CN110786725A - Anti-dry-burning electric heating pot, anti-dry-burning temperature measurement method of electric heating pot and anti-dry-burning alarm - Google Patents

Anti-dry-burning electric heating pot, anti-dry-burning temperature measurement method of electric heating pot and anti-dry-burning alarmDownload PDFInfo

- Publication number

- CN110786725A CN110786725ACN201911252511.1ACN201911252511ACN110786725ACN 110786725 ACN110786725 ACN 110786725ACN 201911252511 ACN201911252511 ACN 201911252511ACN 110786725 ACN110786725 ACN 110786725A

- Authority

- CN

- China

- Prior art keywords

- steam

- heating

- dry

- burning

- pot

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000005485electric heatingMethods0.000titleclaimsabstractdescription22

- 238000000034methodMethods0.000titleclaimsabstractdescription16

- 238000009529body temperature measurementMethods0.000titledescription2

- 238000001514detection methodMethods0.000claimsabstractdescription26

- 238000012544monitoring processMethods0.000claimsabstractdescription9

- 238000010438heat treatmentMethods0.000claimsdescription50

- 241000209094OryzaSpecies0.000claimsdescription10

- 235000007164Oryza sativaNutrition0.000claimsdescription10

- 235000009566riceNutrition0.000claimsdescription10

- 230000017525heat dissipationEffects0.000claimsdescription3

- 238000010411cookingMethods0.000claimsdescription2

- 238000011144upstream manufacturingMethods0.000claimsdescription2

- 239000000919ceramicSubstances0.000abstractdescription4

- 239000011521glassSubstances0.000abstractdescription4

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description9

- 230000007423decreaseEffects0.000description8

- 238000010586diagramMethods0.000description6

- 239000000523sampleSubstances0.000description4

- 238000012360testing methodMethods0.000description3

- 230000006698inductionEffects0.000description2

- 230000005291magnetic effectEffects0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 230000007547defectEffects0.000description1

- 238000001035dryingMethods0.000description1

- 230000005294ferromagnetic effectEffects0.000description1

- 235000013305foodNutrition0.000description1

- 239000002184metalSubstances0.000description1

- 238000012806monitoring deviceMethods0.000description1

- 239000000126substanceSubstances0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J27/00—Cooking-vessels

- A47J27/002—Construction of cooking-vessels; Methods or processes of manufacturing specially adapted for cooking-vessels

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J36/00—Parts, details or accessories of cooking-vessels

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Manufacturing & Machinery (AREA)

- Cookers (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种防干烧电加热锅、电加热锅防干烧测温方法及防干烧报警器。The invention relates to an anti-dry-burning electric heating pot, an anti-dry-burning temperature measuring method for the electric heating pot and an anti-dry-burning alarm.

背景技术Background technique

电加热锅具中,为了防止锅具干烧,均增加了自动控温功能。如用来蒸米饭的电饭煲,则是在锅底附近增加热传感器,当锅内有水时,锅底温度一般在100-104摄氏度左右;而当锅底的没有水时,温度会急剧升高,当超过预定温度时,一般为105摄氏度时则停止加热。In electric heating cookware, in order to prevent the cookware from drying out, an automatic temperature control function is added. For example, a rice cooker used to steam rice adds a heat sensor near the bottom of the pot. When there is water in the pot, the temperature of the bottom of the pot is generally around 100-104 degrees Celsius; and when there is no water at the bottom of the pot, the temperature will rise sharply. , when it exceeds the predetermined temperature, generally 105 degrees Celsius, the heating is stopped.

但是也有一些锅具无法进行锅底测温或锅底测温不准的情况,如电加热的玻璃锅、或陶瓷锅,其锅体本身玻璃或陶瓷等制成,其锅体散热较慢,从而导致锅底测温不准,容易糊锅。However, there are also some cases where the temperature of the bottom of the pot cannot be measured or the temperature of the bottom of the pot is inaccurate, such as electrically heated glass pots or ceramic pots, the pot body itself is made of glass or ceramics, and the heat dissipation of the pot body is slow. As a result, the temperature measurement of the bottom of the pot is not accurate, and it is easy to burn the pot.

发明内容SUMMARY OF THE INVENTION

为克服上述缺陷,本发明提供一种防干烧的锅及方法、防干烧报警器。In order to overcome the above-mentioned defects, the present invention provides a pot and method for preventing dry burning, and an alarm for preventing dry burning.

为达到上述目的,本发明的防干烧电加热锅,在所述的锅体内设置有蒸汽导流通道,在所述的蒸汽导流通道内或导流通道出口处设置有蒸汽参数检测传感器,若加热过程中蒸汽参数检测传感器当监测的蒸汽参数低于预定值时,输出控制信号。In order to achieve the above purpose, the anti-dry-burning electric heating pot of the present invention is provided with a steam diversion channel in the pot body, and a steam parameter detection sensor is arranged in the steam diversion channel or at the outlet of the diversion channel, If the steam parameter detection sensor during the heating process outputs a control signal when the monitored steam parameter is lower than a predetermined value.

为达到上述目的,本发明的防干烧电加热锅,在所述的锅体内设置有蒸汽导流通道,在所述的蒸汽导流通道内沿导流通道长度方向设置有两个以上的温度传感器;In order to achieve the above-mentioned purpose, the anti-dry electric heating pot of the present invention is provided with a steam guiding channel in the pot body, and two or more temperatures are set in the steam guiding channel along the length direction of the guiding channel. sensor;

当加热过程中蒸汽导流通道内下游温度传感器检测到的温度低于上游温度传感器检测到的温度超过预定时间时,输出控制信号。When the temperature detected by the downstream temperature sensor in the steam guiding channel is lower than the temperature detected by the upstream temperature sensor for more than a predetermined time during the heating process, a control signal is output.

进一步的,在所述蒸汽导流通道上设置散热通孔。Further, heat dissipation through holes are arranged on the steam guide channel.

进一步的,所述的蒸汽参数检测传感器为蒸汽温度传感器、蒸汽流量传感器和/或蒸汽电阻检测传感器。Further, the steam parameter detection sensor is a steam temperature sensor, a steam flow sensor and/or a steam resistance detection sensor.

进一步的,所述的蒸汽参数检测传感器偏离蒸汽通道或蒸汽出口预定位置。Further, the steam parameter detection sensor deviates from the predetermined position of the steam channel or the steam outlet.

为达到上述目的,本发明的电加热锅防干烧测温方法,实时监测加热过程中的蒸汽参数,当监测的蒸汽参数低于预定值时,输出控制信号。In order to achieve the above purpose, the method for measuring the temperature of an electric heating pan for preventing dry burning in the present invention monitors the steam parameters in the heating process in real time, and outputs a control signal when the monitored steam parameters are lower than a predetermined value.

进一步的,所述的蒸汽参数为蒸汽温度传感器、蒸汽流量传感器和/或蒸汽电阻检测传感器。Further, the steam parameter is a steam temperature sensor, a steam flow sensor and/or a steam resistance detection sensor.

为达到上述目的,本发明的电加热锅焖米饭的方法,所述的方法至少包括下述步骤:1)用第一加热功率或第一加热程序加热预定时间;In order to achieve the above object, the method for cooking rice in an electric heating pot of the present invention at least comprises the following steps: 1) heating for a predetermined time with a first heating power or a first heating program;

2)用第二加热功率或第二加热程序加热,并实时加热过程中的监测蒸汽参数,当监测的蒸汽参数高于第一预定值后,用第三加热功率或第三加热程序持续加热;2) Heating with the second heating power or the second heating program, and monitoring the steam parameters in the real-time heating process, when the monitored steam parameters are higher than the first predetermined value, continue heating with the third heating power or the third heating program;

3)实时监测加热过程中的蒸汽参数,当监测的蒸汽参数低于预定值时,停止加热或执行第四加热程序或输出控制信号。3) Real-time monitoring of steam parameters in the heating process, when the monitored steam parameters are lower than a predetermined value, stop heating or execute a fourth heating program or output a control signal.

进一步的,所述的第一加热功率小于第二加热功率;所述的第四加热程序为用第四加热功率持续加热预定时间。Further, the first heating power is smaller than the second heating power; and the fourth heating procedure is to continue heating with the fourth heating power for a predetermined time.

为达到上述目的,本发明的防干烧报警器,具有一壳体,在所述的壳体内设置有蒸汽导流通道;在所述的蒸汽导流道内或蒸汽导流通道出口处设置有蒸汽参数检测传感器,若蒸汽参数检测传感器当监测的蒸汽参数低于预定值时,输出报警信号。In order to achieve the above purpose, the anti-dry-burning alarm of the present invention has a casing, and a steam guiding channel is arranged in the casing; a steam guiding channel is arranged in the steam guiding channel or at the outlet of the steam guiding channel. A parameter detection sensor, if the steam parameter detection sensor monitors a steam parameter lower than a predetermined value, it outputs an alarm signal.

本发明用蒸汽参数做为监测数据来判别锅具是否处于干烧状态,从而实现了对玻璃或陶瓷等制成锅体的温度的精确判断。The invention uses steam parameters as monitoring data to determine whether the pot is in a dry burning state, thereby realizing accurate judgment of the temperature of the pot body made of glass or ceramics.

附图说明Description of drawings

图1为本发明实施例1的结构示意图。FIG. 1 is a schematic structural diagram of

图2为本发明实施例2的结构示意图。FIG. 2 is a schematic structural diagram of Embodiment 2 of the present invention.

图3为本发明实施例3的结构示意图。FIG. 3 is a schematic structural diagram of Embodiment 3 of the present invention.

图4为本发明实施例4的结构示意图。FIG. 4 is a schematic structural diagram of Embodiment 4 of the present invention.

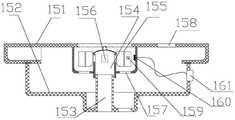

图5为图4的局部放大示意图。FIG. 5 is a partial enlarged schematic view of FIG. 4 .

图6为本发明实施例5的结构示意图。FIG. 6 is a schematic structural diagram of Embodiment 5 of the present invention.

图7为本发明测试结果图。Fig. 7 is the test result graph of the present invention.

图8为本发明实施例6的结构示意图。FIG. 8 is a schematic structural diagram of Embodiment 6 of the present invention.

具体实施方式Detailed ways

下面结合附图和实施例对本发明做进一步的说明。The present invention will be further described below with reference to the accompanying drawings and embodiments.

本发明的实现是依据对蒸汽的监测实现的。The realization of the present invention is realized according to the monitoring of steam.

因此本发明中的蒸汽参数检测传感器是一个概念,即是对通过蒸汽参数能进行检测的传感器的总概念,其包括但不限于蒸汽温度传感器或蒸汽流量传感器。本发明现以蒸汽温度以及蒸汽的流量对本发明进行进一步的说明。Therefore, the steam parameter detection sensor in the present invention is a concept, that is, a general concept of sensors that can detect steam parameters, including but not limited to a steam temperature sensor or a steam flow sensor. The present invention will now be further described with reference to the steam temperature and the flow rate of the steam.

本发明中的锅具包括但不限于是电饭煲。为了说明方便,下述内容以电饭煲为例进行说明。The cookware in the present invention includes, but is not limited to, a rice cooker. For the convenience of description, the following content will be described by taking a rice cooker as an example.

实施例1Example 1

本实施例为以蒸汽温度进行检测,如图1所示,在锅体1上设置有和锅盖11,在锅盖11上设置有蒸汽导流通道12(蒸汽导流通道也可以根据需要设置在锅体内其它位置),在所述的蒸汽导流通道内设置有一个蒸汽温度传感器13,当蒸汽温度传感器当监测的蒸汽温度低于预定值时,输出控制信号。In this embodiment, the temperature of the steam is detected. As shown in FIG. 1 , a

本实施例的原理是:当锅体内的水烧开后,在保持加热的状态下,蒸汽会始终保持一定的量,这时,蒸汽导流通道12蒸汽温度传感器也就能检测出蒸汽的温度。而随着锅体的持续的加热,当锅体内的水逐渐减少时,蒸汽的量会越来越小,而导致蒸汽导流通道12蒸汽温度传感器检测的温度也会逐渐降低。当低于预定值时,即可以判定锅已处于干烧状态,停止加热即可。The principle of this embodiment is: when the water in the pot is boiled, the steam will always keep a certain amount in the heating state, and at this time, the steam temperature sensor of the

图7为测试结果图,其是在导流通道连续设置5个温度传感器,每两个相距10毫米进行测试的结果。从图中可以看出,当锅具处于干烧状态时,5个温度传感器所检测的温度均呈现断崖式下跌。由此可证明,本实施例的方法是有效的。FIG. 7 is a test result graph, which is the result of testing five temperature sensors continuously arranged in the diversion channel, and each two is 10 mm apart. It can be seen from the figure that when the pot is in a dry burning state, the temperatures detected by the five temperature sensors all show a cliff-like drop. Therefore, it can be proved that the method of this embodiment is effective.

实施例2Example 2

本实施例为以蒸汽温度进行检测,如图2所示,在锅体1上设置有和锅盖11,在锅盖11上设置有蒸汽导流通道12,在所述的蒸汽导流通道内设置有三个蒸汽温度传感器13,这样当蒸汽导流通道内最后一个蒸汽温度传感器检测不到蒸汽、而蒸汽导流通道内前两个可以检测到蒸汽温度时,输出控制信号。或者,当蒸汽导流通道内后两个之一蒸汽温度传感器检测不到蒸汽,而蒸汽导流通道内第一个可以检测到蒸汽温度时,输出控制信号。In this embodiment, the temperature is detected by steam. As shown in FIG. 2 , a

本实施例的原理与实施例1类似:当锅体内的水烧开后,在保持加热的状态下,蒸汽会始终保持一定的量,这时,蒸汽导流通道12中的三个蒸汽温度传感器均能检测出蒸汽的温度。而随着锅体的持续的加热,当锅体内的水逐渐减少时,蒸汽的量会越来越小,而导致蒸汽导流通道12蒸汽温度传感器检测的温度也会逐渐降低。这样,当前边的一个或两个能检测出蒸汽温度而后边的一个或两个检测不出蒸汽温度时,则可以判断锅具已处于干烧状态,停止加热即可。The principle of this embodiment is similar to that of Embodiment 1: when the water in the pot is boiled, the steam will always maintain a certain amount in a heated state. At this time, the three steam temperature sensors in the

这种结构,可以防止锅具内的食物溢出而导致蒸汽导流通道堵塞而造成的误判。This structure can prevent misjudgment caused by the clogging of the steam guiding channel caused by the overflow of food in the pot.

当温度传感器为多个时,其间距可以按从小到达逐渐增加。例如,第一个与第二传感器的间距为10毫米;第二个与第三传感器的间距为20毫米;第三个与第四传感器的间距为40毫米;这样,可以防止较近的两个传感器检测的值较为接近,而导致误判。When there are multiple temperature sensors, the distance between them can be gradually increased from small to small. For example, the distance between the first and the second sensor is 10mm; the distance between the second and the third sensor is 20mm; the distance between the third and the fourth sensor is 40mm; The value detected by the sensor is relatively close, resulting in a misjudgment.

实施例3Example 3

本实施例为以蒸汽电阻进行检测,如图3所示,在锅体1上设置有和锅盖11,在锅盖11上设置有蒸汽导流通道12,在所述的蒸汽导流通道内设置有蒸汽电阻传感器14—其为间隔预定距离设置的两个金属探针。两个探针的间距为0.1-2毫米。In this embodiment, steam resistance is used for detection. As shown in FIG. 3 , a

本实施例的原理与实施例1类似:当锅体内的水烧开后,在保持加热的状态下,蒸汽会始终保持一定的量,这时,蒸汽导流通道12中湿度足够大,这时两个探针之间的电阻会比较低。而随着锅体的持续的加热,当锅体内的水逐渐减少时,蒸汽的量会越来越小,这时两个探针之间的电阻会越来越高,当电阻高到一定值时则可以判断锅具已处于干烧状态,停止加热即可。The principle of this embodiment is similar to that of Embodiment 1: when the water in the pot is boiled, the steam will always maintain a certain amount in a heated state. At this time, the humidity in the

实施例4Example 4

本实施例为对蒸汽流量的检测This embodiment is for the detection of steam flow

本实施例为以蒸汽温度进行检测,如图4和图5所示,在锅盖11上设置有蒸汽导流通道12,在所述的蒸汽导流通道内设置有一个蒸汽流量传感器15,若蒸汽流量当监测的蒸汽流量低于预定值时,输出控制信号。In this embodiment, the temperature of the steam is detected. As shown in FIG. 4 and FIG. 5 , a

如图5所示,蒸汽流量传感器15设置有锅盖上方,与蒸汽导流通道12对应设置。蒸汽流量传感器15包括上盖151和下盖152,上、下盖相互扣合,在下盖向上设置有下导流通道153;在上盖上对应下导流通道153设置有叶轮室;叶轮室向下设置有上导流通道154;当上下盖扣合后,下导流通道153、上导流通道154两个导流通道连通。在上导流通道154上段设置有导流通孔156,使蒸汽从导流通道12通过下导流通道15、上导流通道154,然后从导流通孔156中喷出;在上导流通道154旋转设置有一个叶轮155,叶轮的叶片与导流通孔156对应设置。在叶轮室下部设置有出气孔157以及在上盖一侧设置有出气孔158;As shown in FIG. 5 , the

这样,当有蒸汽时,叶轮在蒸汽的作用下,会旋转,而当蒸汽减少时,叶轮的转速就会下降,这样只需通过转速监测装置即可以对其进行判定。即当转速降至预定值时则可以判断锅具已处于干烧状态,停止加热即可。In this way, when there is steam, the impeller will rotate under the action of the steam, and when the steam decreases, the speed of the impeller will decrease, so that it can be judged only by the speed monitoring device. That is, when the rotation speed drops to a predetermined value, it can be judged that the cookware is in a dry-burning state, and the heating can be stopped.

转速检测装置,可以根据需要选择。图5中,是在叶轮155的其中一个叶片上设置铁磁物质159;而在其一侧设置磁感应检测元件160,如霍尔元件即可,这样叶轮每旋转一圈,就会被磁感应检测元件检测到一次,这样,记录旋转一圈所需的时间即可计算其转速。而比较每次的转速,即可以得知现在锅具的蒸汽量。在下盖一侧设置有触点161,用于与锅盖上对应位置的触点接触,以传递转速信号。The rotational speed detection device can be selected according to the needs. In Fig. 5, a

实施例5Example 5

对于实施例4的变形,还可以制备专门的防干烧检测装置,如图6所示。在锅盖11上设置有蒸汽导流通道12,在蒸汽导流通道12的出口处设置有防干烧报警装置,防干烧报警装置包括一底座,底座可以放在锅盖上,底座上设置有竖起设置有旋转叶轮;这样,蒸汽导流通道12上的叶轮在蒸汽作用下会旋转,而在底座内设置有转速检测装置。与实施例类似的,只需监测叶轮的转速即可防止干烧。For the modification of Example 4, a special anti-dry-burn detection device can also be prepared, as shown in FIG. 6 . A

实施例6Example 6

本实施例为实施例1的变形。如图8所示,在锅体1上设置有和锅盖11,在锅盖11上设置有蒸汽导流通道12,在所述的蒸汽导流通道内设置有一个蒸汽温度传感器13,与实施例1不同的是,所述的当蒸汽温度传感器设置在蒸汽出口一侧0.5-5厘米左右。This embodiment is a modification of

这样,当蒸汽量较足时,蒸汽温度传感器13虽然偏离蒸汽一段距离,但也能感受到其温度,并不影响其对温度的检测。而当锅内的水快要即将烧完时,其蒸汽量会明显下降,由于蒸汽温度传感器13偏离蒸汽一段距离,因此其会较早的检测到温度的降低,以便较早的对“烧干锅”现象进行及时干预。In this way, when the amount of steam is sufficient, although the

实施例7Example 7

本实施例电加热锅焖米饭的方法,所述的方法至少包括下述步骤:The method for stewing rice in an electric heating pot of the present embodiment includes at least the following steps:

1)用第一加热功率或第一加热程序加热预定时间;一般是用较小的功率对锅内的米预热,以使米充分吸收水分;1) Use the first heating power or the first heating program to heat the predetermined time; generally, the rice in the pot is preheated with a smaller power, so that the rice can fully absorb the moisture;

2)用第二加热功率或第二加热程序加热,一般是用中功率或大功率进行加热;实时加热过程中的监测蒸汽参数,当监测的蒸汽参数高于第一预定值后,用第三加热功率或第三加热程序持续加热,一般是大功率或中功率进行加热;还可以根据需要,第二加热功率和第三加热功率是同样的功率。2) Use the second heating power or the second heating program to heat, generally use medium power or high power for heating; monitor the steam parameters in the real-time heating process, when the monitored steam parameters are higher than the first predetermined value, use the third The heating power or the third heating program continues to heat, generally high-power or medium-power heating; the second heating power and the third heating power can also be the same power as required.

3)实时监测加热过程中的蒸汽参数,当监测的蒸汽参数低于预定值时,停止加热或执行第四加热程序或输出控制信号。3) Real-time monitoring of steam parameters in the heating process, when the monitored steam parameters are lower than a predetermined value, stop heating or execute a fourth heating program or output a control signal.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911252511.1ACN110786725A (en) | 2019-12-09 | 2019-12-09 | Anti-dry-burning electric heating pot, anti-dry-burning temperature measurement method of electric heating pot and anti-dry-burning alarm |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911252511.1ACN110786725A (en) | 2019-12-09 | 2019-12-09 | Anti-dry-burning electric heating pot, anti-dry-burning temperature measurement method of electric heating pot and anti-dry-burning alarm |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110786725Atrue CN110786725A (en) | 2020-02-14 |

Family

ID=69447911

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911252511.1APendingCN110786725A (en) | 2019-12-09 | 2019-12-09 | Anti-dry-burning electric heating pot, anti-dry-burning temperature measurement method of electric heating pot and anti-dry-burning alarm |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110786725A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111816131A (en)* | 2020-06-05 | 2020-10-23 | 嘉兴行适安车联网信息科技有限公司 | Method for solving slow refreshing of display screen during low-temperature starting |

| CN115844194A (en)* | 2022-11-21 | 2023-03-28 | 纯米科技(上海)股份有限公司 | Cooking appliance, cooking appliance control method and device |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007151648A (en)* | 2005-12-01 | 2007-06-21 | Matsushita Electric Ind Co Ltd | rice cooker |

| CN201123713Y (en)* | 2007-12-06 | 2008-10-01 | 广州乐儿多家用电器有限公司 | Electric heating kettle for burning water and preserving heat |

| EP2154435A2 (en)* | 2008-08-06 | 2010-02-17 | Rational AG | Cooking device and method for monitoring a cooking process |

| JP2010193946A (en)* | 2009-02-23 | 2010-09-09 | Sanyo Electric Co Ltd | Pressure rice cooker |

| CN201840307U (en)* | 2010-08-26 | 2011-05-25 | 华磁科技(宁波)有限公司 | High-power cooking machine |

| CN106308479A (en)* | 2015-07-08 | 2017-01-11 | 浙江苏泊尔家电制造有限公司 | Rice cooker and method of using the rice cooker to keep warm |

| CN107692806A (en)* | 2017-10-25 | 2018-02-16 | 谢勇 | Electric-heating cooking appliance with wireless steam detection means |

| CN212591562U (en)* | 2019-12-09 | 2021-02-26 | 佛山市顺德区智烹科技有限公司 | Dry-burning-prevention electric heating pot and dry-burning-prevention alarm |

- 2019

- 2019-12-09CNCN201911252511.1Apatent/CN110786725A/enactivePending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007151648A (en)* | 2005-12-01 | 2007-06-21 | Matsushita Electric Ind Co Ltd | rice cooker |

| CN201123713Y (en)* | 2007-12-06 | 2008-10-01 | 广州乐儿多家用电器有限公司 | Electric heating kettle for burning water and preserving heat |

| EP2154435A2 (en)* | 2008-08-06 | 2010-02-17 | Rational AG | Cooking device and method for monitoring a cooking process |

| JP2010193946A (en)* | 2009-02-23 | 2010-09-09 | Sanyo Electric Co Ltd | Pressure rice cooker |

| CN201840307U (en)* | 2010-08-26 | 2011-05-25 | 华磁科技(宁波)有限公司 | High-power cooking machine |

| CN106308479A (en)* | 2015-07-08 | 2017-01-11 | 浙江苏泊尔家电制造有限公司 | Rice cooker and method of using the rice cooker to keep warm |

| CN108158393A (en)* | 2015-07-08 | 2018-06-15 | 浙江苏泊尔家电制造有限公司 | Cooker and the method kept the temperature using the cooker |

| CN107692806A (en)* | 2017-10-25 | 2018-02-16 | 谢勇 | Electric-heating cooking appliance with wireless steam detection means |

| CN212591562U (en)* | 2019-12-09 | 2021-02-26 | 佛山市顺德区智烹科技有限公司 | Dry-burning-prevention electric heating pot and dry-burning-prevention alarm |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111816131A (en)* | 2020-06-05 | 2020-10-23 | 嘉兴行适安车联网信息科技有限公司 | Method for solving slow refreshing of display screen during low-temperature starting |

| CN115844194A (en)* | 2022-11-21 | 2023-03-28 | 纯米科技(上海)股份有限公司 | Cooking appliance, cooking appliance control method and device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10390658B2 (en) | Oil level detection system for deep fat fryer | |

| US10278532B2 (en) | Household appliance and electrical heating element for use in a household appliance | |

| US10731869B2 (en) | Automatic oven with humidity sensor | |

| CN107242781A (en) | Dry heating preventing method for electric kettle and electric kettle | |

| CN110786725A (en) | Anti-dry-burning electric heating pot, anti-dry-burning temperature measurement method of electric heating pot and anti-dry-burning alarm | |

| CN106289431A (en) | Identify method and the electricity cooking pot of meter Shui Liang in electricity cooking pot cooking process | |

| CN111449497A (en) | Steam cooking equipment, scale detection method and device therefor, and storage medium | |

| CN102656310A (en) | Method of controlling the drying cycle of a laundry dryer and a machine implementing the method | |

| US10151061B1 (en) | Dryer appliances and methods of operation | |

| CN212591562U (en) | Dry-burning-prevention electric heating pot and dry-burning-prevention alarm | |

| CN105042550A (en) | Bottom type steam generation device and control method thereof | |

| CN105042549B (en) | Bottom-mounted steam generating device and control method for bottom-mounted steam generating device | |

| JP3317017B2 (en) | Temperature detector for induction cooker | |

| CN113069013A (en) | Control method of cooking apparatus, and readable storage medium | |

| CN112120527B (en) | Control method of cooking appliance | |

| CN209285124U (en) | A kind of temperature adjusting steam feedway | |

| CN215723127U (en) | Steam generating device of steam box and steam box | |

| CN208876202U (en) | An anti-dry burning temperature measuring contact device | |

| CN100595488C (en) | Electric heating cooker for accurate temperature measurement and method for accurate temperature measurement of electric heating cooker | |

| CN112197307B (en) | Stove and dry burning prevention control device and method | |

| CN114375076A (en) | Thick-film heater, cooking device having the same, and control method of thick-film heater | |

| WO2007077170A2 (en) | A household appliance | |

| CN113729501B (en) | Steam box control method and steam box | |

| CN207936148U (en) | The panel of electromagnetic cooking appliance and electromagnetic cooking appliance with it | |

| CN111631612B (en) | A control method for abnormal humidity detection of cooking equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |