CN110665050A - Biological adhesive and preparation method thereof - Google Patents

Biological adhesive and preparation method thereofDownload PDFInfo

- Publication number

- CN110665050A CN110665050ACN201911087311.5ACN201911087311ACN110665050ACN 110665050 ACN110665050 ACN 110665050ACN 201911087311 ACN201911087311 ACN 201911087311ACN 110665050 ACN110665050 ACN 110665050A

- Authority

- CN

- China

- Prior art keywords

- structural protein

- solution

- tannic acid

- bioadhesive

- prepared

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L24/00—Surgical adhesives or cements; Adhesives for colostomy devices

- A61L24/04—Surgical adhesives or cements; Adhesives for colostomy devices containing macromolecular materials

- A61L24/10—Polypeptides; Proteins

- A61L24/104—Gelatin

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L24/00—Surgical adhesives or cements; Adhesives for colostomy devices

- A61L24/001—Use of materials characterised by their function or physical properties

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L24/00—Surgical adhesives or cements; Adhesives for colostomy devices

- A61L24/001—Use of materials characterised by their function or physical properties

- A61L24/0042—Materials resorbable by the body

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L24/00—Surgical adhesives or cements; Adhesives for colostomy devices

- A61L24/04—Surgical adhesives or cements; Adhesives for colostomy devices containing macromolecular materials

- A61L24/10—Polypeptides; Proteins

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L24/00—Surgical adhesives or cements; Adhesives for colostomy devices

- A61L24/04—Surgical adhesives or cements; Adhesives for colostomy devices containing macromolecular materials

- A61L24/10—Polypeptides; Proteins

- A61L24/102—Collagen

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2400/00—Materials characterised by their function or physical properties

- A61L2400/06—Flowable or injectable implant compositions

Landscapes

- Health & Medical Sciences (AREA)

- Surgery (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Materials For Medical Uses (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种生物粘合剂及其制备方法,属于生物粘合剂技术领域。The invention relates to a biological adhesive and a preparation method thereof, belonging to the technical field of biological adhesives.

背景技术Background technique

传统的外科手术缝合可以提供很好的抗张强度,以及相对较低的事故率等,但同时存在复杂费时、缝合对伤口造成二次机械损伤、产生细胞排斥免疫、体内残留时间较长时会造成肉芽肿瘤、拆线会带来一定的不适和痛苦等缺点。生物粘合剂是利用生物相容性优异的材料制备而成的无菌、无免疫原性且在一定的时间内能够抑制细菌的生物医学材料。其组分中无溶剂或者溶剂为水,在湿态环境下(即有水、组织液、血液等存在情况下)仍可与机体组织产生一定强度的粘接。生物粘合剂的溶出物等不对机体细胞产生毒性,不影响机体组织的伤口愈合,并且材料自身可降解,满足使用要求后能够被人体组织吸收,并最终被代谢出人体。Traditional surgical suturing can provide good tensile strength and relatively low accident rate, etc., but at the same time, it is complicated and time-consuming, suturing causes secondary mechanical damage to the wound, produces cell rejection immunity, and remains in the body for a long time. The granulation tumor and suture removal will bring some disadvantages such as discomfort and pain. Bioadhesives are sterile, non-immunogenic biomedical materials that are prepared from materials with excellent biocompatibility and can inhibit bacteria within a certain period of time. There is no solvent in its components or the solvent is water, and in a wet environment (that is, in the presence of water, tissue fluid, blood, etc.), it can still produce a certain strength of bonding with the body tissue. The leachables of bioadhesives are not toxic to body cells, do not affect the wound healing of body tissues, and the material itself is degradable, which can be absorbed by body tissues after meeting the requirements of use, and finally metabolized out of the body.

目前,临床上常用的生物粘合剂有纤维蛋白粘合剂和贻贝粘蛋白粘合剂,但这些粘合剂仍存在很多缺陷。如纤维蛋白粘合剂存在着粘合强度低、制备时间长、价格昂贵的缺点以及潜在的病毒感染风险;贻贝粘蛋白粘合剂价格昂贵,美国售价达到115美元/mg。At present, the commonly used bioadhesives in clinical practice include fibrin adhesives and mussel mucin adhesives, but these adhesives still have many defects. For example, fibrin adhesive has the disadvantages of low adhesive strength, long preparation time, high price and potential risk of virus infection; mussel mucin adhesive is expensive, and the US price reaches 115 US dollars/mg.

因此,研究人员一直在研究这两类生物粘合剂的替代品。近年来明胶基粘合剂成为一类重要的生物粘合剂,其粘合强度高,成本低,生物相容性好。如专利CN105879109A公开了一种价格低廉、粘合性强、适用于外科手术的生物粘合剂,该粘合剂由明胶水溶液和戊二醛水溶液混合生成。虽然该专利公开的粘合剂可以满足粘附性和胶化时间的要求,但戊二醛易产生细胞毒性反应,用于患者创面极不安全,因此,达到理想要求的生物粘合剂仍未出现。Therefore, researchers have been investigating alternatives to these two types of bioadhesives. In recent years, gelatin-based adhesives have become an important class of bioadhesives with high bond strength, low cost and good biocompatibility. For example, patent CN105879109A discloses a bioadhesive with low price, strong adhesiveness and suitable for surgical operation. The adhesive is formed by mixing gelatin aqueous solution and glutaraldehyde aqueous solution. Although the adhesive disclosed in this patent can meet the requirements of adhesion and gelation time, glutaraldehyde is prone to cytotoxic reaction, and it is extremely unsafe to use on patient wounds. Therefore, bioadhesives that meet the ideal requirements are still not available. Appear.

发明内容SUMMARY OF THE INVENTION

本发明拟解决现有生物粘合剂价格高昂、生物相容性及可降解性不优良、无抗菌性等缺点,目的提供一种可注射型抗菌性生物粘合剂及其制备方法,本发明提供的生物粘合剂能用注射器精准定位,能牢固粘连结合部位,具有抗水性、抗菌性、封闭止血和无细胞毒性的特点,且该生物粘合剂及其降解产物都具有良好的生物相容性。The present invention intends to solve the shortcomings of the existing biological adhesives such as high price, poor biocompatibility and degradability, and no antibacterial properties, and aims to provide an injectable antibacterial biological adhesive and a preparation method thereof. The provided bioadhesive can be accurately positioned with a syringe, can firmly adhere to the joint site, and has the characteristics of water resistance, antibacterial, closed hemostasis and no cytotoxicity, and the bioadhesive and its degradation products have good biological phase. Capacitance.

本发明的第一个目的是提供一种制备可注射型抗菌性生物粘合剂的方法,该方法包括以下步骤:The first object of the present invention is to provide a method for preparing an injectable antibacterial bioadhesive, the method comprising the following steps:

1):在氧化条件下将结构蛋白和单宁酸进行迈克尔加成反应,得到单宁酸修饰的结构蛋白;1): The structural protein and tannic acid are subjected to Michael addition reaction under oxidative conditions to obtain a tannic acid-modified structural protein;

2):将步骤1)制备的单宁酸修饰的结构蛋白溶于缓冲液中,加入转谷氨酰胺酶,混合均匀后即得该生物粘合剂。2): Dissolve the tannic acid-modified structural protein prepared in step 1) in a buffer, add transglutaminase, and mix uniformly to obtain the biological adhesive.

在一种实施方式中,所述缓冲液为Tris-HCl缓冲液。In one embodiment, the buffer is Tris-HCl buffer.

在一种实施方式中,所述结构蛋白包括明胶或胶原蛋白。In one embodiment, the structural protein comprises gelatin or collagen.

在一种实施方式中,步骤1)中结构蛋白和去离子水质量比(w/w)为(0.005~0.1):1,单宁酸和结构蛋白质量比(w/w)为(0.01~0.1):1。In one embodiment, in step 1), the mass ratio (w/w) of structural protein and deionized water is (0.005~0.1): 1, and the mass ratio (w/w) of tannic acid and structural protein is (0.01~0.01~ 0.1): 1.

在一种实施方式中,步骤1)单宁酸和结构蛋白质量比(w/w)为(0.01~0.1):1。In one embodiment, the mass ratio (w/w) of tannic acid and structural protein in step 1) is (0.01-0.1):1.

在一种实施方式中,步骤1)中迈克尔加成反应的过程具体为:将结构蛋白与去离子水混合,搅拌溶解,反应时间0.5~3.0h,调节溶液pH为碱性,pH=8.0~9.0;加入单宁酸,持续搅拌并通氧气进行反应,维持溶液pH与上述pH一致,于50~70℃反应1.0~4.0h,反应结束后把溶液pH调回中性偏碱性,pH=7.0~7.8。In one embodiment, the process of the Michael addition reaction in step 1) is as follows: mixing the structural protein with deionized water, stirring and dissolving, the reaction time is 0.5-3.0h, and the pH of the solution is adjusted to be alkaline, pH=8.0~ 9.0; Add tannic acid, keep stirring and pass oxygen to react, keep the pH of the solution consistent with the above pH, and react at 50-70°C for 1.0-4.0h, after the reaction, adjust the pH of the solution back to neutral and alkaline, pH= 7.0 to 7.8.

在一种实施方式中,步骤1)迈克尔加成反应后还进行透析、干燥;所述透析是指使用分子量截止值为3500Da的透析管对溶液进行去离子水透析;所述干燥是指冷冻干燥。In one embodiment, dialysis and drying are carried out after the Michael addition reaction in step 1); the dialysis refers to using a dialysis tube with a molecular weight cutoff value of 3500Da to dialysis the solution against deionized water; the drying refers to freeze-drying .

在一种实施方式中,步骤2)中缓冲液为Tris-HCl缓冲液,pH=7.5~9.5。In one embodiment, the buffer in step 2) is Tris-HCl buffer, pH=7.5-9.5.

在一种实施方式中,所述单宁酸修饰的结构蛋白溶于浓度为1~15g/100mL的Tris-HCl缓冲液中;所述转谷氨酰胺酶在Tris-HCl缓冲液中的终浓度为0.1%~5g/100mL,在该范围内,产品结构更稳定,成凝胶时间更短,外观更好。In one embodiment, the tannic acid-modified structural protein is dissolved in a Tris-HCl buffer with a concentration of 1-15 g/100 mL; the final concentration of the transglutaminase in the Tris-HCl buffer Within this range, the product structure is more stable, the gelation time is shorter, and the appearance is better.

在一种实施方式中,所述Tris-HCl缓冲液的浓度为7.5g/100mL,每100mL Tris-HCl缓冲液中含有1~15g的单宁酸修饰的结构蛋白。In one embodiment, the concentration of the Tris-HCl buffer is 7.5 g/100 mL, and each 100 mL of the Tris-HCl buffer contains 1-15 g of the tannic acid-modified structural protein.

在一种实施方式中,所述转谷氨酰胺酶的添加量为3g/100mL,转谷氨酰胺酶的酶活力为200U/g)。In one embodiment, the added amount of the transglutaminase is 3g/100mL, and the enzyme activity of the transglutaminase is 200U/g).

本发明的第二个目的是保护应用上述任一方法制备的经转谷氨酰胺酶交联的基于结构蛋白和单宁酸的生物粘合剂。A second object of the present invention is to protect the transglutaminase-crosslinked structural protein and tannic acid based bioadhesives prepared using any of the above methods.

在一种实施方式中,所述结构蛋白包括但不限于明胶、胶原蛋白。In one embodiment, the structural proteins include, but are not limited to, gelatin, collagen.

本发明还要求保护所述方法或所述生物粘合剂在制备活性生理组织间的粘合、生理性管道的填塞补漏、损伤创面的封闭止血或修复的药物,或医疗器械中的应用。The present invention also claims the application of the method or the bioadhesive in the preparation of adhesives between active physiological tissues, tamponade of physiological pipes, closed hemostasis or repair drugs for damaged wounds, or medical devices.

有益效果:本发明提供了一种可注射型抗菌性生物粘合剂及其制备方法,与现有技术相比:Beneficial effects: The present invention provides an injectable antibacterial bioadhesive and a preparation method thereof, compared with the prior art:

(1)本发明采用结构蛋白、单宁酸、转谷氨酰胺酶等作为原料,具有良好的生物相容性,及良好的抑菌效果(对106CFU细菌具有100%的抑菌率),替代了传统生物粘合剂中所用的有毒化学组分,三者协同作用可使本产品以凝胶状态长时间稳定地粘附于伤口处从而更好地促进伤口修复愈合。(1) The present invention adopts structural protein, tannic acid, transglutaminase, etc. as raw materials, and has good biocompatibility and good bacteriostatic effect (100% bacteriostatic rate to 106 CFU bacteria) , replacing the toxic chemical components used in traditional bio-adhesives, the synergy of the three can make the product stick to the wound stably in a gel state for a long time to better promote wound repair and healing.

(2)本发明具有可注射功能,可填充和粘合任何形状的伤口,使粘合剂紧紧地贴合伤口,从而更好的促进伤口愈合。(2) The present invention has an injectable function, which can fill and bond wounds of any shape, so that the adhesive tightly fits the wound, thereby better promoting wound healing.

(3)本发明有利于促进湿润环境伤口愈合,有相当强的湿组织黏附强度。(3) The present invention is conducive to promoting wound healing in a moist environment, and has a relatively strong wet tissue adhesion strength.

(4)本发明有良好的生物活性,对生物体组织刺激小。(4) The present invention has good biological activity and little stimulation to living tissue.

(5)本发明有良好的力学性能,粘合强度可达5.528KPa,不会因为伤口变形而发生胶体断裂。(5) The present invention has good mechanical properties, the adhesive strength can reach 5.528KPa, and colloid fracture will not occur due to wound deformation.

(6)本发明可生物降解,可有效避免因除去药物而造成的二次伤害。(6) The present invention is biodegradable, and can effectively avoid secondary damage caused by removing the drug.

(7)本发明生产过程无污染,最终产物对环境和人体均无污染,绿色环保。(7) The production process of the present invention is pollution-free, and the final product has no pollution to the environment and the human body, and is green and environmentally friendly.

(8)本发明制备方法简单,对设备要求不高,原料易得,成本低廉,适合大规模生产。(8) The preparation method of the present invention is simple, does not require high equipment, the raw materials are readily available, the cost is low, and is suitable for large-scale production.

附图说明Description of drawings

图1为本发明的技术路线;Fig. 1 is the technical route of the present invention;

图2为本发明制备的生物粘合剂的抗菌试验效果图;Fig. 2 is the antibacterial test effect diagram of the bioadhesive prepared by the present invention;

图3为本发明粘合强度测试的结构示意图;Fig. 3 is the structural representation of bonding strength test of the present invention;

图4为本发明制备的生物粘合剂的粘合强度测试结果;Fig. 4 is the adhesive strength test result of the bioadhesive prepared by the present invention;

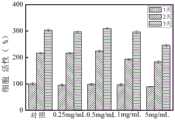

图5为本发明制备的生物粘合剂的细胞毒性试验结果;Fig. 5 is the cytotoxicity test result of the bioadhesive prepared by the present invention;

图6为本发明制备的生物粘合剂的体外降解实验结果;Fig. 6 is the in vitro degradation experiment result of the bioadhesive prepared by the present invention;

图7为本发明实施例3制备的生物粘合剂的SEM图。7 is a SEM image of the bioadhesive prepared in Example 3 of the present invention.

具体实施方式Detailed ways

本发明首先将结构蛋白在去离子水中溶解后将pH调为碱性。本发明对所述结构蛋白的来源无特殊限制,采用本领域技术人员熟知的市售商品或实验室自制品均可。In the present invention, the structural protein is first dissolved in deionized water and the pH is adjusted to alkaline. The source of the structural protein is not particularly limited in the present invention, and commercially available products or laboratory products well-known to those skilled in the art can be used.

粘合强度测试方法:经处理的猪皮于37℃水浴锅中解冻,切成1×4cm2样品,表面水分用吸水纸充分吸收,37℃保温。将制得的生物粘合剂涂在猪皮表面(1×3cm2)后,将两块猪皮粘合,用手指轻按30s,于水浴中保温,待样品凝胶化后将样品在万能机械试验机上用50N称重传感器以十字头速率5mm/min进行单轴拉伸应力-应变试验。每次拉伸至断开作为最终的最大粘合力,计算出相应的粘合强度。Adhesion strength test method: The treated pigskin was thawed in a 37°C water bath, cut into 1 × 4cm2 samples, the surface moisture was fully absorbed with absorbent paper, and the temperature was kept at 37°C. After applying the prepared bioadhesive on the surface of pig skin (1×3cm2 ), glue the two pieces of pig skin, press lightly with fingers for 30s, keep warm in a water bath, and place the sample in the universal after gelation. Uniaxial tensile stress-strain tests were performed on a mechanical testing machine with a 50N load cell at a crosshead rate of 5mm/min. Each stretch to break was taken as the final maximum bond, and the corresponding bond strength was calculated.

为了进一步说明本发明,下面通过以下实施例进行详细说明。In order to further illustrate the present invention, the following examples are used for detailed description.

实施例1Example 1

(1)称取明胶1g,加入100mL去离子水在60℃加热搅拌的条件下溶解明胶2.0h,最终得到质量分数为1%的明胶溶液。(1) Weigh 1 g of gelatin, add 100 mL of deionized water to dissolve the gelatin under heating and stirring at 60° C. for 2.0 h, and finally obtain a gelatin solution with a mass fraction of 1%.

(2)用12mol/L的氢氧化钠溶液调节步骤(1)制备的明胶溶液的pH至8.5,称量34mg单宁酸充分溶解在少量去离子水中,将上述的单宁酸溶液缓慢滴加到调好pH的明胶溶液中,再次用1mol/L的氢氧化钠溶液调节pH至8.5,在60℃搅拌的条件下加热3.0h,用1mol/L的氢氧化钠溶液调节pH使之保持8.5,并连续导入空气。(2) adjust the pH of the gelatin solution prepared in step (1) to 8.5 with 12 mol/L sodium hydroxide solution, weigh 34 mg of tannic acid and fully dissolve it in a small amount of deionized water, and slowly add the above-mentioned tannic acid solution dropwise To the gelatin solution with adjusted pH, adjust the pH to 8.5 with 1 mol/L sodium hydroxide solution again, heat for 3.0 h under stirring at 60 °C, and adjust the pH with 1 mol/L sodium hydroxide solution to keep it at 8.5 , and continuously introduce air.

(3)步骤(2)反应结束后用0.5mol/L的稀盐酸调节pH至7.4,并让上述反应物冷却至室温,再利用分子量截止值为3500Da的透析袋对反应物进行去离子水透析3次,最后再将透析后的物质冷冻干燥。(3) step (2) after the reaction is completed, adjust pH to 7.4 with 0.5mol/L dilute hydrochloric acid, and let the above-mentioned reactants cool to room temperature, and then use a dialysis bag with a molecular weight cutoff value of 3500Da to carry out deionized water dialysis on the

(4)取100mg步骤(3)冻干后样品,与1ml Tris-HCL缓冲液混合均匀得到溶液,加入10mg转谷氨酰胺酶并混合均匀,即得粘合剂。(4) Take 100 mg of the freeze-dried sample in step (3), mix it with 1 ml of Tris-HCL buffer to obtain a solution, add 10 mg of transglutaminase and mix it evenly to obtain an adhesive.

实施例2Example 2

(1)称取明胶1g,加入100mL去离子水在60℃加热搅拌的条件下溶解明胶2.0h,最终得到质量分数为1%的明胶溶液。(1) Weigh 1 g of gelatin, add 100 mL of deionized water to dissolve the gelatin under heating and stirring at 60° C. for 2.0 h, and finally obtain a gelatin solution with a mass fraction of 1%.

(2)用12mol/L的氢氧化钠溶液调节步骤(1)制备的明胶溶液的pH至8.5,称量34mg单宁酸充分溶解在少量去离子水中,将上述的单宁酸溶液缓慢滴加到调好pH的明胶溶液中,再次用1mol/L的氢氧化钠溶液调节pH至8.5,在60℃搅拌的条件下加热3.0h,用1mol/L的氢氧化钠溶液调节pH使之保持8.5,并连续导入空气。(2) adjust the pH of the gelatin solution prepared in step (1) to 8.5 with 12 mol/L sodium hydroxide solution, weigh 34 mg of tannic acid and fully dissolve it in a small amount of deionized water, and slowly add the above-mentioned tannic acid solution dropwise To the gelatin solution with adjusted pH, adjust the pH to 8.5 with 1 mol/L sodium hydroxide solution again, heat for 3.0 h under stirring at 60 °C, and adjust the pH with 1 mol/L sodium hydroxide solution to keep it at 8.5 , and continuously introduce air.

(3)步骤(2)反应结束后用0.5mol/L的稀盐酸调节pH至7.4,并让上述反应物冷却至室温,再利用分子量截止值为3500Da的透析袋对反应物进行去离子水透析3次,最后再将透析后的物质冷冻干燥。(3) step (2) after the reaction is completed, adjust pH to 7.4 with 0.5mol/L dilute hydrochloric acid, and let the above-mentioned reactants cool to room temperature, and then use a dialysis bag with a molecular weight cutoff value of 3500Da to carry out deionized water dialysis on the

(4)取100mg步骤(3)冻干后样品,与1ml Tris-HCL缓冲液混合均匀得到溶液,加入20mg转谷氨酰胺酶并混合均匀,即得粘合剂。(4) Take 100 mg of the freeze-dried sample in step (3), mix it with 1 ml of Tris-HCL buffer to obtain a solution, add 20 mg of transglutaminase and mix it evenly to obtain an adhesive.

实施例3Example 3

(1)称取明胶1g,加入100mL去离子水在60℃加热搅拌的条件下溶解明胶2.0h,最终得到质量分数为1%的明胶溶液。(1) Weigh 1 g of gelatin, add 100 mL of deionized water to dissolve the gelatin under heating and stirring at 60° C. for 2.0 h, and finally obtain a gelatin solution with a mass fraction of 1%.

(2)用12mol/L的氢氧化钠溶液调节步骤(1)制备的明胶溶液的pH至8.5,称量34mg单宁酸充分溶解在少量去离子水中,将上述的单宁酸溶液缓慢滴加到调好pH的明胶溶液中,再次用1mol/L的氢氧化钠溶液调节pH至8.5,在60℃搅拌的条件下加热3.0h,用1mol/L的氢氧化钠溶液调节pH使之保持8.5,并连续导入空气。(2) adjust the pH of the gelatin solution prepared in step (1) to 8.5 with 12 mol/L sodium hydroxide solution, weigh 34 mg of tannic acid and fully dissolve it in a small amount of deionized water, and slowly add the above-mentioned tannic acid solution dropwise To the gelatin solution with adjusted pH, adjust the pH to 8.5 with 1 mol/L sodium hydroxide solution again, heat for 3.0 h under stirring at 60 °C, and adjust the pH with 1 mol/L sodium hydroxide solution to keep it at 8.5 , and continuously introduce air.

(3)步骤(2)反应结束后用0.5mol/L的稀盐酸调节pH至7.4,并让上述反应物冷却至室温,再利用分子量截止值为3500Da的透析袋对反应物进行去离子水透析3次,最后再将透析后的物质冷冻干燥。(3) step (2) after the reaction is completed, adjust pH to 7.4 with 0.5mol/L dilute hydrochloric acid, and let the above-mentioned reactants cool to room temperature, and then use a dialysis bag with a molecular weight cutoff value of 3500Da to carry out deionized water dialysis on the

(4)取100mg步骤(3)冻干后样品,与1mlTris-HCL缓冲液混合均匀得到溶液,加入30mg转谷氨酰胺酶并混合均匀,即得粘合剂。(4) Take 100 mg of the freeze-dried sample in step (3), mix it with 1 ml of Tris-HCL buffer to obtain a solution, add 30 mg of transglutaminase and mix evenly to obtain an adhesive.

实施例4成凝胶时间测试Example 4 gel time test

对实施例1~3制备过程中步骤(4)加入转谷氨酰胺酶后的成凝胶时间进行测定,分别在室温(25℃)和体温(37℃)条件下测定该生物粘合剂的成凝胶时间。结果如表1所示。在25℃下凝胶时间可低至9min。The gelation time after adding transglutaminase in step (4) in the preparation process of Examples 1 to 3 was measured, and the bioadhesives were measured at room temperature (25° C.) and body temperature (37° C.) respectively. gel time. The results are shown in Table 1. The gel time can be as low as 9 min at 25°C.

表1不同实施例制备获得的粘合剂的成凝胶时间结果Table 1 Results of gelation time of adhesives prepared by different examples

实施例5抑菌试验Example 5 Bacteriostatic test

采用菌落计数法测定该生物粘合剂对大肠杆菌ATCC 8739的抑菌效果。The antibacterial effect of the bioadhesive against Escherichia coli ATCC 8739 was determined by colony counting method.

活化菌种:取1mL菌液置于20mL液体培养基中,摇床培养12h(37℃,100r/min)。Activated strains: Take 1 mL of bacterial solution and place it in 20 mL of liquid medium, and culture on a shaker for 12 hours (37°C, 100 r/min).

将50uL活化后菌液转接到20mL液体培养基中,摇床培养2h(37℃,100rpm),分别取20uL菌液(约1×106CFU/mL)加入到放有100uL由实施例1、2和3中制得的生物粘合剂样品的孔板中(3组平行以及3组空白对照),摇床培养2h(37℃,100r)后将菌液稀释104倍,将稀释后的菌液取100uL涂抹于固体培养基上,放入恒温培养箱(37℃)中培养12h,计算菌落总数。Transfer 50uL of the activated bacterial liquid to 20 mL of liquid medium, and cultivate it on a shaking table for 2h (37°C, 100rpm), respectively, take 20uL of bacterial liquid (about 1×106 CFU/mL) and add it to a 100uL solution from Example 1. In the well plates of the bioadhesive samples prepared in , 2 and 3 (3 groups of parallel and 3 groups of blank controls), after culturing in a shaker for 2h (37°C, 100r), the bacterial liquid was diluted 104 times, and the diluted Take 100uL of the bacterial solution and smear it on the solid medium, put it into a constant temperature incubator (37°C) for 12h, and calculate the total number of colonies.

抑菌率(%)=(空白对照菌落总数-生物粘合剂菌落总数)÷空白对照菌落总数×100Bacteriostatic rate (%) = (total number of blank control colonies - total number of bioadhesive colonies) ÷ total number of blank control colonies × 100

实验结果:本发明的生物粘合剂对大肠杆菌的抑菌结果如表2和图2所示,实施例1~3的方法制备的生物粘合剂抑菌率均为100%。Experimental results: The bacteriostatic results of the bioadhesives of the present invention on Escherichia coli are shown in Table 2 and Figure 2, and the bacteriostatic rates of the bioadhesives prepared by the methods of Examples 1 to 3 are all 100%.

表2不同实施例制备获得的粘合剂的抑菌效果The antibacterial effect of the adhesives prepared by different examples of table 2

实施例6粘合强度测试Example 6 Adhesive Strength Test

粘合强度测试方法:经处理的猪皮于37℃水浴锅中解冻,切成1×4cm2样品,表面水分用吸水纸充分吸收,37℃保温。将由实施例1、2、3中制得的生物粘合剂涂在猪皮表面(1×3cm2)后,将两块猪皮粘合,用手指轻按30s,于水浴中保温,待样品凝胶化后将样品在万能机械试验机上用50N称重传感器以十字头速率5mm/min进行单轴拉伸应力-应变试验。每次拉伸至断开作为最终的最大粘合力,计算出相应的粘合强度。结果如表3和图4所示。Adhesion strength test method: The treated pigskin was thawed in a 37°C water bath, cut into 1 × 4cm2 samples, the surface moisture was fully absorbed with absorbent paper, and the temperature was kept at 37°C. After applying the bioadhesive prepared in Examples 1, 2 and 3 on the surface of pig skin (1×3cm2 ), glue the two pieces of pig skin, press lightly with fingers for 30s, keep warm in a water bath, and wait for the sample After gelation, the samples were subjected to a uniaxial tensile stress-strain test on a universal mechanical testing machine with a 50N load cell at a crosshead rate of 5mm/min. Each stretch to break was taken as the final maximum bond, and the corresponding bond strength was calculated. The results are shown in Table 3 and Figure 4.

表3不同实施例制备获得的粘合剂的粘合强度结果Table 3 Adhesive strength results of adhesives prepared by different examples

实施例7细胞毒性试验Example 7 Cytotoxicity test

细胞毒性试验方法:采用MTT法测定该生物粘合剂对3T3成纤维细胞的细胞毒性。Cytotoxicity test method: The cytotoxicity of the bioadhesive to 3T3 fibroblasts was determined by MTT method.

具体操作为:将由实施例3制得的生物粘合剂冷冻干燥,冻干后的粘合剂紫外灭菌0.5h后以10mg/mL的浓度浸泡在细胞培养基中,浸提液用于培养细胞;取生长状态良好的3T3细胞,按3000/孔的密度铺于96孔板中,37℃,5%CO2培养箱中培养24小时;细胞贴壁后加入100μL不同浓度的粘合剂浸提液(0.25,0.5,1,5mg/mL),每个浓度设置6个平行,且每块孔板设置一组空白对照。细胞继续培养24、48、72小时后,弃培养基,加入100μL 0.5mg/ml的MTT,放入细胞培养箱中继续培养4小时终止培养。吸去孔板内上清,每孔加入100μL二甲基亚砜,静置15分钟,用酶标仪检测其在570nm处的吸收值。The specific operation is as follows: freeze-dry the bioadhesive prepared in Example 3, immerse the freeze-dried adhesive in the cell culture medium at a concentration of 10 mg/mL after UV sterilization for 0.5 h, and the extract is used for culturing Cells; take 3T3 cells in good growth state, spread them in a 96-well plate at a density of 3000/well, and culture them in a 37°C, 5% CO2 incubator for 24 hours; add 100 μL of different concentrations of adhesive after the cells adhere to the wall. Extraction (0.25, 0.5, 1, 5 mg/mL), 6 parallels were set for each concentration, and a group of blank controls was set for each well plate. After the cells were cultured for 24, 48, and 72 hours, the culture medium was discarded, 100 μL of 0.5 mg/ml MTT was added, and the cells were placed in a cell culture incubator for 4 hours to terminate the culture. The supernatant in the well plate was aspirated, 100 μL of dimethyl sulfoxide was added to each well, and it was allowed to stand for 15 minutes, and its absorption value at 570 nm was detected with a microplate reader.

实验结果:本发明的生物粘合剂的细胞毒性试验结果如图5所示。实施例3制备的生物粘合剂在0.25、0.5mg/mL的浓度下对细胞生长无抑制作用,在1、2mg/mL的浓度下对细胞生长的影响不显著。Experimental results: The cytotoxicity test results of the bioadhesive of the present invention are shown in FIG. 5 . The bioadhesive prepared in Example 3 had no inhibitory effect on cell growth at concentrations of 0.25 and 0.5 mg/mL, and had no significant effect on cell growth at concentrations of 1 and 2 mg/mL.

实施例8体外降解实验Example 8 In vitro degradation experiment

用胶原酶Ⅰ在PBS中对该生物粘合剂的体外生物降解性进行研究。The in vitro biodegradability of this bioadhesive was studied with collagenase I in PBS.

具体操作为:将由实施例1、2和3制得的生物粘合剂冷冻干燥,冻干后的粘合剂浸泡在胶原酶Ⅰ(1U/ml)的PBS(pH7.4)中,在37℃、100rpm/min条件下下摇匀。离心溶液,定期(1d、3d、7d、14d)去除未反应的酶,将沉淀冻干并称重。另外,设无酶对照组。The specific operation is as follows: freeze-dry the bioadhesives prepared in Examples 1, 2 and 3, and soak the freeze-dried adhesives in PBS (pH 7.4) of collagenase I (1 U/ml), at 37 Shake well at 100rpm/min. The solution was centrifuged, unreacted enzyme was removed periodically (1d, 3d, 7d, 14d), and the pellet was lyophilized and weighed. In addition, an enzyme-free control group was set.

生物降解率(%)=(W0-W1)/W0×100,式中,W0是原始冻干粘合剂的重量,W1是在预定时间冻干后样品的重量。Biodegradation rate (%)=(W0-W1)/W0×100, where W0 is the weight of the original freeze-dried binder, and W1 is the weight of the sample after freeze-drying at a predetermined time.

实验结果:本发明的生物粘合剂的体外降解实验结果如图6所示,在七天后实施例1、2和3的降解率分别达到了60.2%、48.9%和21.3%;在十四天后分别达到了78.7%、67.5%和40.7%。Experimental results: The results of the in vitro degradation experiments of the bioadhesive of the present invention are shown in Figure 6. After seven days, the degradation rates of Examples 1, 2 and 3 reached 60.2%, 48.9% and 21.3% respectively; after fourteen days It reached 78.7%, 67.5% and 40.7%, respectively.

实施例9表观形貌检测Embodiment 9 Appearance and morphology detection

表观形貌检测方法:用扫描电镜(SEM)观察该生物粘合剂的孔隙形态。Appearance Morphology Detection Method: Scanning electron microscope (SEM) was used to observe the pore morphology of the bioadhesive.

具体操作为:(1)附着面检测:经处理的猪皮于37℃水浴锅中解冻,切成1×4cm2样品,表面水分用吸水纸充分吸收,37℃保温。将由实施例3中制得的生物粘合剂涂在猪皮表面(1×3cm2)后,将两块猪皮粘合,用手指轻按30s,于水浴中保温,待样品凝胶化后将样品冷冻干燥。将冷冻干燥后的两块猪皮撕开,样品用于附着面检测。The specific operations are: (1) Adhesion surface detection: The treated pigskin is thawed in a 37°C water bath, cut into 1×4 cm2 samples, the surface moisture is fully absorbed with absorbent paper, and the temperature is kept at 37°C. After applying the bioadhesive prepared in Example 3 on the surface of pig skin (1×3cm2), glue the two pieces of pig skin, press lightly with fingers for 30s, and keep warm in a water bath. Samples were freeze-dried. The two pieces of pig skin after freeze drying were torn apart, and the samples were used for the detection of the adhesion surface.

(2)非粘附表面检测:将由实施例3制得的生物粘合剂冷冻干燥后直接对其表面进行非粘附表面检测。(2) Non-adherent surface detection: The non-adhesive surface detection was carried out directly on the surface of the bioadhesive prepared in Example 3 after freeze-drying.

(3)内部横截面检测:将由实施例3制得的生物粘合剂冷冻干燥,断裂后获得内部横截面,用于内部形貌的研究。(3) Detection of internal cross-section: The bioadhesive prepared in Example 3 was freeze-dried, and the internal cross-section was obtained after fracture, which was used for the study of internal morphology.

实验结果:本发明的生物粘合剂的表观形貌检测结果如图7所示,从图中可以看出,该生物粘合剂具有良好的孔隙结构和较高的孔隙率,不但有利于伤口渗出液的吸收,还可以透湿透气、为细胞增殖创造空间。Experimental results: The detection results of the apparent morphology of the bioadhesive of the present invention are shown in Figure 7. It can be seen from the figure that the bioadhesive has a good pore structure and high porosity, which is not only conducive to The absorption of wound exudate can also be breathable and breathable, creating space for cell proliferation.

虽然本发明已以较佳实施例公开如上,但其并非用以限定本发明,任何熟悉此技术的人,在不脱离本发明的精神和范围内,都可做各种的改动与修饰,因此本发明的保护范围应该以权利要求书所界定的为准。Although the present invention has been disclosed above with preferred embodiments, it is not intended to limit the present invention. Anyone who is familiar with this technology can make various changes and modifications without departing from the spirit and scope of the present invention. Therefore, The protection scope of the present invention should be defined by the claims.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911087311.5ACN110665050B (en) | 2019-11-08 | 2019-11-08 | Biological adhesive and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911087311.5ACN110665050B (en) | 2019-11-08 | 2019-11-08 | Biological adhesive and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110665050Atrue CN110665050A (en) | 2020-01-10 |

| CN110665050B CN110665050B (en) | 2021-02-26 |

Family

ID=69086634

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911087311.5AActiveCN110665050B (en) | 2019-11-08 | 2019-11-08 | Biological adhesive and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110665050B (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111286045A (en)* | 2020-03-11 | 2020-06-16 | 广东省医疗器械研究所 | Polyphenol substance hydrogen bond-enhanced hydrogel |

| CN111760469A (en)* | 2020-07-03 | 2020-10-13 | 华东理工大学 | A kind of preparation method of the film of tannic acid and gelatin hydrophilic coating |

| CN113101407A (en)* | 2021-03-22 | 2021-07-13 | 西南大学 | Preparation method of tannic acid based underwater adhesive and product |

| CN113416326A (en)* | 2021-05-20 | 2021-09-21 | 深圳市人民医院 | Injectable hydrogel and preparation method and application thereof |

| CN113769155A (en)* | 2021-08-12 | 2021-12-10 | 中国人民解放军海军军医大学 | A kind of bioadhesive based on bioengineered protein and preparation method thereof |

| CN117356705A (en)* | 2023-11-24 | 2024-01-09 | 渤海大学 | Food adhesive prepared from tannic acid and vegetable protein and application thereof |

| WO2024040270A3 (en)* | 2022-08-19 | 2024-03-28 | Purdue Research Foundation | Mussel-inspired tissue adhesives and methods of use thereof |

| WO2025069742A1 (en)* | 2023-09-28 | 2025-04-03 | 大日精化工業株式会社 | Biodegradable adhesive composition and biodegradable adhesive composition kit |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102552967A (en)* | 2006-12-15 | 2012-07-11 | 生命连结有限公司 | Gelatin-transglutaminase hemostatic dressings and sealants |

| CN105944139A (en)* | 2016-07-05 | 2016-09-21 | 四川大学 | Soybean protein isolate-based biomedical adhesive and preparation method thereof |

| WO2017194717A1 (en)* | 2016-05-13 | 2017-11-16 | Rockwool International A/S | A method of producing a mineral wool product comprising a multiple of lamellae and a product of such kind |

| CN108744023A (en)* | 2018-06-15 | 2018-11-06 | 福州大学 | A kind of fibroin albumen medical bio adhesive and preparation method thereof |

- 2019

- 2019-11-08CNCN201911087311.5Apatent/CN110665050B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102552967A (en)* | 2006-12-15 | 2012-07-11 | 生命连结有限公司 | Gelatin-transglutaminase hemostatic dressings and sealants |

| WO2017194717A1 (en)* | 2016-05-13 | 2017-11-16 | Rockwool International A/S | A method of producing a mineral wool product comprising a multiple of lamellae and a product of such kind |

| CN109153605A (en)* | 2016-05-13 | 2019-01-04 | 洛科威国际有限公司 | mineral wool product |

| CN105944139A (en)* | 2016-07-05 | 2016-09-21 | 四川大学 | Soybean protein isolate-based biomedical adhesive and preparation method thereof |

| CN108744023A (en)* | 2018-06-15 | 2018-11-06 | 福州大学 | A kind of fibroin albumen medical bio adhesive and preparation method thereof |

Non-Patent Citations (2)

| Title |

|---|

| MCDERMOTT MK等: "《Mechanical properties of biomimetic tissue adhesive based on the microbial transglutaminase-catalyzed crosslinking of gelatin》", 《BIOMACROMOLECULES》* |

| 邓依 等: "《天然植物单宁酸交联改性胶原膜》", 《皮革科学与工程》* |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111286045A (en)* | 2020-03-11 | 2020-06-16 | 广东省医疗器械研究所 | Polyphenol substance hydrogen bond-enhanced hydrogel |

| CN111760469A (en)* | 2020-07-03 | 2020-10-13 | 华东理工大学 | A kind of preparation method of the film of tannic acid and gelatin hydrophilic coating |

| CN113101407A (en)* | 2021-03-22 | 2021-07-13 | 西南大学 | Preparation method of tannic acid based underwater adhesive and product |

| CN113101407B (en)* | 2021-03-22 | 2022-04-15 | 西南大学 | Preparation method of tannic acid based underwater adhesive and product |

| CN113416326A (en)* | 2021-05-20 | 2021-09-21 | 深圳市人民医院 | Injectable hydrogel and preparation method and application thereof |

| CN113416326B (en)* | 2021-05-20 | 2023-01-13 | 深圳市人民医院 | A kind of injectable hydrogel and its preparation method and application |

| CN113769155A (en)* | 2021-08-12 | 2021-12-10 | 中国人民解放军海军军医大学 | A kind of bioadhesive based on bioengineered protein and preparation method thereof |

| WO2024040270A3 (en)* | 2022-08-19 | 2024-03-28 | Purdue Research Foundation | Mussel-inspired tissue adhesives and methods of use thereof |

| WO2025069742A1 (en)* | 2023-09-28 | 2025-04-03 | 大日精化工業株式会社 | Biodegradable adhesive composition and biodegradable adhesive composition kit |

| CN117356705A (en)* | 2023-11-24 | 2024-01-09 | 渤海大学 | Food adhesive prepared from tannic acid and vegetable protein and application thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110665050B (en) | 2021-02-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110665050A (en) | Biological adhesive and preparation method thereof | |

| Huang et al. | A tannin-functionalized soy protein-based adhesive hydrogel as a wound dressing | |

| CN112300420A (en) | An injectable antibacterial interpenetrating double network hydrogel and its preparation method and application | |

| CN113185714B (en) | High-adhesion antibacterial healing-promoting hydrogel and preparation method thereof | |

| CN107823699B (en) | Hemostatic anti-adhesion film and preparation method thereof | |

| CN106039416A (en) | Chitosan-sericin composite biological scaffold as well as preparation method and application thereof | |

| CN113577014B (en) | Medical apparatus and instrument, hydrogel and preparation method and application thereof | |

| Liu et al. | A tough and mechanically stable adhesive hydrogel for non-invasive wound repair | |

| CN113509591A (en) | Antibacterial cationic injectable hydrogel dressing and preparation method thereof | |

| CN115487346A (en) | Tannin-modified gelatin-based hydrogel wound dressing and preparation method thereof | |

| CN101597381A (en) | A kind of calcium alginate composite membrane medical dressing of pasting behind the pin and its production and application that is used for | |

| CN116570758A (en) | Injectable antibacterial hydrogel that can be used for irregular wound repair and its preparation method and application | |

| CN114225113B (en) | Degradable artificial dura mater with double-layer structure and preparation method thereof | |

| CN115364269A (en) | Polysaccharide-based hemostatic sponge and preparation method thereof | |

| CN114177347A (en) | Antibacterial oxygen release functional gel dressing and preparation and application thereof | |

| CN108379650A (en) | A kind of novel rush wound healing biogum and its application | |

| CN108619560A (en) | A kind of preparation method of tissue adhension hemostatic and antibacterial nanometer film | |

| CN115785480B (en) | A baicalein composite hydrogel with fluidity and degradability, and preparation method and application thereof | |

| CN117298332A (en) | Injectable double-network hydrogel with immune regulation function and preparation method and application thereof | |

| CN107583101A (en) | A kind of biological membrane preparations for promoting wound healing and preparation method thereof | |

| CN117159784B (en) | Liquid band-aid for repairing wound surface difficult to heal, and preparation method and application thereof | |

| CN110507846A (en) | Preparation method of a long-acting antibacterial and healing-promoting keratin dressing | |

| CN114652889B (en) | Hyperbranched polyglycidyl ether hydrogel dressing and preparation method and application thereof | |

| CN119868625B (en) | Preparation method of high-adhesion hemostatic antibacterial degradable hydrogel based on irradiation crosslinking and hydrogel | |

| CN114796597B (en) | Sphingosine-based hydrogel and preparation method and application thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20230406 Address after:200000 floor 1, building 1, No. 356, Longgui Road, Pudong New Area, Shanghai Patentee after:Shanghai Zechong Biotechnology Co.,Ltd. Address before:214000 1800 Lihu Avenue, Binhu District, Wuxi, Jiangsu Patentee before:Jiangnan University |