CN110380152B - A battery thermal management module and its control method - Google Patents

A battery thermal management module and its control methodDownload PDFInfo

- Publication number

- CN110380152B CN110380152BCN201910521669.8ACN201910521669ACN110380152BCN 110380152 BCN110380152 BCN 110380152BCN 201910521669 ACN201910521669 ACN 201910521669ACN 110380152 BCN110380152 BCN 110380152B

- Authority

- CN

- China

- Prior art keywords

- water

- valve

- cold

- return

- hot

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription15

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription392

- 230000001105regulatory effectEffects0.000claimsabstractdescription44

- 230000001276controlling effectEffects0.000claimsabstract2

- 239000007788liquidSubstances0.000claimsdescription12

- 230000036760body temperatureEffects0.000claimsdescription3

- 238000010992refluxMethods0.000claims12

- 238000007726management methodMethods0.000claims8

- 230000017525heat dissipationEffects0.000claims2

- 230000000630rising effectEffects0.000claims1

- 238000012423maintenanceMethods0.000abstractdescription4

- 238000013461designMethods0.000abstractdescription3

- 230000000694effectsEffects0.000abstractdescription3

- 125000006850spacer groupChemical group0.000description10

- 239000000498cooling waterSubstances0.000description7

- 238000009529body temperature measurementMethods0.000description3

- 238000001816coolingMethods0.000description3

- 238000010586diagramMethods0.000description3

- 230000009286beneficial effectEffects0.000description2

- 239000012535impuritySubstances0.000description2

- 238000009434installationMethods0.000description2

- 239000000463materialSubstances0.000description2

- RNFJDJUURJAICM-UHFFFAOYSA-N2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-trieneChemical compoundN=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1RNFJDJUURJAICM-UHFFFAOYSA-N0.000description1

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000description1

- 238000004378air conditioningMethods0.000description1

- 229910052782aluminiumInorganic materials0.000description1

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description1

- 238000002485combustion reactionMethods0.000description1

- 239000000428dustSubstances0.000description1

- 239000003063flame retardantSubstances0.000description1

- 239000011810insulating materialSubstances0.000description1

- 238000009413insulationMethods0.000description1

- 239000012774insulation materialSubstances0.000description1

- 229910052744lithiumInorganic materials0.000description1

- 229910001416lithium ionInorganic materials0.000description1

- 229910052751metalInorganic materials0.000description1

- 239000002184metalSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000000737periodic effectEffects0.000description1

- 238000004321preservationMethods0.000description1

- 238000009991scouringMethods0.000description1

- 230000002269spontaneous effectEffects0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/61—Types of temperature control

- H01M10/613—Cooling or keeping cold

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/61—Types of temperature control

- H01M10/615—Heating or keeping warm

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/61—Types of temperature control

- H01M10/617—Types of temperature control for achieving uniformity or desired distribution of temperature

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/62—Heating or cooling; Temperature control specially adapted for specific applications

- H01M10/625—Vehicles

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/63—Control systems

- H01M10/635—Control systems based on ambient temperature

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/65—Means for temperature control structurally associated with the cells

- H01M10/655—Solid structures for heat exchange or heat conduction

- H01M10/6556—Solid parts with flow channel passages or pipes for heat exchange

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/65—Means for temperature control structurally associated with the cells

- H01M10/656—Means for temperature control structurally associated with the cells characterised by the type of heat-exchange fluid

- H01M10/6567—Liquids

- H01M10/6568—Liquids characterised by flow circuits, e.g. loops, located externally to the cells or cell casings

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Automation & Control Theory (AREA)

- Secondary Cells (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及电池运维技术领域,具体涉及一种电池热管理模块及其控制方法。The invention relates to the technical field of battery operation and maintenance, in particular to a battery thermal management module and a control method thereof.

背景技术Background technique

电池,主要指电动汽车上使用的电池包,尤其是锂离子电芯串联组成的电池包,需要运行在合理的温度区间内。如果温度过高,会有自燃的危险,如果温度低于下限阈值,则会影响电池能够有效输出的电量及电压,降低电池包的性能。因而电池包均需要部署温度管理装置,在温度较高时,给电池包降温,在温度较低时,给电池包加热,提高电池包温度。目前电池热管理系统均需要板式换热器、PTC加热器、电磁阀和水泵四个主要零部件,通过管线路与空调及电池相连后实现电池的热管理。主要实现方式为:板式换热器与空调之间需空调管相连,水泵与电磁阀串联并通过电磁阀控制水路通断,从而切换板式换热器及PTC对水路加热或冷却,每个零部件均需与低压线束进行相连。此种方式具有以下不足:一、需要考虑全部零部件的装配,还需考虑彼此管路的连接与走向,在车辆后续维修方面对热管理系统的维修也有较高的成本代价。二、不能精细控制冷却水进入电池包时的温度,容易造成电池包温度在平衡温度附近振荡的问题。因而需要研制一种安装方便简单、温度控制精准的电池热管理方案。Batteries mainly refer to the battery packs used in electric vehicles, especially the battery packs composed of lithium-ion cells in series, which need to operate within a reasonable temperature range. If the temperature is too high, there is a risk of spontaneous combustion. If the temperature is lower than the lower threshold, it will affect the power and voltage that the battery can effectively output, and reduce the performance of the battery pack. Therefore, all battery packs need to deploy a temperature management device. When the temperature is high, the battery pack is cooled, and when the temperature is low, the battery pack is heated to increase the temperature of the battery pack. At present, the battery thermal management system requires four main components: plate heat exchanger, PTC heater, solenoid valve and water pump. After connecting with the air conditioner and the battery through the pipeline, the thermal management of the battery is realized. The main implementation method is: the air-conditioning pipe needs to be connected between the plate heat exchanger and the air conditioner, the water pump is connected in series with the solenoid valve, and the water circuit is controlled by the solenoid valve, so as to switch the plate heat exchanger and the PTC to heat or cool the water circuit. All need to be connected to the low-voltage wiring harness. This method has the following shortcomings: 1. It is necessary to consider the assembly of all components, as well as the connection and direction of each other's pipelines, and the maintenance of the thermal management system also has a higher cost in the subsequent maintenance of the vehicle. 2. The temperature of the cooling water entering the battery pack cannot be precisely controlled, which may easily cause the battery pack temperature to oscillate around the equilibrium temperature. Therefore, it is necessary to develop a battery thermal management solution with convenient and simple installation and accurate temperature control.

如中国专利CN205609706U,公开日2016年9月28日,一种电池模块的热管理系统,包括用以容纳电池模块密封的电池箱体,换热器,以及多组超导热板;所述的超导热铝板一端与换热器连接以进行热交换,另一端被夹持定位在电池模块之间;所述的换热器设置在所述的电池箱体的外部并串接在温控回路上,所述的电池模块上设有与BMS连接的温度传感器,所述的BMS控制所述的温控回路以对所述的换热器加热或者冷却。其技术方案采用水冷代替风冷,将电池模块封闭在电池箱体内部,可以防止灰尘进入以及雨水灌入。但其不能解在电池包部署在电动汽车上时,其水冷系统的水管布线复杂,和温度控制不够精细的技术问题。For example, Chinese patent CN205609706U, published on September 28, 2016, a thermal management system for a battery module, including a battery box sealed for accommodating the battery module, a heat exchanger, and a plurality of groups of superconducting plates; the described One end of the superconducting aluminum plate is connected to a heat exchanger for heat exchange, and the other end is clamped and positioned between the battery modules; the heat exchanger is arranged outside the battery box and connected in series to the temperature control circuit Above, the battery module is provided with a temperature sensor connected to the BMS, and the BMS controls the temperature control loop to heat or cool the heat exchanger. Its technical solution adopts water cooling instead of air cooling, and the battery module is enclosed inside the battery box, which can prevent dust from entering and rainwater from entering. However, it cannot solve the technical problems that the water pipe wiring of the water cooling system is complicated and the temperature control is not precise enough when the battery pack is deployed on the electric vehicle.

发明内容SUMMARY OF THE INVENTION

本发明要解决的技术问题是:目前缺乏部署方便、温度控制精准的电池热管理方案的技术问题。提出了一种部署方便水管连接简单的电池热管理模块及其控制方法。该技术方案还具有温度控制更加精准和均匀的技术效果。The technical problem to be solved by the present invention is: the technical problem of currently lacking a battery thermal management solution with convenient deployment and accurate temperature control. A battery thermal management module with easy deployment and simple water pipe connection and its control method are proposed. The technical solution also has the technical effect of more precise and uniform temperature control.

为解决上述技术问题,本发明所采取的技术方案为:一种电池热管理模块,与电池包的内置水管的进水口以及出水口连接,并通过散热水管与散热水管连接,电池包的内置水管的出水口安装有温度测量单元,测量电池包的内置水管的出水口水体温度,包括控制器、水泵、冷水量调节阀、热水量调节阀、加热器和热交换器,冷水量调节阀、热水量调节阀、水泵以及温度测量单元均与控制器连接,电池包的内置水管的出水口与加热器进水口以及热交换器的进水口连接,加热器出水口通过热水量调节阀与水泵进水口连接,热交换器的出水口通过冷水量调节阀与水泵进水口连接,水泵出水口与电池包的内置水管的进水口连接。通过冷水量调节阀以及热水量调节阀的开度比的调节,获得最适宜的进水口水温,使温度管理更精准,减小温度波动。In order to solve the above technical problems, the technical solution adopted by the present invention is: a battery thermal management module, which is connected to the water inlet and the water outlet of the built-in water pipe of the battery pack, and is connected to the heat-dissipating water pipe through the heat-dissipating water pipe. The built-in water pipe of the battery pack The water outlet of the battery pack is equipped with a temperature measurement unit to measure the water temperature of the water outlet of the built-in water pipe of the battery pack, including the controller, water pump, cold water volume control valve, hot water volume control valve, heater and heat exchanger, cold water volume control valve, The hot water volume regulating valve, water pump and temperature measuring unit are all connected to the controller, the water outlet of the built-in water pipe of the battery pack is connected to the heater water inlet and the water inlet of the heat exchanger, and the heater water outlet is connected to the water volume regulating valve through the hot water volume regulating valve. The water inlet of the water pump is connected, the water outlet of the heat exchanger is connected to the water inlet of the water pump through the cold water volume regulating valve, and the water outlet of the water pump is connected to the water inlet of the built-in water pipe of the battery pack. Through the adjustment of the opening ratio of the cold water volume control valve and the hot water volume control valve, the most suitable water temperature of the water inlet is obtained, so that the temperature management is more accurate and the temperature fluctuation is reduced.

作为优选,还包括左进流阀、左回流阀、右进流阀、右回流阀和回流水箱,左进流阀第一端以及右进流阀第一端均与水泵出水口连通,左进流阀第二端以及左回流阀的第一端均与电池包的内置水管的进水口连通,右进流阀第二端以及右回流阀的第一端均与电池包的内置水管的出水口连通,左回流阀的第二端以及右回流阀的第二端均与回流水箱连通,回流水箱与加热器进水口以及热交换器的进水口连通,左进流阀、左回流阀、右进流阀以及右回流阀均与控制器连接。电池包是由许多个电压仅3.7V左右的锂电芯,串联起来,组成380V甚至更高输出电压的电池包。靠近电池包的内置水管的进水口处的电芯,与水体具有最大的温差,能够有效的进行热交换,随着热交换的进行,水体温度亦发生变化,不仅导致远离进水口处的电芯,与水体的温差较低,热交换效率降低,而且最终热平衡时的温度也不同,导致靠近进水口处的电芯温度与远离进水口处的电芯温度存在明显的差异,进而导致电池包内电芯电压以及电芯内阻的不均衡,影响电池包整体的性能和寿命。通过将电池包的内置水管的进水口和出水口周期性交替互换,可以使电池包内的电芯温度更加均匀,提高电芯寿命。Preferably, it also includes a left inflow valve, a left return valve, a right inflow valve, a right return valve and a return water tank. The first end of the left inflow valve and the first end of the right inflow valve are connected to the water pump outlet, The second end of the flow valve and the first end of the left return valve are both connected to the water inlet of the built-in water pipe of the battery pack, and the second end of the right inflow valve and the first end of the right return valve are both connected to the water outlet of the built-in water pipe of the battery pack The second end of the left return valve and the second end of the right return valve are connected with the return water tank, and the return water tank is connected with the water inlet of the heater and the water inlet of the heat exchanger. The left inlet valve, left return valve, right inlet Both the flow valve and the right return valve are connected to the controller. The battery pack is composed of many lithium cells with a voltage of only about 3.7V, which are connected in series to form a battery pack with an output voltage of 380V or even higher. The battery cells near the water inlet of the built-in water pipe of the battery pack have the largest temperature difference with the water body and can effectively exchange heat. , the temperature difference with the water body is low, the heat exchange efficiency is reduced, and the temperature at the final heat balance is also different, resulting in a significant difference between the temperature of the cell near the water inlet and the temperature of the cell far away from the water inlet, which in turn leads to the inside of the battery pack. Unbalanced cell voltage and cell internal resistance affect the overall performance and life of the battery pack. By periodically exchanging the water inlet and the water outlet of the built-in water pipe of the battery pack, the temperature of the cells in the battery pack can be made more uniform and the life of the cells can be improved.

作为优选,还包括气压调节阀,所述气压调节阀安装在回流水箱上,气压调节阀的开闭受控制器的控制。气压调节阀能够调节水体体积因随温度变化导致的水体压力波动。Preferably, an air pressure regulating valve is also included, the air pressure regulating valve is installed on the return water tank, and the opening and closing of the air pressure regulating valve is controlled by the controller. The air pressure regulating valve can adjust the water pressure fluctuation caused by the temperature change of the water volume.

作为优选,还包括热回流水泵、冷回流水泵、热储水箱以及冷储水箱,热回流水泵以及冷回流水泵的进水口均与回流水箱连通,热回流水泵的出水口加热器的进水口连通,冷回流水泵的出水口热交换器的进水口连通,加热器的出水口与热储水箱进水口连通,热交换器的出水口与冷储水箱的进水口连通,热储水箱的出水口通过热水量调节阀与水泵进水口连通,冷储水箱的出水口通过冷水量调节阀与水泵进水口连通,热储水箱以及冷储水箱均安装有气压调节阀以及液位计,所述两个气压调节阀以及液位计均与控制器连接。通过设置热储水箱以及冷储水箱,在电池包的温度出现短期的快速变化时,能够将其内存储的热水或冷水,加速输入到电池包的内置水管内,使电池包的温度更快的恢复到最佳温度区间,提高电池包应对温度突变的能力。Preferably, it also includes a hot return water pump, a cold return water pump, a hot water storage tank and a cold water storage tank, the water inlets of the hot return water pump and the cold return water pump are connected with the return water tank, and the water outlet of the hot return water pump The water inlet of the heater is connected, The water outlet of the cold return water pump is connected with the water inlet of the heat exchanger, the water outlet of the heater is connected with the water inlet of the hot water storage tank, the water outlet of the heat exchanger is connected with the water inlet of the cold water storage tank, and the water outlet of the hot water storage tank is connected with the water inlet of the hot water storage tank. The water volume regulating valve is communicated with the water inlet of the water pump, and the water outlet of the cold water storage tank is communicated with the water inlet of the water pump through the cold water volume regulating valve. Both the regulating valve and the liquid level gauge are connected to the controller. By setting the hot water storage tank and the cold water storage tank, when the temperature of the battery pack undergoes a short-term rapid change, the hot water or cold water stored in it can be accelerated into the built-in water pipe of the battery pack, so that the temperature of the battery pack can be faster. It can restore to the optimal temperature range and improve the ability of the battery pack to deal with sudden changes in temperature.

作为优选,所述回流水箱底部设置有若干个隔条,所述若干个隔条均与回流箱底部紧密固定连接,所述若干个隔条横竖交织将回流箱底部分割为若干个方形凹腔。隔条形成的凹腔具有容纳异物的功能,能够将因水体冲刷以及磨损脱落的细小材料杂质捕获,限制在凹腔内,起到净化冷却水体的功能。Preferably, the bottom of the return water tank is provided with several spacers, and the several spacers are tightly connected with the bottom of the return tank, and the several spacers are interwoven horizontally and vertically to divide the bottom of the return tank into several square cavities. The cavity formed by the spacer has the function of accommodating foreign objects, which can capture the fine material impurities that fall off due to water scouring and wear, and confine them in the cavity to purify the cooling water body.

作为优选,所述隔条顶部的厚度大于隔条底部的厚度。提高凹腔留住杂质的能力。Preferably, the thickness of the top of the spacer is greater than the thickness of the bottom of the spacer. Improve the ability of the cavity to retain impurities.

作为优选,还包括外壳,所述控制器、水泵、冷水量调节阀、热水量调节阀、加热器、热交换器、左进流阀、左回流阀、右进流阀、右回流阀、回流水箱、热回流水泵、冷回流水泵、热储水箱以及冷储水箱均安装在壳体内。外壳不仅能够防尘,还具有一定的保温功能,减小热储水箱以及冷储水箱内水体温度受外界环境的影响。Preferably, it also includes a casing, the controller, water pump, cold water volume regulating valve, hot water volume regulating valve, heater, heat exchanger, left inlet valve, left return valve, right inlet valve, right return valve, The return water tank, the hot return water pump, the cold return water pump, the hot water storage tank and the cold water storage tank are all installed in the housing. The shell is not only dustproof, but also has a certain heat preservation function, which reduces the influence of the water temperature in the hot water storage tank and the cold water storage tank by the external environment.

作为优选,所述外壳为具有保温功能的外壳。如为双层外壳,层间填充空气或隔热材料。隔热材料需为阻燃材料。Preferably, the casing is a casing with a thermal insulation function. In the case of a double-layer shell, the layers are filled with air or insulating material. The thermal insulation material needs to be a flame retardant material.

一种如前述的电池热管理模块的控制方法,包括以下步骤:A)控制器读取温度测量单元的读数,根据电池包的内置水管的出水口内的水温,计算得出所需散热水管的进水口的水温,控制器控制冷水量调节阀以及热水量调节阀的开度比,混合后得到所需的水温;B)控制器控制左进流阀以及右回流阀开启,左回流阀以及右进流阀关闭,控制器控制水泵运转时间T1,停止运转T2时间,而后控制器控制左回流阀以及右进流阀开启,左进流阀以及右回流阀关闭,控制器控制水泵运转时间T1,停止运转T2时间;C)重复步骤A至B。A control method for a battery thermal management module as described above, comprising the following steps: A) the controller reads the reading of the temperature measurement unit, and calculates the inlet and outlet of the required cooling water pipe according to the water temperature in the water outlet of the built-in water pipe of the battery pack. The water temperature of the water outlet, the controller controls the opening ratio of the cold water volume control valve and the hot water volume control valve, and the required water temperature is obtained after mixing; B) The controller controls the left inlet valve and the right return valve to open, the left return valve and the right return valve. When the inflow valve is closed, the controller controls the running time of the water pump for T1 and stops the operation for T2. Then the controller controls the left return valve and the right inflow valve to open, the left inflow valve and the right return valve are closed, and the controller controls the operation time of the water pump T1, Stop running for T2 time; C) Repeat steps A to B.

作为优选,步骤B还包括以下子步骤:控制器控制水泵、热回流水泵以及冷回流水泵的转速,使热储水箱以及冷储水箱液位基本稳定;当检测到电池包的内置水管的出水口内的水温上升或下降速率超过设定阈值时,加快水泵的转速,但保持热回流水泵以及冷回流水泵的转速,直至热储水箱或者冷储水箱液位低于设定水位下阈值;加快热回流水泵以及冷回流水泵的转速,直至热储水箱或者冷储水箱液位高于设定水位上阈值。Preferably, step B further includes the following sub-steps: the controller controls the rotational speed of the water pump, the hot return water pump and the cold return water pump, so that the liquid levels of the hot water storage tank and the cold water storage tank are basically stable; When the rate of rise or fall of the water temperature exceeds the set threshold, speed up the speed of the water pump, but keep the speed of the hot return water pump and the cold return water pump until the liquid level of the hot water storage tank or the cold water storage tank is lower than the lower threshold of the set water level; speed up the heat return The speed of the water pump and the cold return water pump until the liquid level of the hot water storage tank or the cold water storage tank is higher than the upper threshold of the set water level.

本发明的实质性效果是:通过将零部件集中到外壳内,仅通过预留的水管接口分别为电池包的内置水管以及散热器连接,使需要布设的水管数量大幅下降,方便设计以及部署;通过冷水量调节阀以及热水量调节阀的开度比的调节,获得最适宜的进水口水温,使温度管理更精准,减小温度波动;通过将电池包的内置水管的进水口和出水口周期性交替互换,可以使电池包内的电芯温度更加均匀,提高电芯寿命;通过设置热储水箱以及冷储水箱,在电池包的温度出现短期的快速变化时,能够将其内存储的热水或冷水,加速输入到电池包的内置水管内,使电池包的温度更快的恢复到最佳温度区间,提高电池包应对温度突变的能力。The substantial effect of the present invention is: by concentrating the components in the casing, and connecting the built-in water pipe and the radiator of the battery pack respectively only through the reserved water pipe interface, the number of water pipes to be laid is greatly reduced, which is convenient for design and deployment; Through the adjustment of the opening ratio of the cold water volume regulating valve and the hot water volume regulating valve, the most suitable water temperature of the water inlet is obtained, so that the temperature management is more accurate and the temperature fluctuation is reduced; Periodic exchange can make the temperature of the cells in the battery pack more uniform and improve the life of the cells; by setting the hot water storage tank and the cold water storage tank, when the temperature of the battery pack changes rapidly in the short term, it can be stored in the battery pack. The hot or cold water is quickly input into the built-in water pipe of the battery pack, so that the temperature of the battery pack can return to the optimal temperature range faster, and the ability of the battery pack to cope with sudden changes in temperature is improved.

附图说明Description of drawings

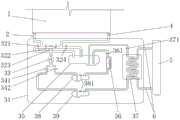

图1为实施例一安装关系示意图。FIG. 1 is a schematic diagram of the installation relationship of the first embodiment.

图2为实施例一结构示意图。FIG. 2 is a schematic structural diagram of the first embodiment.

图3为实施例二结构示意图。FIG. 3 is a schematic structural diagram of the second embodiment.

其中:1、电池包,2、进水口,3、热管理模块,4、出水口,5、散热器,6、散热水管,31、外壳,321、左回流阀,322、左进流阀,323、右进流阀,324、右回流阀,33、水泵,341、冷水量调节阀,342、热水量调节阀,35、回流水箱,36、加热器,361、热回流水泵,37、热交换器,371、冷回流水泵,38、热储水箱,381、气压调节阀,39、冷储水箱。Among them: 1, battery pack, 2, water inlet, 3, thermal management module, 4, water outlet, 5, radiator, 6, cooling water pipe, 31, shell, 321, left return valve, 322, left inlet valve, 323, right inlet valve, 324, right return valve, 33, water pump, 341, cold water volume control valve, 342, hot water volume control valve, 35, return water tank, 36, heater, 361, hot return water pump, 37, Heat exchanger, 371, cold return water pump, 38, hot water storage tank, 381, air pressure regulating valve, 39, cold water storage tank.

具体实施方式Detailed ways

下面通过具体实施例,并结合附图,对本发明的具体实施方式作进一步具体说明。The specific embodiments of the present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

实施例一:Example 1:

一种电池热管理模块,如图1所示,本实施例热管理模块3具有外壳31,外壳31上预留有四个水管接口,其中两个水管接口分别与电池包1的内置水管的进水口2以及出水口4连接,另外两个水管接口分别通过散热水管6与散热器5的进水口以及出水口4连接。散热器5为具有主动热交换功能的散热器5,而非简单的金属片,如空调。A battery thermal management module, as shown in FIG. 1 , the

如图2所示,本实施例包括控制器、水泵33、冷水量调节阀341、热水量调节阀342、加热器36、热交换器37、左进流阀322、左回流阀321、右进流阀323、右回流阀324和回流水箱35,冷水量调节阀341、热水量调节阀342、水泵33、温度测量单元、左进流阀322、左回流阀321、右进流阀323以及右回流阀324均与控制器连接,左进流阀322第一端以及右进流阀323第一端均与水泵33出水口连通,左进流阀322第二端以及左回流阀321的第一端均与电池包1的内置水管的进水口2连通,右进流阀323第二端以及右回流阀324的第一端均与电池包1的内置水管的出水口4连通,构成能够交换水流方向的管道。左回流阀321的第二端以及右回流阀324的第二端均与回流水箱35连通,回流水箱35具有低洼部,加热器36进水口以及热交换器37的进水口与低洼部连通。回流水箱35底部设置有若干个隔条,若干个隔条均与回流箱底部紧密固定连接,若干个隔条横竖交织将回流箱底部分割为若干个方形凹腔。隔条顶部的厚度大于隔条底部的厚度。回流水箱35上安装有气压调节阀381,以平衡水体体积的变化带来压力变化。As shown in FIG. 2, this embodiment includes a controller, a

本实施例的控制方法为:The control method of this embodiment is:

A)控制器读取温度测量单元的读数,根据电池包1的内置水管的出水口4内的水温,计算得出所需散热水管6的进水口的水温,控制器控制冷水量调节阀341以及热水量调节阀342的开度比,混合后得到所需的水温;B)控制器控制左进流阀322以及右回流阀324开启,左回流阀321以及右进流阀323关闭,控制器控制水泵33运转时间T1,停止运转T2时间,而后控制器控制左回流阀321以及右进流阀323开启,左进流阀322以及右回流阀324关闭,控制器控制水泵33运转时间T1,停止运转T2时间;C)重复步骤A至B。计算得出所需散热水管6的进水口的水温,具体方法为:设定最佳工作温度,计算出水口4水体温度与最佳工作温度的温差,进水口2所需水体温度为使进水口2温度按水体比热容为权重,出水口4温度按电池包1的电芯等效比热容为权重,二者的加权平均值基本等于最佳工作温度。A) The controller reads the reading of the temperature measuring unit, calculates the water temperature of the water inlet of the cooling

本实施例的有益效果为:通过将零部件集中到外壳31内,仅通过预留的水管接口分别为电池包1的内置水管以及散热器5连接,使需要布设的水管数量大幅下降,方便设计以及部署;通过冷水量调节阀341以及热水量调节阀342的开度比的调节,获得最适宜的进水口2水温,使温度管理更精准,减小温度波动;通过将电池包1的内置水管的进水口2和出水口4周期性交替互换,可以使电池包1内的电芯温度更加均匀,提高电芯寿命。The beneficial effects of this embodiment are: by concentrating the components in the

实施例二:Embodiment 2:

一种电池热管理模块,本实施例在实施例一的基础上,做了进一步的改进。如图3所示,本实施例在实施例一的基础上,增加了热回流水泵361、冷回流水泵371、热储水箱38以及冷储水箱39,热回流水泵361以及冷回流水泵371的进水口均与回流水箱35连通,热回流水泵361的出水口加热器36的进水口连通,冷回流水泵371的出水口热交换器37的进水口连通,加热器36的出水口与热储水箱38进水口连通,热交换器37的出水口与冷储水箱39的进水口连通,热储水箱38的出水口通过热水量调节阀342与水泵33进水口连通,冷储水箱39的出水口通过冷水量调节阀341与水泵33进水口连通,热储水箱38以及冷储水箱39均安装有气压调节阀381以及液位计,两个气压调节阀381以及液位计均与控制器连接。A battery thermal management module is further improved in this embodiment on the basis of the first embodiment. As shown in FIG. 3 , on the basis of

本实施例的控制方法为:The control method of this embodiment is:

控制器控制水泵33、热回流水泵361以及冷回流水泵371的转速,使热储水箱38以及冷储水箱39液位基本稳定;当检测到电池包1的内置水管的出水口4内的水温上升或下降速率超过设定阈值时,加快水泵33的转速,但保持热回流水泵361以及冷回流水泵371的转速,直至热储水箱38或者冷储水箱39液位低于设定水位下阈值;加快热回流水泵361以及冷回流水泵371的转速,直至热储水箱38或者冷储水箱39液位高于设定水位上阈值。The controller controls the rotational speed of the

本实施例的有益效果为:通过设置热储水箱38以及冷储水箱39,在电池包1的温度出现短期的快速变化时,能够将其内存储的热水或冷水,加速输入到电池包1的内置水管内,使电池包1的温度更快的恢复到最佳温度区间,提高电池包1应对温度突变的能力。The beneficial effect of this embodiment is: by arranging the hot

以上所述的实施例只是本发明的一种较佳的方案,并非对本发明作任何形式上的限制,在不超出权利要求所记载的技术方案的前提下还有其它的变体及改型。The above-mentioned embodiment is only a preferred solution of the present invention, and does not limit the present invention in any form, and there are other variations and modifications under the premise of not exceeding the technical solution recorded in the claims.

Claims (8)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910521669.8ACN110380152B (en) | 2019-06-17 | 2019-06-17 | A battery thermal management module and its control method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910521669.8ACN110380152B (en) | 2019-06-17 | 2019-06-17 | A battery thermal management module and its control method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110380152A CN110380152A (en) | 2019-10-25 |

| CN110380152Btrue CN110380152B (en) | 2020-10-23 |

Family

ID=68250370

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910521669.8AActiveCN110380152B (en) | 2019-06-17 | 2019-06-17 | A battery thermal management module and its control method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110380152B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4430695A4 (en)* | 2021-11-10 | 2025-09-03 | Hydro Quebec | Ultra-high-performance battery module with active and dynamic management of operating temperature and pressure |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113067050A (en)* | 2020-01-02 | 2021-07-02 | 广州汽车集团股份有限公司 | Power battery temperature control system, temperature control method and automobile |

| CN112428883A (en)* | 2020-11-13 | 2021-03-02 | 东风汽车集团有限公司 | Heating method and heating system for power battery of electric automobile |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107946696A (en)* | 2017-12-26 | 2018-04-20 | 山东大学 | A kind of automobile power cell group temperature control device based on liquid medium |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN204885359U (en)* | 2015-07-16 | 2015-12-16 | 金龙联合汽车工业(苏州)有限公司 | Group battery temperature control system |

| CN105680115B (en)* | 2016-03-25 | 2018-07-13 | 东风商用车有限公司 | Battery temperature control system for vehicle and use method thereof |

| CN106785185A (en)* | 2016-10-27 | 2017-05-31 | 骆驼集团新能源电池有限公司 | A kind of liquid is cold and heating integral dynamic lithium battery PACK |

| CN108110372A (en)* | 2017-12-18 | 2018-06-01 | 奇瑞商用车(安徽)有限公司 | Power battery intelligent temperature control system and its control method |

| CN108306072B (en)* | 2018-01-04 | 2020-02-07 | 福建省汽车工业集团云度新能源汽车股份有限公司 | Parallel heat exchange battery pack |

| CN108717985A (en)* | 2018-07-26 | 2018-10-30 | 十堰派生工贸有限公司 | A kind of battery pack with circulating water-cooling function |

| CN108963316A (en)* | 2018-09-14 | 2018-12-07 | 扬州江淮轻型汽车有限公司 | The manufacturing method of battery pack and the battery thermostat for using battery pack |

| CN109830785B (en)* | 2019-03-25 | 2021-07-13 | 合达信科技集团有限公司 | New energy automobile battery cooling system control device |

- 2019

- 2019-06-17CNCN201910521669.8Apatent/CN110380152B/enactiveActive

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107946696A (en)* | 2017-12-26 | 2018-04-20 | 山东大学 | A kind of automobile power cell group temperature control device based on liquid medium |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4430695A4 (en)* | 2021-11-10 | 2025-09-03 | Hydro Quebec | Ultra-high-performance battery module with active and dynamic management of operating temperature and pressure |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110380152A (en) | 2019-10-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110380152B (en) | A battery thermal management module and its control method | |

| CN111403850B (en) | Dynamic liquid cooling thermal management system for power battery | |

| CN110931824B (en) | Fuel cell cooling liquid flow distribution system and control method thereof | |

| CN105552478B (en) | The design method of temperature of powered cell control system and corresponding control system | |

| CN107768774A (en) | A kind of new-energy automobile three guarantees electrokinetic cell cools down heating system | |

| CN101728595B (en) | Battery | |

| CN108550948B (en) | A cold/hot dual cycle system for thermal management of power battery packs | |

| CN109738223A (en) | Fuel cell thermal management test bench and fuel cell thermal management monitoring system | |

| CN111403849B (en) | A hybrid controllable power battery air cooling and heat management experimental system | |

| CN108306072B (en) | Parallel heat exchange battery pack | |

| CN211376819U (en) | Fuel cell thermal management system | |

| CN209311114U (en) | Fuel cell heat management testboard bay and fuel cell heat management monitoring system | |

| CN206282947U (en) | It is applied to the temperature control system of vehicle electronic box | |

| CN108232364A (en) | Battery temperature control device | |

| CN208460926U (en) | A kind of adjustable heat weighing apparatus lithium-ion-power cell group liquid cooling system | |

| CN102082314A (en) | Device and system for controlling temperature of storage battery | |

| CN213150828U (en) | Cooling test system for fuel cell testing | |

| CN201311957Y (en) | Battery pack module | |

| CN210668616U (en) | A power lithium battery pack thermal management device | |

| CN114497806A (en) | Power battery thermal management system and control method | |

| CN109149013A (en) | The pump of semiconductor temperature for electric vehicle drives the two-phase circulatory system and its control method | |

| CN117317467A (en) | Energy storage battery module combined heat dissipation device and control method thereof | |

| CN208580827U (en) | A kind of liquid-cooled temperature equalization electrokinetic cell system and vehicle | |

| CN219832773U (en) | Industrial vehicle lithium battery based on semiconductor temperature control | |

| CN218769633U (en) | A battery stack structure and a liquid flow battery temperature regulation system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP01 | Change in the name or title of a patent holder | ||

| CP01 | Change in the name or title of a patent holder | Address after:310051 1st and 6th floors, no.451 Internet of things street, Binjiang District, Hangzhou City, Zhejiang Province Patentee after:Zhejiang Zero run Technology Co.,Ltd. Address before:310051 1st and 6th floors, no.451 Internet of things street, Binjiang District, Hangzhou City, Zhejiang Province Patentee before:ZHEJIANG LEAPMOTOR TECHNOLOGY Co.,Ltd. |