CN109606268B - Storage box device of electric automobile - Google Patents

Storage box device of electric automobileDownload PDFInfo

- Publication number

- CN109606268B CN109606268BCN201811539338.9ACN201811539338ACN109606268BCN 109606268 BCN109606268 BCN 109606268BCN 201811539338 ACN201811539338 ACN 201811539338ACN 109606268 BCN109606268 BCN 109606268B

- Authority

- CN

- China

- Prior art keywords

- fixing

- fixed

- plate

- elastic band

- storage box

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003860storageMethods0.000titleclaimsabstractdescription23

- 238000003825pressingMethods0.000claimsabstractdescription9

- 230000000149penetrating effectEffects0.000claimsdescription3

- 241000274582Pycnanthus angolensisSpecies0.000abstractdescription5

- 239000011087paperboardSubstances0.000abstractdescription5

- 238000004519manufacturing processMethods0.000abstractdescription3

- 238000000034methodMethods0.000abstractdescription3

- 239000007858starting materialSubstances0.000abstractdescription3

- 238000010586diagramMethods0.000description3

- 230000009286beneficial effectEffects0.000description1

- 238000009434installationMethods0.000description1

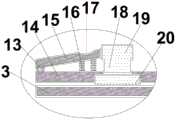

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R7/00—Stowing or holding appliances inside vehicle primarily intended for personal property smaller than suit-cases, e.g. travelling articles, or maps

- B60R7/02—Stowing or holding appliances inside vehicle primarily intended for personal property smaller than suit-cases, e.g. travelling articles, or maps in separate luggage compartment

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Vehicle Step Arrangements And Article Storage (AREA)

Abstract

Description

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811539338.9ACN109606268B (en) | 2018-12-14 | 2018-12-14 | Storage box device of electric automobile |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811539338.9ACN109606268B (en) | 2018-12-14 | 2018-12-14 | Storage box device of electric automobile |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109606268A CN109606268A (en) | 2019-04-12 |

| CN109606268Btrue CN109606268B (en) | 2021-10-29 |

Family

ID=66010169

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811539338.9AActiveCN109606268B (en) | 2018-12-14 | 2018-12-14 | Storage box device of electric automobile |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109606268B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110584374A (en)* | 2019-08-24 | 2019-12-20 | 汪扬皓 | Piano stool |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4844305A (en)* | 1986-10-15 | 1989-07-04 | Mckneely James W | Cargo compartment organizer |

| US6488168B1 (en)* | 2001-07-20 | 2002-12-03 | Chu-Li Wang | Article-storing box placed in an automobile trunk |

| CN107054229A (en)* | 2017-06-19 | 2017-08-18 | 安徽江淮汽车集团股份有限公司 | A kind of automobile storage box |

| CN206870969U (en)* | 2017-05-11 | 2018-01-12 | 浙江阜康机械有限公司 | Roof carrier for vehicles |

| CN108099796A (en)* | 2017-12-18 | 2018-06-01 | 合肥亿恒智能科技股份有限公司 | A kind of separating device of automobile trunk |

| CN207657722U (en)* | 2017-11-16 | 2018-07-27 | 南京视莱尔汽车电子有限公司 | A kind of automobile parcel tray |

| CN207931612U (en)* | 2018-03-21 | 2018-10-02 | 重庆缘得科技有限公司 | A kind of new suitcase parcel tray |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007042365A1 (en)* | 2007-09-06 | 2009-03-12 | GM Global Technology Operations, Inc., Detroit | Guide unit for a height-adjustable loading floor and motor vehicle with such a guide unit and a height-adjustable loading floor |

| US9321402B2 (en)* | 2014-01-22 | 2016-04-26 | Ford Global Technologies, Llc | Multi-function automotive trunk storage drawer |

| US10166928B2 (en)* | 2016-07-13 | 2019-01-01 | Ford Global Technologies, Llc | Storage compartment divider having partition with hinged telescoping sections |

| EP3284686B1 (en)* | 2016-08-16 | 2018-12-26 | Neopost Technologies | Device and method for assembling items for shipment |

- 2018

- 2018-12-14CNCN201811539338.9Apatent/CN109606268B/enactiveActive

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4844305A (en)* | 1986-10-15 | 1989-07-04 | Mckneely James W | Cargo compartment organizer |

| US6488168B1 (en)* | 2001-07-20 | 2002-12-03 | Chu-Li Wang | Article-storing box placed in an automobile trunk |

| CN206870969U (en)* | 2017-05-11 | 2018-01-12 | 浙江阜康机械有限公司 | Roof carrier for vehicles |

| CN107054229A (en)* | 2017-06-19 | 2017-08-18 | 安徽江淮汽车集团股份有限公司 | A kind of automobile storage box |

| CN207657722U (en)* | 2017-11-16 | 2018-07-27 | 南京视莱尔汽车电子有限公司 | A kind of automobile parcel tray |

| CN108099796A (en)* | 2017-12-18 | 2018-06-01 | 合肥亿恒智能科技股份有限公司 | A kind of separating device of automobile trunk |

| CN207931612U (en)* | 2018-03-21 | 2018-10-02 | 重庆缘得科技有限公司 | A kind of new suitcase parcel tray |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109606268A (en) | 2019-04-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109454552B (en) | Clamp for processing steel backing of brake pad | |

| CN109606268B (en) | Storage box device of electric automobile | |

| CN105171569A (en) | Panel polishing machine | |

| KR102044253B1 (en) | Clamping jig for processing battery case of electric vehicle | |

| CN113478324A (en) | Grinding device for producing battery steel shell | |

| CN210628361U (en) | New energy automobile battery that takes precautions against earthquakes | |

| CN210907726U (en) | Shaping die for door corner fitting | |

| CN116673379B (en) | Automobile support stamping forming die | |

| CN214869532U (en) | Corner grinding device of automobile injection molding | |

| CN203380316U (en) | Riveting machine | |

| CN211733057U (en) | Get a manipulator with unhairing limit function | |

| CN202894098U (en) | Riveting jig for cover plate of lock housing of ignition lock for vehicle | |

| CN204366333U (en) | A kind of fixed mechanism carrying out welding for arm shaft | |

| CN213765485U (en) | Positioning tool for new energy automobile part machining | |

| CN204075638U (en) | Shock absorber drawing work platform | |

| CN219543211U (en) | Blanking manipulator capable of being attached at multiple angles for producing automobile plastic parts | |

| CN212634826U (en) | A welding and positioning tool for fixing base of automobile coat rack | |

| CN213212288U (en) | Battery box of electric vehicle | |

| CN212909290U (en) | Business turn over station shaping device is used in electric automobile motor production | |

| CN215614485U (en) | Cloud bus treater upper cover machine-shaping mould | |

| CN221695914U (en) | Tool for sealing ring pressing-in system | |

| CN117753847B (en) | Automotive interior spare mold processing with buffer function | |

| CN218018813U (en) | Auxiliary clamping mechanism for manufacturing automobile luggage compartment | |

| CN212219263U (en) | Plastic thread rolling die | |

| CN217194981U (en) | Rotary clamping tool for automobile parts |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right | Effective date of registration:20210918 Address after:237000 jw-13, Jintiandi Trade City, Yeji District, Lu'an City, Anhui Province Applicant after:Anhui Enterprise Development Productivity Promotion Center Co.,Ltd. Address before:721000 No. 6, building 5, No. 102, Baofu Road, Jintai District, Baoji City, Shaanxi Province Applicant before:Diao Chundi | |

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP01 | Change in the name or title of a patent holder | ||

| CP01 | Change in the name or title of a patent holder | Address after:237000 jw-13, Jintiandi Trade City, Yeji District, Lu'an City, Anhui Province Patentee after:Anhui Zece Technology Co.,Ltd. Address before:237000 jw-13, Jintiandi Trade City, Yeji District, Lu'an City, Anhui Province Patentee before:Anhui Enterprise Development Productivity Promotion Center Co.,Ltd. | |

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20240315 Address after:247000 Jiandong Village, Yaodu Town, Dongzhi County, Chizhou City, Anhui Province Patentee after:Anhui Huapeng Power Equipment Investment Co.,Ltd. Country or region after:China Address before:237000 jw-13, Jintiandi Trade City, Yeji District, Lu'an City, Anhui Province Patentee before:Anhui Zece Technology Co.,Ltd. Country or region before:China |