CN110135477B - Strip steel surface quality defect classifier based on serial/parallel integrated learning framework and classification method thereof - Google Patents

Strip steel surface quality defect classifier based on serial/parallel integrated learning framework and classification method thereofDownload PDFInfo

- Publication number

- CN110135477B CN110135477BCN201910351038.6ACN201910351038ACN110135477BCN 110135477 BCN110135477 BCN 110135477BCN 201910351038 ACN201910351038 ACN 201910351038ACN 110135477 BCN110135477 BCN 110135477B

- Authority

- CN

- China

- Prior art keywords

- defect

- classifier

- defects

- serial

- parallel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/21—Design or setup of recognition systems or techniques; Extraction of features in feature space; Blind source separation

- G06F18/214—Generating training patterns; Bootstrap methods, e.g. bagging or boosting

- G06F18/2148—Generating training patterns; Bootstrap methods, e.g. bagging or boosting characterised by the process organisation or structure, e.g. boosting cascade

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/24—Classification techniques

- G06F18/241—Classification techniques relating to the classification model, e.g. parametric or non-parametric approaches

- G06F18/2411—Classification techniques relating to the classification model, e.g. parametric or non-parametric approaches based on the proximity to a decision surface, e.g. support vector machines

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/24—Classification techniques

- G06F18/243—Classification techniques relating to the number of classes

- G06F18/24323—Tree-organised classifiers

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/04—Architecture, e.g. interconnection topology

- G06N3/045—Combinations of networks

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/08—Learning methods

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/30—Computing systems specially adapted for manufacturing

Landscapes

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Data Mining & Analysis (AREA)

- Physics & Mathematics (AREA)

- Life Sciences & Earth Sciences (AREA)

- Artificial Intelligence (AREA)

- General Physics & Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- Evolutionary Computation (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Evolutionary Biology (AREA)

- Bioinformatics & Computational Biology (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Computational Linguistics (AREA)

- Biomedical Technology (AREA)

- Biophysics (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Molecular Biology (AREA)

- Computing Systems (AREA)

- Mathematical Physics (AREA)

- Software Systems (AREA)

- Image Analysis (AREA)

- Investigating Materials By The Use Of Optical Means Adapted For Particular Applications (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于带钢表面质量缺陷检测和分类技术领域,涉及到计算机视觉和机器学习方法,特别涉及到一种基于串/并行集成学习框架的带钢表面质量缺陷分类方法。The invention belongs to the technical field of strip steel surface quality defect detection and classification, relates to computer vision and machine learning methods, and in particular to a strip steel surface quality defect classification method based on a serial/parallel integrated learning framework.

背景技术Background technique

质量是现代企业的灵魂,是企业赖以生存和发展的基石。Quality is the soul of a modern enterprise and the cornerstone for its survival and development.

在钢铁、造纸、纺织、印染和玻璃等多个国民经济的主流工业门类中,产品表面质量的优劣将直接影响产品最终的质量、性能和价值,同时,由于下游客户对产品表面质量的要求越来越严苛,良好的表面质量成为企业在激烈的市场竞争中胜出的重要法宝,因而,在这些行业中存在着广泛的产品表面质量检测需求。In steel, paper, textile, printing and dyeing, glass and other mainstream industrial categories of the national economy, the quality of the product surface will directly affect the final quality, performance and value of the product. More and more stringent, good surface quality has become an important magic weapon for enterprises to win in the fierce market competition. Therefore, there is a wide range of product surface quality testing needs in these industries.

本发明涉及的是钢铁工业的主要产品之一——带钢的表面质量缺陷检测分类问题。为了准确地识别出带钢表面质量缺陷,传统上一般采用人工目测或离线抽检,或者二者相结合的方式。但是,随着钢铁工业生产水平的发展,传统的检测方式显然已不能满足现代工业生产中高速、高产和高品质的要求,无法得到连续、稳定、多样的表面质量检测结果。机器视觉技术的广泛应用和人工智能理论的蓬勃发展为各行业中表面质量检测问题提供了崭新的思路和解决途径。也正是基于此,应用机器视觉和人工智能方法研究该问题已逐渐成为国内外学者、学术机构和企业研究的热点。The invention relates to one of the main products of the iron and steel industry—the detection and classification of surface quality defects of strip steel. In order to accurately identify the surface quality defects of strip steel, traditionally, manual visual inspection or off-line sampling inspection, or a combination of the two methods are generally used. However, with the development of the production level of the iron and steel industry, the traditional detection methods obviously cannot meet the requirements of high speed, high output and high quality in modern industrial production, and cannot obtain continuous, stable and diverse surface quality detection results. The wide application of machine vision technology and the vigorous development of artificial intelligence theory have provided new ideas and solutions for surface quality inspection problems in various industries. It is also based on this that the application of machine vision and artificial intelligence methods to study this problem has gradually become a hot research topic for domestic and foreign scholars, academic institutions and enterprises.

发明内容Contents of the invention

带钢表面质量缺陷分类是一个复杂生产条件下的多特征、多类别的模式识别问题。提高分类识别的准确度和稳定性是分类器设计所面临的关键科学问题。已有的多分类器组合方法往往“将多个分类器简单并行,然后加权投票确定分类结果”,无任何预处理和中间介入的环节。针对传统的多分类器组合方法中存在的如分类准确率不高,分类器自学习能力和泛化能力弱、实时性能不佳等问题,本发明提出了一种基于串/并行集成学习框架的带钢表面质量缺陷分类方法。The classification of strip surface quality defects is a multi-feature and multi-category pattern recognition problem under complex production conditions. Improving the accuracy and stability of classification recognition is a key scientific problem faced by classifier design. The existing multi-classifier combination method often "simplely parallelizes multiple classifiers, and then determines the classification result by weighted voting", without any preprocessing and intermediate steps. Aiming at the problems existing in the traditional multi-classifier combination method such as low classification accuracy, weak classifier self-learning ability and generalization ability, poor real-time performance, etc., the present invention proposes a serial/parallel integrated learning framework-based Method for classification of strip surface quality defects.

本发明采用的技术方案包含以下技术内容:The technical scheme adopted in the present invention comprises the following technical contents:

一种基于串/并行集成学习框架的带钢表面质量缺陷分类器,其特征在于,分类器为自上而下分的三层串行结构,包含规则表和机器学习分类器,具体是:A strip steel surface quality defect classifier based on a serial/parallel integrated learning framework, characterized in that the classifier is a three-layer serial structure from top to bottom, including a rule table and a machine learning classifier, specifically:

上层是规则表,The upper level is the rule table,

中间层是多个并行的机器学习分类器,The middle layer is multiple parallel machine learning classifiers,

下层是规则表或单一机器学习分类器。The lower layer is a rule table or a single machine learning classifier.

规则表在结构上体现为一种二维表,具体包含两列,分别是序号和对规则具体内容的描述。规则表的行数由规则数量决定。The rule table is structurally embodied as a two-dimensional table, which specifically includes two columns, which are the serial number and the description of the specific content of the rule. The number of rows in the rule table is determined by the number of rules.

在上述的一种基于串/并行集成学习框架的带钢表面质量缺陷分类器,规则表是结合缺陷产生的工艺机理,并借鉴和吸收现场专家的经验和知识,经转化之后形成的分类判定规则。在选择中间层的多个并行学习分类器时,注重它们相互之间的互补性,规则表的构建步骤包括:In the above-mentioned strip steel surface quality defect classifier based on the serial/parallel integrated learning framework, the rule table is a classification and judgment rule formed after transformation by combining the process mechanism of defect generation, and drawing on and absorbing the experience and knowledge of on-site experts . When selecting multiple parallel learning classifiers in the middle layer, pay attention to their complementarity. The construction steps of the rule table include:

S201,寻找一个取值范围与其他所有类别零重叠的特征,如果找到了这样的特征,则将该特征加入上层规则表中,由该特征区分的缺陷类别为上层层级的缺陷。S201. Find a feature whose value range has zero overlap with all other categories. If such a feature is found, add this feature to the upper-level rule table, and the defect category distinguished by this feature is the upper-level defect.

S202,寻找一个取值范围与其他特定类别(非所有类别)零重叠的特征,如果找到了这样的特征,则将该特征加入下层规则表中,由该特征区分的缺陷类别为下层层级的缺陷。S202, look for a feature whose value range has zero overlap with other specific categories (not all categories), if such a feature is found, add the feature to the lower-level rule table, and the defect category distinguished by the feature is the defect of the lower level .

S203,对所有的特征执行遍历比选,直至结束。S203. Perform traversal comparison and selection on all features until the end.

在上述的一种基于串/并行集成学习框架的带钢表面质量缺陷分类器,中间层装配随机森林分类器、自组织神经网络和基于ECOC编码的GentlBoost分类器三种分类器。本发明提出基于串/并行集成学习框架的缺陷分类器,就是为了充分融合现有的机器学习分类识别技术、缺陷产生机理和人工经验规则,进一步提高分类识别的准确度,以及分类器的自学习能力、实时性能和泛化能力。In the above-mentioned strip steel surface quality defect classifier based on the serial/parallel integrated learning framework, the middle layer is equipped with three classifiers: random forest classifier, self-organizing neural network and GentlBoost classifier based on ECOC coding. The present invention proposes a defect classifier based on the serial/parallel integrated learning framework, in order to fully integrate the existing machine learning classification and recognition technology, defect generation mechanism and artificial empirical rules, further improve the accuracy of classification and recognition, and the self-learning of the classifier capabilities, real-time performance, and generalization capabilities.

一种基于串/并行集成学习框架的缺陷分类器的分类方法,其特征在于,包括缺陷合并与分级方法,具体步骤如下:A method for classifying defect classifiers based on a serial/parallel integrated learning framework, characterized in that it includes defect merging and grading methods, and the specific steps are as follows:

S1,把包含在上层规则表的缺陷分离出来作为上层层级的缺陷;S1, separate out the defects included in the upper-level rule table as the upper-level defects;

S2,比较训练集中两种缺陷样本的特征值,设两种缺陷类别序号分别为yi和yj,训练集中对应的样本数量分别为ci和cj,特征值维度为n维,缺陷特征值序列分别为(xi1,xi2,…,xik,…,xin)和(xj1,xj2,…,xjk,…,xjn),其中xik和xjk分别为两种缺陷特征值序列中的分量,计算两种缺陷特征值对应分量的均值,记为:和/>k=1,…,n,进一步计算两个均值偏差百分比,如下:S2. Compare the eigenvalues of the two defect samples in the training set. Set the serial numbers of the two defect categories as yi and yj respectively, the corresponding sample numbers in the training set areci and cj respectively, the eigenvalue dimension is n-dimensional, and the defect feature The value sequences are (xi1 ,xi2 ,…,xik ,…,xin ) and (xj1 ,xj2 ,…,xjk ,…,xjn ), where xik and xjk are two types For the components in the defect eigenvalue sequence, calculate the mean value of the corresponding components of the two defect eigenvalues, which is recorded as: and /> k=1,...,n, further calculate the two mean deviation percentages, as follows:

比较该对应分量均值偏差百分与预先设定的两个阈值δ1和δ2的大小关系。如果该对应分量均值偏差百分比小于阈值δ1的特征值分量的数目占所有特征值维度的百分比大于阈值δ2,则将对应的两种缺陷合并。Compare the relationship between the mean deviation percentage of the corresponding component and the two preset thresholds δ1 and δ2 . If the proportion of the number of eigenvalue components whose mean value deviation percentage of the corresponding component is smaller than the threshold δ1 to all eigenvalue dimensions is greater than the threshold δ2 , then the corresponding two defects are merged.

本发明将阈值δ1取为70%,阈值δ2取为90%。In the present invention, the threshold δ1 is taken as 70%, and the threshold δ2 is taken as 90%.

S3,如果在未合并前两类缺陷分类结果的混淆矩阵中,相互之间的错分率大于阈值δ3,则也将两类缺陷合并。S3, if the mutual misclassification rate is greater than the threshold δ3 in the confusion matrix of the unmerged classification results of the first two types of defects, then also merge the two types of defects.

本发明将阈值δ3取为20%。In the present invention, the threshold δ3 is taken as 20%.

S4,合并后的缺陷放在中间层层级。S4, the merged defects are placed in the middle layer.

S5,其他未分级的缺陷也放在中间层层级中,即把其他未分级的缺陷与合并后的缺陷放在同样的层次,并用本发明提出的基于串/并行集成学习框架的缺陷分类器中间层多个并行的机器学习分类方法实现分类。S5, other ungraded defects are also placed in the middle level, that is, other ungraded defects and merged defects are placed in the same level, and the defect classifier based on the serial/parallel integrated learning framework proposed by the present invention is used in the middle Layer multiple parallel machine learning classification methods to achieve classification.

本发明具有以下优点:基于串/并行集成学习框架的分类器改变常用的“将多个分类器简单并行,然后通过加权投票确定最终分类结果”的思路,把传统的并行分类器结构改造成独特的串/并行集成结构。通过充分融合最新的机器学习分类识别技术、缺陷产生机理和人工经验规则,辅以与分类器结构相适应的缺陷合并和分级方法,进一步提高了带钢表面质量缺陷分类识别的准确度,并改善了分类器的自学习能力、实时性能和泛化能力。The invention has the following advantages: the classifier based on the serial/parallel integrated learning framework changes the commonly used idea of "simplely paralleling multiple classifiers, and then determines the final classification result through weighted voting", and transforms the traditional parallel classifier structure into a unique The serial/parallel integration structure. By fully integrating the latest machine learning classification and identification technology, defect generation mechanism and artificial experience rules, supplemented by the defect merging and grading method adapted to the classifier structure, the accuracy of classification and identification of strip surface quality defects has been further improved, and improved The self-learning ability, real-time performance and generalization ability of the classifier are improved.

附图说明Description of drawings

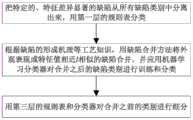

图1为应用本发明所提的基于串/并行集成学习框架的缺陷分类方法对带钢表面质量缺陷进行分类的流程框图。Fig. 1 is a flow chart of classifying steel strip surface quality defects by applying the defect classification method based on the serial/parallel integrated learning framework proposed by the present invention.

图2为本发明所提的一种基于串/并行集成学习框架的带钢表面质量缺陷分类器结构图。Fig. 2 is a structure diagram of a steel strip surface quality defect classifier based on the serial/parallel integrated learning framework proposed by the present invention.

图3a为本发明实施例二中应用的五种不同类型的典型缺陷图片,缺陷类型为焊缝、图3b为本发明实施例二中应用的五种不同类型的典型缺陷图片,缺陷类型为孔洞;Figure 3a is a picture of five different types of typical defects applied in the second embodiment of the present invention, and the defect type is a weld; Figure 3b is a picture of five different types of typical defects applied in the second embodiment of the present invention, and the defect type is a hole ;

图3c为本发明实施例二中应用的五种不同类型的典型缺陷图片,缺陷类型为划伤;Figure 3c is a picture of five different types of typical defects applied in Example 2 of the present invention, and the defect type is scratches;

图3d为本发明实施例二中应用的五种不同类型的典型缺陷图片,缺陷类型为辊印;Figure 3d is a picture of five different types of typical defects applied in Embodiment 2 of the present invention, and the defect type is roller printing;

图3e为本发明实施例二中应用的五种不同类型的典型缺陷图片,缺陷类型为油斑。Fig. 3e is a picture of five different types of typical defects applied in Embodiment 2 of the present invention, and the defect type is oil spots.

具体实施方式Detailed ways

为了使本技术领域的人员更好地理解本发明方案,下面结合附图和具体实施方式对本发明作进一步的详细说明。In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

实施例一Embodiment one

图1为应用本发明所提的基于串/并行集成学习框架的缺陷分类方法对带钢表面质量缺陷进行分类的流程框图。Fig. 1 is a flow chart of classifying steel strip surface quality defects by applying the defect classification method based on the serial/parallel integrated learning framework proposed by the present invention.

如图1所示,具体流程包含3个主要步骤,分别如下:As shown in Figure 1, the specific process includes three main steps, which are as follows:

步骤1,把特定的、特征差异显著的缺陷从所有缺陷类别中分离出来,用第一层的规则表分类;Step 1, separate specific defects with significant feature differences from all defect categories, and use the first-level rule table to classify;

步骤2,然后根据缺陷的形成机理等工艺知识,用缺陷合并方法将外观表现或特征值相近/相似的缺陷合并,机器学习分类器仅对合并之后的缺陷类别进行训练和分类;Step 2. Then, according to the process knowledge such as the defect formation mechanism, use the defect merging method to merge defects with similar appearance or feature values, and the machine learning classifier only trains and classifies the merged defect categories;

步骤3,藉由第三层的规则表和分类器对合并之前的类别进行细分。In step 3, the categories before merging are subdivided by the rule table and classifier of the third layer.

具体的,上述第一层和第三层的规则表的构建方法如下:Specifically, the construction method of the above-mentioned rule table of the first layer and the third layer is as follows:

首先,寻找一个取值范围与其他所有类别零重叠的特征,如果找到了这样的特征,则将该特征加入上层规则表中,由该特征区分的缺陷类别为上层层级的缺陷。First, look for a feature whose value range has zero overlap with all other categories. If such a feature is found, add this feature to the upper-level rule table, and the defect category distinguished by this feature is the upper-level defect.

然后,寻找一个取值范围与其他特定类别(非所有类别)零重叠的特征,如果找到了这样的特征,则将该特征加入下层规则表中,由该特征区分的缺陷类别为下层层级的缺陷。Then, look for a feature whose value range has zero overlap with other specific categories (not all categories). If such a feature is found, add the feature to the lower-level rule table, and the defect category distinguished by this feature is the defect of the lower level. .

需要注意的是,需对所有的特征执行遍历比选,直至结束。It should be noted that all features need to be traversed and selected until the end.

图2为本发明所提的一种基于串/并行集成学习框架的带钢表面质量缺陷分类器结构图。Fig. 2 is a structure diagram of a steel strip surface quality defect classifier based on the serial/parallel integrated learning framework proposed by the present invention.

如图2所示,基于串/并行集成学习框架的缺陷分类器包含规则表和机器学习分类器两种基本构件,总体上表现为一种串行结构,自上而下分为三层,上层是规则表,中间层是多个并行的机器学习分类器,下层也是规则表或单一机器学习分类器。除了结构上体现为串/并行集成学习框架之外,对规则表的融合也是该分类器的技术特征之一。规则表是结合缺陷产生的工艺机理,并借鉴和吸收现场专家的经验和知识,经转化之后形成的分类判定规则。在选择中间层的多个并行学习分类器时,注重它们相互之间的互补性。As shown in Figure 2, the defect classifier based on the serial/parallel ensemble learning framework includes two basic components, the rule table and the machine learning classifier, and generally presents a serial structure, which is divided into three layers from top to bottom, and the upper layer is a rule table, the middle layer is a plurality of parallel machine learning classifiers, and the lower layer is also a rule table or a single machine learning classifier. In addition to being structurally embodied as a serial/parallel ensemble learning framework, the fusion of rule tables is also one of the technical features of this classifier. The rule table is a classification and judgment rule formed after transformation by combining the process mechanism of defect generation, drawing on and absorbing the experience and knowledge of on-site experts. When choosing multiple parallel learning classifiers in the middle layer, pay attention to their complementarity with each other.

优选的,本发明在中间层装配随机森林分类器、自组织神经网络和基于ECOC编码的GentlBoost分类器等三种分类方法。Preferably, the present invention assembles three classification methods such as random forest classifier, self-organizing neural network and GentlBoost classifier based on ECOC coding in the middle layer.

基于串/并行集成学习框架的缺陷分类器融合了先验规则和专家知识,将常用的并行分类器结构改造成独特的串/并行集成结构,兼顾了带钢表面质量缺陷的工艺特性和分类识别方法的通用性,为该分类器应用于带钢之外的其他板带状产品(如造纸行业中的纸张和和纺织行业中的织物等)提供了必要的先决条件。具体应用时,为了满足带钢、纸张和织物等不同产品的表面质量缺陷检测需求,把与产品工艺特性相关的先验知识归纳后写入规则表中,通用性则用经由标准化样本库训练的学习分类器体现。The defect classifier based on the serial/parallel ensemble learning framework integrates prior rules and expert knowledge, and transforms the commonly used parallel classifier structure into a unique serial/parallel ensemble structure, taking into account the process characteristics and classification recognition of strip surface quality defects The generality of the method provides the necessary prerequisites for the classifier to be applied to other plate and strip products (such as paper in the paper industry and fabric in the textile industry, etc.) besides the steel strip. In specific applications, in order to meet the surface quality defect detection requirements of different products such as strip steel, paper and fabrics, the prior knowledge related to the product process characteristics is summarized and written into the rule table, and the generality is based on the standardized sample library training. Learning classifier embodies.

为了充分发挥基于串/并行集成学习框架的缺陷分类器中规则表和机器学习分类器的性能,本发明还提供了一种与所述缺陷分类器结构相适应的缺陷合并与分级方法。In order to give full play to the performance of the rule table and the machine learning classifier in the defect classifier based on the serial/parallel integrated learning framework, the present invention also provides a defect merging and grading method adapted to the structure of the defect classifier.

缺陷合并与分级方法的具体步骤如下:The specific steps of defect merging and grading method are as follows:

S201,把包含在上层规则表的缺陷分离出来作为上层层级的缺陷;S201, separating out the defects included in the upper-level rule table as the upper-level defects;

S202,比较训练集中两种缺陷样本的特征值,设两种缺陷类别序号分别为yi和yj,训练集中对应的样本数量分别为ci和cj,特征值维度为n维,缺陷特征值序列分别为(xi1,xi2,…,xik,…,xin)和(xj1,xj2,…,xjk,…,xjn),其中xik和xjk分别为两种缺陷特征值序列中的分量,计算两种缺陷特征值对应分量的均值,记为:和/>k=1,…,n,进一步计算两个均值偏差百分比,如下:S202. Compare the eigenvalues of the two defect samples in the training set. Set the serial numbers of the two defect categories as yi and yj respectively, the corresponding sample numbers in the training set areci and cj respectively, the eigenvalue dimension is n-dimensional, and the defect feature The value sequences are (xi1 ,xi2 ,…,xik ,…,xin ) and (xj1 ,xj2 ,…,xjk ,…,xjn ), where xik and xjk are two types For the components in the defect eigenvalue sequence, calculate the mean value of the corresponding components of the two defect eigenvalues, which is recorded as: and /> k=1,...,n, further calculate the two mean deviation percentages, as follows:

比较该对应分量均值偏差百分与预先设定的两个阈值δ1和δ2的大小关系。如果该对应分量均值偏差百分比小于阈值δ1的特征值分量的数目占所有特征值维度的百分比大于阈值δ2,则将对应的两种缺陷合并。Compare the relationship between the mean deviation percentage of the corresponding component and the two preset thresholds δ1 and δ2 . If the proportion of the number of eigenvalue components whose mean value deviation percentage of the corresponding component is smaller than the threshold δ1 to all eigenvalue dimensions is greater than the threshold δ2 , then the corresponding two defects are merged.

优选的,本发明将阈值δ1取为70%,阈值δ2取为90%。Preferably, the present invention takes the threshold δ1 as 70%, and the threshold δ2 as 90%.

S203,如果在未合并前两类缺陷分类结果的混淆矩阵中,相互之间的错分率大于阈值δ3,则也将两类缺陷合并。S203, if the mutual misclassification rate is greater than the threshold δ3 in the confusion matrix in which the classification results of the first two types of defects are not combined, also merge the two types of defects.

优选的,本发明将阈值δ3取为20%。Preferably, the present invention takes the thresholdδ3 as 20%.

S203,如果在未合并前两类缺陷分类结果的混淆矩阵中,相互之间的错分率大于阈值δ3,则也将两类缺陷合并。S203, if the mutual misclassification rate is greater than the threshold δ3 in the confusion matrix in which the classification results of the first two types of defects are not combined, also merge the two types of defects.

优选的,本发明将阈值δ3取为20%。Preferably, the present invention takes the thresholdδ3 as 20%.

S204,合并后的缺陷放在中间层层级。S204, the merged defects are placed in the middle layer.

S205,其他未分级的缺陷也放在中间层层级中,即把其他未分级的缺陷与合并后的缺陷放在同样的层次,并用本发明提出的基于串/并行集成学习框架的缺陷分类器中间层多个并行的机器学习分类方法实现分类。S205, other ungraded defects are also placed in the middle level, that is, other ungraded defects and merged defects are placed in the same level, and the defect classifier based on the serial/parallel integrated learning framework proposed by the present invention is used in the middle Layer multiple parallel machine learning classification methods to achieve classification.

实施例二Embodiment two

实施例二计划对五种不同类型的带钢表面质量典型缺陷进行分类,这五种缺陷类型名称分别为焊缝、孔洞、划伤、辊印和油斑,其缺陷图像形貌分别如图3a~图3e所示。Embodiment 2 plans to classify five different types of typical defects on the surface quality of strip steel. The names of these five types of defects are welds, holes, scratches, roll marks and oil spots. The defect images are shown in Figure 3a ~ Figure 3e.

应用本发明所提基于串/并行集成学习框架的带钢表面缺陷分类方法对上述五种缺陷进行分类时,首先把第1种缺陷——焊缝从所有缺陷类别中分离出来,依据是在构建实施例二所涉的规则表时,发现焊缝缺陷的“缺陷图像宽度”和“缺陷图像高度/宽度比值”两个特征与其他所有缺陷类别的相应特征零重叠,很显然,根据本发明所提规则表的构建方法,这两个特征都应加入第一层的规则表中去,第一层的规则表如下表1所示:When applying the strip steel surface defect classification method based on the serial/parallel integrated learning framework proposed by the present invention to classify the above five defects, firstly, the first defect-weld is separated from all defect categories, based on the construction In the rule table involved in the second embodiment, it is found that the two features of "defect image width" and "defect image height/width ratio" of weld defects overlap with the corresponding features of all other defect categories. Obviously, according to the present invention The construction method of the rule table is mentioned. These two features should be added to the rule table of the first layer. The rule table of the first layer is shown in Table 1 below:

表1第一层的规则表Table 1 Rule table of the first layer

再根据本发明所提的缺陷合并与分级方法,应把由“缺陷图像宽度”和“缺陷图像高度/宽度比值”对应的缺陷类别作为上层层级的缺陷,而这两个特征均指向焊缝缺陷!这样,所有的焊缝缺陷均可由第一层的规则表简单确定。According to the defect merging and grading method proposed in the present invention, the defect category corresponding to the "defect image width" and "defect image height/width ratio" should be taken as the defect of the upper layer, and these two features all point to weld defects ! In this way, all weld defects can be simply determined by the rule table of the first layer.

接着,通过对未应用本发明所提的缺陷合并与分级方法之前缺陷分类结果分析发现,划伤和辊印两种缺陷的相互错分率均高于20%,展开来说,即划伤缺陷被错分为辊印缺陷的百分率为26.9582%,辊印缺陷被错分为划伤缺陷的百分率为29.3761%,根据本发明所提的缺陷合并与分级方法,高于阈值δ3,所以将划伤和辊印两种缺陷合并,重新命名为“条状缺陷”,作为中间层级的缺陷,其他未合并的孔洞和油斑也放在这个层级中,这样,中间层级的缺陷包含三种,分别为:Then, through the analysis of the defect classification results before the defect merging and classification method proposed by the present invention, it is found that the mutual misclassification rates of scratches and roll marks are higher than 20%. The percentage of misclassified roller printing defects is 26.9582%, and the percentage of roller printing defects misclassified as scratch defects is29.3761 %. The two defects of damage and roll printing are merged and renamed as "strip defects". As the defects of the middle level, other unmerged holes and oil spots are also placed in this level. In this way, the defects of the middle level include three types, respectively for:

·条状缺陷·Stripe defect

·孔洞·Hole

·油斑·Oil spots

根据本发明所提方法,应用基于串/并行集成学习框架的缺陷分类器中中间层的机器学习分类器对上述中间层级的三种缺陷进行分类。中间层机器学习分类器包含了随机森林分类器、自组织神经网络和基于ECOC编码的GentlBoost分类器,由三种并行的分类器加权确定分类结果。According to the method proposed in the present invention, the machine learning classifier of the middle layer in the defect classifier based on the serial/parallel integrated learning framework is used to classify the three kinds of defects in the above middle layer. The middle layer machine learning classifier includes random forest classifier, self-organizing neural network and GentlBoost classifier based on ECOC coding, and the classification results are determined by weighting of three parallel classifiers.

至此,实施例二中的五种缺陷已经区分出来了四种,分别是由上层规则表确定的焊缝,以及由中间层机器学习分类器确定的条状缺陷、孔洞和油斑,但是,需要注意的是,初始缺陷类别中并不包含条状缺陷,这是划伤和辊印两种缺陷的合集,所以还需要依据第三层规则表和分类器做进一步的分类处理。So far, the five kinds of defects in the second embodiment have been distinguished into four kinds, which are weld seams determined by the upper rule table, and strip defects, holes and oil spots determined by the middle layer machine learning classifier. However, it is necessary to Note that the initial defect category does not include strip defects, which are a collection of scratches and roll marks, so further classification processing is required based on the third-level rule table and classifier.

实施例二中第三层规则表为空,分类器采用支持向量机实现,用支持向量机对由中间层机器学习分类器确定的条状缺陷样本集合进行训练和分类,得到最终的分类结果,即在条状缺陷中把划伤和辊印两种缺陷区分开来。In embodiment two, the rule table of the third layer is empty, and the classifier is implemented by a support vector machine, and the support vector machine is used to train and classify the strip defect sample set determined by the middle layer machine learning classifier, and obtain the final classification result, That is to distinguish between scratches and roll marks in strip defects.

综合最终的分类准确率,如表2所示。The comprehensive final classification accuracy is shown in Table 2.

表2缺陷分类准确率Table 2 Defect classification accuracy

综上所述,本发明公开的一种基于串/并行集成学习框架的带钢表面质量缺陷分类方法,通过充分融合最新的机器学习分类识别技术、缺陷产生机理和人工经验规则,辅以与分类器结构相适应的缺陷合并和分级方法,进一步提高了带钢表面质量缺陷分类识别的准确度,并改善了分类器的自学习能力、实时性能和泛化能力。To sum up, the present invention discloses a strip steel surface quality defect classification method based on the serial/parallel integrated learning framework, which fully integrates the latest machine learning classification and identification technology, defect generation mechanism and artificial experience rules, supplemented with classification The defect merging and grading method adapted to the structure of the classifier further improves the accuracy of the classification and identification of strip surface quality defects, and improves the self-learning ability, real-time performance and generalization ability of the classifier.

本领域普通技术人员还可以理解,实现上述实施例方法中的全部或部分步骤是可以通过程序来指令相关的硬件来完成,所述的程序可以存储于计算机可读取存储介质中,所述的存储介质,包括ROM/RAM、磁盘、光盘等。Those of ordinary skill in the art can also understand that all or part of the steps in the method of the above embodiments can be completed by instructing related hardware through a program, and the program can be stored in a computer-readable storage medium. Storage media, including ROM/RAM, magnetic disk, optical disk, etc.

以上所述仅为本发明的较佳实施例而已,并不用以限制本发明,凡在本发明的精神和原则之内所作的任何修改、等同替换和改进等,均应包含在本发明的保护范围之内。The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention should be included in the protection of the present invention. within range.

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910351038.6ACN110135477B (en) | 2019-04-28 | 2019-04-28 | Strip steel surface quality defect classifier based on serial/parallel integrated learning framework and classification method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910351038.6ACN110135477B (en) | 2019-04-28 | 2019-04-28 | Strip steel surface quality defect classifier based on serial/parallel integrated learning framework and classification method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110135477A CN110135477A (en) | 2019-08-16 |

| CN110135477Btrue CN110135477B (en) | 2023-03-24 |

Family

ID=67575449

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910351038.6AActiveCN110135477B (en) | 2019-04-28 | 2019-04-28 | Strip steel surface quality defect classifier based on serial/parallel integrated learning framework and classification method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110135477B (en) |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108846831A (en)* | 2018-05-28 | 2018-11-20 | 中冶南方工程技术有限公司 | The steel strip surface defect classification method combined based on statistical nature and characteristics of image |

| CN109636772A (en)* | 2018-10-25 | 2019-04-16 | 同济大学 | The defect inspection method on the irregular shape intermetallic composite coating surface based on deep learning |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9898811B2 (en)* | 2015-05-08 | 2018-02-20 | Kla-Tencor Corporation | Method and system for defect classification |

- 2019

- 2019-04-28CNCN201910351038.6Apatent/CN110135477B/enactiveActive

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108846831A (en)* | 2018-05-28 | 2018-11-20 | 中冶南方工程技术有限公司 | The steel strip surface defect classification method combined based on statistical nature and characteristics of image |

| CN109636772A (en)* | 2018-10-25 | 2019-04-16 | 同济大学 | The defect inspection method on the irregular shape intermetallic composite coating surface based on deep learning |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110135477A (en) | 2019-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Zhao et al. | A visual long-short-term memory based integrated CNN model for fabric defect image classification | |

| Yang et al. | Multi-scale triple-attention network for pixelwise crack segmentation | |

| Liu et al. | Steel surface defect detection using GAN and one-class classifier | |

| Yang et al. | Magnetic flux leakage image classification method for pipeline weld based on optimized convolution kernel | |

| Yao et al. | A feature memory rearrangement network for visual inspection of textured surface defects toward edge intelligent manufacturing | |

| CN110210555A (en) | Rail fish scale hurt detection method based on deep learning | |

| CN103839057B (en) | A kind of antimony flotation operating mode's switch method and system | |

| CN107169956A (en) | Yarn dyed fabric defect detection method based on convolutional neural networks | |

| CN109859163A (en) | A kind of LCD defect inspection method based on feature pyramid convolutional neural networks | |

| CN110297852B (en) | A Method of Acquiring Knowledge of Ship Painting Defects Based on PCA-Rough Sets | |

| CN116740051A (en) | Steel surface defect detection method based on improved YOLO model | |

| Xia et al. | Improved faster R‐CNN based surface defect detection algorithm for plates | |

| CN106996935A (en) | A kind of multi-level fuzzy judgment Fabric Defects Inspection detection method and system | |

| CN105956798A (en) | Sparse random forest-based method for assessing running state of distribution network device | |

| CN111667466B (en) | Multi-objective optimization feature selection method for multi-classification of strip steel surface quality defects | |

| Liu et al. | Strip steel surface defect detecting method combined with a multi-layer attention mechanism network | |

| CN110827260A (en) | Cloth defect classification method based on LBP (local binary pattern) features and convolutional neural network | |

| Fang et al. | Automatic zipper tape defect detection using two-stage multi-scale convolutional networks | |

| Mi et al. | Research on steel rail surface defects detection based on improved YOLOv4 network | |

| CN117314904B (en) | Steel plate surface defect detection method | |

| CN113743817A (en) | Enterprise credit rating evaluation method based on cloud platform | |

| CN115439405A (en) | A Classification Method for Steel Plate Surface Defects | |

| CN117576079A (en) | An industrial product surface anomaly detection method, device and system | |

| CN103034868B (en) | Classification method aiming at small sample and high dimensional images | |

| CN110717602A (en) | Machine learning model robustness assessment method based on noise data |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |