CN110744044A - Spark plasma sintering preparation method of fine-grain Ti-48Al-2Cr-8Nb titanium-aluminum alloy - Google Patents

Spark plasma sintering preparation method of fine-grain Ti-48Al-2Cr-8Nb titanium-aluminum alloyDownload PDFInfo

- Publication number

- CN110744044A CN110744044ACN201910784835.3ACN201910784835ACN110744044ACN 110744044 ACN110744044 ACN 110744044ACN 201910784835 ACN201910784835 ACN 201910784835ACN 110744044 ACN110744044 ACN 110744044A

- Authority

- CN

- China

- Prior art keywords

- plasma sintering

- titanium

- fine

- spark plasma

- sintering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000002490spark plasma sinteringMethods0.000titleclaimsabstractdescription17

- 229910000838Al alloyInorganic materials0.000titleclaimsabstractdescription10

- UQZIWOQVLUASCR-UHFFFAOYSA-Nalumane;titaniumChemical compound[AlH3].[Ti]UQZIWOQVLUASCR-UHFFFAOYSA-N0.000titleclaimsabstractdescription10

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription6

- 238000000034methodMethods0.000claimsabstractdescription20

- 238000005245sinteringMethods0.000claimsabstractdescription19

- 229910045601alloyInorganic materials0.000claimsabstractdescription14

- 239000000956alloySubstances0.000claimsabstractdescription14

- 239000000843powderSubstances0.000claimsabstractdescription11

- 229910010038TiAlInorganic materials0.000claimsabstractdescription8

- 238000010438heat treatmentMethods0.000claimsdescription7

- 239000002245particleSubstances0.000claimsdescription2

- 238000003825pressingMethods0.000claimsdescription2

- 235000015895biscuitsNutrition0.000abstract1

- 238000007873sievingMethods0.000abstract1

- 239000000463materialSubstances0.000description10

- 230000008569processEffects0.000description8

- 238000004663powder metallurgyMethods0.000description3

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description2

- PXHVJJICTQNCMI-UHFFFAOYSA-NNickelChemical compound[Ni]PXHVJJICTQNCMI-UHFFFAOYSA-N0.000description2

- 230000007797corrosionEffects0.000description2

- 238000005260corrosionMethods0.000description2

- 238000010586diagramMethods0.000description2

- 238000009689gas atomisationMethods0.000description2

- 229910002804graphiteInorganic materials0.000description2

- 239000010439graphiteSubstances0.000description2

- 239000007788liquidSubstances0.000description2

- 238000004519manufacturing processMethods0.000description2

- 238000002844meltingMethods0.000description2

- 230000008018meltingEffects0.000description2

- 238000005272metallurgyMethods0.000description2

- 230000007704transitionEffects0.000description2

- 229910001018Cast ironInorganic materials0.000description1

- VYZAMTAEIAYCRO-UHFFFAOYSA-NChromiumChemical compound[Cr]VYZAMTAEIAYCRO-UHFFFAOYSA-N0.000description1

- RTAQQCXQSZGOHL-UHFFFAOYSA-NTitaniumChemical compound[Ti]RTAQQCXQSZGOHL-UHFFFAOYSA-N0.000description1

- 238000005275alloyingMethods0.000description1

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description1

- 229910052782aluminiumInorganic materials0.000description1

- 238000005266castingMethods0.000description1

- 229910052804chromiumInorganic materials0.000description1

- 239000011651chromiumSubstances0.000description1

- 238000001816coolingMethods0.000description1

- 230000007547defectEffects0.000description1

- 238000009826distributionMethods0.000description1

- 230000006698inductionEffects0.000description1

- 239000000203mixtureSubstances0.000description1

- 229910052759nickelInorganic materials0.000description1

- 229910052758niobiumInorganic materials0.000description1

- 239000010955niobiumSubstances0.000description1

- GUCVJGMIXFAOAE-UHFFFAOYSA-Nniobium atomChemical compound[Nb]GUCVJGMIXFAOAE-UHFFFAOYSA-N0.000description1

- 230000003287optical effectEffects0.000description1

- 238000000879optical micrographMethods0.000description1

- 230000003647oxidationEffects0.000description1

- 238000007254oxidation reactionMethods0.000description1

- 239000002994raw materialSubstances0.000description1

- 230000009467reductionEffects0.000description1

- 238000007670refiningMethods0.000description1

- 229910000601superalloyInorganic materials0.000description1

- 239000000725suspensionSubstances0.000description1

- 239000010936titaniumSubstances0.000description1

- 229910052719titaniumInorganic materials0.000description1

- 230000009466transformationEffects0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/05—Metallic powder characterised by the size or surface area of the particles

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/14—Both compacting and sintering simultaneously

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C21/00—Alloys based on aluminium

- C22C21/003—Alloys based on aluminium containing at least 2.6% of one or more of the elements: tin, lead, antimony, bismuth, cadmium, and titanium

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C30/00—Alloys containing less than 50% by weight of each constituent

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2999/00—Aspects linked to processes or compositions used in powder metallurgy

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Powder Metallurgy (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于放电等离子烧结材料技术领域,涉及一种细晶Ti-48Al-2Cr-8Nb钛铝合金的等离子烧结制备方法。The invention belongs to the technical field of discharge plasma sintering materials, and relates to a plasma sintering preparation method of fine-grained Ti-48Al-2Cr-8Nb titanium-aluminum alloy.

背景技术Background technique

TiAl合金因其具有较低的密度、良好的高温强度和抗蠕变以及抗氧化性,成为目前代替镍基高温合金制造航空发动机热端零部件的理想材料。然而,钛铝合金的室温塑性较低,严重的限制了其实际应用。目前提高TiAl合金塑性的方法主要有细化晶粒尺寸、控制显微组织结构和实现合金化等。Because of its low density, good high temperature strength, creep resistance and oxidation resistance, TiAl alloy has become an ideal material to replace nickel-based superalloy to manufacture hot end parts of aero-engine. However, the low room temperature plasticity of titanium-aluminum alloys severely limits its practical application. At present, the methods to improve the plasticity of TiAl alloy mainly include refining the grain size, controlling the microstructure and realizing alloying.

传统制备TiAl合金的方法有铸锭冶金(IM)和粉末冶金(PM)法。对比于铸锭冶金工艺的宏观偏析、晶粒粗大和疏松等缺点,粉末冶金法可以制备出相分布均匀且晶粒尺寸较小的TiAl合金。但是,粉末冶金工艺的模具费用要高出铸造模具,在一定程度上增加了制造的成本。The traditional methods of preparing TiAl alloys include ingot metallurgy (IM) and powder metallurgy (PM). Compared with the defects of macrosegregation, coarse grains and looseness of ingot metallurgy, powder metallurgy can prepare TiAl alloys with uniform phase distribution and small grain size. However, the mold cost of the powder metallurgy process is higher than that of the casting mold, which increases the manufacturing cost to a certain extent.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提供一种通过放电等离子多次烧结制备细晶近γ相结构(NG)钛铝合金的方法。该方法采用气雾化Ti-48Al-2Cr-8Nb预合金粉末,优化烧结工艺,在提高材料致密度的同时,提高材料的综合力学性能。The purpose of the present invention is to provide a method for preparing fine-grained near-γ-phase structure (NG) titanium-aluminum alloy by spark plasma multiple times sintering. The method adopts gas atomization of Ti-48Al-2Cr-8Nb pre-alloyed powder, optimizes the sintering process, and improves the comprehensive mechanical properties of the material while improving the density of the material.

实现上述目的的技术方案如下:The technical solutions to achieve the above purpose are as follows:

SPS制备细晶钛铝合金的工艺方法,包括如下步骤:A process method for preparing fine-grained titanium-aluminum alloy by SPS, comprising the following steps:

步骤1,筛取粒径100-150目的气雾化Ti-48Al-2Cr-8Nb预合金粉末;Step 1, sieve out the gas atomized Ti-48Al-2Cr-8Nb pre-alloyed powder with a particle size of 100-150 mesh;

步骤2,将过筛的粉料直接倒入模具中,进行预压;Step 2: Pour the sieved powder directly into the mold for pre-pressing;

步骤3,将预压好的TiAl合金素坯进行两次放电等离子烧结,获得细晶近γ相结构(NG)。In step 3, the pre-pressed TiAl alloy green body is subjected to spark plasma sintering twice to obtain a fine-grained near-γ phase structure (NG).

优选地,步骤3中,第一次等离子烧结是以90-150℃的升温速率升温到1300±50℃,烧结压力为30-70MPa,保温时间5-10分钟,然后保压炉冷至室温(25℃)。Preferably, in step 3, the first plasma sintering is heated to 1300±50°C at a heating rate of 90-150°C, the sintering pressure is 30-70MPa, the holding time is 5-10 minutes, and then the pressure holding furnace is cooled to room temperature ( 25°C).

优选地,步骤3中,第二次等离子烧结是以90-150℃的升温速率升温到1250±25℃,烧结压力为30-70MPa,保温时间3-5分钟,然后保压炉冷至室温(25℃)。Preferably, in step 3, the second plasma sintering is heated to 1250±25°C at a heating rate of 90-150°C, the sintering pressure is 30-70MPa, the holding time is 3-5 minutes, and then the pressure-holding furnace is cooled to room temperature ( 25°C).

与现有的技术相比,本发明具有以下优点:Compared with the prior art, the present invention has the following advantages:

采用放电等离子两次重复烧结得到的材料晶粒尺寸为7-10μm,致密度可达99.5%,其室温抗压强度2537MPa,应变率为37.62%,硬度为293.9HV20。The grain size of the material obtained by two repeated spark plasma sintering is 7-10 μm, the density can reach 99.5%, the room temperature compressive strength is 2537MPa, the strain rate is 37.62%, and the hardness is 293.9HV20 .

附图说明Description of drawings

图1为实施例1中放电等离子一次烧结(1300℃)得到的烧结体表面腐蚀后的光镜图。FIG. 1 is an optical microscope view of the surface of the sintered body obtained by primary spark plasma sintering (1300° C.) in Example 1 after corrosion.

图2为实施例2中放电等离子两次烧结(1300℃+1275℃)得到的烧结体表面腐蚀后的光镜图。FIG. 2 is an optical microscope image of the surface of the sintered body obtained by two-time spark plasma sintering (1300° C.+1275° C.) in Example 2 after corrosion.

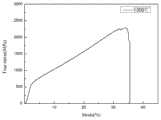

图3为实施例1中放电等离子一次烧结(1300℃)得到的烧结体应力应变图。3 is a stress-strain diagram of a sintered body obtained by primary spark plasma sintering (1300° C.) in Example 1. FIG.

图4为实施例2中放电等离子两次烧结(1300℃+1275℃)得到的烧结体应力应变图。FIG. 4 is a stress-strain diagram of a sintered body obtained by spark plasma sintering twice (1300° C.+1275° C.) in Example 2. FIG.

具体实施方式Detailed ways

下面结合实例和附图对本发明做进一步详细说明。The present invention will be described in further detail below with reference to examples and accompanying drawings.

下面实施例中涉及的气雾化Ti-48Al-2Cr-8Nb预合金粉末的制备步骤为:The preparation steps of the gas atomized Ti-48Al-2Cr-8Nb pre-alloyed powder involved in the following examples are:

首先,采用真空悬浮熔炼法制备Ti-48Al-2Cr-8Nb合金液,按照合金成分配比,称取原料钛、铌、铬和铝(纯度大于99.9%)。First, the Ti-48Al-2Cr-8Nb alloy liquid was prepared by vacuum suspension melting method, and the raw materials titanium, niobium, chromium and aluminum (purity greater than 99.9%) were weighed according to the alloy composition ratio.

其次,将熔炼好的合金液浇铸到铸铁模具中形成φ40×400mm的合金棒。Next, cast the melted alloy liquid into a cast iron mold to form an alloy rod with a diameter of 40×400 mm.

最终,通过电极感应熔炼气雾化(EIGA)法将Ti-48Al-2Cr-8Nb合金棒雾化成Ti-48Al-2Cr-8Nb预合金粉末。Finally, the Ti-48Al-2Cr-8Nb alloy rods were atomized into Ti-48Al-2Cr-8Nb pre-alloyed powders by electrode induction melting gas atomization (EIGA) method.

实施例1Example 1

将过100目筛的气雾化Ti-48Al-2Cr-8Nb预合金粉末称重并直接加入到石墨模具中,在10MPa压力下保压3分钟;将预压过的压坯放入保温装置并置于放电等离子烧结炉中进行放电等离子一次烧结,将炉腔内抽成真空状态,压强至6pa,施加压力为30MPa;以100℃/min的升温速率将试样加热至1300℃,保温5分钟,然后保压炉冷至室温(25℃)取出。The gas-atomized Ti-48Al-2Cr-8Nb pre-alloyed powder that had passed through a 100-mesh sieve was weighed and directly added to the graphite mold, and kept under pressure of 10 MPa for 3 minutes; Placed in a spark plasma sintering furnace for primary spark plasma sintering, the furnace chamber was evacuated to a vacuum state, the pressure was 6pa, and the applied pressure was 30MPa; the sample was heated to 1300°C at a heating rate of 100°C/min, and kept for 5 minutes. , and then cooled to room temperature (25°C) from the pressure-holding furnace.

经测试得,材料的晶粒尺寸为13-20μm,致密度可达99.3%,其室温抗压强度2286MPa,应变率为35.47%,硬度为290HV20。The test shows that the grain size of the material is 13-20μm, the density can reach 99.3%, the room temperature compressive strength is 2286MPa, the strain rate is 35.47%, and the hardness is 290HV20 .

实施例2Example 2

将过100目筛的气雾化Ti-48Al-2Cr-8Nb预合金粉末称重并直接加入到石墨模具中,在10MPa压力下保压3分钟;将预压过的压坯放入保温装置并置于放电等离子烧结炉中,将炉腔内抽成真空状态,压强至6pa,施加压力为30MPa;以100℃/min的升温速率将试样加热至1300℃,保温5分钟,然后保压炉冷至室温(25℃)后,再次烧结素坯,以100℃/min的升温速率将试样加热至1275℃,保温3分钟,然后保压炉冷至室温取出。The gas-atomized Ti-48Al-2Cr-8Nb pre-alloyed powder that had passed through a 100-mesh sieve was weighed and directly added to the graphite mold, and kept under pressure of 10 MPa for 3 minutes; Placed in a spark plasma sintering furnace, the furnace chamber was evacuated to a vacuum state, the pressure was 6pa, and the applied pressure was 30MPa; the sample was heated to 1300°C at a heating rate of 100°C/min, kept for 5 minutes, and then the pressure holding furnace After cooling to room temperature (25°C), the green body was sintered again, and the sample was heated to 1275°C at a heating rate of 100°C/min, kept for 3 minutes, and then cooled to room temperature in a pressure-holding furnace to be taken out.

经测试得,材料的晶粒尺寸为7-10μm,致密度可达99.5%,其室温抗压强度2537MPa,应变率为37.62%,硬度为293HV20。The test shows that the grain size of the material is 7-10μm, the density can reach 99.5%, the room temperature compressive strength is 2537MPa, the strain rate is 37.62%, and the hardness is 293HV20 .

由图1和图2可以看出,两次烧结后,试样的晶粒尺寸有了明显的减小。并结合图3和图4中的室温压缩应力应变曲线可以证明,晶粒细化后的材料的室温抗压强度和塑性有了明显的提升,进而说明SPS烧结加后处理工艺可以通过细化晶粒尺寸提高Ti-48Al-2Cr-8Nb合金的力学性能。It can be seen from Figure 1 and Figure 2 that the grain size of the sample has been significantly reduced after two sintering. Combined with the room temperature compressive stress-strain curves in Figures 3 and 4, it can be proved that the room temperature compressive strength and plasticity of the grain-refined material have been significantly improved, which further indicates that the SPS sintering and post-treatment process can refine the grain. Grain size improves the mechanical properties of Ti-48Al-2Cr-8Nb alloy.

Ti-48Al-2Cr-8Nb材料在烧结过程中随着温度的升高,试样会产生相变过程。During the sintering process of Ti-48Al-2Cr-8Nb material, the sample will undergo a phase transition process with the increase of temperature.

烧结温度为1200℃时,试样位于γ相区,当烧结温度升高到1300℃时,试样进入α+γ双相区,材料产生相变过程。值得注意的是,发现相变过程会使得晶粒尺寸显著减小。基于此原理,设计出通过多次烧结制备细晶钛铝合金的方法。When the sintering temperature is 1200℃, the sample is located in the γ phase region. When the sintering temperature rises to 1300℃, the sample enters the α+γ dual-phase region, and the material undergoes a phase transition process. Notably, the phase transformation process was found to result in a significant reduction in grain size. Based on this principle, a method for preparing fine-grained titanium-aluminum alloy by multiple sintering is designed.

Claims (3)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910784835.3ACN110744044B (en) | 2019-08-23 | 2019-08-23 | Preparation method of fine-grained Ti-48Al-2Cr-8Nb titanium-aluminum alloy by spark plasma sintering |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910784835.3ACN110744044B (en) | 2019-08-23 | 2019-08-23 | Preparation method of fine-grained Ti-48Al-2Cr-8Nb titanium-aluminum alloy by spark plasma sintering |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110744044Atrue CN110744044A (en) | 2020-02-04 |

| CN110744044B CN110744044B (en) | 2022-04-12 |

Family

ID=69275870

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910784835.3AActiveCN110744044B (en) | 2019-08-23 | 2019-08-23 | Preparation method of fine-grained Ti-48Al-2Cr-8Nb titanium-aluminum alloy by spark plasma sintering |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110744044B (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112692281A (en)* | 2020-11-23 | 2021-04-23 | 北京理工大学 | Preparation method of secondary hardening ultrahigh-strength steel by utilizing SPS sintering and deformation |

| CN112756624A (en)* | 2020-12-11 | 2021-05-07 | 丹阳层现三维科技有限公司 | Method for reducing cracks in selective laser melting printing titanium-aluminum alloy |

| CN116103538A (en)* | 2023-02-10 | 2023-05-12 | 广东省科学院新材料研究所 | Fine-grained high-density titanium-aluminum alloy and preparation method thereof |

| CN116200622A (en)* | 2023-04-27 | 2023-06-02 | 西安稀有金属材料研究院有限公司 | Preparation method of superfine crystal TiAl alloy and composite material thereof |

| CN116275068A (en)* | 2023-03-21 | 2023-06-23 | 宁波江丰电子材料股份有限公司 | A kind of preparation method of titanium aluminum alloy target material |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104550956A (en)* | 2015-01-20 | 2015-04-29 | 哈尔滨工业大学 | Component preparation method through beta-gamma titanium-aluminum alloy prealloy powder spark plasma sintering |

| CN104561629A (en)* | 2015-01-20 | 2015-04-29 | 哈尔滨工业大学 | Method for improving properties of TiAl alloy by adding graphene |

| CN104588653A (en)* | 2015-01-20 | 2015-05-06 | 哈尔滨工业大学 | Preparation method of TiAl alloy profile |

| JP2019037992A (en)* | 2017-08-23 | 2019-03-14 | 国立大学法人 名古屋工業大学 | Grain refiner for casting containing heterogeneous core particles in high concentration and method for producing the same |

| KR20190050562A (en)* | 2017-11-03 | 2019-05-13 | (주)차세대소재연구소 | Manufacturing method of aluminum-titanium composite and aluminum-titanium composite manufactured by the same |

| CN110004313A (en)* | 2019-04-11 | 2019-07-12 | 南京理工大学 | A method for preparing cemented carbide based on spark plasma two-step sintering |

- 2019

- 2019-08-23CNCN201910784835.3Apatent/CN110744044B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104550956A (en)* | 2015-01-20 | 2015-04-29 | 哈尔滨工业大学 | Component preparation method through beta-gamma titanium-aluminum alloy prealloy powder spark plasma sintering |

| CN104561629A (en)* | 2015-01-20 | 2015-04-29 | 哈尔滨工业大学 | Method for improving properties of TiAl alloy by adding graphene |

| CN104588653A (en)* | 2015-01-20 | 2015-05-06 | 哈尔滨工业大学 | Preparation method of TiAl alloy profile |

| JP2019037992A (en)* | 2017-08-23 | 2019-03-14 | 国立大学法人 名古屋工業大学 | Grain refiner for casting containing heterogeneous core particles in high concentration and method for producing the same |

| KR20190050562A (en)* | 2017-11-03 | 2019-05-13 | (주)차세대소재연구소 | Manufacturing method of aluminum-titanium composite and aluminum-titanium composite manufactured by the same |

| CN110004313A (en)* | 2019-04-11 | 2019-07-12 | 南京理工大学 | A method for preparing cemented carbide based on spark plasma two-step sintering |

Non-Patent Citations (1)

| Title |

|---|

| 杨鑫: "放电等离子烧结制备钛铝基合金及致密化机理研究", 《中国博士学位论文全文数据库工程科技Ⅰ辑》* |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112692281A (en)* | 2020-11-23 | 2021-04-23 | 北京理工大学 | Preparation method of secondary hardening ultrahigh-strength steel by utilizing SPS sintering and deformation |

| CN112756624A (en)* | 2020-12-11 | 2021-05-07 | 丹阳层现三维科技有限公司 | Method for reducing cracks in selective laser melting printing titanium-aluminum alloy |

| CN116103538A (en)* | 2023-02-10 | 2023-05-12 | 广东省科学院新材料研究所 | Fine-grained high-density titanium-aluminum alloy and preparation method thereof |

| CN116275068A (en)* | 2023-03-21 | 2023-06-23 | 宁波江丰电子材料股份有限公司 | A kind of preparation method of titanium aluminum alloy target material |

| CN116200622A (en)* | 2023-04-27 | 2023-06-02 | 西安稀有金属材料研究院有限公司 | Preparation method of superfine crystal TiAl alloy and composite material thereof |

| CN116200622B (en)* | 2023-04-27 | 2023-08-04 | 西安稀有金属材料研究院有限公司 | Preparation method of superfine crystal TiAl alloy and composite material thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110744044B (en) | 2022-04-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110744044B (en) | Preparation method of fine-grained Ti-48Al-2Cr-8Nb titanium-aluminum alloy by spark plasma sintering | |

| CN108103381B (en) | A kind of high-strength FeCoNiCrMn high-entropy alloy and preparation method thereof | |

| CN102181809B (en) | Large-size metallic glass composite material with tensile ductility and preparation method thereof | |

| CN103752836B (en) | A kind of method preparing fine grain spherical niobium titanium base alloy powder | |

| CN110607464A (en) | A hot isostatic pressing process of Ti2AlNb alloy powder | |

| WO2019085183A1 (en) | Method for fabricating titanium and titanium alloy metallurgical products | |

| CN112391556A (en) | High-strength high-conductivity Cu-Cr-Nb alloy reinforced by double-peak grain size and double-scale nanophase | |

| CN109628867B (en) | Heat treatment method for obtaining peritectic casting TiAl alloy near lamellar structure | |

| CN107043870B (en) | A kind of high Si content high-temperature titanium alloy and preparation method thereof | |

| CN106636741A (en) | Preparation method for TiAl alloy bar | |

| CN114277282B (en) | Copper matrix composite material and preparation method thereof | |

| CN108588534B (en) | A kind of in-situ self-generated carbide dispersion reinforced multi-principal alloy and preparation method thereof | |

| CN111304476A (en) | A kind of preparation method of fine-grained powder superalloy that suppresses the formation of original grain boundaries | |

| CN106001566A (en) | High-strength high-entropy alloy NbMoTaWV and preparation method thereof | |

| CN106435299A (en) | A kind of SiC particle reinforced aluminum matrix composite material and preparation method thereof | |

| CN106435282A (en) | Cobalt base high-temperature alloy and preparation method thereof | |

| CN115070052A (en) | Novel binary-structure nickel-titanium shape memory alloy and 4D printing preparation method and application thereof | |

| JP4994843B2 (en) | Nickel-containing alloy, method for producing the same, and article obtained therefrom | |

| TWI387661B (en) | Manufacturing method of nickel alloy target | |

| CN109112367B (en) | Graphene-reinforced Al-Si-Mg cast aluminum alloy and preparation method thereof | |

| CN110449580B (en) | A powder metallurgy high-strength and toughness boron-containing high-entropy alloy material and its preparation method and application | |

| CN106244988A (en) | A kind of high resistant target manufacture method | |

| CN106756377B (en) | A kind of W/TiNi memory alloy composite materials and preparation method thereof | |

| CN104357783A (en) | Titanium-aluminum alloy powder material for thermal spraying and preparation method thereof | |

| CN111014651A (en) | A kind of short fiber reinforced high temperature titanium alloy powder for 700~750℃ and its preparation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |