CN110211103B - Information entropy additive fuzzy defect characteristic analysis reconstruction method based on infrared thermal imaging - Google Patents

Information entropy additive fuzzy defect characteristic analysis reconstruction method based on infrared thermal imagingDownload PDFInfo

- Publication number

- CN110211103B CN110211103BCN201910433608.6ACN201910433608ACN110211103BCN 110211103 BCN110211103 BCN 110211103BCN 201910433608 ACN201910433608 ACN 201910433608ACN 110211103 BCN110211103 BCN 110211103B

- Authority

- CN

- China

- Prior art keywords

- defect

- matrix

- iteration

- representing

- characteristic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F17/00—Digital computing or data processing equipment or methods, specially adapted for specific functions

- G06F17/10—Complex mathematical operations

- G06F17/16—Matrix or vector computation, e.g. matrix-matrix or matrix-vector multiplication, matrix factorization

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/23—Clustering techniques

- G06F18/232—Non-hierarchical techniques

- G06F18/2321—Non-hierarchical techniques using statistics or function optimisation, e.g. modelling of probability density functions

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T7/00—Image analysis

- G06T7/0002—Inspection of images, e.g. flaw detection

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T7/00—Image analysis

- G06T7/40—Analysis of texture

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T7/00—Image analysis

- G06T7/90—Determination of colour characteristics

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- Data Mining & Analysis (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Mathematical Physics (AREA)

- Computational Mathematics (AREA)

- Mathematical Analysis (AREA)

- Mathematical Optimization (AREA)

- Pure & Applied Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- Computing Systems (AREA)

- Databases & Information Systems (AREA)

- Software Systems (AREA)

- Algebra (AREA)

- Quality & Reliability (AREA)

- Probability & Statistics with Applications (AREA)

- Life Sciences & Earth Sciences (AREA)

- Artificial Intelligence (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Bioinformatics & Computational Biology (AREA)

- Evolutionary Biology (AREA)

- Evolutionary Computation (AREA)

- Investigating Materials By The Use Of Optical Means Adapted For Particular Applications (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于缺陷检测技术领域,更为具体地讲,涉及一种基于红外热成像的信息熵加性模糊缺陷特征分析重构方法。The invention belongs to the technical field of defect detection, and more particularly relates to an information entropy additive fuzzy defect feature analysis and reconstruction method based on infrared thermal imaging.

背景技术Background technique

近年来,红外热成像检测技术得到飞速发展。其不损伤本体、快速高效等特性,能有效地解决传统无损检测方法存在劳动强度大、周期长、效率低、安全性差等问题,实现大面积快速检测、节省大量人力物力。In recent years, infrared thermal imaging detection technology has developed rapidly. It does not damage the body, fast and efficient, and can effectively solve the problems of high labor intensity, long cycle, low efficiency, and poor safety in traditional non-destructive testing methods, realize large-scale rapid testing, and save a lot of manpower and material resources.

如果待检测试件表面存在缺陷,则会影响其热量分布。对待检测试件加热,从而产生高温区和低温区,由于温度的差异性,高温区热量通过热传导向低温区传递,导致被测件不同区域温度发生变化,通过红外热像仪采集试件温度的变化过程,然后将采集的热图像视频交给计算机进行分析处理,来获取被测件相关信息,实现缺陷的定性与定量检测。If there are defects on the surface of the test piece to be tested, it will affect its heat distribution. The test piece to be tested is heated, resulting in a high temperature area and a low temperature area. Due to the difference in temperature, the heat in the high temperature area is transferred to the low temperature area through thermal conduction, resulting in temperature changes in different areas of the test piece. Change process, and then send the collected thermal image video to the computer for analysis and processing to obtain the relevant information of the tested piece, and realize the qualitative and quantitative detection of defects.

传统的缺陷分析方法主要针对于同一空间不同区域的缺陷特征,并且缺陷分布较为明确,通过相应的技术可以清晰的将缺陷进行划分,但对于在航空材料上的缺陷,其分布在不同层的空间中,同时撞击,腐蚀等因素造成不同程度的缺陷分布相互干扰,外界环境也会对缺陷产生影响。所以不同空间的损伤信息会被忽视,从而会对材料的缺陷类型进行了错误的判断。目前,由于外界环境和材料自身属性影响,形成了多种已知缺陷类型,散布坑缺陷,表面裂纹缺陷,内部层裂缺陷,内部剥落缺陷等,这些已知类型缺陷可以作为缺陷评估的建模基础。The traditional defect analysis method is mainly aimed at the defect characteristics of different areas in the same space, and the defect distribution is relatively clear. Through the corresponding technology, the defects can be clearly divided, but for the defects in aviation materials, they are distributed in different layers of space. In the process, simultaneous impact, corrosion and other factors cause different degrees of defect distribution to interfere with each other, and the external environment will also affect the defects. Therefore, the damage information of different spaces will be ignored, which will make a wrong judgment on the defect type of the material. At present, due to the influence of the external environment and the properties of the material itself, a variety of known defect types have been formed, such as scattered pit defects, surface crack defects, internal spalling defects, internal spalling defects, etc. These known types of defects can be used as the modeling for defect evaluation. Base.

由于实际的缺陷信息目标在形态和类属方面存在着中介性,没有确定的边界来区分,所以针对不同区域的缺陷,FCM模糊算法被用在对缺陷信息进行归类和处理。但是传统的FCM算法不能完全的的表达每个元素的特征,不同空间不同程度的缺陷信息在处理过程中会丢失很多的有用像素特征,为了解决这类问题,本发明提出新的目标函数,包含了赞成度,犹豫度,不仅完善了特征元素的信息,同时处理了不同程度缺陷之间的相互干扰。在另一方面,新的目标函数中还用模糊熵对变量的不确定性进行了描述,使缺陷的相关性更为明确。从而能够对不同空间的缺陷精确的进行去干扰聚类。Because the actual defect information target has intermediary in shape and category, and there is no definite boundary to distinguish, so for defects in different regions, FCM fuzzy algorithm is used to classify and process defect information. However, the traditional FCM algorithm cannot fully express the characteristics of each element, and the defect information of different spaces and different degrees will lose a lot of useful pixel characteristics in the processing process. In order to solve such problems, the present invention proposes a new objective function, including The approval degree and hesitation degree are improved, which not only improves the information of characteristic elements, but also deals with the mutual interference between defects of different degrees. On the other hand, fuzzy entropy is used to describe the uncertainty of variables in the new objective function, which makes the correlation of defects more clear. Therefore, it is possible to accurately perform de-interference clustering for defects in different spaces.

为了更加准确的判断材料的缺陷情况,本发明提出了一种有效的检测方法,不仅能够判断待检测材料表面空间损伤,去除噪声干扰,更重要的是能够更精确的获得内层空间的损伤情况。In order to more accurately judge the defect of the material, the present invention proposes an effective detection method, which can not only judge the surface space damage of the material to be tested and remove the noise interference, but more importantly, can obtain the inner space damage more accurately .

发明内容SUMMARY OF THE INVENTION

本发明的目的在于克服现有技术的不足,提供一种基于红外热成像的信息熵加性模糊缺陷特征分析重构方法,通过改进的模糊算法实现不同空间多个区域的缺陷检测及特征提取。The purpose of the present invention is to overcome the deficiencies of the prior art, and provide a method for analyzing and reconstructing information entropy additive fuzzy defect features based on infrared thermal imaging, and realizes defect detection and feature extraction in multiple regions in different spaces through an improved fuzzy algorithm.

为实现上述发明目的,本发明一种基于红外热成像的信息熵加性模糊缺陷特征分析重构方法,其特征在于,包括以下步骤:In order to achieve the above purpose of the invention, a method for analyzing and reconstructing information entropy additive fuzzy defects based on infrared thermal imaging of the present invention is characterized in that, it includes the following steps:

(1)、待检测视频流预处理(1) Preprocessing of the video stream to be detected

(1.1)、将待检测视频流用矩阵块表示为:其中,NI×NJ表示空间信息,NT表示时间信息;(1.1), the video stream to be detected is represented as a matrix block as: Among them, NI ×NJ represents spatial information, and NT represents time information;

(1.2)、通过向量算子Vec()将矩阵块转换为二维矩阵Y;(1.2), convert the matrix block into a two-dimensional matrix Y through the vector operator Vec();

Y=[Vec(Y(1)),Vec(Y(2)),…,Vec(Y(NT))]Y=[Vec(Y(1)),Vec(Y(2)),...,Vec(Y(NT ))]

其中,NIJ=NI×NJ;in, NIJ =NI ×NJ ;

(1.3)、根据先验的l种缺陷类型,将待检测视频流改写为:(1.3), according to a priori l defect types, rewrite the video stream to be detected as:

其中,Xθ(tθ)表示待检测视频流中的第tθ帧第θ种缺陷特征行向量,θ=1,2,…,l,αθ(tθ)为Xθ(tθ)对应的特征系数矩阵列向量,NC表示待检测视频流中表示特征缺陷的总帧数;Among them, Xθ (tθ ) represents the θ-th defect feature row vector of the tθ -th frame in the video stream to be detected, θ=1,2,...,l, αθ (tθ ) is the eigencoefficient matrix column vector corresponding to Xθ (tθ ), NC represents the total number of frames representing characteristic defects in the video stream to be detected;

(2)、缺陷重构(2), defect reconstruction

(2.1)、采用奇异值分解算法将改写后的视频流Y分解为:YT=U∑VT,其中,为左奇异矩阵,为奇异值矩阵,为右奇异矩阵;(2.1), adopt the singular value decomposition algorithm to decompose the rewritten video stream Y into: YT =U∑VT , where, is a left singular matrix, is the singular value matrix, is a right singular matrix;

(2.2)、计算白化矩阵W和混合系数矩阵λ;(2.2), calculate the whitening matrix W and the mixing coefficient matrix λ;

(2.3)、将重构缺陷用矩阵表示为X=W×Y;(2.3), the reconstruction defect is represented by a matrix as X=W×Y;

(2.4)、通过牛顿迭代法消除重构缺陷特征之间的相关性:(2.4) Eliminate the correlation between the reconstructed defect features by the Newton iteration method:

w*=E{xg(wTx)}-E{xg(wTx)}ww*=E{xg(wT x)}-E{xg(wT x)}w

其中,x是X的行向量,w为W的行向量,g(·)是对比度函数G的导数,E{·}表示求期望;Among them, x is the row vector of X, w is the row vector of W, g(·) is the derivative of the contrast function G, and E{·} represents the expectation;

(2.5)、按照步骤(2.4)所述方法对X的所有行进行处理后,得到重构后的缺陷特征信息矩阵:X*=W*×Y,(2.5) After all rows of X are processed according to the method described in step (2.4), a reconstructed defect feature information matrix is obtained: X*=W*×Y,

(2.6)、对白化矩阵W*进行时域分析,得到不同缺陷特征的实际分布情况,再比较W*中行向量w*的曲线趋势,将w*曲线趋势相近的视为相同缺陷类型,否则视为不同缺陷类型;(2.6) Perform time domain analysis on the whitening matrix W* to obtain the actual distribution of different defect characteristics, then compare the curve trend of the row vector w* in W* , and consider the w* curve with similar trends as the same defect type, otherwise it will be regarded as the same defect type. for different defect types;

合并相同缺陷类型的缺陷帧数,构成新的缺陷帧数其中,m=1,2,…χ,且χ≤l,Combine the number of defective frames of the same defect type to form a new number of defective frames Among them, m=1,2,...χ, and χ≤l,

从而从X*中得到张第m类缺陷类型的重构图像,记为thus getting from X* The reconstructed image of the mth defect type, denoted as

(3)、重构图像的特征提取(3) Feature extraction of reconstructed images

(3.1)、利用巴特沃兹滤波器对重构图像进行纹理及色差分割;(3.1), use Butterworth filter to reconstruct the image Perform texture and chromatic aberration segmentation;

特征色差表示为:The characteristic color difference is expressed as:

其中,ti表示中像素点(ti,tj)的行坐标,tj表示中像素点(ti,tj)的列坐标,D0为阈值;in, ti means The row coordinates of the middle pixel point (ti , tj ), tj represents The column coordinates of the middle pixel point (ti , tj ), D0 is the threshold;

特征纹理表示为:The feature texture is represented as:

(3.2)、对特征色差进行优化处理;(3.2), optimize the characteristic chromatic aberration;

(3.2.1)、设置迭代终止条件ε,迭代次数c,最大迭代次数cm,聚类数目τ,操作系数δ,权重系数b,模糊系数λ,赞成度μj(hi)c,犹豫度ξj(hi)c,聚类中心vjc,目标函数Jc;(3.2.1), set the iteration termination condition ε, the number of iterations c, the maximum number of iterations cm , the number of clusters τ, the operation coefficient δ, the weight coefficient b, the fuzzy coefficient λ, the approval degree μj (hi )c , the hesitation degree ξj (hi )c , cluster center vjc , objective function Jc ;

(3.2.2)、计算第c次迭代时每一类中单个像素点的赞成度μj(hi)c;(3.2.2), calculate the approval degree μj (hi )c of a single pixel in each category in the c-th iteration;

其中,hi表示特征色差H中第i个像素点的像素值,j≠s;||·||表示求范数;Among them, hi represents the pixel value of theith pixel in the characteristic color difference H, j≠s; ||·|| represents the norm;

(3.2.3)、计算第c次迭代时每一类的聚类中心vjc;(3.2.3), calculate the cluster center vjc of each class in the c-th iteration;

其中,g表示特征色差H中像素点的个数;Among them, g represents the number of pixels in the characteristic color difference H;

(3.2.4)、计算第c次迭代时每一类中单个像素点的犹豫度ξj(hi)c;(3.2.4), calculate the hesitation degree ξj (hi )c of a single pixel in each category in the c-th iteration;

(3.2.5)、计算第c次迭代时的目标函数Jc值;(3.2.5), calculate the objective function Jc value in the c-th iteration;

(3.2.6)、第c次迭代结束后,判断是否满足关系式:||Jc-Jc-1||≤ε,如果满足,则进入步骤(3.2.7),否则迭代停止,跳转进入步骤(3.3);(3.2.6) After the c-th iteration, judge whether the relational expression is satisfied: ||Jc -Jc-1 || Go to step (3.3);

(3.2.7)、判断当前迭代次数c是否达到设置的最大迭代次数cm,如果c<cm,则将当前迭代次数c增加1,再返回步骤(3.2.2);否则,迭代停止,跳转进入步骤(3.3);(3.2.7), determine whether the current iteration number c reaches the set maximum iteration number cm , if c <cm , increase the current iteration number c by 1, and then return to step (3.2.2); otherwise, the iteration stops, Jump to step (3.3);

(3.3)、根据赞成度最大化准则:Mj=argmax(μj(hi)c),找出最大赞成度Mj,Mj表示第j类的像素点的集合;然后根据Mj对特征色差H进行分类,分类完成后将vjc的数值赋值给对应的Mj,得到优化后的特征色差H*;(3.3) According to the maximization criterion of approval degree: Mj =argmax(μj (hi )c ), find out the maximum approval degree Mj , where Mj represents the set of pixels of the jth class; then according to Mj pair The characteristic color difference H is classified, and after the classification is completed, the value of vjc is assigned to the corresponding Mj to obtain the optimized characteristic color difference H* ;

(3.4)、优化的重构特征为为(3.4), the optimized reconstruction feature is

本发明的发明目的是这样实现的:The purpose of the invention of the present invention is achieved in this way:

本发明基于红外热成像的信息熵加性模糊缺陷特征分析重构方法,通过重构模型和优化的模糊算法,对不同空间不程度缺陷进行提取和特征分析,使不同空间不同程度的缺陷特征能够精确的进行划分;同时,在优化的模糊算法中,构造新的目标函数,一部分包括赞成度与犹豫度的和,丰富了元素的特征信息,另一部分包含了模糊熵,对特征信息的不确定性进行了描述,对缺陷的区分提供了有效的帮助,这样的设计和构造具有良好的稳定性和高效性,对缺陷特征纹理的刻画和特征色差的表征有着突出的作用,能够合理的对不同空间不同程度的缺陷进行精确的评估和分析。The invention is based on the information entropy additive fuzzy defect feature analysis and reconstruction method based on infrared thermal imaging. Through the reconstruction model and the optimized fuzzy algorithm, the defects of different degrees of space are extracted and analyzed, so that the defect features of different degrees of different spaces can be analyzed. Precisely divide; at the same time, in the optimized fuzzy algorithm, construct a new objective function, one part includes the sum of the approval degree and hesitation degree, which enriches the feature information of the elements, and the other part contains the fuzzy entropy, which is uncertain about the feature information. The characteristics of the defect are described, which provides an effective help for the distinction of defects. Such design and structure have good stability and efficiency, and have a prominent role in the characterization of defect characteristic texture and the characterization of characteristic color difference. Accurate assessment and analysis of defects in different degrees of space.

同时,本发明基于红外热成像的信息熵加性模糊缺陷特征分析重构方法还具有以下有益效果:Meanwhile, the information entropy additive fuzzy defect feature analysis and reconstruction method based on infrared thermal imaging also has the following beneficial effects:

(1)、通过对不同空间不同程度的缺陷进行特征模型重构和评估分析,实现了精确的缺陷提取,为进一步对于缺陷模型撞击行为数据库的建立提供了基础理论;(1) By reconstructing the feature model and evaluating and analyzing the defects of different degrees in different spaces, the accurate defect extraction is realized, and the basic theory is provided for the further establishment of the impact behavior database of the defect model;

(2)、优化的模糊目标函数中,赞成度与犹豫度的和,丰富了特征缺陷的色差信息,对于轮廓的描述更加精确,而指数模糊熵的应用,增强了特征元素不确定性的描述,准确的对特征元素进行了聚类,使缺陷的描述更加完整和精确;(2) In the optimized fuzzy objective function, the sum of the degree of approval and the degree of hesitation enriches the color difference information of the feature defects, and the description of the contour is more accurate, and the application of the exponential fuzzy entropy enhances the description of the uncertainty of the feature elements. , clustering the feature elements accurately, making the description of defects more complete and accurate;

(3)、使用巴特沃兹滤波器,将缺陷的特征信息分为特征轮廓和特征色差进行处理,使整体算法过程更加高效。(3) Using Butterworth filter, the characteristic information of defects is divided into characteristic contour and characteristic color difference for processing, which makes the overall algorithm process more efficient.

附图说明Description of drawings

图1是本发明基于红外热成像的信息熵加性模糊缺陷特征分析重构方法流程图;Fig. 1 is the flow chart of the information entropy additive fuzzy defect feature analysis and reconstruction method based on infrared thermal imaging of the present invention;

图2是特征色差优化处理流程图;Fig. 2 is the characteristic color difference optimization processing flow chart;

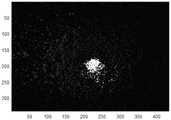

图3是被测试件的缺陷特征示意图;Fig. 3 is the defect characteristic schematic diagram of the test piece;

图4是特征缺陷纹理和特征缺陷色差示意图;Fig. 4 is a schematic diagram of characteristic defect texture and characteristic defect color difference;

图5是优化后的特征缺陷色差图;Fig. 5 is the characteristic defect chromatic aberration diagram after optimization;

图6是提取重构图像的缺陷特征图。FIG. 6 is a defect feature map of the extracted reconstructed image.

具体实施方式Detailed ways

下面结合附图对本发明的具体实施方式进行描述,以便本领域的技术人员更好地理解本发明。需要特别提醒注意的是,在以下的描述中,当已知功能和设计的详细描述也许会淡化本发明的主要内容时,这些描述在这里将被忽略。The specific embodiments of the present invention are described below with reference to the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that, in the following description, when the detailed description of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

实施例Example

图1是本发明基于红外热成像的信息熵加性模糊缺陷特征分析重构方法流程图。FIG. 1 is a flow chart of the method for analyzing and reconstructing information entropy additive fuzzy defect feature based on infrared thermal imaging of the present invention.

在本实施例中,如图1所示,本发明一种基于红外热成像的信息熵加性模糊缺陷特征分析重构方法,主要包括三个步骤:S1、待检测视频流预处理;S2、缺陷重构;S3、重构图像的特征提取;In this embodiment, as shown in FIG. 1 , an information entropy additive fuzzy defect feature analysis and reconstruction method based on infrared thermal imaging of the present invention mainly includes three steps: S1, preprocessing of the video stream to be detected; S2, Defect reconstruction; S3, feature extraction of reconstructed images;

下面我们结合上述三个步骤进行详细说明。Below we combine the above three steps to describe in detail.

S1、待检测视频流预处理S1. Preprocessing of the video stream to be detected

S1.1、将待检测视频流用矩阵块表示为:其中,NI×NJ表示空间信息,NT表示时间信息;S1.1, the video stream to be detected is represented as a matrix block as: Among them, NI ×NJ represents spatial information, and NT represents time information;

S1.2、通过向量算子Vec()将矩阵块转换为二维矩阵Y;S1.2. Convert the matrix block into a two-dimensional matrix Y through the vector operator Vec();

Y=[Vec(Y(1)),Vec(Y(2)),…,Vec(Y(NT))]Y=[Vec(Y(1)),Vec(Y(2)),...,Vec(Y(NT ))]

其中,NIJ=NI×NJ;in, NIJ =NI ×NJ ;

S1.3、为了重构不同的缺陷信息,我们根据先验的l种缺陷类型,将待检测视频流改写为:S1.3. In order to reconstruct different defect information, we rewrite the video stream to be detected as:

其中,Xθ(tθ)表示待检测视频流中的第tθ帧第θ种缺陷特征行向量,θ=1,2,…,l,αθ(tθ)为Xθ(tθ)对应的特征系数矩阵列向量,NC表示待检测视频流中表示特征缺陷的总帧数。Among them, Xθ (tθ ) represents the θ-th defect feature row vector of the tθ -th frame in the video stream to be detected, θ=1,2,...,l, αθ (tθ ) is the eigencoefficient matrix column vector corresponding to Xθ (tθ ), NC represents the total number of frames representing characteristic defects in the video stream to be detected.

S2、缺陷重构S2, defect reconstruction

S2.1、为了重构表面缺陷特征,采用奇异值分解算法将改写后的视频流Y分解为:YT=U∑VT,其中,为左奇异矩阵,为奇异值矩阵,为右奇异矩阵;S2.1. In order to reconstruct the surface defect features, the singular value decomposition algorithm is used to decompose the rewritten video stream Y into: YT =U∑VT , where, is a left singular matrix, is the singular value matrix, is a right singular matrix;

其中,奇异值分解算法对改写后的视频流Y进行分解的具体过程为:The specific process of decomposing the rewritten video stream Y by the singular value decomposition algorithm is as follows:

1)、构造协方差矩阵A;1), construct the covariance matrix A;

2)、计算奇异值;2), calculate the singular value;

通过计算得到右奇异值奇异值和左奇异值其中,表示特征值;via caculation get the right singular value Singular Value and left singular value in, represents the eigenvalue;

3)、根据奇异值构造奇异值矩阵∑';3), according to the singular value Construct singular value matrix ∑';

4)、设置经验阈值aF、aB、aN,且均为正整数;4), set the empirical thresholds aF , aB , aN , and they are all positive integers;

在奇异值矩阵∑'中,将奇异值满足中的表示表面缺陷特征,将奇异值满足时的个表示内部层裂缺陷特征,将奇异值满足时的个表示非缺陷区域特征;In the singular value matrix ∑', the singular value Satisfy middle represents the surface defect feature, and the singular value satisfies the time indivual represents the characteristics of internal spalling defects, and the singular value satisfies the time indivual Represents non-defective area features;

根据个表面缺陷特征、个内部层裂缺陷特征和个非缺陷区域特征更新奇异值矩阵∑',得到更新后的奇异值矩阵∑,然后得到最终改写后的视频流Y被表示为YT=U∑VT。according to surface defect features, internal spalling defect features and The singular value matrix Σ' is updated for each non-defective area feature to obtain the updated singular value matrix Σ, and then the final rewritten video stream Y is obtained, which is expressed as YT =UΣVT .

S2.2、计算白化矩阵W和混合系数矩阵λ;S2.2, calculate the whitening matrix W and the mixing coefficient matrix λ;

S2.3、将重构缺陷用矩阵表示为X=W×Y;S2.3, express the reconstruction defect as X=W×Y with a matrix;

S2.4、通过牛顿迭代法消除重构缺陷特征之间的相关性:S2.4. Eliminate the correlation between the reconstructed defect features by the Newton iteration method:

w*=E{xg(wTx)}-E{xg(wTx)}ww*=E{xg(wT x)}-E{xg(wT x)}w

其中,x是X的行向量,w为W的行向量,g(·)是对比度函数G的导数,E{·}表示求期望;Among them, x is the row vector of X, w is the row vector of W, g(·) is the derivative of the contrast function G, and E{·} represents the expectation;

S2.5、按照步骤S2.4所述方法对X的所有行进行处理后,得到重构后的缺陷特征信息矩阵:X*=W*×Y,S2.5. After all rows of X are processed according to the method described in step S2.4, a reconstructed defect feature information matrix is obtained: X*=W*×Y,

S2.6、在代表不同空间的缺陷特征矩阵中,表示相应缺陷特征的行向量用图像进行特征描述,每一行表示不同空间的损伤特征。S2.6. Defect feature matrix representing different spaces , the row vectors representing the corresponding defect features are described by images, and each row represents the damage features in different spaces.

通过对白化矩阵W*进行时域分析,得到不同缺陷特征的实际分布情况,再比较W*中行向量w*的曲线趋势,将w*曲线趋势相近的视为相同缺陷类型,否则视为不同缺陷类型;Through the time domain analysis of the whitening matrix W* , the actual distribution of different defect characteristics is obtained, and then the curve trend of the row vector w* in W* is compared, and the w* curve with similar trends is regarded as the same defect type, otherwise it is regarded as different defects type;

合并相同缺陷类型的缺陷帧数,构成新的缺陷帧数其中,m=1,2,…χ,且χ≤l,Combine the number of defective frames of the same defect type to form a new number of defective frames Among them, m=1,2,...χ, and χ≤l,

从而从X*中得到张第m类缺陷类型的重构图像,记为thus getting from X* The reconstructed image of the mth defect type, denoted as

S3、重构图像的特征提取S3. Feature extraction of reconstructed images

S3.1、利用巴特沃兹滤波器对重构图像进行纹理及色差分割;S3.1. Use the Butterworth filter to reconstruct the image Perform texture and chromatic aberration segmentation;

特征色差表示为:The characteristic color difference is expressed as:

其中,ti表示中像素点(ti,tj)的行坐标,tj表示中像素点(ti,tj)的列坐标,D0为阈值;in, ti means The row coordinates of the middle pixel point (ti , tj ), tj represents The column coordinates of the middle pixel point (ti , tj ), D0 is the threshold;

特征纹理表示为:The feature texture is represented as:

S3.2、如图2所示,对特征色差进行优化处理,具体过程如下;S3.2. As shown in Figure 2, the characteristic chromatic aberration is optimized, and the specific process is as follows;

S3.2.1、设置迭代终止条件ε,迭代次数c,最大迭代次数cm,聚类数目τ,操作系数δ,权重系数b,模糊系数λ,赞成度μj(hi)c,犹豫度ξj(hi)c,聚类中心vjc,目标函数Jc;S3.2.1. Set the iteration termination condition ε, the number of iterations c, the maximum number of iterations cm , the number of clusters τ, the operation coefficient δ, the weight coefficient b, the fuzzy coefficient λ, the approval degree μj (hi )c , the hesitation degree ξj (hi )c , cluster center vjc , objective function Jc ;

S3.2.2、计算第c次迭代时每一类中单个像素点的赞成度μj(hi)c;S3.2.2. Calculate the approval degree μj (hi )c of a single pixel in each category in the c-th iteration;

其中,hi表示特征色差H中第i个像素点的像素值,j≠s;||·||表示求范数;Among them, hi represents the pixel value of theith pixel in the characteristic color difference H, j≠s; ||·|| represents the norm;

S3.2.3、计算第c次迭代时每一类的聚类中心vjc;S3.2.3. Calculate the cluster center vjc of each class in the c-th iteration;

其中,g表示特征色差H中像素点的个数;Among them, g represents the number of pixels in the characteristic color difference H;

S3.2.4、计算第c次迭代时每一类中单个像素点的犹豫度ξj(hi)c;S3.2.4. Calculate the hesitation degree ξj (hi )c of a single pixel in each category in the c-th iteration;

S3.2.5、计算第c次迭代时的目标函数Jc值;S3.2.5. Calculate the objective function Jc value in the c-th iteration;

在本实施例中,传统的不能完整地表达每个元素的特征,为了解决信息缺失的问题,构造新的目标函数,目标函数的第一部分为,μj(hi)+λξj(hi),其中赞成度μj(hi)和犹豫度ξj(hi)丰富了每个元素的特征信息,同时消除了相同区域,不同损伤之间的相互影响。在另一方面,熵可以度量系统中的不确定性,模糊熵应用在目标函数中,变量的不确定性越高,熵越高,这增加了区域判断的精确性。In this embodiment, the traditional The characteristics of each element cannot be fully expressed. In order to solve the problem of missing information, a new objective function is constructed. The first part of the objective function is, μj (hi )+λξj (hi ), where the approval degreeμ j( hi ) and hesitation degree ξj (hi ) enrich the characteristic information of each element, and eliminate the mutual influence between different damages in the same area. On the other hand, entropy can measure uncertainty in a system, fuzzy entropy Applied to the objective function, the higher the uncertainty of the variable, the higher the entropy, which increases the accuracy of regional judgment.

S3.2.6、第c次迭代结束后,判断是否满足关系式:||Jc-Jc-1||≤ε,如果满足,则进入步骤S3.2.7,否则迭代停止,跳转进入步骤S3.3;S3.2.6. After the c-th iteration, judge whether the relational expression is satisfied: ||Jc -Jc-1 ||≤ε, if it is satisfied, go to step S3.2.7, otherwise stop the iteration, and jump to step S3 .3;

S3.2.7、判断当前迭代次数c是否达到设置的最大迭代次数cm,如果c<cm,则将当前迭代次数c增加1,再返回步骤S3.2.2;否则,迭代停止,跳转进入步骤S3.3;S3.2.7 . Determine whether the current iteration number c reaches the set maximum iteration number cm , if c<cm , increase the current iteration number c by 1, and then return to stepS3.2.2 ; otherwise, stop the iteration and jump to step S3.3;

S3.3、根据赞成度最大化准则:Mj=argmax(μj(hi)c),找出最大赞成度Mj,Mj表示第j类的像素点的集合;然后根据Mj对特征色差H进行分类,分类完成后将vjc的数值赋值给对应的Mj,得到优化后的特征色差H*;S3.3. According to the maximization criterion of approval degree: Mj =argmax(μj (hi )c ), find out the maximum approval degree Mj , where Mj represents the set of pixels of thejth class; The characteristic color difference H is classified, and after the classification is completed, the value of vjc is assigned to the corresponding Mj to obtain the optimized characteristic color difference H* ;

S3.4、优化的重构特征为为S3.4, the optimized reconstruction feature is

实验仿真Experimental simulation

为了能够更好的加强试件缺陷的信息,本实施例在Whipple防护板后板进行缺陷检测。In order to better strengthen the defect information of the test piece, in this embodiment, defect detection is performed on the back plate of the Whipple protective plate.

根据上述算法流程,首先采集试件的原始数据序列,其中NT=543,NI=512,NJ=640,特征选取为NC=3。G(·)采用的是高斯函数,奇异值分解中aF=27,aB=5,aH=3,优化隶属度及聚类中心算法中,迭代终止条件ε=10-5,最大迭代次数cm=100,聚类的数目CL=25,操作系数δ=0.5,模糊系数λ=0.5,权重系数b=2,得到图3所示的缺陷特征。According to the above algorithm flow, first collect the original data sequence of the specimen, wherein NT =543, NI =512, NJ =640, and the feature selection is NC =3. G(·) uses a Gaussian function. In singular value decomposition, aF = 27, aB = 5, aH = 3, and in the optimization of membership and cluster center algorithms, the iteration termination condition ε = 10-5 , the maximum iteration The number of timescm = 100, the number of clusters CL = 25, the operation coefficient δ = 0.5, the blur coefficient λ = 0.5, the weight coefficient b = 2, and the defect characteristics shown in FIG. 3 are obtained.

试件的背景区域反应的是外界热激励的影响,在试件边缘背景区域得到了体现,由于缺陷边缘轮廓的趋肤效应,表面杂质,以及外界环境,光源等因素的影响,导致一些非缺陷区域部分的重构系数过高,影响对实际缺陷的研究,成为干扰损伤程度分析的一大因素,属于冗余干扰信息。The background area of the specimen reflects the influence of external thermal excitation, which is reflected in the background area of the specimen edge. Some non-defects are caused by the skin effect of the edge contour of the defect, surface impurities, the external environment, light source and other factors. The reconstruction coefficient of the regional part is too high, which affects the research on actual defects and becomes a major factor in the analysis of the degree of interference damage, which belongs to redundant interference information.

针对表面缺陷部分,模拟太空撞击实验,以超高速的速率对航空航天材料进行撞击,在试件表面会不均匀的分布着大小各异的撞击坑,撞击的损害表征会随着撞击位置向四周不规律的进行的扩散,从图中可以清晰的观察到经历撞击后,在试件表面形成的缺陷的分布,成聚拢型散状分布,越靠近中心越密集,越边缘越零散。For the surface defect part, simulate the space impact experiment, and impact the aerospace material at an ultra-high speed. Impact craters of different sizes will be unevenly distributed on the surface of the test piece, and the damage of the impact will be characterized with the impact position. Irregular diffusion, it can be clearly observed from the figure that the distribution of defects formed on the surface of the specimen after impact is a clustered scattered distribution, the closer it is to the center, the denser it is, and the more scattered it is at the edge.

针对试件的内部层裂部分,经历超高速撞击后的试件,可以在表面明显的观察到聚拢型散状分布的撞击坑,凭借人眼视觉只能观察到表面坑状的分布,但经过算法模型分析,可以看到实验试件撞击位置的内部,已经形成了被能量波所损坏的区域,由于撞击位置相对集中,能量波在试件内部的扩散不像表面一样分散,而只是集中在撞击位置的内部形成了聚拢型损伤。For the internal spalling part of the test piece, after the test piece has undergone ultra-high-speed impact, the impact craters with a concentrated scattered distribution can be clearly observed on the surface. Algorithm model analysis, it can be seen that the interior of the impact position of the experimental specimen has formed an area damaged by energy waves. Because the impact position is relatively concentrated, the diffusion of energy waves inside the specimen is not as dispersed as the surface, but only concentrated in the The inside of the impact site developed a clustered damage.

在本实施例中,经过巴特沃兹滤波器之后的特征缺陷纹理和特征缺陷色差如下图4所示,经过优化之后的特征缺陷色差如下图5所示,通过对内部层裂轮廓提取可以更清晰的观察到内部缺陷信息,缺陷分布相对聚拢,能量波在材料内部的扩散相对表面较为集中。In this embodiment, the characteristic defect texture and characteristic defect color difference after the Butterworth filter are shown in Figure 4 below, and the optimized characteristic defect color difference is shown in Figure 5 below, which can be clearer by extracting the internal spalling contour The internal defect information is observed, the defect distribution is relatively concentrated, and the diffusion of energy waves inside the material is relatively concentrated relative to the surface.

综合上述算法处理之后。内部缺陷可以表示为图6所示,从上图6中,可以清晰观察到,在表面缺陷中的内部层裂信息。After synthesizing the above algorithm processing. The internal defects can be represented as shown in Figure 6, from the above Figure 6, it can be clearly observed that the internal spalling information in the surface defects.

由于内部层裂缺陷的特殊性,往往容易被人们所忽视,而通过对内部缺陷的分析,以及将表面缺陷与内部层裂相结合的研究,可以完整的对材料的性能,以及相关缺陷机理进行讨论,并合理有效的防御无预估性撞击带来的损害,并保障设备正常的工作性能。Due to the particularity of internal spalling defects, they are often overlooked by people. Through the analysis of internal defects and the combination of surface defects and internal spalling, the performance of materials and related defect mechanisms can be completely analyzed. Discuss, and reasonably and effectively defend against the damage caused by unpredictable impact, and ensure the normal working performance of the equipment.

尽管上面对本发明说明性的具体实施方式进行了描述,以便于本技术领域的技术人员理解本发明,但应该清楚,本发明不限于具体实施方式的范围,对本技术领域的普通技术人员来讲,只要各种变化在所附的权利要求限定和确定的本发明的精神和范围内,这些变化是显而易见的,一切利用本发明构思的发明创造均在保护之列。Although the illustrative specific embodiments of the present invention have been described above to facilitate the understanding of the present invention by those skilled in the art, it should be clear that the present invention is not limited to the scope of the specific embodiments. For those skilled in the art, As long as various changes are within the spirit and scope of the present invention as defined and determined by the appended claims, these changes are obvious, and all inventions and creations utilizing the inventive concept are included in the protection list.

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910433608.6ACN110211103B (en) | 2019-05-23 | 2019-05-23 | Information entropy additive fuzzy defect characteristic analysis reconstruction method based on infrared thermal imaging |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910433608.6ACN110211103B (en) | 2019-05-23 | 2019-05-23 | Information entropy additive fuzzy defect characteristic analysis reconstruction method based on infrared thermal imaging |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110211103A CN110211103A (en) | 2019-09-06 |

| CN110211103Btrue CN110211103B (en) | 2022-03-25 |

Family

ID=67788349

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910433608.6AActiveCN110211103B (en) | 2019-05-23 | 2019-05-23 | Information entropy additive fuzzy defect characteristic analysis reconstruction method based on infrared thermal imaging |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110211103B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112132802B (en)* | 2020-05-27 | 2022-06-14 | 电子科技大学 | Spacecraft collision damage detection method based on self-learning splicing algorithm |

| CN112215830B (en)* | 2020-10-21 | 2022-03-04 | 中国空气动力研究与发展中心超高速空气动力研究所 | Method for judging impact damage characteristic types of aerospace heat-proof materials |

| CN112233099B (en)* | 2020-10-21 | 2022-03-25 | 中国空气动力研究与发展中心超高速空气动力研究所 | Reusable spacecraft surface impact damage characteristic identification method |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1620603A (en)* | 2002-01-23 | 2005-05-25 | 马雷纳系统有限公司 | Employing infrared thermography for defect detection and analysis |

| CN205490868U (en)* | 2016-03-03 | 2016-08-17 | 北京志光伯元科技有限公司 | Target of doing more physical exercises is caught and tracking device |

| CN108288250A (en)* | 2017-12-29 | 2018-07-17 | 郑州升达经贸管理学院 | Infrared remote sensing image super-resolution rebuilding method based on TGV regularizations |

| CN108898602A (en)* | 2018-06-27 | 2018-11-27 | 南京邮电大学 | A kind of FCM medical image cutting method based on improvement QPSO |

| CN109598711A (en)* | 2018-11-30 | 2019-04-09 | 电子科技大学 | A kind of thermal image defect extracting method based on feature mining and neural network |

| CN109767437A (en)* | 2019-01-09 | 2019-05-17 | 电子科技大学 | Infrared thermal image defect feature extraction method based on k-means dynamic multi-target |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7551769B2 (en)* | 2003-02-18 | 2009-06-23 | Marena Systems Corporation | Data structures and algorithms for precise defect location by analyzing artifacts |

| US9222881B2 (en)* | 2012-02-24 | 2015-12-29 | Massachusetts Institute Of Technology | Vibrational spectroscopy for quantitative measurement of analytes |

| CN108320056A (en)* | 2018-02-06 | 2018-07-24 | 广东工业大学 | A kind of Distribution system Optimized model construction method and device |

- 2019

- 2019-05-23CNCN201910433608.6Apatent/CN110211103B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1620603A (en)* | 2002-01-23 | 2005-05-25 | 马雷纳系统有限公司 | Employing infrared thermography for defect detection and analysis |

| CN205490868U (en)* | 2016-03-03 | 2016-08-17 | 北京志光伯元科技有限公司 | Target of doing more physical exercises is caught and tracking device |

| CN108288250A (en)* | 2017-12-29 | 2018-07-17 | 郑州升达经贸管理学院 | Infrared remote sensing image super-resolution rebuilding method based on TGV regularizations |

| CN108898602A (en)* | 2018-06-27 | 2018-11-27 | 南京邮电大学 | A kind of FCM medical image cutting method based on improvement QPSO |

| CN109598711A (en)* | 2018-11-30 | 2019-04-09 | 电子科技大学 | A kind of thermal image defect extracting method based on feature mining and neural network |

| CN109767437A (en)* | 2019-01-09 | 2019-05-17 | 电子科技大学 | Infrared thermal image defect feature extraction method based on k-means dynamic multi-target |

Non-Patent Citations (2)

| Title |

|---|

| Sparse Reconstruction-Based Thermal Imaging for Defect Detection;Deboshree Roy 等;《IEEE Transactions on Instrumentation and Measurement》;20190114;第4550-4558页* |

| 基于多模态特征图融合的红外热图像目标区域提取算法;朱莉 等;《红外与毫米波学报》;20190228;第125-131页* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110211103A (en) | 2019-09-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Malekzadeh et al. | Aircraft fuselage defect detection using deep neural networks | |

| CN110211103B (en) | Information entropy additive fuzzy defect characteristic analysis reconstruction method based on infrared thermal imaging | |

| CN109272500B (en) | Fabric classification method based on adaptive convolutional neural network | |

| CN101923652B (en) | A pornographic image recognition method based on joint detection of skin color and feature parts | |

| CN108765412A (en) | A kind of steel strip surface defect sorting technique | |

| CN112798648A (en) | Defect detection method of composite materials based on thermal image analysis of generative core principal components | |

| CN106407975B (en) | Multi-scale Hierarchical Target Detection Method Based on Spatial-Spectral Structure Constraints | |

| Fan et al. | Application of YOLOv5 Neural Network Based on Improved Attention Mechanism in Recognition of Thangka Image Defects. | |

| CN110222740B (en) | Infrared technology defect reconstruction and feature extraction method based on additive fuzzy | |

| CN108931572B (en) | Thermal imaging defect detection method of pressure vessel based on variable line segmentation and region growing method | |

| CN108765401B (en) | A Thermal Imaging Detection Method Based on Row and Column Variable Step Segmentation and Region Growing Method | |

| Lahoti et al. | Convolutional neural network-assisted adaptive sampling for sparse feature detection in image and video data | |

| Deng et al. | A novel framework for classifying leather surface defects based on a parameter optimized residual network | |

| Nooralishahi et al. | PHM-IRNET: Self-training thermal segmentation approach for thermographic inspection of industrial components | |

| CN110222603B (en) | Exponential entropy multiplicative fuzzy defect characteristic analysis reconstruction method based on infrared thermal imaging | |

| CN109034172B (en) | Product appearance defect detection method based on fuzzy relaxation constraint multi-core learning | |

| Von Zuben et al. | Generative adversarial networks for extrapolation of corrosion in automobile images | |

| CN110390663B (en) | A Reconstruction Method of Information Entropy Multiplicative Fuzzy Defect Feature Analysis Based on Infrared Thermal Imaging | |

| CN110389154B (en) | Analysis and reconstruction method of exponential entropy additive fuzzy defect feature based on infrared thermal imaging | |

| CN119067956A (en) | A surface defect detection method for recycled and recirculated books based on DD-Net architecture | |

| Xin et al. | Detection of apple surface defect based on YOLOv3 | |

| CN116758044A (en) | Terahertz image quality evaluation method based on ResNet network | |

| Lin et al. | A bolt defect recognition algorithm based on attention model | |

| Baoling et al. | Roll contact fatigue defect recognition using computer vision and deep convolutional neural networks with transfer learning | |

| Li et al. | Research on Small Target Detection Technology for River Floating Garbage Based on Improved YOLOv7 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |