CN110099641B - Staple cartridge and arrangement of staples and staple cavities therein - Google Patents

Staple cartridge and arrangement of staples and staple cavities thereinDownload PDFInfo

- Publication number

- CN110099641B CN110099641BCN201780080004.7ACN201780080004ACN110099641BCN 110099641 BCN110099641 BCN 110099641BCN 201780080004 ACN201780080004 ACN 201780080004ACN 110099641 BCN110099641 BCN 110099641B

- Authority

- CN

- China

- Prior art keywords

- staple

- staples

- patent application

- entitled

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Surgical Instruments (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese背景技术Background technique

本发明涉及外科器械,并且在各种布置中,涉及被设计成缝合和切割组织的外科缝合和切割器械及与其一起使用的钉仓。The present invention relates to surgical instruments and, in various arrangements, to surgical stapling and cutting instruments designed to staple and cut tissue and staple cartridges for use therewith.

附图说明Description of drawings

本文所述的实施方案的各种特征连同其优点可结合如下附图根据以下描述来加以理解:The various features of the embodiments described herein, along with their advantages, can be understood from the following description in conjunction with the accompanying drawings:

图1是可操作地联接到柄部组件实施方案的可互换外科工具组件实施方案的透视图;1 is a perspective view of an interchangeable surgical tool assembly embodiment operably coupled to a handle assembly embodiment;

图2是图1的柄部组件和可互换外科工具组件的部分的分解组装视图;Figure 2 is an exploded assembled view of portions of the handle assembly and interchangeable surgical tool assembly of Figure 1;

图3是图1和图2所示的可互换外科工具组件实施方案的远侧部分的透视图,其中为清楚起见省略了其多个部分;Fig. 3 is a perspective view of a distal portion of the embodiment of the interchangeable surgical tool assembly shown in Figs. 1 and 2, with portions thereof omitted for clarity;

图4是图1的可互换外科工具组件的远侧部分的分解组装视图;Figure 4 is an exploded assembled view of the distal portion of the interchangeable surgical tool assembly of Figure 1;

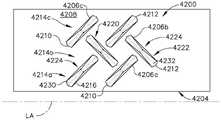

图5是其中限定有多个钉腔的钉仓体的透视图;5 is a perspective view of a staple cartridge body with a plurality of staple cavities defined therein;

图6是图5的钉仓的局部透视底视图;Figure 6 is a partial perspective bottom view of the staple cartridge of Figure 5;

图7是图5的钉仓体的顶部平面图,并且示出了被定位在仓体的纵向狭槽中的切割元件;Fig. 7 is a top plan view of the staple cartridge body of Fig. 5 and showing the cutting element positioned in the longitudinal slot of the cartridge body;

图8是图5的钉仓体的底部平面图,并且示出了被定位在钉腔中的驱动器;8 is a bottom plan view of the staple cartridge body of FIG. 5 and showing the driver positioned in the staple cavity;

图9是植入在缝合组织中并由图5的钉仓体生成的钉线,并且示出了可能从具有虚线的钉线缺失的某些钉;9 is a staple line implanted in sutured tissue and generated by the staple cartridge body of FIG. 5, and showing some staples that may be missing from the staple line with dashed lines;

图10是图9的钉线中的钉的侧正视图;Figure 10 is a side elevational view of a staple in the staple line of Figure 9;

图11是钉的侧正视图;Figure 11 is a side elevational view of the nail;

图12是具有限定于其中的多个钉腔的钉仓体的底部平面图,并且示出了被定位在钉腔中的驱动器;12 is a bottom plan view of a staple cartridge body having a plurality of staple cavities defined therein and showing a driver positioned within the staple cavities;

图13是图8的近侧钉腔中的驱动器的透视图;Figure 13 is a perspective view of the driver in the proximal staple cavity of Figure 8;

图14是图13的驱动器的侧正视图,并且示出了具有虚线的偏置斜坡表面;Fig. 14 is a side elevational view of the driver of Fig. 13 and showing the offset ramp surface with dashed lines;

图15是图13的驱动器的平面图;Figure 15 is a plan view of the driver of Figure 13;

图16是图13的驱动器的前正视图;Figure 16 is a front elevational view of the driver of Figure 13;

图17是图12的钉仓体的近侧钉腔中的驱动器的平面图;Figure 17 is a plan view of the driver in the proximal staple cavity of the staple cartridge body of Figure 12;

图18是图17的驱动器的前正视图;Figure 18 is a front elevational view of the driver of Figure 17;

图19是其中限定有多个钉腔的钉仓体的顶部平面图;19 is a top plan view of a staple cartridge body with a plurality of staple cavities defined therein;

图20是图19的钉仓体的底部平面图,并且示出了被定位在钉腔中的驱动器;Figure 20 is a bottom plan view of the staple cartridge body of Figure 19 and showing the driver positioned in the staple cavity;

图21是图20的近侧钉腔中的驱动器的透视图;Figure 21 is a perspective view of the driver in the proximal staple cavity of Figure 20;

图22是图21的驱动器的前正视图;Figure 22 is a front elevational view of the driver of Figure 21;

图23是图21的驱动器的平面图;Figure 23 is a plan view of the driver of Figure 21;

图24是图21的驱动器的侧正视图,并且示出了具有虚线的偏置斜坡表面;Fig. 24 is a side elevational view of the driver of Fig. 21 and showing the offset ramp surface with dashed lines;

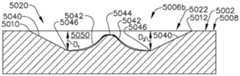

图25是其中限定有多个钉腔的钉仓体的顶部平面图;25 is a top plan view of a staple cartridge body with a plurality of staple cavities defined therein;

图26是图25的钉仓体的底部平面图,并且示出了被定位在钉腔中的驱动器;Figure 26 is a bottom plan view of the staple cartridge body of Figure 25 and showing the driver positioned in the staple cavity;

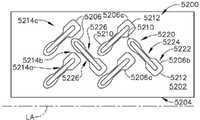

图27是具有限定在其中的多个成角度取向的钉腔的钉仓体的一部分的平面图,并且示出了钉腔中的钉;27 is a plan view of a portion of a staple cartridge body having a plurality of angularly oriented staple cavities defined therein and showing the staples in the staple cavities;

图28是具有限定在其中的多个成角度取向的钉腔的钉仓体的一部分的平面图,并且示出了钉腔中的钉;28 is a plan view of a portion of a staple cartridge body having a plurality of angularly oriented staple cavities defined therein and showing the staples in the staple cavities;

图29是具有限定在其中的多个成角度取向的钉腔的钉仓体的一部分的平面图,并且示出了钉腔中的钉;29 is a plan view of a portion of a staple cartridge body having a plurality of angularly oriented staple cavities defined therein and showing the staples in the staple cavities;

图30是具有限定在其中的多个成角度取向的钉腔的钉仓体的一部分的平面图,并且示出了钉腔中的钉;30 is a plan view of a portion of a staple cartridge body having a plurality of angularly oriented staple cavities defined therein and showing the staples in the staple cavities;

图31是具有限定在其中的多个成角度取向的钉腔的钉仓体的一部分的平面图,并且示出了钉腔中的钉;31 is a plan view of a portion of a staple cartridge body having a plurality of angularly oriented staple cavities defined therein and showing the staples in the staple cavities;

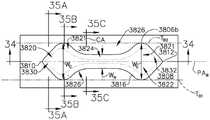

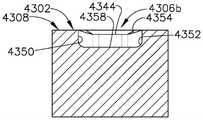

图32是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;32 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

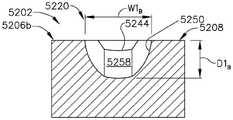

图33是图32的凹坑的细部图;Figure 33 is a detail view of the dimple of Figure 32;

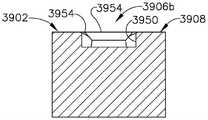

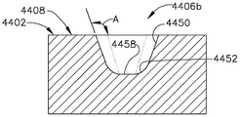

图34-35C是图33的凹坑的横剖视图;Figures 34-35C are cross-sectional views of the dimple of Figure 33;

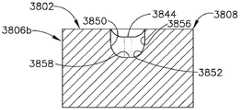

图36是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;36 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图37是图36的凹坑的细部图;Figure 37 is a detail view of the dimple of Figure 36;

图38-39C是图37的凹坑的横剖视图;Figures 38-39C are cross-sectional views of the dimple of Figure 37;

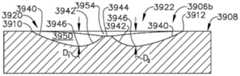

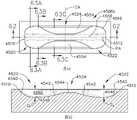

图40是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;40 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图41是图40的凹坑的细部图;Figure 41 is a detail view of the dimple of Figure 40;

图42-43C是图41的凹坑的横剖视图;Figures 42-43C are cross-sectional views of the dimple of Figure 41;

图44是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;44 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

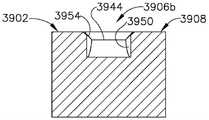

图45是图44的凹坑的细部图;Figure 45 is a detail view of the dimple of Figure 44;

图46-47C是图45的凹坑的横剖视图;Figures 46-47C are cross-sectional views of the dimple of Figure 45;

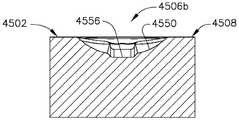

图48是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;48 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图49是图48的凹坑的细部图;Figure 49 is a detail view of the dimple of Figure 48;

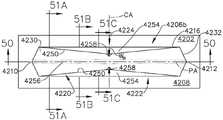

图50-51C是图49的凹坑的横剖视图;Figures 50-51C are cross-sectional views of the dimple of Figure 49;

图52是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;52 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

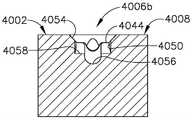

图53是图52的凹坑的细部图;Figure 53 is a detail view of the dimple of Figure 52;

图54-55C是图53的凹坑的横剖视图;Figures 54-55C are cross-sectional views of the dimple of Figure 53;

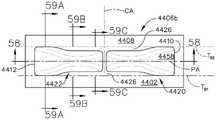

图56是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;56 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图57是图56的凹坑的细部图;Figure 57 is a detail view of the dimple of Figure 56;

图58-59C是图57的凹坑的横剖视图;Figures 58-59C are cross-sectional views of the dimple of Figure 57;

图60是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;60 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图61是图60的凹坑的细部图;Figure 61 is a detail view of the dimple of Figure 60;

图62-63C是图61的凹坑的横剖视图;Figures 62-63C are cross-sectional views of the dimple of Figure 61;

图64是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;64 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图65是图64的凹坑的细部图;Figure 65 is a detail view of the dimple of Figure 64;

图66-67C是图65的凹坑的横剖视图;Figures 66-67C are cross-sectional views of the dimple of Figure 65;

图68是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;68 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图69是图68的凹坑的细部图;Figure 69 is a detail view of the dimple of Figure 68;

图70-71C是图69的凹坑的横剖视图;Figures 70-71C are cross-sectional views of the dimple of Figure 69;

图72是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;72 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

图73是图72的凹坑的细部图;Figure 73 is a detail view of the dimple of Figure 72;

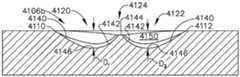

图74-76C是图73 的凹坑的横剖视图;Figures 74-76C are cross-sectional views of the dimple of Figure 73;

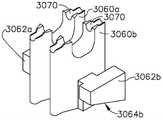

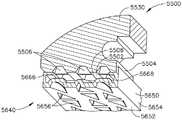

图77是端部执行器和适配器组件的分解透视图;Figure 77 is an exploded perspective view of the end effector and adapter assembly;

图78是图77的端部执行器和适配器组件的一部分的剖面透视图;Figure 78 is a cutaway perspective view of a portion of the end effector and adapter assembly of Figure 77;

图79是图77的端部执行器和适配器组件的剖面透视图;Figure 79 is a cutaway perspective view of the end effector and adapter assembly of Figure 77;

图80是具有限定于其中的多个钉成形凹坑的砧座的一部分的平面图;80 is a plan view of a portion of an anvil having a plurality of staple forming pockets defined therein;

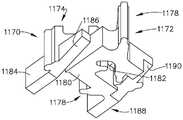

图81是钉驱动器实施方案的顶视图;Figure 81 is a top view of a staple driver embodiment;

图82是图81的钉驱动器实施方案的顶部透视图;并且Figure 82 is a top perspective view of the staple driver embodiment of Figure 81; and

图83是图81和图82的钉驱动器实施方案的底部透视图。83 is a bottom perspective view of the staple driver embodiment of FIGS. 81 and 82. FIG.

在所述若干视图中,对应的参考符号指示对应的部件。本文所述的范例以一种形式示出了本发明的各种实施方案,且这种范例不应被解释为以任何方式限制本发明的范围。Corresponding reference characters indicate corresponding parts throughout the several views. The exemplifications described herein illustrate various embodiments of the invention in one form, and such exemplifications should not be construed to limit the scope of the invention in any way.

具体实施方式Detailed ways

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL STAPLING INSTRUMENTS AND REPLACEABLE TOOL ASSEMBLIESTHEREOF”的美国专利申请序列号15/386,185;- US Patent Application Serial No. 15/386,185 entitled "SURGICAL STAPLING INSTRUMENTS AND REPLACEABLE TOOL ASSEMBLIESTHEREOF";

-名称为“ARTICULATABLE SURGICAL STAPLING INSTRUMENTS”的美国专利申请序列号15/386,230;- US Patent Application Serial No. 15/386,230 entitled "ARTICULATABLE SURGICAL STAPLING INSTRUMENTS";

-名称为“LOCKOUT ARRANGEMENTS FOR SURGICAL END EFFECTORS”的美国专利申请序列号15/386,221;- US Patent Application Serial No. 15/386,221 entitled "LOCKOUT ARRANGEMENTS FOR SURGICAL END EFFECTORS";

-名称为“SURGICAL END EFFECTORS AND FIRING MEMBERS THEREOF”的美国专利申请序列号15/386,209;- US Patent Application Serial No. 15/386,209 entitled "SURGICAL END EFFECTORS AND FIRING MEMBERS THEREOF";

-名称为“LOCKOUT ARRANGEMENTS FOR SURGICAL END EFFECTORS ANDREPLACEABLE TOOL ASSEMBLIES”的美国专利申请序列号15/386,198;以及- US Patent Application Serial No. 15/386,198 entitled "LOCKOUT ARRANGEMENTS FOR SURGICAL END EFFECTORS ANDREPLACEABLE TOOL ASSEMBLIES"; and

-名称为“SURGICAL END EFFECTORS AND ADAPTABLE FIRING MEMBERS THEREFOR”的美国专利申请序列号15/386,240。- US Patent Application Serial No. 15/386,240 entitled "SURGICAL END EFFECTORS AND ADAPTABLE FIRING MEMBERS THEREFOR".

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“STAPLE CARTRIDGES AND ARRANGEMENTS OF STAPLES AND STAPLECAVITIES THEREIN”的美国专利申请序列号15/385,939;- US Patent Application Serial No. 15/385,939 entitled "STAPLE CARTRIDGES AND ARRANGEMENTS OF STAPLES AND STAPLECAVITIES THEREIN";

-名称为“SURGICAL TOOL ASSEMBLIES WITH CLUTCHING ARRANGEMENTS FORSHIFTING BETWEEN CLOSURE SYSTEMS WITH CLOSURE STROKE REDUCTION FEATURES ANDARTICULATION AND FIRING SYSTEMS”的美国专利申请序列号15/385,941;- US Patent Application Serial No. 15/385,941 entitled "SURGICAL TOOL ASSEMBLIES WITH CLUTCHING ARRANGEMENTS FORSHIFTING BETWEEN CLOSURE SYSTEMS WITH CLOSURE STROKE REDUCTION FEATURES ANDARTICULATION AND FIRING SYSTEMS";

-名称为“SURGICAL STAPLING INSTRUMENTS AND STAPLE-FORMING ANVILS”的美国专利申请序列号15/385,943;- US Patent Application Serial No. 15/385,943 entitled "SURGICAL STAPLING INSTRUMENTS AND STAPLE-FORMING ANVILS";

-名称为“SURGICAL TOOL ASSEMBLIES WITH CLOSURE STROKE REDUCTIONFEATURES”的美国专利申请序列号 15/385,950;- US Patent Application Serial No. 15/385,950 entitled "SURGICAL TOOL ASSEMBLIES WITH CLOSURE STROKE REDUCTIONFEATURES";

-名称为“SURGICAL STAPLING INSTRUMENTS AND STAPLE-FORMING ANVILS”的美国专利申请序列号15/385,946;- US Patent Application Serial No. 15/385,946 entitled "SURGICAL STAPLING INSTRUMENTS AND STAPLE-FORMING ANVILS";

-名称为“SURGICAL INSTRUMENTS WITH JAW OPENING FEATURES FOR INCREASINGA JAW OPENING DISTANCE”的美国专利申请序列号15/385,951;- US Patent Application Serial No. 15/385,951 entitled "SURGICAL INSTRUMENTS WITH JAW OPENING FEATURES FOR INCREASINGA JAW OPENING DISTANCE";

-名称为“METHODS OF STAPLING TISSUE”的美国专利申请序列号15/385,953;- US Patent Application Serial No. 15/385,953 entitled "METHODS OF STAPLING TISSUE";

-名称为“FIRING MEMBERS WITH NON-PARALLEL JAW ENGAGEMENT FEATURES FORSURGICAL END EFFECTORS”的美国专利申请序列号15/385,954;- US Patent Application Serial No. 15/385,954 entitled "FIRING MEMBERS WITH NON-PARALLEL JAW ENGAGEMENT FEATURES FORSURGICAL END EFFECTORS";

-名称为“SURGICAL END EFFECTORS WITH EXPANDABLE TISSUE STOPARRANGEMENTS”的美国专利申请序列号 15/385,955;- US Patent Application Serial No. 15/385,955 entitled "SURGICAL END EFFECTORS WITH EXPANDABLE TISSUE STOPARRANGEMENTS";

-名称为“SURGICAL STAPLING INSTRUMENTS AND STAPLE-FORMING ANVILS”的美国专利申请序列号15/385,948;- US Patent Application Serial No. 15/385,948 entitled "SURGICAL STAPLING INSTRUMENTS AND STAPLE-FORMING ANVILS";

-名称为“SURGICAL INSTRUMENTS WITH POSITIVE JAW OPENING FEATURES”的美国专利申请序列号15/385,956;- US Patent Application Serial No. 15/385,956 entitled "SURGICAL INSTRUMENTS WITH POSITIVE JAW OPENING FEATURES";

-名称为“SURGICAL INSTRUMENTS WITH LOCKOUT ARRANGEMENTS FOR PREVENTINGFIRING SYSTEM ACTUATION UNLESS AN UNSPENT STAPLE CARTRIDGE IS PRESENT”的美国专利申请序列号15/385,958;以及- US Patent Application Serial No. 15/385,958 entitled "SURGICAL INSTRUMENTS WITH LOCKOUT ARRANGEMENTS FOR PREVENTINGFIRING SYSTEM ACTUATION UNLESS AN UNSPENT STAPLE CARTRIDGE IS PRESENT"; and

-名称为“STAPLE CARTRIDGES AND ARRANGEMENTS OF STAPLES AND STAPLECAVITIES THEREIN”的美国专利申请序列号15/385,947。- US Patent Application Serial No. 15/385,947 entitled "STAPLE CARTRIDGES AND ARRANGEMENTS OF STAPLES AND STAPLECAVITIES THEREIN".

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“METHOD FOR RESETTING A FUSE OF A SURGICAL INSTRUMENT SHAFT”的美国专利申请序列号15/385,896;- US Patent Application Serial No. 15/385,896 entitled "METHOD FOR RESETTING A FUSE OF A SURGICAL INSTRUMENT SHAFT";

-名称为“STAPLE FORMING POCKET ARRANGEMENT TO ACCOMMODATE DIFFERENTTYPES OF STAPLES”的美国专利申请序列号15/385,898;- US Patent Application Serial No. 15/385,898 entitled "STAPLE FORMING POCKET ARRANGEMENT TO ACCOMMODATE DIFFERENTTYPES OF STAPLES";

-名称为“SURGICAL INSTRUMENT COMPRISING IMPROVED JAW CONTROL”的美国专利申请序列号15/385,899;- US Patent Application Serial No. 15/385,899 entitled "SURGICAL INSTRUMENT COMPRISING IMPROVED JAW CONTROL";

-名称为“STAPLE CARTRIDGE AND STAPLE CARTRIDGE CHANNEL COMPRISINGWINDOWS DEFINED THEREIN”的美国专利申请序列号15/385,901;- US Patent Application Serial No. 15/385,901 entitled "STAPLE CARTRIDGE AND STAPLE CARTRIDGE CHANNEL COMPRISING WINDOWS DEFINED THEREIN";

-名称为“SURGICAL INSTRUMENT COMPRISING A CUTTING MEMBER”的美国专利申请序列号15/385,902;- US Patent Application Serial No. 15/385,902 entitled "SURGICAL INSTRUMENT COMPRISING A CUTTING MEMBER";

-名称为“STAPLE FIRING MEMBER COMPRISING A MISSING CARTRIDGE AND/ORSPENT CARTRIDGE LOCKOUT”的美国专利申请序列号15/385,904;- US Patent Application Serial No. 15/385,904 entitled "STAPLE FIRING MEMBER COMPRISING A MISSING CARTRIDGE AND/ORSPENT CARTRIDGE LOCKOUT";

-名称为“FIRING ASSEMBLY COMPRISING A LOCKOUT”的美国专利申请序列号15/385,905;- US Patent Application Serial No. 15/385,905 entitled "FIRING ASSEMBLY COMPRISING A LOCKOUT";

-名称为“SURGICAL INSTRUMENT SYSTEM COMPRISING AN END EFFECTOR LOCKOUTAND A FIRING ASSEMBLY LOCKOUT”的美国专利申请序列号15/385,907;- US Patent Application Serial No. 15/385,907 entitled "SURGICAL INSTRUMENT SYSTEM COMPRISING AN END EFFECTOR LOCKOUTAND A FIRING ASSEMBLY LOCKOUT";

-名称为“FIRING ASSEMBLY COMPRISING A FUSE”的美国专利申请序列号15/385,908;以及- US Patent Application Serial No. 15/385,908 entitled "FIRING ASSEMBLY COMPRISING A FUSE"; and

-名称为“FIRING ASSEMBLY COMPRISING A MULTIPLE FAILED-STATE FUSE”的美国专利申请序列号15/385,909。- US Patent Application Serial No. 15/385,909 entitled "FIRING ASSEMBLY COMPRISING A MULTIPLE FAILED-STATE FUSE".

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“STAPLE FORMING POCKET ARRANGEMENTS”的美国专利申请序列号15/385,920;- US Patent Application Serial No. 15/385,920 entitled "STAPLE FORMING POCKET ARRANGEMENTS";

-名称为“ANVIL ARRANGEMENTS FOR SURGICAL STAPLERS”的美国专利申请序列号15/385,913;- US Patent Application Serial No. 15/385,913 entitled "ANVIL ARRANGEMENTS FOR SURGICAL STAPLERS";

-名称为“METHOD OF DEFORMING STAPLES FROM TWO DIFFERENT TYPES OFSTAPLE CARTRIDGES WITH THE SAME SURGICAL STAPLING INSTRUMENT”的美国专利申请序列号 15/385,914;- US Patent Application Serial No. 15/385,914 entitled "METHOD OF DEFORMING STAPLES FROM TWO DIFFERENT TYPES OFSTAPLE CARTRIDGES WITH THE SAME SURGICAL STAPLING INSTRUMENT";

-名称为“BILATERALLY ASYMMETRIC STAPLE FORMING POCKET PAIRS”的美国专利申请序列号15/385,893;- US Patent Application Serial No. 15/385,893 entitled "BILATERALLY ASYMMETRIC STAPLE FORMING POCKET PAIRS";

-名称为“CLOSURE MEMBERS WITH CAM SURFACE ARRANGEMENTS FOR SURGICALINSTRUMENTS WITH SEPARATE AND DISTINCT CLOSURE AND FIRING SYSTEMS”的美国专利申请序列号15/385,929;- US Patent Application Serial No. 15/385,929 entitled "CLOSURE MEMBERS WITH CAM SURFACE ARRANGEMENTS FOR SURGICALINSTRUMENTS WITH SEPARATE AND DISTINCT CLOSURE AND FIRING SYSTEMS";

-名称为“SURGICAL STAPLERS WITH INDEPENDENTLY ACTUATABLE CLOSING ANDFIRING SYSTEMS”的美国专利申请序列号15/385,911;- US Patent Application Serial No. 15/385,911 entitled "SURGICAL STAPLERS WITH INDEPENDENTLY ACTUATABLE CLOSING ANDFIRING SYSTEMS";

-名称为“SURGICAL STAPLING INSTRUMENTS WITH SMART STAPLE CARTRIDGES”的美国专利申请序列号15/385,927;- US Patent Application Serial No. 15/385,927 entitled "SURGICAL STAPLING INSTRUMENTS WITH SMART STAPLE CARTRIDGES";

-名称为“STAPLE CARTRIDGE COMPRISING STAPLES WITH DIFFERENT CLAMPINGBREADTHS”的美国专利申请序列号 15/385,917;- US Patent Application Serial No. 15/385,917 entitled "STAPLE CARTRIDGE COMPRISING STAPLES WITH DIFFERENT CLAMPINGBREADTHS";

-名称为“STAPLE FORMING POCKET ARRANGEMENTS COMPRISING PRIMARYSIDEWALLS AND POCKET SIDEWALLS”的美国专利申请序列号15/385,900;- US Patent Application Serial No. 15/385,900 entitled "STAPLE FORMING POCKET ARRANGEMENTS COMPRISING PRIMARYSIDEWALLS AND POCKET SIDEWALLS";

-名称为“NO-CARTRIDGE AND SPENT CARTRIDGE LOCKOUT ARRANGEMENTS FORSURGICAL STAPLERS”的美国专利申请序列号15/385,931;- US Patent Application Serial No. 15/385,931 entitled "NO-CARTRIDGE AND SPENT CARTRIDGE LOCKOUT ARRANGEMENTS FORSURGICAL STAPLERS";

-名称为“FIRING MEMBER PIN ANGLE”的美国专利申请序列号 15/385,915;- US Patent Application Serial No. 15/385,915 entitled "FIRING MEMBER PIN ANGLE";

-名称为“STAPLE FORMING POCKET ARRANGEMENTS COMPRISING ZONED FORMINGSURFACE GROOVES”的美国专利申请序列号15/385,897;- US Patent Application Serial No. 15/385,897 entitled "STAPLE FORMING POCKET ARRANGEMENTS COMPRISING ZONED FORMINGSURFACE GROOVES";

-名称为“SURGICAL INSTRUMENT WITH MULTIPLE FAILURE RESPONSE MODES”的美国专利申请序列号15/385,922;- US Patent Application Serial No. 15/385,922 entitled "SURGICAL INSTRUMENT WITH MULTIPLE FAILURE RESPONSE MODES";

-名称为“SURGICAL INSTRUMENT WITH PRIMARY AND SAFETY PROCESSORS”的美国专利申请序列号15/385,924;- US Patent Application Serial No. 15/385,924 entitled "SURGICAL INSTRUMENT WITH PRIMARY AND SAFETY PROCESSORS";

-名称为“SURGICAL INSTRUMENTS WITH JAWS THAT ARE PIVOTABLE ABOUT AFIXED AXIS AND INCLUDE SEPARATE AND DISTINCT CLOSURE AND FIRING SYSTEMS”的美国专利申请序列号15/385,912;- US Patent Application Serial No. 15/385,912 entitled "SURGICAL INSTRUMENTS WITH JAWS THAT ARE PIVOTABLE ABOUT AFIXED AXIS AND INCLUDE SEPARATE AND DISTINCT CLOSURE AND FIRING SYSTEMS";

-名称为“ANVIL HAVING A KNIFE SLOT WIDTH”的美国专利申请序列号15/385,910;- US Patent Application Serial No. 15/385,910 entitled "ANVIL HAVING A KNIFE SLOT WIDTH";

-名称为“CLOSURE MEMBER ARRANGEMENTS FOR SURGICAL INSTRUMENTS”的美国专利申请序列号15/385,903;以及- US Patent Application Serial No. 15/385,903 entitled "CLOSURE MEMBER ARRANGEMENTS FOR SURGICAL INSTRUMENTS"; and

-名称为“FIRING MEMBER PIN CONFIGURATIONS”的美国专利申请序列号15/385,906。- US Patent Application Serial No. 15/385,906 entitled "FIRING MEMBER PIN CONFIGURATIONS".

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“STEPPED STAPLE CARTRIDGE WITH ASYMMETRICAL STAPLES”的美国专利申请序列号15/386,188;- US Patent Application Serial No. 15/386,188 entitled "STEPPED STAPLE CARTRIDGE WITH ASYMMETRICAL STAPLES";

-名称为“STEPPED STAPLE CARTRIDGE WITH TISSUE RETENTION AND GAPSETTING FEATURES”的美国专利申请序列号15/386,192;- US Patent Application Serial No. 15/386,192 entitled "STEPPED STAPLE CARTRIDGE WITH TISSUE RETENTION AND GAPSETTING FEATURES";

-名称为“STAPLE CARTRIDGE WITH DEFORMABLE DRIVER RETENTION FEATURES”的美国专利申请序列号15/386,206;- US Patent Application Serial No. 15/386,206 entitled "STAPLE CARTRIDGE WITH DEFORMABLE DRIVER RETENTION FEATURES";

-名称为“DURABILITY FEATURES FOR END EFFECTORS AND FIRING ASSEMBLIESOF SURGICAL STAPLING INSTRUMENTS”的美国专利申请序列号15/386,226;- US Patent Application Serial No. 15/386,226 entitled "DURABILITY FEATURES FOR END EFFECTORS AND FIRING ASSEMBLIESOF SURGICAL STAPLING INSTRUMENTS";

-名称为“SURGICAL STAPLING INSTRUMENTS HAVING END EFFECTORS WITHPOSITIVE OPENING FEATURES”的美国专利申请序列号15/386,222;以及- US Patent Application Serial No. 15/386,222 entitled "SURGICAL STAPLING INSTRUMENTS HAVING END EFFECTORS WITHPOSITIVE OPENING FEATURES"; and

-名称为“CONNECTION PORTIONS FOR DISPOSABLE LOADING UNITS FOR SURGICALSTAPLING INSTRUMENTS”的美国专利申请序列号15/386,236。- US Patent Application Serial No. 15/386,236 entitled "CONNECTION PORTIONS FOR DISPOSABLE LOADING UNITS FOR SURGICALSTAPLING INSTRUMENTS".

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“METHOD FOR ATTACHING A SHAFT ASSEMBLY TO A SURGICALINSTRUMENT AND,ALTERNATIVELY,TO A SURGICAL ROBOT”的美国专利申请序列号15/385,887;- US Patent Application Serial No. 15/385,887 entitled "METHOD FOR ATTACHING A SHAFT ASSEMBLY TO A SURGICALINSTRUMENT AND, ALTERNATIVELY, TO A SURGICAL ROBOT";

-名称为“SHAFT ASSEMBLY COMPRISING A MANUALLY-OPERABLE RETRACTIONSYSTEM FOR USE WITH A MOTORIZED SURGICAL INSTRUMENT SYSTEM”的美国专利申请序列号15/385,889;- US Patent Application Serial No. 15/385,889 entitled "SHAFT ASSEMBLY COMPRISING A MANUALLY-OPERABLE RETRACTION SYSTEM FOR USE WITH A MOTORIZED SURGICAL INSTRUMENT SYSTEM";

-名称为“SHAFT ASSEMBLY COMPRISING SEPARATELY ACTUATABLE ANDRETRACTABLE SYSTEMS”的美国专利申请序列号15/385,890;- US Patent Application Serial No. 15/385,890 entitled "SHAFT ASSEMBLY COMPRISING SEPARATELY ACTUATABLE ANDRETRACTABLE SYSTEMS";

-名称为“SHAFT ASSEMBLY COMPRISING A CLUTCH CONFIGURED TO ADAPT THEOUTPUT OF A ROTARY FIRING MEMBER TO TWO DIFFERENT SYSTEMS”的美国专利申请序列号15/385,891;- US Patent Application Serial No. 15/385,891 entitled "SHAFT ASSEMBLY COMPRISING A CLUTCH CONFIGURED TO ADAPT THEOUTPUT OF A ROTARY FIRING MEMBER TO TWO DIFFERENT SYSTEMS";

-名称为“SURGICAL SYSTEM COMPRISING A FIRING MEMBER ROTATABLE INTO ANARTICULATION STATE TO ARTICULATE AN END EFFECTOR OF THE SURGICAL SYSTEM”的美国专利申请序列号15/385,892;- US Patent Application Serial No. 15/385,892 entitled "SURGICAL SYSTEM COMPRISING A FIRING MEMBER ROTATABLE INTO ANARTICULATION STATE TO ARTICULATE AN END EFFECTOR OF THE SURGICAL SYSTEM";

-名称为“SHAFT ASSEMBLY COMPRISING A LOCKOUT”的美国专利申请序列号15/385,894;以及- US Patent Application Serial No. 15/385,894 entitled "SHAFT ASSEMBLY COMPRISING A LOCKOUT"; and

-名称为“SHAFT ASSEMBLY COMPRISING FIRST AND SECOND ARTICULATIONLOCKOUTS”的美国专利申请序列号15/385,895。- US Patent Application Serial No. 15/385,895 entitled "SHAFT ASSEMBLY COMPRISING FIRST AND SECOND ARTICULATION LOCKOUTS".

本申请的申请人拥有与本申请于同一日期提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on the same date as the present application and each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL STAPLING SYSTEMS”的美国专利申请序列号15/385,916;- US Patent Application Serial No. 15/385,916 entitled "SURGICAL STAPLING SYSTEMS";

-名称为“SURGICAL STAPLING SYSTEMS”的美国专利申请序列号15/385,918;- US Patent Application Serial No. 15/385,918 entitled "SURGICAL STAPLING SYSTEMS";

-名称为“SURGICAL STAPLING SYSTEMS”的美国专利申请序列号15/385,919;- US Patent Application Serial No. 15/385,919 entitled "SURGICAL STAPLING SYSTEMS";

-名称为“SURGICAL STAPLE CARTRIDGE WITH MOVABLE CAMMING MEMBERCONFIGURED TO DISENGAGE FIRING MEMBER LOCKOUT FEATURES”的美国专利申请序列号15/385,921;- US Patent Application Serial No. 15/385,921 entitled "SURGICAL STAPLE CARTRIDGE WITH MOVABLE CAMMING MEMBERCONFIGURED TO DISENGAGE FIRING MEMBER LOCKOUT FEATURES";

-名称为“SURGICAL STAPLING SYSTEMS”的美国专利申请序列号15/385,923;- US Patent Application Serial No. 15/385,923 entitled "SURGICAL STAPLING SYSTEMS";

-名称为“JAW ACTUATED LOCK ARRANGEMENTS FOR PREVENTING ADVANCEMENT OFA FIRING MEMBER IN A SURGICAL END EFFECTOR UNLESS AN UNFIRED CARTRIDGE ISINSTALLED IN THE END EFFECTOR”的美国专利申请序列号 15/385,925;- US Patent Application Serial No. 15/385,925 entitled "JAW ACTUATED LOCK ARRANGEMENTS FOR PREVENTING ADVANCEMENT OFA FIRING MEMBER IN A SURGICAL END EFFECTOR UNLESS AN UNFIRED CARTRIDGE ISINSTALLED IN THE END EFFECTOR";

-名称为“AXIALLY MOVABLE CLOSURE SYSTEM ARRANGEMENTS FOR APPLYINGCLOSURE MOTIONS TO JAWS OF SURGICAL INSTRUMENTS”的美国专利申请序列号 15/385,926;- US Patent Application Serial No. 15/385,926 entitled "AXIALLY MOVABLE CLOSURE SYSTEM ARRANGEMENTS FOR APPLYINGCLOSURE MOTIONS TO JAWS OF SURGICAL INSTRUMENTS";

-名称为“PROTECTIVE COVER ARRANGEMENTS FOR A JOINT INTERFACE BETWEEN AMOVABLE JAW AND ACTUATOR SHAFT OF A SURGICAL INSTRUMENT”的美国专利申请序列号15/385,928;- US Patent Application Serial No. 15/385,928 entitled "PROTECTIVE COVER ARRANGEMENTS FOR A JOINT INTERFACE BETWEEN AMOVABLE JAW AND ACTUATOR SHAFT OF A SURGICAL INSTRUMENT";

-名称为“SURGICAL END EFFECTOR WITH TWO SEPARATE COOPERATING OPENINGFEATURES FOR OPENING AND CLOSING END EFFECTOR JAWS”的美国专利申请序列号 15/385,930;- US Patent Application Serial No. 15/385,930 entitled "SURGICAL END EFFECTOR WITH TWO SEPARATE COOPERATING OPENINGFEATURES FOR OPENING AND CLOSING END EFFECTOR JAWS";

-名称为“ARTICULATABLE SURGICAL END EFFECTOR WITH ASYMMETRIC SHAFTARRANGEMENT”的美国专利申请序列号 15/385,932;- US Patent Application Serial No. 15/385,932 entitled "ARTICULATABLE SURGICAL END EFFECTOR WITH ASYMMETRIC SHAFTARRANGEMENT";

-名称为“ARTICULATABLE SURGICAL INSTRUMENT WITH INDEPENDENT PIVOTABLELINKAGE DISTAL OF AN ARTICULATION LOCK”的美国专利申请序列号15/385,933;- US Patent Application Serial No. 15/385,933 entitled "ARTICULATABLE SURGICAL INSTRUMENT WITH INDEPENDENT PIVOTABLELINKAGE DISTAL OF AN ARTICULATION LOCK";

-名称为“ARTICULATION LOCK ARRANGEMENTS FOR LOCKING AN END EFFECTOR INAN ARTICULATED POSITION IN RESPONSE TO ACTUATION OF A JAW CLOSURE SYSTEM”的美国专利申请序列号15/385,934;- US Patent Application Serial No. 15/385,934 entitled "ARTICULATION LOCK ARRANGEMENTS FOR LOCKING AN END EFFECTOR INAN ARTICULATED POSITION IN RESPONSE TO ACTUATION OF A JAW CLOSURE SYSTEM";

-名称为“LATERALLY ACTUATABLE ARTICULATION LOCK ARRANGEMENTS FORLOCKING AN END EFFECTOR OF A SURGICAL INSTRUMENT IN AN ARTICULATEDCONFIGURATION”的美国专利申请序列号15/385,935;以及- US Patent Application Serial No. 15/385,935 entitled "LATERALLY ACTUATABLE ARTICULATION LOCK ARRANGEMENTS FORLOCKING AN END EFFECTOR OF A SURGICAL INSTRUMENT IN AN ARTICULATED CONFIGURATION"; and

-名称为“ARTICULATABLE SURGICAL INSTRUMENTS WITH ARTICULATION STROKEAMPLIFICATION FEATURES”的美国专利申请序列号15/385,936。- US Patent Application Serial No. 15/385,936 entitled "ARTICULATABLE SURGICAL INSTRUMENTS WITH ARTICULATION STROKEAMPLIFICATION FEATURES".

本申请的申请人拥有于2016年6月24日提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on June 24, 2016, each of which is incorporated herein by reference in its entirety:

-名称为“STAPLE CARTRIDGE COMPRISING WIRE STAPLES AND STAMPED STAPLES”的美国专利申请序列号15/191,775;- US Patent Application Serial No. 15/191,775 entitled "STAPLE CARTRIDGE COMPRISING WIRE STAPLES AND STAMPED STAPLES";

-名称为“STAPLING SYSTEM FOR USE WITH WIRE STAPLES AND STAMPEDSTAPLES”的美国专利申请序列号15/191,807;- US Patent Application Serial No. 15/191,807 entitled "STAPLING SYSTEM FOR USE WITH WIRE STAPLES AND STAMPEDSTAPLES";

-名称为“STAMPED STAPLES AND STAPLE CARTRIDGES USING THE SAME”的美国专利申请序列号15/191,834;- US Patent Application Serial No. 15/191,834 entitled "STAMPED STAPLES AND STAPLE CARTRIDGES USING THE SAME";

-名称为“STAPLE CARTRIDGE COMPRISING OVERDRIVEN STAPLES”的美国专利申请序列号15/191,788;以及- US Patent Application Serial No. 15/191,788 entitled "STAPLE CARTRIDGE COMPRISING OVERDRIVEN STAPLES"; and

-名称为“STAPLE CARTRIDGE COMPRISING OFFSET LONGITUDINAL STAPLE ROWS”的美国专利申请序列号 15/191,818。- US Patent Application Serial No. 15/191,818 entitled "STAPLE CARTRIDGE COMPRISING OFFSET LONGITUDINAL STAPLE ROWS".

本申请的申请人拥有于2016年6月24日提交且各自全文以引用方式并入本文的以下美国专利申请:The applicant of the present application has the following US patent applications filed on June 24, 2016, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL FASTENER”的美国设计专利申请序列号 29/569,218;- US Design Patent Application Serial No. 29/569,218 entitled "SURGICAL FASTENER";

-名称为“SURGICAL FASTENER”的美国设计专利申请序列号 29/569,227;- US Design Patent Application Serial No. 29/569,227 entitled "SURGICAL FASTENER";

-名称为“SURGICAL FASTENER CARTRIDGE”的美国设计专利申请序列号29/569,259;以及- US Design Patent Application Serial No. 29/569,259 entitled "SURGICAL FASTENER CARTRIDGE"; and

-名称为“SURGICAL FASTENER CARTRIDGE”的美国设计专利申请序列号29/569,264。- US Design Patent Application Serial No. 29/569,264 entitled "SURGICAL FASTENER CARTRIDGE".

本申请的申请人拥有于2016年4月1日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on April 1, 2016, each of which is incorporated herein by reference in its entirety:

-名称为“METHOD FOR OPERATING A SURGICAL STAPLING SYSTEM”的美国专利申请序列号15/089,325;- US Patent Application Serial No. 15/089,325 entitled "METHOD FOR OPERATING A SURGICAL STAPLING SYSTEM";

-名称为“MODULAR SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY”的美国专利申请序列号15/089,321;- US Patent Application Serial No. 15/089,321 entitled "MODULAR SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY";

-名称为“SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY INCLUDING A RE-ORIENTABLE DISPLAY FIELD”的美国专利申请序列号15/089,326;- US Patent Application Serial No. 15/089,326 entitled "SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY INCLUDING A RE-ORIENTABLE DISPLAY FIELD";

-名称为“SURGICAL INSTRUMENT HANDLE ASSEMBLY WITH RECONFIGURABLE GRIPPORTION”的美国专利申请序列号 15/089,263;- US Patent Application Serial No. 15/089,263 entitled "SURGICAL INSTRUMENT HANDLE ASSEMBLY WITH RECONFIGURABLE GRIPPORTION";

-名称为“ROTARY POWERED SURGICAL INSTRUMENT WITH MANUALLY ACTUATABLEBAILOUT SYSTEM”的美国专利申请序列号15/089,262;- US Patent Application Serial No. 15/089,262 entitled "ROTARY POWERED SURGICAL INSTRUMENT WITH MANUALLY ACTUATABLEBAILOUT SYSTEM";

-名称为“SURGICAL CUTTING AND STAPLING END EFFECTOR WITH ANVILCONCENTRIC DRIVE MEMBER”的美国专利申请序列号15/089,277;- US Patent Application Serial No. 15/089,277 entitled "SURGICAL CUTTING AND STAPLING END EFFECTOR WITH ANVILCONCENTRIC DRIVE MEMBER";

-名称为“INTERCHANGEABLE SURGICAL TOOL ASSEMBLY WITH A SURGICAL ENDEFFECTOR THAT IS SELECTIVELY ROTATABLE ABOUT A SHAFT AXIS”的美国专利申请序列号 15/089,296;- US Patent Application Serial No. 15/089,296 entitled "INTERCHANGEABLE SURGICAL TOOL ASSEMBLY WITH A SURGICAL ENDEFFECTOR THAT IS SELECTIVELY ROTATABLE ABOUT A SHAFT AXIS";

-名称为“SURGICAL STAPLING SYSTEM COMPRISING A SHIFTABLE TRANSMISSION”的美国专利申请序列号15/089,258; -名称为“SURGICAL STAPLING SYSTEM CONFIGUREDTO PROVIDE SELECTIVE CUTTING OF TISSUE”的美国专利申请序列号15/089,278;- US Patent Application Serial No. 15/089,258 entitled "SURGICAL STAPLING SYSTEM COMPRISING A SHIFTABLE TRANSMISSION"; - US Patent Application Serial No. 15/089,278 entitled "SURGICAL STAPLING SYSTEM CONFIGUREDTO PROVIDE SELECTIVE CUTTING OF TISSUE";

-名称为“SURGICAL STAPLING SYSTEM COMPRISING A CONTOURABLE SHAFT”的美国专利申请序列号15/089,284;- US Patent Application Serial No. 15/089,284 entitled "SURGICAL STAPLING SYSTEM COMPRISING A CONTOURABLE SHAFT";

-名称为“SURGICAL STAPLING SYSTEM COMPRISING A TISSUE COMPRESSIONLOCKOUT”的美国专利申请序列号15/089,295; -名称为“SURGICAL STAPLING SYSTEMCOMPRISING AN UNCLAMPING LOCKOUT”的美国专利申请序列号15/089,300; -名称为“SURGICAL STAPLING SYSTEM COMPRISING A JAW CLOSURE LOCKOUT”的美国专利申请序列号15/089,196;- US Patent Application Serial No. 15/089,295 entitled "SURGICAL STAPLING SYSTEM COMPRISING A TISSUE COMPRESSION LOCKOUT"; - US Patent Application Serial No. 15/089,300 entitled "SURGICAL STAPLING SYSTEM COMPRISING AN UNCLAMPING LOCKOUT"; - US Patent Application Serial No. 15/089,300 entitled "SURGICAL STAPLING SYSTEM COMPRISING AN UNCLAMPING LOCKOUT" COMPRISING A JAW CLOSURE LOCKOUT" U.S. Patent Application Serial No. 15/089,196;

-名称为“SURGICAL STAPLING SYSTEM COMPRISING A JAW ATTACHMENT LOCKOUT”的美国专利申请序列号15/089,203; -名称为“SURGICAL STAPLING SYSTEM COMPRISING ASPENT CARTRIDGE LOCKOUT”的美国专利申请序列号15/089,210;- US Patent Application Serial No. 15/089,203 entitled "SURGICAL STAPLING SYSTEM COMPRISING A JAW ATTACHMENT LOCKOUT"; - US Patent Application Serial No. 15/089,210 entitled "SURGICAL STAPLING SYSTEM COMPRISING ASPENT CARTRIDGE LOCKOUT";

-名称为“SURGICAL INSTRUMENT COMPRISING A SHIFTING MECHANISM”的美国专利申请序列号15/089,324;- US Patent Application Serial No. 15/089,324 entitled "SURGICAL INSTRUMENT COMPRISING A SHIFTING MECHANISM";

-名称为“SURGICAL STAPLING INSTRUMENT COMPRISING MULTIPLE LOCKOUTS”的美国专利申请序列号15/089,335;- US Patent Application Serial No. 15/089,335 entitled "SURGICAL STAPLING INSTRUMENT COMPRISING MULTIPLE LOCKOUTS";

-名称为“SURGICAL STAPLING INSTRUMENT”的美国专利申请序列号15/089,339;- US Patent Application Serial No. 15/089,339 entitled "SURGICAL STAPLING INSTRUMENT";

-名称为“SURGICAL STAPLING SYSTEM CONFIGURED TO APPLY ANNULAR ROWS OFSTAPLES HAVING DIFFERENT HEIGHTS”的美国专利申请序列号15/089,253;- US Patent Application Serial No. 15/089,253 entitled "SURGICAL STAPLING SYSTEM CONFIGURED TO APPLY ANNULAR ROWS OFSTAPLES HAVING DIFFERENT HEIGHTS";

-名称为“SURGICAL STAPLING SYSTEM COMPRISING A GROOVED FORMING POCKET”的美国专利申请序列号 15/089,304;- US Patent Application Serial No. 15/089,304 entitled "SURGICAL STAPLING SYSTEM COMPRISING A GROOVED FORMING POCKET";

-名称为“ANVIL MODIFICATION MEMBERS FOR SURGICAL STAPLERS”的美国专利申请序列号15/089,331;- US Patent Application Serial No. 15/089,331 entitled "ANVIL MODIFICATION MEMBERS FOR SURGICAL STAPLERS";

-名称为“STAPLE CARTRIDGES WITH ATRAUMATIC FEATURES”的美国专利申请序列号15/089,336;- US Patent Application Serial No. 15/089,336 entitled "STAPLE CARTRIDGES WITH ATRAUMATIC FEATURES";

-名称为“CIRCULAR STAPLING SYSTEM COMPRISING AN INCISABLE TISSUESUPPORT”的美国专利申请序列号 15/089,312;- US Patent Application Serial No. 15/089,312 entitled "CIRCULAR STAPLING SYSTEM COMPRISING AN INCISABLE TISSUESUPPORT";

-名称为“CIRCULAR STAPLING SYSTEM COMPRISING ROTARY FIRING SYSTEM”的美国专利申请序列号15/089,309;以及- US Patent Application Serial No. 15/089,309 entitled "CIRCULAR STAPLING SYSTEM COMPRISING ROTARY FIRING SYSTEM"; and

-名称为“CIRCULAR STAPLING SYSTEM COMPRISING LOAD CONTROL”的美国专利申请序列号15/089,349。- US Patent Application Serial No. 15/089,349 entitled "CIRCULAR STAPLING SYSTEM COMPRISING LOAD CONTROL".

本申请的申请人还拥有于2015年12月31日提交且各自全文以引用方式并入本文的如下标识的美国专利申请:The applicant of the present application also owns the following identified US patent applications filed on December 31, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“MECHANISMS FOR COMPENSATING FOR BATTERY PACK FAILURE INPOWERED SURGICAL INSTRUMENTS”的美国专利申请序列号14/984,488;- US Patent Application Serial No. 14/984,488 entitled "MECHANISMS FOR COMPENSATING FOR BATTERY PACK FAILURE INPOWERED SURGICAL INSTRUMENTS";

-名称为“MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号14/984,525;以及- US Patent Application Serial No. 14/984,525 entitled "MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS"; and

-名称为“SURGICAL INSTRUMENTS WITH SEPARABLE MOTORS AND MOTOR CONTROLCIRCUITS”的美国专利申请序列号 14/984,552。- US Patent Application Serial No. 14/984,552 entitled "SURGICAL INSTRUMENTS WITH SEPARABLE MOTORS AND MOTOR CONTROLCIRCUITS".

本申请的申请人还拥有于2016年2月9日提交且各自全文以引用方式并入本文的如下标识的美国专利申请:The applicant of the present application also owns the following identified US patent applications filed on February 9, 2016, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL INSTRUMENT WITH ARTICULATING AND AXIALLYTRANSLATABLE END EFFECTOR”的美国专利申请序列号15/019,220;- US Patent Application Serial No. 15/019,220 entitled "SURGICAL INSTRUMENT WITH ARTICULATING AND AXIALLYTRANSLATABLE END EFFECTOR";

-名称为“SURGICAL INSTRUMENTS WITH MULTIPLE LINK ARTICULATIONARRANGEMENTS”的美国专利申请序列号 15/019,228;- US Patent Application Serial No. 15/019,228 entitled "SURGICAL INSTRUMENTS WITH MULTIPLE LINK ARTICULATION ARRANGEMENTS";

-名称为“SURGICAL INSTRUMENT ARTICULATION MECHANISM WITH SLOTTEDSECONDARY CONSTRAINT”的美国专利申请序列号15/019,196;- US Patent Application Serial No. 15/019,196 entitled "SURGICAL INSTRUMENT ARTICULATION MECHANISM WITH SLOTTED SECONDARY CONSTRAINT";

-名称为“SURGICAL INSTRUMENTS WITH AN END EFFECTOR THAT IS HIGHLYARTICULATABLE RELATIVE TO AN ELONGATE SHAFT ASSEMBLY”的美国专利申请序列号 15/019,206;- US Patent Application Serial No. 15/019,206 entitled "SURGICAL INSTRUMENTS WITH AN END EFFECTOR THAT IS HIGHLYARTICULATABLE RELATIVE TO AN ELONGATE SHAFT ASSEMBLY";

-名称为“SURGICAL INSTRUMENTS WITH NON-SYMMETRICAL ARTICULATIONARRANGEMENTS”的美国专利申请序列号 15/019,215;- US Patent Application Serial No. 15/019,215 entitled "SURGICAL INSTRUMENTS WITH NON-SYMMETRICAL ARTICULATION ARRANGEMENTS";

-名称为“ARTICULATABLE SURGICAL INSTRUMENTS WITH SINGLE ARTICULATIONLINK ARRANGEMENTS”的美国专利申请序列号15/019,227;- US Patent Application Serial No. 15/019,227 entitled "ARTICULATABLE SURGICAL INSTRUMENTS WITH SINGLE ARTICULATIONLINK ARRANGEMENTS";

-名称为“SURGICAL INSTRUMENTS WITH TENSIONING ARRANGEMENTS FOR CABLEDRIVEN ARTICULATION SYSTEMS”的美国专利申请序列号15/019,235;- US Patent Application Serial No. 15/019,235 entitled "SURGICAL INSTRUMENTS WITH TENSIONING ARRANGEMENTS FOR CABLEDRIVEN ARTICULATION SYSTEMS";

-名称为“ARTICULATABLE SURGICAL INSTRUMENTS WITH OFF-AXIS FIRING BEAMARRANGEMENTS”的美国专利申请序列号15/019,230;以及- US Patent Application Serial No. 15/019,230 entitled "ARTICULATABLE SURGICAL INSTRUMENTS WITH OFF-AXIS FIRING BEAMARRANGEMENTS"; and

-名称为“SURGICAL INSTRUMENTS WITH CLOSURE STROKE REDUCTIONARRANGEMENTS”的美国专利申请序列号 15/019,245。- US Patent Application Serial No. 15/019,245 entitled "SURGICAL INSTRUMENTS WITH CLOSURE STROKE REDUCTION ARRANGEMENTS".

本申请的申请人还拥有于2016年2月12日提交且各自全文以引用方式并入本文的如下标识的美国专利申请:The applicant of the present application also owns the following identified US patent applications filed on February 12, 2016, each of which is incorporated herein by reference in its entirety:

-名称为“MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号15/043,254;- US Patent Application Serial No. 15/043,254 entitled "MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS";

-名称为“MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号15/043,259;- US Patent Application Serial No. 15/043,259 entitled "MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS";

-名称为“MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号15/043,275;以及- US Patent Application Serial No. 15/043,275 entitled "MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS"; and

-名称为“MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号15/043,289。- US Patent Application Serial No. 15/043,289 entitled "MECHANISMS FOR COMPENSATING FOR DRIVETRAIN FAILURE IN POWEREDSURGICAL INSTRUMENTS".

本申请的申请人拥有于2015年6月18日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on June 18, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL END EFFECTORS WITH POSITIVE JAW OPENINGARRANGEMENTS”的美国专利申请序列号14/742,925;- US Patent Application Serial No. 14/742,925 entitled "SURGICAL END EFFECTORS WITH POSITIVE JAW OPENINGARRANGEMENTS";

-名称为“SURGICAL END EFFECTORS WITH DUAL CAM ACTUATED JAW CLOSINGFEATURES”的美国专利申请序列号 14/742,941;- US Patent Application Serial No. 14/742,941 entitled "SURGICAL END EFFECTORS WITH DUAL CAM ACTUATED JAW CLOSINGFEATURES";

-名称为“MOVABLE FIRING BEAM SUPPORT ARRANGEMENTS FOR ARTICULATABLESURGICAL INSTRUMENTS”的美国专利申请序列号14/742,914;- US Patent Application Serial No. 14/742,914 entitled "MOVABLE FIRING BEAM SUPPORT ARRANGEMENTS FOR ARTICULATABLESURGICAL INSTRUMENTS";

-名称为“ARTICULATABLE SURGICAL INSTRUMENTS WITH COMPOSITE FIRING BEAMSTRUCTURES WITH CENTER FIRING SUPPORT MEMBER FOR ARTICULATION SUPPORT”的美国专利申请序列号14/742,900;- US Patent Application Serial No. 14/742,900 entitled "ARTICULATABLE SURGICAL INSTRUMENTS WITH COMPOSITE FIRING BEAMSTRUCTURES WITH CENTER FIRING SUPPORT MEMBER FOR ARTICULATION SUPPORT";

-名称为“DUAL ARTICULATION DRIVE SYSTEM ARRANGEMENTS FOR ARTICULATABLESURGICAL INSTRUMENTS”的美国专利申请序列号14/742,885;以及- US Patent Application Serial No. 14/742,885 entitled "DUAL ARTICULATION DRIVE SYSTEM ARRANGEMENTS FOR ARTICULATABLESURGICAL INSTRUMENTS"; and

-名称为“PUSH/PULL ARTICULATION DRIVE SYSTEMS FOR ARTICULATABLESURGICAL INSTRUMENTS”的美国专利申请序列号14/742,876。- US Patent Application Serial No. 14/742,876 entitled "PUSH/PULL ARTICULATION DRIVE SYSTEMS FOR ARTICULATABLESURGICAL INSTRUMENTS".

本申请的申请人拥有于2015年3月6日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on March 6, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“POWERED SURGICAL INSTRUMENT”的美国专利申请序列号14/640,746,现为美国专利申请公布2016/0256184;- US Patent Application Serial No. 14/640,746 entitled "POWERED SURGICAL INSTRUMENT", now US Patent Application Publication 2016/0256184;

-名称为“MULTIPLE LEVEL THRESHOLDS TO MODIFY OPERATION OF POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号14/640,795,现为美国专利申请公布2016/02561185;- US Patent Application Serial No. 14/640,795 entitled "MULTIPLE LEVEL THRESHOLDS TO MODIFY OPERATION OF POWEREDSURGICAL INSTRUMENTS", now US Patent Application Publication 2016/02561185;

-名称为“ADAPTIVE TISSUE COMPRESSION TECHNIQUES TO ADJUST CLOSURERATES FOR MULTIPLE TISSUE TYPES”的美国专利申请序列号14/640,832,现为美国专利申请公布 2016/0256154;- US Patent Application Serial No. 14/640,832 entitled "ADAPTIVE TISSUE COMPRESSION TECHNIQUES TO ADJUST CLOSURERATES FOR MULTIPLE TISSUE TYPES", now US Patent Application Publication 2016/0256154;

-名称为“OVERLAID MULTI SENSOR RADIO FREQUENCY(RF)- Named "OVERLAID MULTI SENSOR RADIO FREQUENCY (RF)

ELECTRODE SYSTEM TO MEASURE TISSUE COMPRESSION”的美国专利申请序列号14/640,935,现为美国专利申请公布 2016/0256071;ELECTRODE SYSTEM TO MEASURE TISSUE COMPRESSION" U.S. Patent Application Serial No. 14/640,935, now U.S. Patent Application Publication 2016/0256071;

-名称为“MONITORING SPEED CONTROL AND PRECISION INCREMENTING OF MOTORFOR POWERED SURGICAL INSTRUMENTS”的美国专利申请序列号14/640,831,现为美国专利申请公布2016/0256153;- US Patent Application Serial No. 14/640,831 entitled "MONITORING SPEED CONTROL AND PRECISION INCREMENTING OF MOTORFOR POWERED SURGICAL INSTRUMENTS", now US Patent Application Publication 2016/0256153;

-名称为“TIME DEPENDENT EVALUATION OF SENSOR DATA TO DETERMINESTABILITY,CREEP,AND VISCOELASTIC ELEMENTS OF MEASURES”的美国专利申请序列号14/640,859,现为美国专利申请公布2016/0256187;- US Patent Application Serial No. 14/640,859 entitled "TIME DEPENDENT EVALUATION OF SENSOR DATA TO DETERMINESTABILITY, CREEP, AND VISCOELASTIC ELEMENTS OF MEASURES", now US Patent Application Publication 2016/0256187;

-名称为“INTERACTIVE FEEDBACK SYSTEM FOR POWERED SURGICAL INSTRUMENTS”的美国专利申请序列号14/640,817,现为美国专利申请公布2016/0256186;- US Patent Application Serial No. 14/640,817 entitled "INTERACTIVE FEEDBACK SYSTEM FOR POWERED SURGICAL INSTRUMENTS", now US Patent Application Publication 2016/0256186;

-名称为“CONTROL TECHNIQUES AND SUB-PROCESSOR CONTAINED WITHIN MODULARSHAFT WITH SELECT CONTROL PROCESSING FROM HANDLE”的美国专利申请序列号14/640,844,现为美国专利申请公布2016/0256155;- US Patent Application Serial No. 14/640,844 entitled "CONTROL TECHNIQUES AND SUB-PROCESSOR CONTAINED WITHIN MODULARSHAFT WITH SELECT CONTROL PROCESSING FROM HANDLE", now US Patent Application Publication 2016/0256155;

-名称为“SMART SENSORS WITH LOCAL SIGNAL PROCESSING”的美国专利申请序列号14/640,837,现为美国专利申请公布 2016/0256163;- US Patent Application Serial No. 14/640,837 entitled "SMART SENSORS WITH LOCAL SIGNAL PROCESSING", now US Patent Application Publication 2016/0256163;

-名称为“SYSTEM FOR DETECTING THE MIS-INSERTION OF A STAPLE CARTRIDGEINTO A SURGICAL STAPLER”的美国专利申请序列号14/640,765,现为美国专利申请公布2016/0256160;- US Patent Application Serial No. 14/640,765 entitled "SYSTEM FOR DETECTING THE MIS-INSERTION OF A STAPLE CARTRIDGEINTO A SURGICAL STAPLER", now US Patent Application Publication 2016/0256160;

-名称为“SIGNAL AND POWER COMMUNICATION SYSTEM POSITIONED ON AROTATABLE SHAFT”的美国专利申请序列号 14/640,799,现为美国专利申请公布2016/0256162;以及- US Patent Application Serial No. 14/640,799 entitled "SIGNAL AND POWER COMMUNICATION SYSTEM POSITIONED ON AROTATABLE SHAFT", now US Patent Application Publication 2016/0256162; and

-名称为“SURGICAL INSTRUMENT COMPRISING A LOCKABLE BATTERY HOUSING”的美国专利申请序列号14/640,780,现为美国专利申请公布2016/0256161。- US Patent Application Serial No. 14/640,780 entitled "SURGICAL INSTRUMENT COMPRISING A LOCKABLE BATTERY HOUSING", now US Patent Application Publication 2016/0256161.

本申请的申请人拥有于2015年2月27日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on February 27, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL INSTRUMENT SYSTEM COMPRISING AN INSPECTION STATION”的美国专利申请序列号14/633,576,现为美国专利申请公布2016/0249919;- US Patent Application Serial No. 14/633,576 entitled "SURGICAL INSTRUMENT SYSTEM COMPRISING AN INSPECTION STATION", now US Patent Application Publication 2016/0249919;

-名称为“SURGICAL APPARATUS CONFIGURED TO ASSESS WHETHER A PERFORMANCEPARAMETER OF THE SURGICAL APPARATUS IS WITHIN AN ACCEPTABLE PERFORMANCE BAND”的美国专利申请序列号14/633,546,现为美国专利申请公布2016/0249915;- US Patent Application Serial No. 14/633,546 entitled "SURGICAL APPARATUS CONFIGURED TO ASSESS WHETHER A PERFORMANCEPARAMETER OF THE SURGICAL APPARATUS IS WITHIN AN ACCEPTABLE PERFORMANCE BAND", now US Patent Application Publication 2016/0249915;

-名称为“SURGICAL CHARGING SYSTEM THAT CHARGES AND/OR CONDITIONS ONEOR MORE BATTERIES”的美国专利申请序列号14/633,560,现为美国专利申请公布2016/0249910;- US Patent Application Serial No. 14/633,560 entitled "SURGICAL CHARGING SYSTEM THAT CHARGES AND/OR CONDITIONS ONEOR MORE BATTERIES", now US Patent Application Publication 2016/0249910;

-名称为“CHARGING SYSTEM THAT ENABLES EMERGENCY RESOLUTIONS FORCHARGING A BATTERY”的美国专利申请序列号14/633,566,现为美国专利申请公布2016/0249918;- US Patent Application Serial No. 14/633,566 entitled "CHARGING SYSTEM THAT ENABLES EMERGENCY RESOLUTIONS FORCHARGING A BATTERY", now US Patent Application Publication 2016/0249918;

-名称为“SYSTEM FOR MONITORING WHETHER A SURGICAL INSTRUMENT NEEDS TOBE SERVICED”的美国专利申请序列号 14/633,555,现为美国专利申请公布2016/0249916;- US Patent Application Serial No. 14/633,555 entitled "SYSTEM FOR MONITORING WHETHER A SURGICAL INSTRUMENT NEEDS TOBE SERVICED", now US Patent Application Publication 2016/0249916;

-名称为“REINFORCED BATTERY FOR A SURGICAL INSTRUMENT”的美国专利申请序列号14/633,542,现为美国专利申请公布2016/0249908;- US Patent Application Serial No. 14/633,542 entitled "REINFORCED BATTERY FOR A SURGICAL INSTRUMENT", now US Patent Application Publication 2016/0249908;

-名称为“POWER ADAPTER FOR A SURGICAL INSTRUMENT”的美国专利申请序列号14/633,548,现为美国专利申请公布 2016/0249909;- U.S. Patent Application Serial No. 14/633,548 entitled "POWER ADAPTER FOR A SURGICAL INSTRUMENT", now U.S. Patent Application Publication 2016/0249909;

-名称为“ADAPTABLE SURGICAL INSTRUMENT HANDLE”的美国专利申请序列号14/633,526,现为美国专利申请公布 2016/0249945;- U.S. Patent Application Serial No. 14/633,526 entitled "ADAPTABLE SURGICAL INSTRUMENT HANDLE", now U.S. Patent Application Publication 2016/0249945;

-名称为“MODULAR STAPLING ASSEMBLY”的美国专利申请序列号14/633,541,现为美国专利申请公布2016/0249927;以及- US Patent Application Serial No. 14/633,541 entitled "MODULAR STAPLING ASSEMBLY", now US Patent Application Publication 2016/0249927; and

-名称为“SURGICAL APPARATUS CONFIGURED TO TRACK AN END-OF-LIFEPARAMETER”的美国专利申请序列号14/633,562,- US Patent Application Serial No. 14/633,562 entitled "SURGICAL APPARATUS CONFIGURED TO TRACK AN END-OF-LIFEPARAMETER",

现为美国专利申请公布2016/0249917。Now US Patent Application Publication 2016/0249917.

本申请的申请人拥有于2014年12月18日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on December 18, 2014, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL INSTRUMENT SYSTEMS COMPRISING AN ARTICULATABLE ENDEFFECTOR AND MEANS FOR ADJUSTING THE FIRING STROKE OF A FIRING MEMBER”的美国专利申请序列号14/574,478,现为美国专利申请公布 2016/0174977;-US Patent Application Serial No. 14/574,478 entitled "SURGICAL INSTRUMENT SYSTEMS COMPRISING AN ARTICULATABLE ENDEFFECTOR AND MEANS FOR ADJUSTING THE FIRING STROKE OF A FIRING MEMBER", now US Patent Application Publication 2016/0174977;

-名称为“SURGICAL INSTRUMENT ASSEMBLY COMPRISING LOCKABLE SYSTEMS”的美国专利申请序列号14/574,483,现为美国专利申请公布2016/0174969;- US Patent Application Serial No. 14/574,483 entitled "SURGICAL INSTRUMENT ASSEMBLY COMPRISING LOCKABLE SYSTEMS", now US Patent Application Publication 2016/0174969;

-名称为“DRIVE ARRANGEMENTS FOR ARTICULATABLE SURGICAL INSTRUMENTS”的美国专利申请序列号14/575,139,现为美国专利申请公布2016/0174978;- US Patent Application Serial No. 14/575,139 entitled "DRIVE ARRANGEMENTS FOR ARTICULATABLE SURGICAL INSTRUMENTS", now US Patent Application Publication 2016/0174978;

-名称为“LOCKING ARRANGEMENTS FOR DETACHABLE SHAFT ASSEMBLIES WITHARTICULATABLE SURGICAL END EFFECTORS”的美国专利申请序列号14/575,148,现为美国专利申请公布2016/0174976;- US Patent Application Serial No. 14/575,148 entitled "LOCKING ARRANGEMENTS FOR DETACHABLE SHAFT ASSEMBLIES WITHARTICULATABLE SURGICAL END EFFECTORS", now US Patent Application Publication 2016/0174976;

-名称为“SURGICAL INSTRUMENT WITH AN ANVIL THAT IS SELECTIVELY MOVABLEABOUT A DISCRETE NON-MOVABLE AXIS RELATIVE TO A STAPLE CARTRIDGE”的美国专利申请序列号14/575,130,现为美国专利申请公布2016/0174972;- US Patent Application Serial No. 14/575,130 entitled "SURGICAL INSTRUMENT WITH AN ANVIL THAT IS SELECTIVELY MOVABLEABOUT A DISCRETE NON-MOVABLE AXIS RELATIVE TO A STAPLE CARTRIDGE", now US Patent Application Publication 2016/0174972;

-名称为“SURGICAL INSTRUMENTS WITH IMPROVED CLOSURE ARRANGEMENTS”的美国专利申请序列号14/575,143,现为美国专利申请公布2016/0174983;- US Patent Application Serial No. 14/575,143 entitled "SURGICAL INSTRUMENTS WITH IMPROVED CLOSURE ARRANGEMENTS", now US Patent Application Publication 2016/0174983;

-名称为“SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDMOVABLE FIRING BEAM SUPPORT ARRANGEMENTS”的美国专利申请序列号14/575,117,现为美国专利申请公布2016/0174975;- US Patent Application Serial No. 14/575,117 entitled "SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDMOVABLE FIRING BEAM SUPPORT ARRANGEMENTS", now US Patent Application Publication 2016/0174975;

-名称为“SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDIMPROVED FIRING BEAM SUPPORT ARRANGEMENTS”的美国专利申请序列号14/575,154,现为美国专利申请公布2016/0174973;- US Patent Application Serial No. 14/575,154 entitled "SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDIMPROVED FIRING BEAM SUPPORT ARRANGEMENTS", now US Patent Application Publication 2016/0174973;

-名称为“SURGICAL INSTRUMENT ASSEMBLY COMPRISING A FLEXIBLEARTICULATION SYSTEM”的美国专利申请序列号 14/574,493;现为美国专利申请公布2016/0174970;以及- US Patent Application Serial No. 14/574,493 entitled "SURGICAL INSTRUMENT ASSEMBLY COMPRISING A FLEXIBLEARTICULATION SYSTEM"; now US Patent Application Publication 2016/0174970; and

-名称为“SURGICAL INSTRUMENT ASSEMBLY COMPRISING A LOCKABLEARTICULATION SYSTEM”的美国专利申请序列号 14/574,500,现为美国专利申请公布2016/0174971。-US Patent Application Serial No. 14/574,500 entitled "SURGICAL INSTRUMENT ASSEMBLY COMPRISING A LOCKABLEARTICULATION SYSTEM", now US Patent Application Publication 2016/0174971.

本申请的申请人拥有于2013年3月1日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on March 1, 2013, each of which is incorporated herein by reference in its entirety:

-名称为“Articulatable Surgical Instruments With Conductive PathwaysFor Signal Communication”的美国专利申请序列号13/782,295,现为美国专利申请公布2014/0246471;- US Patent Application Serial No. 13/782,295 entitled "Articulatable Surgical Instruments With Conductive Pathways For Signal Communication", now US Patent Application Publication 2014/0246471;

-名称为“Rotary Powered Articulation Joints For Surgical Instruments”的美国专利申请序列号13/782,323,现为美国专利申请公布 2014/0246472;- U.S. Patent Application Serial No. 13/782,323 entitled "Rotary Powered Articulation Joints For Surgical Instruments", now U.S. Patent Application Publication 2014/0246472;

-名称为“Thumbwheel Switch Arrangements For Surgical Instruments”的美国专利申请序列号13/782,338,现为美国专利申请公布 2014/0249557;- U.S. Patent Application Serial No. 13/782,338 entitled "Thumbwheel Switch Arrangements For Surgical Instruments", now U.S. Patent Application Publication 2014/0249557;

-名称为“Electromechanical Surgical Device with Signal RelayArrangement”的美国专利申请序列号13/782,499,现为美国专利申请公布9,358,003;- US Patent Application Serial No. 13/782,499 entitled "Electromechanical Surgical Device with Signal Relay Arrangement", now US Patent Application Publication 9,358,003;

-名称为“Multiple Processor Motor Control for Modular SurgicalInstruments”的美国专利申请序列号13/782,460,现为美国专利申请公布2014/0246478;- US Patent Application Serial No. 13/782,460 entitled "Multiple Processor Motor Control for Modular Surgical Instruments", now US Patent Application Publication 2014/0246478;

-名称为“Joystick Switch Assemblies For Surgical Instruments”的美国专利申请序列号13/782,358,现为美国专利申请公布9,326,767;- US Patent Application Serial No. 13/782,358 entitled "Joystick Switch Assemblies For Surgical Instruments", now US Patent Application Publication 9,326,767;

-名称为“Sensor Straightened End Effector During Removal ThroughTrocar”的美国专利申请序列号13/782,481,现为美国专利申请公布9,468,438;- US Patent Application Serial No. 13/782,481 entitled "Sensor Straightened End Effector During Removal ThroughTrocar", now US Patent Application Publication 9,468,438;

-名称为“Control Methods for Surgical Instruments with RemovableImplement Portions”的美国专利申请序列号13/782,518,现为美国专利申请公布2014/0246475;- US Patent Application Serial No. 13/782,518 entitled "Control Methods for Surgical Instruments with RemovableImplement Portions", now US Patent Application Publication 2014/0246475;

-名称为“Rotary Powered Surgical Instruments With Multiple Degrees ofFreedom”的美国专利申请序列号13/782,375,现为美国专利申请公布9,398,911;以及- US Patent Application Serial No. 13/782,375 entitled "Rotary Powered Surgical Instruments With Multiple Degrees of Freedom", now US Patent Application Publication 9,398,911; and

-名称为“Surgical Instrument Soft Stop”的美国专利申请序列号 13/782,536,现为美国专利申请公布9,307,986。- US Patent Application Serial No. 13/782,536 entitled "Surgical Instrument Soft Stop", now US Patent Application Publication 9,307,986.

本申请的申请人还拥有于2013年3月14日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on March 14, 2013, each of which is incorporated herein by reference in its entirety:

-名称为“ARTICULATABLE SURGICAL INSTRUMENT COMPRISING A FIRING DRIVE”的美国专利申请序列号 13/803,097,现为美国专利申请公布2014/0263542;- US Patent Application Serial No. 13/803,097 entitled "ARTICULATABLE SURGICAL INSTRUMENT COMPRISING A FIRING DRIVE", now US Patent Application Publication 2014/0263542;

-名称为“CONTROL ARRANGEMENTS FOR A DRIVE MEMBER OF A SURGICALINSTRUMENT”的美国专利申请序列号13/803,193,现为美国专利申请公布9,332,987;- US Patent Application Serial No. 13/803,193 entitled "CONTROL ARRANGEMENTS FOR A DRIVE MEMBER OF A SURGICALINSTRUMENT", now US Patent Application Publication 9,332,987;

-名称为“INTERCHANGEABLE SHAFT ASSEMBLIES FOR USE WITH A SURGICALINSTRUMENT”的美国专利申请序列号 13/803,053,现为美国专利申请公布2014/0263564;- US Patent Application Serial No. 13/803,053 entitled "INTERCHANGEABLE SHAFT ASSEMBLIES FOR USE WITH A SURGICALINSTRUMENT", now US Patent Application Publication 2014/0263564;

-名称为“ARTICULATABLE SURGICAL INSTRUMENT COMPRISING AN ARTICULATIONLOCK”的美国专利申请序列号13/803,086,现为美国专利申请公布2014/0263541;- US Patent Application Serial No. 13/803,086 entitled "ARTICULATABLE SURGICAL INSTRUMENT COMPRISING AN ARTICULATION LOCK", now US Patent Application Publication 2014/0263541;

-名称为“SENSOR ARRANGEMENTS FOR ABSOLUTE POSITIONING SYSTEM FORSURGICAL INSTRUMENTS”的美国专利申请序列号13/803,210,现为美国专利申请公布2014/0263538;- US Patent Application Serial No. 13/803,210 entitled "SENSOR ARRANGEMENTS FOR ABSOLUTE POSITIONING SYSTEM FORSURGICAL INSTRUMENTS", now US Patent Application Publication 2014/0263538;

-名称为“MULTI-FUNCTION MOTOR FOR A SURGICAL INSTRUMENT”的美国专利申请序列号13/803,148,现为美国专利申请公布2014/0263554;- US Patent Application Serial No. 13/803,148 entitled "MULTI-FUNCTION MOTOR FOR A SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0263554;

-名称为“DRIVE SYSTEM LOCKOUT ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS”的美国专利申请序列号 13/803,066,现为美国专利申请公布2014/0263565;- US Patent Application Serial No. 13/803,066 entitled "DRIVE SYSTEM LOCKOUT ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS", now US Patent Application Publication 2014/0263565;

-名称为“ARTICULATION CONTROL SYSTEM FOR ARTICULATABLE SURGICALINSTRUMENTS”的美国专利申请序列号13/803,117,现为美国专利申请公布9,351,726;- US Patent Application Serial No. 13/803,117 entitled "ARTICULATION CONTROL SYSTEM FOR ARTICULATABLE SURGICALINSTRUMENTS", now US Patent Application Publication 9,351,726;

-名称为“DRIVE TRAIN CONTROL ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS”的美国专利申请序列号 13/803,130,现为美国专利申请公布9,351,727;以及-名称为“METHOD AND SYSTEM FOR OPERATING A SURGICAL INSTRUMENT”的美国专利申请序列号13/803,159,现为美国专利申请公布2014/0277017。- US Patent Application Serial No. 13/803,130 entitled "DRIVE TRAIN CONTROL ARRANGEMENTS FOR MODULAR SURGICAL INSTRUMENTS", now US Patent Application Publication 9,351,727; and - US Patent Application Serial No. entitled "METHOD AND SYSTEM FOR OPERATING A SURGICAL INSTRUMENT" 13/803,159, now US Patent Application Publication 2014/0277017.

本申请的申请人还拥有于2014年3月7日提交且全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent application filed on March 7, 2014 and incorporated herein by reference in its entirety:

-名称为“CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS”的美国专利申请序列号14/200,111,现为美国专利申请公布 2014/0263539。- US Patent Application Serial No. 14/200,111 entitled "CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS", now US Patent Application Publication 2014/0263539.

本申请的申请人还拥有于2014年3月26日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on March 26, 2014, each of which is incorporated herein by reference in its entirety:

-名称为“POWER MANAGEMENT CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS”的美国专利申请序列号14/226,106,现为美国专利申请公布2015/0272582;- US Patent Application Serial No. 14/226,106 entitled "POWER MANAGEMENT CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS", now US Patent Application Publication 2015/0272582;

-名称为“STERILIZATION VERIFICATION CIRCUIT”的美国专利申请序列号14/226,099,现为美国专利申请公布2015/0272581;- US Patent Application Serial No. 14/226,099 entitled "STERILIZATION VERIFICATION CIRCUIT", now US Patent Application Publication 2015/0272581;

-名称为“VERIFICATION OF NUMBER OF BATTERY EXCHANGES/PROCEDURE COUNT”的美国专利申请序列号 14/226,094,现为美国专利申请公布2015/0272580;- US Patent Application Serial No. 14/226,094 entitled "VERIFICATION OF NUMBER OF BATTERY EXCHANGES/PROCEDURE COUNT", now US Patent Application Publication 2015/0272580;

-名称为“POWER MANAGEMENT THROUGH SLEEP OPTIONS OF SEGMENTED CIRCUITAND WAKE UP CONTROL”的美国专利申请序列号14/226,117,现为美国专利申请公布2015/0272574;- US Patent Application Serial No. 14/226,117 entitled "POWER MANAGEMENT THROUGH SLEEP OPTIONS OF SEGMENTED CIRCUITAND WAKE UP CONTROL", now US Patent Application Publication 2015/0272574;

-名称为“MODULAR POWERED SURGICAL INSTRUMENT WITH DETACHABLE SHAFTASSEMBLIES”的美国专利申请序列号 14/226,075,现为美国专利申请公布2015/0272579;- US Patent Application Serial No. 14/226,075 entitled "MODULAR POWERED SURGICAL INSTRUMENT WITH DETACHABLE SHAFTASSEMBLIES", now US Patent Application Publication 2015/0272579;

-名称为“FEEDBACK ALGORITHMS FOR MANUAL BAILOUT SYSTEMS FOR SURGICALINSTRUMENTS”的美国专利申请序列号14/226,093,现为美国专利申请公布2015/0272569;- US Patent Application Serial No. 14/226,093 entitled "FEEDBACK ALGORITHMS FOR MANUAL BAILOUT SYSTEMS FOR SURGICALINSTRUMENTS", now US Patent Application Publication 2015/0272569;

-名称为“SURGICAL INSTRUMENT UTILIZING SENSOR ADAPTATION”的美国专利申请序列号14/226,116,现为美国专利申请公布2015/0272571;- US Patent Application Serial No. 14/226,116 entitled "SURGICAL INSTRUMENT UTILIZING SENSOR ADAPTATION", now US Patent Application Publication 2015/0272571;

-名称为“SURGICAL INSTRUMENT CONTROL CIRCUIT HAVING A SAFETYPROCESSOR”的美国专利申请序列号14/226,071,现为美国专利申请公布2015/0272578;- US Patent Application Serial No. 14/226,071 entitled "SURGICAL INSTRUMENT CONTROL CIRCUIT HAVING A SAFETYPROCESSOR", now US Patent Application Publication 2015/0272578;

-名称为“SURGICAL INSTRUMENT COMPRISING INTERACTIVE SYSTEMS”的美国专利申请序列号14/226,097,现为美国专利申请公布2015/0272570;- US Patent Application Serial No. 14/226,097 entitled "SURGICAL INSTRUMENT COMPRISING INTERACTIVE SYSTEMS", now US Patent Application Publication 2015/0272570;

-名称为“INTERFACE SYSTEMS FOR USE WITH SURGICAL INSTRUMENTS”的美国专利申请序列号14/226,126,现为美国专利申请公布2015/0272572;- US Patent Application Serial No. 14/226,126 entitled "INTERFACE SYSTEMS FOR USE WITH SURGICAL INSTRUMENTS", now US Patent Application Publication 2015/0272572;

-名称为“MODULAR SURGICAL INSTRUMENT SYSTEM”的美国专利申请序列号14/226,133,现为美国专利申请公布2015/0272557;- US Patent Application Serial No. 14/226,133 entitled "MODULAR SURGICAL INSTRUMENT SYSTEM", now US Patent Application Publication 2015/0272557;

-名称为“SYSTEMS AND METHODS FOR CONTROLLING A SEGMENTED CIRCUIT”的美国专利申请序列号14/226,081,现为美国专利申请公布2015/0277471;- US Patent Application Serial No. 14/226,081 entitled "SYSTEMS AND METHODS FOR CONTROLLING A SEGMENTED CIRCUIT", now US Patent Application Publication 2015/0277471;

-名称为“POWER MANAGEMENT THROUGH SEGMENTED CIRCUIT AND VARIABLEVOLTAGE PROTECTION”的美国专利申请序列号14/226,076,现为美国专利申请公布2015/0280424;- US Patent Application Serial No. 14/226,076 entitled "POWER MANAGEMENT THROUGH SEGMENTED CIRCUIT AND VARIABLEVOLTAGE PROTECTION", now US Patent Application Publication 2015/0280424;

-名称为“SURGICAL STAPLING INSTRUMENT SYSTEM”的美国专利申请序列号14/226,111,现为美国专利申请公布2015/0272583;以及-名称为“SURGICAL INSTRUMENTCOMPRISING A ROTATABLE SHAFT”的美国专利申请序列号14/226,125,现为美国专利申请公布2015/0280384。- US Patent Application Serial No. 14/226,111 entitled "SURGICAL STAPLING INSTRUMENT SYSTEM", now US Patent Application Publication No. 2015/0272583; and - US Patent Application Serial No. 14/226,125 entitled "SURGICAL INSTRUMENTCOMPRISING A ROTATABLE SHAFT", Now US Patent Application Publication 2015/0280384.

本申请的申请人还拥有于2014年9月5日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on September 5, 2014, each of which is incorporated herein by reference in its entirety:

-名称为“CIRCUITRY AND SENSORS FOR POWERED MEDICAL DEVICE”的美国专利申请序列号14/479,103,现为美国专利申请公布2016/0066912;- US Patent Application Serial No. 14/479,103 entitled "CIRCUITRY AND SENSORS FOR POWERED MEDICAL DEVICE", now US Patent Application Publication 2016/0066912;

-名称为“ADJUNCT WITH INTEGRATED SENSORS TO QUANTIFY TISSUECOMPRESSION”的美国专利申请序列号14/479,119,现为美国专利申请公布2016/0066914;- US Patent Application Serial No. 14/479,119 entitled "ADJUNCT WITH INTEGRATED SENSORS TO QUANTIFY TISSUECOMPRESSION", now US Patent Application Publication 2016/0066914;

-名称为“MONITORING DEVICE DEGRADATION BASED ON COMPONENT EVALUATION”的美国专利申请序列号14/478,908,现为美国专利申请公布2016/0066910;- US Patent Application Serial No. 14/478,908 entitled "MONITORING DEVICE DEGRADATION BASED ON COMPONENT EVALUATION", now US Patent Application Publication 2016/0066910;

-名称为“MULTIPLE SENSORS WITH ONE SENSOR AFFECTING A SECOND SENSOR'SOUTPUT OR INTERPRETATION”的美国专利申请序列号14/478,895,现为美国专利申请公布2016/0066909;- US Patent Application Serial No. 14/478,895 entitled "MULTIPLE SENSORS WITH ONE SENSOR AFFECTING A SECOND SENSOR'SOUTPUT OR INTERPRETATION", now US Patent Application Publication 2016/0066909;

-名称为“POLARITY OF HALL MAGNET TO DETECT MISLOADED CARTRIDGE”的美国专利申请序列号14/479,110,现为美国专利申请公布2016/0066915;- US Patent Application Serial No. 14/479,110 entitled "POLARITY OF HALL MAGNET TO DETECT MISLOADED CARTRIDGE", now US Patent Application Publication 2016/0066915;

-名称为“SMART CARTRIDGE WAKE UP OPERATION AND DATA RETENTION”的美国专利申请序列号14/479,098,现为美国专利申请公布2016/0066911;- US Patent Application Serial No. 14/479,098 entitled "SMART CARTRIDGE WAKE UP OPERATION AND DATA RETENTION", now US Patent Application Publication 2016/0066911;

-名称为“MULTIPLE MOTOR CONTROL FOR POWERED MEDICAL DEVICE”的美国专利申请序列号14/479,115,现为美国专利申请公布2016/0066916;以及- US Patent Application Serial No. 14/479,115 entitled "MULTIPLE MOTOR CONTROL FOR POWERED MEDICAL DEVICE", now US Patent Application Publication 2016/0066916; and

-名称为“LOCAL DISPLAY OF TISSUE PARAMETER STABILIZATION”的美国专利申请序列号14/479,108,现为美国专利申请公布2016/0066913。- US Patent Application Serial No. 14/479,108 entitled "LOCAL DISPLAY OF TISSUE PARAMETER STABILIZATION", now US Patent Application Publication 2016/0066913.

本申请的申请人还拥有于2014年4月9日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on April 9, 2014, each of which is incorporated herein by reference in its entirety:

-名称为“MOTOR DRIVEN SURGICAL INSTRUMENTS WITH LOCKABLE DUAL DRIVESHAFTS”的美国专利申请序列号 14/248,590,现为美国专利申请公布2014/0305987;- US Patent Application Serial No. 14/248,590 entitled "MOTOR DRIVEN SURGICAL INSTRUMENTS WITH LOCKABLE DUAL DRIVESHAFTS", now US Patent Application Publication 2014/0305987;

-名称为“SURGICAL INSTRUMENT COMPRISING A CLOSING DRIVE AND A FIRINGDRIVE OPERATED FROM THE SAME ROTATABLE OUTPUT”的美国专利申请序列号14/248,581,现为美国专利申请公布2014/0305989;- US Patent Application Serial No. 14/248,581 entitled "SURGICAL INSTRUMENT COMPRISING A CLOSING DRIVE AND A FIRINGDRIVE OPERATED FROM THE SAME ROTATABLE OUTPUT", now US Patent Application Publication 2014/0305989;

-名称为“SURGICAL INSTRUMENT SHAFT INCLUDING SWITCHES FOR CONTROLLINGTHE OPERATION OF THE SURGICAL INSTRUMENT”的美国专利申请序列号14/248,595,现为美国专利申请公布2014/0305988;- US Patent Application Serial No. 14/248,595 entitled "SURGICAL INSTRUMENT SHAFT INCLUDING SWITCHES FOR CONTROLLINGTHE OPERATION OF THE SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0305988;

-名称为“POWERED LINEAR SURGICAL STAPLER”的美国专利申请序列号14/248,588,现为美国专利申请公布2014/0309666;- US Patent Application Serial No. 14/248,588 entitled "POWERED LINEAR SURGICAL STAPLER", now US Patent Application Publication 2014/0309666;

-名称为“TRANSMISSION ARRANGEMENT FOR A SURGICAL INSTRUMENT”的美国专利申请序列号14/248,591,现为美国专利申请公布2014/0305991;- US Patent Application Serial No. 14/248,591 entitled "TRANSMISSION ARRANGEMENT FOR A SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0305991;

-名称为“MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH ALIGNMENTFEATURES FOR ALIGNING ROTARY DRIVE SHAFTS WITH SURGICAL END EFFECTOR SHAFTS”的美国专利申请序列号14/248,584,现为美国专利申请公布2014/0305994;- US Patent Application Serial No. 14/248,584 entitled "MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH ALIGNMENTFEATURES FOR ALIGNING ROTARY DRIVE SHAFTS WITH SURGICAL END EFFECTOR SHAFTS", now US Patent Application Publication 2014/0305994;

-名称为“POWERED SURGICAL STAPLER”的美国专利申请序列号14/248,587,现为美国专利申请公布2014/0309665;- US Patent Application Serial No. 14/248,587 entitled "POWERED SURGICAL STAPLER", now US Patent Application Publication 2014/0309665;

-名称为“DRIVE SYSTEM DECOUPLING ARRANGEMENT FOR A SURGICALINSTRUMENT”的美国专利申请序列号14/248,586,现为美国专利申请公布2014/0305990;以及- US Patent Application Serial No. 14/248,586 entitled "DRIVE SYSTEM DECOUPLING ARRANGEMENT FOR A SURGICALINSTRUMENT", now US Patent Application Publication 2014/0305990; and

-名称为“MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH STATUSINDICATION ARRANGEMENTS”的美国专利申请序列号14/248,607,现为美国专利申请公布2014/0305992。- US Patent Application Serial No. 14/248,607 entitled "MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH STATUSINDICATION ARRANGEMENTS", now US Patent Application Publication 2014/0305992.

本申请的申请人还拥有于2013年4月16日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on April 16, 2013, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR”的美国临时专利申请序列号 61/812,365;- U.S. Provisional Patent Application Serial No. 61/812,365 entitled "SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR";

-名称为“LINEAR CUTTER WITH POWER”的美国临时专利申请序列号61/812,376;- US Provisional Patent Application Serial No. 61/812,376 entitled "LINEAR CUTTER WITH POWER";

-名称为“LINEAR CUTTER WITH MOTOR AND PISTOL GRIP”的美国临时专利申请序列号61/812,382;- US Provisional Patent Application Serial No. 61/812,382 entitled "LINEAR CUTTER WITH MOTOR AND PISTOL GRIP";

-名称为“SURGICAL INSTRUMENT HANDLE WITH MULTIPLE ACTUATION MOTORS ANDMOTOR CONTROL”的美国临时专利申请序列号61/812,385;以及- U.S. Provisional Patent Application Serial No. 61/812,385 entitled "SURGICAL INSTRUMENT HANDLE WITH MULTIPLE ACTUATION MOTORS ANDMOTOR CONTROL"; and

-名称为“SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR”的美国临时专利申请序列号 61/812,372。- U.S. Provisional Patent Application Serial No. 61/812,372 entitled "SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR".

本申请的申请人还拥有于2015年9月2日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on September 2, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL STAPLE CARTRIDGE WITH IMPROVED STAPLE DRIVERCONFIGURATIONS”的美国专利申请序列号 14/843,168;- US Patent Application Serial No. 14/843,168 entitled "SURGICAL STAPLE CARTRIDGE WITH IMPROVED STAPLE DRIVERCONFIGURATIONS";

-名称为“SURGICAL STAPLE DRIVER ARRAYS”的美国专利申请序列号14/843,196;- US Patent Application Serial No. 14/843,196 entitled "SURGICAL STAPLE DRIVER ARRAYS";

-名称为“SURGICAL STAPLE CARTRIDGE STAPLE DRIVERS WITH CENTRAL SUPPORTFEATURES”的美国专利申请序列号14/843,216;- US Patent Application Serial No. 14/843,216 entitled "SURGICAL STAPLE CARTRIDGE STAPLE DRIVERS WITH CENTRAL SUPPORTFEATURES";

-名称为“SURGICAL STAPLE CONFIGURATIONS WITH CAMMING SURFACES LOCATEDBETWEEN PORTIONS SUPPORTING SURGICAL STAPLES”的美国专利申请序列号 14/843,243;以及- U.S. Patent Application Serial No. 14/843,243 entitled "SURGICAL STAPLE CONFIGURATIONS WITH CAMMING SURFACES LOCATEDBETWEEN PORTIONS SUPPORTING SURGICAL STAPLES"; and

-名称为“SURGICAL STAPLE CARTRIDGES WITH DRIVER ARRANGEMENTS FORESTABLISHING HERRINGBONE STAPLE PATTERNS”的美国专利申请序列号14/843,267。- US Patent Application Serial No. 14/843,267 entitled "SURGICAL STAPLE CARTRIDGES WITH DRIVER ARRANGEMENTS FORESTABLISHING HERRINGBONE STAPLE PATTERNS".

本申请的申请人还拥有于2014年9月26日提交且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on September 26, 2014, each of which is incorporated herein by reference in its entirety:

-名称为“CIRCULAR FASTENER CARTRIDGES FOR APPLYING RADIALLY EXPANDABLEFASTENER LINES”的美国专利申请序列号14/498,070;现为美国专利申请公布2016/0089146;- US Patent Application Serial No. 14/498,070 entitled "CIRCULAR FASTENER CARTRIDGES FOR APPLYING RADIALLY EXPANDABLEFASTENER LINES"; now US Patent Application Publication 2016/0089146;

-名称为“SURGICAL STAPLE AND DRIVER ARRANGEMENTS FOR STAPLECARTRIDGES”的美国专利申请序列号14/498,087;现为美国专利申请公布2016/0089147;- US Patent Application Serial No. 14/498,087 entitled "SURGICAL STAPLE AND DRIVER ARRANGEMENTS FOR STAPLECARTRIDGES"; now US Patent Application Publication 2016/0089147;

-名称为“SURGICAL STAPLE AND DRIVER ARRANGEMENTS FOR STAPLECARTRIDGES”的美国专利申请序列号14/498,105;现为美国专利申请公布2016/0089148;- US Patent Application Serial No. 14/498,105 entitled "SURGICAL STAPLE AND DRIVER ARRANGEMENTS FOR STAPLECARTRIDGES"; now US Patent Application Publication 2016/0089148;

-名称为“FASTENER CARTRIDGE FOR CREATING A FLEXIBLE STAPLE LINE”的美国专利申请序列号14/498,121;现为美国专利申请公布2016/0089141;- US Patent Application Serial No. 14/498,121 entitled "FASTENER CARTRIDGE FOR CREATING A FLEXIBLE STAPLE LINE"; now US Patent Application Publication 2016/0089141;

-名称为“METHOD FOR CREATING A FLEXIBLE STAPLE LINE”的美国专利申请序列号14/498,145;现为美国专利申请公布 2016/0089142;以及- U.S. Patent Application Serial No. 14/498,145 entitled "METHOD FOR CREATING A FLEXIBLE STAPLE LINE"; now U.S. Patent Application Publication 2016/0089142; and

-名称为“SURGICAL STAPLING BUTTRESSES AND ADJUNCT MATERIALS”的美国专利申请序列号14/498,107;现为美国专利申请公布2016/0089143。- US Patent Application Serial No. 14/498,107 entitled "SURGICAL STAPLING BUTTRESSES AND ADJUNCT MATERIALS"; now US Patent Application Publication 2016/0089143.

本申请的申请人还拥有2013年11月26日发布的名称为“STAPLE CARTRIDGECAVITY CONFIGURATIONS”的美国专利8,590,762,该专利全文以引用方式并入本文。The applicant of the present application also owns US Patent 8,590,762, issued November 26, 2013, entitled "STAPLE CARTRIDGECAVITY CONFIGURATIONS," which is incorporated herein by reference in its entirety.

本申请的申请人还拥有2014年5月20日发布的名称为“STAPLE CARTRIDGE CAVITYCONFIGURATION WITH COOPERATIVE SURGICAL STAPLE”的美国专利8,727,197,该专利全文以引用方式并入本文。The applicant of the present application also owns US Patent 8,727,197, entitled "STAPLE CARTRIDGE CAVITY CONFIGURATION WITH COOPERATIVE SURGICAL STAPLE," issued May 20, 2014, which is incorporated herein by reference in its entirety.

本文列出了许多具体细节,以提供对说明书中所述和附图中所示的实施方案的整体结构、功能、制造和用途的透彻理解。没有详细描述熟知的操作、部件和元件,以免使说明书中描述的实施方案模糊不清。读者将会理解,本文所述和所示的实施方案为非限制性示例,从而可认识到,本文所公开的特定结构和功能细节可为代表性和例示性的。在不脱离权利要求的范围的情况下,可对这些实施方案进行变型和改变。Numerous specific details are set forth herein in order to provide a thorough understanding of the general structure, function, manufacture, and use of the embodiments described in the specification and shown in the accompanying drawings. Well-known operations, components and elements have not been described in detail so as not to obscure the embodiments described in the specification. The reader will understand that the embodiments described and illustrated herein are by way of non-limiting example, so that the specific structural and functional details disclosed herein may be representative and illustrative, and may be appreciated. Variations and changes may be made to these embodiments without departing from the scope of the claims.

术语“包括(comprise)”(以及“包括(comprise)”的任何形式,诸如“包括(comprises)”和“包括(comprising)”)、“具有(have)” (以及“具有(have)”的任何形式,诸如“具有(has)”和“具有(having)”)、“包含(include)”(以及“包含(include)”的任何形式,诸如“包含 (includes)”和“包含(including)”)、以及“含有(contain)”(以及“含有(contain)”的任何形式,诸如“含有(contains)”和“含有 (containing)”)为开放式系动词。因此,“包括”、“具有”、“包含”或“含有”一个或多个元件的外科系统、装置、或设备具有这些一个或多个元件,但不限于仅具有这些一个或多个元件。同样,“包括”、“具有”、“包含”或“含有”一个或多个特征部的系统、装置、或设备的元件具有那些一个或多个特征部,但不限于仅具有那些一个或多个特征部。The term "comprise" (and any form of "comprise" such as "comprises" and "comprising"), "have" (and "have" any form, such as "has" and "having"), "include" (and any form of "include", such as "includes" and "including" "), and "contain" (and any form of "contain" such as "contains" and "containing") are open-ended copulas. Thus, a surgical system, device, or device that "comprises," "has," "comprises," or "contains" one or more elements has those one or more elements, but is not limited to having only those one or more elements. Likewise, an element of a system, apparatus, or device that "comprises," "has," "includes," or "contains" one or more features has those one or more features, but is not limited to having only those one or more features feature part.