CN110749297A - A mobile station limit measuring instrument and measuring method - Google Patents

A mobile station limit measuring instrument and measuring methodDownload PDFInfo

- Publication number

- CN110749297A CN110749297ACN201911213437.2ACN201911213437ACN110749297ACN 110749297 ACN110749297 ACN 110749297ACN 201911213437 ACN201911213437 ACN 201911213437ACN 110749297 ACN110749297 ACN 110749297A

- Authority

- CN

- China

- Prior art keywords

- sensor

- platform

- limit

- host

- measuring instrument

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G01B21/02—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring length, width, or thickness

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/14—Measuring arrangements characterised by the use of optical techniques for measuring distance or clearance between spaced objects or spaced apertures

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/24—Measuring arrangements characterised by the use of optical techniques for measuring contours or curvatures

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G01B21/16—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring distance of clearance between spaced objects

- G—PHYSICS

- G01—MEASURING; TESTING

- G01C—MEASURING DISTANCES, LEVELS OR BEARINGS; SURVEYING; NAVIGATION; GYROSCOPIC INSTRUMENTS; PHOTOGRAMMETRY OR VIDEOGRAMMETRY

- G01C22/00—Measuring distance traversed on the ground by vehicles, persons, animals or other moving solid bodies, e.g. using odometers, using pedometers

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Radar, Positioning & Navigation (AREA)

- Remote Sensing (AREA)

- Length Measuring Devices With Unspecified Measuring Means (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及自动测量技术领域,特别是涉及一种移动式站台限界测量仪和测量方法。The invention relates to the technical field of automatic measurement, in particular to a mobile station limit measurement instrument and a measurement method.

背景技术Background technique

随着近些年铁路的快速发展,列车运行速度越来越快,营运里程不断增加,因此对运输安全的要求也就越来越高。With the rapid development of railways in recent years, the trains are running faster and faster, and the operating mileage is increasing, so the requirements for transportation safety are getting higher and higher.

站台作为一个旅客上下车的场所,列车停稳后车辆与站台之间会有一个间隙,间隙过大时不能保证旅客安全、方便的进出车辆,间隙过小时则易造成列车剐蹭,因此站台边缘相对轨道的横向及垂向尺寸必须满足铁路站台限界的要求。The platform is a place for passengers to get on and off the train. After the train stops, there will be a gap between the vehicle and the platform. If the gap is too large, it cannot ensure the safety and convenience of passengers entering and exiting the vehicle. If the gap is too small, it is easy to cause the train to scratch. The lateral and vertical dimensions of the track must meet the requirements of railway platform boundaries.

随着线路的长期运营,受到多种因素影响,站台相对于线路的位置关系会发生变化,一旦站台某些部位侵入限界之内,有可能发生列车剐蹭事故,给铁路安全运营带来不良影响。按照站台限界管理要求,各房建部门要对管内站台限界实施动态管理,定期检测,全面、及时掌握站台限界的动态变化情况。目前铁路房建部门多采用手持工具进行测量,测量效率低,只能在个别断面进行定点测量,受人为因素的影响较大,检测精度低,耗费时间长、需要人力多。With the long-term operation of the line, affected by various factors, the positional relationship of the platform relative to the line will change. Once some parts of the platform intrude into the limit, train scratching accidents may occur, which will bring adverse effects on the safe operation of the railway. According to the requirements for the management of platform boundaries, each housing construction department shall implement dynamic management of the platform boundaries within the management, conduct regular inspections, and comprehensively and timely grasp the dynamic changes of the platform boundaries. At present, railway housing construction departments mostly use hand-held tools for measurement, and the measurement efficiency is low. Only fixed-point measurement can be carried out on individual sections. It is greatly affected by human factors, and the detection accuracy is low. It takes a long time and requires a lot of manpower.

因此需要研制一种移动式站台限界测量仪,对站台限界进行快速、连续检测。Therefore, it is necessary to develop a mobile platform limit measuring instrument, which can quickly and continuously detect the platform limit.

发明内容SUMMARY OF THE INVENTION

基于背景技术中的技术问题,本发明提出了一种移动式站台限界测量仪和测量方法,以解决现有技术中存在的至少一个技术问题。Based on the technical problems in the background art, the present invention proposes a mobile station limit measuring instrument and a measuring method to solve at least one technical problem existing in the prior art.

本发明的一个方面提出了一种移动式站台限界测量仪,该测量仪包括传感器定位装置、检测框架、第一传感器、第二传感器、倾角仪、编码器、电源和主机;其中,One aspect of the present invention provides a mobile platform limit measuring instrument, which includes a sensor positioning device, a detection frame, a first sensor, a second sensor, an inclinometer, an encoder, a power source and a host; wherein,

所述传感器定位装置安装于检测框架上,所述检测框架的两端底部设有走行轮,所述走行轮沿轨道滚动;The sensor positioning device is installed on the detection frame, and the bottoms of both ends of the detection frame are provided with running wheels, and the running wheels roll along the track;

所述第一传感器、第二传感器、倾角仪和编码器分别与所述主机连接;所述第一传感器、第二传感器、倾角仪、编码器和主机分别与电源连接;The first sensor, the second sensor, the inclinometer and the encoder are respectively connected with the host; the first sensor, the second sensor, the inclinometer, the encoder and the host are respectively connected with the power supply;

所述第一传感器安装于该传感器定位装置上并将获取的站台断面数据传输给主机,所述第二传感器安装于检测框架上并将所测得的位移数据传输给主机;The first sensor is installed on the sensor positioning device and transmits the acquired platform section data to the host computer; the second sensor is mounted on the detection frame and transmits the measured displacement data to the host computer;

所述倾角仪安装于检测框架内,用于测量线路的超高数值;所述编码器安装于所述走行轮的轴头上,该编码器向主机发送脉冲信号,主机根据该脉冲信号数量及走行轮的轮径计算获取里程定位信息。The inclinometer is installed in the detection frame and is used to measure the ultra-high value of the line; the encoder is installed on the shaft head of the traveling wheel, and the encoder sends a pulse signal to the host. The wheel diameter of the running wheel is calculated to obtain the mileage positioning information.

进一步的,所述第一传感器为二维断面测量传感器。Further, the first sensor is a two-dimensional cross-section measurement sensor.

进一步的,所述第二传感器为位移传感器。Further, the second sensor is a displacement sensor.

进一步的,所述传感器定位装置包括立柱和立柱定位组件,所述立柱通过立柱定位组件与检测框架连接。Further, the sensor positioning device includes a column and a column positioning assembly, and the column is connected to the detection frame through the column positioning assembly.

进一步的,所述传感器定位装置还包括滑动定位组件,所述滑动定位组件滑动连接在所述立柱上。Further, the sensor positioning device further includes a sliding positioning assembly, and the sliding positioning assembly is slidably connected to the upright column.

进一步的,所述第一传感器安装在所述滑动定位组件上。Further, the first sensor is mounted on the sliding positioning assembly.

进一步的,立柱上设置有一个或多个定位座,所述定位座将立柱划分为多个检测位置,以调整滑动定位组件以及第一传感器的安装高度。Further, one or more positioning seats are arranged on the upright column, and the positioning seats divide the upright column into a plurality of detection positions, so as to adjust the installation height of the sliding positioning assembly and the first sensor.

本发明的另一个方面提出了一种移动式站台限界测量方法,该测量方法包括利用上述任一所述的移动式站台限界测量仪,其中,该测量方法包括以下步骤:Another aspect of the present invention provides a mobile station limit measurement method, the measurement method includes using any of the above-mentioned mobile station limit measurement instruments, wherein the measurement method includes the following steps:

以轨顶面连线中点为原点,以轨顶面连线为x轴,以垂直于钢轨的轨顶连线为y轴建立坐标系;The coordinate system is established with the midpoint of the connecting line on the rail top surface as the origin, the connecting line on the top surface of the rail as the x-axis, and the connecting line on the rail top perpendicular to the rail as the y-axis;

根据被测站台高度,调整滑动组件定位组件的位置,使站台顶面和侧面处于第一传感器的有效量程范围内;According to the height of the tested platform, adjust the position of the positioning component of the sliding component so that the top and side surfaces of the platform are within the effective range of the first sensor;

第一传感器获取站台断面数据、第二传感器获取位移数据以及倾角仪获取反映轨道超高的角度数据;The first sensor obtains the platform section data, the second sensor obtains the displacement data, and the inclinometer obtains the angle data reflecting the superelevation of the orbit;

主机对站台断面数据、位移数据和所述反映轨道超高的角度数据分别进行计算处理并结合滑动组件位置的高度位置计算得到站台实测限界尺寸、轨距和线路的超高数值;The host computer calculates and processes the platform section data, displacement data and the angle data reflecting the superelevation of the track, and calculates the measured limit size of the platform, the gauge and the superelevation value of the line in combination with the height position of the sliding component position;

将所述站台实测限界尺寸与预设的限界阈值进行比较,判断站台是否侵限。Comparing the actual measured limit size of the station with a preset limit threshold to determine whether the station violates the limit.

进一步的,主机在计算站台实测限界尺寸时,同步获取编码器的信号,并计算得到所测站台限界的里程信息。Further, when the host computer calculates the actual measured limit size of the platform, the signal of the encoder is obtained synchronously, and the mileage information of the measured platform limit is obtained by calculation.

与现有技术相比,本发明的有益效果是:Compared with the prior art, the beneficial effects of the present invention are:

本发明实施例提供的移动式站台限界测量仪可对铁路不同高度站台的垂向及横向限界距离进行移动连续检测,判断其是否满足站台标准限界要求。The mobile platform limit measuring instrument provided by the embodiment of the present invention can continuously detect the vertical and lateral limit distances of railway platforms at different heights, and judge whether they meet the standard limit requirements of the platform.

附图说明Description of drawings

通过下面结合附图进行的详细描述,本发明的上述和其它目的、特点和优点将会变得更加清楚,其中:The above and other objects, features and advantages of the present invention will become more apparent from the following detailed description in conjunction with the accompanying drawings, wherein:

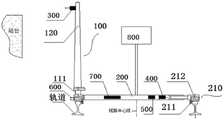

图1是本发明实施例提供的一种移动式站台限界测量仪的主视示意图;1 is a schematic front view of a mobile station limit measuring instrument provided by an embodiment of the present invention;

图2是本发明实施例提供的一种移动式站台限界测量仪的俯视示意图;2 is a schematic top view of a mobile station limit measuring instrument provided by an embodiment of the present invention;

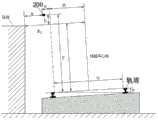

图3是本发明实施例提供的一种移动式站台限界测量仪的测量原理示意图;3 is a schematic diagram of the measurement principle of a mobile station limit measuring instrument provided by an embodiment of the present invention;

图4是本发明实施例提供的一种站台限界测量方法的流程示意图;4 is a schematic flowchart of a method for measuring a station limit provided by an embodiment of the present invention;

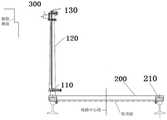

图5是本发明实施例提供的一种传感器定位装置的总体结构示意图;5 is a schematic diagram of the overall structure of a sensor positioning device provided by an embodiment of the present invention;

图6是本发明实施例提供的一种立柱定位组件的结构示意图;6 is a schematic structural diagram of a column positioning assembly provided by an embodiment of the present invention;

图7是本发明实施例提供的一种滑动定位组件的结构示意图。FIG. 7 is a schematic structural diagram of a sliding positioning assembly provided by an embodiment of the present invention.

其中,传感器定位装置-100,立柱定位组件-110;基座-111、第一滑动槽-112,定位块-113、顶块-114,第二凹槽-115、限位销-116、第三紧固装置-117、轴承-118;立柱-120;滑动定位组件-130;传感器底座-131、定位座-132、滑块-133、导轨-134、第一紧固装置-135、第一螺母-136;Among them, the sensor positioning device-100, the column positioning assembly-110; the base-111, the first sliding groove-112, the positioning block-113, the top block-114, the second groove-115, the limit pin-116, the first Three fastening devices-117, bearing-118; column-120; sliding positioning assembly-130; sensor base-131, positioning seat-132, slider-133, guide rail-134, first fastening device-135, first Nut-136;

检测框架-200,走行轮-210;横向走行轮-211,纵向走行轮-212;第一传感器-300、第二传感器-400、倾角仪-500、编码器-600、电源-700和主机-800。Detection frame-200, traveling wheel-210; horizontal traveling wheel-211, longitudinal traveling wheel-212; first sensor-300, second sensor-400, inclinometer-500, encoder-600, power supply-700 and host- 800.

具体实施方式Detailed ways

为使本发明实施的目的、技术方案和优点更加清楚,下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行更加详细的描述。在附图中,自始至终相同或类似的标号表示相同或类似的元件或具有相同或类似功能的元件。所描述的实施例是本发明一部分实施例,而不是全部的实施例。下面通过参考附图描述的实施例是示例性的,旨在用于解释本发明,而不能理解为对本发明的限制。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below with reference to the accompanying drawings in the embodiments of the present invention. Throughout the drawings, the same or similar reference numbers refer to the same or similar elements or elements having the same or similar functions. The described embodiments are some, but not all, of the embodiments of the present invention. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

图1、图2分别是本发明实施例提供的一种移动式站台限界测量仪的主视和俯视示意图;参见图1和2,该移动式站台限界测量仪包括传感器定位装置100、检测框架200、第一传感器300、第二传感器400、倾角仪500、编码器600、电源700和主机800;其中,所述传感器定位装置100安装于检测框架200上,所述检测框架200的两端底部设有走行轮210,所述走行轮210沿轨道滚动,设有走行轮210可以实现该站台限界测量仪在轨道上的移动检测,提高了测量效率;FIG. 1 and FIG. 2 are respectively the front view and top view of a mobile platform limit measuring instrument provided by an embodiment of the present invention; referring to FIGS. 1 and 2 , the mobile platform limit measuring instrument includes a

所述第一传感器300、第二传感器400、倾角仪500和编码器600分别与所述主机800连接,所述主机800用于显示第一传感器300、第二传感器400、倾角仪500和编码器600所传输的数据,所述主机800将获得的测量数据实时处理并可同步显示测量结果;所述第一传感器300、第二传感器400、倾角仪500、编码器600和主机800分别与电源700连接,该电源700向这些设备(即第一传感器300、第二传感器400、倾角仪500、编码器600和主机800分别与电源700)提供电能,所述电源700也安装于所述检测框架200上;优选的,该电源700位于该检测框架200的内部,用以保护所述电源700;The

所述第一传感器300安装于该传感器定位装置100并将获取的站台断面数据传输给主机800,所述第二传感器400安装于检测框架200内并将所测得的位移数据传输给主机800;The

所述倾角仪500安装于检测框架200内,用于测量线路的超高数值;所述编码器600安装于所述走行轮210的轴头上,该编码器600通过走行轮210向主机800发送脉冲信号,根据该脉冲信号的脉冲数量向主机800提供里程定位信息。The

进一步的,所述第一传感器300为二维断面测量传感器,由于第一传感器采用的是断面测量测量传感器,属于二维传感器,因此该第一传感器300可同时输出站台的纵向和水平尺寸;优选的,第一传感器300选用的断面测量传感器为高频测量传感器(例如可以是型号为ZLDS200的传感器),这里的高频指第一传感器300的频率范围例如可以是1kHz,可以理解的是,本发明不限于该频率范围,可对站台连续测量,获得实时数据;该第一传感器300安装于检测立柱上,检测区域包含了站台上表面及站台侧面,第一传感器300在其检测区域内对站台距离线路中心及轨顶面的横向和纵向尺寸实时测量。推动检测框架200进行移动连续测量时,通过编码器600提供的脉冲触发信号,第一传感器300可设置为每10mm甚至更低至1mm测量一次站台断面数据,从而提高了该移动式站台限界测量仪的测量效率和测量的准确可靠性,实现移动连续测量。Further, the

进一步的,所述第二传感器400为位移传感器,用于对轨距进行实时准确测量,该第二传感器400在安装时,其径向中心线与两个垂向走行轮的中心线相平行;本实施通过利用该位移传感器及倾角仪500,可对线路轨距和超高数据进行测量,从而该移动式站台限界测量仪的输出结果为站台距离轨顶面和线路中心线的纵向距离和水平距离,数值更为准确。Further, the

进一步的,所述传感器定位装置100包括立柱120和立柱定位组件110,所述立柱120通过立柱定位组件110与检测框架200连接,所述立柱定位组件110用于对所述立柱120进行定位;优选的,立柱120上设置有一个或多个定位座132,所述定位座132将立柱120划分为多个检测位置;因此该传感器定位装置100可实现在拆卸、安装过程中的重复定位准确,且能满足不同高度的各种规格站台的测量。Further, the

可选的,所述第二传感器400安装于轨道之间,用以实时地检测轨距并将所测得的轨距数值传输给主机800;优选的,所述第二传感器400位于检测框架200的内部;Optionally, the

所述倾角仪500安装于检测框架200内,用于测量线路的超高数值;The

所述编码器600安装于所述走行轮210的轴头上,该编码器600通过走行轮210向主机800发送脉冲信号,根据该脉冲信号的脉冲数量向主机800提供里程定位信息。The

可选的,所述检测框架200为车架,倾角仪500安装在车架的梁内。Optionally, the

可选的,所述立柱定位组件110包括基座111,立柱120与基座111可通过销轴进行定位,并利用紧固或定位装置将立柱120固定在所述基座111上;优选的,所述车架为T字型,可以理解的是,在其他实施例中,该车架也可为工字形或其他形状。Optionally, the

可选的,所述走行轮210包括横向走行轮211和垂向走行轮212。Optionally, the running

优选的,横向走行轮211位于车架的两侧且水平放置,其中心线在轨顶面以下16mm,用于保证检测框架走行顺畅;Preferably, the

垂向走行轮212位于检测小车车架的两侧且垂直放置,用于承载车架的重量及保证检测框架走行顺畅。可以理解的是,所述横向走行轮211可以为1个或多个,同理,所述垂向走行轮212也可以为多个。The

可选的,所述垂向走行轮(212)有两个。Optionally, there are two vertical running wheels (212).

可选的,参见图5和图6,所述传感器定位装置100还包括滑动定位组件130,所述立柱120连接所述滑动定位组件130,所述滑动定位组件130滑动连接在所述立柱120上;优选的,所述第一传感器300滑动连接在所述立柱120上,以便在立柱120的不同位置进行高、低方向的调整,从而实现对不同高度各种规格站台的测量;所述滑动定位组件130上安装所述第一传感器300;Optionally, referring to FIGS. 5 and 6 , the

所述立柱定位组件110包括定位块113,在所述基座111内设置有第一滑动槽112,将定位块113安装于所述第一滑动槽112内并通过第二紧固装置(图中未示出)将定位块113与立柱120连接;定位块113的一侧设有与定位块113相配合的顶块114;基座111的一侧设置有第二凹槽115,第三紧固装置117的一端伸入第二凹槽115内,在第三紧固装置117与顶块114之间设置轴承118,所述顶块114随着第三紧固装置117的旋转在所述第二凹槽115中移动;通过设置立柱定位组件110,保证了立柱120与检测框架200之间的重复定位的准确性,并且本实施例的立柱定位组件110的具体结构,实现了立柱120与检测框架200的拆卸、拼装简单便捷。The

参见图5和图7,所述滑动定位组件130包括传感器底座131、定位座132、滑块133和导轨134;立柱120的一侧安装有所述导轨134,该导轨134上安装有滑块133;其中,滑块133与导轨134之间紧密配合,以使得滑块133可在立柱120上纵向地自由滑动;可以理解的是,所述滑块133根据实际应用需要可以设置多个;同理,所述导轨也可以设置多个;5 and 7 , the sliding

立柱120的另一侧设置有一个或多个定位座132,多个定位座132将立柱120划分为多个检测位置,以调整滑动定位组件130以及第一传感器300的安装高度,如图7所示,检测位置可以为N个,这里的N≥1,设置N个检测位置可以实现第一传感器300的多级定位,以使第一传感器300可根据检测的高度需要在立柱110上滑动至所需的检测位置,从而保证了在对第一传感器300重复定位时,该检测位置相对于立柱120的高度一致和准确;The other side of the

该滑块133上固定安装有传感器底座131,第一传感器300安装于所述传感器底座131上,第一紧固装置135穿过所述定位座132将传感器底座131连接在所述导轨134上;A

其中,第一紧固装置135可以将传感器底座131、第一传感器300和滑块133组合为一个整体;优选的,在第一紧固装置135上设置第一螺母136,利用该第一螺母136可以将第一紧固装置135进行移动(例如进行前、后移动);通过在立柱120上设置上述滑动定位组件450,可以使第一传感器300能检测到不同高度的线路限界的检测数据。The

可选的,限位销116锚固于所述基座111上,该限位销116用于对立柱120在顺线路方向(这里的“顺线路方向”是指按照线路的里程方向)定位。Optionally, the

图4是本发明实施例提供的一种移动式站台限界测量方法的流程示意图;参见图4,该测量方法包括以下步骤:FIG. 4 is a schematic flowchart of a method for measuring the limit of a mobile station according to an embodiment of the present invention; referring to FIG. 4 , the measuring method includes the following steps:

S100:以轨顶面连线中点为原点,以轨顶面连线为x轴,以垂直于钢轨轨顶连线为y轴建立坐标系;S100: take the midpoint of the connecting line on the top surface of the rail as the origin, take the connecting line on the top surface of the rail as the x-axis, and establish a coordinate system with the connecting line perpendicular to the rail top as the y-axis;

S200:根据被测站台高度,调整滑动组件定位组件130的位置,使站台顶面和侧面处于第一传感器300的有效量程范围内;S200: According to the height of the tested platform, adjust the position of the sliding

S300:第一传感器300获取站台断面数据,第二传感器400获取位移数据以及倾角仪(500)获取反映轨道超高的角度数据;S300: The

S400:主机800对所述站台断面数据、位移数据和所述反映轨道超高的角度数据分别进行计算处理,并结合滑动组件位置130的高度位置计算得到站台实测限界尺寸(即站台实测限界的横向距离和垂向距离)、轨距和线路的超高数值;1S400: The

S500:将所述站台实测限界尺寸与预设的限界阈值进行比较,判断站台是否侵入限界。S500: Compare the actual measured limit size of the platform with a preset limit threshold to determine whether the platform invades the limit.

优选的,利用倾角仪500测量获得线路的超高数值。Preferably, the

优选的,主机800在计算站台实测限界尺寸时,同步获取编码器600的信号,并计算得到所测站台限界的里程信息这样可以定位获得线路横断面的信息。Preferably, the

根据上述判断得到站台是否侵入线路的信息,移动该站台限界测量仪,对整个线路进行测量从而可以获取整个站台的实际限界信息。According to the above judgment, the information of whether the station invades the line is obtained, and the limit measuring instrument of the station is moved to measure the entire line so as to obtain the actual limit information of the entire station.

图3是本发明实施例提供的一种移动式站台限界测量仪的测量原理示意图,参照图3;本实例以轨道的轨顶面连线中点为原点,以钢轨顶面连线为x轴,以垂直于钢轨轨顶连线为y轴建立的坐标系;3 is a schematic diagram of the measurement principle of a mobile platform limit measuring instrument provided by an embodiment of the present invention, with reference to FIG. 3; in this example, the midpoint of the connecting line of the rail top surface of the track is the origin, and the line connecting the top surface of the rail is the x-axis , the coordinate system established with the line perpendicular to the rail top as the y-axis;

将第一传感器300固定在立柱120上后获取站台断面数据,主机800对该站台断面数据进行识别、处理最终获得站台边缘轮廓数据;该站台边缘轮廓数据包括第一横向距离e和第一纵向距离f,其中,所述第一横向距离e是第一传感器300距离靠近站台一侧的轨道轨距点的横向距离值;所述第一纵向距离f是第一传感器300距离轨顶面的垂向距离值,这里的数值e和f可在标定台上通过测量而得到,为可知的定值;After the

该站台边缘轮廓数据还包括第二横向距离a和第二纵向距离b;其中,第二横向距离a为第一传感器300距离站台限界的横向距离值,第二纵向距离b为第一传感器300距离站台限界的纵向距离值,这里的数值a和b是由第一传感器200在轨道上的移动检测过程中实时测量得到;The platform edge profile data also includes a second lateral distance a and a second longitudinal distance b; wherein, the second lateral distance a is the lateral distance value between the

第二传感器400实时获取轨距n;The

根据第一横向距离e、第一纵向距离f、第二横向距离a、第二纵向距离b以及轨距n得到站台实测限界的横向距离x1和垂向距离y1,具体公式如下:According to the first lateral distance e, the first longitudinal distance f, the second lateral distance a, the second longitudinal distance b and the gauge n, the lateral distance x1 and the vertical distance y1 of the actual measured limit of the platform are obtained. The specific formulas are as follows:

x1=a+e+m=a+e+n/2;x1 =a+e+m=a+e+n/2;

y1=f-b;y1 =fb;

其中,m=n/2;x1、y1分别为站台实测限界的横向、垂向距离。Among them, m=n/2; x1 and y1 are the lateral and vertical distances of the actual measured limit of the station, respectively.

本发明的有益效果:Beneficial effects of the present invention:

本发明实施例提供的移动式站台限界测量仪和测量方法,可实现对站台限界尺寸的移动连续测量,显著提高测量效率。The mobile station limit measuring instrument and the measuring method provided by the embodiments of the present invention can realize the moving and continuous measurement of the limit size of the station, and significantly improve the measurement efficiency.

具体体现在:Specifically reflected in:

(1)采用二维传感器快速获取站台断面数据,检测速度快,检测精度高。其断面采集间隔可小于10mm,相当于对站台的连续检测,因此在纵向上不会遗漏最不利断面;,在横断面上,同样为连续采集,无需人工定位最不利点,因此确保了测量的准确性和快速性。(1) Two-dimensional sensors are used to quickly obtain platform cross-section data, with fast detection speed and high detection accuracy. The section collection interval can be less than 10mm, which is equivalent to the continuous detection of the platform, so the most unfavorable section will not be missed in the longitudinal direction. Accuracy and speed.

(2)传感器定位装置通过在立柱上设置滑动定位组件,可以使传感器检测到不同高度站台的限界检测数据;通过设置立柱定位组件,保证了立柱与检测框架之间的重复定位的准确性,并且本实施例的立柱定位组件的具体结构,实现了立柱与检测框架的拆卸、拼装简单便捷,易于操作、节省时间,安全可靠,并且便于运输及存放的效果,并且保证立柱与检测框架的重复定位的准确性。(2) The sensor positioning device can enable the sensor to detect the limit detection data of platforms of different heights by setting the sliding positioning assembly on the column; by setting the column positioning assembly, the accuracy of repeated positioning between the column and the detection frame is ensured, and The specific structure of the column positioning assembly in this embodiment realizes the simple and convenient disassembly and assembly of the column and the detection frame, is easy to operate, saves time, is safe and reliable, and is convenient for transportation and storage, and ensures the repeated positioning of the column and the detection frame. accuracy.

(3)采用检测框架实现测量仪的平稳移动,在测量过程中操作人员只需平稳推动测量仪即可,大大降低了操作人员的工作复杂度。(3) The detection frame is used to realize the smooth movement of the measuring instrument. During the measurement process, the operator only needs to push the measuring instrument smoothly, which greatly reduces the work complexity of the operator.

最后需要指出的是:以上实施例仅用以说明本发明的技术方案,而非对其限制。尽管参照前述实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的精神和范围。Finally, it should be pointed out that the above embodiments are only used to illustrate the technical solutions of the present invention, but not to limit them. Although the present invention has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand that: it is still possible to modify the technical solutions described in the foregoing embodiments, or perform equivalent replacements to some of the technical features; and these Modifications or substitutions do not make the essence of the corresponding technical solutions deviate from the spirit and scope of the technical solutions of the embodiments of the present invention.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911213437.2ACN110749297A (en) | 2019-12-02 | 2019-12-02 | A mobile station limit measuring instrument and measuring method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911213437.2ACN110749297A (en) | 2019-12-02 | 2019-12-02 | A mobile station limit measuring instrument and measuring method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110749297Atrue CN110749297A (en) | 2020-02-04 |

Family

ID=69285311

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911213437.2APendingCN110749297A (en) | 2019-12-02 | 2019-12-02 | A mobile station limit measuring instrument and measuring method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110749297A (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111750829A (en)* | 2020-07-02 | 2020-10-09 | 沈阳铁道科学技术研究所有限公司 | A method for judging vertical sections in non-contact measurement of railway platform boundaries |

| CN112678023A (en)* | 2021-01-04 | 2021-04-20 | 天津路安工程咨询有限公司 | Rail transit clearance detection device and detection method |

| CN112797941A (en)* | 2021-01-29 | 2021-05-14 | 中国铁路北京局集团有限公司北京科学技术研究所 | A railway platform limit measuring instrument verification device |

| CN112902939A (en)* | 2021-03-30 | 2021-06-04 | 中铁十一局集团第三工程有限公司 | Rail clearance measuring device and rail clearance measuring method |

| CN112937631A (en)* | 2021-01-29 | 2021-06-11 | 吉林市盈冲科技有限公司 | Detection method for railway tunnel clearance |

| CN113776490A (en)* | 2021-08-19 | 2021-12-10 | 铁科检测有限公司 | A self-propelled platform limit detection equipment |

| CN115355863A (en)* | 2022-09-13 | 2022-11-18 | 江西日月明测控科技股份有限公司 | Platform limit measuring device |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007064890A (en)* | 2005-09-01 | 2007-03-15 | Tokimec Inc | Home separation measuring method and apparatus |

| CN102211590A (en)* | 2011-04-07 | 2011-10-12 | 同济大学 | Detecting vehicle for tunnel |

| CN104775342A (en)* | 2015-04-10 | 2015-07-15 | 北京力铁轨道交通设备有限公司 | Quick geometrical state measuring instrument for track |

| CN106152963A (en)* | 2016-06-16 | 2016-11-23 | 罗建雄 | A kind of platform limit measuring instrument and measuring method thereof automatically |

| CN206330548U (en)* | 2016-12-27 | 2017-07-14 | 上海铁路局科学技术研究所 | A kind of high-speed railway platform dividing measures dolly |

| CN107505334A (en)* | 2017-10-13 | 2017-12-22 | 成都精工华耀机械制造有限公司 | A kind of railway rail clip abnormality detection system based on pointolite array linear array imaging |

| CN107621229A (en)* | 2017-10-23 | 2018-01-23 | 福州大学 | Real-time railway track width measurement system and method based on area array black and white camera |

| CN107642014A (en)* | 2017-10-23 | 2018-01-30 | 福州大学 | Railroad track superelevation of outer rail measuring system and method |

| CN108413885A (en)* | 2018-03-29 | 2018-08-17 | 吴立滨 | A kind of station platform clearance survey device and measurement method |

| CN207832155U (en)* | 2018-03-08 | 2018-09-07 | 郑小飞 | A kind of portable platform clearance survey equipment |

| CN110304105A (en)* | 2019-06-18 | 2019-10-08 | 上海同岩土木工程科技股份有限公司 | A kind of Metro Clearance dynamic detection vehicle and detection method |

| CN211060871U (en)* | 2019-12-02 | 2020-07-21 | 中国铁道科学研究院集团有限公司铁道建筑研究所 | A mobile platform limit measuring instrument |

- 2019

- 2019-12-02CNCN201911213437.2Apatent/CN110749297A/enactivePending

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007064890A (en)* | 2005-09-01 | 2007-03-15 | Tokimec Inc | Home separation measuring method and apparatus |

| CN102211590A (en)* | 2011-04-07 | 2011-10-12 | 同济大学 | Detecting vehicle for tunnel |

| CN104775342A (en)* | 2015-04-10 | 2015-07-15 | 北京力铁轨道交通设备有限公司 | Quick geometrical state measuring instrument for track |

| CN106152963A (en)* | 2016-06-16 | 2016-11-23 | 罗建雄 | A kind of platform limit measuring instrument and measuring method thereof automatically |

| CN206330548U (en)* | 2016-12-27 | 2017-07-14 | 上海铁路局科学技术研究所 | A kind of high-speed railway platform dividing measures dolly |

| CN107505334A (en)* | 2017-10-13 | 2017-12-22 | 成都精工华耀机械制造有限公司 | A kind of railway rail clip abnormality detection system based on pointolite array linear array imaging |

| CN107621229A (en)* | 2017-10-23 | 2018-01-23 | 福州大学 | Real-time railway track width measurement system and method based on area array black and white camera |

| CN107642014A (en)* | 2017-10-23 | 2018-01-30 | 福州大学 | Railroad track superelevation of outer rail measuring system and method |

| CN207832155U (en)* | 2018-03-08 | 2018-09-07 | 郑小飞 | A kind of portable platform clearance survey equipment |

| CN108413885A (en)* | 2018-03-29 | 2018-08-17 | 吴立滨 | A kind of station platform clearance survey device and measurement method |

| CN110304105A (en)* | 2019-06-18 | 2019-10-08 | 上海同岩土木工程科技股份有限公司 | A kind of Metro Clearance dynamic detection vehicle and detection method |

| CN211060871U (en)* | 2019-12-02 | 2020-07-21 | 中国铁道科学研究院集团有限公司铁道建筑研究所 | A mobile platform limit measuring instrument |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111750829A (en)* | 2020-07-02 | 2020-10-09 | 沈阳铁道科学技术研究所有限公司 | A method for judging vertical sections in non-contact measurement of railway platform boundaries |

| CN111750829B (en)* | 2020-07-02 | 2022-06-03 | 沈阳铁道科学技术研究所有限公司 | Method for judging vertical section in non-contact measurement of railway platform clearance |

| CN112678023A (en)* | 2021-01-04 | 2021-04-20 | 天津路安工程咨询有限公司 | Rail transit clearance detection device and detection method |

| CN112797941A (en)* | 2021-01-29 | 2021-05-14 | 中国铁路北京局集团有限公司北京科学技术研究所 | A railway platform limit measuring instrument verification device |

| CN112937631A (en)* | 2021-01-29 | 2021-06-11 | 吉林市盈冲科技有限公司 | Detection method for railway tunnel clearance |

| CN112937631B (en)* | 2021-01-29 | 2022-12-06 | 吉林市盈冲科技有限公司 | A detection method for railway tunnel boundary |

| CN112902939A (en)* | 2021-03-30 | 2021-06-04 | 中铁十一局集团第三工程有限公司 | Rail clearance measuring device and rail clearance measuring method |

| CN113776490A (en)* | 2021-08-19 | 2021-12-10 | 铁科检测有限公司 | A self-propelled platform limit detection equipment |

| CN115355863A (en)* | 2022-09-13 | 2022-11-18 | 江西日月明测控科技股份有限公司 | Platform limit measuring device |

| CN115355863B (en)* | 2022-09-13 | 2025-07-11 | 江西日月明测控科技股份有限公司 | Platform limit measuring device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110749297A (en) | A mobile station limit measuring instrument and measuring method | |

| CN201103084Y (en) | Rail anchor point and construction clearance measuring apparatus | |

| CA2574051C (en) | Apparatus for detecting hunting and angle of attack of a rail vehicle wheelset | |

| CN107401979B (en) | Vehicle body vibration displacement compensation device and method for catenary detection | |

| CN106091951A (en) | A kind of municipal rail train wheel rim parameter on-line detecting system and method | |

| CN109781019A (en) | A gauge measuring device and measuring method | |

| CN201795776U (en) | A flatness measuring instrument | |

| CN102951179A (en) | Movable steel rail inner profile detection trolley | |

| CN107200041A (en) | Tramcar wheel out of round degree on-line measuring device and method based on array laser | |

| CN203923823U (en) | Simple and easy track geometric parameter measurement instrument | |

| CN211060871U (en) | A mobile platform limit measuring instrument | |

| CN106758602A (en) | A kind of staticaccelerator track ride comfort detecting system and method | |

| CN103591902B (en) | A kind of wheel diameter of urban rail vehicle detecting device based on laser sensor and method | |

| CN203148402U (en) | Dynamic flatness detection device for steel rail | |

| CN206266964U (en) | A kind of rail of subway ripple mill measures sanding apparatus in real time | |

| CN109668515A (en) | Detector for train wheel pair size dynamic detection system and detection method | |

| CN103507832B (en) | A kind of Rail inspection detecting device | |

| CN206787495U (en) | Multi-angle two dimensional laser scanning gage measurement instrument under track checking car | |

| CN102901455B (en) | Radius of spherical crown quick online detection device | |

| CN119705539A (en) | A contact rail, induction plate and track static geometric parameter comprehensive inspection instrument and inspection method | |

| CN107139968A (en) | Wheel out of round degree detection means and method based on laser displacement sensor | |

| CN111452829A (en) | Bidirectional rail clearance measuring method | |

| CN201795777U (en) | A mobile wave wear detector | |

| CN202641743U (en) | Building line detection device of arrival-departure track for railway station | |

| CN203511689U (en) | Rail geometric dimension detecting device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200204 | |

| RJ01 | Rejection of invention patent application after publication |