CN109583043B - Self-adaptive compensation method for tightening torque for bolt connection - Google Patents

Self-adaptive compensation method for tightening torque for bolt connectionDownload PDFInfo

- Publication number

- CN109583043B CN109583043BCN201811328102.0ACN201811328102ACN109583043BCN 109583043 BCN109583043 BCN 109583043BCN 201811328102 ACN201811328102 ACN 201811328102ACN 109583043 BCN109583043 BCN 109583043B

- Authority

- CN

- China

- Prior art keywords

- tightening torque

- value

- vector

- tightening

- clustering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/23—Clustering techniques

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/24—Classification techniques

- G06F18/241—Classification techniques relating to the classification model, e.g. parametric or non-parametric approaches

- G06F18/2411—Classification techniques relating to the classification model, e.g. parametric or non-parametric approaches based on the proximity to a decision surface, e.g. support vector machines

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/04—Architecture, e.g. interconnection topology

- G06N3/045—Combinations of networks

Landscapes

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Physics & Mathematics (AREA)

- Data Mining & Analysis (AREA)

- General Physics & Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- Evolutionary Computation (AREA)

- Life Sciences & Earth Sciences (AREA)

- Artificial Intelligence (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Evolutionary Biology (AREA)

- Bioinformatics & Computational Biology (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Computational Linguistics (AREA)

- Biomedical Technology (AREA)

- Biophysics (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Molecular Biology (AREA)

- Computing Systems (AREA)

- Mathematical Physics (AREA)

- Software Systems (AREA)

- Computer Hardware Design (AREA)

- Geometry (AREA)

- Feedback Control In General (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种用于螺栓联接的拧紧力矩自适应补偿方法,属于机械装备技术领域。The invention relates to a tightening torque self-adaptive compensation method for bolt connection, and belongs to the technical field of mechanical equipment.

背景技术Background technique

螺栓联接是装配体最为常见和广泛的连接形式,螺栓联接的合格与否直接影响着产品装配质量和装配效率。工程实际中,通常采用控制拧紧力矩的方式实现螺栓拧紧。拧紧力矩值求解一般有理论公式法和实验获取法两种,但上述方法都有相应缺陷和不足:关于理论公式法,目前通用的理论公式过于理想,并未考虑复杂的实际情况(如螺纹加工精度、螺纹副摩擦系数以及润滑程度);实验获取法则无法适应条件不断变化的实际环境,一旦螺栓品种规格更替或装配环境与训练环境有差异,那么之前计算的拧紧力矩值将毫无参考意义。因此,螺栓拧紧问题依然是装配过程的质量和效率瓶颈。Bolted connection is the most common and extensive connection form of assemblies. The qualification of bolted connection directly affects the quality and efficiency of product assembly. In engineering practice, bolt tightening is usually achieved by controlling the tightening torque. There are generally two methods for solving the tightening torque value: the theoretical formula method and the experimental method, but the above methods have corresponding defects and shortcomings: Regarding the theoretical formula method, the current general theoretical formula is too ideal, and does not consider the complex actual situation (such as thread processing). Accuracy, thread pair friction coefficient and lubrication degree); the experimental acquisition rule cannot adapt to the actual environment with changing conditions. Once the bolt varieties and specifications are replaced or the assembly environment is different from the training environment, the previously calculated tightening torque value will be useless. Therefore, the problem of bolt tightening remains a bottleneck for the quality and efficiency of the assembly process.

传统的专家系统通过建立海量专家知识和规则结构来实现对现有状态下的值预估,一方面该专家系统建立难度大,另一方面一旦环境中出现知识库里没有的情况则专家系统无法得出结论,整个系统缺乏自适应性。The traditional expert system realizes the value estimation under the existing state by establishing massive expert knowledge and rule structure. On the one hand, it is difficult to establish the expert system. It is concluded that the entire system lacks adaptability.

发明内容SUMMARY OF THE INVENTION

本发明的目的是提出一种用于螺栓联接的拧紧力矩自适应补偿方法,用于识别动态环境变化(加工精度、润滑程度、上一工艺残留碎屑等)对拧紧力阈值影响规律,对螺栓拧紧力进行自适应迭代更新补偿,以适应不断变化的装配环境以及实时改变的加工精度对拧紧力矩的要求。The purpose of the present invention is to propose a tightening torque adaptive compensation method for bolt connection, which is used to identify the influence of dynamic environmental changes (machining accuracy, degree of lubrication, residual debris in the previous process, etc.) The tightening force is adaptively updated and compensated to adapt to the changing assembly environment and the real-time changing machining accuracy requirements for tightening torque.

本发明提出的用于螺栓联接的拧紧力矩自适应补偿方法,包括以下步骤:The tightening torque adaptive compensation method for bolt connection proposed by the present invention includes the following steps:

(1)采集多个螺栓在拧紧时分别所需的拧紧力矩,并分别记录拧紧时的环境属性,包括螺栓的加工精度、润滑度、表面碎屑和环境温度,多个螺栓所需的拧紧力矩组成一个向量,记为H={h1,h2,…,hc},对向量中的每一拧紧力矩进行延展升维,得到一个f×1维度的拧紧力矩向量:(1) Collect the tightening torques required by multiple bolts when tightening, and record the environmental attributes during tightening, including the machining accuracy, lubrication, surface debris and ambient temperature of the bolts, and the tightening torque required for multiple bolts. A vector is formed, denoted as H={h1 , h2 ,...,hc }, and each tightening torque in the vector is extended and dimensioned to obtain a tightening torque vector of f×1 dimension:

H1=(h1,h1,…,h1)TH1 =(h1 ,h1 ,...,h1 )T

H2=(h2,h2,…,h2)TH2 =(h2 ,h2 ,...,h2 )T

Hc=(hc,hc,…,hc)THc =(hc ,hc ,...,hc )T

其中,f为延展升维后得到拧紧力矩向量的长度值,f取值大于所记录的环境属性的个数,c为螺栓个数,上标T为向量转置;Among them, f is the length value of the tightening torque vector obtained after extending the dimension, the value of f is greater than the number of recorded environmental attributes, c is the number of bolts, and the superscript T is the vector transpose;

(2)根据上述拧紧力矩向量,建立一个意识反应模型,表达式如下:(2) According to the above tightening torque vector, establish a conscious response model, the expression is as follows:

yi(n)=Hi(n)+αWHi(n)yi (n)=Hi (n)+αWHi (n)

其中,yi(n)为第i个螺栓的拧紧力矩向量在意识反应模型中第n次迭代下超立方体空间上的坐标位置表示,α为拧紧力矩调整因子,取值范围为[0,1],n为意识反应模型的迭代次数,V为意识反应模型的门限值,表示意识反应模型的超立方体边缘点,Hi(n)为对第i个螺栓的拧紧力矩进行延展后得到的向量,Hi,j(n)为第n次迭代下第i个螺栓的第j个拧紧力矩,j=1,2,…,f,W是f×f矩阵,f为延展升维后得到拧紧力矩向量的长度值,即意识反应模型中为神经元数目,W满足如下条件,以保证聚类角点拥有吸引力:Among them, yi (n) is the coordinate position of the tightening torque vector of the ith bolt on the hypercube space at the nth iteration in the conscious response model, α is the tightening torque adjustment factor, and the value range is [0,1 ], n is the number of iterations of the conscious response model, V is the threshold value of the conscious response model, and represents the edge point of the hypercube of the conscious response model, Hi (n) is obtained by extending the tightening torque of the ith bolt Vector, Hi,j (n) is the j-th tightening torque of the i-th bolt under the n-th iteration, j=1,2,...,f, W is the f×f matrix, and f is obtained after extending the dimension The length value of the tightening torque vector, that is, the number of neurons in the conscious response model, W satisfies the following conditions to ensure that the clustering corners are attractive:

W=WTW=WT

λmin≥0,λmim为W的最小特征值λmin ≥ 0, λmim is the smallest eigenvalue of W

ωi,j是W的第i行第j列元素值 ωi,j is the element value of the i-th row and the j-th column of W

ε是正常数, ε is a positive constant,

为超立方体函数,用于限制意识反应模型的超立方体边界; is the hypercube function, which is used to limit the hypercube boundary of the conscious response model;

(3)向上述意识反应模型中输入步骤(1)的f×1维度的拧紧力矩向量,得到第i个螺栓的拧紧力矩分类标记Hi(n),重复本步骤,得到所有螺栓的拧紧力矩分类标记;(3) Input the tightening torque vector of the dimension f×1 in step (1) into the above conscious response model, and obtain the tightening torque classification mark Hi (n) of the ith bolt, repeat this step to obtain the tightening torque of all bolts classification mark;

(4)根据步骤(3)所有螺栓的拧紧力矩分类标记,利用下式,计算步骤(1)中拧紧时螺栓的加工精度、润滑度、表面碎屑和环境温度的Gini指标:(4) According to the classification and marking of the tightening torque of all bolts in step (3), use the following formula to calculate the Gini index of the machining accuracy, lubricity, surface debris and ambient temperature of the bolts when tightening in step (1):

其中,e是步骤(1)的环境属性的序号,d是同一聚类角点的拧紧力矩值个数,l是在同一聚类角点中拧紧力矩序号,p为比率,是指以环境属性e作为分类标准,对步骤(2)的意识反应模型聚类角点上的聚类值即拧紧力矩进行分类,分到各环境属性序号的拧紧力矩个数占总拧紧力矩个数的比率;Among them, e is the sequence number of the environmental attribute in step (1), d is the number of tightening torque values in the same cluster corner, l is the tightening torque sequence number in the same cluster corner, p is the ratio, which refers to the environmental attribute e as the classification standard, classify the clustering values on the clustering corners of the consciousness response model in step (2), namely the tightening torque, and the ratio of the number of tightening torques assigned to each environmental attribute serial number to the total number of tightening torques;

一个聚类角点上的所有拧紧力矩向量构成一个聚类集,计算每一个聚类集与各环境属性相对应的Gini指标,以与该聚类集相对应的Gini指标中的最低Gini指标作为相应环境属性的聚类标签,并将相同聚类标签的聚类角点合并为一个带有聚类标签的聚类集;All the tightening torque vectors on a cluster corner constitute a cluster set, calculate the Gini index corresponding to each cluster set and each environmental attribute, and take the lowest Gini index among the Gini indices corresponding to the cluster set as the Cluster labels of the corresponding environmental attributes, and merge the cluster corners of the same cluster label into a cluster set with a cluster label;

(5)建立一个基于记忆方法的补偿神经网络,补偿神经网络的模型如下:(5) Establish a compensation neural network based on the memory method. The model of the compensation neural network is as follows:

ht=tanh(Xt)·Otht =tanh(Xt )·Ot

Xt=Xt-1st+I(t)tanh(Ct)tanh(ht-1)+tanh(ht)Xt =Xt-1 st +I(t)tanh(Ct )tanh(ht-1 )+tanh(ht )

st=μ(Ws·[Xt-1,ht-1,Ct]+bs)st =μ(Ws ·[Xt-1 ,ht-1 ,Ct ]+bs )

It=μ(WI·[Xt-1,ht-1,Ct]+bI)It = μ(WI ·[Xt-1 , ht-1 , Ct ]+bI )

Ot=μ(WO·[Xt-1,ht-1,Ct]+bO)Ot = μ(WO ·[Xt-1 , ht-1 , Ct ]+bO )

其中,tanh符号为双曲正切函数,其表达式如下:Among them, the tanh symbol is the hyperbolic tangent function, and its expression is as follows:

Xt-1为取值在[0,1]之间的记忆细胞,表示对历史输入值hi(i=1,2,…,t-1)的保留程度,当Xt-1的取值为1时,表示“对t-1之前时刻所有输入值hi(i=1,2,…,t-1)完全保留并进入下一公式”,当Xt-1的取值为0时,表示“对t-1之前时刻所有输入值hi(i=1,2,…,t-1)完全舍弃并进入下一公式”,Xt为补偿神经网络的记忆细胞输出,输出值范围为[0,1],Ct为t时刻环境属性序号,ht-1,ht分别为第t-1和t时刻的拧紧力矩,st、It、Ot分别为短时记忆网络、输入网络、输出网络的结果输出,Ws,bs,WI,bI,WO,bO分别为短时记忆网络、输入网络、输出网络的权值向量和偏置;Xt-1 is a memory cell with a value between [0, 1], indicating the degree of retention of the historical input value hi (i =1, 2,..., t-1), when Xt-1 is taken When the value is 1, it means that "all input values hi (i =1,2,...,t-1) at the time before t-1 are completely reserved and entered into the next formula", when the value of Xt-1 is 0 , it means "completely discard all input values hi (i =1,2,...,t-1) before t-1 and enter the next formula", Xt is the memory cell output of the compensation neural network, the output value The range is [0,1], Ct is the serial number of the environmental attribute at time t, ht-1 , ht are the tightening torque at time t-1 and time t, respectively, st , Itt , Ot are short-term memory, respectively The result output of the network, input network, and output network, Ws , bs , WI , bI , WO , bO are the weight vector and bias of the short-term memory network, input network, and output network, respectively;

(6)将步骤(1)得到的第t-1时刻拧紧力矩值、第t时刻的环境属性序号作为步骤(5)的补偿神经网络的输入,步骤(1)的第t时刻的拧紧力矩值作为指导输出,对步骤(5)的补偿神经网络模型中的权值向量、偏置和记忆细胞Xt-1进行随机初始化,训练过程中,将第t-1时刻拧紧力矩值、第t时刻的环境属性序号和记忆细胞Xt-1输入步骤(5)的补偿神经网络,计算输出结果与指导输出的差值,根据该差值对补偿神经网络的权值向量和偏置进行反馈调整,重复上述训练过程,直到输出结果与指导输出的差值小于设定阈值,结束训练过程,并将此时的权值向量和偏置作为补偿神经网络中短时记忆网络、输入网络、输出网络的权值向量和偏置,得到训练成熟的补偿神经网络;(6) Take the tightening torque value at time t-1 obtained in step (1) and the environmental attribute serial number at time t as the input of the compensation neural network in step (5), and the tightening torque value at time t in step (1) As a guide output, the weight vector, bias and memory cell Xt-1 in the compensation neural network model in step (5) are randomly initialized. During the training process, the tightening torque value at time t-1 and the The environmental attribute serial number and the memory cell Xt-1 are input into the compensation neural network of step (5), the difference between the output result and the guidance output is calculated, and the weight vector and bias of the compensation neural network are feedback adjusted according to the difference. Repeat the above training process until the difference between the output result and the guidance output is less than the set threshold, end the training process, and use the weight vector and bias at this time as compensation for the short-term memory network, input network, and output network in the neural network. Weight vector and bias to get a well-trained compensating neural network;

(7)设当前时刻为g时刻,将第g-1时刻的拧紧力矩值hg-1、当前g时刻的环境属性序号值Cg以及第g-1时刻记忆细胞Xg-1输入到步骤(6)训练成熟的补偿神经网络中,输出的hg即为当前g时刻的补偿后的拧紧力矩值。(7) Set the current time as time g, and input the tightening torque value hg-1 at the g-1 time, the environmental attribute serial number value Cg at the current g time, and the

本发明提出的用于螺栓联接的拧紧力矩自适应补偿方法,其优点是:The self-adaptive compensation method for tightening torque for bolt connection proposed by the present invention has the following advantages:

1、本发明提出的用于螺栓联接的拧紧力矩自适应补偿方法,模仿人类专家思考和记忆,提取建立自适应补偿方法,避免了传统专家系统对海量规则库、知识库的建立和维护,而且无需采集、转换、输入专家知识,从样本数据中自学习数据规律,并启发训练、记忆存储和提取,从而估计下一时刻拧紧力矩值。1. The self-adaptive compensation method of tightening torque for bolt connection proposed by the present invention imitates the thinking and memory of human experts, extracts and establishes the self-adaptive compensation method, avoids the establishment and maintenance of massive rule bases and knowledge bases by traditional expert systems, and No need to collect, convert, input expert knowledge, self-learn data rules from sample data, and inspire training, memory storage and retrieval, so as to estimate the tightening torque value at the next moment.

2、本发明方法为一种基于神经学理论建立的拧紧力矩阈值补偿方法,避免了传统建立理论公式模型适用对象单一、未考虑螺栓拧紧会受到螺纹加工精度、螺纹副摩擦系数以及上一工艺涂料等外在因素对拧紧值的影响,因此本发明将加工精度、润滑条件等动态环境变化纳入补偿方法建立过程,提高了方法的普适性和精确度。2. The method of the present invention is a tightening torque threshold compensation method based on neurological theory, which avoids that the traditional theoretical formula model is applicable to a single object, and the bolt tightening is not considered, which will be affected by the thread machining accuracy, the friction coefficient of the thread pair and the coating of the previous process. Therefore, the present invention incorporates dynamic environmental changes such as machining accuracy and lubrication conditions into the process of establishing the compensation method, thereby improving the universality and accuracy of the method.

附图说明Description of drawings

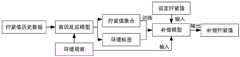

图1是本发明方法的流程框图。Fig. 1 is a flow chart of the method of the present invention.

图2是本发明方法涉及的意识反应模型示意图。Fig. 2 is a schematic diagram of a conscious response model involved in the method of the present invention.

图3是本发明方法涉及的意识反应模型的超立方体边界示意图。Fig. 3 is a schematic diagram of a hypercube boundary of a conscious response model involved in the method of the present invention.

图4是本发明方法涉及的意识反应模型的三维空间点示意图。FIG. 4 is a schematic diagram of three-dimensional space points of the conscious response model involved in the method of the present invention.

图5是本发明方法涉及的基于记忆方法的补偿神经网络示意图。FIG. 5 is a schematic diagram of the compensation neural network based on the memory method involved in the method of the present invention.

图6是本发明方法的一个实施例中的拧紧力矩值三峰分布概率密度图。6 is a probability density diagram of a trimodal distribution of tightening torque values in an embodiment of the method of the present invention.

具体实施方式Detailed ways

本发明提出的用于螺栓联接的拧紧力矩自适应补偿方法,其流程框图如图1所示,包括以下步骤:The self-adaptive compensation method for tightening torque for bolt connection proposed by the present invention has a flow chart as shown in Figure 1, including the following steps:

(1)采集多个螺栓在拧紧时分别所需的拧紧力矩,并分别记录拧紧时的环境属性,包括螺栓的加工精度、润滑度、表面碎屑和环境温度,多个螺栓所需的拧紧力矩组成一个向量,记为H={h1,h2,…,hc},对向量中的每一拧紧力矩进行延展升维,得到一个f×1维度的拧紧力矩向量:(1) Collect the tightening torques required by multiple bolts when tightening, and record the environmental attributes during tightening, including the machining accuracy, lubrication, surface debris and ambient temperature of the bolts, and the tightening torque required for multiple bolts. A vector is formed, denoted as H={h1 , h2 ,...,hc }, and each tightening torque in the vector is extended and dimensioned to obtain a tightening torque vector of f×1 dimension:

H1=(h1,h1,…,h1)TH1 =(h1 ,h1 ,...,h1 )T

H2=(h2,h2,…,h2)TH2 =(h2 ,h2 ,...,h2 )T

其中,f为延展升维后得到拧紧力矩向量的长度值,f取值大于所记录的环境属性的个数,c为螺栓个数,上标T为向量转置;Among them, f is the length value of the tightening torque vector obtained after extending the dimension, the value of f is greater than the number of recorded environmental attributes, c is the number of bolts, and the superscript T is the vector transpose;

(2)利用上述f×1维度向量,建立意识反应模型,如图2所示,该模型将所有上述拧紧力矩向量放置于f维超立方体空间(一个f维向量在f维空间即视为一个点),并通过刺激激励方式使每一个点在超立方体空间运动,直到每个拧紧力矩点均稳定停留在各个超立方体的角点。根据上述拧紧力矩向量,建立一个意识反应模型,表达式如下:(2) Use the above f×1 dimension vector to establish a conscious response model, as shown in Figure 2, the model places all the above tightening torque vectors in the f-dimensional hypercube space (an f-dimensional vector in the f-dimensional space is regarded as a point), and make each point move in the hypercube space by way of stimulation until each tightening torque point stably stays at the corner of each hypercube. According to the above tightening torque vector, a conscious response model is established, and the expression is as follows:

yi(n)=Hi(n)+αWHi(n)yi (n)=Hi (n)+αWHi (n)

其中,yi(n)为第i个螺栓的拧紧力矩向量在意识反应模型中第n次迭代下超立方体空间上的坐标位置表示,α为拧紧力矩调整因子,取值范围为[0,1],n为意识反应模型的迭代次数,V为意识反应模型的门限值,表示意识反应模型的超立方体边缘点,Hi(n)为对第i个螺栓的拧紧力矩进行延展后得到的向量,Hi,j(n)为第n次迭代下第i个螺栓的第j个拧紧力矩,j=1,2,…,f,W是f×f矩阵,f为延展升维后得到拧紧力矩向量的长度值,即意识反应模型中为神经元数目,可以理解为单层线性神经网络,为了使拧紧力矩值点能够最终稳定落在各聚类角点,W满足如下条件,以保证聚类角点拥有吸引力:Among them, yi (n) is the coordinate position of the tightening torque vector of the ith bolt on the hypercube space at the nth iteration in the conscious response model, α is the tightening torque adjustment factor, and the value range is [0,1 ], n is the number of iterations of the conscious response model, V is the threshold value of the conscious response model, and represents the edge point of the hypercube of the conscious response model, Hi (n) is obtained by extending the tightening torque of the ith bolt Vector, Hi,j (n) is the j-th tightening torque of the i-th bolt under the n-th iteration, j=1,2,...,f, W is the f×f matrix, and f is obtained after extending the dimension The length value of the tightening torque vector, that is, the number of neurons in the conscious response model, can be understood as a single-layer linear neural network. In order to make the tightening torque value point stably fall on each cluster corner, W satisfies the following conditions to ensure Clustering corners are attractive:

W=WTW=WT

λmin≥0,λmim为W的最小特征值λmin ≥ 0, λmim is the smallest eigenvalue of W

ωi,j是W的第i行第j列元素值 ωi,j is the element value of the i-th row and the j-th column of W

ε是正常数, ε is a positive constant,

为超立方体函数,用于限制意识反应模型的超立方体边界,如图3所示。 is the hypercube function, which is used to limit the hypercube boundary of the conscious response model, as shown in Figure 3.

(3)向上述意识反应模型中输入步骤(1)的f×1维度的拧紧力矩向量,得到第i个螺栓的拧紧力矩分类标记Hi(n),重复本步骤,得到所有螺栓的拧紧力矩分类标记;(3) Input the tightening torque vector of the dimension f×1 in step (1) into the above conscious response model, and obtain the tightening torque classification mark Hi (n) of the ith bolt, repeat this step to obtain the tightening torque of all bolts classification mark;

该模型运行原理为:拧紧力矩向量Hi(n)经意识反应模型第1步处理,得到对角点具有吸引力的拧紧力矩向量yi(n),拧紧力矩向量yi(n)中的每个拧紧力矩值yi,j(n),j=1,2,…,f均在超立方体边界之内(不包括边界),则该拧紧力矩向量处于游离态,即该拧紧力矩向量处于超立方体函数中间陡斜率段,意味着其拧紧力矩向量经由超立方体函数映射得到拧紧力矩向量输出值变化幅度大,该状态点经由超立方体函数映射获得更新的状态值Hi,j(n+1)。不断循环迭代直到Hi(n)位置处于超立方体边界,则该拧紧力矩向量点状态变更为沿壁态,该拧紧力矩向量点将缓慢沿壁爬行,直到进入稳定态;当拧紧力矩向量点位置落于角点位置,即稳定态,所述稳定状态即为超立方体角点位置状态,每一角点代表一个类别。超立方体函数在中间位置曲率大,边缘位置曲率小,目的是让空间点在混沌状态能够尽快靠近超立方体的边缘壁,当到达边缘壁后即以较小的速度选择落点,降低算法收敛时间且提高算法分类准确度。意识反应模型的三维空间图如图4所示。The operating principle of the model is as follows: the tightening torque vector Hi (n) is processed in the first step of the conscious response model, and the tightening torque vector yi (n) with an attractive diagonal point is obtained. The tightening torque vector y i( n) in the Each tightening torque valueyi,j (n), j=1,2,...,f is within the boundary of the hypercube (excluding the boundary), then the tightening torque vector is in the free state, that is, the tightening torque vector is in the hypercube The steep slope segment in the middle of the cube function means that its tightening torque vector is mapped through the hypercube function to obtain the tightening torque vector output value with a large change range, and the state point is mapped through the hypercube function to obtain the updated state value Hi,j (n+1) . Iterate continuously until the position of Hi (n) is at the hypercube boundary, then the state of the tightening torque vector point changes to the state along the wall, and the tightening torque vector point will slowly crawl along the wall until it enters a stable state; when the tightening torque vector point position The position of the corner points is the stable state, and the stable state is the position of the corner points of the hypercube, and each corner point represents a category. The hypercube function has a large curvature in the middle position and a small curvature at the edge position. The purpose is to make the space point close to the edge wall of the hypercube as soon as possible in the chaotic state. And improve the classification accuracy of the algorithm. The three-dimensional space diagram of the conscious response model is shown in Figure 4.

(4)根据步骤(3)所有螺栓的拧紧力矩分类标记,利用下式,计算步骤(1)中拧紧时螺栓的加工精度、润滑度、表面碎屑和环境温度的Gini指标:(4) According to the classification and marking of the tightening torque of all bolts in step (3), use the following formula to calculate the Gini index of the machining accuracy, lubricity, surface debris and ambient temperature of the bolts when tightening in step (1):

其中,e是步骤(1)的环境属性的序号,d是同一聚类角点的拧紧力矩值个数,l是在同一聚类角点中拧紧力矩序号,p为比率,是指以环境属性e作为分类标准,对步骤(2)的意识反应模型聚类角点上的聚类值即拧紧力矩进行分类,分到各环境属性序号的拧紧力矩个数占总拧紧力矩个数的比率;Gini指标越小,说明聚类角点受该环境属性分类影响越小,聚类角点越有可能属于该环境属性。Among them, e is the sequence number of the environmental attribute in step (1), d is the number of tightening torque values in the same cluster corner, l is the tightening torque sequence number in the same cluster corner, p is the ratio, which refers to the environmental attribute e As the classification standard, classify the clustering values on the clustering corners of the consciousness response model in step (2), that is, the tightening torque, and the ratio of the number of tightening torques assigned to each environmental attribute serial number to the total number of tightening torques; Gini The smaller the index is, the less the clustering corners are affected by the classification of the environmental attribute, and the more likely the clustering corners belong to the environmental attribute.

一个聚类角点上的所有拧紧力矩向量构成一个聚类集,计算每一个聚类集与各环境属性相对应的Gini指标,以与该聚类集相对应的Gini指标中的最低Gini指标作为相应环境属性的聚类标签,并将相同聚类标签的聚类角点合并为一个带有聚类标签的聚类集;所述环境属性包括但不限于加工精度、润滑度、表面碎屑和环境温度。All the tightening torque vectors on a cluster corner constitute a cluster set, calculate the Gini index corresponding to each cluster set and each environmental attribute, and take the lowest Gini index among the Gini indices corresponding to the cluster set as the cluster labels of corresponding environmental attributes, and merge the cluster corners of the same cluster label into a cluster set with a cluster label; the environmental attributes include but are not limited to machining accuracy, lubricity, surface debris and ambient temperature.

(5)建立一个基于记忆方法的补偿神经网络,如图5所示,补偿神经网络的模型如下:(5) Establish a compensation neural network based on the memory method, as shown in Figure 5, the model of the compensation neural network is as follows:

ht=tanh(Xt)·Otht =tanh(Xt )·Ot

Xt=Xt-1st+I(t)tanh(Ct)tanh(ht-1)+tanh(ht)Xt =Xt-1 st +I(t)tanh(Ct )tanh(ht-1 )+tanh(ht )

st=μ(Ws·[Xt-1,ht-1,Ct]+bs)st =μ(Ws ·[Xt-1 ,ht-1 ,Ct ]+bs )

It=μ(WI·[Xt-1,ht-1,Ct]+bI)It = μ(WI ·[Xt-1 , ht-1 , Ct ]+bI )

Ot=μ(WO·[Xt-1,ht-1,Ct]+bO)Ot = μ(WO ·[Xt-1 , ht-1 , Ct ]+bO )

其中,tanh符号为双曲正切函数,其表达式如下:Among them, the tanh symbol is the hyperbolic tangent function, and its expression is as follows:

Xt-1为取值在[0,1]之间的记忆细胞,表示对历史输入值hi(i=1,2,…,t-1)的保留程度,当Xt-1的取值为1时,表示“对t-1之前时刻所有输入值hi(i=1,2,…,t-1)完全保留并进入下一公式”,当Xt-1的取值为0时,表示“对t-1之前时刻所有输入值hi(i=1,2,…,t-1)完全舍弃并进入下一公式”,Xt为补偿神经网络的记忆细胞输出,输出值范围为[0,1],Ct为t时刻环境属性序号,ht-1,ht分别为第t-1和t时刻的拧紧力矩,st、It、Ot分别为短时记忆网络、输入网络、输出网络的结果输出,Ws,bs,WI,bI,WO,bO分别为短时记忆网络、输入网络、输出网络的权值向量和偏置;Xt-1 is a memory cell with a value between [0, 1], indicating the degree of retention of the historical input value hi (i =1, 2,..., t-1), when Xt-1 is taken When the value is 1, it means that "all input values hi (i =1,2,...,t-1) at the time before t-1 are completely reserved and entered into the next formula", when the value of Xt-1 is 0 , it means "completely discard all input values hi (i =1,2,...,t-1) before t-1 and enter the next formula", Xt is the memory cell output of the compensation neural network, the output value The range is [0,1], Ct is the serial number of the environmental attribute at time t, ht-1 , ht are the tightening torque at time t-1 and time t, respectively, st , Itt , Ot are short-term memory, respectively The result output of the network, input network, and output network, Ws , bs , WI , bI , WO , bO are the weight vector and bias of the short-term memory network, input network, and output network, respectively;

(6)将步骤(1)得到的第t-1时刻拧紧力矩值、第t时刻的环境属性序号作为步骤(5)的补偿神经网络的输入,步骤(1)的第t时刻的拧紧力矩值作为指导输出,对步骤(5)的补偿神经网络模型中的权值向量、偏置和记忆细胞Xt-1进行随机初始化,训练过程中,将第t-1时刻拧紧力矩值、第t时刻的环境属性序号和记忆细胞Xt-1输入步骤(5)的补偿神经网络,计算输出结果与指导输出的差值,根据该差值对补偿神经网络的权值向量和偏置进行反馈调整,反馈调整的方法可以为梯度下降法等;重复上述训练过程,直到输出结果与指导输出的差值小于设定阈值,该阈值的取值根据模型的精度要求设定,本发明的一个实施例中,取值为10-5,结束训练过程,并将此时的权值向量和偏置作为补偿神经网络中短时记忆网络、输入网络、输出网络的权值向量和偏置,得到训练成熟的补偿神经网络;(6) Take the tightening torque value at time t-1 obtained in step (1) and the environmental attribute serial number at time t as the input of the compensation neural network in step (5), and the tightening torque value at time t in step (1) As a guide output, the weight vector, bias and memory cell Xt-1 in the compensation neural network model in step (5) are randomly initialized. During the training process, the tightening torque value at time t-1 and the The environmental attribute serial number and the memory cell Xt-1 are input into the compensation neural network of step (5), the difference between the output result and the guidance output is calculated, and the weight vector and bias of the compensation neural network are feedback adjusted according to the difference. The feedback adjustment method can be a gradient descent method, etc.; the above-mentioned training process is repeated until the difference between the output result and the guidance output is less than a set threshold value, and the value of the threshold value is set according to the accuracy requirements of the model. In one embodiment of the present invention , the value is 10-5 , end the training process, and use the weight vector and bias at this time as the weight vector and bias of the short-term memory network, input network, and output network in the compensation neural network, and get a mature training Compensation neural network;

(7)设当前时刻为g时刻,将第g-1时刻的拧紧力矩值hg-1、当前g时刻的环境属性序号值Cg以及第g-1时刻记忆细胞Xg-1输入到步骤(6)训练成熟的补偿神经网络中,输出的hg即为当前g时刻的补偿后的拧紧力矩值。(7) Set the current time as time g, and input the tightening torque value hg-1 at the g-1 time, the environmental attribute serial number value Cg at the current g time, and the

下面介绍本发明方法的一个实施例:An embodiment of the method of the present invention is introduced below:

理想状态下,采集的拧紧力矩值呈现正态分布;但由于动态环境的变化,拧紧力矩值往往呈现多峰分布(环境属性数目与峰数目呈正相关)。本发明用计算机模拟生成受动态环境变化影响的拧紧力矩值样本,多峰分布函数如下:Ideally, the collected tightening torque values show a normal distribution; however, due to changes in the dynamic environment, the tightening torque values often show a multimodal distribution (the number of environmental attributes is positively correlated with the number of peaks). The invention uses computer simulation to generate samples of tightening torque values affected by dynamic environmental changes, and the multi-peak distribution function is as follows:

其中本实施例将各参数设置为:a1=60,σ1=2,k1=0.3;a2=65,σ2=2,k2=0.3;a3=60,σ3=2,k3=0.3。如图6所示。In this embodiment, the parameters are set as: a1 =60, σ1 =2, k1 =0.3; a2 =65,σ2 =2,k2 =0.3;a3 =60,σ3 =2, k3 =0.3. As shown in Figure 6.

根据上述概率密度函数进行模拟采样,共生成3304个拧紧力矩,部分样本值如表2所示。According to the above probability density function, a total of 3304 tightening torques are generated by simulation sampling, and some sample values are shown in Table 2.

取f=3,将上述一维拧紧力矩值扩展为三维向量,如下所示:Taking f=3, the above one-dimensional tightening torque value is expanded into a three-dimensional vector, as shown below:

H1=(66.2,66.2,66.2)TH1 = (66.2, 66.2, 66.2)T

H2=(67.0,67.0,67.0)TH2 = (67.0, 67.0, 67.0)T

H3304=(70.2,70.2,70.2)TH3304 = (70.2, 70.2, 70.2)T

将上述三维阈值向量输入意识反应模型进行训练和聚类,聚类结果集中在(-1,-1,-1)、(1,1,1)、(-1,1,1)、(1,-1,-1)四个角点。因此上述输入样本被意识反应模型分为四类。The above three-dimensional threshold vector is input into the conscious response model for training and clustering, and the clustering results are concentrated in (-1, -1, -1), (1, 1, 1), (-1, 1, 1), (1 , -1, -1) four corner points. Therefore, the above input samples are classified into four categories by the conscious response model.

考虑三种环境属性,分别为润滑程度(无润滑)、加工精度(加工不合格)、上一工艺涂料残留度(有残留物),某一实施例下的Gini系数表如下:Considering three environmental attributes, namely, the degree of lubrication (no lubrication), the processing accuracy (unqualified processing), and the degree of paint residue in the previous process (with residues), the Gini coefficient table under a certain embodiment is as follows:

从上表可知,归为(-1,-1,-1)的集合点为润滑程度不足情况下的拧紧值;归为(1,1,1)的集合点为涂料有残余情况下的拧紧值;归为(-1,1,1)的集合点为加工精度不足情况下的拧紧值;归为(1,-1,-1)的集合点也为加工精度不足情况下的拧紧值。设置标签,令润滑程度标签为-1,加工精度标签为2和-2,涂料残余标签为1,可生成带标签训练数据(共3478条训练数据)如下:It can be seen from the above table that the set point classified as (-1, -1, -1) is the tightening value when the degree of lubrication is insufficient; the set point classified as (1, 1, 1) is the tightening value when there is residual paint value; the set point classified as (-1, 1, 1) is the tightening value when the machining accuracy is insufficient; the set point classified as (1, -1, -1) is also the tightening value when the machining accuracy is insufficient. Set the labels so that the lubrication level label is -1, the machining accuracy label is 2 and -2, and the paint residue label is 1, and the labeled training data (3478 pieces of training data in total) can be generated as follows:

将上述带标签数据按时间序列训练补偿神经网络,直到输出结果与指导输出的差值小于设定阈值,该阈值的取值根据模型的精度要求设定,本发明的一个实施例中,取值为10-5,结束训练过程,并将此时的权值向量和偏置作为补偿神经网络中短时记忆网络、输入网络、输出网络的权值向量和偏置,得到训练成熟的补偿神经网络,训练成熟神经网络即具备补偿功能。The above-mentioned labeled data is trained in a time series to compensate the neural network until the difference between the output result and the guidance output is less than the set threshold, and the value of the threshold is set according to the accuracy requirements of the model. In one embodiment of the present invention, the value of is 10-5 , end the training process, and use the weight vector and bias at this time as the weight vector and bias of the short-term memory network, input network, and output network in the compensation neural network, and obtain a well-trained compensation neural network , the training of mature neural network has the compensation function.

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811328102.0ACN109583043B (en) | 2018-11-09 | 2018-11-09 | Self-adaptive compensation method for tightening torque for bolt connection |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811328102.0ACN109583043B (en) | 2018-11-09 | 2018-11-09 | Self-adaptive compensation method for tightening torque for bolt connection |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109583043A CN109583043A (en) | 2019-04-05 |

| CN109583043Btrue CN109583043B (en) | 2020-09-22 |

Family

ID=65921870

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811328102.0AActiveCN109583043B (en) | 2018-11-09 | 2018-11-09 | Self-adaptive compensation method for tightening torque for bolt connection |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109583043B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111252166B (en)* | 2020-01-20 | 2021-08-31 | 山东大学 | A method and device for assembly process control of bulldozer handling assembly based on K-means clustering algorithm |

| CN112404965B (en)* | 2020-10-27 | 2021-11-23 | 中国科学院沈阳自动化研究所 | High-flexibility screwing assembly method for large length-diameter ratio easily-deformed cylinder section threads |

| CN112692532A (en)* | 2020-12-15 | 2021-04-23 | 大连光洋科技集团有限公司 | Digital assembly system and method based on Internet of things |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102590348A (en)* | 2012-01-19 | 2012-07-18 | 清华大学 | Method and system for detecting local impedance change of objects |

| EP2544124A1 (en)* | 2011-07-04 | 2013-01-09 | Sabirmedical, S.L. | Methods and systems for non-invasive measurement of glucose levels |

| CN103440527A (en)* | 2013-07-29 | 2013-12-11 | 辽宁大学 | Method for improving ant colony algorithm optimization support vector machine parameters |

| CN103793853A (en)* | 2014-01-21 | 2014-05-14 | 中国南方电网有限责任公司超高压输电公司检修试验中心 | Overhead power transmission line running state assessment method based on bidirectional Bayesian network |

| CN104985807A (en)* | 2015-06-19 | 2015-10-21 | 大连理工大学 | Pressure self-adaptation device used for precise ultrasonic welding of POCT chip product |

| CN105938485A (en)* | 2016-04-14 | 2016-09-14 | 北京工业大学 | Image description method based on convolution cyclic hybrid model |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9575013B2 (en)* | 2011-05-17 | 2017-02-21 | Gii Acquisition, Llc | Non-contact method and system for inspecting a manufactured part at an inspection station having a measurement axis |

- 2018

- 2018-11-09CNCN201811328102.0Apatent/CN109583043B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2544124A1 (en)* | 2011-07-04 | 2013-01-09 | Sabirmedical, S.L. | Methods and systems for non-invasive measurement of glucose levels |

| CN102590348A (en)* | 2012-01-19 | 2012-07-18 | 清华大学 | Method and system for detecting local impedance change of objects |

| CN103440527A (en)* | 2013-07-29 | 2013-12-11 | 辽宁大学 | Method for improving ant colony algorithm optimization support vector machine parameters |

| CN103793853A (en)* | 2014-01-21 | 2014-05-14 | 中国南方电网有限责任公司超高压输电公司检修试验中心 | Overhead power transmission line running state assessment method based on bidirectional Bayesian network |

| CN104985807A (en)* | 2015-06-19 | 2015-10-21 | 大连理工大学 | Pressure self-adaptation device used for precise ultrasonic welding of POCT chip product |

| CN105938485A (en)* | 2016-04-14 | 2016-09-14 | 北京工业大学 | Image description method based on convolution cyclic hybrid model |

Non-Patent Citations (4)

| Title |

|---|

| Bolt tightening control using neural networks;T. Fujinaka .etal;《2001 IEEE International Conference on Systems, Man and Cybernetics. e-Systems and e-Man for Cybernetics in Cyberspace (Cat.No.01CH37236)》;20020806;1390-1395页* |

| Interface contact pressure-based virtual gradient material model for the dynamic analysis of the bolted joint in machine tools;Jingping Liao .etal;《Journal of Mechanical Science and Technology》;20161019;4511-4521页* |

| 原位检测系统中触发式测头半径误差分析与建模;韩如聪 等;《组合机床与自动化加工技术》;20141226(第12期);60-64页* |

| 结构动力学鲁棒设计方法及应用;杨隽;《中国优秀硕士学位论文全文数据库-工程科技Ⅱ辑》;20150215(第2期);C029-56页* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109583043A (en) | 2019-04-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109583043B (en) | Self-adaptive compensation method for tightening torque for bolt connection | |

| CN107798349B (en) | A transfer learning method based on deep sparse autoencoder | |

| CN110941734B (en) | Deep unsupervised image retrieval method based on sparse graph structure | |

| Liu et al. | A fault diagnosis intelligent algorithm based on improved BP neural network | |

| CN107016241A (en) | Based on the rotating machinery lifetime stage recognition methods for adding sample enhancing depth own coding learning network of making an uproar | |

| CN106503867A (en) | A kind of genetic algorithm least square wind power forecasting method | |

| CN103077408B (en) | Method for converting seabed sonar image into acoustic substrate classification based on wavelet neutral network | |

| CN111239137B (en) | Grain quality detection method based on transfer learning and adaptive deep convolution neural network | |

| CN115561005B (en) | Chemical process fault diagnosis method based on EEMD decomposition and lightweight neural network | |

| CN114399642B (en) | Convolutional neural network fluorescence spectrum feature extraction method | |

| CN105701512A (en) | Image classification method based on BBO-MLP and texture characteristic | |

| CN107169117A (en) | A kind of manual draw human motion search method based on autocoder and DTW | |

| CN110163437B (en) | Day-ahead photovoltaic power generation power prediction method based on DPK-means | |

| CN110110794B (en) | Image classification method for updating neural network parameters based on feature function filtering | |

| CN112381027B (en) | Wheel polygon wave depth estimation method based on train axle box vertical acceleration signal | |

| CN114049305A (en) | Pin defect detection method for distribution line based on improved ALI and Faster-RCNN | |

| CN115935941B (en) | A data alignment method for power business system based on graph convolutional neural network | |

| CN118036809A (en) | Fault current prediction method and medium based on snow melting optimized recurrent neural network | |

| CN107045659A (en) | Predict the method and device of photovoltaic generation power | |

| CN115761868A (en) | A Robust Adaptive Update Method for Facial Expression Classification in Uncertain Environments | |

| CN111275256A (en) | A day-ahead prediction method for photovoltaic power generation based on image feature extraction | |

| CN117422960B (en) | Image recognition continuous learning method based on meta learning | |

| CN115114967A (en) | Automatic classification method of steel microstructure based on self-organizing incremental-graph convolutional neural network | |

| CN112712192A (en) | Coal mine gas concentration prediction method combining integrated learning and weighted extreme learning machine | |

| Mishra et al. | Identification of real-time maglev plant using long-short term memory network based deep learning technique |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |