CN110082548B - Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method - Google Patents

Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning methodDownload PDFInfo

- Publication number

- CN110082548B CN110082548BCN201810073746.3ACN201810073746ACN110082548BCN 110082548 BCN110082548 BCN 110082548BCN 201810073746 ACN201810073746 ACN 201810073746ACN 110082548 BCN110082548 BCN 110082548B

- Authority

- CN

- China

- Prior art keywords

- cleaning

- reaction cup

- magnetic bead

- holes

- assembly

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

- G01N33/50—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing

- G01N33/53—Immunoassay; Biospecific binding assay; Materials therefor

- G01N33/543—Immunoassay; Biospecific binding assay; Materials therefor with an insoluble carrier for immobilising immunochemicals

- G01N33/54313—Immunoassay; Biospecific binding assay; Materials therefor with an insoluble carrier for immobilising immunochemicals the carrier being characterised by its particulate form

- G01N33/54326—Magnetic particles

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/02—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor using a plurality of sample containers moved by a conveyor system past one or more treatment or analysis stations

- G01N35/04—Details of the conveyor system

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/10—Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices

- G01N35/1004—Cleaning sample transfer devices

Landscapes

- Health & Medical Sciences (AREA)

- Immunology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- Pathology (AREA)

- Physics & Mathematics (AREA)

- Urology & Nephrology (AREA)

- Hematology (AREA)

- Molecular Biology (AREA)

- Biomedical Technology (AREA)

- Biotechnology (AREA)

- Cell Biology (AREA)

- Microbiology (AREA)

- Food Science & Technology (AREA)

- Medicinal Chemistry (AREA)

- Automatic Analysis And Handling Materials Therefor (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及医疗器械技术领域,特别是涉及一种磁珠复合物吸附机构,包含该磁珠复合物吸附机构的清洗装置,包含该清洗装置的化学发光检测仪以及清洗方法。The invention relates to the technical field of medical devices, in particular to a magnetic bead complex adsorption mechanism, a cleaning device including the magnetic bead complex adsorption mechanism, a chemiluminescence detector including the cleaning device, and a cleaning method.

背景技术Background technique

化学发光免疫分析法是将抗原抗体免疫反应和发光反应所结合的一种体外检测分析技术,它以免疫学理论为基础,以发光标记物为示踪信号,通过收集光信号来检测多种标志物,具有灵敏度高、非特异性吸附低、准确率高的优势。随着生物医药设备的高速发展,实现化学发光检测仪的全自动化具备了一定的条件。Chemiluminescence immunoassay is an in vitro detection and analysis technology that combines antigen-antibody immune reaction and luminescence reaction. It is based on immunological theory, uses luminescent markers as tracer signals, and detects various markers by collecting optical signals. , has the advantages of high sensitivity, low non-specific adsorption, and high accuracy. With the rapid development of biomedical equipment, the realization of full automation of chemiluminescence detectors has certain conditions.

通常,基于生物化学发光免疫分析法的化学发光检测仪已经成为成熟的医疗诊断设备。然而,通用型化学发光检测仪设备价格昂贵、体积笨重、功耗巨大,难以普及和推广。而随着生物医药设备的高速发展,实现化学发光检测仪的全自动化具备了一定的条件。Generally, chemiluminescence detectors based on biochemiluminescence immunoassays have become mature medical diagnostic equipment. However, general-purpose chemiluminescence detector equipment is expensive, bulky, and consumes huge amounts of power, making it difficult to popularize and popularize. With the rapid development of biomedical equipment, the realization of full automation of chemiluminescence detectors has certain conditions.

化学发光检测仪主要包括反应杯加载装置、加样本和试剂装置、温育反应装置、清洗装置、发光测量装置、控制系统以及软件系统。一般的清洗装置在反应杯一侧面设置带磁性的装置,该装置主要用于将混合物中的有用物质即磁珠复合物吸附在反应杯该侧面上。在清洗时,将装有样本和试剂混合物的反应杯中加入一定量的清洗液,由于磁性装置设置在反应杯的一侧面,因此导致吸附在该侧面上的磁珠复合物中掺杂有部分杂质无法清洗彻底,导致清洗效果不佳,进而影响测量结果的准确性。The chemiluminescence detector mainly includes a cuvette loading device, a sample and reagent addition device, an incubation reaction device, a cleaning device, a luminescence measurement device, a control system and a software system. A general cleaning device is provided with a magnetic device on one side of the cuvette, and the device is mainly used to adsorb the useful substance in the mixture, that is, the magnetic bead complex, on the side of the cuvette. During cleaning, a certain amount of cleaning solution is added to the cuvette containing the sample and reagent mixture. Since the magnetic device is arranged on one side of the cuvette, the magnetic bead complex adsorbed on the side is doped with a certain amount of cleaning solution. Impurities cannot be cleaned thoroughly, resulting in poor cleaning effect, which in turn affects the accuracy of measurement results.

发明内容SUMMARY OF THE INVENTION

基于此,有必要提供一种能提高清洗效果的磁珠复合物吸附机构、清洗装置、化学发光检测仪及清洗方法。Based on this, it is necessary to provide a magnetic bead complex adsorption mechanism, a cleaning device, a chemiluminescence detector and a cleaning method that can improve the cleaning effect.

一种磁珠复合物吸附机构,用于吸附绕中心轴线公转的反应杯中的磁珠复合物,该磁珠复合物吸附机构设置有供所述反应杯进出的输入工位和主输出工位,该磁珠复合物吸附机构包括底座及固定在所述底座上的多个侧吸组件,该多个侧吸组件环绕所述中心轴线设置且位于所述输入工位和主输出工位之间;相邻两个所述侧吸组件相互间隔形成供所述反应杯运行的通道;A magnetic bead complex adsorption mechanism for adsorbing magnetic bead complexes in a cuvette revolving around a central axis, the magnetic bead complex adsorption mechanism is provided with an input station and a main output station for the cuvette to enter and exit , the magnetic bead complex adsorption mechanism includes a base and a plurality of side suction components fixed on the base, the plurality of side suction components are arranged around the central axis and located between the input station and the main output station ; The adjacent two side suction assemblies are spaced apart from each other to form a channel for the cuvette to run;

其中,当所述反应杯公转时,多个所述侧吸组件使得所述磁珠复合物交替吸附在所述反应杯相对设置的第一内侧面和第二内侧面上。Wherein, when the cuvette revolves, a plurality of the side suction components make the magnetic bead composite alternately adsorb on the first inner side surface and the second inner side surface of the cuvette which are arranged opposite to each other.

在其中一个实施例中,该多个侧吸组件交替设置于该反应杯的公转轨迹的内侧和外侧,该多个侧吸组件的磁吸面朝向该反应杯的公转轨迹,相邻两个侧吸组件沿所述反应杯的公转轨迹的周向相互间隔。In one embodiment, the plurality of side suction components are alternately arranged on the inner side and the outer side of the revolution track of the cuvette, the magnetic attraction surfaces of the plurality of side suction components face the revolution track of the cuvette, and two adjacent sides are adjacent to each other. The suction components are spaced apart from each other along the circumferential direction of the revolution track of the cuvette.

在其中一个实施例中,每一所述侧吸组件包括沿该反应杯公转轨迹方向排布的第一对磁铁和第二对磁铁,所述第二对磁铁位于每一所述侧吸组件沿该反应杯公转轨迹方向的尾部,所述第一对磁铁的磁吸面积大于所述第二对磁铁的磁吸面积,使得吸附在该反应杯的第一内侧面或第二内侧面的磁珠复合物包括对应的第一聚拢状态和第二聚拢状态,该第一聚拢状态的紧密程度小于该第二聚拢状态的紧密程度。In one embodiment, each of the side suction components includes a first pair of magnets and a second pair of magnets arranged along the direction of the revolving track of the cuvette, and the second pair of magnets are located along the side of each of the side suction components. At the end of the revolving track of the cuvette, the magnetic attraction area of the first pair of magnets is larger than the magnetic attraction area of the second pair of magnets, so that the magnetic beads adsorbed on the first inner side or the second inner side of the cuvette The composite includes a corresponding first gathered state and a second gathered state, the first gathered state being less dense than the second gathered state.

在其中一个实施例中,靠近该主输出工位的侧吸组件包括第一对磁铁、第二对磁铁和第三对磁铁,所述第三对磁铁位于该侧吸组件沿该反应杯公转轨迹方向的尾部,所述第一对磁铁、第二对磁铁和第三对磁铁的磁吸面积依次缩小,使得吸附在该反应杯的第一内侧面或第二内侧面的磁珠复合物包括对应的第一聚拢状态、第二聚拢状态和第三聚拢状态,该第一聚拢状态、第二聚拢状态和第三聚拢状态的紧密程度依次减少。In one embodiment, the side suction component near the main output station includes a first pair of magnets, a second pair of magnets and a third pair of magnets, the third pair of magnets is located on the side suction component along the revolving track of the cuvette At the end of the direction, the magnetic attraction areas of the first pair of magnets, the second pair of magnets and the third pair of magnets are sequentially reduced, so that the magnetic bead complexes adsorbed on the first inner side or the second inner side of the cuvette include corresponding The first gathered state, the second gathered state and the third gathered state of , and the tightness of the first gathered state, the second gathered state and the third gathered state is successively decreased.

在其中一个实施例中,沿该反应杯公转方向,多个所述侧吸组件使得所述磁珠复合物在所述反应杯内侧面的吸附位置逐渐靠近挨近所述反应杯底面的距离。In one embodiment, along the revolving direction of the cuvette, a plurality of the side suction components make the adsorption position of the magnetic bead composite on the inner side of the cuvette gradually approach a distance close to the bottom surface of the cuvette.

在其中一个实施例中,所述多个侧吸组件沿所述反应杯转动方向依次首尾相对设置,所述侧吸组件包括带有与所述中心轴线同轴的圆弧形安装面的安装体,及设置在所述圆弧形安装面上并与所述反应杯相对的若干磁性体;分布在所述输入工位与主输出工位之间的任意相邻两个所述侧吸组件的圆弧形安装面位于所述反应杯运动轨迹的异侧、并相对所述中心轴线的朝向相反。In one embodiment, the plurality of side suction assemblies are arranged end to end in sequence along the rotation direction of the cuvette, and the side suction assemblies include a mounting body with an arc-shaped mounting surface coaxial with the central axis , and a number of magnetic bodies arranged on the arc-shaped mounting surface and opposite to the reaction cup; any two adjacent side suction assemblies distributed between the input station and the main output station The arc-shaped mounting surfaces are located on opposite sides of the motion track of the cuvette, and are oriented opposite to the central axis.

在其中一个实施例中,包括四个侧吸组件,所述四个侧吸组件包括沿所述反应杯转动方向依次首尾相对设置的第一侧吸组件、第二侧吸组件、第三侧吸组件和第四侧吸组件,所述第一侧吸组件上靠近所述第四侧吸组件的一端与所述输入工位对应,所述第四侧吸组件上靠近所述第一侧吸组件的一端与所述主输出工位对应,所述第一侧吸组件上的所述圆弧形安装面面对所述中心轴线。In one of the embodiments, four side suction assemblies are included, and the four side suction assemblies include a first side suction assembly, a second side suction assembly, and a third side suction assembly, which are arranged in turn opposite to each other along the rotation direction of the cuvette. assembly and a fourth side suction assembly, one end of the first side suction assembly close to the fourth side suction assembly corresponds to the input station, and the fourth side suction assembly is close to the first side suction assembly One end of the first side suction assembly corresponds to the main output station, and the arc-shaped mounting surface on the first side suction assembly faces the central axis.

在其中一个实施例中,任意不相邻的两个所述侧吸组件上的所述圆弧形安装面到所述中心轴线的距离相等。In one embodiment, the distances from the arc-shaped mounting surfaces on any two non-adjacent side suction assemblies to the central axis are the same.

在其中一个实施例中,所述安装体包括固定座和插装板;所述固定座上设置有沿所述圆弧形安装面的周向延伸的第一安装槽,所述圆弧形安装面上开设有与所述第一安装槽连通的若干安装孔,所述插装板与所述第一安装槽配合,所述磁性体容置在所述安装孔中且其端部与所述插装板连接。In one embodiment, the mounting body includes a fixing base and an inserting plate; the fixing base is provided with a first mounting groove extending along the circumferential direction of the arc-shaped mounting surface, and the arc-shaped mounting surface is provided with a first mounting groove. The surface is provided with a plurality of installation holes communicating with the first installation groove, the insertion plate is matched with the first installation groove, the magnetic body is accommodated in the installation holes and its end is connected with the first installation groove. Plug-in board connection.

在其中一个实施例中,所述固定座上与所述圆弧形安装面相对的一面上开设有与所述第一安装槽连通的第二安装槽,所述插装板上设置有与所述第二安装槽配合的限位凸条,所述限位凸条与所述固定座螺栓连接。In one of the embodiments, a second installation groove communicated with the first installation groove is opened on the side of the fixed seat opposite to the arc-shaped installation surface, and the insertion plate is provided with a second installation groove connected to the first installation groove. The limiting protruding strip is matched with the second installation groove, and the limiting protruding strip is bolted to the fixing seat.

在其中一个实施例中,还包括如下中的任意一个:In one of the embodiments, it also includes any one of the following:

同一所述侧吸组件上的若干所述安装孔到所述底座的距离相等或不相等;The distances from the mounting holes on the same side suction assembly to the base are equal or unequal;

不同所述侧吸组件上的若干所述安装孔相对所述底座的距离不相等。The distances of the mounting holes on the different side suction assemblies relative to the base are not equal.

在其中一个实施例中,所述安装孔包括与所述反应杯转入方向对应的若干对第一通孔,及与所述反应杯转出方向对应的若干对第三通孔;In one of the embodiments, the mounting holes include a plurality of pairs of first through holes corresponding to the rotation direction of the cuvette, and a plurality of pairs of third through holes corresponding to the rotation direction of the cuvette;

所述磁性体包括位于所述第一通孔中的第一磁铁,及位于所述第三通孔中的第三磁铁;The magnetic body includes a first magnet located in the first through hole, and a third magnet located in the third through hole;

其中:任意一对所述第一通孔中的两个所述第一磁铁之间的磁吸面积为D1,任意一对所述第三通孔中的两个所述第三磁铁之间的磁吸面积为D3,D1>D3。Wherein: the magnetic attraction area between the two first magnets in any pair of the first through holes is D1 , and the area between the two third magnets in any pair of the third through holes is

在其中一个实施例中,所述安装孔还包括位于所述第一通孔和所述第三通孔之间的若干对第二通孔,所述磁性体还包括位于所述第二通孔中的第二磁铁;In one embodiment, the mounting hole further includes a plurality of pairs of second through holes located between the first through hole and the third through hole, and the magnetic body further includes a plurality of pairs of second through holes located between the first through hole and the third through hole. the second magnet in;

其中:任意一对所述第二通孔中的两个所述第二磁铁之间的磁吸面积为D2,D1>D2>D3。Wherein: the magnetic attraction area between the two second magnets in any pair of the second through holes is D2 , and D1 >D2 >D3 .

在其中一个实施例中,在所述第一侧吸组件中、第二侧吸组件和第三侧吸组件中,所述第一通孔的数量均为三对,所述第三通孔的数量均为两对;在所述第四侧吸组件中,所述第一通孔的数量为一对,所述第二通孔的数量为三对,所述第三通孔的数量为三对。In one of the embodiments, in the first side suction assembly, the second side suction assembly and the third side suction assembly, the number of the first through holes is three pairs, and the number of the third through holes is three pairs. The number is two pairs; in the fourth side suction assembly, the number of the first through holes is one pair, the number of the second through holes is three pairs, and the number of the third through holes is three pairs right.

在其中一个实施例中,在所述第一侧吸组件中、第二侧吸组件和第三侧吸组件中,所述第一通孔的数量均为三个,所述第二通孔的数量均为两对,所述第三通孔的数量均为三对;在所述第四侧吸组件中,所述第一通孔的数量为一对,所述第二通孔的数量为三对,所述第三通孔的数量均三对。In one embodiment, in the first side suction assembly, the second side suction assembly and the third side suction assembly, the number of the first through holes is three, and the number of the second through holes is three. The number is two pairs, and the number of the third through holes is three pairs; in the fourth side suction assembly, the number of the first through holes is one pair, and the number of the second through holes is Three pairs, and the number of the third through holes is all three pairs.

在其中一个实施例中,在所述第一侧吸组件中,所述第一通孔的数量为一个,所述第二通孔的数量为一对,所述第三通孔的数量为六对;在所述第二侧吸组件和第三侧吸组件中,所述第二通孔的数量均为两对,所述第三通孔的数量均为六对;在所述第四侧吸组件中,所述所述第一通孔的数量为三个,所述第二通孔的数量为三对,所述第三通孔的数量为两对。In one embodiment, in the first side suction assembly, the number of the first through holes is one, the number of the second through holes is one pair, and the number of the third through holes is six Yes; in the second side suction assembly and the third side suction assembly, the number of the second through holes is two pairs, and the number of the third through holes is six pairs; in the fourth side In the suction assembly, the number of the first through holes is three, the number of the second through holes is three pairs, and the number of the third through holes is two pairs.

在其中一个实施例中,所述安装孔的截面形状为圆弧、半圆弧或优弧。In one of the embodiments, the cross-sectional shape of the mounting hole is a circular arc, a semi-circular arc or an arc.

在其中一个实施例中,还包括固定在所述底座上、并环绕所述中心轴线且沿所述反应杯转动方向依次首尾相对设置的多个圆弧形定位块,所述圆弧形定位块与所述侧吸组件一一对应;In one embodiment, it further includes a plurality of arc-shaped positioning blocks that are fixed on the base, surround the central axis, and are arranged end to end in sequence along the rotation direction of the cuvette. The arc-shaped positioning blocks One-to-one correspondence with the side suction components;

其中:相互对应的所述圆弧形定位块与所述侧吸组件分居所述反应杯运动轨迹的异侧、并围设成供所述反应杯运行的通道。Wherein, the arc-shaped positioning block and the side suction assembly corresponding to each other are located on opposite sides of the motion track of the cuvette, and are surrounded by a channel for the cuvette to run.

在其中一个实施例中,所述底座包括垫板,与所述垫板相对设置的底板,及连接在所述垫板与所述底板之间的支撑柱;所述侧吸组件固定在所述底板上。In one embodiment, the base includes a backing plate, a bottom plate opposite to the backing plate, and a support column connected between the backing plate and the bottom plate; the side suction assembly is fixed on the on the bottom plate.

一种清洗装置,包括上述任一的磁珠复合物吸附机构。A cleaning device includes any one of the above-mentioned magnetic bead complex adsorption mechanisms.

在其中一个实施例中,还包括与所述底座转动连接并用于承载所述反应杯的转盘,及安装在所述底座上的主清洗机构和副清洗机构,所述转盘与所述磁珠复合物吸附机构相对设置。In one of the embodiments, it further includes a turntable rotatably connected to the base and used for carrying the reaction cup, and a main cleaning mechanism and a secondary cleaning mechanism installed on the base, the turntable and the magnetic beads are compounded The substance adsorption mechanism is relatively set.

在其中一个实施例中,所述副清洗机构与所述主输出工位对应,所述主清洗机构环绕所述侧吸组件设置并位于所述副清洗机构与所述输入工位之间,所述主清洗机构与所述侧吸组件的端部对应。In one embodiment, the auxiliary cleaning mechanism corresponds to the main output station, the main cleaning mechanism is arranged around the side suction assembly and is located between the auxiliary cleaning mechanism and the input station, so The main cleaning mechanism corresponds to the end of the side suction assembly.

在其中一个实施例中,所述主清洗机构包括固定在所述底座上的第一安装架,与所述第一安装架滑动配合的第一支撑架,与所述第一安装架连接并驱动所述第一支撑架往复滑动的第一驱动组件,设置在所述第一安装架和所述第一支撑架上并用于支撑注液管和抽液管的管夹,及安装在所述第一支撑架上并与所述反应杯对应的若干个主清洗组件。In one of the embodiments, the main cleaning mechanism includes a first mounting bracket fixed on the base, a first supporting bracket slidably matched with the first mounting bracket, connected with the first mounting bracket and driven The first drive assembly for the reciprocating sliding of the first support frame is arranged on the first installation frame and the first support frame and is used for supporting the liquid injection pipe and the liquid suction pipe. Several main cleaning components on a support frame and corresponding to the reaction cups.

在其中一个实施例中,所述主清洗组件包括固定在所述第一支撑架上的针套,与所述针套转动连接的针座,穿设在所述针座中并与所述注液管连接的注液针,及穿设在所述针座中并与所述抽液管连接且能伸入所述反应杯中的抽液针,所述注液针的输出口贴附在所述抽液针的外壁面上。In one of the embodiments, the main cleaning assembly includes a needle cover fixed on the first support frame, a needle seat rotatably connected with the needle cover, passing through the needle seat and connected with the injector A liquid injection needle connected with a liquid pipe, and a liquid suction needle that is penetrated in the needle seat and connected to the liquid suction pipe and can extend into the reaction cup, the output port of the liquid injection needle is attached to the on the outer wall of the liquid aspiration needle.

在其中一个实施例中,所述副清洗机构包括固定在所述底座上的第二安装架,与所述第二安装架滑动配合的第二支撑架,与所述第二安装架连接并驱动所述第二支撑架往复滑动的第二驱动组件,设置在所述第二安装架和所述第二支撑架上并用于支撑抽液管的管夹,及安装在所述第二支撑架上并与所述反应杯对应的副清洗组件。In one of the embodiments, the auxiliary cleaning mechanism includes a second mounting frame fixed on the base, a second supporting frame slidably matched with the second mounting frame, connected with the second mounting frame and driven The second drive assembly for the reciprocating sliding of the second support frame is arranged on the second installation frame and the second support frame and is used for supporting the pipe clamp of the suction pipe, and is installed on the second support frame And the auxiliary cleaning component corresponding to the reaction cup.

在其中一个实施例中,所述副清洗组件包括固定在所述第二支撑架上的针套,与所述针套转动连接的针座,及穿设在所述针座中并与所述抽液管连接且能伸入所述反应杯中的抽液针。In one of the embodiments, the auxiliary cleaning assembly includes a needle cover fixed on the second support frame, a needle seat rotatably connected with the needle cover, and a needle seat passed through the needle seat and connected to the needle cover. The aspiration tube is connected to and can extend into the aspiration needle in the cuvette.

在其中一个实施例中,所述副清洗机构还包括固定在所述底座上并用于清洗所述副清洗组件的清洗槽。In one embodiment, the auxiliary cleaning mechanism further includes a cleaning tank fixed on the base and used for cleaning the auxiliary cleaning assembly.

在其中一个实施例中,所述第二支撑架包括与所述第二安装架滑动配合的第二滑板,固定在所述第二滑板上的支撑框,与所述支撑框转动连接的转轴,与所述转轴连接并用于安装所述副清洗组件的第二固定板,及驱动所述转轴旋转的第三驱动组件。In one of the embodiments, the second support frame includes a second slide plate slidably matched with the second mounting frame, a support frame fixed on the second slide plate, a rotating shaft rotatably connected to the support frame, A second fixing plate connected with the rotating shaft and used for installing the auxiliary cleaning assembly, and a third driving component for driving the rotating shaft to rotate.

一种化学发光检测仪,包括上述任一的清洗装置。A chemiluminescence detector, comprising any of the above cleaning devices.

一种清洗方法,用于清洗反应杯中的磁珠复合物,包括如下步骤:A cleaning method for cleaning the magnetic bead complex in a reaction cup, comprising the following steps:

将经过第一次加样后的反应杯从清洗装置的输入工位进入、并围绕清洗装置的转盘的中心轴线公转;Enter the reaction cup after the first sample addition from the input station of the cleaning device, and revolve around the central axis of the turntable of the cleaning device;

主清洗,清洗装置将磁珠复合物多次交替吸附在反应杯的第一内侧面和第二内侧面上,清洗液对在第一内侧面和第二内侧面之间泳动的磁珠复合物进行清洗,清洗装置在该磁珠复合物每一次泳动之前对反应杯抽废液后重新注入新的清洗液;In the main cleaning, the cleaning device adsorbs the magnetic bead complexes alternately on the first inner side and the second inner side of the cuvette for many times, and the cleaning solution compoundes the magnetic beads swimming between the first inner side and the second inner side. Before each movement of the magnetic bead complex, the cleaning device sucks the waste liquid into the reaction cup and re-injects the new cleaning solution;

副清洗,将磁珠复合物吸附在第一内侧面或第二内侧面上接近反应杯底面的位置处、并对反应杯抽废液处理;Secondary cleaning, the magnetic bead complex is adsorbed on the first inner side or the second inner side at a position close to the bottom surface of the cuvette, and the cuvette is pumped for waste liquid treatment;

将第一次公转至所述清洗装置的主输出工位的反应杯输送至测量室。The cuvette that has revolved for the first time to the main output station of the cleaning device is transported to the measurement chamber.

在其中一个实施例中,使所述清洗装置的输入工位与主输出工位处于同一位置。In one embodiment, the input station of the cleaning device is co-located with the main output station.

在其中一个实施例中,所述主清洗包括如下步骤:In one embodiment, the main cleaning includes the steps of:

第一次清洗,反应杯公转,磁珠复合物脱离第一内侧面而在清洗液中泳动并吸附至第二内侧面上;In the first cleaning, the cuvette revolves, and the magnetic bead complex is separated from the first inner side and swims in the cleaning solution and is adsorbed to the second inner side;

反应杯停止公转,对反应杯进行抽废液后重新注入新的清洗液;Stop the revolution of the reaction cup, pump the waste liquid into the reaction cup and re-fill it with new cleaning solution;

第二次清洗,反应杯沿原方向公转,磁珠复合物脱离第二内侧面而在清洗液中泳动并吸附至第一内侧面上;In the second cleaning, the cuvette revolves in the original direction, and the magnetic bead complex is separated from the second inner side and swims in the cleaning solution and is adsorbed to the first inner side;

反应杯停止公转,对反应杯进行抽废液后重新注入新的清洗液;Stop the revolution of the reaction cup, pump the waste liquid into the reaction cup and re-fill it with new cleaning solution;

第三次清洗,反应杯沿原方向公转,磁珠复合物脱离第一内侧面而在清洗液中泳动并吸附至第二内侧面上。In the third cleaning, the cuvette revolves in the original direction, and the magnetic bead complex is separated from the first inner side and swims in the cleaning solution and is adsorbed to the second inner side.

在其中一个实施例中,在所述第二次清洗步骤到所述第三次清洗步骤之间,逐渐减少磁珠复合物的吸附位置相对反应杯底面的距离。In one embodiment, between the second cleaning step and the third cleaning step, the distance between the adsorption position of the magnetic bead complex and the bottom surface of the cuvette is gradually reduced.

在其中一个实施例中,当反应杯即将停止公转以抽废液时,逐渐减少磁珠复合物在第一内侧面或第二内侧面上的吸附面积。In one embodiment, when the cuvette is about to stop revolving to extract the waste liquid, the adsorption area of the magnetic bead complex on the first inner side or the second inner side is gradually reduced.

在其中一个实施例中,在所述副清洗步骤中,使磁珠复合物的吸附位置相对反应杯底面的距离最近。In one embodiment, in the secondary cleaning step, the distance between the adsorption position of the magnetic bead complex and the bottom surface of the cuvette is the shortest.

在其中一个实施例中,在所述主清洗步骤中,当对反应杯抽废液后,将新注入的清洗液对清洗装置上的抽液针进行清洗。In one embodiment, in the main cleaning step, after the waste liquid is extracted from the cuvette, the newly injected cleaning solution is used to clean the extraction needle on the cleaning device.

在其中一个实施例中,在所述副清洗步骤中,当对反应杯抽废液后,将清洗装置上的抽液针转移至设置在清洗装置上的清洗槽进行清洗。In one embodiment, in the secondary cleaning step, after the waste liquid is extracted from the reaction cup, the liquid extraction needle on the cleaning device is transferred to a cleaning tank provided on the cleaning device for cleaning.

在其中一个实施例中,在所述副清洗步骤中,对所述反应杯抽废液时,使磁珠复合物在第一内侧面或第二内侧面上的吸附面积最小。In one embodiment, in the secondary cleaning step, the adsorption area of the magnetic bead complex on the first inner side surface or the second inner side surface is minimized when the waste liquid is extracted from the cuvette.

本发明提供的磁珠复合物吸附机构、清洗装置、化学发光检测仪及清洗方法,由于反应杯在绕中心轴线公转的过程中,多个侧吸组件使得磁珠复合物交替吸附在反应杯相对设置的第一内侧面和第二内侧面上,清洗液对在第一内侧面和第二内侧面之间来回泳动的磁珠复合物进行清洗,即全方位的清洗磁珠复合物,提高了对磁珠复合物的清洗效果,进而保证了测量结果的准确性。In the magnetic bead complex adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method provided by the present invention, since the cuvette revolves around the central axis, a plurality of side suction components make the magnetic bead complex alternately adsorbed on the cuvette relative to each other. The first inner side surface and the second inner side surface are arranged, and the cleaning liquid cleans the magnetic bead complexes that swim back and forth between the first inner side surface and the second inner side surface, that is, cleaning the magnetic bead complexes in all directions, improving the performance of the magnetic bead complexes. The cleaning effect of the magnetic bead complex is ensured, thereby ensuring the accuracy of the measurement results.

附图说明Description of drawings

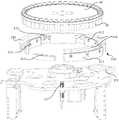

图1为一实施例提供的清洗装置的立体结构示意图;1 is a schematic three-dimensional structure diagram of a cleaning device provided by an embodiment;

图2为一实施例提供的清洗装置的局部分解结构示意图;2 is a schematic diagram of a partially exploded structure of a cleaning device provided by an embodiment;

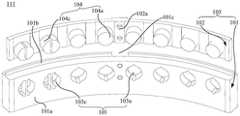

图3为一实施例提供的清洗装置中磁珠复合物吸附机构的俯视示意图;3 is a schematic top view of a magnetic bead complex adsorption mechanism in a cleaning device provided by an embodiment;

图4为一实施例提供的清洗装置的局部结构俯视示意图;4 is a schematic top view of a partial structure of a cleaning device provided by an embodiment;

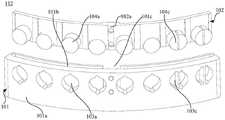

图5为一实施例提供的清洗装置中第一侧吸组件的分解结构示意图;5 is a schematic diagram of an exploded structure of a first side suction component in a cleaning device provided by an embodiment;

图6为一实施例提供的清洗装置中第二侧吸组件的分解结构示意图;6 is a schematic diagram of an exploded structure of a second side suction assembly in a cleaning device provided by an embodiment;

图7为一实施例提供的清洗装置中第三侧吸组件的分解结构示意图;7 is a schematic diagram of an exploded structure of a third side suction component in a cleaning device provided by an embodiment;

图8为图7中的主视示意图;Fig. 8 is the front view schematic diagram in Fig. 7;

图9为一实施例提供的清洗装置中第四侧吸组件的分解结构示意图;9 is a schematic diagram of an exploded structure of a fourth side suction assembly in a cleaning device provided by an embodiment;

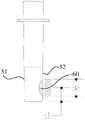

图10为一实施例提供的清洗装置中底吸组件的分解结构示意图;10 is a schematic diagram of an exploded structure of a bottom suction assembly in a cleaning device provided by an embodiment;

图11为装有磁珠复合物的反应杯的结构示意图;Figure 11 is a schematic structural diagram of a cuvette containing a magnetic bead complex;

图12为反应杯对应第一侧吸组件的首端时磁珠复合物的吸附状态示意图;12 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the head end of the first side suction component;

图13为反应杯对应第一侧吸组件的尾端时磁珠复合物的吸附状态示意图;13 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the tail end of the first side suction component;

图14为反应杯对应第二侧吸组件的首端时磁珠复合物的吸附状态示意图;14 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the head end of the second side suction component;

图15为反应杯对应第二侧吸组件的尾端时磁珠复合物的吸附状态示意图;15 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the tail end of the second side suction component;

图16为反应杯对应第三侧吸组件的首端时磁珠复合物的吸附状态示意图;16 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the head end of the third side suction component;

图17为反应杯对应第三侧吸组件的尾端时磁珠复合物的吸附状态示意图;17 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the tail end of the third side suction component;

图18为反应杯对应第四侧吸组件的首端时磁珠复合物的吸附状态示意图;18 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the head end of the fourth side suction component;

图19为反应杯对应第四侧吸组件的中端时磁珠复合物的吸附状态示意图;19 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the middle end of the fourth side suction component;

图20为反应杯对应第四侧吸组件的尾端时磁珠复合物的吸附状态示意图;20 is a schematic diagram of the adsorption state of the magnetic bead composite when the cuvette corresponds to the tail end of the fourth side suction component;

图21为反应杯对应底吸组件时磁珠复合物的吸附状态示意图;Figure 21 is a schematic diagram of the adsorption state of the magnetic bead complex when the cuvette corresponds to the bottom suction component;

图22为一实施例提供的清洗装置中主清洗机构的结构示意图;22 is a schematic structural diagram of a main cleaning mechanism in a cleaning device provided by an embodiment;

图23为一实施例提供的清洗装置中第一种主清洗组件的结构示意图;23 is a schematic structural diagram of a first main cleaning assembly in a cleaning device provided by an embodiment;

图24为图23的剖视结构示意图;Figure 24 is a schematic cross-sectional structure diagram of Figure 23;

图25为一实施例提供的清洗装置中第二种主清洗组件的结构示意图;25 is a schematic structural diagram of a second type of main cleaning assembly in a cleaning device provided by an embodiment;

图26为一实施例提供的清洗装置中第三种主清洗组件的剖视结构示意图;26 is a schematic cross-sectional structural diagram of a third type of main cleaning assembly in the cleaning device provided by an embodiment;

图27为图26的立体结构示意图;Fig. 27 is the three-dimensional schematic diagram of Fig. 26;

图28为一实施例提供的清洗装置中副清洗机构的结构示意图;28 is a schematic structural diagram of a secondary cleaning mechanism in a cleaning device provided by an embodiment;

图29为一实施例提供的清洗装置中管夹的立体结构示意图;29 is a schematic three-dimensional structural diagram of a pipe clamp in a cleaning device provided by an embodiment;

图30为一实施例提供的清洗装置中管夹的平面结构示意图;30 is a schematic plan view of a pipe clamp in a cleaning device provided by an embodiment;

图31为以实施例提供的清洗方法的流程框图。FIG. 31 is a flowchart of a cleaning method provided by an embodiment.

具体实施方式Detailed ways

为了便于理解本发明,下面将参照相关附图对本发明进行更全面的描述。附图中给出了本发明的较佳实施方式。但是,本发明可以以许多不同的形式来实现,并不限于本文所描述的实施方式。相反地,提供这些实施方式的目的是使对本发明的公开内容理解的更加透彻全面。In order to facilitate understanding of the present invention, the present invention will be described more fully hereinafter with reference to the related drawings. The preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention may be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that a thorough and complete understanding of the present disclosure is provided.

需要说明的是,当元件被称为“固定于”另一个元件,它可以直接在另一个元件上或者也可以存在居中的元件。当一个元件被认为是“连接”另一个元件,它可以是直接连接到另一个元件或者可能同时存在居中元件。本文所使用的术语“内”、“外”、“左”、“右”以及类似的表述只是为了说明的目的,并不表示是唯一的实施方式。It should be noted that when an element is referred to as being "fixed to" another element, it can be directly on the other element or intervening elements may also be present. When an element is referred to as being "connected" to another element, it can be directly connected to the other element or intervening elements may also be present. The terms "inner", "outer", "left", "right" and similar expressions used herein are for the purpose of illustration only and do not represent the only embodiment.

参阅图1,图12和图14,一种清洗装置,用于清洗反应杯50中的磁珠复合物60,该清洗装置包括转盘40、主清洗机构20、副清洗机构30和磁珠复合物吸附机构10。转盘40、主清洗机构20和副清洗机构30均安装在磁珠复合物吸附机构10上。多个反应杯50均匀间隔的承载在转盘40的外周上,当转盘40转动时,反应杯50绕转盘40的中心轴线做公转运动,在磁珠复合物吸附机构10的作用下,磁珠复合物60多次交替吸附在反应杯50上相对设置的第一内侧面51和第二内侧面52上,主清洗机构20可以注入清洗液,清洗液将对在第一内侧面51和第二内侧面52之间来回泳动的磁珠复合物60进行清洗,当然,以一定速度注入的清洗液同样将对磁珠复合物60进行清洗。Referring to FIG. 1, FIG. 12 and FIG. 14, a cleaning device is used for cleaning the

同时参阅图1至图4,在一些实施例中,磁珠复合物吸附机构10包括底座12和多个侧吸组件11。底座12上设置有输入工位14和主输出工位15,反应杯50从输入工位14进入磁珠复合物吸附机构10,绕中心轴线公转一定角度后从主输出工位15输送至测量室进行下一步检测。沿反应杯50的公转方向,多个侧吸组件11环绕转盘40的中心轴线设置,并位于输入工位14与主输出工位15之间,多个侧吸组件11交替设置于反应杯50的公转轨迹的内侧和外侧,相邻两个侧吸组件11沿转盘40的径向相互间隔一定的距离(换句话说,相邻两个侧吸组件11与反应杯公转中心轴线的径向距离不同),以形成供反应杯50运行的通道,多个侧吸组件11的磁吸面朝向反应杯50的公转轨迹。相邻两个侧吸组件11沿反应杯50的公转轨迹的周向相互间隔一定的距离。当反应杯50公转时,多个侧吸组件11使得磁珠复合物60交替吸附在反应杯50的第一内侧面51和第二内侧面52上。Referring to FIGS. 1 to 4 at the same time, in some embodiments, the magnetic bead

参阅图1和图2,在其它实施例中,磁珠复合物吸附机构10包括底座12、底吸组件115和多个侧吸组件11。底座12上设置有输入工位14、主输出工位15和副输出工位16,副输出工位16处于输入工位14与主输出工位15之间。沿反应杯50的公转方向,多个侧吸组件11环绕转盘40的中心轴线设置,并位于输入工位14与主输出工位15之间,相邻两个侧吸组件11沿转盘40的径向相互间隔一定的距离,以形成供反应杯50运行的通道。沿反应杯50的公转方向,底吸组件115位于主输出工位15和副输出工位16之间。反应杯50从输入工位14进入磁珠复合物吸附机构10后,有三种运动模式:①反应杯50绕中心轴线公转(小于一周)并第一次抵达主输出工位15,并从主输出工位15输出至测量室进行下一步检测;②反应杯50绕中心轴线公转(小于一周),经主输出工位15并第一次抵达副输出工位16,并从副输出工位16输出至反应盘以进行第二次加样;③反应杯50绕中心轴线公转若干周,最后从主输出工位15输出至测量室。Referring to FIGS. 1 and 2 , in other embodiments, the magnetic bead

参阅图2至图4,多个侧吸组件11沿反应杯50公转方向依次首尾相对设置(即依次交错排列在一段优弧的两侧),侧吸组件11包括安装体105和若干磁性体104,安装体105大致呈圆弧状,安装体105上设置有圆弧形安装面101a(为竖直面),圆弧形安装面101a的轴线与转盘40的中心轴线重合,圆弧形安装面101a上安装有若干磁性体104,该磁性体104用于对反应杯50中的磁珠复合物60产生吸附力。沿反应杯50公转方向,对于从输入工位14依次排列至主输出工位15之间的任意相邻两个侧吸组件11,该两个侧吸组件11的圆弧形安装面101a分别位于反应杯运动轨迹54的异侧,并且两个圆弧形安装面101a相对中心轴线的朝向相反。换言之,一个圆弧形安装面101a(凹面)位于反应杯50转动轨迹的外侧并面对中心轴线,另一圆弧形安装面101a(凸面)则位于反应杯50转动轨迹的内侧并背向中心轴线。Referring to FIGS. 2 to 4 , a plurality of side suction assemblies 11 are arranged in turn opposite to each other along the revolution direction of the cuvette 50 (that is, they are arranged staggered on both sides of a segment of the arc), and the side suction assemblies 11 include a mounting

参阅图2至图4,侧吸组件11的数量为四个,当然,根据实际情况需要,侧吸组件11的数量可以做适当增减,例如三个或五个等。四个侧吸组件11包括第一侧吸组件111、第二侧吸组件112、第三侧吸组件113和第四侧吸组件114,四者沿反应杯50公转方向依次排列。以反应杯50公转方向(逆时针)为参考,第一侧吸组件111与输入工位14对应的一端为首端,其另一端为尾端,依次类推,第二侧吸组件112与第一侧吸组件111尾端对应的一端为首端,其另一端为尾端,第四侧吸组件114的尾端与主输出工位15对应。第一侧吸组件111位于反应杯运动轨迹54的外侧,即第一侧吸组件111上的圆弧形安装面101a为凹面,并面向中心轴线。根据相邻两个侧吸组件11的排布规律,第二侧吸组件112的圆弧形安装面101a(凸面)背向中心轴线,第三侧吸组件113的圆弧形安装面101a(凹面)面向中心轴线,第四侧吸组件114的圆弧形安装面101a(凸面)背向中心轴线。2 to 4 , the number of side suction components 11 is four. Of course, the number of side suction components 11 can be appropriately increased or decreased according to actual needs, such as three or five. The four side suction assemblies 11 include a first

参阅图2、图5、图10和图21,对于设置有底吸组件115的磁珠复合物吸附机构10,底吸组件115的数量为一个,侧吸组件11的数量同样为四个,底吸组件115的首端与第四侧吸组件114的尾端相对,底吸组件115的尾端与副输出工位16对应,底吸组件115同样可以包括安装体105和磁性体104,磁性体104安装在安装体105的圆弧形安装面101a(为水平面)上。因此,侧吸组件11的圆弧形安装面101a(竖直面)环绕反应杯50的侧壁,可以将磁珠复合物60吸附在反应杯50的第一内侧面51或者第二内侧面52上;底吸组件115的圆弧形安装面101a(水平面)位于反应杯50的底壁的正下方,可以将磁珠复合物60吸附在反应杯50的底面53上。Referring to FIGS. 2 , 5 , 10 and 21 , for the magnetic bead

第一侧吸组件111与第三侧吸组件113上的圆弧形安装面101a到中心轴线的距离相等,第二侧吸组件112与第四侧吸组件114上的圆弧形安装面101a到中心轴线的距离相等。The distances from the arc-shaped

参阅图5,安装体105包括固定座101和插装板102,固定座101的顶壁上开设有第一安装槽101b,第一安装槽101b沿圆弧形安装面101a的周向延伸,即第一安装槽101b的内侧面与圆弧形安装面101a平行设置。圆弧形安装面101a开设有若干安装孔103,该安装孔103与第一安装槽101b连通,当然,安装孔103的中心线可以垂直圆弧形安装面101a。插装板102与第一安装槽101b配合,即插装板102插置在第一安装槽101b中,磁性体104容置在安装孔103中,磁性体104的一端与插装板102的侧壁连接。Referring to FIG. 5 , the mounting

参阅图5至图7,固定座101上还可以开设第二安装槽101c,第二安装槽101c设置在固定座101上与圆弧形安装面101a相对的侧面上,第二安装槽101c沿圆弧形安装面101a的轴向延伸(竖直设置),第二安装槽101c与第一安装槽101b连通。例如,沿固定座101的周向,第二安装槽101c到固定座101的两端的距离相等,即第二安装槽101c位于固定座101的正中间,当然,第二安装槽101c也可以偏离固定座101的正中间位置。插装板102的侧壁上设置有竖直的限位凸条102a,限位凸条102a与第二安装槽101c配合。当插装板102安装在固定座101上时,通过螺栓将限位凸条102a固定在固定座101上。Referring to FIGS. 5 to 7 , a

侧吸组件11安装时,首先,将插装板102放置在第一安装槽101b中,并使限位凸条102a与第二安装槽101c配合,然后,将磁性体104放入安装孔103中,并使磁性体104的端部吸附在插装板102上,同时,将限位凸条102a与固定座101螺栓连接。最后,在安装孔103注入胶水,使磁性体104与固定座101和插装板102连接固定。When installing the side suction assembly 11 , first, place the plug-in

安装孔103的截面形状可以为圆周形(中心角为360°)、半圆弧形(中心角为180°)或优弧形(中心角为位于180°与360°之间),即安装孔103可以为圆孔、半圆孔或优弧孔。安装孔103包括若干对第一通孔103a和若干对第三通孔103c,第一通孔103a与反应杯50的转入方向对应(即靠近侧吸组件11的首端),第三通孔103c与反应杯50的转出方向对应(即靠近侧吸组件11的尾端)。磁性体104包括第一磁铁104a和第三磁铁104c,第一磁铁104a位于第一通孔103a中,第三磁铁104c位于第三通孔103c中。其中,任意一对第一通孔103a中的两个第一磁铁104a之间的磁吸面积(对应磁场的有效辐射范围)为D1,任意一对第三通孔103c中的两个第三磁铁104c之间的磁吸面积(对应磁场的有效辐射范围)为D3,D1>D3。因此,当反应杯50对应从每一个侧吸组件11的首端公转至尾端时,由于D1>D3,磁吸面积的减少且磁铁磁力足够,使得磁珠复合物60聚集的更加紧密(磁珠复合物60的总量保持不变),进而使磁珠复合物60在反应杯50上的吸附面积减少,同时,反应杯50运动至对应侧吸组件11的尾端时,必须对其进行抽废液处理,由于磁珠复合物60吸附面积的减少,磁珠复合物60在反应杯50上更加紧密聚集,可以避免磁珠复合物60跟随废液被抽走,防止磁珠复合物60损失。The cross-sectional shape of the mounting

安装孔103还可以包括若干对第二通孔103b,第二通孔103b位于第一通孔103a和第三通孔103c之间,磁性体104还包括第二磁铁104b,第二磁铁104b安装在第二通孔103b中。其中,任意一对第二通孔103b中的两个第二磁铁104b之间的磁吸面积为D2,D1>D2>D3。The mounting

同一侧吸组件11上的若干安装孔103到底座12的距离相等,也可以不相等。不同侧吸组件11上的若干安装孔103相对底座12的距离不相等,也可以相等。对于同一侧吸组件11,沿其首端至尾端,安装孔103相对底座12的距离逐渐减小时,磁性体104相对底座12的距离减小,当反应杯50对应首端公转至尾端时,磁珠复合物60在反应杯50上的吸附位置越靠近反应杯50的底面53,实现磁珠复合物60吸附位置下拉的效果。The distances from the mounting

在一实施例(实施例1)中,参阅图5,图11至图13,例如:第一侧吸组件111上设置有三对第一通孔103a和两对第三通孔103c,第一通孔103a为圆孔,第三通孔103c为半圆孔,对应的,第一磁铁104a为圆柱形,第三磁铁104c为半圆柱形。圆孔与半圆孔的半径相等,一对第一通孔103a之间的间距大于一对半圆孔之间的间距,因此,一对第一磁铁104a之间的磁吸面积大于一对第三磁铁104c之间的磁吸面积。第一通孔103a和第三通孔103c到底座12的距离均相等(即在圆弧形安装面101a上的高度相等)。因此,当反应杯50对应从第一侧吸组件111的首端公转至尾端时,磁珠复合物60在反应杯50上对应的磁性体104的有效高度d1(对应磁吸面积D1)减少至d2(对应磁吸面积D3),即由分散聚拢(对应第一聚拢状态)变为半紧密聚拢(对应第二聚拢状态);同时,磁珠复合物60在反应杯50上的吸附位置的中心(对应磁性体中心高度t1)相对其底面53的距离保持不变。In an embodiment (Embodiment 1), referring to FIG. 5, FIG. 11 to FIG. 13, for example: the first

参阅图6,图14和图15,第二侧吸组件112的结构与第一侧吸组件111的结构大致相同,第二侧吸组件112上安装孔103相对底座12的距离等于第一侧吸组件111中安装孔103相对底座12的距离,第二侧吸组件112同样设置有三对圆形的第一通孔103a和两对半圆形的第三通孔103c。圆孔与半圆孔的半径相等,一对第一通孔103a之间的间距大于一对半圆孔之间的间距,当反应杯50对应从第二侧吸组件112的首端公转至尾端时,磁珠复合物60在反应杯50上的有效高度d1(对应磁吸面积D1)减少至d2(对应磁吸面积D3),即由分散聚拢(对应第一聚拢状态)变为半紧密聚拢(对应第二聚拢状态);同时,磁珠复合物60在反应杯50上的吸附位置的中心(对应磁性体中心高度t1)相对其底面53的距离保持不变。6, 14 and 15, the structure of the second

参阅图7和图8,图16和图17,第三侧吸组件113上第一通孔103a相对底座12的距离等于第二侧吸组件112中安装孔103相对底座12的距离,同时,从第三侧吸组件113的首端至尾端,安装孔103相对底座12的距离逐渐降低。第三侧吸组件113上设置有三对圆形的第一通孔103a和两对半圆形的第三通孔103c,圆孔与半圆孔的半径相等,一对第一通孔103a之间的间距大于一对半圆孔之间的间距,当反应杯50对应从第三侧吸组件113的首端公转至尾端时,磁珠复合物60在反应杯50上对应的磁性体104的有效高度d1(对应磁吸面积D1)减少至d2(对应磁吸面积D3),即由分散聚拢(对应第一聚拢状态)变为半紧密聚拢(对应第二聚拢状态);同时,磁性体中心高度t1减少至t2,磁性体104所产生磁性力的作用位置相对底面53的距离减少,因此,磁珠复合物60在反应杯50上的吸附位置的中心相对其底面53的距离同样减少,即将磁珠复合物60相对底面53往下拉近一定的距离。7, 8, 16 and 17, the distance between the first through

参阅图9,图18至图20,第四侧吸组件114上安装孔103相对底座12的距离等于第三侧吸组件113中安装孔103相对底座12的最小距离,同时,各安装孔103相对底座12的距离相等。第四侧吸组件114上设置有一对圆形的第一通孔103a、三对半圆形的第二通孔103b和三对优弧形的第三通孔103c。第一通孔103a与第二通孔103b的半径相等,第三通孔103c的半径小于第二通孔103b的半径,第一通孔103a的横截面面积最大,第二通孔103b的横截面面积次之,第三通孔103c的横截面面积最小;同时,磁性体104均为与安装孔103相适配的条形磁铁,第一磁铁104a的体积最大,第二磁铁104b的体积次之,第三磁铁104c的体积最小。因此,位于第一通孔103a中的两个第一磁铁104a的磁吸面积最大(为D1),位于第二通孔103b中的两个第二磁铁104b的磁吸面积次之(为D2),位于第三通孔103c中的两个第三磁铁104c的磁吸面积最小(为D3)。当反应杯50对应从第四侧吸组件114的首端公转至尾端时,磁珠复合物60在反应杯50上对应的磁性体104的有效高度d1(对应磁吸面积D1)减少至d2(对应磁吸面积D2)、最后减少至d3(对应磁吸面积D3),即首先由分散聚拢(对应第一聚拢状态)变为半紧密聚拢(对应第二聚拢状态),最后有半紧密聚拢(对应第二聚拢状态)变为全紧密聚拢(对应第三聚拢状态);同时,磁珠复合物60在反应杯50上的吸附位置的中心(对应磁性体中心高度t2)相对其底面53的距离保持不变。9, 18 to 20, the distance between the mounting

因此,对于上述实例1,在第一侧吸组件111中、第二侧吸组件112和第三侧吸组件113中,第一通孔103a(圆形)的数量均为三对,第三通孔103c(半圆形)的数量均为两对;在第四侧吸组件114中,第一通孔103a(圆形)的数量为一对,第二通孔103b(半圆形)的数量为三对,第三通孔103c(优弧形)的数量为三对。Therefore, for the above example 1, in the first

当然,还存在实施例2,对于该实施例,在第一侧吸组件111、第二侧吸组件112和第三侧吸组件113中,第一通孔103a(圆形)的数量均为三个,第二通孔103b(半圆形)的数量均为两对,第三通孔103c(优弧形)的数量均为三对。在第四侧吸组件114中,第一通孔103a(圆形)的数量为一对,第二通孔103b(半圆形)的数量为三对,第三通孔103c(优弧形)的数量均三对。第一通孔的半径最大,第二通孔103b的半径次之,第三通孔103c的半径最小Of course, there is also

还存在实施例3,对于该实施例,在第一侧吸组件111中,第一通孔103a(圆形)的数量为一个,第二通孔103b(半圆形)的数量为一对,第三通孔103c(优弧形)的数量为六对;在第二侧吸组件112和第三侧吸组件113中,第二通孔103b(半圆形)的数量均为两对,第三通孔103c(优弧形)的数量均为六对,在第四侧吸组件114中,第一通孔103a(圆形)的数量为三个,第二通孔103b(半圆形)的数量为三对,第三通孔103c(优弧形)的数量为两对。第一通孔103a的半径最大,第二通孔103b的半径次之,第三通孔103c的半径最小。There is also

为描述方便起见,实施1记为W1,实施例2记为W2,实施例3记为W3,当然,还存在另外五个实施例,分别记为W4,W5,W6,W7和W8。For the convenience of description,

在W4中,每个侧吸组件11上均设置四个第一通孔103a(圆形)和四对第三通孔103c(半圆形)。在W5中,每个侧吸组件11均设置四对第一通孔103a(半圆形)和四个第三通孔103c(圆形)。在W6中,每个侧吸组件11上均设置八个第一通孔103a(圆形)。在W7中,每个侧吸组件11上均设置八对第二通孔103b(半圆形),在W8中,每个侧吸组件11上均设置八对第三通孔103c(优弧形)。In W4, each side suction assembly 11 is provided with four first through

对于上述八个实施例,在后续磁珠复合物的清洗完毕后,分别从分析灵敏度(空白限)结果、测试准确度和非特异性吸附三个角度对其效果进行评估。For the above eight examples, after the subsequent cleaning of the magnetic bead complex, its effects were evaluated from three perspectives of analytical sensitivity (blank limit) results, test accuracy and non-specific adsorption.

1、对于分析灵敏度(空白限)结果检测:1. For the detection of analytical sensitivity (blank limit) results:

a)测试样本:美国Scantibodies公司的去激素的人血清(确定不含HBsAg、Anti-HCV、Anti-HIV I和Anti-HIV II)。a) Test sample: Dehormone human serum from Scantibodies, USA (determined to be free of HBsAg, Anti-HCV, Anti-HIV I and Anti-HIV II).

b)检测的试剂盒为新产业生物医学工程股份有限公司自制的HBsAg试剂盒,本试剂的阴性参考区间为<1.0index/mL,试剂盒检测范围为0-10000index/mL。b) The detection kit is the HBsAg kit made by New Industry Biomedical Engineering Co., Ltd. The negative reference interval of this reagent is <1.0 index/mL, and the detection range of the kit is 0-10000 index/mL.

c)新产业生物医学工程股份有限公司的HBsAg试剂盒检测具体包括以下步骤:c) The detection of HBsAg kit by New Industry Biomedical Engineering Co., Ltd. specifically includes the following steps:

1)一次加样:100μL测试样本、100μL缓冲液和20μL的磁性微球体系混合,温育20min,形成复合物;1) One-time sample addition: 100 μL of test sample, 100 μL of buffer and 20 μL of magnetic microsphere system were mixed, and incubated for 20 min to form a complex;

2)清洗:外加磁场将上述反应产物沉淀,去除上清液,并以缓冲液清洗;2) Cleaning: the above-mentioned reaction product is precipitated by an external magnetic field, the supernatant is removed, and washed with a buffer;

3)二次加样:将ABEI标记物体系加入上述沉淀中,混合均匀,温育20min。3) Secondary sample addition: Add the ABEI marker system to the above-mentioned precipitation, mix well, and incubate for 20 min.

4)检测:外加磁场将上述复合物沉淀,去除上清液,清洗后,加入发光底物,检测发出的相对光强度,计算得到HBsAg的含量。4) Detection: the above-mentioned complexes are precipitated by an external magnetic field, the supernatant is removed, and after washing, a luminescent substrate is added, and the relative light intensity emitted is detected, and the content of HBsAg is calculated.

发光信号强度采用全自动化学发光仪对测试样本进行测定。重复测定待测样本20次,并计算20次测量结果的平均值M和标准差SD,M+2SD的值即为分析灵敏度(空白限),(由于去激素人血清确认不含HBsAg,所以空白限越低,则分析灵敏度越高)。The intensity of the luminescent signal was measured by an automatic chemiluminescence instrument. Repeat the measurement of the sample to be tested 20 times, and calculate the mean value M and standard deviation SD of the 20 measurement results. The value of M+2SD is the analytical sensitivity (blank limit), (because the hormone-free human serum is confirmed to be free of HBsAg, so the blank The lower the limit, the higher the analytical sensitivity).

检测结果参阅下表1:The test results are shown in Table 1 below:

表1分析灵敏度(空白限)测定结果Table 1 Analysis Sensitivity (Blank Limit) Measurement Results

表1中数据的单位index/mL为公司产品自定义的单位,与WHO单位换算关系为1index/mL=0.1IU/mL。The unit index/mL of the data in Table 1 is the self-defined unit of the company's products, and the conversion relationship with the WHO unit is 1index/mL=0.1IU/mL.

由表1可以看出,W1对应的空白限计算结果为0.078index/mL,远小于其它实施例,且远低于试剂盒设定的截断值1.0index/mL,这是因为W1采用的扩散聚拢的清洗模式和内外交错式的结构实现往复搅拌混匀的作用,有效减少了非特异性的吸附,因此其分析灵敏度得到了显著提高。It can be seen from Table 1 that the calculated result of the blank limit corresponding to W1 is 0.078 index/mL, which is much smaller than that of other examples, and is much lower than the cut-off value of 1.0 index/mL set by the kit. This is because the diffusion aggregation adopted by W1 The cleaning mode and the internal and external staggered structure realize the effect of reciprocating stirring and mixing, which effectively reduces non-specific adsorption, so its analytical sensitivity has been significantly improved.

2、对于HBsAg国家参考品测定结果:2. For the determination results of HBsAg national reference materials:

a)测试样本:中国食品药品检定研究院制备的乙型肝炎病毒表面抗原(HBsAg)的国家参考品(300003-201002),其组成为:a) Test sample: National reference substance (300003-201002) of hepatitis B virus surface antigen (HBsAg) prepared by China National Institute for Food and Drug Control, which consists of:

1)阴性参考品20份,0.5mL/支。1) 20 negative reference products, 0.5mL/piece.

2)阳性参考品3份,0.5mL/支。2) 3 copies of positive reference products, 0.5mL/piece.

3)灵敏度参考品:9份,0.5mL/支。3) Sensitivity reference product: 9 copies, 0.5mL/piece.

adr亚型:adr-1(0.05IU/mL)、adr-2(0.1IU/mL)、adr-3(0.2IU/mL),各1支,0.5mL/支adr subtypes: adr-1 (0.05IU/mL), adr-2 (0.1IU/mL), adr-3 (0.2IU/mL), 1 each, 0.5mL/piece

adw亚型:adw-1(0.05IU/mL)、adw-2(0.1IU/mL)、adw-3(0.2IU/mL),各1支,0.5mL/支adw subtypes: adw-1 (0.05IU/mL), adw-2 (0.1IU/mL), adw-3 (0.2IU/mL), 1 each, 0.5mL/piece

ay亚型:ay-1(0.1IU/mL)、ay-2(0.2IU/mL)、ay-3(0.4IU/mL),各1支,0.5mL/支ay subtypes: ay-1 (0.1IU/mL), ay-2 (0.2IU/mL), ay-3 (0.4IU/mL), 1 each, 0.5mL/piece

b)新产业生物医学工程股份有限公司自制的HBsAg试剂盒,本试剂的阴性参考区间为<1.0index/mL,试剂盒检测范围为0-10000index/mL。b) The HBsAg kit made by New Industry Biomedical Engineering Co., Ltd. The negative reference interval of this reagent is <1.0 index/mL, and the detection range of the kit is 0-10000 index/mL.

c)新产业生物医学工程股份有限公司的HBsAg试剂盒检测具体包括以下步骤:c) The detection of HBsAg kit by New Industry Biomedical Engineering Co., Ltd. specifically includes the following steps:

1)一次加样:100μL测试样本、100μL缓冲液和20μL的磁性微球体系混合,温育20min,形成复合物;1) One-time sample addition: 100 μL of test sample, 100 μL of buffer and 20 μL of magnetic microsphere system were mixed, and incubated for 20 min to form a complex;

2)清洗:外加磁场将上述反应产物沉淀,去除上清液,并以缓冲液清洗;2) Cleaning: the above-mentioned reaction product is precipitated by an external magnetic field, the supernatant is removed, and washed with a buffer;

3)二次加样:将ABEI标记物体系加入上述沉淀中,混合均匀,温育20min。3) Secondary sample addition: Add the ABEI marker system to the above-mentioned precipitation, mix well, and incubate for 20 min.

4)检测:外加磁场将上述复合物沉淀,去除上清液,清洗后,加入发光底物,检测发出的相对光强度,计算得到HBsAg的含量。4) Detection: the above-mentioned complexes are precipitated by an external magnetic field, the supernatant is removed, and after washing, a luminescent substrate is added, and the relative light intensity emitted is detected, and the content of HBsAg is calculated.

发光信号强度采用全自动化学发光仪对测试样本进行测定,检测结果如表2所示。The luminescence signal intensity was measured by an automatic chemiluminescence instrument, and the detection results are shown in Table 2.

表2HBsAg国家参考品测定结果。Table 2 HBsAg national reference test results.

表2中数据单位为index/mL,为公司产品自定义的单位,与WHO单位换算关系为1index/mL=0.1IU/mLThe data unit in Table 2 is index/mL, which is a customized unit of the company's products, and the conversion relationship with the WHO unit is 1index/mL=0.1IU/mL

HBsAg国家参考品的检测标准为:阴性国家参考品(N1-N10)结果符合率达到20/20,阳性国家参考品(P1-P3)结果符合率达到3/3,adr亚型灵敏度参考品、adw亚型灵敏度参考品、ay亚型灵敏度参考品的最低检出限分别0.1IU/mL、0.1IU/mL、0.2IU/mL。The detection standards of HBsAg national reference products are: the coincidence rate of negative national reference products (N1-N10) results is 20/20, the coincidence rate of positive national reference products (P1-P3) results is 3/3, adr subtype sensitivity reference products, The minimum detection limits of the adw subtype sensitivity reference material and the ay subtype sensitivity reference material were 0.1IU/mL, 0.1IU/mL, and 0.2IU/mL, respectively.

结合表2,在W1至W7对应的结果中,阴性国家参考品符合率达到20/20,清洗站W8对应的阴性国家参考品符合率为19/20,因清洗效果的不同导致的非特意吸附使得W2~W8的表观HBsAg测定浓度略大于W1。清洗站W1~W8中3份阳性参考品的符合率均为3/3,且对高浓度阳性参考品不存在HOOK效应。清洗站W1中三种亚型参考品的灵敏度最低检出量分别为adr 0.1IU/mL、adw 0.05IU/mL、ay 0.1IU/mL,检测结果均达到国家标准,其对adw和ay的灵敏度甚至优于国家标准。由此可见,W1~W8通过不同的清洗方式使得对消除非特异吸附的影响程度不同,W1的准确度和灵敏度最优。Combined with Table 2, in the results corresponding to W1 to W7, the conformity rate of the negative country reference product reached 20/20, and the conformity rate of the negative country reference product corresponding to the cleaning station W8 was 19/20. Unintentional adsorption caused by different cleaning effects The apparent HBsAg measured concentrations of W2-W8 were slightly higher than that of W1. The coincidence rates of the three positive reference products in the cleaning stations W1-W8 were all 3/3, and there was no HOOK effect on the high-concentration positive reference products. The lowest sensitivity detection levels of the three subtype reference materials in the cleaning station W1 are adr 0.1IU/mL, adw 0.05IU/mL, ay 0.1IU/mL, and the detection results all meet the national standards, and their sensitivity to adw and ay Even better than the national standard. It can be seen that W1-W8 have different effects on eliminating non-specific adsorption through different cleaning methods, and W1 has the best accuracy and sensitivity.

3、对于临床样本HBsAg浓度测定结果:3. For the determination of HBsAg concentration in clinical samples:

a)测试样本:经过临床验证确认的阴性和阳性血各10例共20例。并分别采取这20个样本的血清和血浆进行测定HBsAg浓度测定。a) Test samples: 10 cases of negative and 10 positive blood confirmed by clinical verification, a total of 20 cases. The serum and plasma of these 20 samples were taken to determine the HBsAg concentration.

b)使用深圳市新产业生物医学工程股份有限公司提供乙肝表面抗原(HBsAg)测定试剂盒,本试剂的阴性参考区间为<1.0index/mL,试剂盒检测范围为0-10000index/mL。b) Use the Hepatitis B Surface Antigen (HBsAg) assay kit provided by Shenzhen New Industry Biomedical Engineering Co., Ltd. The negative reference interval of this reagent is <1.0index/mL, and the detection range of the kit is 0-10000index/mL.

c)新产业生物医学工程股份有限公司的HBsAg试剂盒检测具体包括以下步骤:c) The detection of HBsAg kit by New Industry Biomedical Engineering Co., Ltd. specifically includes the following steps:

1)一次加样:100μL测试样本、100μL缓冲液和20μL的磁性微球体系混合,温育20min,形成复合物;1) One-time sample addition: 100 μL of test sample, 100 μL of buffer and 20 μL of magnetic microsphere system were mixed, and incubated for 20 min to form a complex;

2)清洗:外加磁场将上述反应产物沉淀,去除上清液,并以缓冲液清洗;2) Cleaning: the above-mentioned reaction product is precipitated by an external magnetic field, the supernatant is removed, and washed with a buffer;

3)二次加样:将ABEI标记物体系加入上述沉淀中,混合均匀,温育20min。3) Secondary sample addition: Add the ABEI marker system to the above-mentioned precipitation, mix well, and incubate for 20 min.

4)检测:外加磁场将上述复合物沉淀,去除上清液,清洗后,加入发光底物,检测发出的相对光强度,计算得到HBsAg的含量。4) Detection: the above-mentioned complexes are precipitated by an external magnetic field, the supernatant is removed, and after washing, a luminescent substrate is added, and the relative light intensity emitted is detected, and the content of HBsAg is calculated.

发光信号强度采用全自动化学发光仪对测试样本进行测定,检测结果如表3所示。The luminescence signal intensity was measured by an automatic chemiluminescence instrument, and the detection results are shown in Table 3.

检测结果参阅下表3:The test results are shown in Table 3 below:

表3临床样本HBsAg浓度测定结果Table 3 Results of the determination of HBsAg concentration in clinical samples

表3中数据单位为index/mL。为公司产品自定义的单位,与WHO单位换算关系为1index/mL=0.1IU/mLThe unit of data in Table 3 is index/mL. The unit customized for the company's products, and the conversion relationship with the WHO unit is 1index/mL=0.1IU/mL

由表3可以看出:W2~W8对应的同一样本的血浆表观HBsAg浓度往往不同程度地大于血清中测定的浓度,这是由于于血浆当中的纤维蛋白等物质的干扰造成的,而W1因为采用了最优的扩散聚拢的清洗模式和内外交错式的结构方案实现往复搅拌混匀的作用,有效地改善了纤维蛋白絮状物对检测的干扰,使得W1中的血浆和血清测定的HBsAg浓度的一致性优于W2~W8的一致性。并且通过一致性的差异可以看出W8至W1呈现越来越优化的清洗效果。It can be seen from Table 3 that the plasma apparent HBsAg concentration of the same sample corresponding to W2 to W8 is often greater than the concentration measured in serum to varying degrees, which is caused by the interference of fibrin and other substances in the plasma, while W1 is due to the interference of fibrin and other substances in the plasma. The optimal cleaning mode of diffusion and gathering and the internal and external staggered structure scheme are adopted to realize the effect of reciprocating stirring and mixing, which effectively improves the interference of fibrin flocs on the detection, and makes the HBsAg concentration in plasma and serum determined in W1. The consistency is better than that of W2-W8. And through the difference in consistency, it can be seen that W8 to W1 present more and more optimized cleaning effects.

综上,W1的清洗效果最好,能有效降低非特异,提高试剂检测灵敏度和准确性。In conclusion, W1 has the best cleaning effect, which can effectively reduce non-specificity and improve the sensitivity and accuracy of reagent detection.

参阅图2和图3,磁珠复合物吸附机构10还可以包括多个圆弧形定位块116,圆弧形定位块116固定在底座12上,多个圆弧形定位块116沿反应杯50转动方向依次首尾相对设置,圆弧形定位块116与侧吸组件11相对反应杯50公转圆周的径向一一对应。相互对应的圆弧形定位块116与侧吸组件11分居反应杯运动轨迹54的异侧,两者围设成供反应杯50运行的通道。当反应杯50被公转时,圆弧形定位块116可以对反应杯50起到限位作用,防止其晃动,从而规范反应杯50的运动轨迹54,确保侧吸组件11对磁珠复合物60的吸附效果。圆弧形定位块116的端部可以与侧吸组件11连接为一体,也可以不连接。2 and 3 , the magnetic bead

参阅图1至图5,底座12包括垫板123、底板121和支撑柱122。底板121与垫板123相对设置,底板121位于垫板123的正上方,支撑柱122的上端与底板121连接,支撑柱122的下端与垫板123连接。侧吸组件11,底吸组件115和圆弧形定位块116均固定在底板121上。当然,底座12还可以包括检测光耦13,检测光耦13安装在底板121上,检测光耦13用于检测转盘40上是否有反应杯50(即空杯检测)。检测光耦13根据反射光强度确定是否有空杯现象,当反射光强度很低或几乎没有时,表明转盘40上出现空位,该位置处没有反应杯50,如果反射光强度较高,说明该位置处存在反应杯50。还可以根据主清洗机构20或副清洗机构30上的抽液针244来确定是否存在空杯现象,例如,如果抽液针244下行到一定位置时,抽液针244的电阻没有产生变化,说明该位置出现空杯,如果电阻有明显变化,则说明抽液针244已接触到反应杯50中的液体,说明此处存在反应杯50。Referring to FIGS. 1 to 5 , the base 12 includes a backing plate 123 , a

转盘40与底座12上的底板121转动连接,主清洗机构20和副清洗机构30均固定安装在底座12上,转盘40位于磁珠复合物吸附机构10的正上方,反应杯50的下端与侧吸组件11和底吸组件115相对应。副清洗机构30与主输出工位15相邻,主清洗机构20环绕侧吸组件11设置、并位于输入工位14与主输出工位15之间。主清洗机构20与侧吸组件11的端部对应。The

参阅图22,主清洗机构20包括第一安装架21、第一支撑架22、第一驱动组件23、管夹25和若干个主清洗组件24。第一安装架21固定在底座12上,第一支撑架22与第一安装架21滑动配合,第一驱动组件23与第一安装架21连接,第一驱动组件23驱动第一支撑架22上下滑动。管夹25可以为多个,管夹25安装在第一安装架21和第一支撑架22上、并用于支撑注液管71和抽液管72。主清洗组件24的数量可以为三个,三个主清洗组件24安装在第一支撑架22上。Referring to FIG. 22 , the

参阅图22,第一安装架21可以包括支撑板211、滑座212和加强板213,支撑板211水平设置并固定在底座12上,滑座212竖直设置并与支撑板211连接,滑座212上开设有与第一支撑架22滑动配合的滑轨。加强板213连接在支撑板211与滑座212之间。Referring to FIG. 22 , the first mounting

第一支撑架22包括第一滑板221和第一固定板222。第一滑板221与第一安装架21上的滑座212滑动配合,第一固定板222与第一滑板221的顶端连接,第一固定板222水平设置并呈圆弧状,三个主清洗组件24间隔设置在第一固定板222上,每一个清洗组件24与侧吸组件11的尾端对应。The

第一驱动组件23包括第一电机231、第一齿轮232和第一齿条233。第一电机231固定在第一安装架21上,第一齿轮232与第一电机231的输出轴连接,第一齿条233固定在第一滑板221上、并与第一齿轮232啮合,通过第一齿轮232与第一齿条233的啮合作用,当第一电机231正转或反转时,可以驱动第一滑板221沿第一安装架21上下滑动,从而带动主清洗组件24靠近或远离反应杯50。The

参阅图29和图30,在一些实施例中,管夹25包括卡座251和压板252。压板252的一端与卡座251转动连接,压板252的另一端与卡座251卡扣连接。卡座251上设置若干个容置槽250,容置槽250包括第一卡槽253和第二卡槽254,第一卡槽253和第二卡槽254相互连通,第一卡槽253与抽液管72配合,第二卡槽254与注液管71配合。当注液管71和抽液管72安装在容置槽250中时,压板252盖合容置槽250并与卡座251卡扣连接,从而将注液管71和抽液管72夹置在卡座251中。在其它实施例中,管夹25可以为第一固定板222上开设的夹孔等。Referring to FIGS. 29 and 30 , in some embodiments, the

参阅图22至图25,在一些实施例中,主清洗组件24包括针套241、针座242、注液针243和抽液针244。针套241固定第一支撑架22的第一固定板222上,针座242与针套241连接,注液针243穿设在针座242中并与注液管71连接,抽液针244穿设在针座242中并与抽液管72连接,抽废液时,抽液针244插入反应杯50的液体中。通过改变针套241在第一固定板222上的安装位置,可以适当调整抽液针244相对反应杯50中心轴线的距离,因此,在抽废液时,抽液针244可适当远离磁珠复合物60的吸附位置,避免磁珠复合物60跟随废液被抽走。注液针243的输出口靠近抽液针244的外壁面,当抽液完毕并注入清洗液的过程中,清洗液将沿抽液针244顺流而下,从而对抽液针244起到清洗作用,防止对反应杯50之间的交叉污染。当然,还可以在抽液针244上套设漏斗形的分流管246,注液针243的输出口位于分流管246内,注液时,清洗液先汇聚在分流管246内,再通过分流管246与抽液针244之间的间隙沿抽液针244的外壁面顺流而下。Referring to FIGS. 22 to 25 , in some embodiments, the

参阅图23至图25,针套241上设置有装配孔,装配孔的内壁上开设有呈辐射状布置的若干限位槽241a,限位槽241a沿装配孔的轴向延伸,针座242的外壁上安装有限位柱242a,限位柱242a与限位槽241a配合,限位柱242a安装在针座242的外壁上、限位柱242a沿针座242的径向向外延伸。其中,当限位柱242a与不同限位槽241a配合时,针座242相对针套241旋转设定角度,从而调整注液针243相对第一固定板222的位置。操作时,将针座242相对针套241向上提拉一定的距离,解除限位柱242a与限位槽241a配合,然后旋转所需要的角度,再放下针座242,从而使限位柱242a与另一限位槽241a配合,最终达到针座242相对针套241旋转设定角度的目的。Referring to FIGS. 23 to 25 , the

参阅图1、图4和图22,三个主清洗组件24上的抽液针244刚好与侧吸组件11的尾端相对应,例如,第一个主清洗组件24上的抽液针244与第一侧吸组件111的尾端对应(即位于该尾端的正上方),第二个主清洗组件24上的抽液针244与第二侧吸组件112的尾端对应,第三个主清洗组件24上的抽液针244与第三侧吸组件113的尾端对应。Referring to FIGS. 1 , 4 and 22 , the liquid suction needles 244 on the three

参阅图23至图25,主清洗组件24还可以包括压缩弹簧245,压缩弹簧245套设在针座242的上端,压缩弹簧245的下端与针座242上的凸台抵接,压缩弹簧245的上端与第一固定板222抵接。当针座242旋转一定角度并向下运动以使限位柱242a与限位槽241a配合时,压缩弹簧245的弹力可以起到对针座242的复位作用;同时,当抽液针244与反应杯50的底壁接触时,压缩弹簧245可以起到适当的缓冲作用,避免抽液针244损坏。参阅图26和图27,当然,压缩弹簧245可以不套设在针座242上,例如,第一固定板222上开设台阶孔,压缩弹簧245位于该台阶孔与针座242之间的间隙中,台阶孔的上方开口处固定一盖板247,压缩弹簧245的一端与盖板247抵接,压缩弹簧245的另一端与针座242上的限位柱242a抵接,当抽液针244与反应杯50的底壁抵触时,针座242向上运动并对压缩弹簧245产生挤压力,同样起到缓冲作用,防止抽液针244损坏。23 to 25, the

参阅图22,可以理解,主清洗机构20还可以包括第一拉伸弹簧26、限位螺钉27、第一光耦281和第一挡片282等。第一拉伸弹簧26的一端固定在第一安装架21的滑座212上,第一拉伸弹簧26的另一端与第一支撑架22上第一滑板221的底端连接,由于突发故障等外界因素导致主清洗组件24跟随第一支撑架22下滑时,第一拉伸弹簧26产生的拉力将对第一支撑架22下滑起到减速作用,避免抽液针244与反应杯50的底面53产生碰撞。Referring to FIG. 22 , it can be understood that the

限位螺钉27安装在第一安装架21上滑座212的底端,限位螺钉27能与第一滑板221相抵接。当第一滑板221相对第一安装架21滑动到最低位置时,限位螺钉27将与第一滑板221抵接,防止第一滑板221继续下滑,从而起到限制第一滑板221向下最大滑动行程的作用。The

第一光耦281固定在第一安装架21的滑座212上,第一光耦281与第一支撑架22的初始位置相对应,第一挡片282固定在第一滑板221上,当第一挡片282运动至第一光耦281处时,第一光耦281将被激发产生电平信号,从而起到检测和确定主清洗机构20初始位置的作用。The

参阅图28,副清洗机构30包括第二安装架31、第二支撑架32、第二驱动组件33、管夹25和副清洗组件34。第二安装架31的结构可以与第一安装架21的结构大致相同,第二支撑架32与第二安装架31滑动配合,第二驱动组件33驱动第二支撑架32上下往复滑动,管夹25设置在第二安装架31和第二支撑架32上,管夹25用于支撑抽液管72,副清洗组件34安装在第二支撑架32上。Referring to FIG. 28 , the

第二驱动组件33包括第二电机331、第二齿轮332和第二齿条333。第二电机331固定在第二安装架31上,第二齿轮332安装在第二电机331的输出轴上,第二齿条333固定在第二支撑架32上,第二齿条333与第二齿轮332啮合,当第二电机331正转或反转时,通过第二齿条333与第二齿轮332的啮合作用,可以驱动第二支撑架32沿第二安装架31上下滑动。The

副清洗组件34与主清洗组件24的结构大致相同,主要区别在于副清洗组件34不包括注液针243,即副清洗组件34可以只进行抽废液,而不注入新的清洗液。具体的,副清洗组件34包括针套241、针座242和抽液针244,三者的连接关系可以参考主清洗组件24,针套241固定在第二支撑架32上,针座242与针套241转动连接,抽液针244能伸入反应杯50中。副清洗组件34上的抽液针244与第四侧吸组件114的尾端对应(即对应该尾端的正上方)。第二支撑架32包括第二滑板321、支撑框322、转轴323、第二固定板324和第三驱动组件325。第二滑板321与第二安装架31滑动配合,支撑框322固定在第二滑板321上,转轴323与支撑框322转动连接,第二固定板324固定在转轴323的顶端,副清洗组件34安装在第二固定板324上,第三驱动组件325驱动转轴323转动。当然,第三驱动组件325可以自带编码器,编码器可以记录转动的转动行程。The

第三驱动组件325包括第三电机325a、主动齿轮325b和从动齿轮325c。第三电机325a固定在支撑框322上,主动齿轮325b与第三电机325a的输出轴连接,从动齿轮325c与转轴323的底端连接并与主动齿轮325b啮合。当第三电机325a正转或反转时,通过主动齿轮325b与从动齿轮325c的啮合作用,可以驱动转轴323转动,进而带动副清洗组件34跟随第二固定板324转动。当然,转轴323上还可安装轴承323a,轴承323a的内圈与转轴323过盈配合,轴承323a的外圈通过轴承座固定在支撑框322上。这样能提高转轴323的旋转精度。The

参阅图1和图28,副清洗机构30还包括清洗槽340,清洗槽340固定在底座12上,当副清洗机构30的抽液针244抽完废液后,第三电机325a转动一定的角度,从而带动副清洗组件34转动至清洗槽340的上方,然后,第二电机331转动一定的角度,以带动副清洗组件34上抽液针244下降到清洗槽340中,通过清洗槽340中的清洗液对抽液针244进行清洗,以避免抽液针244给反应杯50带来的交叉污染。1 and 28 , the

当然,副清洗机构30还可以包括第二拉伸弹簧35、限位螺钉、第二光耦361和第二挡片362。第二拉伸弹簧35与第一拉伸弹簧26的作用大致相同,具体的,第二拉伸弹簧35的一端固定在第二安装架31上,第二拉伸弹簧35的另一端与第二支撑架32上第二滑板321的底端连接,由于突发故障等外界因素导致副清洗组件34跟随第二支撑架32下滑时,第二拉伸弹簧35产生的拉力将对第二支撑架32下滑起到减速作用,避免抽液针244与反应杯50的底面53产生碰撞。Of course, the

限位螺钉安装在第二安装架31上的底端,限位螺钉能与第二滑板321相抵接。当第二滑板321相对第二安装架31滑动到最低位置时,限位螺钉将与第二滑板321抵接,防止第二滑板321继续下滑,从而起到限制第二滑板321向下最大滑动行程的作用。The limit screw is installed on the bottom end of the second mounting

第二光耦361固定在第二安装架31上,第二光耦361与第二支撑架32的初始位置相对应,第二挡片362固定在第二滑板321上,当第二挡片362运动至第二光耦361处时,第二光耦361将被激发产生电平信号,从而起到检测和确定副清洗机构30初始位置的作用。The second

该清洗装置的工作原理如下:首先,转盘40带动反应杯50从输入工位14进入磁珠复合物吸附机构10,反应杯50对应从第一侧吸组件111的首端公转至其尾端并停止转动,磁珠复合物60在转盘40转动的过程中被逐渐吸附在反应杯50的第一内侧面51上。此时,第一电机231工作,带动第一个主清洗组件24向下运动,抽液针244伸入反应杯50进行抽废液处理,当废液全部抽取完毕后,注液针243沿抽液针244的外壁面向反应杯50中注入一定量的清洗液,然后,抽液针244向上运动直至完全脱离反应杯50。The working principle of the cleaning device is as follows: First, the

其次,转盘40带动反应杯50从对应第一侧吸组件111的尾端公转至第二侧吸组件112的尾端并停止转动,当反应杯50公转至对应第二侧吸组件112的首端时,磁珠复合物60吸附在反应杯50的第二内侧面52上,清洗液将对从第一内侧面51泳动至第二内侧面52上的磁珠复合物60进行第一次清洗。当反应杯50公转至对应第二侧吸组件112的尾端时,第一电机231工作,带动第二个主清洗组件24向下运动,抽液针244伸入反应杯50进行抽废液处理,当废液全部抽取完毕后,注液针243沿抽液针244的外壁面向反应杯50中注入一定量的清洗液,然后,抽液针244向上运动直至完全脱离反应杯50。Next, the

再次,转盘40带动反应杯50从对应第二侧吸组件112的尾端公转至第三侧吸组件113的尾端并停止转动,当反应杯50公转至对应第三侧吸组件113的首端时,磁珠复合物60被重新吸附在反应杯50的第一内侧面51上。在转盘40转动过程中,清洗液将对从第二内侧面52泳动至第一内侧面51上的磁珠复合物60进行第二次清洗。当反应杯50公转至对应第三侧吸组件113的尾端时,第一电机231工作,带动第三个主清洗组件24向下运动,抽液针244伸入反应杯50进行抽废液处理,当废液全部抽取完毕后,注液针243沿抽液针244的外壁面向反应杯50中注入一定量的清洗液,然后,抽液针244向上运动直至完全脱离反应杯50。Again, the

最后,转盘40带动反应杯50从对应第三侧吸组件113的尾端公转至第四侧吸组件114的尾端并停止转动,当反应杯50公转至对应第四侧吸组件114的首端时,磁珠复合物60再次被吸附在反应杯50的第二内侧面52上。在转盘40转动过程中,清洗液将对从第一内侧面51泳动至第二内侧面52上的磁珠复合物60进行第三次清洗。当反应杯50公转至对应第四侧吸组件114的尾端时,第二电机331工作,带动副清洗组件34向下运动,抽液针244伸入反应杯50进行抽废液处理。当废液全部抽取完毕后,抽液针244向上运动直至完全脱离反应杯50,仅吸附有磁珠复合物60的反应杯50可以从主输出工位15输出至测量室进行测量;同时,第三电机325a工作,通过转轴323带动副清洗组件34转动至清洗槽340的上方,然后,第二电机331带动抽液针244向下运动并伸入清洗槽340中清洗,可以洗去抽液针244壁面上粘附的残留废液,避免下次抽废液过程中交叉污染。Finally, the

当反应杯50对应从第三侧吸组件113的首端公转至其尾端时,磁珠复合物60的吸附位置相对反应杯的底面53的距离逐渐减少至最低,即将磁珠复合物60的吸附位置全程拉低。当反应杯50公转至第四侧吸组件114的尾端时,磁珠复合物60在反应杯50上对应的磁性体104的有效高度d3最小,处于全紧密聚拢状态,尽可能的防止磁珠复合物60在抽废液过程中的损耗;同时,磁珠复合物60在反应杯50上的吸附位置的中心(对应磁性体中心高度t3)相对反应杯50的底面53最低,便于下一步的测量工作,也便于磁珠复合物60在下一步更加快捷的吸附至反应杯50的底面53上。When the

事实上,反应杯50从第一侧吸组件111的首端公转至第四侧吸组件114的首端的过程为主清洗,反应杯50从第四侧吸组件114的首端公转至其尾端的过程为副清洗。清洗液不仅对在第一内侧面51和第二内侧面52之间泳动的磁珠复合物60进行清洗。同时,在磁珠复合物60由分散聚拢状态转化为半紧密聚拢状态、全紧密聚拢状态的过程中,或者当磁珠复合物60的吸附位置相对反应杯50的底面53的距离改变时,磁珠复合物60相对清洗液产生运动,清洗液同样对磁珠复合物60产生一定程度的清洗作用,因此,清洗液对磁珠复合物60进行了多次全方面、无死角的清洗,大幅提高了磁珠复合物60的清洗效果,进而保证测试结果的准确性。In fact, the process of revolving the

当然,当反应杯50在第四侧吸组件114的尾端进行抽废液处理后,可以不从主输出工位15输送至测量室,而是继续公转至底吸组件115的尾端,并从副输出工位16输送至反应盘进行第二次加样。在反应杯50从底吸组件115的首端公转至其尾端时,在底吸组件115和磁珠复合物60重力的共同作用下,磁珠复合物60将从反应杯50的第二内侧面52上吸附至反应杯50的底面53上,以便第二次加样。Of course, after the

可以理解,当反应杯50第一次抵达主输出工位15或副输出工位16时,反应杯50继续做公转,转盘40带动反应杯50公转若干周之后,当反应杯50最后抵达主输出工位15时,反应杯50将从主输出工位15输送至测量室进行测量。因此,在反应杯50公转若干周的过程中,清洗液将对磁珠复合物60进行多次主清洗和副清洗。It can be understood that when the

当磁珠复合物吸附机构10中没有底吸组件115时,输入工位14可以与主输出工位15处于同一位置;当磁珠复合物吸附机构10中包含有底吸组件115时,输入工位14可以与副输出工位16处于同一位置。When there is no

当多个反应杯50同时跟随转盘40公转时,根据实际情况的需要,可以使某一部分反应杯50在公转一周之内从主输出工位15或副输出工位16输出,也可以使另一部分反应杯50公转多周之后从主输出工位15输出。例如,当转盘40停止转动时,可以将分别与主输出工位15或副输出工位16对应的两个反应杯50(两者公转均小于一周)同时输出;也可以将对应主输出工位15的反应杯50(公转若干周)和对应副输出工位16的反应杯50(公转小于一周)同时输出。When a plurality of reaction cups 50 revolve with the

本发明还提供一种化学发光检测仪,该化学发光检测仪包括上述的清洗装置。The present invention also provides a chemiluminescence detector comprising the above cleaning device.

参阅图31,对于转盘40上的单个反应杯50,本发明还提供一种清洗方法:Referring to FIG. 31 , for a

在一些实施例中,主要包括如下清洗步骤:In some embodiments, it mainly includes the following cleaning steps:

S810,将经过第一次加样后的反应杯50从清洗装置的输入工位14进入、并围绕清洗装置的中心轴线公转;S810, enter the

S820,主清洗,清洗装置将磁珠复合物60多次交替吸附在反应杯50的第一内侧面51和第二内侧面52上,清洗液对在第一内侧面51和第二内侧面52之间来回泳动的磁珠复合物60进行清洗;S820, main cleaning, the cleaning device adsorbs the

S830,副清洗,将磁珠复合物60吸附在第一内侧面51或第二内侧面52上接近反应杯50底面53的位置处、并对反应杯50抽废液处理;S830, secondary cleaning, adsorbing the

S840,将第一次公转至所述清洗装置的主输出工位15的反应杯50输送至测量室。S840, the

在其它实施例中,该清洗方法主要包括如下清洗步骤:In other embodiments, the cleaning method mainly includes the following cleaning steps:

S810,将经过第一次加样后的反应杯50从清洗装置的输入工位14进入、并开始围绕清洗装置的中心轴线公转;S810, enter the

S820,主清洗,清洗装置将磁珠复合物60多次交替吸附在反应杯50的第一内侧面51和第二内侧面52上,清洗液对在第一内侧面51和第二内侧面52之间来回泳动的磁珠复合物60进行清洗;S820, main cleaning, the cleaning device adsorbs the

S830,副清洗,将磁珠复合物60吸附在第一内侧面51或第二内侧面52上接近反应杯50底面53的位置处、并对反应杯50抽废液处理;S830, secondary cleaning, adsorbing the

S850,将磁珠复合物60吸附在反应杯50的底面53上;S850, adsorbing the

S860,将第一次公转至所述清洗装置的副输出工位16的反应杯50输送至反应盘进行第二次加样。S860, the

对于转盘40上的若干反应杯50,该清洗方法主要包括如下清洗步骤:For several reaction cups 50 on the

将经过第一次加样后的反应杯50从清洗装置的输入工位14进入、并围绕清洗装置的中心轴线公转;Enter the

主清洗,清洗装置将磁珠复合物60多次交替吸附在反应杯50的第一内侧面51和第二内侧面52上,清洗液对在第一内侧面51和第二内侧面52之间来回泳动的磁珠复合物60进行清洗;In the main cleaning, the cleaning device adsorbs the

副清洗,将磁珠复合物60吸附在第一内侧面51或第二内侧面52上接近反应杯50底面53的位置处、并对反应杯50抽废液处理;Secondary cleaning, the

在将第一次公转至所述清洗装置的副输出工位16的反应杯50输送至反应盘进行第二次加样的同时,将第一次公转至或公转多周至所述主输出工位15的反应杯50输送至测量室。While transporting the

主清洗主要包括如下步骤:The main cleaning mainly includes the following steps:

第一次清洗,反应杯50公转,磁珠复合物60脱离第一内侧面51而在清洗液中泳动并吸附至第二内侧面52上;For the first cleaning, the

反应杯50停止公转,对反应杯50进行抽废液后重新注入新的清洗液;The

第二次清洗,反应杯50沿原方向公转,磁珠复合物60脱离第二内侧面52而在清洗液中泳动并吸附至第一内侧面51上;In the second cleaning, the

反应杯50停止公转,对反应杯50进行抽废液后重新注入新的清洗液;The

第三次清洗,反应杯50沿原方向公转,磁珠复合物60脱离第一内侧面51而在清洗液中泳动并吸附至第二内侧面52上。In the third cleaning, the

在第二次清洗步骤到第三次清洗步骤之间,逐渐减少磁珠复合物60的吸附位置相对反应杯50底面53的距离。即拉低磁珠复合物60的吸附位置,以便反应杯50输出至测量室,或者使得底吸组件115更快捷的将磁珠复合物60拉至反应杯50的底面53上。Between the second cleaning step and the third cleaning step, the distance between the adsorption position of the

当反应杯50即将停止公转以抽废液时,逐渐减少磁珠复合物60在第一内侧面51或第二内侧面52上的吸附面积,使磁珠复合物60由分散聚拢状态转变为半紧密聚拢状体、或全紧密聚拢状态,避免磁珠复合物60跟随废液抽走;同时,在磁珠复合物60的聚拢状态的变化过程中,磁珠复合物60相对清洗液产生运动,清洗液件将对磁珠复合物60产生一定程度的清洗。When the

在副清洗步骤中,使磁珠复合物60的吸附位置相对反应杯50底面53的距离最近。对反应杯50抽废液时,使磁珠复合物60在第一内侧面51或第二内侧面52上的吸附面积最小。对反应杯50抽废液后,将清洗装置上的抽液针244转移至设置在清洗装置上的清洗槽340进行清洗以减少交叉污染。In the secondary cleaning step, the distance between the adsorption position of the

在主清洗步骤中,当对反应杯50抽废液后,将新注入的清洗液对清洗装置上的抽液针244进行清洗以减少交叉污染。注液针243输出的清洗液沿抽液针244的外壁流入反应杯50中,清洗液将对粘附在抽液针244的外壁上残留的废液进行清洗。In the main cleaning step, after the waste liquid is extracted from the

以上所述实施例的各技术特征可以进行任意的组合,为使描述简洁,未对上述实施例中的各个技术特征所有可能的组合都进行描述,然而,只要这些技术特征的组合不存在矛盾,都应当认为是本说明书记载的范围。The technical features of the above-described embodiments can be combined arbitrarily. For the sake of brevity, all possible combinations of the technical features in the above-described embodiments are not described. However, as long as there is no contradiction between the combinations of these technical features, All should be regarded as the scope described in this specification.

以上所述实施例仅表达了本发明的几种实施方式,其描述较为具体和详细,但并不能因此而理解为对发明专利范围的限制。应当指出的是,对于本领域的普通技术人员来说,在不脱离本发明构思的前提下,还可以做出若干变形和改进,这些都属于本发明的保护范围。因此,本发明专利的保护范围应以所附权利要求为准。The above-mentioned embodiments only represent several embodiments of the present invention, and the descriptions thereof are specific and detailed, but should not be construed as a limitation on the scope of the invention patent. It should be pointed out that for those of ordinary skill in the art, without departing from the concept of the present invention, several modifications and improvements can also be made, which all belong to the protection scope of the present invention. Therefore, the protection scope of the patent of the present invention should be subject to the appended claims.

Claims (38)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810073746.3ACN110082548B (en) | 2018-01-25 | 2018-01-25 | Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810073746.3ACN110082548B (en) | 2018-01-25 | 2018-01-25 | Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110082548A CN110082548A (en) | 2019-08-02 |

| CN110082548Btrue CN110082548B (en) | 2022-07-15 |

Family

ID=67412153

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201810073746.3AActiveCN110082548B (en) | 2018-01-25 | 2018-01-25 | Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110082548B (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110082343B (en)* | 2018-01-25 | 2024-03-19 | 深圳市新产业生物医学工程股份有限公司 | Side suction assembly |

| CN110586557B (en)* | 2019-09-11 | 2021-08-20 | 苏州长光华医生物医学工程有限公司 | Cleaning and separating device |

| CN110508548B (en)* | 2019-09-19 | 2024-06-25 | 南京仁迈生物科技有限公司 | Flushing chamber adsorption system of chemiluminescent analyzer |

| CN110749743B (en)* | 2019-11-30 | 2025-02-11 | 威海威高生物科技有限公司 | Washing device for chemiluminescent immunoassay analyzer |

| CN110749744B (en)* | 2019-12-01 | 2025-03-07 | 威海威高生物科技有限公司 | Washing device for chemiluminescent immunoassay analyzer |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6143578A (en)* | 1996-05-10 | 2000-11-07 | Bayer Corporation | Method and apparatus for wash, resuspension, recollection and localization of magnetizable particles in assays using magnetic separation technology |

| CN101786089A (en)* | 2010-02-05 | 2010-07-28 | 深圳市新产业生物医学工程有限公司 | Automatic cleaning device and cleaning method thereof |

| CN203737677U (en)* | 2014-02-24 | 2014-07-30 | 湖南康博生物科技有限公司 | Magnetic bead swimming motility washing device for chemical luminescence immunity analyzer |

| CN104330578A (en)* | 2014-10-20 | 2015-02-04 | 深圳市新产业生物医学工程股份有限公司 | Cleaning equipment and chemiluminiscence measurer adopting same |

| CN205379974U (en)* | 2016-02-24 | 2016-07-13 | 南京诺尔曼生物技术有限公司 | Magnetic separation device |

| CN105891113A (en)* | 2014-12-16 | 2016-08-24 | 合肥运涛光电科技有限公司 | Reaction vessel for luminescence tester and cleaning and separating mechanism thereof |

- 2018

- 2018-01-25CNCN201810073746.3Apatent/CN110082548B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6143578A (en)* | 1996-05-10 | 2000-11-07 | Bayer Corporation | Method and apparatus for wash, resuspension, recollection and localization of magnetizable particles in assays using magnetic separation technology |

| CN101786089A (en)* | 2010-02-05 | 2010-07-28 | 深圳市新产业生物医学工程有限公司 | Automatic cleaning device and cleaning method thereof |

| CN203737677U (en)* | 2014-02-24 | 2014-07-30 | 湖南康博生物科技有限公司 | Magnetic bead swimming motility washing device for chemical luminescence immunity analyzer |

| CN104330578A (en)* | 2014-10-20 | 2015-02-04 | 深圳市新产业生物医学工程股份有限公司 | Cleaning equipment and chemiluminiscence measurer adopting same |

| CN105891113A (en)* | 2014-12-16 | 2016-08-24 | 合肥运涛光电科技有限公司 | Reaction vessel for luminescence tester and cleaning and separating mechanism thereof |

| CN205379974U (en)* | 2016-02-24 | 2016-07-13 | 南京诺尔曼生物技术有限公司 | Magnetic separation device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110082548A (en) | 2019-08-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110082548B (en) | Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method | |

| CN110082291B (en) | Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method | |

| CN110883039B (en) | Adsorption mechanism, cleaning device, chemiluminescence detector and cleaning method | |

| CN110082549B (en) | Cleaning device and chemiluminescence detector | |

| CN104483499B (en) | Full-automatic specific protein analyser | |

| CN110076154B (en) | Reaction cup cleaning method of rotating disc type reaction cup cleaning device | |

| WO2020062946A1 (en) | Magnetic bead cleaning device and chemiluminescence immunoassay analyzer | |

| CN109865704B (en) | Magnetic bead cleaning device suitable for in-vitro diagnostic equipment | |

| CN208131617U (en) | Cleaning assembly, wiper mechanism and chemiluminescence detector | |

| CN111562400B (en) | Cleaning device and chemiluminescent immunoassay analyzer | |

| CN111381054A (en) | Magnetic separation device, sample analyzer, and flow type fluorescence immunoassay analyzer | |

| CN204462161U (en) | Protein analyzer liquid feeding mixed structure | |

| CN107782888B (en) | Immunoassay analyzer | |

| CN114019178A (en) | A kind of automatic immune-biochemical integrated analyzer and using method | |

| WO2019127016A1 (en) | Automatic cleaning and separating device | |

| CN113916780B (en) | A magnetic bead cleaning, incubation and photometry device | |

| CN118209746B (en) | Chemiluminescent immunoassay analyzer and operation method | |

| CN111381056A (en) | Magnetic separation device, sample analyzer, and flow type fluorescence immunoassay analyzer | |

| CN214539645U (en) | Magnetic separation device | |

| CN220473159U (en) | Mixing mechanism, cleaning device and sample analyzer | |

| CN209715874U (en) | Magnetic Bead Washing Device for In Vitro Diagnostic Devices | |

| CN220239462U (en) | Magnetic separation cleaning device for chemiluminescence immunoassay analyzer | |

| CN209673815U (en) | Magnetic separating device, sample analyser and streaming fluorescence immunity analyzer | |

| CN211453368U (en) | Be used for abluent load bearing device, washing module and sample analysis appearance | |

| CN110076155B (en) | Cleaning assembly, cleaning mechanism and chemiluminescent detector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |