CN110793585B - Wet air flow online measurement method and device based on V cone pressure loss ratio segmentation characteristic - Google Patents

Wet air flow online measurement method and device based on V cone pressure loss ratio segmentation characteristicDownload PDFInfo

- Publication number

- CN110793585B CN110793585BCN201911054870.6ACN201911054870ACN110793585BCN 110793585 BCN110793585 BCN 110793585BCN 201911054870 ACN201911054870 ACN 201911054870ACN 110793585 BCN110793585 BCN 110793585B

- Authority

- CN

- China

- Prior art keywords

- cone

- flow

- pressure loss

- phase

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000691measurement methodMethods0.000titleclaimsabstractdescription16

- 230000011218segmentationEffects0.000title1

- 238000005259measurementMethods0.000claimsabstractdescription25

- 230000005514two-phase flowEffects0.000claimsabstractdescription22

- 238000000034methodMethods0.000claimsabstractdescription13

- 239000012071phaseSubstances0.000claimsdescription55

- 239000007788liquidSubstances0.000claimsdescription43

- 239000007791liquid phaseSubstances0.000claimsdescription32

- 238000011144upstream manufacturingMethods0.000claimsdescription20

- 238000004364calculation methodMethods0.000claimsdescription14

- 239000012530fluidSubstances0.000claimsdescription7

- 238000012545processingMethods0.000claimsdescription7

- 238000009736wettingMethods0.000claims1

- 239000007789gasSubstances0.000description35

- 230000000694effectsEffects0.000description3

- 241000531897LomaSpecies0.000description2

- 230000001186cumulative effectEffects0.000description2

- 238000011161developmentMethods0.000description2

- 238000010586diagramMethods0.000description2

- 238000002474experimental methodMethods0.000description2

- 230000001133accelerationEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 238000009530blood pressure measurementMethods0.000description1

- 238000013461designMethods0.000description1

- 230000005484gravityEffects0.000description1

- 238000009434installationMethods0.000description1

- 230000007774longtermEffects0.000description1

- 238000012423maintenanceMethods0.000description1

- 238000005272metallurgyMethods0.000description1

- 230000005855radiationEffects0.000description1

- 238000011160researchMethods0.000description1

- 238000004086separation measurement methodMethods0.000description1

- 238000000926separation methodMethods0.000description1

- 239000000126substanceSubstances0.000description1

- 238000003466weldingMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F1/00—Measuring the volume flow or mass flow of fluid or fluent solid material wherein the fluid passes through a meter in a continuous flow

- G01F1/76—Devices for measuring mass flow of a fluid or a fluent solid material

- G01F1/86—Indirect mass flowmeters, e.g. measuring volume flow and density, temperature or pressure

Landscapes

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- General Physics & Mathematics (AREA)

- Measuring Volume Flow (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于多相流测量领域,具体涉及一种基于V锥压损比分段特性的湿气流量在线测量方法及装置。The invention belongs to the field of multiphase flow measurement, and in particular relates to an online measurement method and device for wet gas flow based on the segmental characteristics of the V-cone pressure loss ratio.

背景技术Background technique

湿气广泛存在于核能、化工、冶金和动力等领域的科学研究和工程实践中,湿气中气液两相流量的精确测量一直是多相流领域研究热点之一。Wet gas is widely present in scientific research and engineering practice in the fields of nuclear energy, chemical industry, metallurgy and power. The accurate measurement of gas-liquid two-phase flow in wet gas has always been one of the hotspots in the field of multiphase flow.

气液两相流量的测量目前主要分为分离法和在线法两类,分离测量法设备设备庞大、投资成本高且无法实时测量,在实际应用中推广程度较低;而在线测量方法中以差压式流量计应用较为广泛,代表性的有单相流量计组合、单相流量计与相含率传感器组合两类。单相流量计组合法为两个或多个差压式流量计组合,代表性的有专利CN86207384U、CN101413817A、CN101187660A。为减小上、下游节流元件间信号干扰,节流装置间需留有一定的流动发展空间,导致流量计整体尺寸较大,不便于运输及安装。此外,上、下游节流元件的压差响应特性应具有明显的差异性,以保证两相流量的顺利迭代求解,这对结构设计提出了较高要求。而单相流量计与相含率传感器结合的方法,则是借助于超声波、声纳、射线等手段实现相含率测量,配合单相流量计实现双参数测量,代表性的有专利CN106352931A、CN207730269U、CN208012684U。由于配套的相含率传感器多为接触测量,在长期高温高压,强腐蚀性工况等恶劣工况下,这类仪表运行稳定性较差。此外,射线类传感设备在运行、检修过程中所造成的辐射危害持续存在,不便于工业现场安全管理。受制于结构复杂,造价高昂,安全可靠性差等因素,单相流量计与相含率传感器结合的方法在推广应用上也受到了限制。At present, the measurement of gas-liquid two-phase flow is mainly divided into two categories: separation method and online method. The separation measurement method has large equipment, high investment cost, and cannot be measured in real time. The degree of promotion in practical applications is low; while the online measurement method is poor. Pressure flowmeters are widely used, and there are two representative types: single-phase flowmeter combination, single-phase flowmeter and phase holdup sensor combination. The single-phase flowmeter combination method is a combination of two or more differential pressure flowmeters, representative patents CN86207384U, CN101413817A, CN101187660A. In order to reduce the signal interference between the upstream and downstream throttling elements, a certain space for flow development needs to be reserved between the throttling devices, resulting in a large overall size of the flowmeter, which is inconvenient for transportation and installation. In addition, the differential pressure response characteristics of the upstream and downstream throttling elements should have obvious differences to ensure the smooth iterative solution of the two-phase flow, which puts forward higher requirements for structural design. The method of combining single-phase flowmeter and phase holdup sensor is to realize phase holdup measurement by means of ultrasonic waves, sonar, rays, etc., and to realize dual-parameter measurement with single-phase flowmeter. Representative patents CN106352931A, CN207730269U , CN208012684U. Because most of the supporting phase holdup sensors are contact measurement, under long-term high temperature and high pressure, strong corrosive conditions and other harsh conditions, the stability of this type of instrument is poor. In addition, radiation hazards caused by the operation and maintenance of ray-based sensing equipment persist, which is inconvenient for industrial site safety management. Due to the complex structure, high cost, poor safety and reliability and other factors, the method of combining single-phase flowmeter and phase holdup sensor is also limited in promotion and application.

发明内容SUMMARY OF THE INVENTION

针对现有技术中气液两相流量测量装置结构复杂、造价昂贵以及安全可靠性差的问题,提供一种基于V锥压损比分段特性的湿气流量在线测量方法及装置,具有结构简单、成本低廉、安全可靠的优点,测量精度可满足工业测量需求。Aiming at the problems of complex structure, high cost and poor safety and reliability of the gas-liquid two-phase flow measurement device in the prior art, a method and device for online measurement of wet gas flow based on the segmental characteristics of the V-cone pressure loss ratio are provided, which have the advantages of simple structure, The advantages of low cost, safety and reliability, and the measurement accuracy can meet the needs of industrial measurement.

本发明是通过以下技术方案来实现:The present invention is achieved through the following technical solutions:

基于V锥压损比分段特性的湿气流量在线测量方法,包括以下步骤:The online measurement method of wet gas flow based on the segmented characteristics of the V-cone pressure loss ratio includes the following steps:

1)确定两相流表观质量流量;1) Determine the apparent mass flow rate of the two-phase flow;

2)根据两相流表观质量流量,并基于两相质量流量系数建立气相流量预测模型;2) According to the apparent mass flow rate of the two-phase flow, and based on the two-phase mass flow coefficient, a gas-phase flow prediction model is established;

3)基于压损比分段特性建立液相流量预测关联式;3) Establish a liquid flow prediction correlation based on the segmental characteristics of the pressure loss ratio;

压损比δ定义为流体流经V锥后的总压力损失与V锥上游至喉部的前压差之比;The pressure loss ratio δ is defined as the ratio of the total pressure loss after the fluid flows through the V-cone to the front pressure difference from the upstream of the V-cone to the throat;

其中,ΔPwg-m为流体流经V锥后的总压力损失,ΔPwg为V锥上游至V锥喉部的前压差;Among them, ΔPwg-m is the total pressure loss after the fluid flows through the V cone, and ΔPwg is the front pressure difference from the upstream of the V cone to the throat of the V cone;

4)根据步骤2)得到的气相流量预测模型和步骤3)得到的液相流量预测关联式,得到气相流量的测量值和液相流量的预测值;4) according to the gas-phase flow prediction model obtained in step 2) and the liquid-phase flow prediction correlation obtained in step 3), obtain the measured value of gas-phase flow and the predicted value of liquid-phase flow;

5)根据步骤4)得到的气相流量的测量值和液相流量的预测值,基于构建的锥前液膜厚度计算模型,确定锥前液膜厚度H;5) According to the measured value of the gas phase flow rate and the predicted value of the liquid phase flow rate obtained in step 4), based on the constructed liquid film thickness calculation model in front of the cone, determine the liquid film thickness H in front of the cone;

当H≥h,步骤4)得到的液相流量的预测值,即为液相流量的最终测量值;When H≥h, the predicted value of the liquid flow rate obtained in step 4) is the final measured value of the liquid phase flow rate;

当H<h,执行步骤6);When H<h, execute step 6);

h为V锥下沿距管道底部的距离;h is the distance between the lower edge of the V cone and the bottom of the pipe;

6)当H<h,则基于压损比分段特性建立的液相流量测量关联式,确定液相流量的测量值。6) When H<h, the measured value of the liquid flow is determined based on the liquid flow measurement correlation established by the segmental characteristics of the pressure loss ratio.

优选的,步骤1)中确定两相流表观质量流量的方法如下:Preferably, the method for determining the apparent mass flow rate of the two-phase flow in step 1) is as follows:

在管道中设置V锥,根据管道中的压力和温度进行两相密度补偿,并结合V锥上游至V锥喉部的压降,计算两相流表观质量流量mapparent:Set a V cone in the pipeline, perform two-phase density compensation according to the pressure and temperature in the pipeline, and combine the pressure drop from the upstream of the V cone to the throat of the V cone to calculate the two-phase flow apparent mass flow mapparent :

其中,A为管道的截面积,β为V锥的节流比,ρg为气相密度,ΔPwg为V锥上游至V锥喉部的前压差。Among them, A is the cross-sectional area of the pipeline, β is the throttle ratio of the V cone, ρg is the gas phase density, and ΔPwg is the front pressure difference from the upstream of the V cone to the throat of the V cone.

优选的,步骤2)的气相流量预测关联式具体如下:Preferably, the gas-phase flow prediction correlation formula of step 2) is specifically as follows:

其中,Frg和Frl分别为气体和液体密度弗鲁德数,ρg和ρl分别为气相和液相密度,K为两相质量流量系数。Among them, Frg and Frl are the Froude numbers of the gas and liquid densities, respectively, ρg and ρl are the gas and liquid densities, respectively, and K is the two-phase mass flow coefficient.

优选的,步骤2)中两相质量流量系数K的拟合关系式K=f(Frl,Frg,DR)通过标定实验得到,K的定义式为;Preferably, the fitting relationship K=f(Frl , Frg , DR) of the two-phase mass flow coefficient K in step 2) is obtained through calibration experiments, and the definition formula of K is;

其中,mg和ml分别为气相和液相的质量流量,DR为气、液两相密度比,DR=ρg/ρl。Among them, mg and ml are the mass flow rates of the gas phase and the liquid phase, respectively, DR is the density ratio of the gas and liquid phases, and DR=ρg /ρl .

优选的,步骤3)中液相流量预测关联式如下:Preferably, the liquid phase flow prediction correlation formula in step 3) is as follows:

Frl=f(DR,δ)Frl =f(DR,δ)

优选的,步骤5)中锥前液膜厚度计算模型如下:Preferably, in step 5), the calculation model of the liquid film thickness in front of the cone is as follows:

其中,εL为截面含气率,D为管道内径,θ为圆周润湿率。Among them, εL is the gas content of the section, D is the inner diameter of the pipe, and θ is the circumferential wettability.

优选的,步骤5)中V锥下沿距管道底部的距离h的计算方法如下:Preferably, in step 5), the calculation method of the distance h between the lower edge of the V cone and the bottom of the pipeline is as follows:

优选的,步骤6)中液相流量测量关联式如下:Preferably, in step 6), the liquid flow measurement correlation formula is as follows:

Frl=f(Frg,DR,δ)Frl =f(Frg ,DR,δ)

本发明还提供了一种基于V锥压损比分段特性的湿气流量在线测量装置,包括管道,管道中设置有V锥,管道上还设置有第一压差表、第二压差表、压力表和温度计;The invention also provides an on-line measurement device for wet gas flow based on the segmented characteristics of the V-cone pressure loss ratio, comprising a pipeline, a V-cone is arranged in the pipeline, and a first differential pressure gauge and a second differential pressure gauge are also arranged on the pipeline , pressure gauges and thermometers;

第一压差表、第二压差表、压力表和温度计与数据处理单元连接;The first differential pressure gauge, the second differential pressure gauge, the pressure gauge and the thermometer are connected with the data processing unit;

第一压差表,用于测量V锥上游至V锥喉部的前差压ΔPwg;a first differential pressure gauge, used to measure the front differential pressure ΔPwg from the upstream of the V cone to the throat of the V cone;

第二压差表,用于测量流体流经V锥后的总压力损失ΔPwg-m;The second differential pressure gauge is used to measure the total pressure loss ΔPwg -m after the fluid flows through the V cone;

数据处理单元,用于接收管内的压力、温度、前差压ΔPwg和总压力损失ΔPwg-m,并根据上述方法进行迭代求解,输出气相和液相的质量流量。The data processing unit is used to receive the pressure, temperature, front differential pressure ΔPwg and total pressure loss ΔPwg-m in the pipe, and iteratively solve according to the above method, and output the mass flow of the gas phase and the liquid phase.

优选的,所述V锥包括支撑环、支柱和锥体;Preferably, the V-cone includes a support ring, a strut and a cone;

所述支撑环的两端分别与两个管道的端部卡接,锥体设置在支撑环的中心,锥体的端部通过三个支柱与支撑环的内壁连接。The two ends of the support ring are respectively clamped with the ends of the two pipes, the cone is arranged in the center of the support ring, and the end of the cone is connected with the inner wall of the support ring through three struts.

与现有技术相比,本发明具有以下有益的技术效果:Compared with the prior art, the present invention has the following beneficial technical effects:

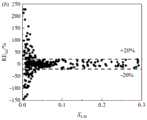

本发明提供的基于V锥压损比分段特性的湿气流量双参数在线测量方法,通过引入两相质量流量系数K建立了气相流量预测模型,基于V锥压损比分段特性建立了液相流量预测关联式,建立锥前液膜厚度计算模型实现了分段计算方法的实施。本发明提出的湿气流量双参数在线测量方法测量精度较高,其中,气相流量误差在±5%以内,液相流量误差控制在±20%内。此外,两相误差均呈现一定对称分布,这有利于累计误差的进一步降低。本发明提出的测量方法稳定可靠,测量精度可满足工业应用需求。The invention provides a dual-parameter online measurement method for wet gas flow rate based on the segmental characteristics of the V-cone pressure loss ratio, establishes a gas-phase flow rate prediction model by introducing the two-phase mass flow coefficient K, and establishes a liquid-phase flow rate prediction model based on the segmental characteristics of the V-cone pressure loss ratio The phase flow prediction correlation formula is established, and the calculation model of the liquid film thickness before the cone is established to realize the implementation of the subsection calculation method. The dual-parameter on-line measurement method for wet gas flow proposed by the invention has high measurement accuracy, wherein the gas flow error is within ±5%, and the liquid flow error is controlled within ±20%. In addition, the two-phase errors show a certain symmetrical distribution, which is conducive to further reducing the cumulative error. The measurement method proposed by the invention is stable and reliable, and the measurement accuracy can meet the requirements of industrial applications.

本发明还提供了上述基于V锥压损比分段特性的湿气流量双参数在线测量方法的装置,通过在管道内设置V锥和压力表、温度表和差压表,进而获得管道中的压力、温度和压差参数,根据上述方法即可得到气相和液相质量流量。The present invention also provides the device for the above-mentioned dual-parameter online measurement method for wet gas flow based on the segmental characteristics of the V-cone pressure loss ratio. By setting the V-cone and a pressure gauge, a temperature gauge and a differential pressure gauge in the pipeline, the The pressure, temperature and differential pressure parameters can be obtained according to the above method to obtain the mass flow rate of the gas phase and the liquid phase.

进一步,V锥通过周向均布三支柱固定于支撑环,锥体的抗冲击能力和装置可靠性得以提升;支撑环的端部与管道同心卡接,可有效保证锥体与管道的同心度,提高测量精度。Further, the V-cone is fixed to the support ring by three pillars evenly distributed in the circumferential direction, the impact resistance of the cone and the reliability of the device are improved; measurement accuracy.

附图说明Description of drawings

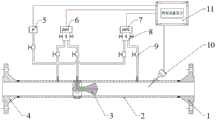

图1为本发明采用的湿气流量双参数在线测量装置的系统布置图;Fig. 1 is the system layout diagram of the wet gas flow dual-parameter online measuring device adopted in the present invention;

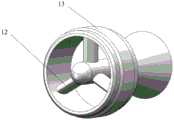

图2为本发明采用的V锥结构及其周向均布三支柱固定方式示意图;Fig. 2 is the V-cone structure adopted by the present invention and the schematic diagram of the three-pillar fixing mode uniformly distributed in the circumferential direction;

图3为本发明进行两相流量迭代计算求解的流程图;Fig. 3 is the flow chart that the present invention carries out two-phase flow iterative calculation and solution;

图4为本发明采用的锥前液膜厚度计算模型;Fig. 4 is the calculation model of the liquid film thickness in front of the cone adopted by the present invention;

图5为本发明在线求解的气相流量误差分布;Fig. 5 is the gas-phase flow error distribution of the online solution of the present invention;

图6为本发明在线求解的液相流量误差分布。FIG. 6 is the liquid flow rate error distribution obtained online by the present invention.

图中:1、下游法兰;2、管道;3、V锥;4、上游法兰;5、压力表;6、第一差压表;7、第二差压表;8、三阀组;9、手阀;10、温度计;11、数据处理单元;12、支柱;13、支撑环。In the figure: 1. Downstream flange; 2. Pipeline; 3. V-cone; 4. Upstream flange; 5. Pressure gauge; 6. First differential pressure gauge; 7. Second differential pressure gauge; 8. Three-valve manifold ; 9, hand valve; 10, thermometer; 11, data processing unit; 12, pillar; 13, support ring.

具体实施方式Detailed ways

下面结合附图对本发明做进一步的详细说明,所述是对本发明的解释而不是限定。The present invention will be further described in detail below in conjunction with the accompanying drawings, which are to explain rather than limit the present invention.

参阅图1,一种基于V锥压损比分段特性的湿气流量在线测量装置,包括下游法兰1、管道2、V锥3和上游法兰4。Referring to FIG. 1 , an on-line measurement device for wet gas flow based on the segmental characteristics of the V-cone pressure loss ratio includes a

上游法兰1和下游法兰4通过焊接实现与管道2连接,并位于管道的两端,压力表5用于管道2内压力测量,差压表6用于V锥3上游与V锥3喉部位置前差压测量,V锥3喉部位置压力通过在V锥3背锥的顶点处开孔,穿过锥体由支撑杆引出管道2。差压表7用于测量V锥3上游取压点和下游取压点间的总压力损失。The

在第一差压表6和第二差压表7下均安装有三阀组8,用于强冲击工况下对差压表的保护。在压力表5,差压表6和差压表7取压管道上均设有手阀9,便于仪表在线更换,在管道2下游安装温度计10用于测量管道2内温度。数据处理单元11采集各仪表信号,基于建立的两相流量在线测量方法进行迭代求解,可实现两相流量在线测量。A three-

参阅图2,V锥3包括支撑环13、支柱12和锥体;支撑环13的两端分别与两个管道的端部卡接,锥体设置在支撑环13的中心,锥体的端部通过三支柱与支撑环13的内壁连接;三支柱周向均布在支撑环13中。Referring to FIG. 2 , the V-

支撑环13两端均设置有嵌置台阶,支撑环13与管道2连接,嵌置台阶位于管道的内部。为保证两相流动充分发展,V锥3上游的直管段长度为5~7倍管道内径,下游直管段长度为3~6倍管道内径。Both ends of the

V锥3通过周向均布的三支柱12固定于支撑环13,提升了锥体的抗冲击能力和装置可靠性,支撑环13的端部嵌装在管道中,可有效保证V锥3锥体与管道2的同心度。The V-

本案例选用的V锥3的节流比为0.45,前锥角和后锥角分别为45°和135°,管道2内径为50mm。The throttle ratio of the

参阅图3,一种基于V锥压损比分段特性的湿气流量在线测量方法,包括以下步骤:Referring to Figure 3, an online measurement method for wet gas flow based on the segmental characteristics of the V-cone pressure loss ratio includes the following steps:

1)确定两相流表观质量流量。1) Determine the apparent mass flow rate of the two-phase flow.

在管道中设置V锥,获取管道中的压力和温度进行两相密度补偿,然后结合V锥上游至V锥喉部的压差,确定两相流表观质量流量;Set the V cone in the pipeline, obtain the pressure and temperature in the pipeline for two-phase density compensation, and then combine the pressure difference from the upstream of the V cone to the throat of the V cone to determine the apparent mass flow of the two-phase flow;

具体为,基于压力表5获得的管内压力P以及温度计10测得的管内温度T,完成两相密度补偿,结合第一差压表6获得的前压差ΔPwg,计算两相流表观质量流量mapparent,公式如下:Specifically, the two-phase density compensation is completed based on the inner pressure P obtained by the

其中,A为管道2的截面积,β为V锥3的节流比,ρg为气相密度,ΔPwg为第一差压表6测得的前压差。Among them, A is the cross-sectional area of the

2)根据两相流表观质量流量mapparent,并基于两相质量流量系数K建立气相流量预测模型。2) According to the two-phase flow apparent mass flow mapparent , and based on the two-phase mass flow coefficient K, a gas-phase flow prediction model is established.

具体方法如下,通过标定实验获得K与液体密度弗鲁德数Frl间的拟合关系式。The specific method is as follows. The fitting relationship between K and the liquid density Froude number Frl is obtained through calibration experiments.

K=a·Frl+bK=a·Frl +b

a=f(DR,Frg),b=f(DR,Frg)a=f(DR, Frg ), b=f(DR, Frg )

气体和液体密度弗鲁德数定义如下:The Froude number for the density of gases and liquids is defined as follows:

其中,密度比DR=ρg/ρl,ρl为液相密度;Usg、Usl分别为气、液两相的表观速度,Usg=4mg/(πD2·ρg),Usl=4ml/(πD2·ρl);g为重力加速度,D为管道内径。Among them, the density ratio DR=ρg /ρl, ρl is the density of the liquid phase; Usg and Usl are the apparent velocities of the gas and liquid phases, respectively, Usg =4mg /(πD2 ·ρg ), Usl =4ml/(πD2 ·ρl) ; g is the acceleration of gravity, and D is the inner diameter of the pipe.

在实施例中K的具体关系式如式(4)所示。The specific relational formula of K in the embodiment is shown in formula (4).

将所得K的关系式带入到式,在液量流量已知的前提下,气相流量可直接通过(2)式求解计算。Bringing the obtained relational expression of K into the formula, on the premise that the liquid flow rate is known, the gas flow rate can be directly solved and calculated by formula (2).

3)基于压损比δ分段特性建立液相流量预测关系式。3) Based on the segmental characteristics of the pressure loss ratio δ, the liquid flow rate prediction relationship is established.

定义压损比δ为流体流经V锥后的总压力损失ΔPwg-m与V锥上游与V锥喉部的前压差ΔPwg之比。The pressure loss ratio δ is defined as the ratio of the total pressure loss ΔPwg-m after the fluid flows through the V cone to the front pressure difference ΔPwg between the upstream of the V cone and the throat of the V cone.

当锥前液膜较薄未触及锥体下沿时,压损比δ为气体密度弗鲁德数Frg,液体密度弗鲁德数Frl和密度比DR的函数,即δ=f(Frl,Frg,DR);When the liquid film in front of the cone is thin and does not touch the lower edge of the cone, the pressure loss ratio δ is a function of the gas density Froude number Frg , the liquid density Froude number Frl and the density ratio DR, that is, δ=f(Frl ,Frg ,DR);

当锥前液膜厚度增加至触及锥体下沿时,受喉部射流作用影响,锥后气液夹带增加,气相流量对δ的影响较小,δ为液体密度弗鲁德数Frl和密度比DR的函数,即δ=f(Frl,DR)。When the thickness of the liquid film in front of the cone increases to touch the lower edge of the cone, due to the effect of the jet in the throat, the gas-liquid entrainment behind the cone increases, and the gas flow has little effect on δ, where δ is the liquid density Froude number Frl and density A function of the ratio DR, ie δ=f(Frl ,DR).

4)根据Frl=f(DR,δ)并结合步骤2)建立的气相流量预测模型,计算液相流量预测值和气相流量测量值mg。4) According to Frl =f(DR,δ) and combined with the gas-phase flow prediction model established in step 2), calculate the liquid-phase flow prediction value and gas-phase flow measurement mg .

具体为,通过建立的气相流量预测模型和液相流量预测关联式Frl=f(DR,δ),通过数据处理单元11进行两相流量初步迭代求解计算,得到液相流量预测值和气相流量测量值mg。Specifically, through the established gas-phase flow rate prediction model and the liquid-phase flow rate prediction correlation formula Frl =f(DR,δ), the

5)根据液相流量的预测值和气相流量的测量值mg,基于构建的锥前液膜厚度计算模型,确定锥前液膜厚度H。5) According to the predicted value of liquid flow and the measured value of the gas phase flow rate mg , based on the constructed calculation model of the liquid film thickness in front of the cone, determine the thickness H of the liquid film in front of the cone.

参阅图4,其为本发明涉及的锥前液膜厚度计算模型,图中D为管道内径,H为锥前液膜厚度,Φ0为液膜对应的圆心角的一半。锥前液膜厚度可通过计算。4, which is the calculation model of the liquid film thickness in front of the cone involved in the present invention, where D is the inner diameter of the pipe, H is the thickness of the liquid film in front of the cone, and Φ0 is half of the central angle corresponding to the liquid film. The thickness of the liquid film in front of the cone can be obtained by calculate.

其中,εL为截面含气率,通过进行计算,Usg,Usl采用(4)所得液相流量的预测值和气相流量的测量值mg求得;θ为圆周润湿率,通过计算。Among them, εL is the gas content of the section, through Calculate, Usg , Usl using the predicted value of liquid flow rate obtained in (4) and the measured value of gas flow mg ; θ is the circumferential wettability, through calculate.

V锥3下沿距管道2底部的距离由计算,本例中h=2.67mm。The distance between the lower edge of

将锥前液膜厚度H与h比较,当H≥2.67mm时,将步骤4)得到的液相流量预测值Frl=f(DR,δ),作为液相流量测量值输出,计算关联式见(5)。Compare the thickness H of the liquid film in front of the cone with h, when H≥2.67mm, the liquid flow predicted value Frl =f(DR,δ) obtained in step 4) is output as the liquid flow measurement value, and the correlation formula is calculated See (5).

Frl=1.2003-116.0315DR/ln(DR)+7.3206δ2lnδ (5)Frl =1.2003-116.0315DR/ln(DR)+7.3206δ2 lnδ (5)

当H<2.67mm时,根据Frl=f(Frg,DR,δ)结合气相流量预测模型,计算液相流量测量值,计算关联式见(6)When H<2.67mm, according to Frl =f(Frg ,DR,δ) combined with the gas-phase flow rate prediction model, calculate the liquid-phase flow rate measurement value, see (6) for the calculation correlation

Frl=-3.8016-0.0475Frg+22.7954DR+4.4909δ0.5 (6)Frl = -3.8016-0.0475Frg +22.7954DR+4.4909δ0.5 (6)

图5和图6分别为湿气范围内,即洛玛参数XLM<0.3时(洛玛参数XLM,用来表征湿气中液相含率的大小,其定义式为),采用本发明所涉及的湿气流量双参数在线测量方法所得的气、液相流量相对误差,气相流量误差在±5%以内,除极低含液条件XLM<0.02外,液相流量误差在±20%内,可满足工业应用需求。此外,两相误差均呈现一定对称分布,这有利于累计误差的进一步降低。Figures 5 and 6 are respectively in the humidity range, that is, when the Loma parameter XLM <0.3 (the Loma parameter XLM , which is used to characterize the liquid phase content in the wet gas, and its definition formula is ), the relative error of gas and liquid flow obtained by the dual-parameter online measurement method of wet gas flow involved in the present invention, the gas flow error is within ±5%, except for the extremely low liquid-containing condition XLM <0.02, the liquid flow The error is within ±20%, which can meet the needs of industrial applications. In addition, the two-phase errors show a certain symmetrical distribution, which is conducive to further reducing the cumulative error.

以上内容仅为说明本发明的技术思想,不能以此限定本发明的保护范围,凡是按照本发明提出的技术思想,在技术方案基础上所做的任何改动,均落入本发明权利要求书的保护范围之内。The above content is only to illustrate the technical idea of the present invention, and cannot limit the protection scope of the present invention. Any changes made on the basis of the technical solution according to the technical idea proposed by the present invention all fall within the scope of the claims of the present invention. within the scope of protection.

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911054870.6ACN110793585B (en) | 2019-10-31 | 2019-10-31 | Wet air flow online measurement method and device based on V cone pressure loss ratio segmentation characteristic |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911054870.6ACN110793585B (en) | 2019-10-31 | 2019-10-31 | Wet air flow online measurement method and device based on V cone pressure loss ratio segmentation characteristic |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110793585A CN110793585A (en) | 2020-02-14 |

| CN110793585Btrue CN110793585B (en) | 2020-11-10 |

Family

ID=69440670

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911054870.6AActiveCN110793585B (en) | 2019-10-31 | 2019-10-31 | Wet air flow online measurement method and device based on V cone pressure loss ratio segmentation characteristic |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110793585B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114440961B (en)* | 2020-11-06 | 2024-04-19 | 中国石油化工股份有限公司 | Small-sized non-separation two-phase metering device and metering system |

| DE102021127850A1 (en)* | 2021-10-26 | 2023-04-27 | Endress+Hauser Flowtec Ag | Method for determining a mass fraction of the gas phase and/or the mass flow rate of the gas phase, of a multi-phase medium flowing in a measuring tube with a liquid phase and a gas phase, and a sensor therefor |

| CN115355959B (en)* | 2022-08-22 | 2025-09-02 | 西安交通大学 | Gas-liquid two-phase flow measurement method and system based on machine learning and physical constraints |

| CN119026302A (en)* | 2023-05-26 | 2024-11-26 | 中国石油化工股份有限公司 | A differential pressure metering method and system based on flow pattern discrimination |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104075766A (en)* | 2014-06-19 | 2014-10-01 | 西安交通大学 | Pipe internal-phase separation type high-gas-containing-rate gas-liquid two-phase fluid flow measurement device and method |

| EP2985597A1 (en)* | 2014-08-14 | 2016-02-17 | Alstom Technology Ltd | Steam wetness measurement device |

| CN107843297A (en)* | 2017-10-17 | 2018-03-27 | 西安交通大学 | Low air void biphase gas and liquid flow liquid phase flow on-line measurement device and method based on V cones |

| CN110031046A (en)* | 2018-03-22 | 2019-07-19 | 天津大学 | A kind of gas-liquid two-phase flow measuring system |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016048801A1 (en)* | 2014-09-24 | 2016-03-31 | Sisler John R | Weight-based phase composition ratio determination |

- 2019

- 2019-10-31CNCN201911054870.6Apatent/CN110793585B/enactiveActive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104075766A (en)* | 2014-06-19 | 2014-10-01 | 西安交通大学 | Pipe internal-phase separation type high-gas-containing-rate gas-liquid two-phase fluid flow measurement device and method |

| EP2985597A1 (en)* | 2014-08-14 | 2016-02-17 | Alstom Technology Ltd | Steam wetness measurement device |

| CN107843297A (en)* | 2017-10-17 | 2018-03-27 | 西安交通大学 | Low air void biphase gas and liquid flow liquid phase flow on-line measurement device and method based on V cones |

| CN110031046A (en)* | 2018-03-22 | 2019-07-19 | 天津大学 | A kind of gas-liquid two-phase flow measuring system |

Non-Patent Citations (2)

| Title |

|---|

| Online measurement of gas and liquid flow rate in wet gas through one V-Cone throttle device;Denghui He, Bofeng Bai, Jun Zhang, Xianwen Wang;《Experimental Thermal and Fluid Science》;20160731;第75卷;129-136* |

| 基于单V锥节流装置的湿气气液流量在线测量;贺登辉,张锋,曹洪贵,杨园园,白博峰;《机械工程学报》;20160430;第52卷(第8期);192-197* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110793585A (en) | 2020-02-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110793585B (en) | Wet air flow online measurement method and device based on V cone pressure loss ratio segmentation characteristic | |

| CN100437046C (en) | Measuring method of gas-liquid two-phase flow based on section measuring and apparatus thereof | |

| CN110514257B (en) | Venturi-based low liquid content moisture two-phase flow measuring device and method | |

| CN107843297B (en) | On-line measurement device and method for liquid phase flow rate of gas-liquid two-phase flow with low gas fraction based on V-cone | |

| CN102759383B (en) | Method and device for online measurement of gas-phase flow rate of gas-liquid two-phase flow based on single throttling element | |

| CN210293314U (en) | Necking type precession vortex flowmeter | |

| Li et al. | A non-invasive measurement method of pipeline flow rate based on dual FBG sensors | |

| Hua et al. | Wet gas meter based on the vortex precession frequency and differential pressure combination of swirlmeter | |

| CN106768097A (en) | A kind of inside and outside tubular type gas flowmeter and flow rate testing methods | |

| CN114547892B (en) | Vortex wet gas phase separation flow measurement method based on liquid film flow parameter modeling | |

| CN107806912A (en) | Bidirectional traffics measurement apparatus | |

| CN108896120A (en) | Vortex street throttling integrated gas-liquid two-phase flowmeter and application method thereof | |

| CN111323087A (en) | Device and method for real-time measurement of wet gas flow based on forced annular flow technology | |

| CN110455363A (en) | Gas mass flow meter and method for measuring gas mass flow | |

| CN110186522A (en) | Reading compensation and flow-measuring method are crossed in conjunction with the moisture of vortex street amplitude characteristic | |

| CN108931270A (en) | Diphasic stream parameter detection method based on porous restriction and acoustic emission | |

| CN111397678A (en) | A multi-stage rectifier MEMS gas flow meter | |

| CN111442809A (en) | Gas-liquid section plug flow online measurement method based on vertical Venturi tube | |

| CN220542149U (en) | A venturi flow meter | |

| CN112945326A (en) | Gas flow measuring device and method | |

| CN115307696B (en) | Device and method for online measurement of slug flow two-phase flow based on multi-sensor fusion | |

| CN216954650U (en) | Microminiature temperature and pressure integrated vortex shedding flowmeter | |

| CN116558591A (en) | A Large Diameter Natural Gas Ultrasonic Mass Flowmeter | |

| CN204514400U (en) | A kind of compact gas-liquid stratified flow measurement mechanism | |

| CN206339270U (en) | A kind of inside and outside tubular type gas flowmeter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |