CN109487103B - Preparation method of tungsten-tantalum-rhenium alloy with high hardness - Google Patents

Preparation method of tungsten-tantalum-rhenium alloy with high hardnessDownload PDFInfo

- Publication number

- CN109487103B CN109487103BCN201910026643.6ACN201910026643ACN109487103BCN 109487103 BCN109487103 BCN 109487103BCN 201910026643 ACN201910026643 ACN 201910026643ACN 109487103 BCN109487103 BCN 109487103B

- Authority

- CN

- China

- Prior art keywords

- powder

- tungsten

- tantalum

- sintering

- laser

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C1/00—Making non-ferrous alloys

- C22C1/04—Making non-ferrous alloys by powder metallurgy

- C22C1/045—Alloys based on refractory metals

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/20—Direct sintering or melting

- B22F10/28—Powder bed fusion, e.g. selective laser melting [SLM] or electron beam melting [EBM]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/14—Treatment of metallic powder

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/20—Direct sintering or melting

- B22F10/25—Direct deposition of metal particles, e.g. direct metal deposition [DMD] or laser engineered net shaping [LENS]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/30—Process control

- B22F10/34—Process control of powder characteristics, e.g. density, oxidation or flowability

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/60—Treatment of workpieces or articles after build-up

- B22F10/64—Treatment of workpieces or articles after build-up by thermal means

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y10/00—Processes of additive manufacturing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y70/00—Materials specially adapted for additive manufacturing

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C27/00—Alloys based on rhenium or a refractory metal not mentioned in groups C22C14/00 or C22C16/00

- C22C27/04—Alloys based on tungsten or molybdenum

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/16—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of other metals or alloys based thereon

- C22F1/18—High-melting or refractory metals or alloys based thereon

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B22F2003/248—Thermal after-treatment

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- Automation & Control Theory (AREA)

- Plasma & Fusion (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Powder Metallurgy (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种硬度高的合金的制备方法,具体涉及一种硬度高的钨钽铼合金的制备方法。The invention relates to a preparation method of an alloy with high hardness, in particular to a preparation method of a tungsten-tantalum-rhenium alloy with high hardness.

背景技术Background technique

钨的碳化物具有高的硬度、耐磨性和难熔性。这些合金含有85%—95%的碳化钨和5%—14%的钴,钴是作为粘结剂金属,它使合金具有必要的强度。主要用于加工钢的某些合金中,还含有钛、钽和铌的碳化物。所有这些合金都是用粉末冶金法制造的。当加热到1000—1100℃时,它们仍具有高的硬度和耐磨性。硬质合金刀具的切削速度远远地超过了最好的工具钢刀具的切削速度。硬质合金主要用于切削工具、矿山工具和拉丝模等。Tungsten carbides have high hardness, wear resistance and refractoriness. These alloys contain 85%-95% tungsten carbide and 5%-14% cobalt, which acts as a binder metal, which gives the alloy the necessary strength. Some alloys mainly used for machining steel also contain carbides of titanium, tantalum and niobium. All of these alloys are manufactured by powder metallurgy. When heated to 1000-1100 ℃, they still have high hardness and wear resistance. The cutting speed of carbide tools far exceeds the cutting speed of the best tool steel tools. Carbide is mainly used in cutting tools, mining tools and wire drawing dies.

金属钨及其合金是广泛用于灯丝、高温热电偶等方面的重要难熔合金材料,金属钨是目前发现熔点最高的金属材料,其熔点达到3410℃,但金属钨本身韧性、抗震性差,无法满足如汽车、振动设备等振动场所的需求,铼和钽分别是熔点第二和第四高的金属,其熔点分别达到3180℃和2996℃,这两种金属不仅熔点高,韧性和抗震性也明显优于钨,但钨-钽-铼合金的烧结却非常苦难,一般来讲制备钨-钽-铼合金的原材料为粉体,经过混料、蜜炼、压力成形、催化脱脂或溶剂脱脂、垂熔烧结等多道工序制成,制备过程非常复杂,能耗高、对环境有污染。另一方面,现有方法不适合一次制得较小零件,需先制得较大棒材,经过锻压开坯、机加工等工序方能制得最终零部件,终产品晶粒均匀性较差,硬度不够理想。如王华森等研究的钨块体烧结尺寸分别为52×27×65mm3和96×30×660mm3,重量分别为14千克和33千克,其烧结功率需要600kW。北京有色金属研究总院的李全旺等研制的垂熔烧结方法要求钨棒尺寸为其烧结功率为100kW。可见传统垂熔烧结法生产钨及其合金需要样品尺寸大,能耗高。Metal tungsten and its alloys are important refractory alloy materials widely used in filaments, high-temperature thermocouples, etc. Metal tungsten is the metal material with the highest melting point, and its melting point reaches 3410 ° C, but metal tungsten itself has poor toughness and shock resistance. To meet the needs of vibration places such as automobiles and vibration equipment, rhenium and tantalum are the metals with the second and fourth highest melting points respectively, and their melting points reach 3180 ° C and 2996 ° C respectively. These two metals not only have high melting points, but also have high toughness and shock resistance. It is obviously better than tungsten, but the sintering of tungsten-tantalum-rhenium alloy is very difficult. Generally speaking, the raw material for preparing tungsten-tantalum-rhenium alloy is powder. After mixing, honey refining, pressure forming, catalytic degreasing or solvent degreasing, It is made by multiple processes such as vertical melting and sintering. The preparation process is very complicated, with high energy consumption and environmental pollution. On the other hand, the existing method is not suitable for producing smaller parts at one time. Larger bars need to be produced first, and then the final parts can be produced through processes such as forging, blanking, machining, etc., and the grain uniformity of the final product is poor. Hardness is not ideal. For example, the sintering size of the tungsten block studied by Wang Huasen et al. is 52×27×65mm3 and 96×30×660mm3 respectively, the weight is 14kg and 33kg respectively, and the sintering power needs 600kW. The vertical melting sintering method developed by Li Quanwang of Beijing Nonferrous Metals Research Institute requires the size of the tungsten rod to be Its sintering power is 100kW. It can be seen that the production of tungsten and its alloys by the traditional vertical melting sintering method requires large sample size and high energy consumption.

目前钨钽铼合金的制备方法主要存在制备过程复杂,能耗高,对环境污染较大,无法一次制得较小零件,制备过程易出现团聚,也易收缩厉害出现凹坑状,应力太大易出现开裂,终产品容易产生气孔,还易形成疏松块,钨容易被氧化而致密性不好,成分不均匀,影响力学性能等技术问题亟需解决。At present, the preparation methods of tungsten-tantalum-rhenium alloys mainly include complex preparation process, high energy consumption, and large environmental pollution, and it is impossible to prepare smaller parts at one time. It is easy to crack, the final product is easy to produce pores, and it is easy to form loose blocks. Tungsten is easily oxidized and has poor compactness, uneven composition, and mechanical properties. Technical problems need to be solved urgently.

发明内容SUMMARY OF THE INVENTION

本发明目的在于提供一种硬度高的钨钽铼合金的制备方法。The purpose of the present invention is to provide a preparation method of a tungsten-tantalum-rhenium alloy with high hardness.

本发明目的通过如下技术方案实现:The object of the present invention is achieved through the following technical solutions:

一种硬度高的钨钽铼合金的制备方法,它包括原料球磨处理、激光烧结、二次烧结、试样后处理,其特征在于,在原料球磨处理之后,激光烧结之前,还需进行脱氧处理步骤,所述脱氧处理步骤是将球磨处理后的粉末置于真空手套箱中,温度设定至80~90℃,通入氩气,保持氩气压强为0.100Mpa~0.105Mpa,保持时间2~2.5小时,处理结束,密闭备用。A method for preparing a tungsten-tantalum-rhenium alloy with high hardness, which comprises raw material ball milling, laser sintering, secondary sintering, and sample post-treatment, and is characterized in that, after the raw material ball milling and before laser sintering, deoxidation treatment is required. Step, the deoxidation treatment step is to place the ball-milled powder in a vacuum glove box, set the temperature to 80-90° C., pass argon gas, keep the argon pressure at 0.100Mpa-0.105Mpa, and keep the time 2- After 2.5 hours, the treatment was completed, and it was sealed for use.

一种硬度高的钨钽铼合金的制备方法,它包括原料球磨处理、激光烧结、二次烧结、试样后处理,其特征在于,所述原料球磨处理是将钨粉、钽粉、铼粉置于球磨机中,再加入无水乙醇作为过程控制制剂,进行球磨24~28小时,球磨结束再用无水乙醇进行清洗2次,清洗结束,置于离心机中进行分离,离心结束收集粉末置于真空干燥箱中,设置干燥温度为60~70℃,干燥8~12小时,干燥结束后置于玛瑙研钵研磨28~32min,研磨结束,置于干燥瓶中,备用。A method for preparing a tungsten-tantalum-rhenium alloy with high hardness, which comprises raw material ball milling, laser sintering, secondary sintering, and sample post-treatment, and is characterized in that the raw material ball milling treatment is to mix tungsten powder, tantalum powder and rhenium powder. Put it in a ball mill, add absolute ethanol as a process control agent, and perform ball milling for 24 to 28 hours. After the ball milling is completed, wash it twice with absolute ethanol. After the cleaning is completed, place it in a centrifuge for separation. In a vacuum drying box, set the drying temperature to 60-70°C, dry for 8-12 hours, place it in an agate mortar and grind for 28-32 minutes after drying, and place it in a drying bottle for later use after grinding.

一种硬度高的钨钽铼合金的制备方法,它包括原料球磨处理、激光烧结、二次烧结、试样后处理,其特征在于,上述钨粉、钽粉、铼粉质量比为95:3:2,所述过程控制制剂无水乙醇加入量为钨粉、钽粉、铼粉总质量的20%~25%;清洗用无水乙醇用量为钨粉、钽粉、铼粉总质量的10~15倍,上述钨粉需过500目筛、上述钽粉需过500目筛、上述铼粉需过400目筛,所述球磨过程中的球料比为10:1。A method for preparing a tungsten-tantalum-rhenium alloy with high hardness, which comprises raw material ball milling, laser sintering, secondary sintering, and sample post-processing, and is characterized in that the mass ratio of the tungsten powder, tantalum powder, and rhenium powder is 95:3 : 2, the addition amount of absolute ethanol of the process control preparation is 20% to 25% of the total mass of tungsten powder, tantalum powder and rhenium powder; the amount of absolute ethanol used for cleaning is 10% of the total mass of tungsten powder, tantalum powder and rhenium powder. ~ 15 times, the above-mentioned tungsten powder needs to pass through a 500-mesh sieve, the above-mentioned tantalum powder needs to pass through a 500-mesh sieve, and the above-mentioned rhenium powder needs to pass through a 400-mesh sieve, and the ball-to-material ratio in the ball milling process is 10:1.

一种硬度高的钨钽铼合金的制备方法,它包括原料球磨处理、激光烧结、二次烧结、试样后处理,其特征在于,所述激光烧结是将脱氧后的混合粉末置于激光烧结自动化操作平台送粉器中,设置激光光斑为5×4mm2方形光斑,激光扫描速度为2mm/s,激光头单次行程为100~150mm,行距为3~4mm,单层往复次数为2~10,层距为0.5~1mm,铺粉层数为2~10层;所述激光烧结是采用烧结与熔覆相结合的复合成形法,激光头在每一个行程往返一次,行程的去程为烧结过程,回程为熔覆过程,激光器烧结过程功率设定在1.8~2kW,熔覆过程功率设定在2.6~2.8kW。A preparation method of tungsten-tantalum-rhenium alloy with high hardness, which comprises raw material ball milling treatment, laser sintering, secondary sintering, and sample post-treatment, characterized in that, the laser sintering is to place the deoxidized mixed powder in laser sintering In the powder feeder of the automatic operation platform, the laser spot is set as a 5×4mm2 square spot, the laser scanning speed is2mm /s, the single stroke of the laser head is 100~150mm, the line spacing is 3~4mm, and the number of single-layer reciprocation is 2~ 10. The layer distance is 0.5-1mm, and the number of powder layers is 2-10 layers; the laser sintering is a composite forming method combining sintering and cladding. In the sintering process, the return trip is the cladding process, the power of the laser sintering process is set at 1.8-2kW, and the power in the cladding process is set at 2.6-2.8kW.

进一步,所述激光烧结过程还需要持续通入氩气进行保护,所述氩气纯度为99.999%,氩气压强为0.100~0.105MPa,流量为8~10L/min,激光头还需通入循环水进行冷却处理。Further, the laser sintering process also needs to be protected by continuous introduction of argon gas, the purity of the argon gas is 99.999%, the argon pressure is 0.100-0.105MPa, the flow rate is 8-10L/min, and the laser head needs to be circulated water for cooling.

为了使得材料更加致密,所述二次烧结是再次重复激光烧结过程。In order to make the material more dense, the secondary sintering is to repeat the laser sintering process again.

一种硬度高的钨钽铼合金的制备方法,它包括原料球磨处理、激光烧结、二次烧结、试样后处理,其特征在于,所述试样后处理是将激光烧结试样进行线切割,然后进行去应力退火;所述退火是将试样在50~60min以升温速率为8~12℃/min升到600℃,然后保温30~40min,再在45~50min以升温速率为6~8℃/min的升温速率升温至900℃,然后再保温60min,最后随炉冷却,即得。A method for preparing a tungsten-tantalum-rhenium alloy with high hardness, which comprises raw material ball milling, laser sintering, secondary sintering, and sample post-processing, characterized in that the sample post-processing is to wire-cut the laser sintered sample , and then perform stress relief annealing; the annealing is to raise the sample to 600°C at a heating rate of 8 to 12°C/min for 50 to 60 minutes, then keep the temperature for 30 to 40 minutes, and then at a heating rate of 6 to 50 minutes for 45 to 50 minutes. The heating rate of 8°C/min was raised to 900°C, then kept for 60min, and finally cooled with the furnace.

本发明具有如下的有益效果:The present invention has the following beneficial effects:

本发明可一次成型制得小零件,不会出现团聚现象,且终产品表面均匀,不会出现凹坑、气孔等不良产品,也不会出现疏松块,材质均匀、结构致密、较大应力也不会出现开裂现象,产品致密度好,大于99%,产品硬度高,可高达870.7,韧性好,熔点高,可高达3450℃以上,制备工艺简单可行,节能环保,可直接制备简单形状的零部件,产品晶粒平均粒径为3.4μm,晶粒尺寸分布均匀,接近等轴晶,密度均匀,平均密度为19.2g/cm3,值得市场推广应用。The invention can produce small parts by one-time molding, no agglomeration phenomenon occurs, and the surface of the final product is uniform, no bad products such as pits and pores, and no loose blocks, uniform material, dense structure, and high stress. There is no cracking phenomenon, the product has good density, more than 99%, high product hardness, up to 870.7, good toughness, high melting point, up to 3450 ℃, simple and feasible preparation process, energy saving and environmental protection, can directly prepare simple shape zero Parts, the average grain size of the product is 3.4μm, the grain size distribution is uniform, close to equiaxed crystal, the density is uniform, and the average density is 19.2g/cm3 , which is worthy of market promotion and application.

附图说明Description of drawings

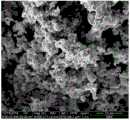

图1为本发明钨-钽-铼合金混料后的粉末扫面电镜图。Fig. 1 is the powder scanning electron microscope image of the tungsten-tantalum-rhenium alloy mixture of the present invention.

图2为本发明钨-钽-铼混料的EDS能谱图。Fig. 2 is the EDS energy spectrum of the tungsten-tantalum-rhenium mixture of the present invention.

图3为本发明激光烧结后通过线切割获得的钨-钽-铼合金试样图。3 is a diagram of a sample of tungsten-tantalum-rhenium alloy obtained by wire cutting after laser sintering in the present invention.

图4为本发明扫描电镜获得的钨-钽-铼合金微观组织图。Fig. 4 is the microstructure diagram of the tungsten-tantalum-rhenium alloy obtained by the scanning electron microscope of the present invention.

具体实施方式Detailed ways

下面通过实施例对本发明进行具体的描述,有必要在此指出的是以下实施例只用于对本发明进行进一步说明,不能理解为对本发明保护范围的限制,该领域的技术人员可以根据上述本发明内容对本发明作出一些非本质的改进和调整。The present invention will be specifically described by the following examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. The content makes some non-essential improvements and adjustments to the present invention.

实施例1钨钽铼合金的制备:The preparation of embodiment 1 tungsten-tantalum-rhenium alloy:

(1)原料处理(1) Raw material processing

混料质量百分比为钨粉:钽粉:铼粉=95:3:2(配料总量为50g)。三种粉体粒径分别为:铼粉500目,钨粉为500目,钽粉为400目。球磨罐内衬为陶瓷材质,采用直径为10mm的瓷球为磨球,球料比为10:1,过程控制剂为23%无水乙醇,球磨时间为36h。原料球磨后利用无水乙醇进行清洗两次,每次用650g无水乙醇清洗,然后置于离心机中设置离心转速为1500转/min,离心时间为2分钟进行分离,将洗涤好的粉末在真空干燥箱中进行干燥,温度设定为65℃,干燥时间10小时。干燥后的粉末利用玛瑙研钵研磨30min,将得到的粉体放置于干燥瓶中待用,制备好的粉体如图1所示。将球磨处理后的粉末置于真空手套箱中,温度设定至85℃,通入氩气,保持氩气压强为0.103MPa,保持时间2小时,处理结束,密闭备用。The mass percentage of the mixture is tungsten powder: tantalum powder: rhenium powder = 95:3:2 (the total amount of ingredients is 50g). The particle sizes of the three powders are: 500 mesh for rhenium powder, 500 mesh for tungsten powder, and 400 mesh for tantalum powder. The inner lining of the ball mill is made of ceramic material, and the ceramic ball with a diameter of 10mm is used as the grinding ball. After the raw material is ball-milled, it is washed twice with absolute ethanol, each time with 650 g of absolute ethanol, and then placed in a centrifuge with a centrifugal speed of 1500 rpm and a centrifugation time of 2 minutes for separation. Drying was performed in a vacuum drying oven, the temperature was set to 65°C, and the drying time was 10 hours. The dried powder was ground in an agate mortar for 30 minutes, and the obtained powder was placed in a drying bottle for use. The prepared powder was shown in Figure 1. The ball-milled powder was placed in a vacuum glove box, the temperature was set to 85° C., and argon gas was introduced to keep the argon pressure at 0.103 MPa for 2 hours. After the treatment, it was sealed for use.

(2)激光烧结工艺参数设置(2) Laser sintering process parameter setting

将脱氧后的混合粉末置于激光烧结自动化操作平台送粉器中,设置激光光斑为5×4mm2方形光斑,激光扫描速度为2mm/s,激光头单次行程为130mm,行距为3.5mm,单层往复次数为8,层距为0.7mm,铺粉层数为8层;所述激光烧结是采用烧结与熔覆相结合的复合成形法,激光头在每一个行程往返一次,行程的去程为烧结过程,回程为熔覆过程,激光器烧结过程功率设定在1.8~2kW,熔覆过程功率设定在2.6~2.8kW;所述氩气纯度为99.999%,氩气压强0.103MPa,流量为9L/min,激光头还需通入循环水进行冷却处理。重复上述激光烧结工艺,即为第二次烧结。Place the deoxidized mixed powder in the powder feeder of the laser sintering automatic operation platform, set the laser spot to be5 ×4mm2 square spot, the laser scanning speed to be 2mm/s, the single stroke of the laser head to be 130mm, and the line spacing to be 3.5mm. The number of single-layer reciprocation is 8, the layer distance is 0.7mm, and the number of powder layers is 8; the laser sintering is a composite forming method combining sintering and cladding. The process is the sintering process, the return process is the cladding process, the power of the laser sintering process is set at 1.8-2kW, and the power of the cladding process is set at 2.6-2.8kW; the purity of the argon gas is 99.999%, the argon pressure is 0.103MPa, and the flow rate is 0.103MPa. 9L/min, the laser head needs to be cooled with circulating water. Repeating the above laser sintering process is the second sintering.

(3)试样后处理(3) Sample post-processing

将激光烧结试样进行线切割,分割成尺寸为6×6×3mm3的小试样,如图3所示。然后进行去应力退火,以消除残余应力。所述退火是将试样在55min以内升温速率为10℃/min升到600℃,然后保温35min,再在48min以内升温速率为7℃/min的升温速率升温至900℃,然后再保温60min,最后随炉冷却,即得。The laser sintered samples were wire-cut and divided into small samples with a size of 6 × 6 ×3 mm, as shown in Figure 3. Then a stress relief annealing is performed to remove residual stress. The annealing is to raise the temperature of the sample to 600°C at a heating rate of 10°C/min within 55min, then keep the temperature for 35min, and then heat the sample to 900°C with a heating rate of 7°C/min within 48min, and then keep the temperature for 60min. Finally, it is cooled with the furnace and it is obtained.

将实施例1制得的试样进行组织观察、密度测试和硬度测试,实验结果分别如图4、表1和表2所示。图4为利用扫描电镜观察到的试样晶粒组织,获得的样品的晶粒平均粒径为3.4μm,晶粒尺寸分布较为均匀,接近等轴晶。对试样进行了密度测试,同等条件下测量10次,取平均值,如表1所示,得到样品的平均密度为19.20g/cm3。对试样进行了显微硬度测试,在样品的磨光表面上随机进行10次测试,取平均值,如表1所示,得到样品的平均维氏硬度为870.7。The sample prepared in Example 1 was subjected to tissue observation, density test and hardness test. The experimental results are shown in Figure 4, Table 1 and Table 2, respectively. Figure 4 shows the grain structure of the sample observed by scanning electron microscope. The average grain size of the obtained sample is 3.4 μm, and the grain size distribution is relatively uniform and close to equiaxed. The sample was tested for density, measured 10 times under the same conditions, and the average value was taken. As shown in Table 1, the average density of the obtained sample was 19.20 g/cm3 . The microhardness test was carried out on the sample, and 10 tests were randomly carried out on the polished surface of the sample, and the average value was taken. As shown in Table 1, the average Vickers hardness of the sample was 870.7.

表1平均密度测试值Table 1 Average Density Test Values

表2维氏硬度测试值Table 2 Vickers hardness test value

实验1:将实施例1制得的产品进行致密度测定Experiment 1: Density determination of the product prepared in Example 1

先用电子天平测出待测试样的质量m1;再在量筒中装入适量的水(所谓适量是指既能将物体完全浸没又不会超过量筒的最大刻度),并将量筒至于电子天平上,将电子天平回零。用细丝(放入水中体积可忽略不计)将物体拴住,沿量筒壁缓缓滑下直至完全浸没,读出此时的质量数m2;利用密度公式即可求出物体的密度:ρ=m1ρ水/m2。First measure the mass m1 of the sample to be tested with an electronic balance; then put an appropriate amount of water in the measuring cylinder (the so-called appropriate amount means that the object can be completely immersed without exceeding the maximum scale of the measuring cylinder), and the measuring cylinder is placed in the electronic On the balance, reset the electronic balance to zero. Tie the object with a filament (the volume in water is negligible), slowly slide down the wall of the measuring cylinder until it is completely submerged, and read the mass number m2 at this time; the density of the object can be obtained by using the density formula: ρ =m1 ρwater /m2 .

经测定,实施例1产品致密度99.5%。It was determined that the product of Example 1 had a density of 99.5%.

实验2:将实施例1制得的产品进行熔点测定Experiment 2: Determination of the melting point of the product prepared in Example 1

采用西安红外检测仪器有限公司生产的ST200-F型蓝牙红外测温仪结合温度场模拟获取激光烧结时的试样最高温度。The ST200-F Bluetooth infrared thermometer produced by Xi'an Infrared Detection Instrument Co., Ltd. was used to obtain the maximum temperature of the sample during laser sintering combined with temperature field simulation.

表3激光烧结过程中的试样实际测算温度Table 3 The actual measured temperature of the sample during the laser sintering process

实施例2钨钽铼合金的制备:The preparation of embodiment 2 tungsten-tantalum-rhenium alloy:

(1)原料处理(1) Raw material processing

混料质量百分比为钨粉:钽粉:铼粉=95:3:2(配料总量为50g)。三种粉体粒径分别为:铼粉500目,钨粉为500目,钽粉为400目。球磨罐内衬为陶瓷材质,采用直径为10mm的瓷球为磨球,球料比为10:1,过程控制剂为25%无水乙醇,球磨时间为48h。原料球磨后利用无水乙醇进行清洗两次,每次用750g无水乙醇清洗,然后置于离心机中设置离心转速为2000转/min,离心时间为2分钟进行分离,将洗涤好的粉末在真空干燥箱中进行干燥,温度设定为70℃,干燥时间8小时。干燥后的粉末利用玛瑙研钵研磨32min,将得到的粉体放置于干燥瓶中待用,制备好的粉体如图1所示。将球磨处理后的粉末置于真空手套箱中,温度设定至90℃,通入氩气,保持氩气压强为0.105MPa,保持时间2.5小时,处理结束,密闭备用。The mass percentage of the mixture is tungsten powder: tantalum powder: rhenium powder = 95:3:2 (the total amount of ingredients is 50g). The particle sizes of the three powders are: 500 mesh for rhenium powder, 500 mesh for tungsten powder, and 400 mesh for tantalum powder. The lining of the ball mill tank is made of ceramic material, and the ceramic ball with a diameter of 10mm is used as the grinding ball. After the raw material is ball-milled, it is washed twice with absolute ethanol, each time with 750 g of absolute ethanol, and then placed in a centrifuge with a centrifugal speed of 2000 rpm and a centrifugation time of 2 minutes for separation. Drying was carried out in a vacuum drying oven, the temperature was set to 70°C, and the drying time was 8 hours. The dried powder was ground in an agate mortar for 32 minutes, and the obtained powder was placed in a drying bottle for use. The prepared powder was shown in Figure 1. The ball-milled powder was placed in a vacuum glove box, the temperature was set to 90° C., and argon gas was introduced to keep the argon pressure at 0.105 MPa for 2.5 hours. After the treatment, it was sealed for use.

(2)激光烧结工艺参数设置(2) Laser sintering process parameter setting

将脱氧后的混合粉末置于激光烧结自动化操作平台送粉器中,设置激光光斑为5×4mm2方形光斑,激光扫描速度为2mm/s,激光头单次行程为150mm,行距为4mm,单层往复次数为10,层距为1mm,铺粉层数为10层;所述激光烧结是采用烧结与熔覆相结合的复合成形法,激光头在每一个行程往返一次,行程的去程为烧结过程,回程为熔覆过程,激光器烧结过程功率设定在1.8~2kW,熔覆过程功率设定在2.6~2.8kW;所述氩气纯度为99.999%,氩气压强0.105MPa,流量为10L/min,激光头还需通入循环水进行冷却处理。重复上述激光烧结工艺,即为第二次烧结。Place the deoxidized mixed powder in the powder feeder of the laser sintering automatic operation platform, set the laser spot to be 5×4mm2 square spot, the laser scanning speed to be 2mm/s, the single stroke of the laser head to be 150mm, the line spacing to be 4mm, and the single stroke of the laser head to be 150mm. The number of layers reciprocating is 10, the layer spacing is 1mm, and the number of powder layers is 10; the laser sintering is a composite forming method combining sintering and cladding. In the sintering process, the return process is the cladding process, the power of the laser sintering process is set at 1.8-2kW, and the power of the cladding process is set at 2.6-2.8kW; the purity of the argon gas is 99.999%, the argon pressure is 0.105MPa, and the flow rate is 10L /min, the laser head needs to be cooled with circulating water. Repeating the above laser sintering process is the second sintering.

(3)试样后处理(3) Sample post-processing

将激光烧结试样进行线切割,分割成尺寸为6×5×4mm3的小试样,然后进行去应力退火,以消除残余应力。所述退火是将试样在60min以内升温速率为10℃/min升到600℃,然后保温40min,再在50min以内升温速率为6℃/min的升温速率升温至900℃,然后再保温60min,最后随炉冷却,即得。The laser sintered samples were wire-cut, divided into small samples with a size of 6 ×5 × 4 mm, and then subjected to stress relief annealing to eliminate residual stress. The annealing is to raise the temperature of the sample to 600°C at a heating rate of 10°C/min within 60min, then keep the temperature for 40min, and then heat the sample to 900°C with a heating rate of 6°C/min within 50min, and then keep the temperature for 60min. Finally, it is cooled with the furnace and it is obtained.

实施例2样品按实施例1的方法进行实验,结果表明本品表面均匀,无凹坑、无气孔,产品材质均匀、结构致密、致密度为99.3%、无开裂现象,产品致密度好,硬度高,韧性好,熔点高,可高达3450℃以上,晶粒尺寸分布均匀,接近等轴晶,密度均匀。Example 2 The sample was tested according to the method of Example 1. The results showed that the surface of the product was uniform, without pits and pores, the product material was uniform, the structure was dense, the density was 99.3%, and there was no cracking phenomenon. The product had good density and hardness. High, good toughness, high melting point, can be as high as 3450 ℃ or more, uniform grain size distribution, close to equiaxed crystal, uniform density.

实施例3钨钽铼合金的制备:The preparation of

(1)原料处理(1) Raw material processing

混料质量百分比为钨粉:钽粉:铼粉=95:3:2(配料总量为50g)。三种粉体粒径分别为:铼粉500目,钨粉为500目,钽粉为400目。球磨罐内衬为陶瓷材质,采用直径为10mm的瓷球为磨球,球料比为10:1,过程控制剂为20%无水乙醇,球磨时间为24h。原料球磨后利用无水乙醇进行清洗两次,每次用500g无水乙醇清洗,然后置于离心机中设置离心转速为1000转/min,离心时间为2分钟进行分离,将洗涤好的粉末在真空干燥箱中进行干燥,温度设定为60℃,干燥时间12小时。干燥后的粉末利用玛瑙研钵研磨32min,将得到的粉体放置于干燥瓶中待用,制备好的粉体如图1所示。将球磨处理后的粉末置于真空手套箱中,温度设定至90℃,通入氩气,保持氩气压强为0.100MPa,保持时间2.5小时,处理结束,密闭备用。The mass percentage of the mixture is tungsten powder: tantalum powder: rhenium powder = 95:3:2 (the total amount of ingredients is 50g). The particle sizes of the three powders are: 500 mesh for rhenium powder, 500 mesh for tungsten powder, and 400 mesh for tantalum powder. The inner lining of the ball mill is made of ceramic material, and the ceramic ball with a diameter of 10mm is used as the grinding ball. After the raw material is ball-milled, it is washed twice with anhydrous ethanol, each time with 500 g of anhydrous ethanol, and then placed in a centrifuge to set the centrifugation speed to 1000 rpm, and the centrifugation time to be 2 minutes for separation. Drying was carried out in a vacuum drying oven, the temperature was set to 60°C, and the drying time was 12 hours. The dried powder was ground in an agate mortar for 32 minutes, and the obtained powder was placed in a drying bottle for use. The prepared powder was shown in Figure 1. The ball-milled powder was placed in a vacuum glove box, the temperature was set to 90° C., and argon gas was introduced to keep the argon pressure at 0.100 MPa for 2.5 hours.

(2)激光烧结工艺参数设置(2) Laser sintering process parameter setting

将脱氧后的混合粉末置于激光烧结自动化操作平台送粉器中,设置激光光斑为5×4mm2方形光斑,激光扫描速度为2mm/s,激光头单次行程为100mm,行距为3mm,单层往复次数为2,层距为1mm,铺粉层数为10层;所述激光烧结是采用烧结与熔覆相结合的复合成形法,激光头在每一个行程往返一次,行程的去程为烧结过程,回程为熔覆过程,激光器烧结过程功率设定在1.8~2kW,熔覆过程功率设定在2.6~2.8kW;所述氩气纯度为99.999%,氩气压强0.100MPa,流量为8L/min,激光头还需通入循环水进行冷却处理。重复上述激光烧结工艺,即为第二次烧结。Place the deoxidized mixed powder in the powder feeder of the laser sintering automatic operation platform, set the laser spot to be 5×4mm2 square spot, the laser scanning speed to be 2mm/s, the single stroke of the laser head to be 100mm, the line spacing to be 3mm, and the single stroke of the laser head to be 100mm. The number of layers reciprocating is 2, the layer spacing is 1mm, and the number of powder layers is 10; the laser sintering is a composite forming method combining sintering and cladding. In the sintering process, the return process is the cladding process, the power of the laser sintering process is set at 1.8-2kW, and the power in the cladding process is set at 2.6-2.8kW; the purity of the argon gas is 99.999%, the argon pressure is 0.100MPa, and the flow rate is 8L /min, the laser head needs to be cooled with circulating water. Repeating the above laser sintering process is the second sintering.

(3)试样后处理(3) Sample post-processing

将激光烧结试样进行线切割,分割成尺寸为6×7×2mm3的小试样。然后进行去应力退火,以消除残余应力。所述退火是将试样在50min以内升温速率为12℃/min升到600℃,然后保温30min以内,再在50min以内升温速率为8℃/min的升温速率升温至900℃,然后再保温60min,最后随炉冷却,即得。The laser sintered samples were wire-cut and divided into small samples with dimensions of 6 × 7 × 2 mm3 . Then a stress relief annealing is performed to remove residual stress. The annealing method is to raise the temperature of the sample to 600°C at a heating rate of 12°C/min within 50min, then keep the temperature within 30min, and then heat the sample to 900°C with a heating rate of 8°C/min within 50min, and then keep the temperature for 60min. , and finally cooled with the furnace, that is.

实施例3样品按实施例1的方法进行实验,结果表明本品表面均匀,无凹坑、无气孔,产品材质均匀、结构致密、、致密度为99.1%、无开裂现象,产品致密度好,硬度高,韧性好,熔点高,可高达3450℃以上,晶粒尺寸分布均匀,接近等轴晶,密度均匀。Example 3 The sample was tested according to the method of Example 1. The results showed that the surface of the product was uniform, without pits and pores, the product material was uniform, the structure was dense, the density was 99.1%, and there was no cracking phenomenon, and the product had good density. High hardness, good toughness, high melting point, can be as high as 3450 ℃, uniform grain size distribution, close to equiaxed crystal, uniform density.

Claims (5)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910026643.6ACN109487103B (en) | 2019-01-11 | 2019-01-11 | Preparation method of tungsten-tantalum-rhenium alloy with high hardness |

| CN202010097233.3ACN111321313A (en) | 2019-01-11 | 2019-01-11 | Preparation method of high-hardness tungsten-based alloy material |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910026643.6ACN109487103B (en) | 2019-01-11 | 2019-01-11 | Preparation method of tungsten-tantalum-rhenium alloy with high hardness |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010097233.3ADivisionCN111321313A (en) | 2019-01-11 | 2019-01-11 | Preparation method of high-hardness tungsten-based alloy material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109487103A CN109487103A (en) | 2019-03-19 |

| CN109487103Btrue CN109487103B (en) | 2020-02-07 |

Family

ID=65714437

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910026643.6AActiveCN109487103B (en) | 2019-01-11 | 2019-01-11 | Preparation method of tungsten-tantalum-rhenium alloy with high hardness |

| CN202010097233.3AWithdrawnCN111321313A (en) | 2019-01-11 | 2019-01-11 | Preparation method of high-hardness tungsten-based alloy material |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010097233.3AWithdrawnCN111321313A (en) | 2019-01-11 | 2019-01-11 | Preparation method of high-hardness tungsten-based alloy material |

Country Status (1)

| Country | Link |

|---|---|

| CN (2) | CN109487103B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113077989B (en)* | 2021-03-31 | 2023-05-12 | 中国振华(集团)新云电子元器件有限责任公司(国营第四三二六厂) | Preparation method of anode tantalum block of low-oxygen-content solid electrolyte tantalum capacitor |

| CN114959682A (en)* | 2022-05-13 | 2022-08-30 | 东华大学 | Preparation of Al on surface of aluminum alloy 3 Laser cladding method of Ti coating |

| CN117701967A (en)* | 2023-12-18 | 2024-03-15 | 中南大学 | High Jiang Wu-tantalum-rhenium alloy and preparation method and application thereof |

| CN118443693B (en)* | 2024-07-01 | 2024-10-18 | 崇义章源钨业股份有限公司 | Method for rapidly identifying hard alloy mixture |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101522342A (en)* | 2006-10-03 | 2009-09-02 | H.C.施塔克公司 | Process for preparing metal powders having low oxygen content, powders so-produced and uses thereof |

| CN105970012A (en)* | 2016-05-13 | 2016-09-28 | 西安华山金属制品有限公司 | Method for improving hardness of tungsten alloy |

| CN107541633A (en)* | 2017-08-15 | 2018-01-05 | 清华大学 | Tungsten alloy and preparation method thereof |

- 2019

- 2019-01-11CNCN201910026643.6Apatent/CN109487103B/enactiveActive

- 2019-01-11CNCN202010097233.3Apatent/CN111321313A/ennot_activeWithdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101522342A (en)* | 2006-10-03 | 2009-09-02 | H.C.施塔克公司 | Process for preparing metal powders having low oxygen content, powders so-produced and uses thereof |

| CN105970012A (en)* | 2016-05-13 | 2016-09-28 | 西安华山金属制品有限公司 | Method for improving hardness of tungsten alloy |

| CN107541633A (en)* | 2017-08-15 | 2018-01-05 | 清华大学 | Tungsten alloy and preparation method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111321313A (en) | 2020-06-23 |

| CN109487103A (en) | 2019-03-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109487103B (en) | Preparation method of tungsten-tantalum-rhenium alloy with high hardness | |

| CN109680173B (en) | Preparation method of tungsten-tantalum-rhenium refractory alloy | |

| CN111088450B (en) | Rare earth-added ultrafine-grained high-toughness WC-10Co hard alloy material and preparation method thereof | |

| CN105562694A (en) | Hot isostatic pressing three-control method suitable for additive manufacturing parts | |

| CN103194630A (en) | Preparation method of SiCp/Al composite material with high volume fraction | |

| CN101397613B (en) | A kind of preparation method of molybdenum-silicon-boron alloy | |

| Gülsoy et al. | Microstructural and mechanical properties of injection moulded gas and water atomised 17-4 PH stainless steel powder | |

| CN113798495B (en) | A high-entropy alloy sintering forming process with double-element equivalent transformation | |

| CN109439991A (en) | A kind of TiB2Whisker high temperature Strengthening and Toughening Ti (C, N) base metal-ceramic material preparation method | |

| CN113846277A (en) | A kind of preparation method of TiB whisker reinforced titanium matrix composite material | |

| CN1958817A (en) | Method for preparing alloy material of high niobium-titanium-aluminum by discharging plasma agglomeration | |

| CN106002131B (en) | A kind of embedded alloy high-performance shearing dise knife and its processing method | |

| CN111136276A (en) | Preparation method of high-speed steel cutter | |

| CN108396199A (en) | A kind of cobalt chrome-nickel material and its method for preparing powder metallurgy | |

| CN116590564A (en) | A kind of aluminum matrix composite material and preparation method thereof | |

| CN104962794A (en) | A TiCN/Al2O3 cermet tool and its microwave preparation process | |

| CN103521704A (en) | Method for casting blade | |

| CN114540723A (en) | Multiphase reinforced WC-Ni3Al hard alloy and preparation method thereof | |

| CN106834870B (en) | Ni-Al2O3Composite material near-net-shape method | |

| CN118527654A (en) | Preparation method of high-performance magnesium alloy material | |

| CN114101554A (en) | A kind of multidirectional forging method of nickel-rich nickel-titanium intermetallic compound | |

| CN117943528A (en) | Non-pressure impregnation near-net shape preparation method of high-volume aluminum-based composite material | |

| Chang et al. | Effects of vacuum sintering, HIP and HP treatments on the microstructure, mechanical and electrical properties of Cr70Cu30 alloys | |

| CN109351980B (en) | Method for preparing multi-scale precipitation-strengthened magnesium alloy material by hot pressing sintering | |

| CN111454062B (en) | AlMgB14Preparation method of ceramic material powder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | Effective date of registration:20220517 Address after:401147 tianlinjing 7-7-5, No. 388, Xinnan Road, Longshan street, Yubei District, Chongqing Patentee after:Chongqing Rui Numerical Control Technology Co.,Ltd. Address before:402160 Shuangzhu Town, Yongchuan District, Chongqing Patentee before:CHONGQING University OF ARTS AND SCIENCES | |

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20220624 Address after:402160, Honghe Avenue, Yongchuan District, Chongqing, 319 Patentee after:Deng Ying Address before:401147 tianlinjing 7-7-5, No. 388, Xinnan Road, Longshan street, Yubei District, Chongqing Patentee before:Chongqing Rui Numerical Control Technology Co.,Ltd. | |

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20220901 Address after:402760 No.92 Donglin Avenue, Biquan street, Bishan District, Chongqing Patentee after:Chongqing Jinrui New Material Technology Research Institute Co.,Ltd. Address before:402160, Honghe Avenue, Yongchuan District, Chongqing, 319 Patentee before:Deng Ying | |

| TR01 | Transfer of patent right |