CN110791971A - A coating finishing technology of intelligent temperature-regulating textiles based on phase-change microcapsules - Google Patents

A coating finishing technology of intelligent temperature-regulating textiles based on phase-change microcapsulesDownload PDFInfo

- Publication number

- CN110791971A CN110791971ACN201910814033.2ACN201910814033ACN110791971ACN 110791971 ACN110791971 ACN 110791971ACN 201910814033 ACN201910814033 ACN 201910814033ACN 110791971 ACN110791971 ACN 110791971A

- Authority

- CN

- China

- Prior art keywords

- parts

- phase

- coating

- microcapsules

- phase change

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0002—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the substrate

- D06N3/0015—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the substrate using fibres of specified chemical or physical nature, e.g. natural silk

- D06N3/0036—Polyester fibres

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0056—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the compounding ingredients of the macro-molecular coating

- D06N3/0059—Organic ingredients with special effects, e.g. oil- or water-repellent, antimicrobial, flame-resistant, magnetic, bactericidal, odour-influencing agents; perfumes

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0056—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the compounding ingredients of the macro-molecular coating

- D06N3/0063—Inorganic compounding ingredients, e.g. metals, carbon fibres, Na2CO3, metal layers; Post-treatment with inorganic compounds

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0056—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the compounding ingredients of the macro-molecular coating

- D06N3/0068—Polymeric granules, particles or powder, e.g. core-shell particles, microcapsules

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/007—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by mechanical or physical treatments

- D06N3/0077—Embossing; Pressing of the surface; Tumbling and crumbling; Cracking; Cooling; Heating, e.g. mirror finish

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/04—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof with macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06N3/042—Acrylic polymers

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2205/00—Condition, form or state of the materials

- D06N2205/08—Microballoons, microcapsules

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2209/00—Properties of the materials

- D06N2209/06—Properties of the materials having thermal properties

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Inorganic Chemistry (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于织物涂层制备领域,具体涉及了一种基于相变微胶囊的智能调温纺织品的涂层整理技术。The invention belongs to the field of fabric coating preparation, and particularly relates to a coating finishing technology for intelligent temperature-regulating textiles based on phase-change microcapsules.

背景技术Background technique

相变材料(PCMs)是一类能够储能蓄热,高效利用热量的材料。相变材料的种类繁多,其中固-液型相变材料由于相变过程的可控性强和可多次循环利用,应用最为广泛,这种材料在相变过程中总是要经历物态的变化,例如固态和液态的相转变,在转变过程中会发生体积的变化、易熔融泄露等问题,在很大程度上限制了应用。Phase change materials (PCMs) are a class of materials that can store heat and utilize heat efficiently. There are many types of phase change materials, among which solid-liquid phase change materials are the most widely used due to their strong controllability and recyclability of the phase change process. Changes, such as the phase transition between solid state and liquid state, have problems such as volume change and easy melting and leakage during the transition process, which limit the application to a large extent.

相变材料微胶囊化能有效的解决相变材料易熔融泄露等问题,即选择合适的壁材,对相变材料进行包覆制备成相变微胶囊(MEPCMs),这种做法极大的提高了相变材料的利用率同时也拓宽了其应用范围。例如,Sara等人首次采用sol-gel法,研究了以PA(棕榈酸)为芯材,SiO2为壁材的纳米相变微胶囊的制备,制备的SiO2/PA纳米微胶囊具有良好的热性能、化学稳定性和较高的热导率;Tivadar采用石蜡和十六醇相变材料为载体,三甲氧基(甲基)硅烷为水解液,采用sol-gel法制备了二氧化硅包覆微球,这类相变微胶囊显示出相对较高的潜热储存能力;Chen等人采用sol-gel法制备了以SiO2为壁材的复合储能微胶囊化硬脂酸(SA),防止了熔融硬脂酸的泄漏。Microencapsulation of phase change materials can effectively solve the problems of easy melting and leakage of phase change materials, that is, selecting appropriate wall materials and coating the phase change materials to prepare phase change microcapsules (MEPCMs), which greatly improves the The utilization rate of phase change materials is also broadened. For example, Sara et al. used the sol-gel method for the first time to study the preparation of nano-phase change microcapsules with PA (palmitic acid) as the core material and SiO2 as the wall material. The prepared SiO2 /PA nano-microcapsules have good Thermal performance, chemical stability and high thermal conductivity; Tivadar uses paraffin and cetyl alcohol phase change material as the carrier, trimethoxy (methyl) silane as the hydrolyzate, and the sol-gel method is used to prepare the silica package Coated microspheres, this type of phase change microcapsules showed relatively high latent heat storage capacity; Chen et al. prepared the composite energy storage microencapsulated stearic acid (SA) withSiO2 as the wall material by the sol-gel method, The leakage of molten stearic acid is prevented.

相变微胶囊制备技术的发展,为功能纺织品行业提供了一个新的方向,即利用相变微胶囊制备能实现智能调温的蓄热调温纺织品。蓄热调温纺织品的工作原理是附着在织物表面或填充到纤维内部的相变材料在遇冷或受热后会发生物态转变,从而释放或吸收热量,实现温度变化动态平衡的效果,起到调温的作用。The development of phase change microcapsule preparation technology provides a new direction for the functional textile industry, that is, the use of phase change microcapsules to prepare thermal storage and temperature regulation textiles that can realize intelligent temperature regulation. The working principle of thermal storage and temperature-adjusting textiles is that the phase change material attached to the surface of the fabric or filled into the fiber will undergo a physical state transformation after being cooled or heated, thereby releasing or absorbing heat, realizing the effect of dynamic balance of temperature change, and playing a role in The role of temperature regulation.

目前相变微胶囊主要通过纺丝和后整理两种方式应用到织物上。例如,Li等采用丙烯酸系共聚壁材对正十八烷进行微胶囊化,并对所得微胶囊进行高温高压处理,采用湿法纺丝法制备了含有微胶囊的海藻酸纤维;胡春华等对服饰用相变调温纺织品进行研究,探究了用于低温条件下蓄热调温纺织品的相变材料复配比和面料性能对相变效果的影响,得出正十六烷和正十八烷这两种相变材料的最佳复配比为0.2:0.8;钱惺悦等以石蜡为芯材制备微胶囊,并将微胶囊配成整理液,采取浸轧方式将其应用到涤纶和纯棉织物上。At present, phase change microcapsules are mainly applied to fabrics by spinning and finishing. For example, Li et al. used acrylic copolymer wall material to microencapsulate n-octadecane, and the obtained microcapsules were treated with high temperature and high pressure, and alginate fibers containing microcapsules were prepared by wet spinning method; Hu Chunhua et al. The phase-change temperature-adjusting textiles were used for research, and the effect of the phase-change material compound ratio and fabric properties on the phase-change effect of the heat-storage and temperature-adjusting textiles under low temperature conditions was investigated, and it was concluded that n-hexadecane and n-octadecane The optimal compounding ratio of these phase change materials is 0.2:0.8; Qian Xingyue et al. prepared microcapsules with paraffin as the core material, formulated the microcapsules into a finishing solution, and applied them to polyester and cotton fabrics by padding. superior.

中国发明专利CN00105837《自动调温纤维及其制品》,提供了一种以三聚氰胺、环氧树脂、脲醛树脂或硅酸钙为囊壁,采用原位聚合法合成微胶囊,但目前以脲醛树脂等聚合物做壁材,都无法解决甲醛残留的问题,故而限制了其应用。The Chinese invention patent CN00105837 "Automatic Thermoregulating Fiber and Its Products" provides a kind of microcapsules with melamine, epoxy resin, urea-formaldehyde resin or calcium silicate as the capsule wall, and the in-situ polymerization method is used to synthesize microcapsules. Polymers used as wall materials cannot solve the problem of formaldehyde residues, which limits its application.

中国发明专利CN200710057493《一种智能调温纺织品及其制备》,提供了一种以醇类相变材料为芯材,以二氧化硅凝胶为壳材,在二氧化硅的吸附作用下制取微胶囊。但此种微胶囊通常只适合做蓄热涂料,而不适用于制备蓄热调温纺织品。Chinese invention patent CN200710057493 "An intelligent temperature-adjusting textile and its preparation" provides a kind of alcohol phase change material as the core material and silica gel as the shell material, prepared under the adsorption of silica Microcapsules. However, such microcapsules are usually only suitable for thermal storage coatings, not for the preparation of thermal storage and temperature-regulating textiles.

中国发明专利CN102733192《一种纳米相变微胶囊蓄热调温智能纺织品织物印染布的整理工艺》提供了一种将微胶囊配成整理液,在交联剂的作用下通过浸轧,整理到纺织上。但在整理过程中可能出现微胶囊破裂,芯材泄露的情况。Chinese invention patent CN102733192 "A Finishing Process of Nanometer Phase Change Microcapsule Heat Storage and Temperature Adjusting Intelligent Textile Fabric Printing and Dyeing Cloth" provides a method of preparing microcapsules into a finishing solution, and by padding under the action of a crosslinking agent, finishing to textile. However, during the finishing process, the microcapsules may rupture and the core material leaks.

虽然目前已有大量专家学者对该领域进行了研究,但相变微胶囊在纺织品上的应用还存在着诸多问题,例如石蜡等芯材导热系数低,价格较高,使用的壁材会阻碍热量传递,且对芯材的包覆率较低,导致调温性能不明显。更重要的是,经过整理后,织物上含有的微胶囊较少,微胶囊与纤维或织物的结合率较低。Although a large number of experts and scholars have carried out research in this field, there are still many problems in the application of phase change microcapsules in textiles. For example, core materials such as paraffin have low thermal conductivity and high prices, and the wall materials used will hinder heat. transfer, and the covering rate of the core material is low, resulting in insignificant temperature regulation performance. What's more, after finishing, the fabric contains less microcapsules, and the microcapsules are less bound to the fiber or fabric.

有鉴于此,本发明在经过一系列的实验和研究的基础上,总结出了一种基于相变微胶囊的智能调温纺织品的涂层整理技术方案。In view of this, on the basis of a series of experiments and researches, the present invention summarizes a technical solution for coating finishing of intelligent temperature-regulating textiles based on phase-change microcapsules.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提供一种基于相变微胶囊的智能调温纺织品的涂层整理技术,该相变微胶囊绿色环保,价格低廉,导热系数高,形成的涂层整理织物具有高结合率的优点,解决相变微胶囊与织物结合牢度不强,结合率较低的问题。The purpose of the present invention is to provide a coating finishing technology for intelligent temperature-adjusting textiles based on phase change microcapsules. The phase change microcapsules are environmentally friendly, low in price, high in thermal conductivity, and the formed coating finishing fabric has high bonding rate. It has the advantages of solving the problems of weak bonding fastness and low bonding rate between phase change microcapsules and fabrics.

为了解决上述技术问题,采用如下技术方案:In order to solve the above technical problems, the following technical solutions are adopted:

一种基于相变微胶囊的智能调温纺织品的涂层整理技术,其特征在于包括如下步骤:A coating finishing technology for intelligent temperature-adjusting textiles based on phase-change microcapsules is characterized by comprising the following steps:

(1)原料准备:所用织物为涤纶织物;(1) Preparation of raw materials: the fabric used is polyester fabric;

(2)相变微胶囊的制备;(2) preparation of phase change microcapsules;

(3)相变微胶囊与涤纶织物结合的涂层整理工艺:先将40-50份水和1-3份分散剂混合均匀,在高速搅拌下依次加入10-15份水性聚丙烯酸酯涂层剂,再以2000r/min的转速搅拌10min后加入25-30份相变微胶囊粉末,最后以800r/min的转速搅拌30min后加入2-5份交联剂和1-3份增稠剂,低速搅拌均匀形成浆料后备用;(3) Coating finishing process of combining phase change microcapsules with polyester fabric: first mix 40-50 parts of water and 1-3 parts of dispersant evenly, and then add 10-15 parts of water-based polyacrylate coating in turn under high-speed stirring Add 25-30 parts of phase change microcapsule powder after stirring at 2000r/min for 10min, and finally add 2-5 parts of crosslinking agent and 1-3 parts of thickener after stirring at 800r/min for 30min. Stir at low speed to form a slurry for later use;

设置涂布速度为6m/min,涂层厚度为40-60um,将配制好的浆料采用干法涂层方式用刮刀式涂布机涂布到涤纶织物上,随后进行烘干处理。Set the coating speed to 6m/min and the coating thickness to 40-60um, apply the prepared slurry to the polyester fabric by dry coating method with a blade coater, and then dry it.

优选后,所用的涤纶织物需经前处理和预定形。After optimization, the polyester fabric used needs to be pre-treated and pre-shaped.

优选后,所述步骤(2)中相变微胶囊的制备步骤为:将250-270份水和2-5份CTAB乳化剂混合均匀,在高速搅拌下加入35-40份月桂酸十二醇酯相变芯材形成稳定O/W乳液;然后将配制好的20-25份正硅酸乙酯与160-180份乙醇的混合溶液滴加到O/W乳液中,反应24h即可,取反应完成的微胶囊乳液,离心后取出固体烘干即可得到SiO2相变微胶囊粉末,备用。After optimization, the preparation steps of the phase change microcapsules in the step (2) are as follows: mixing 250-270 parts of water and 2-5 parts of CTAB emulsifier evenly, adding 35-40 parts of dodecyl laurate under high-speed stirring The ester phase change core material forms a stable O/W emulsion; then the prepared mixed solution of 20-25 parts of ethyl orthosilicate and 160-180 parts of ethanol is added dropwise to the O/W emulsion, and the reaction is done for 24 hours. The reaction-completed microcapsule emulsion is centrifuged and the solid is taken out and dried to obtain SiO2 phase-change microcapsule powder, which is for later use.

优选后,在加入芯材后,将溶液置于恒温35℃-45℃的水浴锅中水浴加热,以10000r/min的转速搅拌乳化15-20min形成稳定O/W乳液,并滴加氨水调节pH值为8~9。After optimization, after adding the core material, the solution is placed in a water bath with a constant temperature of 35°C-45°C and heated in a water bath, stirred and emulsified at a speed of 10000r/min for 15-20min to form a stable O/W emulsion, and ammonia water is added dropwise to adjust the pH. The value is 8 to 9.

优选后,在形成O/W乳液后,调整转速为360r/min,然后将配制好的20-25份正硅酸乙酯与160-180份乙醇的混合溶液滴加到O/W乳液中,滴加完成之后,再次调节转速为300r/min,反应24h。After optimization, after forming the O/W emulsion, adjust the rotation speed to 360r/min, and then drop the prepared mixed solution of 20-25 parts of ethyl orthosilicate and 160-180 parts of ethanol into the O/W emulsion, After the dropwise addition was completed, the rotating speed was adjusted to 300r/min again, and the reaction was carried out for 24h.

优选后,制备获得的相变微胶囊平均粒径大小为200nm-400nm。After optimization, the prepared phase change microcapsules have an average particle size of 200nm-400nm.

优选后,所用的CTAB乳化剂用量占水相总质量的1.2%。After optimization, the amount of CTAB emulsifier used accounts for 1.2% of the total mass of the water phase.

优选后,所用的水性聚丙烯酸酯涂层剂为高性能丙烯酸醋酸乙烯新型乳液,该乳液固含量为40%-45%。After optimization, the water-based polyacrylate coating agent used is a new high-performance acrylic vinyl acetate latex, and the solid content of the latex is 40%-45%.

优选后,所用的增稠剂为海藻酸钠、聚氨酯醚类流变增稠剂、丙烯酸碱溶胀增稠剂这三种中的一种。交联剂可以选用聚丙烯酸酯、聚烷基丙烯酸酯及聚苯二甲酸二烯丙酯等。After optimization, the thickener used is one of sodium alginate, polyurethane ether rheological thickener, and acrylic acid alkali swelling thickener. The cross-linking agent can be selected from polyacrylate, polyalkylacrylate and polydiallyl phthalate.

优选后,烘干处理过程中,先在80-100℃的温度下预烘5-10min再进行焙烘,焙烘温度为110-130℃,时间为60s-80s。After optimization, in the drying process, pre-bake at a temperature of 80-100°C for 5-10 minutes before baking, the baking temperature is 110-130°C, and the time is 60s-80s.

由于采用上述技术方案,具有以下有益效果:Due to the adoption of the above technical solution, the following beneficial effects are obtained:

本发明的有益效果是:本发明制备的相变微胶囊具有高包覆率,高相变焓,且通过设置合理的涂层浆配方,将相变微胶囊通过刮刀涂布机涂布到涤纶织物上,在保证其微胶囊芯材无泄漏的前提下,使其与涤纶织物具有高结合率;本发明生产成本较低,制作工艺简单,安全环保,利于工业生产及推广。The beneficial effects of the present invention are: the phase-change microcapsules prepared by the present invention have high coating rate and high phase-change enthalpy, and by setting a reasonable coating slurry formulation, the phase-change microcapsules are coated on polyester fibers by a doctor blade coater On the fabric, under the premise of ensuring that the microcapsule core material does not leak, it has a high bonding rate with the polyester fabric; the invention has low production cost, simple production process, safety and environmental protection, and is beneficial to industrial production and popularization.

通过在含有水性聚丙烯酸酯涂层剂的涂层浆中加入相变微胶囊,利用刮刀涂布机涂布到涤纶织物上,可以在织物表面形成连续且均匀的孔隙结构。一方面增强了相变微胶囊与织物的结合率,另一方面可能由于水分的挥发,在织物表面形成了大量均匀的孔隙结构,使织物的透气透湿性下降不大。且由于自制的相变微胶囊具有高包覆率,高相变焓,故而由其制备的蓄热调温织物的调温效果明显。By adding phase-change microcapsules to the coating slurry containing the aqueous polyacrylate coating agent and coating it on the polyester fabric with a doctor blade coater, a continuous and uniform pore structure can be formed on the surface of the fabric. On the one hand, the bonding rate between the phase change microcapsules and the fabric is enhanced, and on the other hand, a large number of uniform pore structures may be formed on the surface of the fabric due to the volatilization of water, so that the air permeability and moisture permeability of the fabric are not greatly reduced. And because the self-made phase change microcapsules have high coating rate and high phase change enthalpy, the heat storage and temperature adjustment fabric prepared by the self-made microcapsules has obvious temperature adjustment effect.

附图说明Description of drawings

图1为制备的相变微胶囊的FESEM照片;Fig. 1 is the FESEM photograph of the prepared phase change microcapsules;

图2为制备的相变微胶囊的DSC曲线;Fig. 2 is the DSC curve of the prepared phase change microcapsules;

图3为制备的相变微胶囊整理涤纶织物的FESEM照片(a);Figure 3 is a FESEM photograph (a) of the prepared polyester fabric with phase change microcapsules;

图4为制备的相变微胶囊整理涤纶织物的FESEM照片(b);Figure 4 is a FESEM photograph (b) of the prepared polyester fabric with phase change microcapsules;

图5为制备的相变微胶囊整理涤纶织物的降温曲线;Fig. 5 is the cooling curve of the prepared polyester fabric with phase change microcapsules;

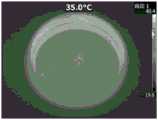

图6为制备的相变微胶囊整理涤纶织物的玻璃培养皿热成像照片;Figure 6 is a thermal imaging photo of a glass petri dish prepared with phase change microcapsules finishing polyester fabric;

图7为制备的相变微胶囊整理涤纶织物的原织物热成像照片;Fig. 7 is the thermal imaging photo of the original fabric of the prepared polyester fabric with phase change microcapsules;

图8为制备的相变微胶囊整理涤纶织物的涂层整理织物热成像照片。Figure 8 is a thermal imaging photo of the prepared polyester fabric with phase change microcapsules finishing the coated fabric.

具体实施方式Detailed ways

申请人在研究中发现,通过在含有水性聚丙烯酸酯涂层剂的涂层浆中加入相变微胶囊,利用刮刀涂布机涂布到涤纶织物上,可以在织物表面形成连续且均匀的孔隙结构。一方面增强了相变微胶囊与织物的结合率,另一方面可能由于水分的挥发,在织物表面形成了大量均匀的孔隙结构,使织物的透气透湿性下降不大。且由于自制的相变微胶囊具有高包覆率,高相变焓,故而由其制备的蓄热调温织物的调温效果明显。The applicant found in the research that continuous and uniform pores can be formed on the surface of the fabric by adding phase-change microcapsules to the coating slurry containing the aqueous polyacrylate coating agent and coating it on the polyester fabric with a doctor blade coater. structure. On the one hand, the bonding rate between the phase change microcapsules and the fabric is enhanced, and on the other hand, a large number of uniform pore structures may be formed on the surface of the fabric due to the volatilization of water, so that the air permeability and moisture permeability of the fabric are not greatly reduced. And because the self-made phase change microcapsules have high coating rate and high phase change enthalpy, the heat storage and temperature adjustment fabric prepared by the self-made microcapsules has obvious temperature adjustment effect.

下面结合具体的实施例对本发明作进一步说明:Below in conjunction with specific embodiment, the present invention will be further described:

实施例一:Example 1:

1.原料准备:本发明所用的织物为经前处理和预定形的涤纶织物。1. Preparation of raw materials: The fabric used in the present invention is a pre-treated and pre-shaped polyester fabric.

2.相变微胶囊的制备:将250份水和3份CTAB乳化剂混合均匀,在高速搅拌下加入40份芯材,置于恒温40℃的水浴锅中水浴加热的同时以10000r/min的转速搅拌至形成稳定O/W乳液,滴加氨水调节pH值为8.5。再调整转速为360r/min,将配制好的正硅酸乙酯(20份)与乙醇(178份)的混合溶液逐滴滴加到乳液中,滴加完成之后,调整转速为300r/min,反应24h。取反应完成的微胶囊乳液,离心后取出固体烘干即可得到SiO2相变微胶囊粉末。2. Preparation of phase change microcapsules: Mix 250 parts of water and 3 parts of CTAB emulsifier evenly, add 40 parts of core material under high-speed stirring, and place it in a water bath with a constant temperature of 40 °C while heating in a water bath at 10,000 r/min. The rotating speed was stirred until a stable O/W emulsion was formed, and ammonia water was added dropwise to adjust the pH value to 8.5. Then adjust the rotation speed to 360r/min, add the mixed solution of prepared ethyl orthosilicate (20 parts) and ethanol (178 parts) dropwise to the emulsion, after the dropwise addition is completed, adjust the rotation speed to 300r/min, Reaction for 24h. Take the reaction-completed microcapsule emulsion, centrifuge and take out the solid to dry to obtain SiO2 phase change microcapsule powder.

3.相变微胶囊与涤纶织物结合的涂层整理工艺:将50份水和3份分散剂混合均匀,在高速搅拌下依次加入10份水性聚丙烯酸酯涂层剂,再以2000r/min的转速搅拌10min后加入30份相变微胶囊粉末,最后以800r/min的转速搅拌30min后加入2份交联剂和3份丙烯酸碱溶胀增稠剂,低速搅拌均匀形成浆料后备用。设置涂布速度为6m/min,涂层厚度为40um,将配制好的浆料采用干法涂层方式用刮刀式涂布机涂布到涤纶织物上,随后在80℃下预烘5min,再进行焙烘,焙烘温度为130℃,时间为70s,制得蓄热调温织物。3. Coating finishing process combining phase change microcapsules and polyester fabric:

实施例二:Embodiment 2:

1.原料准备:本发明所用的织物为经前处理和预定形的涤纶织物。1. Preparation of raw materials: The fabric used in the present invention is a pre-treated and pre-shaped polyester fabric.

2.相变微胶囊的制备:将255份水和2.5份CTAB乳化剂混合均匀,在高速搅拌下加入35份芯材,置于恒温45℃的水浴锅中水浴加热的同时以10000r/min的转速搅拌至形成稳定O/W乳液,滴加氨水调节pH值为8。再调整转速为360r/min,将配制好的正硅酸乙酯(18份)与乙醇(165份)的混合溶液滴加到乳液中,滴加完成之后,调整转速为300r/min,反应24h。取反应完成的微胶囊乳液,离心后取出固体烘干即可得到SiO2相变微胶囊粉末。2. Preparation of phase-change microcapsules: Mix 255 parts of water and 2.5 parts of CTAB emulsifier evenly, add 35 parts of core material under high-speed stirring, and place it in a water bath with a constant temperature of 45 ° C while heating in a water bath at 10000 r/min. The rotating speed is stirred until a stable O/W emulsion is formed, and ammonia water is added dropwise to adjust the pH value to 8. Then adjust the rotation speed to 360r/min, add the prepared mixed solution of ethyl orthosilicate (18 parts) and ethanol (165 parts) dropwise into the emulsion, after the dropwise addition is completed, adjust the rotation speed to 300r/min, and react for 24h . Take the reaction-completed microcapsule emulsion, centrifuge and take out the solid to dry to obtain SiO2 phase change microcapsule powder.

3.相变微胶囊与涤纶织物结合的涂层整理工艺:将45份水和1份分散剂混合均匀,在高速搅拌下依次加入10份水性聚丙烯酸酯涂层剂,再以2000r/min的转速搅拌10min后加入25份相变微胶囊粉末,最后以800r/min的转速搅拌30min后加入1份交联剂和2份聚氨酯醚类流变增稠剂,低速搅拌均匀形成浆料后备用。设置涂布速度为6m/min,涂层厚度为40um,将配制好的浆料采用干法涂层方式用刮刀式涂布机涂布到涤纶织物上,随后在80℃下预烘10min,再进行焙烘,焙烘温度为120℃,时间为80s,制得蓄热调温织物。3. Coating finishing process combining phase change microcapsules and polyester fabric: Mix 45 parts of water and 1 part of dispersant evenly, add 10 parts of water-based polyacrylate coating agent in turn under high-speed stirring, and then add 2000r/min. Add 25 parts of phase change microcapsule powder after stirring at a speed of 10 minutes, and finally add 1 part of crosslinking agent and 2 parts of polyurethane ether rheological thickener after stirring at a speed of 800 r/min for 30 minutes, and stir at low speed to form a slurry for later use. Set the coating speed to 6m/min and the coating thickness to 40um, apply the prepared slurry to the polyester fabric by dry coating method with a blade coater, then pre-bake at 80°C for 10min, and then Baking was carried out, and the baking temperature was 120° C. and the time was 80 s to obtain a heat storage temperature-adjusting fabric.

实施例三:Embodiment three:

1.原料准备:本发明所用的织物为经前处理和预定形的涤纶织物。1. Preparation of raw materials: The fabric used in the present invention is a pre-treated and pre-shaped polyester fabric.

2.相变微胶囊的制备:将265份水和3份CTAB乳化剂混合均匀,在高速搅拌下加入40份芯材,置于恒温35℃的水浴锅中水浴加热的同时以10000r/min的转速搅拌至形成稳定O/W乳液,滴加氨水调节pH值为9。再调整转速为360r/min,将配制好的正硅酸乙酯(20份)与乙醇(175份)的混合溶液滴加到乳液中,滴加完成之后,调整转速为300r/min,反应24h。取反应完成的微胶囊乳液,离心后取出固体烘干即可得到SiO2相变微胶囊粉末。2. Preparation of phase change microcapsules: Mix 265 parts of water and 3 parts of CTAB emulsifier evenly, add 40 parts of core material under high-speed stirring, and place it in a water bath with a constant temperature of 35 °C while heating in a water bath at 10000 r/min. The rotating speed was stirred until a stable O/W emulsion was formed, and ammonia water was added dropwise to adjust the pH value to 9. Then adjust the rotation speed to 360r/min, add the prepared mixed solution of ethyl orthosilicate (20 parts) and ethanol (175 parts) dropwise into the emulsion, after the dropwise addition is completed, adjust the rotation speed to 300r/min, and react for 24h . Take the reaction-completed microcapsule emulsion, centrifuge and take out the solid to dry to obtain SiO2 phase change microcapsule powder.

3.相变微胶囊与涤纶织物结合的涂层整理工艺:将50份水和2份分散剂混合均匀,在高速搅拌下依次加入15份水性聚丙烯酸酯涂层剂,再以2000r/min的转速搅拌10min后加入30份相变微胶囊粉末,最后以800r/min的转速搅拌30min后加入2份交联剂和1份海藻酸钠,低速搅拌均匀形成浆料后备用。设置涂布速度为6m/min,涂层厚度为60um,将配制好的浆料采用干法涂层方式用刮刀式涂布机涂布到涤纶织物上,随后在85℃下预烘10min,再进行焙烘,焙烘温度为125℃,时间为80s,制得蓄热调温织物。3. Coating finishing process combining phase change microcapsules with polyester fabric:

实施例四:Embodiment 4:

1.原料准备:本发明所用的织物为经前处理和预定形的涤纶织物。1. Preparation of raw materials: The fabric used in the present invention is a pre-treated and pre-shaped polyester fabric.

2.相变微胶囊的制备:将270份水和2.5份CTAB乳化剂混合均匀,在高速搅拌下加入38份芯材,置于恒温45℃的水浴锅中水浴加热的同时以10000r/min的转速搅拌至形成稳定O/W乳液,滴加氨水调节pH值为8。再调整转速为360r/min,将配制好的正硅酸乙酯(20份)与乙醇(180份)的混合溶液逐滴滴加到乳液中,滴加完成之后,调整转速为300r/min,反应24h。取反应完成的微胶囊乳液,离心后取出固体烘干即可得到SiO2相变微胶囊粉末。2. Preparation of phase change microcapsules: Mix 270 parts of water and 2.5 parts of CTAB emulsifier evenly, add 38 parts of core material under high-speed stirring, and place it in a water bath with a constant temperature of 45 °C while heating in a water bath at 10000 r/min. The rotating speed is stirred until a stable O/W emulsion is formed, and ammonia water is added dropwise to adjust the pH value to 8. Then adjust the rotation speed to 360r/min, add the mixed solution of prepared ethyl orthosilicate (20 parts) and ethanol (180 parts) dropwise to the emulsion, after the dropwise addition is completed, adjust the rotation speed to 300r/min, Reaction for 24h. Take the reaction-completed microcapsule emulsion, centrifuge and take out the solid to dry to obtain SiO2 phase change microcapsule powder.

3.相变微胶囊与涤纶织物结合的涂层整理工艺:将40份水和2份分散剂混合均匀,在高速搅拌下依次加入12份水性聚丙烯酸酯涂层剂,再以2000r/min的转速搅拌10min后加入27份相变微胶囊粉末,最后以800r/min的转速搅拌30min后加入2份交联剂和3份丙烯酸碱溶胀增稠剂,低速搅拌均匀形成浆料后备用。设置涂布速度为6m/min,涂层厚度为50um,将配制好的浆料采用干法涂层方式用刮刀式涂布机涂布到涤纶织物上,随后在90℃下预烘5min,再进行焙烘,焙烘温度为110℃,时间为70s,制得蓄热调温织物。3. Coating finishing process combining phase change microcapsules and polyester fabrics:

以上仅为本发明的具体实施例,但本发明的技术特征并不局限于此。任何以本发明为基础,为解决基本相同的技术问题,实现基本相同的技术效果,所作出地简单变化、等同替换或者修饰等,皆涵盖于本发明的保护范围之中。The above are only specific embodiments of the present invention, but the technical features of the present invention are not limited thereto. Any simple changes, equivalent replacements or modifications made based on the present invention in order to solve basically the same technical problems and achieve basically the same technical effects are all included in the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910814033.2ACN110791971A (en) | 2019-08-30 | 2019-08-30 | A coating finishing technology of intelligent temperature-regulating textiles based on phase-change microcapsules |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910814033.2ACN110791971A (en) | 2019-08-30 | 2019-08-30 | A coating finishing technology of intelligent temperature-regulating textiles based on phase-change microcapsules |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110791971Atrue CN110791971A (en) | 2020-02-14 |

Family

ID=69427182

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910814033.2APendingCN110791971A (en) | 2019-08-30 | 2019-08-30 | A coating finishing technology of intelligent temperature-regulating textiles based on phase-change microcapsules |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110791971A (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111945429A (en)* | 2020-08-14 | 2020-11-17 | 浙江中科微瑞新材料股份有限公司 | Method for preparing polyester textile with lasting temperature adjustment by adopting intelligent microparticles |

| CN111961445A (en)* | 2020-08-31 | 2020-11-20 | 湖南世东环保节能科技有限公司 | Microencapsulated composite phase-change material and production and application thereof |

| CN112522957A (en)* | 2020-12-01 | 2021-03-19 | 杭州英诺克新材料有限公司 | Capsule, fabric containing capsule, preparation method and application thereof |

| CN112949030A (en)* | 2021-01-27 | 2021-06-11 | 浙江理工大学 | Method for predicting equivalent thermal conductivity of woven fabric based on structural parameters |

| CN114561743A (en)* | 2021-12-13 | 2022-05-31 | 杭州诺邦无纺股份有限公司 | Preparation method of phase-change non-woven material |

| CN114775292A (en)* | 2022-03-25 | 2022-07-22 | 江南大学 | A kind of preparation method of down feather fiber with heat storage and temperature regulation function |

| CN116141781A (en)* | 2022-12-16 | 2023-05-23 | 中国第一汽车股份有限公司 | A phase-change temperature-adjusting ceiling and its production method |

| CN117166267A (en)* | 2023-09-05 | 2023-12-05 | 浙江帝宏家纺有限公司 | Preparation method of color-changing temperature-adjusting four-piece sleeve based on phase-change microcapsules |

| WO2024130549A1 (en)* | 2022-12-20 | 2024-06-27 | Dow Global Technologies Llc | Artificial leather with cool surface feature |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040011989A1 (en)* | 2002-07-08 | 2004-01-22 | China Textile Institute | Fabric coating composition with latent heat effect and a method for fabricating the same |

| CN101070679A (en)* | 2007-05-30 | 2007-11-14 | 天津工业大学 | Intelligent temperature-regulation fabric and preparing method |

| CN101503618A (en)* | 2009-03-09 | 2009-08-12 | 中国科学技术大学 | Silicon dioxide gel micro-encapsulated phase change energy storage material and preparation thereof |

| US20120056341A1 (en)* | 2009-03-12 | 2012-03-08 | Yissum Research Development Company Of The Hebrew University Of Jerusalem, Ltd. | Silica nanocapsules from nano-emulsions obtained by phase inversion |

| CN102720054A (en)* | 2012-03-31 | 2012-10-10 | 上海嘉乐股份有限公司 | Ultraviolet resistant cold-feeling finishing fabric and processing method, and application of silica coated dodecanol microcapsule to fabric |

| CN103451939A (en)* | 2013-09-11 | 2013-12-18 | 上海应用技术学院 | Double-layer aromatic phase change microcapsule textile finishing liquor as well as preparation method and application thereof |

| CN103898763A (en)* | 2013-08-19 | 2014-07-02 | 杭州新生印染有限公司 | Method for preparing seat cushion with temperature regulation function |

| CN104153203A (en)* | 2014-08-19 | 2014-11-19 | 盐城朝阳服饰辅料有限公司 | Intelligent temperature adjustment textile and making method thereof |

| CN104449590A (en)* | 2014-12-05 | 2015-03-25 | 中国工程物理研究院化工材料研究所 | Phase-change energy-storage material nanocapsule and preparation method thereof |

| CN106436356A (en)* | 2016-08-31 | 2017-02-22 | 西达(无锡)生物科技有限公司 | Environment-friendly emulsion-like textile size composition and preparation method and application thereof |

| KR20190004189A (en)* | 2017-07-03 | 2019-01-11 | 한경대학교 산학협력단 | The water repellant silica microcapsules and a method for their preparation |

- 2019

- 2019-08-30CNCN201910814033.2Apatent/CN110791971A/enactivePending

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040011989A1 (en)* | 2002-07-08 | 2004-01-22 | China Textile Institute | Fabric coating composition with latent heat effect and a method for fabricating the same |

| CN101070679A (en)* | 2007-05-30 | 2007-11-14 | 天津工业大学 | Intelligent temperature-regulation fabric and preparing method |

| CN101503618A (en)* | 2009-03-09 | 2009-08-12 | 中国科学技术大学 | Silicon dioxide gel micro-encapsulated phase change energy storage material and preparation thereof |

| US20120056341A1 (en)* | 2009-03-12 | 2012-03-08 | Yissum Research Development Company Of The Hebrew University Of Jerusalem, Ltd. | Silica nanocapsules from nano-emulsions obtained by phase inversion |

| CN102720054A (en)* | 2012-03-31 | 2012-10-10 | 上海嘉乐股份有限公司 | Ultraviolet resistant cold-feeling finishing fabric and processing method, and application of silica coated dodecanol microcapsule to fabric |

| CN103898763A (en)* | 2013-08-19 | 2014-07-02 | 杭州新生印染有限公司 | Method for preparing seat cushion with temperature regulation function |

| CN103451939A (en)* | 2013-09-11 | 2013-12-18 | 上海应用技术学院 | Double-layer aromatic phase change microcapsule textile finishing liquor as well as preparation method and application thereof |

| CN104153203A (en)* | 2014-08-19 | 2014-11-19 | 盐城朝阳服饰辅料有限公司 | Intelligent temperature adjustment textile and making method thereof |

| CN104449590A (en)* | 2014-12-05 | 2015-03-25 | 中国工程物理研究院化工材料研究所 | Phase-change energy-storage material nanocapsule and preparation method thereof |

| CN106436356A (en)* | 2016-08-31 | 2017-02-22 | 西达(无锡)生物科技有限公司 | Environment-friendly emulsion-like textile size composition and preparation method and application thereof |

| KR20190004189A (en)* | 2017-07-03 | 2019-01-11 | 한경대학교 산학협력단 | The water repellant silica microcapsules and a method for their preparation |

Non-Patent Citations (2)

| Title |

|---|

| 史汝琨: "《基于相变微胶囊涂层的智能调温织物的制备与性能研究》", 《中国优秀硕士论文全文数据库,工程科技I辑》* |

| 耿丽霞: "《正十二醇/二氧化硅微胶囊相变材料的制备及热物性研究》", 《中国优秀硕士论文全文数据库 工程科技I辑》* |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111945429A (en)* | 2020-08-14 | 2020-11-17 | 浙江中科微瑞新材料股份有限公司 | Method for preparing polyester textile with lasting temperature adjustment by adopting intelligent microparticles |

| CN111961445A (en)* | 2020-08-31 | 2020-11-20 | 湖南世东环保节能科技有限公司 | Microencapsulated composite phase-change material and production and application thereof |

| CN112522957A (en)* | 2020-12-01 | 2021-03-19 | 杭州英诺克新材料有限公司 | Capsule, fabric containing capsule, preparation method and application thereof |

| CN112949030A (en)* | 2021-01-27 | 2021-06-11 | 浙江理工大学 | Method for predicting equivalent thermal conductivity of woven fabric based on structural parameters |

| CN112949030B (en)* | 2021-01-27 | 2024-02-13 | 浙江理工大学 | A prediction method for equivalent thermal conductivity of woven fabrics based on structural parameters |

| CN114561743A (en)* | 2021-12-13 | 2022-05-31 | 杭州诺邦无纺股份有限公司 | Preparation method of phase-change non-woven material |

| CN114775292A (en)* | 2022-03-25 | 2022-07-22 | 江南大学 | A kind of preparation method of down feather fiber with heat storage and temperature regulation function |

| CN114775292B (en)* | 2022-03-25 | 2024-02-09 | 江南大学 | A method for preparing down and feather fiber with heat storage and temperature regulation function |

| CN116141781A (en)* | 2022-12-16 | 2023-05-23 | 中国第一汽车股份有限公司 | A phase-change temperature-adjusting ceiling and its production method |

| CN116141781B (en)* | 2022-12-16 | 2025-08-01 | 中国第一汽车股份有限公司 | Production method of phase-change temperature-regulating ceiling |

| WO2024130549A1 (en)* | 2022-12-20 | 2024-06-27 | Dow Global Technologies Llc | Artificial leather with cool surface feature |

| CN117166267A (en)* | 2023-09-05 | 2023-12-05 | 浙江帝宏家纺有限公司 | Preparation method of color-changing temperature-adjusting four-piece sleeve based on phase-change microcapsules |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110791971A (en) | A coating finishing technology of intelligent temperature-regulating textiles based on phase-change microcapsules | |

| CN105797659B (en) | A kind of preparation method of silica chitosan bivalve heat accumulation microcapsules | |

| CN102002343B (en) | Heat-storage and heat-preservation microcapsules and preparation method and application thereof | |

| CN104153203B (en) | A kind of intelligent temperature-regulation fabric and preparation method thereof | |

| CN100489187C (en) | Intelligent temperature-regulation fabric and preparing method | |

| CN101250245B (en) | Polymer phase-change microsphere and preparation method thereof | |

| CN107954429A (en) | Silicon dioxide hollow microsphere and preparation method thereof and the application in insulating moulding coating | |

| CN103937461A (en) | Phase change micro-capsule for clothing thermoregulation as well as preparation method and application thereof | |

| CN102311720A (en) | Phase-change energy storage capsule and preparation method thereof | |

| CN102732225A (en) | Thermal storage and insulation microcapsule for building material and preparation method thereof | |

| CN104861935A (en) | Preparation method of phase change microcapsule | |

| CN111910279B (en) | Phase-change fiber with temperature adjusting function and preparation method and application thereof | |

| CN111944495B (en) | Preparation method of hydrated inorganic salt-expanded vermiculite-paraffin-PAM composite phase change energy storage material | |

| CN108218273B (en) | Micro-nano latent heat storage capsule suitable for cement-based materials and preparation method thereof | |

| CN108251067B (en) | Phase-change fluid based on graphene oxide and titanium dioxide coated paraffin and preparation method thereof | |

| CN104804711B (en) | Embedded thermal conductivity enhanced phase change energy storage microcapsule and preparation method thereof | |

| CN114058337A (en) | A ternary composite mineral microsphere-based phase change heat storage material and its preparation method and application | |

| CN112940690B (en) | A kind of phase change energy storage material with pod structure and preparation method and application thereof | |

| CN112226208A (en) | Low-melting-point metal phase change microcapsule and preparation method and application thereof | |

| CN110479194A (en) | A kind of phase-change microcapsule and preparation method thereof having both strong mechanical performance and high thermal conductivity | |

| CN111978037B (en) | Environment-friendly light full-decoration ground heating mortar | |

| CN113355055A (en) | Microcapsule with high phase change enthalpy and preparation method thereof | |

| CN110252220B (en) | Preparation method of temperature- and humidity-adjustable microcapsules based on graphene oxide | |

| CN110343511A (en) | A kind of nano-zirconium carbide modified paraffin phase-change microcapsule and preparation method thereof | |

| CN109989266A (en) | A kind of heat-accumulation temperature-adjustment top finish liquid and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200214 |