CN110694563A - Microchannel reactor with unsupported self-forming nylon membrane and preparation method - Google Patents

Microchannel reactor with unsupported self-forming nylon membrane and preparation methodDownload PDFInfo

- Publication number

- CN110694563A CN110694563ACN201911055555.5ACN201911055555ACN110694563ACN 110694563 ACN110694563 ACN 110694563ACN 201911055555 ACN201911055555 ACN 201911055555ACN 110694563 ACN110694563 ACN 110694563A

- Authority

- CN

- China

- Prior art keywords

- microchannel reactor

- nylon membrane

- main channel

- inlets

- solution

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000012528membraneSubstances0.000titleclaimsabstractdescription75

- 239000004677NylonSubstances0.000titleclaimsabstractdescription63

- 229920001778nylonPolymers0.000titleclaimsabstractdescription63

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription11

- NAQMVNRVTILPCV-UHFFFAOYSA-Nhexane-1,6-diamineChemical compoundNCCCCCCNNAQMVNRVTILPCV-UHFFFAOYSA-N0.000claimsabstractdescription60

- 239000000243solutionSubstances0.000claimsabstractdescription60

- PWAXUOGZOSVGBO-UHFFFAOYSA-Nadipoyl chlorideChemical compoundClC(=O)CCCCC(Cl)=OPWAXUOGZOSVGBO-UHFFFAOYSA-N0.000claimsabstractdescription36

- 239000007864aqueous solutionSubstances0.000claimsabstractdescription23

- 239000003960organic solventSubstances0.000claimsabstractdescription23

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription19

- 238000000034methodMethods0.000claimsabstractdescription17

- 239000008367deionised waterSubstances0.000claimsabstractdescription12

- 229910021641deionized waterInorganic materials0.000claimsabstractdescription12

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000claimsabstractdescription10

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsabstractdescription10

- 238000006068polycondensation reactionMethods0.000claimsabstractdescription10

- 239000000843powderSubstances0.000claimsabstractdescription7

- 239000004952PolyamideSubstances0.000claimsabstractdescription6

- 229920002647polyamidePolymers0.000claimsabstractdescription6

- 229910052757nitrogenInorganic materials0.000claimsabstractdescription5

- 238000006243chemical reactionMethods0.000claimsdescription13

- 238000011065in-situ storageMethods0.000claimsdescription6

- 238000001308synthesis methodMethods0.000claimsdescription5

- 239000000463materialSubstances0.000claimsdescription4

- 238000004519manufacturing processMethods0.000claimsdescription3

- 229920006284nylon filmPolymers0.000claimsdescription3

- 230000003287optical effectEffects0.000claimsdescription3

- 239000004568cementSubstances0.000claims1

- 238000010926purgeMethods0.000abstractdescription4

- 239000000126substanceSubstances0.000abstractdescription4

- 230000007613environmental effectEffects0.000abstractdescription2

- 230000015572biosynthetic processEffects0.000abstract1

- UHOVQNZJYSORNB-UHFFFAOYSA-NBenzeneChemical compoundC1=CC=CC=C1UHOVQNZJYSORNB-UHFFFAOYSA-N0.000description9

- RTZKZFJDLAIYFH-UHFFFAOYSA-NDiethyl etherChemical compoundCCOCCRTZKZFJDLAIYFH-UHFFFAOYSA-N0.000description7

- CTQNGGLPUBDAKN-UHFFFAOYSA-NO-XyleneChemical compoundCC1=CC=CC=C1CCTQNGGLPUBDAKN-UHFFFAOYSA-N0.000description7

- 239000008096xyleneSubstances0.000description7

- 230000009471actionEffects0.000description3

- 238000010586diagramMethods0.000description3

- 150000004985diaminesChemical class0.000description2

- 238000005516engineering processMethods0.000description2

- 239000012530fluidSubstances0.000description2

- 239000000376reactantSubstances0.000description2

- 239000012780transparent materialSubstances0.000description2

- NGNBDVOYPDDBFK-UHFFFAOYSA-N2-[2,4-di(pentan-2-yl)phenoxy]acetyl chlorideChemical compoundCCCC(C)C1=CC=C(OCC(Cl)=O)C(C(C)CCC)=C1NGNBDVOYPDDBFK-UHFFFAOYSA-N0.000description1

- 238000003848UV Light-CuringMethods0.000description1

- 229910021536ZeoliteInorganic materials0.000description1

- 239000000853adhesiveSubstances0.000description1

- 230000001070adhesive effectEffects0.000description1

- 230000004075alterationEffects0.000description1

- 150000001412aminesChemical class0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000005540biological transmissionEffects0.000description1

- 238000006555catalytic reactionMethods0.000description1

- 238000001311chemical methods and processMethods0.000description1

- 208000012839conversion diseaseDiseases0.000description1

- 230000007812deficiencyEffects0.000description1

- 239000004205dimethyl polysiloxaneSubstances0.000description1

- HNPSIPDUKPIQMN-UHFFFAOYSA-Ndioxosilane;oxo(oxoalumanyloxy)alumaneChemical compoundO=[Si]=O.O=[Al]O[Al]=OHNPSIPDUKPIQMN-UHFFFAOYSA-N0.000description1

- 238000005265energy consumptionMethods0.000description1

- 239000003292glueSubstances0.000description1

- 239000012510hollow fiberSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 229920000435poly(dimethylsiloxane)Polymers0.000description1

- -1polydimethylsiloxanePolymers0.000description1

- 230000008569processEffects0.000description1

- 230000035484reaction timeEffects0.000description1

- 239000007787solidSubstances0.000description1

- 239000002904solventSubstances0.000description1

- 238000005728strengtheningMethods0.000description1

- 238000006467substitution reactionMethods0.000description1

- 238000010189synthetic methodMethods0.000description1

- 239000010457zeoliteSubstances0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/0093—Microreactors, e.g. miniaturised or microfabricated reactors

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D65/00—Accessories or auxiliary operations, in general, for separation processes or apparatus using semi-permeable membranes

- B01D65/02—Membrane cleaning or sterilisation ; Membrane regeneration

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D67/00—Processes specially adapted for manufacturing semi-permeable membranes for separation processes or apparatus

- B01D67/0002—Organic membrane manufacture

- B01D67/0006—Organic membrane manufacture by chemical reactions

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D71/00—Semi-permeable membranes for separation processes or apparatus characterised by the material; Manufacturing processes specially adapted therefor

- B01D71/06—Organic material

- B01D71/48—Polyesters

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Organic Chemistry (AREA)

- Polyamides (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及微通道反应器领域,具体涉及一种具有无支撑体的自形成尼龙膜的微通道反应器及制备方法。The invention relates to the field of microchannel reactors, in particular to a microchannel reactor with a self-forming nylon membrane without a support and a preparation method thereof.

背景技术Background technique

微通道反应器具有较大的比表面积,是强化化工过程的重要设备。当化学反应在微通道反应器内进行时,传热效率和传质效率都能够有效提高,进而极大地提高反应转化率及选择性,实现化工产业降低能耗的生产目标。对于多相化学反应来说,在微通道内制备出一层膜结构,能够有效地分离及渗透不同的反应物,增大反应物之间的接触面积,更进一步提高反应效率。The microchannel reactor has a large specific surface area and is an important equipment for strengthening the chemical process. When the chemical reaction is carried out in the microchannel reactor, the heat transfer efficiency and mass transfer efficiency can be effectively improved, thereby greatly improving the reaction conversion rate and selectivity, and achieving the production goal of reducing energy consumption in the chemical industry. For heterogeneous chemical reactions, a layer of membrane structure is prepared in the microchannel, which can effectively separate and penetrate different reactants, increase the contact area between the reactants, and further improve the reaction efficiency.

在微通道反应器内制备出膜结构,是将微流体反应器技术与膜技术结合起来,膜的结构及制备方式的不同使带有膜结构的微通道反应器具有不同的作用。Wan等人在微通道内制备出沸石膜,对反应起到分离及催化作用。Aran等人将中空纤维丝膜置于微通道中,构建的微反应器应用于气液固三相催化反应中。此外,在不同的微通道中夹杂一层功能性薄膜也是常见的方法。然而采用这些方法制备的膜结构,大多存在膜厚度不易控制,机械强度较差,反应物质在膜内的传输受阻的情况,以及膜与微通道之间键合不紧密等问题,最终导致微反应器的性能下降。The membrane structure is prepared in the microchannel reactor, which combines the microfluidic reactor technology with the membrane technology. The difference in the structure and preparation method of the membrane makes the microchannel reactor with the membrane structure have different functions. Wan et al. prepared zeolite membranes in microchannels to separate and catalyze the reaction. Aran et al. placed the hollow fiber membrane in the microchannel, and the constructed microreactor was applied to the gas-liquid-solid three-phase catalytic reaction. In addition, it is also a common method to incorporate a functional film in different microchannels. However, most of the membrane structures prepared by these methods have problems such as difficult to control the membrane thickness, poor mechanical strength, hindered transport of reactive substances in the membrane, and poor bonding between the membrane and the microchannel, which eventually lead to microreactions. performance of the device is degraded.

发明内容SUMMARY OF THE INVENTION

本发明针对现有技术存在的不足,提出了一种具有无支撑体的自形成尼龙膜的微通道反应器及制备方法。Aiming at the deficiencies in the prior art, the present invention proposes a microchannel reactor with a self-forming nylon membrane without a support and a preparation method.

本发明的第一个技术方案是:一种在微通道反应器内制备无支撑体的自形成尼龙膜的方法,其特征在于:该方法包括如下步骤:The first technical solution of the present invention is: a method for preparing a self-forming nylon membrane without a support in a microchannel reactor, characterized in that: the method comprises the following steps:

A、制备Y型微通道反应器;该Y型微通道反应器包括主体和底板;主体设置在底板上;所述主体包括两个对称的入口通道、一个主通道、二个入口以及一个出口,两个对称的入口通道和一个主通道构成Y型结构,两个对称的入口通道在Y型结构的交叉点与主通道汇合。二个入口分别为二个对称的入口通道的输入口,出口为主通道的输出口。A. Prepare a Y-type microchannel reactor; the Y-type microchannel reactor includes a main body and a bottom plate; the main body is arranged on the bottom plate; the main body includes two symmetrical inlet channels, a main channel, two inlets and an outlet, Two symmetrical inlet channels and one main channel form a Y-shaped structure, and the two symmetrical inlet channels merge with the main channel at the intersection of the Y-shaped structure. The two inlets are the input ports of the two symmetrical inlet channels respectively, and the outlet is the output port of the main channel.

B、制备制膜溶液:将己二胺粉末溶解于去离子水中,得到己二胺的水溶液;将己二酰氯溶液溶解于有机溶剂中,得到己二酰氯的有机溶液;所述有机溶剂为不溶于水,但能溶解己二酰氯的有机溶剂。B. Preparation of film-forming solution: dissolving hexamethylenediamine powder in deionized water to obtain an aqueous solution of hexamethylenediamine; dissolving adipic acid chloride solution in an organic solvent to obtain an organic solution of adipic acid chloride; the organic solvent is an insoluble In water, but can dissolve adipoyl chloride organic solvent.

C、将己二胺的水溶液以及己二酰氯的有机溶液分别注入到Y型微通道反应器的两个入口中,两种制膜溶液在“Y”型交叉点汇合后在主通道形成稳定的分层流动,两种溶液在交界面通过缩聚反应生成聚酰胺,由此在主通道内形成一层致密均匀的尼龙膜。即在主通道内自动形成无支撑体的尼龙膜;尼龙膜将主通道分隔为对称的二个通道。C. The aqueous solution of hexamethylene diamine and the organic solution of adipic acid chloride were injected into the two inlets of the Y-type microchannel reactor, respectively, and the two membrane-forming solutions formed a stable membrane in the main channel after the "Y"-shaped intersection merged. Layered flow, the two solutions generate polyamide through polycondensation at the interface, thereby forming a dense and uniform nylon membrane in the main channel. That is, a nylon membrane without a support is automatically formed in the main channel; the nylon membrane divides the main channel into two symmetrical channels.

D、先将乙醇注入到Y型微通道反应器的两个入口中对尼龙膜进行冲洗,再将去离子水溶液注入到Y型微通道反应器的两个入口中对尼龙膜进行冲洗,最后将氮气注入到Y型微通道反应器的两个入口中对尼龙膜进行吹扫。D. First, inject ethanol into the two inlets of the Y-type microchannel reactor to rinse the nylon membrane, and then inject deionized aqueous solution into the two inlets of the Y-type microchannel reactor to rinse the nylon membrane. Nitrogen was injected into the two inlets of the Y-shaped microchannel reactor to purge the nylon membrane.

本发明利用流体在微通道内的层流运动特性,选用不互溶的去离子水以及有机溶剂作为溶剂,己二胺与己二酰氯作为溶质分别溶于去离子水以及有机溶剂中;再将己二胺的水溶液与己二酰氯的有机溶液同时注入到微通道的两个入口中,由于去离子水与有机溶剂彼此无法互溶,两个制膜溶液在微通道内形成稳定的层流运动,并且己二胺与己二酰氯在接触界面上发生缩聚反应,作用一段时间后,即在无支撑体的情况下,通过己二胺与己二酰氯的界面缩聚反应自发形成尼龙膜。The invention utilizes the laminar flow motion characteristic of fluid in the microchannel, selects immiscible deionized water and organic solvent as solvent, and hexamethylenediamine and adipoyl chloride as solutes are dissolved in deionized water and organic solvent respectively; The aqueous solution of diamine and the organic solution of adipoyl chloride were injected into the two inlets of the microchannel at the same time. Since deionized water and organic solvent were immiscible with each other, the two membrane-forming solutions formed a stable laminar flow in the microchannel, and A polycondensation reaction occurs between hexamethylene diamine and adipoyl chloride on the contact interface, and after a period of action, namely without a support, a nylon membrane is spontaneously formed through the interface polycondensation reaction between hexamethylene diamine and adipoyl chloride.

根据本发明所述的在微通道反应器内制备无支撑体的自形成尼龙膜的方法的优选方案,步骤A中制备Y型微通道反应器的材料为紫外固化光学胶。According to the preferred solution of the method for preparing a support-free self-forming nylon membrane in a microchannel reactor of the present invention, the material for preparing the Y-shaped microchannel reactor in step A is UV-curable optical glue.

根据本发明所述的在微通道反应器内制备无支撑体的自形成尼龙膜的方法的优选方案,步骤B中配制的己二胺水溶液浓度为10-60mM,己二酰氯的二甲苯溶液浓度为30-50mM。通过对制膜溶液浓度以及作用时间的调控,能够有效控制尼龙膜的厚度。According to the preferred version of the method for preparing a self-forming nylon membrane without a support in a microchannel reactor according to the present invention, the concentration of the aqueous solution of hexamethylenediamine prepared in step B is 10-60 mM, and the concentration of the xylene solution of adipoyl chloride is 10-60 mM. 30-50mM. The thickness of the nylon membrane can be effectively controlled by adjusting the concentration of the membrane-forming solution and the action time.

本发明的第二个技术方案是,一种具有无支撑体的自形成尼龙膜的微通道反应器,该微通道反应器为Y型微通道反应器,该Y型微通道反应器包括主体和底板;主体设置在底板上;所述主体包括两个对称的入口通道、一个主通道、二个入口以及一个出口,两个对称的入口通道和一个主通道构成Y型结构,两个对称的入口通道在Y型结构的交叉点处与主通道汇合;二个入口分别为二个对称的入口通道的输入口,出口为主通道的输出口;其特征在于:在主通道内通过原位化学反应合成方法制备有一层无支撑体的自形成尼龙膜;该尼龙膜将主通道分隔为对称的二个通道。The second technical solution of the present invention is a microchannel reactor with a self-forming nylon membrane without a support, the microchannel reactor is a Y-type microchannel reactor, and the Y-type microchannel reactor includes a main body and a bottom plate; the main body is arranged on the bottom plate; the main body includes two symmetrical inlet channels, one main channel, two inlets and one outlet, the two symmetrical inlet channels and one main channel form a Y-shaped structure, and the two symmetrical inlets The channel merges with the main channel at the intersection of the Y-shaped structure; the two inlets are respectively the input ports of the two symmetrical inlet channels, and the outlet is the output port of the main channel; it is characterized in that: the in-situ chemical reaction is carried out in the main channel The synthetic method prepares a layer of self-forming nylon membrane without support; the nylon membrane divides the main channel into two symmetrical channels.

根据本发明所述的具有无支撑体的自形成尼龙膜的微通道反应器的优选方案,在主通道内通过原位化学反应合成方法制备有一层无支撑体的自形成尼龙膜;具体为:将两种制膜溶液分别注入到Y型微通道反应器的两个入口中,两种制膜溶液在“Y”型交叉点汇合后在主通道内形成稳定的分层流动,两种溶液在交界面通过缩聚反应生成聚酰胺,由此在主通道内形成一层无支撑体的尼龙膜;所述两种制膜溶液分别采用己二胺的水溶液和己二酰氯的有机溶液;所述己二胺的水溶液为将己二胺粉末溶解于去离子水中,得到己二胺的水溶液;所述己二酰氯的有机溶液为将己二酰氯溶液溶解于有机溶剂中得到。该有机溶剂采用不溶于水,但能溶解己二酰氯的有机溶剂。According to the preferred solution of the microchannel reactor with unsupported self-forming nylon membrane of the present invention, a layer of unsupported self-forming nylon membrane is prepared in the main channel by an in-situ chemical reaction synthesis method; specifically: The two membrane-forming solutions were injected into the two inlets of the Y-shaped microchannel reactor respectively. After the two membrane-forming solutions converged at the "Y"-shaped intersection, a stable stratified flow was formed in the main channel. Polyamide is formed at the interface through polycondensation reaction, thereby forming a layer of nylon film without support in the main channel; the two kinds of film-making solutions are respectively an aqueous solution of hexamethylene diamine and an organic solution of adipic acid chloride; the hexamethylene diamine The aqueous solution of amine is obtained by dissolving hexamethylenediamine powder in deionized water to obtain the aqueous solution of hexamethylenediamine; the organic solution of adipic acid chloride is obtained by dissolving the adipic acid chloride solution in an organic solvent. The organic solvent is an organic solvent that is insoluble in water but can dissolve adipoyl chloride.

本发明所述的具有无支撑体的自形成尼龙膜的微通道反应器及制备方法的有益效果是:本发明制备的尼龙膜在无外界支撑体的情况下,在制膜溶液界面处发生缩聚反应生成;通过对制膜溶液浓度以及作用时间的调控,能够有效控制尼龙膜的厚度,具备良好的机械强度,由于尼龙膜是在微通道内自发生长,因此与微通道间键合良好;该发明工艺简单,操作方便,可根据微通道反应器不同的作用要求对膜厚进行有效调控,强化反应物质在膜内的传输过程,最终微通道反应器的性能得到提升;本发明可广泛应用在能源、环保等领域。The beneficial effects of the microchannel reactor with a self-forming nylon membrane without a support and the preparation method of the present invention are as follows: the nylon membrane prepared by the present invention undergoes polycondensation at the interface of the membrane-forming solution without an external support. The reaction is generated; by adjusting the concentration of the membrane-making solution and the action time, the thickness of the nylon membrane can be effectively controlled, and it has good mechanical strength. Since the nylon membrane grows spontaneously in the microchannel, it is well bonded with the microchannel; the The invention has the advantages of simple process and convenient operation, and can effectively control the film thickness according to different function requirements of the microchannel reactor, strengthen the transmission process of the reaction substance in the film, and finally improve the performance of the microchannel reactor; the invention can be widely used in energy, environmental protection and other fields.

附图说明Description of drawings

图1是本发明所述的在微通道反应器内制备无支撑体的自形成尼龙膜的方法的流程图。FIG. 1 is a flow chart of the method for preparing a support-free self-forming nylon membrane in a microchannel reactor according to the present invention.

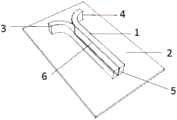

图2是本发明所述的Y型微通道反应器的结构示意图。Figure 2 is a schematic structural diagram of the Y-type microchannel reactor according to the present invention.

图3是本发明所述的一种具有无支撑体的自形成尼龙膜的微通道反应器的结构示意图。3 is a schematic structural diagram of a microchannel reactor with a self-forming nylon membrane without a support according to the present invention.

图4是图3的分解结构示意图。FIG. 4 is a schematic diagram of the exploded structure of FIG. 3 .

具体实施方式Detailed ways

下面结合附图和具体实施实例对本发明的技术方案进行进一步详细的说明。但应该指出,本发明的实施不限于以下的实施方式。The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and specific implementation examples. However, it should be noted that the implementation of the present invention is not limited to the following embodiments.

参见图1至图4,一种在微通道反应器内制备无支撑体的自形成尼龙膜的方法,该方法包括如下步骤:Referring to Figures 1 to 4, a method for preparing a support-free self-forming nylon membrane in a microchannel reactor includes the following steps:

A、制备Y型微通道反应器;将紫外固化光学胶NOA81溶液通入Y型聚二甲基硅氧烷模板中,经紫外光固化机进行固化成型,得到反应器的主体1,然后将主体粘附于底板2上构成Y型微通道反应器,该主体包括两个对称的入口通道、一个主通道、二个入口3、4以及一个出口5,两个对称的入口通道和一个主通道构成Y型结构,两个对称的入口通道在Y型结构的交叉点处与主通道汇合;二个入口分别为二个对称的入口通道的输入口,出口5为主通道的输出口。A. Prepare a Y-type microchannel reactor; pass the UV-curable optical adhesive NOA81 solution into the Y-type polydimethylsiloxane template, and cure and shape by a UV curing machine to obtain the

B、制备制膜溶液:将己二胺粉末溶解于去离子水中,得到己二胺的水溶液;配制的己二胺水溶液浓度为10-60mM;己二酰氯溶液溶解于有机溶剂中,得到己二酰氯的有机溶液;所述有机溶剂为不溶于水,但能溶解己二酰氯的有机溶剂;有机溶剂可采用二甲苯、苯、乙醚等。B. Preparation of film-forming solution: dissolving hexamethylenediamine powder in deionized water to obtain an aqueous solution of hexamethylenediamine; the prepared hexamethylenediamine aqueous solution has a concentration of 10-60 mM; adipic acid chloride solution is dissolved in an organic solvent to obtain hexamethylenediamine The organic solution of acid chloride; the organic solvent is an organic solvent that is insoluble in water but can dissolve adipoyl chloride; the organic solvent can be xylene, benzene, ether, etc.

比如将己二酰氯溶液溶解于二甲苯中,得到己二酰氯的二甲苯溶液;配制的己二酰氯的二甲苯溶液浓度为30-50mM。For example, the adipoyl chloride solution is dissolved in xylene to obtain a xylene solution of adipoyl chloride; the concentration of the prepared adipoyl chloride solution in xylene is 30-50 mM.

C、将己二胺的水溶液以及己二酰氯的有机溶液以60-100μL/min的流量分别注入到Y型微通道反应器的两个入口3、4中,由于流体在主通道内流动的层流特性,两种制膜溶液在“Y”型交叉点汇合后在主通道形成稳定的分层流动,己二胺与己二酰氯在接触界面上发生缩聚反应,持续通入5-30min后,即可在主通道内形成一层致密均匀的尼龙膜6。该尼龙膜在主通道内沿Y型结构的交叉点处延伸到出口5。当两个入口通道设置为左、右对称的入口通道时,尼龙膜6将主通道分隔为左、右对称的二个通道。当两个入口通道设置为上、下对称的入口通道时,尼龙膜6将主通道分隔为上、下对称的二个通道。C. The aqueous solution of hexamethylene diamine and the organic solution of adipic acid chloride are injected into the two

D、最后,先将乙醇注入到Y型微通道反应器的两个入口中对尼龙膜进行冲洗,再将去离子水溶液注入到Y型微通道反应器的两个入口中对尼龙膜进行冲洗,再将氮气注入到Y型微通道反应器的两个入口中对尼龙膜进行吹扫。D. Finally, firstly inject ethanol into the two inlets of the Y-type microchannel reactor to rinse the nylon membrane, and then inject deionized aqueous solution into the two inlets of the Y-type microchannel reactor to rinse the nylon membrane, Then nitrogen was injected into the two inlets of the Y-shaped microchannel reactor to purge the nylon membrane.

在具体实施例中,步骤A中制备Y型微通道反应器的材料也可以采用其他不溶于有机溶剂的透明材料。In a specific embodiment, the material for preparing the Y-shaped microchannel reactor in step A can also use other transparent materials that are insoluble in organic solvents.

实施例2,参见图2至图4,一种具有无支撑体的自形成尼龙膜的微通道反应器,该微通道反应器为Y型微通道反应器,该Y型微通道反应器包括主体1和底板2;主体1设置在底板2上;所述主体1包括两个对称的入口通道、一个主通道、二个入口以及一个出口,两个对称的入口通道和一个主通道构成Y型结构,两个对称的入口通道在Y型结构的交叉点处与主通道汇合;二个入口3、4分别为二个对称的入口通道的输入口,出口5为主通道的输出口;在主通道内通过原位化学反应合成方法制备有一层无支撑体的自形成尼龙膜6;该尼龙膜在主通道内沿Y型结构的交叉点处延伸到出口5处,尼龙膜将主通道分隔为对称的二个通道。当两个入口通道设置为左、右对称的入口通道时,尼龙膜6将主通道分隔为左、右对称的二个通道。当两个入口通道设置为上、下对称的入口通道时,尼龙膜6将主通道分隔为上、下对称的二个通道。

在主通道内通过原位化学反应合成方法制备有一层无支撑体的自形成尼龙膜6;具体为:将两种制膜溶液以60-100μL/min的流量分别注入到Y型微通道反应器的两个入口3、4中,两种制膜溶液在“Y”型交叉点汇合后在主通道内形成稳定的分层流动,两种溶液在交界面通过缩聚反应生成聚酰胺,由此在主通道内形成一层无支撑体的尼龙膜;最后,先将乙醇注入到Y型微通道反应器的两个入口中对尼龙膜进行冲洗,再将去离子水溶液注入到Y型微通道反应器的两个入口中对尼龙膜进行冲洗,再将氮气注入到Y型微通道反应器的两个入口中对尼龙膜进行吹扫,得到具有无支撑体的自形成尼龙膜的微通道反应器。In the main channel, a layer of self-forming

所述两种制膜溶液分别采用己二胺的水溶液和己二酰氯的有机溶液;所述己二胺的水溶液为将己二胺粉末溶解于去离子水中,得到己二胺的水溶液;配制的己二胺水溶液浓度为10-60mM。所述己二酰氯的有机溶液为将己二酰氯溶液溶解于有机溶剂中得到。配制的己二酰氯的有机溶液浓度为30-50mM。该有机溶剂采用不溶于水,但能溶解己二酰氯的有机溶剂。有机溶剂可采用二甲苯、苯、乙醚等。The two kinds of film-making solutions are respectively an aqueous solution of hexamethylenediamine and an organic solution of adipic acid chloride; the aqueous solution of hexamethylenediamine is obtained by dissolving hexamethylenediamine powder in deionized water to obtain an aqueous solution of hexamethylenediamine; The diamine aqueous solution has a concentration of 10-60 mM. The organic solution of adipoyl chloride is obtained by dissolving the adipoyl chloride solution in an organic solvent. The organic solution of adipoyl chloride was prepared at a concentration of 30-50 mM. The organic solvent is an organic solvent that is insoluble in water but can dissolve adipoyl chloride. As the organic solvent, xylene, benzene, diethyl ether and the like can be used.

Y型微通道反应器的材料可以采用其他不溶于二甲苯、苯、乙醚等的透明材料。The material of the Y-type microchannel reactor can use other transparent materials that are insoluble in xylene, benzene, ether, etc.

采用本发明所制备的尼龙膜由于是在微通道内直接生成,与微通道壁面具有较好的键合特性,通过对缩聚反应时间的控制,能够有效控制尼龙膜的厚度,提高反应物质在微通道反应器内的传质效率。Since the nylon membrane prepared by the method is directly generated in the microchannel, it has good bonding characteristics with the wall surface of the microchannel. By controlling the reaction time of the polycondensation, the thickness of the nylon membrane can be effectively controlled, and the reaction mass in the microchannel can be improved. Mass transfer efficiency within a channel reactor.

尽管已经示出和描述了本发明的实施例,本领域的普通技术人员可以理解:在不脱离本发明的原理和宗旨的情况下可以对这些实施例进行多种变化、修改、替换和变型,本发明的范围由权利要求及其等同物限定。Although embodiments of the present invention have been shown and described, it will be understood by those of ordinary skill in the art that various changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, The scope of the invention is defined by the claims and their equivalents.

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911055555.5ACN110694563A (en) | 2019-10-31 | 2019-10-31 | Microchannel reactor with unsupported self-forming nylon membrane and preparation method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911055555.5ACN110694563A (en) | 2019-10-31 | 2019-10-31 | Microchannel reactor with unsupported self-forming nylon membrane and preparation method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110694563Atrue CN110694563A (en) | 2020-01-17 |

Family

ID=69204007

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911055555.5APendingCN110694563A (en) | 2019-10-31 | 2019-10-31 | Microchannel reactor with unsupported self-forming nylon membrane and preparation method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110694563A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002075324A1 (en)* | 2001-03-15 | 2002-09-26 | Kanagawa Academy Of Science And Technology | Method of manufacturing micro channel structural body and functional high polymer film |

| CN1699984A (en)* | 2005-05-19 | 2005-11-23 | 复旦大学 | A multi-channel microfluidic chip, its preparation method and application |

| CN104667846A (en)* | 2015-02-13 | 2015-06-03 | 清华大学 | Micro-reaction system and micro-reaction method for preparing para/meta-aramid |

| CN106243348A (en)* | 2016-09-11 | 2016-12-21 | 上海会博新材料科技有限公司 | Micro passage reaction is used to prepare the device of meta-aramid resin solution continuously |

| CN106622054A (en)* | 2016-12-19 | 2017-05-10 | 天津大学 | Method for preparing polyamide double-layer microcapsule |

| CN107200843A (en)* | 2017-07-24 | 2017-09-26 | 上海方纶新材料科技有限公司 | A kind of method that use microreactor prepares aramid fiber |

- 2019

- 2019-10-31CNCN201911055555.5Apatent/CN110694563A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002075324A1 (en)* | 2001-03-15 | 2002-09-26 | Kanagawa Academy Of Science And Technology | Method of manufacturing micro channel structural body and functional high polymer film |

| CN1699984A (en)* | 2005-05-19 | 2005-11-23 | 复旦大学 | A multi-channel microfluidic chip, its preparation method and application |

| CN104667846A (en)* | 2015-02-13 | 2015-06-03 | 清华大学 | Micro-reaction system and micro-reaction method for preparing para/meta-aramid |

| CN106243348A (en)* | 2016-09-11 | 2016-12-21 | 上海会博新材料科技有限公司 | Micro passage reaction is used to prepare the device of meta-aramid resin solution continuously |

| CN106622054A (en)* | 2016-12-19 | 2017-05-10 | 天津大学 | Method for preparing polyamide double-layer microcapsule |

| CN107200843A (en)* | 2017-07-24 | 2017-09-26 | 上海方纶新材料科技有限公司 | A kind of method that use microreactor prepares aramid fiber |

Non-Patent Citations (3)

| Title |

|---|

| HIDEAKI HISAMOTO ET AL.: "Chemicofunctional Membrane for Integrated Chemical Processes on a Microchip", 《ANAL. CHEM》* |

| J. GARGIULI ET AL.: ""Microfluidic systems for in situ formation of nylon 6,6 membranes"", 《JOURNAL OF MEMBRANE SCIENCE》* |

| JAVIER ATENCIA ET AL.: "Controlled microfluidic interfaces", 《NATURE》* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Chan et al. | Direct, one-step molding of 3D-printed structures for convenient fabrication of truly 3D PDMS microfluidic chips | |

| Hisamoto et al. | Chemicofunctional membrane for integrated chemical processes on a microchip | |

| CN100460054C (en) | Porous film microstructure device and its manufacturing method | |

| CN103755777B (en) | A gas-controlled solid-phase polypeptide synthesis microfluidic chip device and its application | |

| CN110090557B (en) | A kind of preparation method of porous superhydrophobic membrane with structural gradient change | |

| CN107305214B (en) | A kind of production method of hard micro-fluid chip | |

| CN109126885A (en) | A kind of copper cobalt dual-metal organic frame/nano-fiber composite material and its preparation method and application | |

| CN110756055B (en) | Bipolar membrane and preparation method thereof | |

| US9574167B2 (en) | Methods and apparatus for independent control of product and reactant concentrations | |

| CN106215990A (en) | The micro-fluidic module of drop is prepared in a kind of scale | |

| CN105363503A (en) | Multicomponent micro droplet microfluidic chip and processing method thereof | |

| Li et al. | Ultra-monodisperse droplet formation using PMMA microchannels integrated with low-pulsation electrolysis micropumps | |

| Pramanik et al. | Switchable microvalves employing a conducting polymer and their automatic operation in conjunction with micropumps with a superabsorbent polymer | |

| CN110694563A (en) | Microchannel reactor with unsupported self-forming nylon membrane and preparation method | |

| CN101318836A (en) | A kind of preparation method of pH sensitive intelligent ceramic composite membrane | |

| CN114849800B (en) | Microfluidic chip and preparation method and application of zinc oxide nanorod array patterned growth | |

| CN103623712A (en) | Stain resistant homogeneous ion exchange membrane and moulding method thereof | |

| Zhang et al. | Asymmetric nanoporous alumina membranes for nanofluidic osmotic energy conversion | |

| CN105521750B (en) | Based on the Piezoelectric Driving micro fluid reaction chip for focusing on surface acoustic wave | |

| Liu et al. | Composition gradient high-throughput polymer libraries enabled by passive mixing and elevated temperature operability | |

| CN113499811B (en) | Microfluidic chip and application based on surface-grown ZnO nanowire glass microspheres | |

| CN106238114A (en) | A kind of embedded three-dimensional runner based on PMMA material declines fluidic chip and manufacture method | |

| CN109248567B (en) | A kind of PIMs ultra-thin layer composite hollow fiber membrane and its preparation and application | |

| CN208320758U (en) | A kind of microlayer model makeup of pure polyamine is set | |

| CN211274596U (en) | Laminated micro-channel reactor with uniformly distributed channel flow velocity |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200117 |