CN110641554A - Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame - Google Patents

Automobile front upright post upper edge beam structure, side door frame assembly and automobile frameDownload PDFInfo

- Publication number

- CN110641554A CN110641554ACN201911046871.6ACN201911046871ACN110641554ACN 110641554 ACN110641554 ACN 110641554ACN 201911046871 ACN201911046871 ACN 201911046871ACN 110641554 ACN110641554 ACN 110641554A

- Authority

- CN

- China

- Prior art keywords

- vehicle body

- front pillar

- upper side

- roof

- door frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D25/00—Superstructure or monocoque structure sub-units; Parts or details thereof not otherwise provided for

- B62D25/04—Door pillars ; windshield pillars

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Body Structure For Vehicles (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本申请涉及汽车结构技术领域,更具体地说,尤其涉及一种汽车前立柱上边梁结构。The present application relates to the technical field of automobile structures, and more particularly, to an upper side beam structure of an automobile front pillar.

背景技术Background technique

目前市场上乘用车上边梁主要由冲压件拼焊而成,零件数量多,结构复杂,开发周期长,开发成本高,而当前的市场要求车型更新换代的速度越来越快,迫切需要一种低成本、开发周期短的上边梁结构来满足需求。At present, the upper side beams of passenger cars on the market are mainly made of stamping parts, which have a large number of parts, complex structures, long development cycles and high development costs. A low-cost, short development period of the upper side beam structure to meet the demand.

现有技术中,市场上解决这一问题的思路是采用铝合金挤压型材上边梁,从后顶横梁处直接连接到车体前立柱,车体前立柱也是铝挤压型材,但是车体前立柱与上边梁是两个零件,通过焊接固定在一起。这种方案用挤压铝型材替代了冲压件,减轻了车身重量,降低了模具开发成本,但是两种不同截面的型材焊接到一起接头强度难以保证,且铝材成本高,挤压完的型材需要热处理,生产周期长,而且铝结构的车体维修工艺复杂,技术不成熟,售后维修保养价格高问题一直无法解决,导致该方案只能在高端车型上进行应用,中低端车型由于成本压力无法采用。In the prior art, the idea to solve this problem in the market is to use an aluminum alloy extruded profile upper side beam, which is directly connected to the front pillar of the vehicle body from the rear roof beam. The front pillar of the vehicle body is also an extruded aluminum profile, but the front The upright column and the upper edge beam are two parts, which are fixed together by welding. This scheme replaces stamping parts with extruded aluminum profiles, which reduces the weight of the body and the cost of mold development. However, it is difficult to ensure the joint strength of two profiles with different cross-sections welded together, and the cost of aluminum materials is high. Extruded profiles Heat treatment is required, the production cycle is long, and the aluminum structure car body maintenance process is complex and the technology is immature. cannot be used.

因此,如何提供一种汽车前立柱上边梁结构,能够简化车身结构,提高车架整体强度,缩短研发周期,降低生产成本,已经成为本领域技术人员亟待解决的技术问题。Therefore, how to provide an upper side beam structure of an automobile front column, which can simplify the body structure, improve the overall strength of the frame, shorten the research and development period, and reduce the production cost, has become a technical problem to be solved urgently by those skilled in the art.

发明内容SUMMARY OF THE INVENTION

为解决上述技术问题,本申请提供一种汽车前立柱上边梁结构,将车体前立柱(A柱)及上边梁合为一体,取消了接头,结构更简单、紧凑,能够简化车身结构,提高车架整体强度,缩短研发周期,降低生产成本。本申请还提供一种侧门框总成和汽车车架,同样具备上述有益效果。In order to solve the above-mentioned technical problems, the present application provides an upper side beam structure of an automobile front column, which integrates the front column (A-pillar) and the upper side beam of the vehicle body, eliminates the joint, and has a simpler and more compact structure, which can simplify the body structure and improve the performance of the vehicle body. The overall strength of the frame shortens the development cycle and reduces the production cost. The present application also provides a side door frame assembly and a vehicle frame, which also have the above beneficial effects.

本申请提供的技术方案如下:The technical solutions provided by this application are as follows:

本申请提供一种汽车前立柱上边梁结构,包括:车体前立柱;与所述车体前立柱上端连接的上边梁;所述上边梁与所述车体前立柱一体成型。The application provides an upper side beam structure of a front column of a vehicle, comprising: a front column of a vehicle body; an upper side beam connected to the upper end of the front column of the vehicle body; the upper side beam and the front column of the vehicle body are integrally formed.

进一步地,在本发明一种优选的方式中,所述车体前立柱和所述上边梁的横截面形状相同。Further, in a preferred manner of the present invention, the cross-sectional shapes of the vehicle body front pillar and the roof side rail are the same.

进一步地,在本发明一种优选的方式中,所述横截面形状包括:大圆弧区;与所述大圆弧区相对设置的小圆弧区;用于连接所述大圆弧区和所述小圆弧区两端的凹陷区。Further, in a preferred mode of the present invention, the cross-sectional shape includes: a large circular arc area; a small circular arc area arranged opposite to the large circular arc area; used to connect the large circular arc area and the The concave areas at both ends of the small arc area.

进一步地,在本发明一种优选的方式中,所述大圆弧区沿所述车体前立柱和所述上边梁的轴线掠过的区域朝向车架车架外侧;所述小圆弧区沿所述车体前立柱和所述上边梁的轴线掠过的区域朝向车架车架内侧。Further, in a preferred manner of the present invention, the large arc area is swept along the axis of the front pillar of the vehicle body and the upper side rail and faces the outside of the frame; the small arc area The area swept along the axis of the front pillar of the vehicle body and the roof side rail faces the inner side of the frame.

进一步地,在本发明一种优选的方式中,所述上边梁包括:与所述车体前立柱上端连接的倾斜前梁;与所述倾斜梁远离所述车体前立柱一端连接的侧顶梁,所述侧顶梁与所述倾斜前梁一体成型。Further, in a preferred mode of the present invention, the roof side beam comprises: an inclined front beam connected with the upper end of the front pillar of the vehicle body; a side roof connected with the end of the inclined beam away from the front pillar of the vehicle body The side roof beam and the inclined front beam are integrally formed.

进一步地,在本发明一种优选的方式中,所述上边梁还包括:与所述侧顶梁远离所述倾斜前梁一端连接的倾斜后梁,所述倾斜后梁与所述侧顶梁一体成型。Further, in a preferred mode of the present invention, the roof beam further comprises: an inclined rear beam connected to an end of the side roof beam away from the inclined front beam, the inclined rear beam and the side roof beam are integrally formed .

本申请还提供一种侧门框总成,包括:上述的汽车前立柱上边梁结构;与所述车体前立柱底端连接的门框底梁;与所述侧顶梁的中部和所述门框底梁的中部连接的车体中立柱,与所述上边梁和所述门框底梁连接的车体后立柱,所述车体后立柱的一端与所述上边梁远离所述车体前立柱的一端连接,所述车体后立柱的另一端与所述门框底梁远离所述车体前立柱的一端连接。The application also provides a side door frame assembly, comprising: the above-mentioned upper side beam structure of the front pillar of the automobile; a door frame bottom beam connected with the bottom end of the front pillar of the vehicle body; the middle part of the side roof beam and the door frame bottom The center pillar of the vehicle body connected with the middle part of the beam, the rear pillar of the vehicle body connected to the upper side beam and the bottom beam of the door frame, one end of the rear pillar of the vehicle body and the end of the upper side beam away from the front pillar of the vehicle body The other end of the rear pillar of the vehicle body is connected to the end of the door frame bottom beam away from the front pillar of the vehicle body.

其中,车体中立柱的顶端与所述上边梁的中部连接,所述车体中立柱的底端与所述门框底梁的中部连接;Wherein, the top end of the vehicle body center pillar is connected with the middle part of the upper side beam, and the bottom end of the vehicle body center pillar is connected with the middle part of the door frame bottom beam;

本申请还提供一种汽车车架,包括:底板总成;设置在所述底板总成两侧的上述侧门框总成;与所述上边梁连接的顶板总成。The present application also provides an automobile frame, comprising: a bottom plate assembly; the above-mentioned side door frame assemblies disposed on both sides of the bottom plate assembly; and a top plate assembly connected with the upper side beam.

进一步地,在本发明一种优选的方式中,所述顶板总成包括:与所述倾斜前梁和所述侧顶梁的连接处连接的前顶横梁;与所述侧顶梁的中部连接的中顶横梁;与所述侧顶梁远离所述倾斜前梁一端连接的后顶横梁。Further, in a preferred mode of the present invention, the roof assembly includes: a front roof beam connected to the connection between the inclined front beam and the side roof beam; connected to the middle of the side roof beam The middle roof beam; the rear roof beam connected with the end of the side roof beam away from the inclined front beam.

进一步地,在本发明一种优选的方式中,所述底板总成包括:与所述车体前立柱和所述门框底梁连接处连接的前底横梁;与所述车体中立柱和所述门框底梁连接处连接的中底横梁;与所述门框底梁远离所述车体前立柱的一端连接的后底横梁。Further, in a preferred mode of the present invention, the bottom plate assembly includes: a front bottom beam connected to the connection between the vehicle body front pillar and the door frame bottom beam; and the vehicle body center pillar and all the A midsole beam connected at the connection of the door frame bottom beam; a rear bottom beam connected with the end of the door frame bottom beam away from the front pillar of the vehicle body.

本发明提供的一种汽车前立柱上边梁结构,与现有技术相比,包括:车体前立柱;与所述车体前立柱上端连接的上边梁;所述上边梁与所述车体前立柱一体成型。本申请提供的技术方案将车体前立柱及上边梁合为一体,取消了接头,结构更简单、紧凑,能够简化车身结构,提高车架整体强度,缩短研发周期,降低研发及生产成本。Compared with the prior art, the present invention provides an upper side beam structure of a front pillar of an automobile, comprising: a front pillar of a vehicle body; an upper side beam connected with the upper end of the front pillar of the vehicle body; The column is integrally formed. The technical solution provided by the application integrates the front column and the upper side beam of the vehicle body into one body, eliminates the joint, and has a simpler and more compact structure, which can simplify the vehicle body structure, improve the overall strength of the vehicle frame, shorten the research and development period, and reduce the research and development and production costs.

附图说明Description of drawings

为了更清楚地说明本申请实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本申请的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the embodiments of the present application or the technical solutions in the prior art, the following briefly introduces the accompanying drawings required for the description of the embodiments or the prior art. Obviously, the drawings in the following description are only These are some embodiments of the present application. For those of ordinary skill in the art, other drawings can also be obtained based on these drawings without any creative effort.

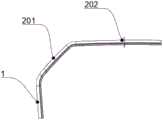

图1为本发明实施例提供的汽车前立柱上边梁结构的外形示意图;Fig. 1 is the outline schematic diagram of the upper side beam structure of the front pillar of the automobile provided by the embodiment of the present invention;

图2为本发明实施例提供的汽车前立柱上边梁结构的横截面形状示意图;2 is a schematic diagram of a cross-sectional shape of an upper side beam structure of an automobile front pillar provided by an embodiment of the present invention;

图3为本发明实施例提供的汽车前立柱上边梁结构的细节示意图;3 is a detailed schematic diagram of an upper side beam structure of an automobile front pillar according to an embodiment of the present invention;

图4为本发明实施例的汽车前立柱上边梁结构在汽车车架上的位置示意图。FIG. 4 is a schematic diagram of the position of the upper side beam structure of the front pillar of the automobile on the vehicle frame according to the embodiment of the present invention.

具体实施方式Detailed ways

为了使本领域的技术人员更好地理解本申请中的技术方案,下面将结合本申请实施例中的附图对本申请实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本申请的一部分实施例,而不是全部的实施例。基于本申请中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本申请保护的范围。In order for those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the drawings in the embodiments of the present application. Obviously, the described implementation The examples are only some of the embodiments of the present application, but not all of the embodiments. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present application.

需要说明的是,当元件被称为“固定于”或“设置于”另一个元件上,它可以直接在另一个元件上或者间接设置在另一个元件上;当一个元件被称为是“连接于”另一个元件,它可以是直接连接到另一个元件或间接连接至另一个元件上。It should be noted that when an element is referred to as being "fixed" or "disposed on" another element, it can be directly or indirectly disposed on the other element; when an element is referred to as being "connected" "to" another element, it may be directly connected to another element or indirectly connected to another element.

需要理解的是,术语“长度”、“宽度”、“上”、下”、“前”、“后”、“第一”、“第二”、“竖直”、“水平”、“顶”、“底”“内”、“外”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本申请和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本申请的限制。It is to be understood that the terms "length", "width", "upper", "lower", "front", "rear", "first", "second", "vertical", "horizontal", "top" "," "bottom", "inside", "outside" and other indicated orientations or positional relationships are based on the orientations or positional relationships shown in the accompanying drawings, which are only for the convenience of describing the present application and simplifying the description, rather than indicating or implying the indicated A device or element must have a particular orientation, be constructed and operate in a particular orientation, and therefore should not be construed as a limitation of the present application.

此外,术语“第一”、“第二”仅用于描述目的,而不能理解为指示或暗示相对重要性或者隐含指明所指示的技术特征的数量。由此,限定有“第一”、“第二”的特征可以明示或者隐含地包括一个或者更多个该特征。在本申请的描述中,“多个”、“若干个”的含义是两个或两个以上,除非另有明确具体的限定。In addition, the terms "first" and "second" are only used for descriptive purposes, and should not be construed as indicating or implying relative importance or implying the number of indicated technical features. Thus, a feature defined as "first" or "second" may expressly or implicitly include one or more of that feature. In the description of the present application, "plurality" and "several" mean two or more, unless otherwise expressly and specifically defined.

须知,本说明书附图所绘示的结构、比例、大小等,均仅用以配合说明书所揭示的内容,以供熟悉此技术的人士了解与阅读,并非用以限定本申请可实施的限定条件,故不具技术上的实质意义,任何结构的修饰、比例关系的改变或大小的调整,在不影响本申请所能产生的功效及所能达成的目的下,均应仍落在本申请所揭示的技术内容得能涵盖的范围内。It should be noted that the structures, proportions, sizes, etc. shown in the drawings of this specification are only used to cooperate with the contents disclosed in the specification for the understanding and reading of those who are familiar with this technology, and are not used to limit the conditions that the application can implement. Therefore, it has no technical substantive significance. Any structural modification, proportional relationship change or size adjustment should still fall within the scope of the disclosure in this application, without affecting the effect that the application can produce and the purpose that can be achieved. The technical content must be able to cover the scope.

请如图1至图4所示,本申请实施例提供的汽车前立柱上边梁结构,包括:车体前立柱1;与所述车体前立柱1上端连接的上边梁2;所述上边梁2与所述车体前立柱1一体成型。As shown in FIG. 1 to FIG. 4 , the upper side beam structure of the front pillar of the automobile provided by the embodiment of the present application includes: the

本发明实施例提供一种汽车前立柱上边梁结构,具体包括:车体前立柱1;与所述车体前立柱1上端连接的上边梁2;所述上边梁2与所述车体前立柱1一体成型。本申请提供的技术方案将车体前立柱1及上边梁2合为一体,取消了接头,结构更简单、紧凑,能够简化车身结构,提高车架整体强度,缩短研发周期,降低研发及生产成本。An embodiment of the present invention provides an upper side beam structure of a front pillar of an automobile, which specifically includes: a

本发明实施例中,汽车前立柱上边梁结构为一体式结构,汽车前立柱上边梁结构是利用弯管机对挤压型材根据设计要求进行三维弯曲而成,其将传统的上边梁2和车体前立柱1合并,强度更好,结构更紧凑。In the embodiment of the present invention, the upper side beam structure of the front pillar of the automobile is an integrated structure, and the upper side beam structure of the front pillar of the automobile is formed by three-dimensionally bending the extruded profiles according to the design requirements by a pipe bender. The

具体地,在本发明实施例中,所述车体前立柱1和所述上边梁2的横截面形状相同。Specifically, in the embodiment of the present invention, the cross-sectional shapes of the vehicle

本发明实施例中,车体前立柱1和上边梁2的横截面形状相同且车体前立柱1和上边梁2一体成型,车体前立柱1和上边梁2由同一根挤压型材通过弯管机三维弯曲而成。In the embodiment of the present invention, the cross-sectional shapes of the vehicle

具体地,在本发明实施例中,所述横截面形状包括:大圆弧区301;与所述大圆弧区301相对设置的小圆弧区302;用于连接所述大圆弧区301和所述小圆弧区302两端的凹陷区303。Specifically, in the embodiment of the present invention, the cross-sectional shape includes: a large

具体地,在本发明实施例中,所述大圆弧区301沿所述车体前立柱1和所述上边梁2的轴线掠过的区域朝向车架车架外侧;所述小圆弧区302沿所述车体前立柱1和所述上边梁2的轴线掠过的区域朝向车架车架内侧。Specifically, in the embodiment of the present invention, the area swept by the

具体地,在本发明实施例中,所述上边梁2包括:与所述车体前立柱1上端连接的倾斜前梁201;与所述倾斜梁远离所述车体前立柱1一端连接的侧顶梁202,所述侧顶梁202与所述倾斜前梁201一体成型。Specifically, in the embodiment of the present invention, the

具体地,在本发明实施例中,所述上边梁2还包括:与所述侧顶梁202远离所述倾斜前梁201一端连接的倾斜后梁,所述倾斜后梁与所述侧顶梁202一体成型。Specifically, in the embodiment of the present invention, the

本申请提供一种侧门框总成,包括:上述的汽车前立柱上边梁结构;与所述车体前立柱1底端连接的门框底梁4;与所述侧顶梁202的中部和所述门框底梁4的中部连接的车体中立柱5,与所述上边梁2和所述门框底梁4连接的车体后立柱6,所述车体后立柱6的一端与所述上边梁2远离所述车体前立柱1的一端连接,所述车体后立柱6的另一端与所述门框底梁4远离所述车体前立柱1的一端连接。The application provides a side door frame assembly, comprising: the above-mentioned upper side beam structure of the front pillar of the automobile; a door

需要说明的是,所述车体中立柱5的顶端与所述上边梁2的中部连接,所述车体中立柱5的底端与所述门框底梁4的中部连接;It should be noted that the top end of the vehicle

本申请提供一种汽车车架,包括:底板总成;设置在所述底板总成两侧的上述侧门框总成;与所述上边梁2连接的顶板总成。The present application provides an automobile frame, comprising: a bottom plate assembly; the above-mentioned side door frame assemblies disposed on both sides of the bottom plate assembly; and a top plate assembly connected with the

具体地,在本发明实施例中,所述顶板总成包括:与所述倾斜前梁201和所述侧顶梁202的连接处连接的前顶横梁;与所述侧顶梁202的中部连接的中顶横梁;与所述侧顶梁202远离所述倾斜前梁201一端连接的后顶横梁。Specifically, in the embodiment of the present invention, the roof assembly includes: a front roof beam connected to the connection between the

具体地,在本发明实施例中,所述底板总成包括:与所述车体前立柱1和所述门框底梁4连接处连接的前底横梁;与所述车体中立柱5和所述门框底梁4连接处连接的中底横梁;与所述门框底梁4远离所述车体前立柱1的一端连接的后底横梁。Specifically, in the embodiment of the present invention, the floor assembly includes: a front bottom beam connected to the connection between the vehicle

更为具体地阐述,在现有技术中面临的问题有如下几点,上边梁零件采用冲压成型,零件多,结构复杂,而且很多零件采用热成型技术,需要特殊冲压生产线;上边梁重量大,不满足轻量化设计要求;上边梁与车体前立柱搭接结构复杂,接头易成为结构弱点;模具开发费用高,而且拼焊夹具种类多,结构复杂,综合成本高;开发周期长,无法满足市场对新车型开发周期缩短的要求。More specifically, the problems faced in the prior art are as follows. The upper side beam parts are formed by stamping, which has many parts and a complex structure, and many parts use thermoforming technology, which requires special stamping production lines; Does not meet the requirements of lightweight design; the overlapping structure of the upper side beam and the front column of the car body is complex, and the joint is easy to become a structural weakness; the mold development cost is high, and there are many types of tailor-welding fixtures, complex structure, and high comprehensive cost; long development cycle, unable to meet The market's requirement for shortening the development cycle of new models.

在本申请实施例涉及的汽车前立柱上边梁结构中,将拼焊式上边梁改为一体式,简化上边梁结构,减少零件数量,降低成本;将冲压式上边梁改为挤压型材弯曲成型,降低模具开发费用,减小开发周期;将上边梁与车体前立柱合成一体,取消了接头,结构更紧凑,强度更好;挤压型材选用高强度钢,强度高,重量低;In the upper side beam structure of the front column of the automobile involved in the embodiment of the present application, the tailor-welded upper side beam is changed into an integrated type, which simplifies the upper side beam structure, reduces the number of parts, and reduces the cost; the stamping type upper side beam is changed to extrusion profile bending forming , reduce the cost of mold development and shorten the development cycle; the upper side beam and the front column of the car body are integrated, the joint is eliminated, the structure is more compact, and the strength is better; the extruded profile is made of high-strength steel, which has high strength and low weight;

需要说明的是,在本申请实施例中涉及的上边梁解释为:侧围上部从前到后的腔体结构,一般由内板、加强板、外板组成,是车身的主受力结构;It should be noted that the upper side beam involved in the embodiments of the present application is interpreted as: the cavity structure of the upper part of the side panel from front to rear, generally composed of an inner plate, a reinforcing plate, and an outer plate, is the main stress structure of the vehicle body;

在本申请实施例中涉及的车体前立柱也称为A柱,解释为:在车辆前方,连接门槛和上边梁的柱体,同时为前门铰链提供安装点,是车身的主受力结构。The front column of the vehicle body involved in the embodiments of the present application is also called A-pillar, which is explained as: in front of the vehicle, the column connecting the door sill and the upper side beam, and at the same time providing the installation point for the front door hinge, is the main stress structure of the vehicle body.

对所公开的实施例的上述说明,使本领域专业技术人员能够实现或使用本发明。对这些实施例的多种修改对本领域的专业技术人员来说将是显而易见的,本文中所定义的一般原理可以在不脱离本发明的精神或范围的情况下,在其他实施例中实现。因此,本发明将不会被限制于本文所示的这些实施例,而是要符合与本文所公开的原理和新颖特点相一致的最宽的范围。The above description of the disclosed embodiments enables any person skilled in the art to make or use the present invention. Various modifications to these embodiments will be readily apparent to those skilled in the art, and the generic principles defined herein may be implemented in other embodiments without departing from the spirit or scope of the invention. Thus, the present invention is not intended to be limited to the embodiments shown herein, but is to be accorded the widest scope consistent with the principles and novel features disclosed herein.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911046871.6ACN110641554A (en) | 2019-10-30 | 2019-10-30 | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911046871.6ACN110641554A (en) | 2019-10-30 | 2019-10-30 | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN110641554Atrue CN110641554A (en) | 2020-01-03 |

Family

ID=68995183

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911046871.6APendingCN110641554A (en) | 2019-10-30 | 2019-10-30 | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110641554A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116279830A (en)* | 2023-03-24 | 2023-06-23 | 航宇智造(北京)工程技术有限公司 | Multi-component material mixed integrally formed tubular beam type vehicle body framework without B column |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040075265A1 (en)* | 2002-10-18 | 2004-04-22 | Honda Motor Co., Ltd. | Structure for controlled deformation of body side structure |

| EP1767438A1 (en)* | 2005-09-21 | 2007-03-28 | Renault s.a.s. | A-pillar for the body of a motor vehicle |

| JP2008168856A (en)* | 2007-01-15 | 2008-07-24 | Toyota Motor Corp | Body rigidity imparting device |

| CN101898586A (en)* | 2009-03-20 | 2010-12-01 | 福特全球技术公司 | Body structure |

| CN102963435A (en)* | 2012-11-23 | 2013-03-13 | 浙江吉利汽车研究院有限公司杭州分公司 | Front upright post reinforcing structure of passenger compartment |

| CN206510980U (en)* | 2017-02-24 | 2017-09-22 | 浙江春风动力股份有限公司 | One kind top thick stick and a kind of vehicle |

| CN107554617A (en)* | 2017-10-18 | 2018-01-09 | 洛阳北方易初摩托车有限公司 | A kind of four-wheel low-speed electronic car B posts |

| CN107651021A (en)* | 2017-09-19 | 2018-02-02 | 广西艾盛创制科技有限公司 | A kind of electric automobile car body of aluminum alloy structure |

| CN207617806U (en)* | 2017-11-23 | 2018-07-17 | 上汽通用五菱汽车股份有限公司 | A kind of reinforcing plate assembly of side-wall outer-plate |

| CN208264353U (en)* | 2018-04-28 | 2018-12-21 | 长城汽车股份有限公司 | A kind of side wall stiffening plate and vehicle |

| CN109249990A (en)* | 2018-10-16 | 2019-01-22 | 河南御捷时代汽车有限公司 | A kind of New pipe beam type Truck Frame Structure |

| CN208484743U (en)* | 2018-07-02 | 2019-02-12 | 一拖(洛阳)福莱格车身有限公司 | A kind of tractor cab front column shape tube |

| CN208881920U (en)* | 2018-08-27 | 2019-05-21 | 北京长城华冠汽车科技股份有限公司 | A top frame of an automobile and an automobile |

| CN211364725U (en)* | 2019-10-30 | 2020-08-28 | 湖南恒润汽车有限公司 | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame |

- 2019

- 2019-10-30CNCN201911046871.6Apatent/CN110641554A/enactivePending

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040075265A1 (en)* | 2002-10-18 | 2004-04-22 | Honda Motor Co., Ltd. | Structure for controlled deformation of body side structure |

| EP1767438A1 (en)* | 2005-09-21 | 2007-03-28 | Renault s.a.s. | A-pillar for the body of a motor vehicle |

| JP2008168856A (en)* | 2007-01-15 | 2008-07-24 | Toyota Motor Corp | Body rigidity imparting device |

| CN101898586A (en)* | 2009-03-20 | 2010-12-01 | 福特全球技术公司 | Body structure |

| CN102963435A (en)* | 2012-11-23 | 2013-03-13 | 浙江吉利汽车研究院有限公司杭州分公司 | Front upright post reinforcing structure of passenger compartment |

| CN206510980U (en)* | 2017-02-24 | 2017-09-22 | 浙江春风动力股份有限公司 | One kind top thick stick and a kind of vehicle |

| CN107651021A (en)* | 2017-09-19 | 2018-02-02 | 广西艾盛创制科技有限公司 | A kind of electric automobile car body of aluminum alloy structure |

| CN107554617A (en)* | 2017-10-18 | 2018-01-09 | 洛阳北方易初摩托车有限公司 | A kind of four-wheel low-speed electronic car B posts |

| CN207617806U (en)* | 2017-11-23 | 2018-07-17 | 上汽通用五菱汽车股份有限公司 | A kind of reinforcing plate assembly of side-wall outer-plate |

| CN208264353U (en)* | 2018-04-28 | 2018-12-21 | 长城汽车股份有限公司 | A kind of side wall stiffening plate and vehicle |

| CN208484743U (en)* | 2018-07-02 | 2019-02-12 | 一拖(洛阳)福莱格车身有限公司 | A kind of tractor cab front column shape tube |

| CN208881920U (en)* | 2018-08-27 | 2019-05-21 | 北京长城华冠汽车科技股份有限公司 | A top frame of an automobile and an automobile |

| CN109249990A (en)* | 2018-10-16 | 2019-01-22 | 河南御捷时代汽车有限公司 | A kind of New pipe beam type Truck Frame Structure |

| CN211364725U (en)* | 2019-10-30 | 2020-08-28 | 湖南恒润汽车有限公司 | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116279830A (en)* | 2023-03-24 | 2023-06-23 | 航宇智造(北京)工程技术有限公司 | Multi-component material mixed integrally formed tubular beam type vehicle body framework without B column |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN218229147U (en) | Automobile door ring structure and automobile | |

| CN110466550B (en) | Rail vehicle side wall structure and rail vehicle | |

| CN108556924A (en) | A kind of A -pillar structure for improving 40% biasing and touching security performance | |

| CN213921230U (en) | Force transmission mechanism on upper portion of automobile body and automobile | |

| WO2025145984A1 (en) | Vehicle door ring structure and vehicle | |

| CN110641554A (en) | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame | |

| CN209870061U (en) | A car rear door structure | |

| CN211364725U (en) | Automobile front upright post upper edge beam structure, side door frame assembly and automobile frame | |

| CN211731598U (en) | Longitudinal beam rear section connecting structure | |

| CN208530701U (en) | Sill strip and vehicle | |

| CN220053944U (en) | A die-cast body C-pillar and D-pillar structure | |

| CN218172396U (en) | Automobile front door frame structure and automobile | |

| CN206678994U (en) | Train head car and its headstock skeleton | |

| CN215322871U (en) | B-pillar structure of automobile | |

| CN114620143A (en) | A vehicle body side wall assembly, a vehicle body assembly and a vehicle | |

| CN115257935A (en) | A side panel assembly and vehicle | |

| CN211391270U (en) | Rail vehicle side wall structure and train body | |

| CN220549106U (en) | Side panels and vehicles | |

| CN114275051A (en) | Integral B post inner panel and middle cross beam supporting plate structure | |

| CN217864376U (en) | An installation structure between the front end of the instrument panel beam and the vehicle body | |

| CN220220909U (en) | Side panels, side panels assemblies and vehicles | |

| CN115782937B (en) | Rail vehicle end wall and rail vehicle | |

| CN221820121U (en) | A-pillar assembly, body-in-white and vehicle | |

| CN222959581U (en) | Door window frame reinforcement structure and vehicle | |

| CN216709442U (en) | Sectional type D post planking assembly and car |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WD01 | Invention patent application deemed withdrawn after publication | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20200103 |