CN110717259A - User-oriented battery energy storage configuration and operation optimization method - Google Patents

User-oriented battery energy storage configuration and operation optimization methodDownload PDFInfo

- Publication number

- CN110717259A CN110717259ACN201910910953.4ACN201910910953ACN110717259ACN 110717259 ACN110717259 ACN 110717259ACN 201910910953 ACN201910910953 ACN 201910910953ACN 110717259 ACN110717259 ACN 110717259A

- Authority

- CN

- China

- Prior art keywords

- energy storage

- optimization

- day

- user

- monthly

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/04—Forecasting or optimisation specially adapted for administrative or management purposes, e.g. linear programming or "cutting stock problem"

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q50/00—Information and communication technology [ICT] specially adapted for implementation of business processes of specific business sectors, e.g. utilities or tourism

- G06Q50/06—Energy or water supply

Landscapes

- Business, Economics & Management (AREA)

- Engineering & Computer Science (AREA)

- Economics (AREA)

- Human Resources & Organizations (AREA)

- Strategic Management (AREA)

- Theoretical Computer Science (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Marketing (AREA)

- General Physics & Mathematics (AREA)

- General Business, Economics & Management (AREA)

- Tourism & Hospitality (AREA)

- Quality & Reliability (AREA)

- Game Theory and Decision Science (AREA)

- Operations Research (AREA)

- Development Economics (AREA)

- Entrepreneurship & Innovation (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- General Health & Medical Sciences (AREA)

- Primary Health Care (AREA)

- Supply And Distribution Of Alternating Current (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于电力系统技术领域,具体是针对用户侧电池储能进行配置与运行优化方法。The invention belongs to the technical field of power systems, in particular to a configuration and operation optimization method for user-side battery energy storage.

背景技术Background technique

用电成本是电力大用户经营成本的重要组成部分。电池储能(下文简称“储能”)可通过“低储高放”策略,即在用户电力负荷及电价较低的时候存储电能,在用户电力负荷及电价较高的时候放出电能,在不改变用户用电行为的情况下,削减用户负荷月最大需量值,减少基本电费的同时产生削峰填谷收益。并且,用户侧储能服务对象明确,变化因素较少,更有利于储能的运行。同时,国家出台了《关于促进储能技术与产业发展的指导意见》、《关于北方地区清洁能源供暖价格政策的意见》等一系列政策,不仅大力支持用户侧储能的发展,而且提出要适当扩大销售侧峰谷电价差,未来用户峰谷价差有望继续拉大,这些都有助于提升用户侧储能的投资效益。因此用户侧安装储能是降低电力大用户经营成本的重要手段。The cost of electricity is an important part of the operating cost of large power users. Battery energy storage (hereinafter referred to as "energy storage") can adopt the strategy of "low storage and high discharge", that is, to store electric energy when the user's power load and electricity price are low, and release electricity when the user's power load and electricity price are high. In the case of changing the user's electricity consumption behavior, the monthly maximum demand value of the user's load is reduced, and the basic electricity fee is reduced while generating peak-shaving and valley-filling benefits. In addition, the user-side energy storage service object is clear, and there are few changing factors, which is more conducive to the operation of energy storage. At the same time, the state has issued a series of policies such as "Guiding Opinions on Promoting Energy Storage Technology and Industrial Development" and "Opinions on Clean Energy Heating Price Policies in Northern Regions", which not only vigorously support the development of user-side energy storage, but also propose that appropriate Expanding the peak-valley electricity price difference on the sales side, and the future user peak-valley price difference is expected to continue to widen, all of which will help improve the investment efficiency of user-side energy storage. Therefore, installing energy storage on the user side is an important means to reduce the operating cost of large power users.

我国用户侧储能市场发展空间巨大,然而目前,用户侧储能的发展并没有达到预期,一方面用户仍难以承担储能较高的投资成本,另一方面,储能运行效率较低,未能充分发挥储能优化运行带来的经济效益。因此,对用户侧储能的配置及运行进行优化研究,具有重要意义。my country's consumer-side energy storage market has a huge space for development. However, at present, the development of consumer-side energy storage has not met expectations. On the one hand, users are still unable to bear the high investment cost of energy storage. It can give full play to the economic benefits brought by the optimized operation of energy storage. Therefore, it is of great significance to optimize the configuration and operation of user-side energy storage.

目前储能配置及运行优化研究分为电网侧和用户侧。电网侧的储能优化研究主要为了保证电网的安全可靠运行、解决负荷平衡等问题,而用户侧储能优化研究的目的在于合理转移负荷、提高用户安装储能后的经济性,所以电网侧储能优化研究成果难以直接应用到户侧。用户侧储能优化的研究中,部分研究只针对储能配置或运行中的一方面进行优化,部分研究只考虑削峰填谷或需量防守的经济性。还有部分研究通过预先确定调度策略进行储能容量配置及日前运行规划,这种方法不仅很难得到储能最佳配置容量,而且因为没有考虑电力负荷预测误差的影响,导致储能日内实际运行时表现不佳。因此,目前缺少既同时考虑储能配置及运行优化,又在储能运行时考虑负荷预测误差影响实现实时滚动优化的研究。At present, energy storage configuration and operation optimization research is divided into grid side and user side. The energy storage optimization research on the grid side is mainly to ensure the safe and reliable operation of the grid and solve problems such as load balance, while the purpose of the energy storage optimization research on the user side is to reasonably transfer the load and improve the economy after the user installs energy storage. It is difficult to directly apply the research results to the household side. In the research on user-side energy storage optimization, some studies only optimize one aspect of energy storage configuration or operation, and some studies only consider the economics of peak shaving and valley filling or demand defense. In some studies, energy storage capacity allocation and day-ahead operation planning are carried out by pre-determining dispatching strategies. This method not only makes it difficult to obtain the optimal configuration capacity of energy storage, but also does not consider the influence of power load forecast errors, resulting in the actual operation of energy storage during the day. poor performance. Therefore, there is currently a lack of research that considers both energy storage configuration and operation optimization, and considers the influence of load forecast errors during energy storage operation to achieve real-time rolling optimization.

发明内容SUMMARY OF THE INVENTION

本发明所要解决的技术问题是克服上述现有技术存在的缺陷,提出一种针对用户侧电池储能的配置与运行进行优化的方法,该方法以大工业用户电费的计费规则为基础,建立需量防守与削峰填谷相结合的储能配置优化模型;为了保证在储能投入运行后实现最佳的经济效益,提出了储能电池充放电状态转换次数约束,然后结合负荷预测数据,构建了储能月前和日内滚动优化模型。与日前运行优化相比,日内滚动优化通过实时更新实际负荷数据及月需量防守值,不断修正负荷预测误差,使用户获得更高的收益。The technical problem to be solved by the present invention is to overcome the above-mentioned defects in the prior art, and propose a method for optimizing the configuration and operation of battery energy storage on the user side. The energy storage configuration optimization model combining demand defense and peak shaving and valley filling; in order to ensure the best economic benefits after the energy storage is put into operation, a constraint on the number of transitions between the charging and discharging states of the energy storage battery is proposed, and then combined with the load forecast data, The pre-month and intra-day rolling optimization models for energy storage are constructed. Compared with the day-ahead operation optimization, the intra-day rolling optimization continuously corrects the load forecast error by updating the actual load data and the monthly demand defense value in real time, so that users can obtain higher benefits.

本发明方法包括以下步骤:The method of the present invention comprises the following steps:

步骤1:基于工业大用户的电费计费规则,针对储能可以通过“低储高放”等策略合理地对用户电力负荷进行转移,降低用户用电的月最大需量的特点,通过建立储能收益模型,计算用户加装储能后获得的削峰填谷收益及月需量防守收益。Step 1: Based on the electricity billing rules of large industrial users, according to the characteristics of energy storage, the user's power load can be transferred reasonably through strategies such as "low storage and high discharge" to reduce the monthly maximum demand of users' electricity. The energy income model is used to calculate the peak shaving and valley filling income and monthly demand defense income obtained by users after installing energy storage.

步骤2:针对储能电池运行的硬性物理要求,建立储能电池物理约束条件;同时考虑保证储能运行时具有良好的性能,建立储能电池性能约束条件。Step 2: According to the hard physical requirements of the operation of the energy storage battery, establish the physical constraints of the energy storage battery; at the same time, consider ensuring the good performance of the energy storage battery during operation, and establish the performance constraints of the energy storage battery.

步骤3:制定储能配置优化和运行优化策略,确定负荷预测模型,并利用用户历史负荷数据,进行月前负荷预测和日前负荷预测。Step 3: Formulate energy storage configuration optimization and operation optimization strategies, determine the load forecast model, and use the user's historical load data to carry out monthly load forecasting and day-ahead load forecasting.

步骤4:以用户安装储能后每月综合效益最高为目标,构建储能配置优化模型,优化储能配置的功率与容量。Step 4: With the goal of achieving the highest monthly comprehensive benefit after users install energy storage, build an energy storage configuration optimization model to optimize the power and capacity of energy storage configuration.

步骤5:以优化月的需量防守收益与削峰填谷收益之和最高为目标,构建储能运行月前优化模型。Step 5: With the goal of achieving the highest sum of demand defense benefits and peak-shaving and valley-filling benefits in the optimization month, build an optimization model for energy storage before the month of operation.

步骤6:以用户每天的削峰填谷收益最大为目标函数,构建储能日前运行优化模型。Step 6: Build an optimization model for energy storage day-ahead operation based on the objective function that the user's daily peak-shaving and valley-filling benefits are maximized.

步骤7:在MATLAB软件中基于YALMIP工具箱调用CPLEX求解器对储能优化中各模型进行求解。Step 7: In the MATLAB software, the CPLEX solver is called based on the YALMIP toolbox to solve each model in the energy storage optimization.

本发明针对电力大用户负荷情况,结合峰谷电价及用户电费的计费规则,对用户侧储能的配置与运行进行了优化研究。利用本发明既能同时对储能的配置及运行进行优化,又能在储能运行时考虑负荷预测误差影响实现实时滚动优化,且本发明的滚动优化算法能够更加合理地调度储能,为用户带来更多的经济效益,有效降低用户用电成本。Aiming at the load situation of large power users, the present invention conducts optimization research on the configuration and operation of energy storage on the user side in combination with the peak-valley electricity price and the billing rules of the user's electricity price. The present invention can not only optimize the configuration and operation of energy storage, but also realize real-time rolling optimization considering the influence of load prediction error during the operation of energy storage. Bring more economic benefits and effectively reduce the cost of electricity for users.

附图说明Description of drawings

图1为用户侧储能优化策略图。Figure 1 shows the optimization strategy of user-side energy storage.

图2为储能运行调度滚动优化算法流程图。Figure 2 is the flow chart of the energy storage operation scheduling rolling optimization algorithm.

图3为峰谷电价时间分布图。Figure 3 shows the time distribution of peak and valley electricity prices.

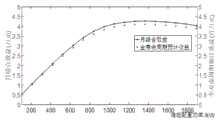

图4为不同储能配置下收益变化图。Figure 4 shows the change of income under different energy storage configurations.

图5为有无性能约束储能日内运行结果对比图。Figure 5 is a comparison chart of the intra-day operation results of energy storage with and without performance constraints.

图6为两种模型储能日运行优化结果图。Figure 6 shows the optimization results of the daily operation of the two models of energy storage.

图7为储能日前运行优化结果图。Figure 7 is a graph showing the optimization results of the energy storage's day-ahead operation.

图8为储能日内运行滚动优化结果图。Figure 8 shows the result of rolling optimization of energy storage operation within a day.

具体实施方式Detailed ways

以下结合附图对本发明作进一步说明,本发明包括以下步骤:The present invention is further described below in conjunction with the accompanying drawings, the present invention comprises the following steps:

步骤1:计算用户加装储能收益Step 1: Calculate the benefit of adding energy storage to users

对于工业大用户,供电公司收取的电费分为基本电费和电度电费两部分。其中用户需要支付的基本电费的收取形式有多种,目前大部分用户选择的都是按实际需量计费(每月实际记录到的最大需量),即当月的最大需量乘以基本电费价格(各地区不同);电度电费则是根据用户的实时用电量乘以对应时刻电价得到。For large industrial users, the electricity fee charged by the power supply company is divided into two parts: the basic electricity fee and the electricity fee. Among them, there are various forms of basic electricity charges that users need to pay. At present, most users choose to charge according to actual demand (the maximum demand actually recorded every month), that is, the maximum demand of the month multiplied by the basic electricity charge The price (different in each region); the electricity price is obtained by multiplying the real-time electricity consumption of the user by the electricity price at the corresponding time.

若用户预先安装储能电池,利用储能灵活的电功率吞吐特性,通过“低储高放”等策略合理地对用户电力负荷进行转移,能够降低用户用电的月最大需量值,从而产生月需量防守收益。同时,目前电力市场采用分时电价机制,储能通过谷时电价期间充电,峰时电价期间放电,利用峰谷电价差可产生削峰填谷收益。具体计算公式如下:If the user pre-installs the energy storage battery, utilizes the flexible electric power throughput characteristics of the energy storage, and reasonably transfers the user's power load through strategies such as "low storage and high discharge", which can reduce the monthly maximum demand value of the user's electricity, thereby generating a monthly Defensive gains in demand. At the same time, the current electricity market adopts a time-of-use electricity price mechanism. Energy storage is charged during the valley electricity price period and discharged during the peak electricity price period. The peak-valley electricity price difference can be used to generate peak-shaving and valley-filling benefits. The specific calculation formula is as follows:

Rj=m(PLmaxj-Pmaxj) (1)Rj =m(PLmaxj -Pmaxj ) (1)

式中:Rj为第j月的月需量防守收益,m为基本电费价格,PLmaxj、Pmaxj分别为第j月未加装储能时用户月最大负荷、加装储能后能够防守的最大需量值,即月需量防守值。Ri为第i天的削峰填谷收益,k为该日的时刻点总数,mt为调度日第t个时刻的峰谷电价;pcsi,t为第i天第t个时刻的储能运行功率,其中充电功率为正,放电功率为负。h为时间窗口长度,单位为小时。In the formula: Rj is the monthly demand defense income of the jth month, m is the basic electricity price, PLmaxj and Pmaxj are the monthly maximum load of the user when the energy storage is not installed in the jth month, and can be defended after the energy storage is installed. The maximum demand value of , that is, the monthly demand defense value. Ri is the income of peak shaving and valley filling on the ith day, k is the total number of time points on the day, mt is the peak and valley electricity price at the t th time on the dispatch day; pcsi,t is the storage price at the t th time on the ith day. The operating power, where the charging power is positive and the discharging power is negative. h is the length of the time window in hours.

步骤2:建立储能运行约束条件Step 2: Establish energy storage operation constraints

(1)储能电池物理约束(1) Physical constraints of energy storage batteries

1)储能充放电功率约束1) Energy storage charge and discharge power constraints

储能充放电功率不能超过储能额定功率:The charging and discharging power of the energy storage cannot exceed the rated power of the energy storage:

-PCS,N≤PCS,i,t≤PCS,N (3)-PCS,N ≤PCS,i,t ≤PCS,N (3)

式中,PCS,N为储能配置的额定功率。In the formula,PCS,N is the rated power of the energy storage configuration.

2)储能电池容量约束2) Energy storage battery capacity constraints

各个时刻储能电池内的电量应当在电池电量约束的上下限之间:The power in the energy storage battery at each moment should be between the upper and lower limits of the battery power constraint:

0.17SN≤Si,t≤SN (4)0.17SN ≤Si,t ≤SN (4)

式中,Si,t为第i天第t个时刻储能电池内的电量,SN为储能配置的额定容量。由于运行过程中储能电池荷电量一般不能达到或接近零,本文选取储能电池电量的下限为0.17SN,并选取储能电池初始荷电量为0.17SN。In the formula, Si,t is the power in the energy storage battery at the t-th time of the i-th day, and SN is the rated capacity of the energy-storage configuration. Since the charge of the energy storage battery generally cannot reach or approach zero during the operation, the lower limit of the energy storage battery is selected as 0.17SN in this paper, and the initial charge of the energy storage battery is selected as 0.17SN .

3)储能倍率约束3) Energy storage rate constraints

PCS,N=SN/η (5)PCS,N =SN /η (5)

式中,η为储能电池的能量倍率。In the formula, η is the energy rate of the energy storage battery.

(2)功率约束(2) Power constraints

用户实际负荷加上储能的运行功率不能小于0而向电网倒送功率,也不能超过用户月最大负荷值,否则就失去了需量防守的功能。The actual load of the user plus the operating power of the energy storage cannot be less than 0 and the power sent back to the power grid cannot exceed the monthly maximum load value of the user, otherwise the function of demand defense will be lost.

0≤PL,i,t+PCS,i,t≤PLmax,j (6)0≤PL,i,t +PCS,i,t ≤PLmax,j (6)

式中,PL,i,t为第i天第t个时刻用户实际负荷。In the formula,PL,i,t is the actual load of the user at the t-th time of the i-th day.

(3)储能电池性能约束(3) Energy storage battery performance constraints

储能运行时,确定状态下充放电功率的变化对储能的性能影响较小,充放电状态及待机状态之间的转换直接影响储能的调节成本及电池损耗。其次,储能的寿命损耗与吞吐量密切相关,减少吞吐量可延长其使用寿命。为更加合理地利用储能,结合峰谷电价对实际用户负荷数据进行了储能日内运行仿真对比,由仿真结果发现,对储能电池的日吞吐量进行限制,不仅减少了储能的吞吐量,而且能够很好地限制储能一天内充放电状态转换的次数。日吞吐量指一天内储能电池总的充电与放电电量之和,约束如下式所示:When the energy storage is running, the change of the charging and discharging power in the certain state has little effect on the performance of the energy storage, and the transition between the charging and discharging state and the standby state directly affects the adjustment cost of the energy storage and battery loss. Second, the lifetime loss of energy storage is closely related to throughput, and reducing throughput can extend its lifetime. In order to make more rational use of energy storage, combined with the peak-valley electricity price, a simulation comparison of energy storage intraday operation was carried out on the actual user load data. From the simulation results, it was found that limiting the daily throughput of energy storage batteries not only reduced the throughput of energy storage , and can well limit the number of charge-discharge state transitions of the energy storage in a day. The daily throughput refers to the sum of the total charge and discharge of the energy storage battery in one day, and the constraints are as follows:

Qi≤Qmax (7)Qi ≤Qmax (7)

式中:Qi为第i天储能的日吞吐量,Qmax为储能日吞吐量上限,其取值根据用户负荷、峰谷电价分布、PCS性能要求等因素综合考虑而定。In the formula: Qi is the daily throughput of the energy storage on the i-th day, and Qmax is the upper limit of the daily throughput of the energy storage.

步骤3:构建储能优化策略及进行负荷预测Step 3: Build an energy storage optimization strategy and perform load forecasting

储能优化分为配置优化和运行优化两部分。首先,基于用户的历史负荷数据,构建储能配置优化模型,求解确定最优的储能配置功率及容量。然后,基于已确定的储能配置功率及容量,利用月前负荷预测数据,构建月前优化模型确定一个预测的月需量防守值。在尽量满足月需量防守值要求的基础上,结合日前负荷预测数据,构建储能日内运行调度优化模型。同时,考虑负荷预测误差的影响,对储能日内运行调度进行实时滚动优化,及时更新月需量防守值,最终得到储能的日调度指令,储能优化的整体策略如图1所示。Energy storage optimization is divided into two parts: configuration optimization and operation optimization. First, based on the user's historical load data, an energy storage configuration optimization model is constructed to solve and determine the optimal energy storage configuration power and capacity. Then, based on the determined energy storage configuration power and capacity, using the pre-month load forecast data, a pre-month optimization model is constructed to determine a predicted monthly demand defense value. On the basis of meeting the requirements of the monthly demand defense value as much as possible, combined with the day-ahead load forecast data, an optimization model for the daily operation and scheduling of energy storage is constructed. At the same time, considering the influence of load forecasting error, real-time rolling optimization is carried out on the daily operation scheduling of energy storage, and the defensive value of monthly demand is updated in time, and the daily scheduling instruction of energy storage is finally obtained. The overall strategy of energy storage optimization is shown in Figure 1.

储能配置优化及月前优化时,目的是确定合适的配置选型及月需量防守值以获得最优收益,时间窗口设为供电企业的电量采集时间15min,即每天k=96个时刻点。在进行储能日运行调度优化时,关注的是储能每个时刻的运行功率,以实现需量防守并获得削峰填谷收益,为充分发挥储能的分钟级乃至秒级的快速响应性能,灵活地调节负荷功率,时间窗口设为5min,即每天k=288个时刻点。When the energy storage configuration is optimized and optimized before the month, the purpose is to determine the appropriate configuration selection and monthly demand defense value to obtain the optimal benefit. The time window is set to the power collection time of the power supply enterprise 15min, that is, k = 96 time points per day . When optimizing the daily operation and scheduling of energy storage, the focus is on the operating power of energy storage at each moment, in order to achieve demand defense and obtain benefits from peak shaving and valley filling, in order to give full play to the minute-level or even second-level rapid response performance of energy storage. , flexibly adjust the load power, the time window is set to 5min, that is, k=288 time points per day.

在储能运行优化时需要进行负荷预测,本文采用机器学习方法进行负荷预测,在python3.5中,基于Tensorflow中的keras框架搭建长短期记忆(LSTM)模型,利用历史负荷数据进行月前及日前负荷预测。月前预测和日前预测的预测结果与真实负荷数据之间的平均绝对误差百分比MAPE分别为8.756488和7.263825,负荷预测准确度能够满足储能运行调度优化的需求。Load forecasting is required when energy storage operation is optimized. In this paper, the machine learning method is used for load forecasting. In python3.5, a long short-term memory (LSTM) model is built based on the keras framework in Tensorflow. Load Forecasting. The average absolute error percentage MAPE between the forecast results of the month-ahead forecast and the day-ahead forecast and the real load data is 8.756488 and 7.263825, respectively, and the load forecasting accuracy can meet the needs of energy storage operation scheduling optimization.

步骤4:构建储能配置优化模型Step 4: Build an energy storage configuration optimization model

储能配置优化模型以用户安装储能后每月综合效益最高为目标,优化储能配置的功率与容量。The energy storage configuration optimization model aims at the highest monthly comprehensive benefit after the user installs the energy storage, and optimizes the power and capacity of the energy storage configuration.

为计算用户加装储能后的月综合效益,将用户加装储能的总投资进行折算,得到每个月的月折算成本费用C,具体计算见下式:In order to calculate the monthly comprehensive benefit after the user installs energy storage, the total investment of the user installed energy storage is converted to obtain the monthly converted cost C per month. The specific calculation is shown in the following formula:

式中:mp为储能每kW的购买价格,my为储能每kW的运维成本;mB为储能每kWh的投资单价;N为储能寿命。In the formula:mp is the purchase price of energy storage per kW, my is the operation and maintenance cost of energy storage per kW; mB is the investment unit price of energy storage per kWh; N is the life of energy storage.

储能配置优化模型的目标函数F1为储能月收益与月折算成本的差值,具体计算见公式(9)。The objective function F1of the energy storage configuration optimization model is the difference between the monthly revenue of energy storage and the monthly converted cost, and the specific calculation is shown in formula (9).

式中,y和d分别为仿真周期内总的月份数和天数。where y and d are the total number of months and days in the simulation period, respectively.

因此,储能配置优化模型以储能的配置功率、配置容量、各月的需量防守值及各时刻点储能的运行功率为自变量,且各自变量受公式(3)至(7)的约束。该模型仿真周期为多个月,可根据用户实际负荷数据情况进行设置。Therefore, the energy storage configuration optimization model takes the energy storage configuration power, configuration capacity, monthly demand defense value and energy storage operation power at each time point as independent variables, and the respective variables are subject to formulas (3) to (7). constraint. The simulation period of the model is several months, which can be set according to the actual load data of the user.

步骤5:构建储能运行月前优化模型Step 5: Build an optimization model for energy storage before operation

基于优化得到的储能配置及月负荷预测数据,寻求合理的月需量防守值时,优化模型的目标函数F2为优化月的需量防守收益与削峰填谷收益之和,具体公式如下:Based on the optimized energy storage configuration and monthly load forecast data, when seeking a reasonable monthly demand defense value, the objective function F2 of the optimization model is the sum of the optimal monthly demand defense income and the peak- shaving and valley-filling income. The specific formula is as follows :

该模型与储能配置优化模型不同的是模型中储能电池的配置为已知量,已由储能配置优化模型求解确定;模型的自变量为月需量防守值及储能电池每个时刻的运行功率,仿真周期为一个月,dj为第j月份对应天数,约束条件公式(3)至(7)所示。The difference between this model and the energy storage configuration optimization model is that the configuration of the energy storage battery in the model is a known quantity, which has been determined by the energy storage configuration optimization model; the independent variables of the model are the monthly demand defense value and the energy storage battery at each moment. The running power of , the simulation period is one month, dj is the number of days corresponding to the jth month, and the constraint formulas (3) to (7) are shown.

步骤6:构建日内运行滚动优化模型Step 6: Build an intraday running rolling optimization model

储能日前运行优化模型的目标函数F3通常为用户每天的削峰填谷收益,具体公式如下:The objective function F3 of the energy storage optimization model for the day-to-day operation is usually the daily peak-shaving and valley-filling benefit of the user. The specific formula is as follows:

储能日前优化模型以月前优化得到的月需量防守值Pmax为标准,不会更新月需量防守值,最终的月最大需量值为经过储能调度后的用户月负荷最大值。若完全按照日前优化的结果进行储能调度,当电力负荷实际值偏高时,最后该月份的月最大需量值就会比月前优化得到的Pmax高,导致优化结果不理想。若考虑负荷预测误差,为控制储能实际运行调度时实际最大需量值在月前优化得到的Pmax之下,储能不完全按照日前优化结果进行调度,则在电力负荷真实值偏高的时刻点,与日前优化结果相比,储能系统会放出更多的电量,可能会导致储能电池的电量提前耗尽,失去对剩余时间的调峰能力。因此,为解决以上问题需构建日内运行滚动优化模型。The energy storage day-ahead optimization model takes the defensive monthly demand valuePmax obtained by optimization a month ago as the standard, and will not update the defensive monthly demand value. The final maximum monthly demand value is the maximum monthly load of users after energy storage scheduling. If the energy storage scheduling is carried out completely according to the results of the previous optimization, when the actual value of the power load is too high, the monthly maximum demand value of the last month will be higher than thePmax optimized before the month, resulting in an unsatisfactory optimization result. If the load prediction error is considered, in order to control the actual operation and dispatch of the energy storage, the actual maximum demand value is below thePmax optimized a month ago, and the energy storage is not completely dispatched according to the optimization results of the day before, then the actual value of the power load is higher when the actual value of the power load is high. At this point in time, compared with the previous optimization results, the energy storage system will release more power, which may cause the power of the energy storage battery to be exhausted in advance and lose its peak-shaving ability for the remaining time. Therefore, in order to solve the above problems, it is necessary to build an intraday running rolling optimization model.

构建日内运行滚动优化模型过程中发现,若直接采用式(11)为目标函数,储能在电价谷时段充电时间较为随机,在第一个电价谷时段会出现电池能充满但并未充满的情况。这是因为算法为实时滚动优化,若后面出现电价谷时段无法充满,此时过去的时刻点储能运行功率已无法改变。为实现储能在电价谷时段的前面时刻点优先充电,将储能电量作为电价谷时段目标函数的一部分,使得在电价谷时段储能会选择尽早的充电,实现目标函数最大。此时日内运行滚动优化模型的目标函数采用分段函数F4表示:In the process of building the rolling optimization model for intraday operation, it is found that if Equation (11) is directly used as the objective function, the charging time of energy storage during the electricity price valley period is relatively random, and the battery can be fully charged but not fully charged during the first electricity price valley period. . This is because the algorithm is optimized for real-time rolling. If the electricity price valley cannot be fully charged later, the operating power of the energy storage at the past time point cannot be changed. In order to realize the priority charging of energy storage at the previous time point of the electricity price valley period, the energy storage capacity is taken as a part of the objective function of the electricity price valley period, so that the energy storage will choose to charge as soon as possible during the electricity price valley period to achieve the maximum objective function. At this time, the objective function of the intraday running rolling optimization model is represented by the piecewise functionF4 :

式中,Si,t为第i天第t个时刻储能电池内的电量,w为权重系数,其取值由仿真测试决定。In the formula, Si,t is the power in the energy storage battery at the t-th time of the i-th day, and w is the weight coefficient, the value of which is determined by the simulation test.

日内运行优化模型的仿真周期为一天,即k=288;该模型的约束条件与月前优化模型类似,不同的是自变量约束条件中的功率约束由式(6)变为式(13),即储能电池运行功率与用户负荷之和不能超过目前确定的月需量防守值。The simulation period of the intraday operation optimization model is one day, that is, k=288; the constraints of this model are similar to those of the previous optimization model, the difference is that the power constraint in the independent variable constraints is changed from equation (6) to equation (13), That is, the sum of the operating power of the energy storage battery and the user's load cannot exceed the currently determined monthly demand defense value.

0≤PL,τ+PCS,τ≤Pmax (13)0≤PL,τ +PCS,τ ≤Pmax (13)

式中,τ表示采集点时刻,由于供电企业采集每15min负荷平均值中的最大值作为最大需量,即采集点固定为每小时的0分、15分、30分和45分,因此模型中只需在上述采集点进行判断;PL,τ、PCS,τ分别为用户负荷及储能运行功率在采集点时刻前15min的平均值。In the formula, τ represents the time of the collection point. Since the power supply enterprise collects the maximum value of the average load every 15 minutes as the maximum demand, that is, the collection point is fixed at 0 minutes, 15 minutes, 30 minutes and 45 minutes per hour, so in the model It only needs to be judged at the above collection points;PL,τ andPCS,τ are the average values of user load and energy storage operating power 15 minutes before the collection point.

如若上述模型求解出错,则说明该时刻储能电池无法实现优化确定的月需量防守值,故以该日的日综合效益最高为目标,寻找调度日当前时刻储能能够防守的月最大需量最优值,对月需量防守值进行更新。月需量防守值更新模型的优化目标函数F5如下式所示:If there is an error in the solution of the above model, it means that the energy storage battery cannot achieve the optimally determined monthly demand defense value at this moment. Therefore, aiming at the highest daily comprehensive benefit on that day, find the maximum monthly demand that the energy storage can defend at the current moment of the dispatch day. Optimal value, update the defensive value of monthly demand. The optimization objective functionF5 of the monthly demand defense value update model is as follows:

目标函数第一部分表示第j月需量防守收益平均到每一天的数值,第二部分为该日削峰填谷收益。此时,计算Rj的公式(1)中的PLmax,j为该月第t个时刻之前的已知实际负荷与第t个及之后时刻的月前负荷预测数据中的最大值;第t个时刻之前PCS,i,t已确定,该模型以需量防守值及储能电池第t个及之后时刻的调度功率为自变量,约束条件如公式(3)、(4)、(7)及公式(13)所示。The first part of the objective function represents the average value of the demand defense income of the jth month to each day, and the second part is the peak-shaving and valley-filling income of that day. At this time, PLmax,j in the formula (1) for calculating Rj is the maximum value in the known actual load before the t-th time of the month and the pre-monthly load prediction data at the t-th and subsequent times;PCS,i,t has been determined before the time, the model takes the demand defense value and the dispatching power of the energy storage battery at the tth and subsequent times as independent variables, and the constraints are as follows: formulas (3), (4), (7) ) and formula (13).

步骤7:构建基于CPLEX求解器的储能优化算法Step 7: Build an energy storage optimization algorithm based on the CPLEX solver

储能优化中各模型均在MATLAB软件中基于YALMIP工具箱调用CPLEX求解器进行求解。其中,储能运行优化包含月前优化与日内运行调度滚动优化,算法流程如图2所示,具体步骤如下:Each model in the energy storage optimization is solved by calling the CPLEX solver based on the YALMIP toolbox in MATLAB software. Among them, energy storage operation optimization includes monthly optimization and daily operation scheduling rolling optimization. The algorithm flow is shown in Figure 2, and the specific steps are as follows:

1)基于月负荷预测数据,优化得到该月的需量防守值Pmax。1) Based on the monthly load forecast data, optimize the demand defense value Pmax of the month.

2)对于调度日的第t个时刻,优化所用的日负荷数据在第t个时刻之前为已知实际负荷数据,第t个及之后时刻为日前负荷预测数据。根据月需量防守值Pmax及约束条件,求解日内调度优化模型;若求解成功,则得到该日每个时刻的储能运行功率,从中获取第t个时刻的储能运行功率,并下令给储能实施调度,继续执行步骤(4);若求解出错,则执行步骤(3)。2) For the t-th time of the scheduling day, the daily load data used for optimization is the known actual load data before the t-th time, and the t-th and subsequent times are the day-ahead load forecast data. According to the monthly demand defense value Pmax and the constraints, solve the intraday scheduling optimization model; if the solution is successful, the energy storage operating power at each moment of the day will be obtained, and the energy storage operating power at the t-th moment will be obtained from it, and ordered to give The energy storage implements scheduling, and proceeds to step (4); if there is an error in the solution, proceed to step (3).

3)基于当前优化日的日负荷数据,求解月需量防守值更新模型,得到新的需量防守值Pmax,并获得第t个时刻点的储能运行功率,下令给储能实施调度。3) Based on the daily load data of the current optimization day, solve the monthly demand defense value update model, obtain a new demand defense value Pmax , and obtain the energy storage operating power at the t-th time point, and order the energy storage to implement scheduling.

4)判断第t个时刻是否属于电量采集点τ,若t∈τ,进行步骤(5),否则进行步骤(6)。4) Determine whether the t-th moment belongs to the power collection point τ, if t∈τ, go to step (5), otherwise go to step (6).

5)计算包括第t个时刻的前15min内,计入储能功率调整后的用户负荷的平均值PJ,并判断其是否超过Pmax,若超过则替换,即Pmax=PJ;若未超过执行步骤(6)。5) The calculation includes the average value PJ of the user load after the adjustment of the energy storage power within the first 15min of the t-th time, and judges whether it exceeds Pmax , if it exceeds, replace it, that is, Pmax =PJ ; if Step (6) is not exceeded.

6)判断t是否超过日时刻点总数k,若未超过则t=t+1,更新第t个时刻后的负荷预测数据,继续执行步骤(2);若超过k,则结束优化算法。6) Determine whether t exceeds the total number k of daily time points, if not, then t=t+1, update the load forecast data after the t-th time, and continue to perform step (2); if it exceeds k, end the optimization algorithm.

为验证本发明所述用户侧电池储能配置及运行优化策略的有效性和合理性,以某工业园区为例,分析其储能配置与运行策略。该园区供电电压等级为10kV,基本电费电价m为40元/千瓦,采取该省大工业两部制电价计价,峰谷电价时间分布如图3所示。目前,市场中适用于用户侧储能优化的电池类型主要以锂电池、铅酸电池、钠硫电池三种为主,其相关参数如下表所示:In order to verify the validity and rationality of the user-side battery energy storage configuration and operation optimization strategy of the present invention, an industrial park is taken as an example to analyze its energy storage configuration and operation strategy. The power supply voltage level of the park is 10kV, and the basic electricity price m is 40 yuan/kW. At present, the battery types suitable for user-side energy storage optimization in the market are mainly lithium batteries, lead-acid batteries, and sodium-sulfur batteries. The relevant parameters are shown in the following table:

表1三类储能电池参数Table 1 Parameters of three types of energy storage batteries

针对该园区的历史负荷数据及峰谷电价分布特点,经仿真测试后确定Qmax=2SN,w=0.083,对这三种电池进行储能配置优化,并利用投资回报率进行评估比较,结果如表2所示。According to the historical load data and peak-valley electricity price distribution characteristics of the park, Qmax=2SN and w=0.083 were determined after simulation tests. The energy storage configuration was optimized for these three batteries, and the return on investment was used for evaluation and comparison. The results are shown in the table below. 2 shown.

表2储能配置优化结果Table 2 Optimization results of energy storage configuration

由表2可知,该园区用户铁锂电池的投资回报率最高,铁锂电池能够以较小的投资成本获得更高的效益。故该园区选择配置铁锂电池最合适,最优配置功率为1365kW,配置容量为2730kWh。It can be seen from Table 2 that the iron-lithium battery for users in this park has the highest return on investment, and the iron-lithium battery can obtain higher benefits with a smaller investment cost. Therefore, it is most suitable to configure iron-lithium batteries in this park, with an optimal configuration power of 1365kW and a configuration capacity of 2730kWh.

为进一步说明,储能配置对用户效益的影响,以铁锂电池为例,仿真得到不同储能配置下该用户的月综合效益和全寿命周期预计收益,如图4所示。由图可以看出,随着储能配置容量的增加,月综合效益和全寿命周期预计收益均先增后降,这是因为储能达到一定容量后,月收益的增长幅度不足以抵消储能成本的增长幅度。储能功率为1365kW时,月综合效益和全寿命周期预计收益均达到最大。In order to further illustrate the impact of energy storage configuration on user benefits, taking iron-lithium batteries as an example, the monthly comprehensive benefits and life cycle expected benefits of the user under different energy storage configurations are simulated, as shown in Figure 4. It can be seen from the figure that with the increase of energy storage allocation capacity, the monthly comprehensive benefit and the expected income of the whole life cycle both increase first and then decrease. This is because after the energy storage reaches a certain capacity, the growth rate of the monthly income is not enough to offset the energy storage. increase in cost. When the energy storage power is 1365kW, the monthly comprehensive benefit and the expected benefit of the whole life cycle both reach the maximum.

为充分验证本发明所述优化策略的合理性和有效性,下面分别对所提储能性能约束、日内滚动优化模型目标函数进行仿真验证,并将本发明所提日内滚动优化方法的结果与已有研究中的日前运行优化方法结果进行对比分析:In order to fully verify the rationality and effectiveness of the optimization strategy of the present invention, the following simulations are carried out to verify the proposed energy storage performance constraints and the objective function of the intraday rolling optimization model, and the results of the intraday rolling optimization method proposed in the present invention are compared with the existing ones. Comparative analysis of the results of the optimization method of the previous run in the study:

(1)储能性能约束验证(1) Energy storage performance constraint verification

为验证本发明所提的储能性能约束条件的合理性,利用实际用户负荷数据,对有无储能性能约束条件下储能日内运行优化分段模型进行了仿真对比,优化结果如图5所示。由图中可以看出,与无性能约束相比,加上性能约束条件后,优化结果中储能的吞吐量、充放电状态及待机状态之间相互转换的次数显著减少,能够减少储能运行损耗,延长使用寿命。In order to verify the rationality of the energy storage performance constraints proposed in the present invention, the actual user load data is used to simulate and compare the optimal segmented models of energy storage intraday operation with or without energy storage performance constraints. The optimization results are shown in Figure 5. Show. It can be seen from the figure that compared with no performance constraints, after adding the performance constraints, the number of mutual conversions between the throughput, charging and discharging states and standby states of the energy storage in the optimization results is significantly reduced, which can reduce the operation of energy storage. loss and prolong service life.

(2)日内滚动优化模型目标函数验证(2) Intraday rolling optimization model objective function verification

在该园区储能配置确定后,以该园区某月份的实际历史负荷数据为例,分别采用单段函数模型式(11)和分段函数模型式(12),对该月份某一日进行储能运行优化仿真对比,优化结果如图6所示。由图可以看出,单段函数模型下储能在谷时充电时间较为随机,会出现第一个谷时段充不满的情况;本文所提的分段函数模型下储能充电集中在谷时段,且谷时段在前面的时刻点开始充电,能够保证储能电池电量满充,满足峰时段放电,获得更高的削峰填谷收益。After the energy storage configuration of the park is determined, taking the actual historical load data of a certain month in the park as an example, the single-segment function model formula (11) and the piecewise function model formula (12) are respectively used to store storage on a certain day of the month. The optimization simulation comparison can be run, and the optimization results are shown in Figure 6. It can be seen from the figure that under the single-segment function model, the charging time of the energy storage during the valley period is relatively random, and there will be a situation where the first valley period is not fully charged; under the piecewise function model proposed in this paper, the energy storage charging is concentrated in the valley period. In addition, the charging starts at the previous time point during the valley period, which can ensure that the energy storage battery is fully charged, meet the discharge during the peak period, and obtain higher peak-shaving and valley-filling benefits.

(3)日前运行优化与日内滚动优化结果对比(3) Comparison of results between day-ahead operation optimization and intra-day rolling optimization

首先对某月进行月负荷预测,求得该月的月负荷最大值为7732.9kw,采用2.3.1节的模型,优化得到月需量防守值6006kW。然后选择该月中某一日,按照日前运行优化调度的结果如图7所示,日削锋填谷收益为2178.69元;在此调度日之前,经过储能调整后的用户负荷最大值已经达到6731.33kW,则该调度日平均到每一天的需量防守收益为1335.43元,日综合效益为3541.12元。First, the monthly load forecast is carried out for a certain month, and the maximum monthly load of the month is obtained as 7732.9kw. Using the model in Section 2.3.1, the optimal monthly demand defense value is 6006kW. Then select a certain day in the month, as shown in Figure 7, according to the results of the optimized scheduling operation the day before, the daily income from cutting the front and filling the valley is 2178.69 yuan; before this scheduling day, the maximum user load adjusted by energy storage has reached 6731.33kW, then the average demand defense income of the dispatching day to each day is 1335.43 yuan, and the daily comprehensive benefit is 3541.12 yuan.

为验证本文滚动优化算法的有效性,同一日储能日内运行滚动优化结果如图8所示。此时的月需量防守值已更新为6584.96kW,日削锋填谷收益为2317.59元。该日实际负荷经过储能调整后的日负荷最大值为6583.31kW,未超出此时的月需量防守值,则该调度日平均到每一天的需量防守收益为1530.59元,日综合效益为3848.18元。储能在谷时段充电时间较为集中,比较合理。In order to verify the validity of the rolling optimization algorithm in this paper, the rolling optimization results of the energy storage operation within the same day are shown in Figure 8. At this time, the monthly demand defense value has been updated to 6584.96kW, and the daily income from cutting the front and filling the valley is 2317.59 yuan. The maximum daily load of the actual load on that day after the energy storage adjustment is 6583.31kW, which does not exceed the monthly demand defense value at this time, then the average demand defense income of the dispatch day to each day is 1530.59 yuan, and the daily comprehensive benefit is 3848.18 yuan. The charging time of energy storage during the valley period is relatively concentrated and reasonable.

两种方法仿真结果对比可以发现,该调度日下,本文所提日内运行滚动优化算法得到的日综合收益,比日前运行优化算法高出334.06元。对该月份每一天都分别进行两种方法下的储能日运行优化仿真,对比结果发现:日内运行滚动优化与日前运行优化算法下,该月份最终的月最大需量值分别为6631.66kW与6731.33kW,月综合收益分别为103402.4元与94400.13元,即日内运行滚动优化比日前运行优化月综合收益高出9002.27元。具体到日,日内运行滚动优化比日前运行优化日综合收益最高高出了668.5元,故本文所提日内运行滚动优化算法能够更合理地调度储能,为用户带来更多的经济效益,更好的降低用户用电成本。Comparing the simulation results of the two methods, it can be found that under this scheduling day, the daily comprehensive income obtained by running the rolling optimization algorithm proposed in this paper is 334.06 yuan higher than that of the optimization algorithm running the day before. The daily operation optimization simulation of energy storage under the two methods is carried out for each day of the month, and the comparison results show that: under the rolling optimization algorithm of intraday operation and the optimization algorithm of day-ahead operation, the final monthly maximum demand values of the month are 6631.66kW and 6731.33 respectively. kW, the monthly comprehensive income is 103,402.4 yuan and 94,400.13 yuan respectively, that is, the monthly comprehensive income of the rolling optimization of the intraday operation is 9002.27 yuan higher than that of the optimization of the day-to-day operation. Specific to the day, the daily operation rolling optimization in the day is higher than the daily comprehensive income of 668.5 yuan. Therefore, the intraday operation rolling optimization algorithm proposed in this paper can schedule energy storage more reasonably, bring more economic benefits to users, and improve the efficiency of energy storage. It is good to reduce the user's electricity cost.

本发明同时考虑储能配置及运行优化,针对不同的用户,能够利用投资回报率评估选择出最合适的储能电池类型及配置容量。在构建各优化模型时加入储能运行性能约束,储能在各电价时段不会随机充放电,储能日吞吐量、充放电状态及待机状态之间转换的次数明显减少,储能运行更加合理,能够减少运行损耗,延长储能寿命。在储能日运行优化时,对每一个时刻点之前的数据采用实际负荷数据,之后的数据采用预测负荷数据,并将储能荷电状态作为目标函数的一部分,构建了以分段函数为目标函数的日内运行调度优化模型,实现了实时滚动优化;其次,构建了月需量防守值更新模型,在储能无法防守现有的月最大需量值时,及时更新月需量防守值,不断修正负荷预测误差的影响。算例验证本发明所提滚动优化算法能够更加合理地调度储能,为用户带来更多的经济效益,有效降低用户用电成本。The present invention simultaneously considers energy storage configuration and operation optimization, and can select the most suitable energy storage battery type and configuration capacity by evaluating the return on investment for different users. The energy storage operation performance constraints are added in the construction of each optimization model, the energy storage will not be randomly charged and discharged during each electricity price period, the daily throughput of the energy storage, the number of transitions between the charging and discharging states and the standby state are significantly reduced, and the energy storage operation is more reasonable. , which can reduce operating losses and prolong the life of energy storage. When optimizing the daily operation of energy storage, the actual load data is used for the data before each time point, and the predicted load data is used for the subsequent data, and the state of charge of the energy storage is used as a part of the objective function to construct a piecewise function as the objective. The intraday operation scheduling optimization model of the function realizes real-time rolling optimization; secondly, an update model of the monthly demand defense value is constructed, and when the energy storage cannot defend the existing maximum monthly demand value, the monthly demand defense value is updated in time, and the monthly demand defense value is continuously updated. Correct the effect of load forecast errors. The calculation example verifies that the rolling optimization algorithm proposed in the present invention can schedule energy storage more reasonably, bring more economic benefits to users, and effectively reduce the electricity cost of users.

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910910953.4ACN110717259B (en) | 2019-09-25 | 2019-09-25 | User-oriented battery energy storage configuration and operation optimization method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910910953.4ACN110717259B (en) | 2019-09-25 | 2019-09-25 | User-oriented battery energy storage configuration and operation optimization method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110717259Atrue CN110717259A (en) | 2020-01-21 |

| CN110717259B CN110717259B (en) | 2021-08-03 |

Family

ID=69210824

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910910953.4AActiveCN110717259B (en) | 2019-09-25 | 2019-09-25 | User-oriented battery energy storage configuration and operation optimization method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110717259B (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112001598A (en)* | 2020-07-28 | 2020-11-27 | 四川大学 | Energy storage configuration evaluation and operation optimization method for different users based on energy storage selection |

| CN112086977A (en)* | 2020-08-28 | 2020-12-15 | 华南理工大学 | A user energy storage capacity allocation method based on the maximization of energy storage profit space |

| CN112668918A (en)* | 2021-01-04 | 2021-04-16 | 国网上海市电力公司 | Energy storage model selection method based on data model algorithm |

| CN112686463A (en)* | 2021-01-07 | 2021-04-20 | 合肥阳光新能源科技有限公司 | Demand data processing method and device and electronic equipment |

| CN113629705A (en)* | 2021-08-06 | 2021-11-09 | 河海大学 | User side energy storage optimal configuration method |

| US20220043414A1 (en)* | 2020-08-05 | 2022-02-10 | Korea Advanced Institute Of Science And Technology | Apparatus and method for operating energy storage system |

| CN114928054A (en)* | 2022-07-18 | 2022-08-19 | 国网江西省电力有限公司经济技术研究院 | Energy storage multi-target coordination optimization method and system considering new energy uncertainty |

| CN115693720A (en)* | 2022-08-16 | 2023-02-03 | 国网浙江省电力有限公司湖州供电公司 | A user-side energy storage optimization operation method |

| CN116187099A (en)* | 2023-04-24 | 2023-05-30 | 山东理工大学 | User side energy storage configuration method based on double-layer iteration |

| CN116308880A (en)* | 2023-03-02 | 2023-06-23 | 浙江万里扬能源科技有限公司 | A method for maximizing the benefits of operation and maintenance of user-side electrochemical energy storage power stations |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20090124231A1 (en)* | 1997-07-16 | 2009-05-14 | Kroll Family Trust | Self Defense Cell Phone With Projectiles |

| CN102361327A (en)* | 2011-10-17 | 2012-02-22 | 张家港智电可再生能源与储能技术研究所有限公司 | Battery energy storage system peaking cutting and valley filling method with consideration of battery service life |

| CN102622475A (en)* | 2012-02-29 | 2012-08-01 | 中国南方电网有限责任公司调峰调频发电公司 | Secondary programming model-based peak clipping and valley filling day-ahead optimization method for battery energy storage system |

| CN103514363A (en)* | 2013-07-18 | 2014-01-15 | 浙江大学 | Method for online setting of power network backup protection according to increment factors |

| CN108470240A (en)* | 2018-03-02 | 2018-08-31 | 东南大学 | A kind of energy storage two-phase optimization method based on requirement management |

- 2019

- 2019-09-25CNCN201910910953.4Apatent/CN110717259B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20090124231A1 (en)* | 1997-07-16 | 2009-05-14 | Kroll Family Trust | Self Defense Cell Phone With Projectiles |

| CN102361327A (en)* | 2011-10-17 | 2012-02-22 | 张家港智电可再生能源与储能技术研究所有限公司 | Battery energy storage system peaking cutting and valley filling method with consideration of battery service life |

| CN102622475A (en)* | 2012-02-29 | 2012-08-01 | 中国南方电网有限责任公司调峰调频发电公司 | Secondary programming model-based peak clipping and valley filling day-ahead optimization method for battery energy storage system |

| CN103514363A (en)* | 2013-07-18 | 2014-01-15 | 浙江大学 | Method for online setting of power network backup protection according to increment factors |

| CN108470240A (en)* | 2018-03-02 | 2018-08-31 | 东南大学 | A kind of energy storage two-phase optimization method based on requirement management |

Non-Patent Citations (4)

| Title |

|---|

| SHAOFEI SHEN等: "Regional Area Protection Scheme for Modern Distribution System", 《IEEE TRANSACTIONS ON SMART GRID》* |

| YUANYUAN SHI等: "Using Battery Storage for Peak Shaving and Frequency Regulation: Joint Optimization for Superlinear Gains", 《IEEE TRANSACTIONS ON POWER SYSTEMS》* |

| 王艳辉等: "基于专利分析的钠硫电池技术发展趋势研究", 《高技术通讯》* |

| 陈丽娟等: "基于需量管理的两阶段大用户储能优化模型", 《电力系统自动化》* |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112001598A (en)* | 2020-07-28 | 2020-11-27 | 四川大学 | Energy storage configuration evaluation and operation optimization method for different users based on energy storage selection |

| US20220043414A1 (en)* | 2020-08-05 | 2022-02-10 | Korea Advanced Institute Of Science And Technology | Apparatus and method for operating energy storage system |

| CN112086977A (en)* | 2020-08-28 | 2020-12-15 | 华南理工大学 | A user energy storage capacity allocation method based on the maximization of energy storage profit space |

| CN112086977B (en)* | 2020-08-28 | 2022-08-30 | 华南理工大学 | User energy storage capacity configuration method based on energy storage profit space maximization |

| CN112668918A (en)* | 2021-01-04 | 2021-04-16 | 国网上海市电力公司 | Energy storage model selection method based on data model algorithm |

| CN112686463A (en)* | 2021-01-07 | 2021-04-20 | 合肥阳光新能源科技有限公司 | Demand data processing method and device and electronic equipment |

| CN113629705B (en)* | 2021-08-06 | 2023-08-01 | 河海大学 | A user-side energy storage optimization configuration method |

| CN113629705A (en)* | 2021-08-06 | 2021-11-09 | 河海大学 | User side energy storage optimal configuration method |

| CN114928054A (en)* | 2022-07-18 | 2022-08-19 | 国网江西省电力有限公司经济技术研究院 | Energy storage multi-target coordination optimization method and system considering new energy uncertainty |

| CN114928054B (en)* | 2022-07-18 | 2022-11-08 | 国网江西省电力有限公司经济技术研究院 | Multi-objective coordinated optimization method and system for energy storage considering new energy uncertainty |

| CN115693720A (en)* | 2022-08-16 | 2023-02-03 | 国网浙江省电力有限公司湖州供电公司 | A user-side energy storage optimization operation method |

| CN116308880A (en)* | 2023-03-02 | 2023-06-23 | 浙江万里扬能源科技有限公司 | A method for maximizing the benefits of operation and maintenance of user-side electrochemical energy storage power stations |

| CN116187099A (en)* | 2023-04-24 | 2023-05-30 | 山东理工大学 | User side energy storage configuration method based on double-layer iteration |

| CN116187099B (en)* | 2023-04-24 | 2023-07-28 | 山东理工大学 | User side energy storage configuration method based on double-layer iteration |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110717259B (en) | 2021-08-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110717259A (en) | User-oriented battery energy storage configuration and operation optimization method | |

| CN112488362B (en) | An energy storage optimization configuration method for coordinating electric vehicles to participate in the auxiliary service market | |

| CN107370170B (en) | Energy storage system capacity configuration method considering capacity electricity price and load prediction error | |

| CN116151486B (en) | Multi-time-scale stochastic optimization method and device for photovoltaic charging station with energy storage system | |

| CN111244985B (en) | Distributed energy storage sequence optimization configuration method based on node comprehensive sensitivity coefficient | |

| CN108875992A (en) | A kind of virtual plant Optimization Scheduling a few days ago considering demand response | |

| CN110633854A (en) | An optimization planning method for the whole life cycle of energy storage battery multi-segment services | |

| CN114784907A (en) | Wind power plant energy storage capacity configuration method considering battery running state | |

| CN110086187A (en) | The energy storage peak shaving Optimization Scheduling a few days ago of meter and part throttle characteristics | |

| US12294214B1 (en) | Method and system for optimized scheduling of integrated energy system and electronic apparatus | |

| CN111859605B (en) | Echelon battery energy storage capacity configuration method considering full life cycle economy | |

| CN107453407A (en) | A kind of intelligent micro-grid distributed energy dispatching method | |

| CN115133607A (en) | User-side retired battery energy storage capacity configuration method, system, device and medium | |

| CN112928767B (en) | Distributed energy storage cooperative control method | |

| CN116702943A (en) | A wind farm energy storage capacity optimization allocation method considering output planning curve | |

| CN108683211B (en) | A Combination Optimization Method and Model of Virtual Power Plant Considering Distributed Power Volatility | |

| CN118228933A (en) | Light storage configuration scheduling method considering demand management and battery life loss | |

| CN115660327A (en) | Improved chaotic particle swarm energy storage optimization configuration method considering battery operation efficiency and attenuation characteristics | |

| CN119518783A (en) | A low-carbon optimal dispatching method for wind power system considering demand response | |

| CN115186962A (en) | User side energy storage scheduling optimization method, device and system considering demand | |

| CN118281917B (en) | Distribution network source-storage collaborative planning method, system, equipment and medium considering driving factors | |

| CN117394404A (en) | Wind farm energy storage capacity allocation method considering carbon efficiency and auxiliary frequency regulation | |

| CN117154783A (en) | Bidding method for photovoltaic and storage systems to participate in the energy-frequency market considering carbon emission reduction benefits | |

| CN115441494A (en) | Converter station capacity optimal configuration method and device based on flexible direct current interconnection system | |

| CN115062811A (en) | Optimization method and system of new energy planning scheme integrating economic factors and energy factors |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |