 is the element distribution diagram of maleic hydrazide and praseodymium nitrate hexahydrate metal-organic complex microsphere, wherein C, N, O and Pr element distribution diagram; Accompanying drawing 2 is maleic hydrazide and hexahydrate Element distribution diagram of rare earth metal organic complex microspheres of praseodymium nitrate hexahydrate and lanthanum nitrate hexahydrate mixture; accompanying drawing 3 is a mixture of maleic hydrazide and praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate and cerium nitrate hexahydrate mixture rare earth metal organic The element distribution diagram of the complex microsphere; accompanying drawing 4 is the element distribution of the rare earth metal organic complex microsphere of maleic hydrazide and praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, cerium nitrate hexahydrate and gadolinium nitrate hexahydrate mixture picture. It can be seen from the accompanying drawings 1-4 that they are microspheres with a diameter of 750-850 nm in which rare earth metals are uniformly distributed.

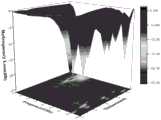

根据同轴法使用由美国安捷伦公司销售的E8363B矢量网络分析仪测定了它的电磁波吸收性能,其分析结果参见附图5-8。According to the coaxial method, its electromagnetic wave absorption performance was measured using the E8363B vector network analyzer sold by Agilent in the United States, and the analysis results are shown in Figures 5-8.

所述稀土金属有机配合物微球吸波材料具有下述吸波性能:The rare earth metal-organic complex microsphere wave-absorbing material has the following wave-absorbing properties:

它的最大反射损耗是-12.118dB;Its maximum reflection loss is -12.118dB;

该微球吸波材料厚度为2mm时,它的反射损耗是-10dB以下,即该微球吸波材料对电磁波具有90%以上的电磁波吸收。When the thickness of the microsphere absorbing material is 2mm, its reflection loss is below -10dB, that is, the microsphere absorbing material has more than 90% electromagnetic wave absorption for electromagnetic waves.

[有益效果][Beneficial effect]

本发明的有益效果是:与现有技术相比,本发明稀土金属有机配合物微球吸波材料制备方法极其简单,无须高温碳化,操作安全,极为有利于实现工业化生产,并且高度符合节能减排价值观,同时该微球吸波材料的吸波性能优异,其最大反射损耗为-12.118dB,极具十分实际应用价值。The beneficial effects of the invention are: compared with the prior art, the preparation method of the rare earth metal organic complex microsphere wave absorbing material of the invention is extremely simple, does not require high temperature carbonization, is safe to operate, is extremely conducive to realizing industrialized production, and is highly compatible with energy saving and reduction. At the same time, the absorbing performance of the microsphere absorbing material is excellent, and its maximum reflection loss is -12.118dB, which is of great practical application value.

【附图说明】【Description of drawings】

图1是顺丁烯二酰肼与六水硝酸镨金属有机配合物微球元素分布图;Fig. 1 is the element distribution diagram of maleic hydrazide and praseodymium nitrate hexahydrate metal-organic complex microsphere;

左上-C元素;右上-N元素;左下-O元素;右下-Pr元素;Upper left - C element; upper right - N element; lower left - O element; lower right - Pr element;

图2是顺丁烯二酰肼与六水硝酸镨、六水硝酸镧金属有机配合物微球元素分布图;Fig. 2 is maleic hydrazide, praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate metal-organic complex microsphere element distribution diagram;

左上-C元素;右上-O元素;左下-N元素;右下-Pr元素;右-La元素;Upper left - C element; upper right - O element; lower left - N element; lower right - Pr element; right - La element;

图3是顺丁烯二酰肼与六水硝酸镨、六水硝酸镧、六水硝酸铈金属有机配合物微球元素分布图;Fig. 3 is maleic hydrazide and praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, cerium nitrate hexahydrate metal-organic complex microsphere element distribution diagram;

左上-Pr元素;上中-N元素;右上-Ce元素;左下-O元素;下中-La元素;右下-C元素;Upper left-Pr element; upper middle-N element; upper right-Ce element; lower left-O element; lower middle-La element; lower right-C element;

图4是顺丁烯二酰肼与六水硝酸镨、六水硝酸镧、六水硝酸铈、六水硝酸钆金属有机配合物微球元素分布图;Fig. 4 is maleic hydrazide and praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, cerium nitrate hexahydrate, gadolinium nitrate hexahydrate metal-organic complex microsphere element distribution diagram;

左上-C元素;上中-Pr元素;右上-N元素;左下-Ce元素;下中-Gd元素;右下-O元素;右-La元素;Upper left-C element; upper middle-Pr element; upper right-N element; lower left-Ce element; lower middle-Gd element; lower right-O element; right-La element;

图5是实施例1制备不同厚度顺丁烯二酰肼与六水硝酸镨配合物微球收电磁波性能图;Fig. 5 is embodiment 1 prepares different thickness maleic hydrazide and praseodymium nitrate hexahydrate complex microspheres to receive electromagnetic wave performance figure;

图6是实施例2制备不同厚度顺丁烯二酰肼与六水硝酸镨、六水硝酸镧金属有机配合物微球吸收电磁波性能图;Fig. 6 is that embodiment 2 prepares the performance diagram of electromagnetic wave absorption performance of maleic hydrazide and praseodymium nitrate hexahydrate and lanthanum nitrate hexahydrate metal-organic complex microspheres with different thicknesses;

图7是实施例2制备不同厚度顺丁烯二酰肼与六水硝酸镨、六水硝酸镧、六水硝酸铈金属有机配合物微球吸收电磁波性能图;Fig. 7 is that embodiment 2 prepares different thickness maleic hydrazide and praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, cerium nitrate hexahydrate metal-organic complex microsphere absorption electromagnetic wave performance figure;

图8是实施例2制备不同厚度六水硝酸镨、六水硝酸镧、六水硝酸铈、六水硝酸钆金属有机配合物微球吸收电磁波性能图。8 is a graph showing the electromagnetic wave absorption performance of praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, cerium nitrate hexahydrate, and gadolinium nitrate hexahydrate metal-organic complex microspheres with different thicknesses prepared in Example 2.

【具体实施方式】【Detailed ways】

通过下述实施例将能够更好地理解本发明。The present invention will be better understood by the following examples.

实施例1:本发明稀土金属有机配合物微球吸波材料制备Example 1: Preparation of the rare earth metal organic complex microsphere absorbing material of the present invention

该实施例的实施步骤如下:The implementation steps of this embodiment are as follows:

A、制备混合物溶液A. Prepare the mixture solution

按照以克计稀土金属盐与以毫升计溶剂的比1:4,六水硝酸镨稀土金属盐与顺丁烯二酰肼按照其摩尔比1:4在DMF溶剂中,在超声频率20kHz与功率密度0.30W/cm2的超声波作用下溶解35min,得到一种混合物溶液;According to the ratio of rare earth metal salt in grams to solvent in milliliters 1:4, praseodymium nitrate hexahydrate rare earth metal salt and maleic hydrazide in accordance with their molar ratio 1:4 in DMF solvent, at ultrasonic frequency 20kHz and power Dissolve for 35min under the action of ultrasonic waves with a density of 0.30W/cm2 to obtain a mixture solution;

B、微波催化反应B, microwave catalytic reaction

将步骤A得到的混合物溶液在微波反应釜中在微波功率90W、温度100160℃与压力16bar的条件下进行反应40min;The mixture solution obtained in step A was reacted in a microwave reactor for 40min under the conditions of microwave power 90W, temperature 100-160°C and pressure 16bar;

C、洗涤C. to wash

让步骤B得到的反应液自然降温至室温,过滤,分离的滤渣用DMF洗涤液按照体积比1:4洗涤3次,得到稀土金属有机配合物微球粉末;The reaction solution obtained in step B is naturally cooled to room temperature, filtered, and the separated filter residue is washed 3 times with DMF washing solution according to a volume ratio of 1:4 to obtain rare earth metal organic complex microsphere powder;

D、浸泡D. to soak

按照稀土金属有机配合物微球粉末与DMF的体积比为1:8,将步骤C得到的稀土金属有机配合物微球粉末在室温下在DMF中重复浸泡,每次浸泡12h,接着按照稀土金属有机配合物微球粉末与丙酮的体积比1:6重复浸泡,每次浸泡12h;According to the volume ratio of the rare earth metal organic complex microsphere powder to DMF is 1:8, the rare earth metal organic complex microsphere powder obtained in step C was repeatedly soaked in DMF at room temperature for 12 hours each time, and then the rare earth metal organic complex microsphere powder was soaked in DMF at room temperature for 12 hours. The volume ratio of organic complex microsphere powder to acetone was 1:6 for repeated soaking for 12h each time;

E、热处理E. Heat treatment

步骤D浸泡的稀土金属有机配合物微球粉末在温度200℃下进行活化处理1h,得到直径为750~850nm的稀土金属有机配合物微球吸波材料,其透射电子显微镜检测元素分布结果参见附图1。The rare earth metal-organic complex microsphere powder soaked in step D is activated at a temperature of 200 ° C for 1 h to obtain a rare earth metal-organic complex microsphere absorbing material with a diameter of 750-850 nm. The transmission electron microscope detection element distribution results are shown in the appendix. figure 1.

根据本说明书描述的方法测定了该实施例制备的稀土金属有机配合物吸波材料吸波性能,其检测结果列于附图5。附图5表明不同厚度的吸波材料对不同频率电磁波的吸收情况。由附图5可以看出,在吸波材料厚度达到2.0mm时,该微球吸波材料具有-10dB以下的反射损耗。当厚度为5.5mm时,最大反射损耗为-12.118dB,说明该实施例制备的吸波材料具有优异的吸波性能。According to the method described in this specification, the absorbing properties of the rare earth metal-organic complex absorbing material prepared in this example were measured, and the testing results are shown in FIG. 5 . FIG. 5 shows the absorption of electromagnetic waves of different frequencies by absorbing materials of different thicknesses. It can be seen from FIG. 5 that when the thickness of the wave absorbing material reaches 2.0 mm, the microsphere wave absorbing material has a reflection loss below -10 dB. When the thickness is 5.5mm, the maximum reflection loss is -12.118dB, indicating that the absorbing material prepared in this example has excellent absorbing performance.

实施例2:本发明稀土金属有机配合物微球吸波材料制备Example 2: Preparation of the rare earth metal organic complex microsphere absorbing material of the present invention

该实施例的实施步骤如下:The implementation steps of this embodiment are as follows:

A、制备混合物溶液A. Prepare the mixture solution

按照以克计稀土金属盐与以毫升计溶剂的比1:5,六水硝酸镨与六水硝酸镧混合物(重量比1:1)稀土金属盐与顺丁烯二酰肼按照其摩尔比1:1在乙醇溶剂中,在超声频率25kHz与功率密度0.35W/cm2的超声波作用下溶解28min,得到一种混合物溶液;According to the ratio of rare earth metal salt in grams to the solvent in milliliters 1:5, the mixture of praseodymium nitrate hexahydrate and lanthanum nitrate hexahydrate (weight ratio 1:1) rare earth metal salt and maleic hydrazide according to its molar ratio 1 : 1 Dissolve in ethanol solvent for 28 min under the action of ultrasonic frequency of 25 kHz and power density of 0.35 W/cm2 to obtain a mixture solution;

B、微波催化反应B, microwave catalytic reaction

将步骤A得到的混合物溶液在微波反应釜中在微波功率150W、温度160℃与20bar的条件下进行反应5min;The mixture solution obtained in step A was reacted in a microwave reactor under the conditions of microwave power 150W, temperature 160°C and 20bar for 5min;

C、洗涤C. to wash

让步骤B得到的反应液自然降温至室温,过滤,分离的滤渣用乙醇洗涤液按照体积比1:8洗涤4次,得到稀土金属有机配合物微球粉末;The reaction solution obtained in step B is naturally cooled to room temperature, filtered, and the separated filter residue is washed 4 times with ethanol washing solution according to a volume ratio of 1:8 to obtain rare earth metal organic complex microsphere powder;

D、浸泡D. to soak

按照稀土金属有机配合物微球粉末与DMF的体积比为1:5,将步骤C得到的稀土金属有机配合物微球粉末在室温下在DMF中重复浸泡,每次浸泡12h,接着按照稀土金属有机配合物微球粉末与丙酮的体积比1:3重复浸泡,每次浸泡12h;According to the volume ratio of the rare earth metal organic complex microsphere powder to DMF is 1:5, the rare earth metal organic complex microsphere powder obtained in step C was repeatedly soaked in DMF at room temperature for 12 hours each time, and then the rare earth metal organic complex microsphere powder was soaked for 12 hours at room temperature. The volume ratio of organic complex microsphere powder to acetone was 1:3 and soaked repeatedly for 12 hours each time;

E、热处理E. Heat treatment

步骤D浸泡的稀土金属有机配合物微球粉末在温度180℃下进行活化处理4h,得到直径为750~850nm的稀土金属有机配合物微球吸波材料,其透射电子显微镜检测元素分布结果参见附图2。The rare earth metal-organic complex microsphere powder soaked in step D is activated at a temperature of 180 ° C for 4 hours to obtain a rare earth metal-organic complex microsphere absorbing material with a diameter of 750-850 nm. The transmission electron microscope detection element distribution results are shown in the appendix. figure 2.

根据本说明书描述的方法测定了该实施例制备的稀土金属有机配合物吸波材料吸波性能,其检测结果列于附图6,附图6表明不同厚度的吸波材料对不同频率电磁波的吸收情况。由附图6可以看出,在吸波材料厚度达到2.5mm时,该微球吸波材料具有-10dB以下的反射损耗。当厚度为2.5mm时,最大反射损耗为-22.056dB,说明该实施例制备的吸波材料具有优异的吸波性能。According to the method described in this specification, the absorbing properties of the rare earth metal-organic complex absorbing materials prepared in this example were measured, and the test results are listed in Figure 6, which shows the absorption of different frequencies of electromagnetic waves by absorbing materials with different thicknesses Happening. It can be seen from FIG. 6 that when the thickness of the wave absorbing material reaches 2.5 mm, the microsphere wave absorbing material has a reflection loss below -10 dB. When the thickness is 2.5mm, the maximum reflection loss is -22.056dB, indicating that the absorbing material prepared in this example has excellent absorbing performance.

实施例3:本发明稀土金属有机配合物微球吸波材料制备Example 3: Preparation of the rare earth metal organic complex microsphere absorbing material of the present invention

该实施例的实施步骤如下:The implementation steps of this embodiment are as follows:

A、制备混合物溶液A. Prepare the mixture solution

按照以克计稀土金属盐与以毫升计溶剂的比1:8,六水硝酸镨、六水硝酸镧与六水硝酸铈混合物(重量比1:1:1)稀土金属盐与顺丁烯二酰肼按照其摩尔比1:5在水溶剂中,在超声频率30kHz与功率密度0.32W/cm2的超声波作用下溶解25min,得到一种混合物溶液;According to the ratio of rare earth metal salt in grams to solvent in milliliters 1:8, a mixture of praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate and cerium nitrate hexahydrate (weight ratio 1:1:1) rare earth metal salt and maleic The hydrazide is dissolved in a water solvent according to its molar ratio of 1:5, under the action of ultrasonic waves with an ultrasonic frequency of 30 kHz and a power density of 0.32 W/cm2 for 25 minutes to obtain a mixture solution;

B、微波催化反应B, microwave catalytic reaction

将步骤A得到的混合物溶液在微波反应釜中在微波功率100W、温度130℃与压力14bar的条件下进行反应80min;The mixture solution obtained in step A was reacted in a microwave reactor for 80min under the conditions of microwave power 100W, temperature 130°C and pressure 14bar;

C、洗涤C. to wash

让步骤B得到的反应液自然降温至室温,过滤,分离的滤渣用水洗涤液按照体积比1:5洗涤3次,得到稀土金属有机配合物微球粉末;The reaction solution obtained in step B is naturally cooled to room temperature, filtered, and the separated filter residue is washed three times with water washing solution in a volume ratio of 1:5 to obtain rare earth metal organic complex microsphere powder;

D、浸泡D. to soak

按照稀土金属有机配合物微球粉末与DMF的体积比为1:3,将步骤C得到的稀土金属有机配合物微球粉末在室温下在DMF中重复浸泡,每次浸泡12h,接着按照稀土金属有机配合物微球粉末与丙酮的体积比1:5重复浸泡,每次浸泡12h;According to the volume ratio of the rare earth metal organic complex microsphere powder to DMF is 1:3, the rare earth metal organic complex microsphere powder obtained in step C was repeatedly soaked in DMF at room temperature for 12 hours each time, and then the rare earth metal organic complex microsphere powder was soaked in DMF at room temperature for 12 hours. The volume ratio of organic complex microsphere powder to acetone was 1:5 and soaked repeatedly for 12h each time;

E、热处理E. Heat treatment

步骤D浸泡的稀土金属有机配合物微球粉末在温度120℃下进行活化处理12h,得到直径为750~850nm的稀土金属有机配合物微球吸波材料,其透射电子显微镜检测元素分布结果参见附图3。The rare earth metal-organic complex microsphere powder soaked in step D is activated at a temperature of 120 ° C for 12 hours to obtain a rare earth metal-organic complex microsphere absorbing material with a diameter of 750-850 nm. The element distribution results of transmission electron microscopy are shown in the appendix. image 3.

根据本说明书描述的方法测定了该实施例制备的稀土金属有机配合物吸波材料吸波性能,其检测结果列于附图7。附图7表明不同厚度的吸波材料对不同频率电磁波的吸收情况。由附图7可以看出,在吸波材料厚度达到2.0mm时,该微球吸波材料具有-10dB以下的反射损耗。当厚度为3.0mm时,最大反射损耗为-15.649dB,说明该实施例制备的吸波材料具有优异的吸波性能。According to the method described in this specification, the wave absorbing properties of the rare earth metal-organic complex wave absorbing material prepared in this example were measured, and the detection results are shown in FIG. 7 . FIG. 7 shows the absorption of electromagnetic waves of different frequencies by absorbing materials of different thicknesses. It can be seen from FIG. 7 that when the thickness of the wave absorbing material reaches 2.0 mm, the microsphere wave absorbing material has a reflection loss below -10 dB. When the thickness is 3.0mm, the maximum reflection loss is -15.649dB, indicating that the absorbing material prepared in this example has excellent absorbing performance.

实施例4:本发明稀土金属有机配合物微球吸波材料制备Example 4: Preparation of the rare earth metal organic complex microsphere absorbing material of the present invention

该实施例的实施步骤如下:The implementation steps of this embodiment are as follows:

A、制备混合物溶液A. Prepare the mixture solution

按照以克计稀土金属盐与以毫升计溶剂的比1:7,六水硝酸镨、六水硝酸镧、六水硝酸铈与六水硝酸钆混合物(重量比1:1:1:1)稀土金属盐与顺丁烯二酰肼按照其摩尔比1:3在DMF溶剂中,在超声频率40kHz与功率密度0.34W/cm2的超声波作用下溶解32min,得到一种混合物溶液;According to the ratio of rare earth metal salt in grams to solvent in milliliters 1:7, praseodymium nitrate hexahydrate, lanthanum nitrate hexahydrate, cerium nitrate hexahydrate and gadolinium nitrate hexahydrate mixture (weight ratio 1:1:1:1) rare earth Metal salt and maleic hydrazide are dissolved in DMF solvent according to their molar ratio of 1:3, under the action of ultrasonic waves of ultrasonic frequency 40kHz and power density 0.34W/cm2 for 32min to obtain a mixture solution;

B、微波催化反应B, microwave catalytic reaction

将步骤A得到的混合物溶液在微波反应釜中在微波功率40W、温度200℃与压力10bar的条件下进行反应120min;The mixture solution obtained in step A was reacted in a microwave reactor for 120min under the conditions of microwave power 40W,

C、洗涤C. to wash

让步骤B得到的反应液自然降温至室温,过滤,分离的滤渣用DMF洗涤液按照体积比1:6洗涤4次,得到稀土金属有机配合物微球粉末;The reaction solution obtained in step B is naturally cooled to room temperature, filtered, and the separated filter residue is washed 4 times with DMF washing solution according to a volume ratio of 1:6 to obtain rare earth metal organic complex microsphere powder;

D、浸泡D. to soak

按照稀土金属有机配合物微球粉末与DMF的体积比为1:6,将步骤C得到的稀土金属有机配合物微球粉末在室温下在DMF中重复浸泡,每次浸泡12h,接着按照稀土金属有机配合物微球粉末与丙酮的体积比1:8重复浸泡,每次浸泡12h;According to the volume ratio of the rare earth metal organic complex microsphere powder to DMF is 1:6, the rare earth metal organic complex microsphere powder obtained in step C was repeatedly soaked in DMF at room temperature for 12 hours each time, and then the rare earth metal organic complex microsphere powder was soaked in DMF at room temperature for 12 hours. The volume ratio of organic complex microsphere powder to acetone was 1:8 and soaked repeatedly for 12 hours each time;

E、热处理E. Heat treatment

步骤D浸泡的稀土金属有机配合物微球粉末在温度150℃下进行活化处理8h,得到直径为750~850nm的稀土金属有机配合物微球吸波材料,其透射电子显微镜检测元素分布结果参见附图4。The rare earth metal-organic complex microsphere powder soaked in step D is activated at a temperature of 150 ° C for 8 hours to obtain a rare earth metal-organic complex microsphere absorbing material with a diameter of 750-850 nm. The transmission electron microscope detection element distribution results are shown in the appendix. Figure 4.

根据本说明书描述的方法测定了该实施例制备的稀土金属有机配合物吸波材料吸波性能,其检测结果列于附图8。附图8表明不同厚度的吸波材料对不同频率电磁波的吸收情况。由附图8可以看出,在吸波材料厚度达到1.0mm时,该微球吸波材料具有-10dB以下的反射损耗。当厚度为4.5mm时,最大反射损耗为-25.045dB,说明该实施例制备的吸波材料具有优异的吸波性能。According to the method described in this specification, the wave absorbing properties of the rare earth metal-organic complex wave absorbing material prepared in this example were measured, and the test results are shown in FIG. 8 . FIG. 8 shows the absorption of electromagnetic waves of different frequencies by absorbing materials of different thicknesses. It can be seen from FIG. 8 that when the thickness of the wave absorbing material reaches 1.0 mm, the microsphere wave absorbing material has a reflection loss below -10 dB. When the thickness is 4.5mm, the maximum reflection loss is -25.045dB, indicating that the absorbing material prepared in this example has excellent absorbing performance.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911140534.3ACN110845523B (en) | 2019-11-20 | 2019-11-20 | A kind of rare earth metal organic complex microsphere wave absorbing material and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911140534.3ACN110845523B (en) | 2019-11-20 | 2019-11-20 | A kind of rare earth metal organic complex microsphere wave absorbing material and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110845523Atrue CN110845523A (en) | 2020-02-28 |

| CN110845523B CN110845523B (en) | 2021-06-15 |

Family

ID=69602730

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911140534.3AActiveCN110845523B (en) | 2019-11-20 | 2019-11-20 | A kind of rare earth metal organic complex microsphere wave absorbing material and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110845523B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116161692A (en)* | 2022-12-02 | 2023-05-26 | 铜陵欣诺科新材料有限公司 | Preparation method and application of anhydrous scandium trichloride |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108347871A (en)* | 2018-01-25 | 2018-07-31 | 宁波大学 | A kind of ultra micro capsule material and the preparation method and application thereof |

| CN109012722A (en)* | 2018-06-12 | 2018-12-18 | 广东工业大学 | It is a kind of using Ce-MOF as the ceria of presoma/titanium nitride nano pipe and its preparation method and application |

- 2019

- 2019-11-20CNCN201911140534.3Apatent/CN110845523B/enactiveActive

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108347871A (en)* | 2018-01-25 | 2018-07-31 | 宁波大学 | A kind of ultra micro capsule material and the preparation method and application thereof |

| CN109012722A (en)* | 2018-06-12 | 2018-12-18 | 广东工业大学 | It is a kind of using Ce-MOF as the ceria of presoma/titanium nitride nano pipe and its preparation method and application |

Non-Patent Citations (3)

| Title |

|---|

| M.GREEN等: "Ferric metal-organic framework for microwave absorption", 《MATERIALS TODAY CHEMISTRY》* |

| NANNAN WU等: "Achieving superior electromagnetic wave absorbers through the novel metal-organic frameworks derived magnetic porous carbon nanorods", 《CARBON》* |

| 邓青锋 等: "两个双核稀土金属配位聚合物的溶剂热合成、晶体结构及荧光性质", 《无机化学学报》* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116161692A (en)* | 2022-12-02 | 2023-05-26 | 铜陵欣诺科新材料有限公司 | Preparation method and application of anhydrous scandium trichloride |

| CN116161692B (en)* | 2022-12-02 | 2025-04-25 | 铜陵欣诺科新材料有限公司 | Preparation method and application of anhydrous scandium trichloride |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110845523B (en) | 2021-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108521754B (en) | Porous carbon-based electromagnetic wave absorption agent of one kind and preparation method thereof | |

| CN108154984B (en) | A porous ferric oxide/carbon nanorod-shaped electromagnetic wave absorbing material and its preparation method and application | |

| CN113840528B (en) | A MOF-derived composite absorbing material and its preparation method and application | |

| WO2019109830A1 (en) | Method of preparing molybdate complex hollow microspheres and application thereof | |

| CN110577820B (en) | A kind of porous structure Ni/NiO-C composite material and its preparation method and application | |

| CN113258301B (en) | A kind of composite material and its preparation method and application | |

| CN110787790B (en) | Sea urchin-like metal oxide porous photocatalytic material and preparation method and application thereof | |

| CN108176364A (en) | Preparation method of cobalt/carbon nanocomposite derived from metal organic framework | |

| Zhu et al. | Simple and green method for preparing copper nanoparticles supported on carbonized cotton as a heterogeneous Fenton-like catalyst | |

| CN111804274B (en) | Preparation method and application of bamboo activated carbon coated cuprous oxide/copper oxide composite nano material | |

| CN103464784A (en) | Preparation method of nano nickel supported on carbon | |

| CN114395371B (en) | A kind of composite wave absorbing agent derived from tetrazolium acetate copper-iron complex and its preparation method | |

| CN107973352A (en) | A kind of method of iron/copper bi-metal oxide degradation tetracycline | |

| CN114479762B (en) | Magnetic metal/metal oxide/carbon nanocomposite material, preparation method and application thereof | |

| CN116315732B (en) | Nano hollow heterogeneous double-shell structure electromagnetic wave absorbing material and preparation method thereof | |

| CN105441029A (en) | A kind of Ag@Fe3O4/reduced graphene oxide ternary composite absorbing material and its preparation method | |

| CN110845523B (en) | A kind of rare earth metal organic complex microsphere wave absorbing material and preparation method thereof | |

| CN113015422A (en) | Cobalt-nickel alloy/reduced graphene oxide nanocomposite for shielding high-frequency electromagnetic waves, and preparation method and application thereof | |

| CN112430450A (en) | Modified graphene nanosheet composite powder and preparation method thereof | |

| CN113328262B (en) | A kind of preparation method of manganese oxide@Ni-Co/graphitic carbon nano-microwave absorption composite | |

| CN110615807B (en) | Rare earth metal organic complex wave-absorbing material and preparation method thereof | |

| CN115322744B (en) | Nickel-carbon composite material that absorbs electromagnetic waves and preparation method thereof | |

| CN113578338B (en) | Preparation method of graphite alkyne coated carbon coated hollow manganese ferrite nano photocatalytic composite material | |

| CN105062092A (en) | Chiral poly(Schiff base) salt ternary composite wave absorbing material | |

| CN115636443A (en) | Preparation method of magnetic nanoparticle coated microcapsule-shaped carbon-based composite material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |