CN110820443A - A kind of emergency lifting device for railway turnout grinding car and using method thereof - Google Patents

A kind of emergency lifting device for railway turnout grinding car and using method thereofDownload PDFInfo

- Publication number

- CN110820443A CN110820443ACN201911084647.6ACN201911084647ACN110820443ACN 110820443 ACN110820443 ACN 110820443ACN 201911084647 ACN201911084647 ACN 201911084647ACN 110820443 ACN110820443 ACN 110820443A

- Authority

- CN

- China

- Prior art keywords

- wheelset

- plate

- wheel support

- lifting device

- guide plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B31/00—Working rails, sleepers, baseplates, or the like, in or on the line; Machines, tools, or auxiliary devices specially designed therefor

- E01B31/02—Working rail or other metal track components on the spot

- E01B31/12—Removing metal from rails, rail joints, or baseplates, e.g. for deburring welds, reconditioning worn rails

- E01B31/17—Removing metal from rails, rail joints, or baseplates, e.g. for deburring welds, reconditioning worn rails by grinding

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及铁路列车故障处理设备技术领域,尤其涉及一种铁路道岔打磨车应急起复装置及其使用方法。The invention relates to the technical field of railway train fault handling equipment, in particular to an emergency recovery device for a railway turnout grinding car and a method for using the same.

背景技术Background technique

道岔区作为铁路线路重要组成部分,相较于区间线路,道岔区轨道结构复杂,钢轨磨耗速率快,导致病害频发,日常轨道养护工作中需要利用道岔打磨车对道岔区钢轨进行打磨作业,消除钢轨病害,维护道岔正常服役状态。The turnout area is an important part of the railway line. Compared with the interval line, the turnout area has a complex track structure and a fast rail wear rate, which leads to frequent diseases. In the daily track maintenance work, it is necessary to use a turnout grinding car to grind the rails in the turnout area to eliminate Rail disease, maintain the normal service state of the switch.

在打磨作业过程中,打磨车通过液压压力将砂轮压在钢轨上对钢轨进行磨削,达到维护钢轨廓形的目的,此时,在打磨车与钢轨之间形成相互作用力,即打磨车受到钢轨反力,加之道岔打磨车轴重相比铁路普通车辆轻,这些因素导致道岔打磨车在施工作业中存在极大的脱轨掉道风险,特别是在新建线路打磨作业时,由于线路轨道几何尺寸尚未稳定,掉道事故时有发生。During the grinding operation, the grinding car presses the grinding wheel on the rail to grind the rail through hydraulic pressure to achieve the purpose of maintaining the profile of the rail. At this time, an interaction force is formed between the grinding car and the rail, that is, the grinding car is subjected to The reaction force of the rails, coupled with the lighter axle weight of the turnout grinding car than that of ordinary railway vehicles, these factors lead to a great risk of derailment and falling off the track in the construction operation of the turnout grinding car, especially in the grinding operation of the new line, because the geometric size of the line track has not been Stable, but accidents do occur from time to time.

铁路道岔打磨现场作业中,遇到车辆在道岔区脱轨时,由于道岔打磨车车底空间狭小,大型应急设备存在无空间、无位置摆放和安装等情况,并且打磨车后转向架构造特殊,无合适的设备起复支撑点,导致普通起复设备无法实现道岔打磨车后转向架的起复,此外,车辆在脱轨后会发生偏斜,假如偏斜量过大,普通起复设备对车辆的校正困难较大。During the on-site operation of railway turnout grinding, when the vehicle derails in the turnout area, due to the narrow space at the bottom of the turnout grinding car, there is no space, no location for placement and installation of large emergency equipment, and the structure of the bogie behind the grinding car is special. There is no suitable lifting support point for the equipment, so that the ordinary lifting equipment cannot realize the lifting and recovery of the bogie after the turnout grinding car. In addition, the vehicle will deflect after derailment. If the deflection is too large, it is more difficult for the ordinary lifting equipment to correct the vehicle. big.

综上所述,现有的铁路车辆起复设备和技术,在应急抢险中所需设备配件数量多、重量大,造成起复救援工作效率低,同时安全风险大且易造成二次事故。因此,研发与铁路线路作业环境匹配度高,便于组装和操作的可携带式应急救援装置,对掌握现场科学应急方法,提升铁路车辆非正常应急处置能力具有重要现实意义。To sum up, the existing railway vehicle recovery equipment and technology requires a large number of equipment accessories and heavy weight in emergency rescue, resulting in low recovery and rescue work efficiency, and at the same time, high safety risks and easy to cause secondary accidents. Therefore, it is of great practical significance to develop a portable emergency rescue device that is highly compatible with the railway line operating environment and is easy to assemble and operate.

发明内容SUMMARY OF THE INVENTION

本发明的目的是根据上述现有技术的不足,提供了一种铁路道岔打磨车应急起复装置及其使用方法,通过横移导向机构、转向架起复动力系统的配合实现铁路道岔打磨车轮对的精确位移,实现快速应急起复。The purpose of the present invention is to provide an emergency recovery device for a railway turnout grinding vehicle and a method of using the same according to the deficiencies of the above-mentioned prior art, so as to realize the precision of the railway turnout grinding wheel pair through the cooperation of the traverse guide mechanism and the bogie lifting and recovery power system. Displacement, to achieve rapid emergency recovery.

本发明目的实现由以下技术方案完成:The realization of the object of the present invention is accomplished by the following technical solutions:

一种铁路道岔打磨车应急起复装置,其特征在于:包括轮对横移导向机构、转向架起复动力系统、起复装置支撑构架,其中所述轮对横移导向机构包括两个车轮支撑导向板,所述车轮支撑导向板用于支撑铁路道岔打磨车的轮对,所述转向架起复动力系统安装在所述轮对横移导向机构的上部,使车辆轮对沿着所述车轮支撑导向板的引导方向滑动,所述起复装置支撑构架安装在所述轮对横移导向机构的下部以对其进行支撑。An emergency lifting device for a railway turnout grinding car is characterized in that it comprises a wheelset traverse guide mechanism, a bogie lifting power system, and a support structure of the lifting device, wherein the wheelset traverse guide mechanism comprises two wheel support guide plates, The wheel support guide plate is used to support the wheel set of the railway turnout grinding car, and the bogie recovery power system is installed on the upper part of the wheel set traverse guide mechanism, so that the vehicle wheel set follows the wheel support guide plate. The guide direction slides, and the lifting device support frame is mounted on the lower part of the wheelset traverse guide mechanism to support it.

所述轮对横移导向机构由车轮支撑导向板、轮对运动导向块、起复感应反馈装置构成,所述车轮支撑导向板的上下方分别设置有挡板,其中下部挡板用于与钢轨的轨头侧面贴合,上部挡板用于限制所述轮对在所述车轮支撑导向板上的横移范围;在所述车轮支撑导向板上设置有轮对运动导向块。The wheelset traverse guide mechanism is composed of a wheel support guide plate, a wheelset motion guide block, and a reversing induction feedback device. The upper and lower parts of the wheel support guide plate are respectively provided with baffle plates, wherein the lower baffle plate is used for connecting with the rail. The side surfaces of the rail heads are fitted, and the upper baffle plate is used to limit the traverse range of the wheelset on the wheel support guide plate; a wheelset motion guide block is arranged on the wheel support guide plate.

所述上部挡板一侧设置有起复感应反馈装置。One side of the upper baffle plate is provided with a recovery induction feedback device.

所述转向架起复动力系统包括电机、螺纹杆、螺纹杆导向块、直角板,其中所述螺纹杆由所述电机连接驱动,所述直角板设置在所述车轮支撑导向板上,所述螺纹杆可顶进所述直角板,所述螺纹杆穿过所述螺纹杆导向块上的导向螺纹孔。The bogie recovery power system includes a motor, a threaded rod, a threaded rod guide block, and a right-angle plate, wherein the threaded rod is connected and driven by the motor, the right-angle plate is arranged on the wheel support guide plate, and the threaded rod is connected and driven by the motor. The rod can be pushed into the right-angle plate, and the threaded rod passes through the guide threaded hole on the threaded rod guide block.

所述车轮支撑导向板上开设有导槽,所述转向架起复动力系统包括一直角板,所述直角板的底部设有挡板,所述挡板设置在所述导槽内且两者之间构成滑动配合,所述直角板可在所述螺纹杆的顶进下沿所述导槽移动。The wheel support guide plate is provided with a guide groove, and the bogie recovery power system includes a right-angle plate, the bottom of the right-angle plate is provided with a baffle plate, and the baffle plate is arranged in the guide groove and the other is between the two. A sliding fit is formed between them, and the right-angle plate can move along the guide groove under the pushing of the threaded rod.

所述起复装置支撑构件包括三脚架、支撑板、地面板,三者通过焊接成为整体,其中所述支撑板与所述车轮支撑导向板之间连接固定。The support member of the lifting device includes a tripod, a support plate, and a floor plate, which are welded into a whole, wherein the support plate and the wheel support guide plate are connected and fixed.

所述起复装置支撑构架的底面设置有不规则凸起花纹。The bottom surface of the support frame of the lifting device is provided with irregular raised patterns.

一种涉及上述的铁路道岔打磨车应急起复装置的使用方法,其特征在于:所述方法至少包括以下步骤:A method for using the emergency lifting device for the above-mentioned railway turnout grinding car, characterized in that the method at least comprises the following steps:

架设铁路道岔打磨车应急起复装置,使车轮支撑导向板的下部挡板与钢轨的轨头侧面贴合,使铁路道岔打磨车的轮对支撑在所述车轮支撑导向板上;An emergency lifting device for the railway turnout grinding car is erected, so that the lower baffle of the wheel support guide plate is attached to the side of the rail head of the rail, so that the wheelset of the railway turnout grinding car is supported on the wheel support guide plate;

启动转向架起复动力系统,使电机带动螺纹杆旋转,螺纹杆螺纹顶进穿过螺纹杆导向块上的导向螺纹孔,顶至直角板侧面,直角板通过底部挡板与车轮支撑导向板上导槽的滑动配合产生滑动,实现传递顶进力使轮对在所述车轮支撑导向板开始横移;Start the bogie recovery power system, make the motor drive the threaded rod to rotate, the threaded rod thread is pushed through the guide threaded hole on the guide block of the threaded rod, and is pushed to the side of the right-angle plate, and the right-angle plate is guided through the bottom baffle and the wheel support guide plate. The sliding fit of the grooves produces sliding, so as to transmit the jacking force, so that the wheelset starts to move laterally on the wheel support guide plate;

所述轮对逐渐开始移动,在到达所述车轮支撑导向板边缘时,所述起复感应反馈装置触发信号,所述电机停止工作,在轮对运动导向块的引导下,所述轮对返回所述钢轨上,完成所述铁路道岔打磨车的应急起复。The wheelset starts to move gradually. When reaching the edge of the wheel support guide plate, the reciprocating induction feedback device triggers a signal, and the motor stops working. Under the guidance of the wheelset motion guide block, the wheelset returns to the desired position. On the steel rail, the emergency recovery of the railway turnout grinding car is completed.

在所述车轮支撑导向板的下部架设起复装置支撑构架,通过调整所述起复装置支撑构架的高度,使所述车轮支撑导向板的设置位置及受力满足设计要求。A lifting device support frame is erected on the lower part of the wheel support guide plate, and by adjusting the height of the lift device support frame, the setting position and force of the wheel support guide plate can meet the design requirements.

本发明的优点是:设备现场适应性强,既能在不同的道岔位置快速起复前、后转向架,也能在直线、曲线上快速起复前、后转向架;该套设备能节约大量前期准备时间,组装部件少,现拿现用,起复时间极大缩短;设备操作简单,施工现场用本设备,能快速的将前、后转向架轮对复位;操作该套设备安全性高,在起复过程中无需人员在车底操作,由于有轮对限位组件,不存在轮对横移过量导致滑动倾覆的危险,较现有设备提高了安全性;该设备构造简单,操作方便,现场适应性强,在道岔区和区间线路中都能实现快速起复,与传统的应急起复处理方法相比操作简便,作业时间短,安全性更高,能够大大提高整个应急起复工作的效率。The advantages of the present invention are: the equipment has strong field adaptability, and can quickly lift the front and rear bogies at different switch positions, as well as quickly lift the front and rear bogies on straight lines and curves; the set of equipment can save a lot of preliminary preparations Time, less assembly parts, ready-to-use, greatly shortened recovery time; simple equipment operation, using this equipment on the construction site, can quickly reset the front and rear bogie wheels; the operation of this set of equipment is safe During the process, there is no need for personnel to operate under the vehicle. Due to the wheelset limiting components, there is no danger of sliding and overturning caused by excessive lateral movement of the wheelset, which improves the safety compared with the existing equipment; the equipment is simple in structure, easy to operate, and adaptable to the site. Compared with the traditional emergency recovery method, the operation is simple, the operation time is short, and the safety is higher, which can greatly improve the efficiency of the entire emergency recovery work.

附图说明Description of drawings

图1为本发明的工作状态示意图;Fig. 1 is the working state schematic diagram of the present invention;

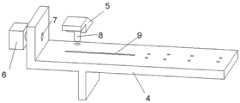

图2为本发明中轮对横移导向机构组件图;Fig. 2 is the assembly diagram of the wheelset traverse guide mechanism in the present invention;

图3为本发明中转向架起复动力系统组件图;Fig. 3 is the component diagram of bogie lifting power system in the present invention;

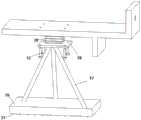

图4为本发明中轮对横移导向机构和起复装置支撑构架连接结构示意图;4 is a schematic diagram of the connection structure of the wheelset traverse guide mechanism and the support frame of the lifting device in the present invention;

图5为本发明中起复装置支撑构架组件图;Fig. 5 is the assembly diagram of the support structure of the lifting device in the present invention;

图6为本发明的整体组件图。FIG. 6 is an overall assembly diagram of the present invention.

具体实施方式Detailed ways

以下结合附图通过实施例对本发明特征及其它相关特征作进一步详细说明,以便于同行业技术人员的理解:Below in conjunction with the accompanying drawings, the features of the present invention and other related features will be described in further detail by embodiments, so as to facilitate the understanding of those skilled in the same industry:

如图1-6所示,图中标记1-21分别表示为:轮对横移导向机构1、转向架起复动力系统2、起复装置支撑构架3、车轮支撑导向板4、轮对运动导向块5、起复感应反馈装置6、螺孔7、运动块螺栓8、导槽9、直角板底部挡板10、导向螺纹孔固定螺栓11、支撑板连接螺栓12、电机13、螺纹杆14、螺纹杆导向块15、直角板16、三脚架17、支撑板18、地面板19、垫片20、不规则凸起花纹21。As shown in Figure 1-6, the marks 1-21 in the figure are respectively: wheelset

实施例:本实施例中的铁路道岔打磨车应急起复装置,如图1所示,其结构包括轮对横移导向机构1、转向架起复动力系统2、起复装置支撑构架3,其中1与钢轨顶面贴合连接使铁路道岔打磨车的轮对可以在其车轮支撑导向板上平移,转向架起复动力系统2通过螺栓固定在轮对横移导向机构1的上部,用于为轮对的平移提供动力,起复装置支撑构架3上端与轮对横移导向机构1底面通过螺栓连接,其用于在特殊情况下轮对横移导向机构1无法平稳放置时对应急起复装置进行支撑并且使其高度与操作要求相符。Example: The emergency recovery device of the railway turnout grinding car in this example, as shown in Figure 1, its structure includes a wheelset

如图2所示,轮对横移导向机构1由车轮支撑导向板4、轮对运动导向块5、起复感应反馈装置6构成。其中,车轮支撑导向板4上下方各有一部分凸起挡板,这两部分挡板均垂直于车轮支撑导向板4布置。位于车轮支撑导向板4下方的下部挡板用于与轨头侧面贴合,从而对轮对横移导向机构1的架设位置进行限位,保证后续应急起复工作的顺利进行和精度;而位于车轮支撑导向板4上方的上部挡板用于限制轮对横移范围,防止轮对横移过量。在上部挡板中心开有螺孔7,用于安装起复感应反馈装置,在车轮支撑导向板4边缘开孔,方便与轮对运动导向块5之间通过螺栓8固定,在车轮支撑导向板4表面轮对横移范围内开设有导槽9,与转向架起复动力系统2中的直角板底部挡板10相配合。在车轮支撑导向板4上表面靠外位置设有两个螺栓孔11,用于安装转向架起复动力系统的螺纹杆导向块15。此外,在车轮支撑导向板4底面开有螺栓孔,用于连接起复装置支撑构架3。As shown in FIG. 2 , the wheelset

如图3、图4所示,转向架起复动力系统2由电机13、螺纹杆14、螺纹杆导向块15、直角板16构成。在螺纹杆14的杆帽处设置连接键,方便与电机13配合连接,使螺纹杆14与电机13构成传动配合,其可在电机13的驱动下转动。螺纹杆导向块15上设有贯通的螺纹导向孔,该螺纹导向孔设有与螺纹杆14相配合的丝口,在使用时,螺纹杆14穿过两个螺纹杆导向块15,通过转动伸缩的方式推动直角板16。螺纹杆导向块15上的螺纹导向孔布置在一条直线上,确保动力垂直作用于车轮侧面。螺纹杆导向块15的下部焊有固定螺栓11,与车轮支撑导向板4通过该固定螺栓11相连接固定。直角板16下部焊有一块轴向固定挡板10,保持在一条直线上,直角板16的下部固定挡板部分落在车轮支撑导向板的导槽9中,保证直角板16的轴向移动。As shown in FIGS. 3 and 4 , the bogie lifting

如图5所示,起复装置支撑构架由三脚架17、支撑板18、地面板19组成,三脚架17顶端与支撑板18焊接,底端则与地面板19焊接,三者通过焊接成为一个整体。支撑板18的四个边角与车轮支撑导向板4之间通过螺栓12固定,固定螺栓选用长螺栓,通过在支撑板18与车轮支撑导向板4之间设置垫片20来实现起复装置支撑构架3的高度调整,地面板19的底面设置不规则凸起花纹21,以实现起复装置支撑构架3的固定,防止起复装置支撑构架3在道床上产生水平移。As shown in Figure 5, the support structure of the lifting device is composed of a

本实施例在实际工作时,具有如下工作方法:When this embodiment is actually working, it has the following working methods:

第一步:起复作业人员挑选出本实施例中的应急起复装置各个零件,对应急起复装置进行组装,并放置在掉道的铁路道岔打磨车的转向架轮对前后钢轨上。旋紧轮对运动导向块5与车轮支撑导向板4的运动块螺栓8,使其与钢轨方向保持一致。起复感应反馈装置6通过螺孔7与车轮支撑导向板4连接固定,电机13固定安装在螺纹杆14杆帽上,螺纹杆14旋入一部分进螺纹杆导向块15,车轮支撑导向板4分别贴合在两侧钢轨顶面和轨头侧面。Step 1: The recovery operator selects each part of the emergency recovery device in this embodiment, assembles the emergency recovery device, and places it on the front and rear rails of the bogie wheelset of the railway turnout grinding car that has fallen off the track. Tighten the moving

第二步:使用起复油缸顶升转向架,在把转向架顶升到高于轨面的高度后,将本实施例中的应急起复装置推入轮对正下方的轨面上,使得轮对能落在车轮支撑导向板4上,在车轮下落前,若现场条件需要对起复装置进行稳定,则将起复支撑构架组装,将地面板19设置的不规则凸起花纹21深深插入道砟中,防止地面板水平移动,通过增减垫片20调整起复装置支撑构架3高度,确保车轮支撑导向板4受力平稳。此外,还需在车轮支撑导向板4表面涂抹润滑剂,防止车轮轮缘因摩擦产生损伤。Step 2: Use the lifting cylinder to lift the bogie. After the bogie is lifted to a height higher than the rail surface, push the emergency lifting device in this embodiment into the rail surface directly below the wheel set, so that the wheel set It can fall on the wheel

第三步:启动转向架起复动力系统2,电机13带动螺纹杆14旋转,螺纹杆14螺纹顶进穿过螺纹杆导向块15,顶至直角板16侧面,直角板16通过底部挡板10与导槽9的滑动匹配产生滑动,以实现传递顶进力,使轮对开始横移。The third step: start the bogie

第四步:轮对逐渐开始移动,在到达车轮支撑导向板4边缘时,起复感应反馈装置6的接近开关因车轮金属性质触发电磁铁得电,内部电路接通,蜂鸣器开始工作,发出警报声,警报灯也开始闪烁,此时,作业人员停止电机13,轮对移动到了正确的位置。Step 4: The wheelset starts to move gradually. When it reaches the edge of the wheel

第五步:车上作业人员在车下人员指挥下驾驶铁路道岔打磨车缓慢向前行驶,在转向架一旁,安排人员监控,确保轮对运动方向正确,防止再次掉道。车轮踏面与轮对运动导向块5贴合接触,均匀受力,轮对运动导向块引导轮对安全回到轨道上。Step 5: The operator on the car drives the railway turnout grinding car slowly forward under the command of the personnel off the car. Beside the bogie, arrange personnel to monitor to ensure that the wheelset moves in the correct direction and prevent it from falling off the road again. The wheel tread is in contact with the wheelset

第六步:拆除道岔打磨车起复装置,工作人员确认车辆状态后及时撤离现场。Step 6: Remove the lifting device of the turnout grinding vehicle, and the staff will evacuate the site in time after confirming the state of the vehicle.

虽然以上实施例已经参照附图对本发明目的的构思和实施例做了详细说明,但本领域普通技术人员可以认识到,在没有脱离权利要求限定范围的前提条件下,仍然可以对本发明作出各种改进和变换故在此不一一赘述。Although the above embodiments have described in detail the concept and embodiments of the present invention with reference to the accompanying drawings, those of ordinary skill in the art can recognize that various modifications to the present invention can still be made without departing from the scope of the claims. Improvements and transformations are therefore not described here.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911084647.6ACN110820443A (en) | 2019-11-08 | 2019-11-08 | A kind of emergency lifting device for railway turnout grinding car and using method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911084647.6ACN110820443A (en) | 2019-11-08 | 2019-11-08 | A kind of emergency lifting device for railway turnout grinding car and using method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110820443Atrue CN110820443A (en) | 2020-02-21 |

Family

ID=69553355

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911084647.6APendingCN110820443A (en) | 2019-11-08 | 2019-11-08 | A kind of emergency lifting device for railway turnout grinding car and using method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110820443A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114318974A (en)* | 2021-12-29 | 2022-04-12 | 河北大学 | Spraying equipment with rust cleaning mechanism |

| KR20240059817A (en)* | 2022-10-27 | 2024-05-08 | 이정환 | Wheel position adjustment device for derailment recovery of railway vehicles |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB195899A (en)* | 1925-02-12 | 1923-04-12 | William Amos Marchant | An improved ramp for re-railing railway and tramway vehicles |

| CN201023483Y (en)* | 2006-08-21 | 2008-02-20 | 刘健 | Pulley type rerailer |

| CN101725095A (en)* | 2009-11-23 | 2010-06-09 | 株洲新通铁路装备有限公司 | Railway construction machine guard rail hoisting device and rail replacing locomotive guard rail hoisting device |

| CN205777736U (en)* | 2016-05-20 | 2016-12-07 | 淮安市魔方泊车自动车库有限公司 | A kind of transition driving mechanism |

| CN207632322U (en)* | 2017-12-20 | 2018-07-20 | 中国神华能源股份有限公司 | Hoisting device and continous way tamping car |

| CN207997341U (en)* | 2018-02-05 | 2018-10-23 | 昆明爱美科光电有限公司 | A kind of high-precision roof prism processing unit (plant) |

| CN211645801U (en)* | 2019-11-08 | 2020-10-09 | 华东交通大学 | Emergency lifting device of railway turnout grinding wagon |

- 2019

- 2019-11-08CNCN201911084647.6Apatent/CN110820443A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB195899A (en)* | 1925-02-12 | 1923-04-12 | William Amos Marchant | An improved ramp for re-railing railway and tramway vehicles |

| CN201023483Y (en)* | 2006-08-21 | 2008-02-20 | 刘健 | Pulley type rerailer |

| CN101725095A (en)* | 2009-11-23 | 2010-06-09 | 株洲新通铁路装备有限公司 | Railway construction machine guard rail hoisting device and rail replacing locomotive guard rail hoisting device |

| CN205777736U (en)* | 2016-05-20 | 2016-12-07 | 淮安市魔方泊车自动车库有限公司 | A kind of transition driving mechanism |

| CN207632322U (en)* | 2017-12-20 | 2018-07-20 | 中国神华能源股份有限公司 | Hoisting device and continous way tamping car |

| CN207997341U (en)* | 2018-02-05 | 2018-10-23 | 昆明爱美科光电有限公司 | A kind of high-precision roof prism processing unit (plant) |

| CN211645801U (en)* | 2019-11-08 | 2020-10-09 | 华东交通大学 | Emergency lifting device of railway turnout grinding wagon |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114318974A (en)* | 2021-12-29 | 2022-04-12 | 河北大学 | Spraying equipment with rust cleaning mechanism |

| CN114318974B (en)* | 2021-12-29 | 2023-09-26 | 河北大学 | A kind of spraying equipment with rust removal mechanism |

| KR20240059817A (en)* | 2022-10-27 | 2024-05-08 | 이정환 | Wheel position adjustment device for derailment recovery of railway vehicles |

| KR102817355B1 (en)* | 2022-10-27 | 2025-06-09 | 이정환 | Wheel position adjustment device for derailment recovery of railway vehicles |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5583858B2 (en) | Lateral adjustment mechanism for bidirectional semi-spring type load bearing head | |

| CN107419625B (en) | Full-automatic numerical control hydraulic turnout tamping car | |

| CN103332081B (en) | Road and rail dual-purpose tractor | |

| JP7173696B2 (en) | Bogie exchange equipment for railway vehicles | |

| CN111661107B (en) | A new type of EMU bogie replacement unit | |

| WO2013185520A1 (en) | Segmented inverting cover plate apparatus for underfloor vehicle lifting jack | |

| CN111776003B (en) | Lifting type rescue method | |

| CN112338856B (en) | Disassembling machine for car coupler buffer | |

| WO2013185519A1 (en) | Compatible train lifting unit of pit-type train lifter | |

| AU2014221509A1 (en) | Lifting column, lifting system and method for lifting a vehicle such as a rail-car | |

| CN110820443A (en) | A kind of emergency lifting device for railway turnout grinding car and using method thereof | |

| CN111559394A (en) | Long steel rail transportation loading and unloading vehicle and transport vehicle group composed of same | |

| CN214267689U (en) | Railway vehicle coupler buffering dismounting trolley | |

| CN211645801U (en) | Emergency lifting device of railway turnout grinding wagon | |

| JP4270401B2 (en) | Railway maintenance vehicle | |

| CN111942425A (en) | Wheel set replacing device for 160 km-per-hour power centralized motor train unit | |

| RU120057U1 (en) | COMPLEX OF EQUIPMENT FOR REMOVAL AND INSTALLATION OF RAILWAY RAILWAY CARS ON WHEELS | |

| CN221500550U (en) | Rail lifting device | |

| CN212247708U (en) | Intelligent combined turnout laying and replacing unit | |

| RU2626425C1 (en) | Method for replacing wheel pairs of railway carriage (versions) | |

| RU185020U1 (en) | RAILWAY MACHINE FOR INSTALLATION AND IMMERSION OF PILES AND PILED FOUNDATIONS OF CONTACT NETWORK SUPPORTS | |

| CN211169688U (en) | Lateral shifting-out device for locomotive bogie | |

| CN204222884U (en) | Complex function traverse table | |

| CN220720736U (en) | Wheel changing device of monorail vehicle | |

| CN207528067U (en) | Ultrathin electric trailer with bidirectional hydraulic car pusher |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |