CN109310437B - Cartridge Locking Arrangement for Rotating Powered Surgical Cutting and Stapling Instruments - Google Patents

Cartridge Locking Arrangement for Rotating Powered Surgical Cutting and Stapling InstrumentsDownload PDFInfo

- Publication number

- CN109310437B CN109310437BCN201780037720.7ACN201780037720ACN109310437BCN 109310437 BCN109310437 BCN 109310437BCN 201780037720 ACN201780037720 ACN 201780037720ACN 109310437 BCN109310437 BCN 109310437B

- Authority

- CN

- China

- Prior art keywords

- firing

- cartridge

- staple

- end effector

- firing member

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Surgical Instruments (AREA)

Abstract

Description

Translated fromChinese背景技术Background technique

本发明涉及外科器械,并且在各种布置中,涉及被设计成缝合和切割组织的外科缝合和切割器械及与其一起使用的钉仓。The present invention relates to surgical instruments and, in various arrangements, to surgical stapling and cutting instruments and staple cartridges for use therewith designed to staple and cut tissue.

附图说明Description of drawings

本文所述的实施方案的各种特征连同其优点可结合如下附图根据以下描述来加以理解:The various features of the embodiments described herein, along with their advantages, can be understood from the following description in conjunction with the accompanying drawings:

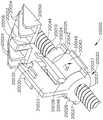

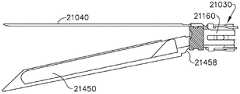

图1为根据至少一个实施方案的外科器械系统的透视图;1 is a perspective view of a surgical instrument system in accordance with at least one embodiment;

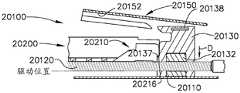

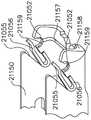

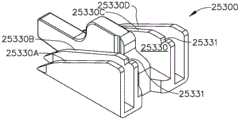

图2为根据至少一个实施方案的旋转从动击发组件的一部分和外科钉仓的滑动件的透视图,其中滑动件处于起始位置并且击发组件处于第一“解锁”位置;2 is a perspective view of a portion of a rotationally driven firing assembly and a slider of a surgical staple cartridge with the slider in a home position and the firing assembly in a first "unlocked" position, according to at least one embodiment;

图3为图2的旋转从动击发组件实施方案的一部分处于第二“锁定”位置的另一个透视图,其中滑动件不在起始位置;Figure 3 is another perspective view of a portion of the rotary driven firing assembly embodiment of Figure 2 in a second "locked" position with the slider not in the home position;

图4为根据至少一个实施方案的外科钉仓的侧正视图,该外科钉仓最初安装在外科端部执行器中,该外科端部执行器被构造成能够切割和缝合组织;4 is a side elevational view of a surgical staple cartridge initially installed in a surgical end effector configured to cut and staple tissue, according to at least one embodiment;

图5为坐置在图4的外科端部执行器的通道中的外科钉仓的另一侧正视图,其中外科钉仓的滑动件处于起始位置并且与外科器械的击发构件接合;5 is another side elevational view of the surgical staple cartridge seated in the channel of the surgical end effector of FIG. 4 with the surgical staple cartridge sled in a starting position and engaged with a firing member of a surgical instrument;

图6为坐置在图4的外科端部执行器的通道中的部分使用的外科钉仓的另一侧正视图,其中外科钉仓的滑动件不处于起始位置;6 is another side elevational view of the partially used surgical staple cartridge seated in the channel of the surgical end effector of FIG. 4 with the slider of the surgical staple cartridge not in the home position;

图7为根据至少一个实施方案的旋转从动击发组件的一部分和外科切割和缝合端部执行器的通道的透视图,其中击发组件处于“锁定”位置;7 is a perspective view of a portion of a rotationally driven firing assembly and a channel of a surgical cutting and stapling end effector with the firing assembly in a "locked" position, according to at least one embodiment;

图8为图7的旋转驱动击发组件的一部分和外科钉仓的滑动件的另一透视图,其中滑动件处于起始位置并且击发组件处于“解锁”位置;8 is another perspective view of a portion of the rotationally driven firing assembly of FIG. 7 and the slider of the surgical staple cartridge with the slider in a home position and the firing assembly in an "unlocked" position;

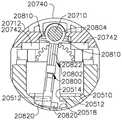

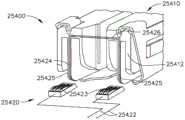

图9为根据至少一个实施方案的螺纹螺母部分的透视图;9 is a perspective view of a threaded nut portion in accordance with at least one embodiment;

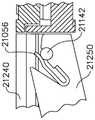

图10为图9的螺纹螺母部分安装在以横截面示出的对应的通道实施方案中的透视图;10 is a perspective view of the threaded nut portion of FIG. 9 installed in a corresponding channel embodiment shown in cross-section;

图11为图10的通道和螺纹螺母部分的横截面正视图,其中螺纹螺母部分处于锁定位置;Figure 11 is a cross-sectional elevation view of the channel and threaded nut portion of Figure 10 with the threaded nut portion in a locked position;

图12为图10和图11的通道和螺纹螺母部分的另一个横截面正视图,其中螺母部分处于解锁位置;Figure 12 is another cross-sectional elevation view of the channel and threaded nut portion of Figures 10 and 11 with the nut portion in an unlocked position;

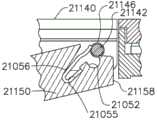

图13为图10至图12的通道和螺纹螺母部分的另一横截面正视图,其中螺纹螺母部分处于锁定位置并且示出了外科钉仓的滑动件初始安装到通道中,其中为了清除起见省略仓主体;13 is another cross-sectional elevation view of the channel and threaded nut portion of FIGS. 10-12 with the threaded nut portion in the locked position and showing the initial installation of the slider of the surgical cartridge into the channel, omitted for clarity warehouse main body;

图14为图13的通道、螺纹螺母部分和滑动件的另一横截面正视图,其中安装滑动件以便将螺母部分移动到解锁位置;Figure 14 is another cross-sectional elevation view of the channel, threaded nut portion, and slide of Figure 13 with the slide installed to move the nut portion to the unlocked position;

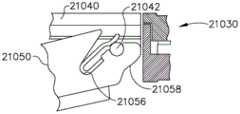

图15为根据至少一个实施方案的外科切割和缝合端部执行器的横截面侧正视图;15 is a cross-sectional side elevation view of a surgical cutting and stapling end effector according to at least one embodiment;

图16为图15的外科端部执行器的砧座组件的分解透视组装图;Figure 16 is an exploded perspective assembled view of the anvil assembly of the surgical end effector of Figure 15;

图17为图16的砧座组件的横截面视图;Figure 17 is a cross-sectional view of the anvil assembly of Figure 16;

图18为图15的外科端部执行器的横截面视图,其中其击发构件组件处于锁定位置;Figure 18 is a cross-sectional view of the surgical end effector of Figure 15 with its firing member assembly in a locked position;

图19为图18的外科端部执行器在其近侧端部处截取的另一横截面视图,其中击发构件组件处于解锁位置;Figure 19 is another cross-sectional view of the surgical end effector of Figure 18 taken at its proximal end with the firing member assembly in an unlocked position;

图20为图18的外科端部执行器在图19的视图远侧的位置处截取的另一横截面视图;20 is another cross-sectional view of the surgical end effector of FIG. 18 taken at a position distal to the view of FIG. 19;

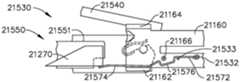

图21为根据至少一个实施方案的外科缝合器械的透视图,该外科缝合器械包括柄部和可替换的装载单元;Figure 21 is a perspective view of a surgical stapling instrument including a handle and a replaceable loading unit according to at least one embodiment;

图22为图21的装载单元的透视图,示出了具有从装载单元拆卸的钉仓夹具;FIG. 22 is a perspective view of the loading unit of FIG. 21, shown with the cartridge clamp detached from the loading unit;

图23为根据至少一个实施方案的外科缝合器械的透视图,该外科缝合器械包括柄部和可替换的装载单元;Figure 23 is a perspective view of a surgical stapling instrument including a handle and a replaceable loading unit according to at least one embodiment;

图24为图23的装载单元的透视图;Figure 24 is a perspective view of the loading unit of Figure 23;

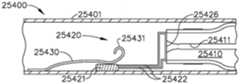

图25示出了图23的柄部和装载单元的连接部分;Figure 25 shows the connection portion of the handle and loading unit of Figure 23;

图26为图21的装载单元的端部执行器的横截面视图;Figure 26 is a cross-sectional view of the end effector of the loading unit of Figure 21;

图27为图21的钉仓夹具和钉装载单元的框架之间的附接的详细视图;Figure 27 is a detailed view of the attachment between the staple cartridge clamp of Figure 21 and the frame of the staple loading unit;

图28为根据至少一个实施方案的装载单元的端部执行器的横截面视图;28 is a cross-sectional view of an end effector of a loading unit according to at least one embodiment;

图29为图28的钉仓夹具和装载单元的框架之间的附接的详细视图;Figure 29 is a detailed view of the attachment between the cartridge clamp of Figure 28 and the frame of the loading unit;

图30为图28的装载单元的框架的透视图;Figure 30 is a perspective view of the frame of the loading unit of Figure 28;

图31为图28的钉仓夹具的近侧的详细视图;Figure 31 is a detailed view of the proximal side of the cartridge clamp of Figure 28;

图32为示出图28的框架和钉仓夹具之间的连接的详细视图;Figure 32 is a detailed view showing the connection between the frame of Figure 28 and the cartridge clamp;

图33为根据至少一个实施方案的钉仓夹具的分解视图;33 is an exploded view of a staple cartridge clamp in accordance with at least one embodiment;

图34为根据至少一个实施方案的装载单元的局部透视图;34 is a partial perspective view of a loading unit according to at least one embodiment;

图35为根据所示的至少一个实施方案的装载单元的框架的局部正视图,其中没有钉仓夹具附接到该框架;35 is a partial front view of the frame of the loading unit according to at least one embodiment shown, with no cartridge clamps attached to the frame;

图36为附接到图35的装载单元的框架的钉仓夹具的局部正视图;Figure 36 is a partial front view of the cartridge clamp attached to the frame of the loading unit of Figure 35;

图37为以夹紧构造示出的图35的装载单元的局部正视图;37 is a partial front view of the loading unit of FIG. 35 shown in a clamped configuration;

图38为以部分击发构造示出的图35的装载单元的局部正视图;38 is a partial front view of the loading unit of FIG. 35 shown in a partially fired configuration;

图39为根据所示的至少一个实施方案的装载单元的框架的局部正视图,其中没有附接钉仓夹具;39 is a partial front view of the frame of the loading unit according to at least one embodiment shown without the cartridge clamp attached;

图40为附接到图39的装载单元的框架的钉仓夹具的局部正视图;Figure 40 is a partial front view of the cartridge clamp attached to the frame of the loading unit of Figure 39;

图41为以夹紧构造示出的图39的装载单元的局部正视图;Figure 41 is a partial front view of the loading unit of Figure 39 shown in a clamped configuration;

图42为以部分击发构造示出的图39的装载单元的局部正视图;Figure 42 is a partial front view of the loading unit of Figure 39 shown in a partially fired configuration;

图43为所示的图39的装载单元的局部透视图,其中钉仓夹具附接到框架;43 is a partial perspective view of the loading unit of FIG. 39 shown with the cartridge clamp attached to the frame;

图44为根据至少一个实施方案的钉仓夹具的局部透视图,该钉仓夹具附接到装载单元的框架。44 is a partial perspective view of a staple cartridge clamp attached to a frame of a loading unit, according to at least one embodiment.

图45为试图将图44的钉仓夹具附接到装载单元的局部正视图,该装载单元被构造成接收不同的钉仓夹具;45 is a partial front view of an attempt to attach the cartridge clamp of FIG. 44 to a loading unit configured to receive a different cartridge clamp;

图46为图44的钉仓夹具的局部正视图,该钉仓夹具附接到图44的装载单元的框架;46 is a partial front view of the cartridge clamp of FIG. 44 attached to the frame of the loading unit of FIG. 44;

图47为根据至少一个实施方案的钉仓夹具和装载单元的框架之间的连接的局部正视图;47 is a partial front view of the connection between the cartridge clamp and the frame of the loading unit in accordance with at least one embodiment;

图48为图47的装载单元的局部正视图;Figure 48 is a partial front view of the loading unit of Figure 47;

图49为钉仓夹具的局部正视图,该钉仓夹具被构造成能够与除图47的装载单元之外的不同的装载单元一起使用,该装载单元附接到图47的装载单元;49 is a partial front view of a staple cartridge clamp configured for use with a different loading unit than the loading unit of FIG. 47 attached to the loading unit of FIG. 47;

图50为外科器械系统的局部正视图,该外科器械系统包括以闭锁构造示出的可偏转锁定布置;Figure 50 is a partial front view of a surgical instrument system including a deflectable locking arrangement shown in a latched configuration;

图51为图50的外科器械系统的局部正视图,其中闭锁布置以解锁构造示出;Figure 51 is a partial front view of the surgical instrument system of Figure 50 with the latching arrangement shown in an unlocked configuration;

图52为外科器械系统的局部正视图,该外科器械系统包括以闭锁构造示出的磁性锁定布置;Figure 52 is a partial front view of a surgical instrument system including a magnetic locking arrangement shown in a latched configuration;

图53为图52的外科器械系统的局部正视图,其中磁性闭锁布置以解锁构造示出;Figure 53 is a partial front view of the surgical instrument system of Figure 52 with the magnetic latch arrangement shown in an unlocked configuration;

图54为图52的外科器械系统的局部正视图,以部分击发的构造示出;Figure 54 is a partial front view of the surgical instrument system of Figure 52, shown in a partially fired configuration;

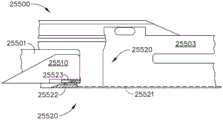

图55为用于外科器械系统的钉仓的局部透视图,其中钉仓包括构造成能够控制外科器械系统的闭锁布置的驱动器;55 is a partial perspective view of a staple cartridge for a surgical instrument system, wherein the staple cartridge includes a driver configured to control a latching arrangement of the surgical instrument system;

图56为用于与图55的钉仓一起使用的滑动件的透视图;Figure 56 is a perspective view of a slider for use with the staple cartridge of Figure 55;

图57为图55的钉仓的假驱动器的透视图;Figure 57 is a perspective view of a dummy driver of the staple cartridge of Figure 55;

图58为利用图55的钉仓的外科器械系统的局部正视图,其中外科器械系统包括闭锁布置,该闭锁布置被构造成能够限制击发构件的运动,直到钉仓被装载到外科器械系统中;58 is a partial front view of a surgical instrument system utilizing the staple cartridge of FIG. 55, wherein the surgical instrument system includes a latching arrangement configured to restrict movement of the firing member until the staple cartridge is loaded into the surgical instrument system;

图59为图58的外科器械系统的局部正视图,其中闭锁布置以解锁构造示出;Fig. 59 is a partial front view of the surgical instrument system of Fig. 58 with the latching arrangement shown in an unlocked configuration;

图60为以部分击发构造示出的图58的外科器械系统的局部正视图;Figure 60 is a partial front view of the surgical instrument system of Figure 58 shown in a partially fired configuration;

图61为用于与外科器械系统一起使用的钉仓的局部透视图,其中外科器械系统包括闭锁电路,该闭锁电路包括可分离构件;61 is a partial perspective view of a staple cartridge for use with a surgical instrument system, wherein the surgical instrument system includes a latching circuit including a detachable member;

图62为图61的外科器械系统的横截面平面视图,其中外科器械系统还包括电磁体和闭锁构件,其中闭锁构件被示出处于解锁位置,并且其中闭锁电路处于闭合构造;62 is a cross-sectional plan view of the surgical instrument system of FIG. 61 , wherein the surgical instrument system further includes an electromagnet and a latching member, wherein the latching member is shown in an unlocked position, and wherein the latching circuit is in a closed configuration;

图63为图61的外科器械系统的横截面平面视图,其中闭锁构件被示出处于锁定位置,并且其中闭锁电路处于打开构造;Figure 63 is a cross-sectional plan view of the surgical instrument system of Figure 61 with the latching member shown in a locked position and with the latching circuit in an open configuration;

图64为外科器械系统的透视图,其中外科器械系统包括电路闭锁布置,该电路闭锁布置包括定位在滑动件上用于与钉仓一起使用的电接触件;Figure 64 is a perspective view of a surgical instrument system, wherein the surgical instrument system includes an electrical latching arrangement including electrical contacts positioned on a slider for use with a staple cartridge;

图65为图64的外科器械系统的局部正视图;Figure 65 is a partial front view of the surgical instrument system of Figure 64;

图66为击发构件闭锁件的局部横截面视图,示出了处于锁定构造的击发构件闭锁件;Figure 66 is a partial cross-sectional view of the firing member latch showing the firing member latch in a locked configuration;

图67为沿图66中的线67-67截取的图66的击发构件闭锁件的横截面视图;Figure 67 is a cross-sectional view of the firing member lockout of Figure 66 taken along line 67-67 in Figure 66;

图68为图66的击发构件闭锁件的局部横截面视图,示出了处于解锁构造的击发构件闭锁件;Figure 68 is a partial cross-sectional view of the firing member lockout of Figure 66, showing the firing member lockout in an unlocked configuration;

图69为沿图68中的线69-69截取的图66的击发构件闭锁件的横截面视图;Figure 69 is a cross-sectional view of the firing member lockout of Figure 66 taken along line 69-69 in Figure 68;

图70为沿图68中的线70-70截取的图66的击发构件闭锁件的横截面平面视图;Figure 70 is a cross-sectional plan view of the firing member lockout of Figure 66 taken along line 70-70 in Figure 68;

图71为根据至少一个实施方案的包括未用过的钉仓的缝合组件的局部正视图;71 is a partial front view of a stapling assembly including an unused staple cartridge, according to at least one embodiment;

图72为图71的缝合组件的局部平面视图;Figure 72 is a partial plan view of the suturing assembly of Figure 71;

图73为在用尽状态下示出的图71的缝合组件的局部正视图;Figure 73 is a partial front view of the suture assembly of Figure 71 shown in an exhausted state;

图74为图73的状态下所示的图71的缝合组件的局部平面视图;Figure 74 is a partial plan view of the suture assembly of Figure 71 shown in the state of Figure 73;

图75为根据至少一个实施方案的包括未用过的钉仓的缝合组件的局部透视图;75 is a partial perspective view of a stapling assembly including an unused staple cartridge, according to at least one embodiment;

图76为在用尽状态下示出的图75的缝合组件的局部透视图;Figure 76 is a partial perspective view of the suture assembly of Figure 75 shown in an exhausted state;

图77为所示缝合组件的局部透视图,其中为了说明的目的移除了部件;Figure 77 is a partial perspective view of the illustrated suturing assembly with components removed for illustration purposes;

图78示出了图77的缝合组件的销,其被构造成能够影响缝合组件的检测电路;Fig. 78 shows a pin of the suturing assembly of Fig. 77 configured to affect a detection circuit of the suturing assembly;

图79为图77的缝合组件的某些部件的局部透视图;Figure 79 is a partial perspective view of certain components of the suturing assembly of Figure 77;

图80为图77的缝合组件的轴壳体的局部透视图;Figure 80 is a partial perspective view of the shaft housing of the suture assembly of Figure 77;

图81为根据至少一个实施方案的钉仓的局部平面视图;81 is a partial plan view of a staple cartridge according to at least one embodiment;

图81A示出了在至少一个实施方案中击发钉仓时所经历的击发力曲线;Figure 81A shows a firing force profile experienced when firing a staple cartridge in at least one embodiment;

图82为根据至少一个实施方案的包括闭锁件的缝合组件的局部横截面视图;82 is a partial cross-sectional view of a suturing assembly including a closure according to at least one embodiment;

图83为以闭锁构造示出的图82的缝合组件的局部横截面视图;83 is a partial cross-sectional view of the suturing assembly of FIG. 82 shown in a closed configuration;

图84为根据至少一个实施方案的包括闭锁件的缝合组件的局部横截面视图;84 is a partial cross-sectional view of a suturing assembly including a closure according to at least one embodiment;

图85为根据至少一个实施方案的包括闭锁件的缝合组件的局部横截面视图;85 is a partial cross-sectional view of a suturing assembly including a closure according to at least one embodiment;

图86为根据至少一个实施方案的包括制动器的缝合组件的局部横截面视图;Figure 86 is a partial cross-sectional view of a suture assembly including a stopper, according to at least one embodiment;

图87为根据至少一个实施方案的包括阻尼系统的缝合组件的局部横截面视图;87 is a partial cross-sectional view of a suture assembly including a damping system according to at least one embodiment;

图88为示出根据至少一个实施方案的包括电磁制动器的缝合组件的示意图;88 is a schematic diagram illustrating a suturing assembly including an electromagnetic actuator in accordance with at least one embodiment;

图89为根据至少一个实施方案的包括阻尼系统的缝合组件的局部横截面视图;89 is a partial cross-sectional view of a suture assembly including a damping system according to at least one embodiment;

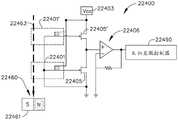

图90为构造成能够检测钉击发构件的位置和前进的电路,示出了钉击发构件处于完全击发位置;Figure 90 is a circuit configured to detect the position and advancement of the staple firing member, showing the staple firing member in a fully fired position;

图91示出了处于完全缩回位置的图90的钉击发构件;Figure 91 shows the staple firing member of Figure 90 in a fully retracted position;

图92为根据以解锁构造示出的至少一个实施方案的缝合组件的横截面视图,该缝合组件包括闭锁件;92 is a cross-sectional view of a suturing assembly including a latch according to at least one embodiment shown in an unlocked configuration;

图93为以解锁构造示出的图92的缝合组件的横截面端视图;Figure 93 is a cross-sectional end view of the suture assembly of Figure 92 shown in an unlocked configuration;

图94为以锁定构造示出的图92的缝合组件的横截面视图;并且Fig. 94 is a cross-sectional view of the suturing assembly of Fig. 92 shown in a locked configuration; and

图95为以其锁定构造示出的图92的缝合组件的横截面端视图。95 is a cross-sectional end view of the suture assembly of FIG. 92 shown in its locked configuration.

在所述若干视图中,对应的参考符号指示对应的部件。本文所述的范例以一种形式示出了本发明的各种实施方案,且这种范例不应被解释为以任何方式限制本发明的范围。Corresponding reference characters indicate corresponding parts throughout the several views. The exemplifications described herein illustrate various embodiments of the invention in one form, and such exemplifications should not be construed to limit the scope of the invention in any way.

具体实施方式Detailed ways

本申请的申请人拥有以下美国专利申请,所述美国专利申请与本申请于同一日期提交且各自全文以引用方式并入本文:The applicant of the present application owns the following US patent applications, which were filed on the same date as this application and each of which is incorporated herein by reference in its entirety:

-名称为“包括闭锁件的外科器械(SURGICAL INSTRUMENT COMPRISING ALOCKOUT)”的美国专利申请序列号15/131,311;代理人案卷号END7828USNP/150542;- US Patent Application Serial No. 15/131,311 entitled "SURGICAL INSTRUMENT COMPRISING ALOCKOUT"; Attorney Docket No. END7828USNP/150542;

-名称为“包括主要击发闭锁件和次级击发闭锁件的外科器械(SURGICALINSTRUMENT COMPRISING A PRIMARY FIRING LOCKOUT AND A SECONDARY FIRINGLOCKOUT)”的美国专利申请序列号15/131,304;代理人案卷号END7787USNP/150522;- US Patent Application Serial No. 15/131,304 entitled "SURGICAL INSTRUMENT COMPRISING A PRIMARY FIRING LOCKOUT AND A SECONDARY FIRING LOCKOUT"; Attorney Docket No. END7787USNP/150522;

-名称为“包括磁性闭锁件的外科器械系统(SURGICAL INSTRUMENT COMPRISING APRIMARY FIRING LOCKOUT AND A SECONDARY FIRING LOCKOUT)”的美国专利申请序列号15/131,282;代理人案卷号END7789USNP/150503;以及- US Patent Application Serial No. 15/131,282 entitled "SURGICAL INSTRUMENT COMPRISING APRIMARY FIRING LOCKOUT AND A SECONDARY FIRING LOCKOUT"; Attorney Docket No. END7789USNP/150503; and

-名称为“包括可替换仓夹具的外科器械(SURGICAL INSTRUMENT COMPRISING AREPLACEABLE CARTRIDGE JAW)”的美国专利申请序列号15/131,289;代理人案卷号END7790USNP/150504。- US Patent Application Serial No. 15/131,289 entitled "SURGICAL INSTRUMENT COMPRISING AREPLACEABLE CARTRIDGE JAW"; Attorney Docket No. END7790USNP/150504.

本申请的申请人拥有以下专利申请,这些专利申请于2016年4月15日提交,并且各自以引用方式全文并入本文:The applicant of the present application has the following patent applications, which were filed on April 15, 2016, and each of which is hereby incorporated by reference in its entirety:

-名称为“钉形成检测机构(STAPLE FORMATION DETECTION MECHANISMS)”的美国专利申请序列号15/130,575;- US Patent Application Serial No. 15/130,575 entitled "STAPLE FORMATION DETECTION MECHANISMS";

-名称为“具有检测传感器的外科器械(SURGICAL INSTRUMENT WITH DETECTIONSENSORS)”的美国专利申请序列号15/130,582;- US Patent Application Serial No. 15/130,582 entitled "SURGICAL INSTRUMENT WITH DETECTIONSENSORS";

-名称为“在击发运动期间具有改善的停止/起动控制的外科器械(SURGICALINSTRUMENT WITH IMPROVED STOP/START CONTROL DURING A FIRING MOTION)”的美国专利申请序列号15/130,588;- US Patent Application Serial No. 15/130,588 entitled "SURGICAL INSTRUMENT WITH IMPROVED STOP/START CONTROL DURING A FIRING MOTION";

-名称为“在击发运动期间具有可调节停止/起动控制的外科器械(SURGICALINSTRUMENT WITH ADJUSTABLE STOP/START CONTROL DURING A FIRING MOTION)”的美国专利申请序列号15/130,595;- US Patent Application Serial No. 15/130,595 entitled "SURGICAL INSTRUMENT WITH ADJUSTABLE STOP/START CONTROL DURING A FIRING MOTION";

-名称为“在击发运动期间具有多个程序响应的外科器械(SURGICAL INSTRUMENTWITH MULTIPLE PROGRAM RESPONSES DURING A FIRING MOTION)”的美国专利申请序列号15/130,566;- US Patent Application Serial No. 15/130,566 entitled "SURGICAL INSTRUMENTWITH MULTIPLE PROGRAM RESPONSES DURING A FIRING MOTION";

-名称为“在击发运动期间具有多个程序响应的外科器械(SURGICAL INSTRUMENTWITH MULTIPLE PROGRAM RESPONSES DURING A FIRING MOTION)”美国专利申请序列号15/130,571;- US Patent Application Serial No. 15/130,571 entitled "SURGICAL INSTRUMENTWITH MULTIPLE PROGRAM RESPONSES DURING A FIRING MOTION" entitled "SURGICAL INSTRUMENTWITH MULTIPLE PROGRAM RESPONSES DURING A FIRING MOTION";

-名称为“具有可构造操作模式的模块化外科器械(MODULAR SURGICALINSTRUMENT WITH CONFIGURABLE OPERATING MODE)”的美国专利申请序列号15/130,581;- US Patent Application Serial No. 15/130,581 entitled "MODULAR SURGICALINSTRUMENT WITH CONFIGURABLE OPERATING MODE";

-名称为“用于控制外科缝合和切割器械的系统和方法(SYSTEMS AND METHODSFOR CONTROLLING A SURGICAL STAPLING AND CUTTING INSTRUMENT)”的美国专利申请序列号15/130,590;以及- US Patent Application Serial No. 15/130,590 entitled "SYSTEMS AND METHODSFOR CONTROLLING A SURGICAL STAPLING AND CUTTING INSTRUMENT"; and

-名称为“用于控制外科缝合和切割器械的系统和方法(SYSTEMS AND METHODSFOR CONTROLLING A SURGICAL STAPLING AND CUTTING INSTRUMENT)”的美国专利申请序列号15/130,596。- US Patent Application Serial No. 15/130,596 entitled "SYSTEMS AND METHODSFOR CONTROLLING A SURGICAL STAPLING AND CUTTING INSTRUMENT".

本申请的申请人拥有以下美国专利申请,这些申请于2016年4月1日提交,并且各自以引用方式全文并入本文:The applicant of the present application has the following US patent applications, which were filed on April 1, 2016, and each of which is hereby incorporated by reference in its entirety:

-名称为“用于操作外科缝合系统的方法(METHOD FOR OPERATING A SURGICALSTAPLING SYSTEM)”的美国专利申请序列号15/089,325;- US Patent Application Serial No. 15/089,325 entitled "METHOD FOR OPERATING A SURGICAL STAPLING SYSTEM";

-名称为“包括显示器的模块化外科缝合系统(MODULAR SURGICAL STAPLINGSYSTEM COMPRISING A DISPLAY)”的美国专利申请序列号15/089,321;- US Patent Application Serial No. 15/089,321 entitled "MODULAR SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY";

-名称为“包括包括可重复显示区域的显示器的外科缝合系统(SURGICALSTAPLING SYSTEM COMPRISING A DISPLAY INCLUDING A RE-ORIENTABLE DISPLAYFIELD)”的美国专利申请序列号15/089,326;- US Patent Application Serial No. 15/089,326 entitled "SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY INCLUDING A RE-ORIENTABLE DISPLAY FIELD" entitled "SURGICAL STAPLING SYSTEM COMPRISING A DISPLAY INCLUDING A RE-ORIENTABLE DISPLAY FIELD";

-名称为“具有可重新构造的夹持部分的外科器械柄部组件(SURGICALINSTRUMENT HANDLE ASSEMBLY WITH RECONFIGURABLE GRIP PORTION)”美国专利申请序列号15/089,263;- US Patent Application Serial No. 15/089,263 entitled "SURGICAL INSTRUMENT HANDLE ASSEMBLY WITH RECONFIGURABLE GRIP PORTION" entitled "SURGICAL INSTRUMENT HANDLE ASSEMBLY WITH RECONFIGURABLE GRIP PORTION";

-名称为“具有可手动致动的应急系统的旋转电动外科器械(ROTARY POWEREDSURGICAL INSTRUMENT WITH MANUALLY ACTUATABLE BAILOUT SYSTEM)”美国专利申请序列号15/089,262;- US Patent Application Serial No. 15/089,262 entitled "ROTARY POWEREDSURGICAL INSTRUMENT WITH MANUALLY ACTUATABLE BAILOUT SYSTEM";

-名称为“具有砧座驱动构件的外科切割和缝合端部执行器(SURGICAL CUTTINGAND STAPLING END EFFECTOR WITH ANVIL CONCENTRIC DRIVE MEMBER)”的美国专利申请序列号15/089,277;- US Patent Application Serial No. 15/089,277 entitled "SURGICAL CUTTINGAND STAPLING END EFFECTOR WITH ANVIL CONCENTRIC DRIVE MEMBER";

-名称为“用于具有分离和不同的击发轴的外科切割和缝合设备的闭合系统布置(CLOSURE SYSTEM ARRANGEMENTS FOR SURGICAL CUTTING AND STAPLING DEVICES WITHSEPARATE AND DISTINCT FIRING SHAFTS)”美国专利申请序列号15/089,283;- US Patent Application Serial No. 15/089,283 entitled "CLOSURE SYSTEM ARRANGEMENTS FOR SURGICAL CUTTING AND STAPLING DEVICES WITHSEPARATE AND DISTINCT FIRING SHAFTS" entitled "CLOSURE SYSTEM ARRANGEMENTS FOR SURGICAL CUTTING AND STAPLING DEVICES WITHSEPARATE AND DISTINCT FIRING SHAFTS";

-名称为“具有能够选择性地围绕轴轴线旋转的外科端部执行器的可互换的外科工具组件(INTERCHANGEABLE SURGICAL TOOL ASSEMBLY WITH A SURGICAL END EFFECTORTHAT IS SELECTIVELY ROTATABLE ABOUT A SHAFT AXIS)”美国专利申请序列号15/089,296;- US Patent Application Serial entitled "INTERCHANGEABLE SURGICAL TOOL ASSEMBLY WITH A SURGICAL END EFFECTORTHAT IS SELECTIVELY ROTATABLE ABOUT A SHAFT AXIS" No. 15/089,296;

-名称为“包括可移位传输的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A SHIFTABLE TRANSMISSION)”的美国专利申请序列号15/089,258;- US Patent Application Serial No. 15/089,258 entitled "SURGICAL STAPLING SYSTEM COMPRISING A SHIFTABLE TRANSMISSION";

-名称为“被构造成能够提供组织的选择性切割的外科缝合系统(SURGICALSTAPLING SYSTEM COMPRISING A SHIFTABLE TRANSMISSION)”的美国专利申请序列号15/089,278;- US Patent Application Serial No. 15/089,278 entitled "SURGICAL STAPLING SYSTEM COMPRISING A SHIFTABLE TRANSMISSION";

-名称为“包括可仿形轴的外科分缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A CONTOURABLE SHAFT)”的美国专利申请序列号15/089,284;- US Patent Application Serial No. 15/089,284 entitled "SURGICAL STAPLING SYSTEMCOMPRISING A CONTOURABLE SHAFT";

-名称为“包括组织压缩闭锁件的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A TISSUE COMPRESSION LOCKOUT)”的美国专利申请序列号15/089,295;- US Patent Application Serial No. 15/089,295 entitled "SURGICAL STAPLING SYSTEMCOMPRISING A TISSUE COMPRESSION LOCKOUT";

-名称为“包括未夹紧闭锁件的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING AN UNCLAMPING LOCKOUT)”美国专利申请序列号15/089,300;- US Patent Application Serial No. 15/089,300 entitled "SURGICAL STAPLING SYSTEMCOMPRISING AN UNCLAMPING LOCKOUT" entitled "SURGICAL STAPLING SYSTEMCOMPRISING AN UNCLAMPING LOCKOUT";

-名称为“包括夹具闭合闭锁件的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A JAW CLOSURE LOCKOUT)”的美国专利申请序列号15/089,196;- US Patent Application Serial No. 15/089,196 entitled "SURGICAL STAPLING SYSTEMCOMPRISING A JAW CLOSURE LOCKOUT";

-名称为“包括夹具附接闭锁件的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A JAW ATTACHMENT LOCKOUT)”的美国专利申请序列号15/089,203;- US Patent Application Serial No. 15/089,203 entitled "SURGICAL STAPLING SYSTEMCOMPRISING A JAW ATTACHMENT LOCKOUT";

-名称为“包括用尽的仓闭锁件的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A SPENT CARTRIDGE LOCKOUT)”的美国专利申请序列号15/089,210;- US Patent Application Serial No. 15/089,210 entitled "SURGICAL STAPLING SYSTEMCOMPRISING A SPENT CARTRIDGE LOCKOUT";

-名称为“包括移位机构的外科器械(SURGICAL INSTRUMENT COMPRISING ASHIFTING MECHANISM)”的美国专利申请序列号15/089,324;- US Patent Application Serial No. 15/089,324 entitled "SURGICAL INSTRUMENT COMPRISING ASHIFTING MECHANISM";

-名称为“包括多个闭锁件的外科缝合器械(SURGICAL STAPLING INSTRUMENTCOMPRISING MULTIPLE LOCKOUTS)”的美国专利申请序列号15/089,335;- US Patent Application Serial No. 15/089,335 entitled "SURGICAL STAPLING INSTRUMENT COMPRISING MULTIPLE LOCKOUTS";

-名称为“外科缝合器械(SURGICAL STAPLING INSTRUMENT)”的美国专利申请序列号15/089,339;- US Patent Application Serial No. 15/089,339 entitled "SURGICAL STAPLING INSTRUMENT";

-名称为“被构造成能够应用具有不同高度的环形钉排的外科缝合系统(SURGICALSTAPLING SYSTEM CONFIGURED TO APPLY ANNULAR ROWS OF STAPLES HAVING DIFFERENTHEIGHTS)”的美国专利申请序列号15/089,253;- US Patent Application Serial No. 15/089,253 entitled "SURGICAL STAPLING SYSTEM CONFIGURED TO APPLY ANNULAR ROWS OF STAPLES HAVING DIFFERENTHEIGHTS";

-名称为“包括凹槽成形凹坑的外科缝合系统(SURGICAL STAPLING SYSTEMCOMPRISING A GROOVED FORMING POCKET)”的美国专利申请序列号15/089,304;- US Patent Application Serial No. 15/089,304 entitled "SURGICAL STAPLING SYSTEMCOMPRISING A GROOVED FORMING POCKET";

-名称为“用于外科缝合器的砧座修改构件(ANVIL MODIFICATION MEMBERS FORSURGICAL STAPLERS)”美国专利申请序列号15/089,331;- US Patent Application Serial No. 15/089,331 entitled "ANVIL MODIFICATION MEMBERS FORSURGICAL STAPLERS";

-名称为“具有无创伤特征的钉仓(STAPLE CARTRIDGES WITH ATRAUMATICFEATURES)”的美国专利申请序列号15/089,336;- US Patent Application Serial No. 15/089,336 entitled "STAPLE CARTRIDGES WITH ATRAUMATICFEATURES";

-名称为“包括可切入组织支撑件的圆形缝合系统(CIRCULAR STAPLING SYSTEMCOMPRISING AN INCISABLE TISSUE SUPPORT)”美国专利申请序列号15/089,312;- US Patent Application Serial No. 15/089,312 entitled "CIRCULAR STAPLING SYSTEMCOMPRISING AN INCISABLE TISSUE SUPPORT" entitled "CIRCULAR STAPLING SYSTEMCOMPRISING AN INCISABLE TISSUE SUPPORT";

-名称为“包括旋转击发系统的圆形缝合系统(CIRCULAR STAPLING SYSTEMCOMPRISING ROTARY FIRING SYSTEM)”的美国专利申请序列号15/089,309;以及- US Patent Application Serial No. 15/089,309 entitled "CIRCULAR STAPLING SYSTEMCOMPRISING ROTARY FIRING SYSTEM"; and

-名称为“包括负载控制的圆形缝合系统(CIRCULAR STAPLING SYSTEMCOMPRISING LOAD CONTROL)”美国专利申请序列号15/089,349;- US Patent Application Serial No. 15/089,349 entitled "CIRCULAR STAPLING SYSTEMCOMPRISING LOAD CONTROL";

本申请的申请人还拥有下面识别的美国专利申请,这些申请于2015年12月31日提交,其各自以引用方式全文并入本文:The applicant of the present application also owns the following identified US patent applications, filed on December 31, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“用于补偿电动外科器械中的电池组故障的机构(MECHANISMS FORCOMPENSATING FOR BATTERY PACK FAILURE IN POWERED SURGICAL INSTRUMENTS)”的美国专利申请序列号14/984,488;- US Patent Application Serial No. 14/984,488 entitled "MECHANISMS FORCOMPENSATING FOR BATTERY PACK FAILURE IN POWERED SURGICAL INSTRUMENTS";

-名称为“用于补偿电动外科器械中的驱动系故障的机构(MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS)”美国专利申请序列号14/984,525;以及- US Patent Application Serial No. 14/984,525 entitled "MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS" entitled "MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS"; and

-名称为“具有可分离马达和马达控制电路的外科器械(SURGICAL INSTRUMENTSWITH SEPARABLE MOTORS AND MOTOR CONTROL CIRCUITS)”的美国专利申请序列号14/984,552。- US Patent Application Serial No. 14/984,552 entitled "SURGICAL INSTRUMENTSWITH SEPARABLE MOTORS AND MOTOR CONTROL CIRCUITS".

本申请的申请人还拥有下面识别的美国专利申请,这些申请于2016年2月9日提交,各自以引用方式全文并入本文:The applicant of the present application also owns the following identified US patent applications, which were filed on February 9, 2016, each of which is hereby incorporated by reference in its entirety:

-名称为“具有关节运动的和可轴向平移的端部执行器的外科器械(SURGICALINSTRUMENT WITH ARTICULATING AND AXILEY TRANSLATABLE END EFFECTOR)”的美国专利申请序列号15/019,220;- US Patent Application Serial No. 15/019,220 entitled "SURGICAL INSTRUMENT WITH ARTICULATING AND AXILEY TRANSLATABLE END EFFECTOR";

-名称为“具有多个链接关节运动布置的外科器械(SURGICAL INSTRUMENTS WITHMULTIPLE LINK ARTICULATION ARRANGEMENTS)”的美国专利申请序列号15/019,228;- US Patent Application Serial No. 15/019,228 entitled "SURGICAL INSTRUMENTS WITH MULTIPLE LINK ARTICULATION ARRANGEMENTS";

-名称为“具有狭缝次级约束的外科器械关节运动机构(SURGICAL INSTRUMENTARTICULATION MECHANISM WITH SLOTTED SECONDARY CONSTRAINT)”的美国专利申请序列号15/019,196;- US Patent Application Serial No. 15/019,196 entitled "SURGICAL INSTRUMENTARTICULATION MECHANISM WITH SLOTTED SECONDARY CONSTRAINT";

-名称为“具有相对于细长轴组件可高度关节运动的端部执行器的外科器械(SURGICAL INSTRUMENTS WITH AN END EFFECTOR THAT IS HIGHLY ARTICULATABLERELATIVE TO AN ELONGATE SHAFT ASSEMBLY)”的美国专利申请序列号15/019,206;- US Patent Application Serial No. 15/019,206 entitled "SURGICAL INSTRUMENTS WITH AN END EFFECTOR THAT IS HIGHLY ARTICULATABLE RELATIVE TO AN ELONGATE SHAFT ASSEMBLY" ;

-名称为“具有非对称关节运动布置的外科器械(SURGICAL INSTRUMENTS WITHNON-SYMMETRICAL ARTICULATION ARRANGEMENTS)”的美国专利申请序列号15/019,215;- US Patent Application Serial No. 15/019,215 entitled "SURGICAL INSTRUMENTS WITHNON-SYMMETRICAL ARTICULATION ARRANGEMENTS";

-名称为“具有单一关节运动链接布置的可关节运动的外科器械(ARTICULATABLESURGICAL INSTRUMENTS WITH SINGLE ARTICULATION LINK ARRANGEMENTS)”的美国专利申请序列号15/019,227;- US Patent Application Serial No. 15/019,227 entitled "ARTICULATABLESURGICAL INSTRUMENTS WITH SINGLE ARTICULATION LINK ARRANGEMENTS";

-名称为“具有用于电缆驱动的关节运动系统的张紧布置的外科器械(SURGICALINSTRUMENTS WITH TENSIONING ARRANGEMENTS FOR CABLE DRIVEN ARTICULATIONSYSTEMS)”的美国专利申请序列号15/019,235;- US Patent Application Serial No. 15/019,235 entitled "SURGICAL INSTRUMENTS WITH TENSIONING ARRANGEMENTS FOR CABLE DRIVEN ARTICULATION SYSTEMS";

-名称为“具有离轴击发束布置的可关节运动外科器械(ARTICULATABLE SURGICALINSTRUMENTS WITH OFF-AXIS FIRING BEAM ARRANGEMENTS)”的美国专利申请序列号15/019,230;以及- US Patent Application Serial No. 15/019,230 entitled "ARTICULATABLE SURGICALINSTRUMENTS WITH OFF-AXIS FIRING BEAM ARRANGEMENTS"; and

-名称为“具有闭合冲程还原布置的外科器械(SURGICAL INSTRUMENTS WITHCLOSURE STROKE REDUCTION ARRANGEMENTS)”的美国专利申请序列号15/019,245。- US Patent Application Serial No. 15/019,245 entitled "SURGICAL INSTRUMENTS WITH CLOSURE STROKE REDUCTION ARRANGEMENTS".

本申请的申请人还拥有下面识别的美国专利申请,这些申请于2016年2月12日提交,各自以引用方式全文并入本文:The applicant of the present application also owns the following identified US patent applications, which were filed on February 12, 2016, each of which is hereby incorporated by reference in its entirety:

-名称为“用于补偿电动外科器械中的驱动系故障的机构(MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS)”的美国专利申请序列号15/043,254;- US Patent Application Serial No. 15/043,254 entitled "MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS";

-名称为“用于补偿电动外科器械中的驱动系故障的机构(MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS)”的美国专利申请序列号15/043,259;- US Patent Application Serial No. 15/043,259 entitled "MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS";

-名称为“用于补偿电动外科器械中的驱动系故障的机构(MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS)”的美国专利申请序列号15/043,275;以及- US Patent Application Serial No. 15/043,275 entitled "MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS"; and

-名称为“用于补偿电动外科器械中的驱动系故障的机构(MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS)”的美国专利申请序列号15/043,289。- US Patent Application Serial No. 15/043,289 entitled "MECHANISMS FORCOMPENSATING FOR DRIVETRAIN FAILURE IN POWERED SURGICAL INSTRUMENTS".

本申请的申请人拥有2015年6月18日提交并且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on June 18, 2015 and each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL END EFFECTORS WITH POSITIVE JAW OPENINGARRANGEMENTS”的美国专利申请序列号14/742,925;- US Patent Application Serial No. 14/742,925 entitled "SURGICAL END EFFECTORS WITH POSITIVE JAW OPENINGARRANGEMENTS";

-名称为“SURGICAL END EFFECTORS WITH DUAL CAM ACTUATED JAW CLOSINGFEATURES”的美国专利申请序列号14/742,941;- US Patent Application Serial No. 14/742,941 entitled "SURGICAL END EFFECTORS WITH DUAL CAM ACTUATED JAW CLOSINGFEATURES";

-名称为“MOVABLE FIRING BEAM SUPPORT ARRANGEMENTS FOR ARTICULATABLESURGICAL INSTRUMENTS”的美国专利申请序列号14/742,914;- US Patent Application Serial No. 14/742,914 entitled "MOVABLE FIRING BEAM SUPPORT ARRANGEMENTS FOR ARTICULATABLESURGICAL INSTRUMENTS";

-名称为“ARTICULATABLE SURGICAL INSTRUMENTS WITH COMPOSITE FIRING BEAMSTRUCTURES WITH CENTER FIRING SUPPORT MEMBER FOR ARTICULATION SUPPORT”的美国专利申请序列号14/742,900;- US Patent Application Serial No. 14/742,900 entitled "ARTICULATABLE SURGICAL INSTRUMENTS WITH COMPOSITE FIRING BEAMSTRUCTURES WITH CENTER FIRING SUPPORT MEMBER FOR ARTICULATION SUPPORT";

-名称为“用于可进行关节运动的外科器械的双关节运动驱动系统布置(DUALARTICULATION DRIVE SYSTEM ARRANGEMENTS FOR ARTICULATABLE SURGICALINSTRUMENTS)”的美国专利申请序列号14/742,885;以及- US Patent Application Serial No. 14/742,885 entitled "DUALARTICULATION DRIVE SYSTEM ARRANGEMENTS FOR ARTICULATABLE SURGICALINSTRUMENTS"; and

-名称为“PUSH/PULL ARTICULATION DRIVE SYSTEMS FOR ARTICULATABLESURGICAL INSTRUMENTS”的美国专利申请序列号14/742,876。- US Patent Application Serial No. 14/742,876 entitled "PUSH/PULL ARTICULATION DRIVE SYSTEMS FOR ARTICULATABLESURGICAL INSTRUMENTS".

本申请的申请人拥有2015年3月6日提交并且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on March 6, 2015, each of which is incorporated herein by reference in its entirety:

-名称为“POWERED SURGICAL INSTRUMENT”的美国专利申请序列号14/640,746;- US Patent Application Serial No. 14/640,746 entitled "POWERED SURGICAL INSTRUMENT";

-名称为“MULTIPLE LEVEL THRESHOLDS TO MODIFY OPERATION OF POWEREDSURGICAL INSTRUMENTS”的美国专利申请序列号14/640,795;- US Patent Application Serial No. 14/640,795 entitled "MULTIPLE LEVEL THRESHOLDS TO MODIFY OPERATION OF POWEREDSURGICAL INSTRUMENTS";

-名称为“ADAPTIVE TISSUE COMPRESSION TECHNIQUES TO ADJUST CLOSURERATES FOR MULTIPLE TISSUE TYPES”的美国专利申请序列号14/640,832;代理人案卷号END7557USNP/140482;- US Patent Application Serial No. 14/640,832 entitled "ADAPTIVE TISSUE COMPRESSION TECHNIQUES TO ADJUST CLOSURERATES FOR MULTIPLE TISSUE TYPES"; Attorney's Docket No. END7557USNP/140482;

-名称为“OVERLAID MULTI SENSOR RADIO FREQUENCY(RF)ELECTRODE SYSTEM TOMEASURE TISSUE COMPRESSION”的美国专利申请序列号14/640,935;- US Patent Application Serial No. 14/640,935 entitled "OVERLAID MULTI SENSOR RADIO FREQUENCY (RF) ELECTRODE SYSTEM TOMEASURE TISSUE COMPRESSION";

-名称为“MONITORING SPEED CONTROL AND PRECISION INCREMENTING OF MOTORFOR POWERED SURGICAL INSTRUMENTS”的美国专利申请序列号14/640,831;- US Patent Application Serial No. 14/640,831 entitled "MONITORING SPEED CONTROL AND PRECISION INCREMENTING OF MOTORFOR POWERED SURGICAL INSTRUMENTS";

-名称为“TIME DEPENDENT EVALUATION OF SENSOR DATA TO DETERMINESTABILITY,CREEP,AND VISCOELASTIC ELEMENTS OF MEASURES”的美国专利申请序列号14/640,859;- US Patent Application Serial No. 14/640,859 entitled "TIME DEPENDENT EVALUATION OF SENSOR DATA TO DETERMINESTABILITY, CREEP, AND VISCOELASTIC ELEMENTS OF MEASURES";

-名称为“INTERACTIVE FEEDBACK SYSTEM FOR POWERED SURGICAL INSTRUMENTS”的美国专利申请序列号14/640,817;- US Patent Application Serial No. 14/640,817 entitled "INTERACTIVE FEEDBACK SYSTEM FOR POWERED SURGICAL INSTRUMENTS";

-名称为“CONTROL TECHNIQUES AND SUB-PROCESSOR CONTAINED WITHIN MODULARSHAFT WITH SELECT CONTROL PROCESSING FROM HANDLE”的美国专利申请序列号14/640,844;- US Patent Application Serial No. 14/640,844 entitled "CONTROL TECHNIQUES AND SUB-PROCESSOR CONTAINED WITHIN MODULARSHAFT WITH SELECT CONTROL PROCESSING FROM HANDLE";

-名称为“SMART SENSORS WITH LOCAL SIGNAL PROCESSING”的美国专利申请序列号14/640,837;- US Patent Application Serial No. 14/640,837 entitled "SMART SENSORS WITH LOCAL SIGNAL PROCESSING";

-名称为“SYSTEM FOR DETECTING THE MIS-INSERTION OF A STAPLE CARTRIDGEINTO A SURGICAL STAPLER”的美国专利申请序列号14/640,765;- US Patent Application Serial No. 14/640,765 entitled "SYSTEM FOR DETECTING THE MIS-INSERTION OF A STAPLE CARTRIDGEINTO A SURGICAL STAPLER";

-名称为“SIGNAL AND POWER COMMUNICATION SYSTEM POSITIONED ON AROTATABLE SHAFT”的美国专利申请序列号14/640,799;以及- US Patent Application Serial No. 14/640,799 entitled "SIGNAL AND POWER COMMUNICATION SYSTEM POSITIONED ON AROTATABLE SHAFT"; and

-名称为“SURGICAL INSTRUMENT COMPRISING A LOCKABLE BATTERY HOUSING”的美国专利申请序列号14/640,780。- US Patent Application Serial No. 14/640,780 entitled "SURGICAL INSTRUMENT COMPRISING A LOCKABLE BATTERY HOUSING".

本申请的申请人拥有2015年2月27日提交并且全文各自以引用的方式并入本文的以下专利申请:The applicant of the present application owns the following patent applications filed on February 27, 2015 and each of which is hereby incorporated by reference in its entirety:

-名称为“SURGICAL INSTRUMENT SYSTEM COMPRISING AN INSPECTION STATION”的美国专利申请序列号14/633,576;- US Patent Application Serial No. 14/633,576 entitled "SURGICAL INSTRUMENT SYSTEM COMPRISING AN INSPECTION STATION";

-名称为“SURGICAL APPARATUS CONFIGURED TO ASSESS WHETHER A PERFORMANCEPARAMETER OF THE SURGICAL APPARATUS IS WITHIN AN ACCEPTABLE PERFORMANCE BAND”的美国专利申请序列号14/633,546;- US Patent Application Serial No. 14/633,546 entitled "SURGICAL APPARATUS CONFIGURED TO ASSESS WHETHER A PERFORMANCEPARAMETER OF THE SURGICAL APPARATUS IS WITHIN AN ACCEPTABLE PERFORMANCE BAND";

-名称为“SURGICAL CHARGING SYSTEM THAT CHARGES AND/OR CONDITIONS ONEOR MORE BATTERIES”的美国专利申请序列号14/633,576;- US Patent Application Serial No. 14/633,576 entitled "SURGICAL CHARGING SYSTEM THAT CHARGES AND/OR CONDITIONS ONEOR MORE BATTERIES";

-名称为“CHARGING SYSTEM THAT ENABLES EMERGENCY RESOLUTIONS FORCHARGING A BATTERY”的美国专利申请序列号14/633,566;- US Patent Application Serial No. 14/633,566 entitled "CHARGING SYSTEM THAT ENABLES EMERGENCY RESOLUTIONS FORCHARGING A BATTERY";

-名称为“SYSTEM FOR MONITORING WHETHER A SURGICAL INSTRUMENT NEEDS TOBE SERVICED”的美国专利申请序列号14/633,555;- US Patent Application Serial No. 14/633,555 entitled "SYSTEM FOR MONITORING WHETHER A SURGICAL INSTRUMENT NEEDS TOBE SERVICED";

-名称为“REINFORCED BATTERY FOR A SURGICAL INSTRUMENT”的美国专利申请序列号14/633,542;- US Patent Application Serial No. 14/633,542 entitled "REINFORCED BATTERY FOR A SURGICAL INSTRUMENT";

-名称为“POWER ADAPTER FOR A SURGICAL INSTRUMENT”的美国专利申请序列号14/633,548;- US Patent Application Serial No. 14/633,548 entitled "POWER ADAPTER FOR A SURGICAL INSTRUMENT";

-名称为“ADAPTABLE SURGICAL INSTRUMENT HANDLE”的美国专利申请序列号14/633,526;- US Patent Application Serial No. 14/633,526 entitled "ADAPTABLE SURGICAL INSTRUMENT HANDLE";

-名称为“MODULAR STAPLING ASSEMBLY”的美国专利申请序列号14/633,541;以及- US Patent Application Serial No. 14/633,541 entitled "MODULAR STAPLING ASSEMBLY"; and

-名称为“SURGICAL APPARATUS CONFIGURED TO TRACK AN END-OF-LIFEPARAMETER”的美国专利申请序列号14/633,562;- US Patent Application Serial No. 14/633,562 entitled "SURGICAL APPARATUS CONFIGURED TO TRACK AN END-OF-LIFEPARAMETER";

本申请的申请人拥有2014年12月18日提交并且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on December 18, 2014 and each of which is incorporated herein by reference in its entirety:

-名称为“SURGICAL INSTRUMENT SYSTEMS COMPRISING AN ARTICULATABLE ENDEFFECTOR AND MEANS FOR ADJUSTING THE FIRING STROKE OF A FIRING”的美国专利申请序列号14/574,478;- US Patent Application Serial No. 14/574,478 entitled "SURGICAL INSTRUMENT SYSTEMS COMPRISING AN ARTICULATABLE ENDEFFECTOR AND MEANS FOR ADJUSTING THE FIRING STROKE OF A FIRING";

-名称为“SURGICAL INSTRUMENT ASSEMBLY COMPRISING LOCKABLE SYSTEMS”的美国专利申请序列号14/574,483;- US Patent Application Serial No. 14/574,483 entitled "SURGICAL INSTRUMENT ASSEMBLY COMPRISING LOCKABLE SYSTEMS";

-名称为“DRIVE ARRANGEMENTS FOR ARTICULATABLE SURGICAL INSTRUMENTS”的美国专利申请序列号14/575,139;- US Patent Application Serial No. 14/575,139 entitled "DRIVE ARRANGEMENTS FOR ARTICULATABLE SURGICAL INSTRUMENTS";

-名称为“LOCKING ARRANGEMENTS FOR DETACHABLE SHAFT ASSEMBLIES WITHARTICULATABLE SURGICAL END EFFECTORS”的美国专利申请序列号14/575,148;- US Patent Application Serial No. 14/575,148 entitled "LOCKING ARRANGEMENTS FOR DETACHABLE SHAFT ASSEMBLIES WITHARTICULATABLE SURGICAL END EFFECTORS";

-名称为“SURGICAL INSTRUMENT WITH AN ANVIL THAT IS SELECTIVELY MOVABLEABOUT A DISCRETE NON-MOVABLE AXIS RELATIVE TO A STAPLE CARTRIDGE”的美国专利申请序列号14/575,130;- US Patent Application Serial No. 14/575,130 entitled "SURGICAL INSTRUMENT WITH AN ANVIL THAT IS SELECTIVELY MOVABLEABOUT A DISCRETE NON-MOVABLE AXIS RELATIVE TO A STAPLE CARTRIDGE";

-名称为“SURGICAL INSTRUMENTS WITH IMPROVED CLOSURE ARRANGEMENTS”的美国专利申请序列号14/575,143;- US Patent Application Serial No. 14/575,143 entitled "SURGICAL INSTRUMENTS WITH IMPROVED CLOSURE ARRANGEMENTS";

-名称为“SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDMOVABLE FIRING BEAM SUPPORT ARRANGEMENTS”的美国专利申请序列号14/575,117;- US Patent Application Serial No. 14/575,117 entitled "SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDMOVABLE FIRING BEAM SUPPORT ARRANGEMENTS";

-名称为“SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDIMPROVED FIRING BEAM SUPPORT ARRANGEMENTS”的美国专利申请序列号14/575,154;- US Patent Application Serial No. 14/575,154 entitled "SURGICAL INSTRUMENTS WITH ARTICULATABLE END EFFECTORS ANDIMPROVED FIRING BEAM SUPPORT ARRANGEMENTS";

-名称为“SURGICAL INSTRUMENT ASSEMBLY COMPRISING A FLEXIBLEARTICULATION SYSTEM”的美国专利申请序列号14/574,493;以及- US Patent Application Serial No. 14/574,493 entitled "SURGICAL INSTRUMENT ASSEMBLY COMPRISING A FLEXIBLEARTICULATION SYSTEM"; and

-名称为“SURGICAL INSTRUMENT ASSEMBLY COMPRISING A LOCKABLEARTICULATION SYSTEM”的美国专利申请序列号14/574,500。- US Patent Application Serial No. 14/574,500 entitled "SURGICAL INSTRUMENT ASSEMBLY COMPRISING A LOCKABLEARTICULATION SYSTEM".

本申请的申请人拥有2013年3月1日提交并且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application has the following patent applications filed on March 1, 2013 and each of which is incorporated herein by reference in its entirety:

-名称为“Articulatable Surgical Instruments With Conductive PathwaysFor Signal Communication”的美国专利申请序列号13/782,295,现为美国专利申请公布2014/0246471;- US Patent Application Serial No. 13/782,295 entitled "Articulatable Surgical Instruments With Conductive Pathways For Signal Communication", now US Patent Application Publication 2014/0246471;

-名称为“Rotary Powered Articulation Joints For Surgical Instruments”的美国专利申请序列号13/782,323,现为美国专利申请公布2014/0246472;- US Patent Application Serial No. 13/782,323 entitled "Rotary Powered Articulation Joints For Surgical Instruments", now US Patent Application Publication 2014/0246472;

-名称为“Thumbwheel Switch Arrangements For Surgical Instruments”的美国专利申请序列号13/782,338,现为美国专利申请公布2014/0249557;- US Patent Application Serial No. 13/782,338 entitled "Thumbwheel Switch Arrangements For Surgical Instruments", now US Patent Application Publication 2014/0249557;

-名称为“Electromechanical Surgical Device with Signal RelayArrangement”的美国专利申请序列号13/782,499,现为美国专利申请公布2014/0246474;- US Patent Application Serial No. 13/782,499 entitled "Electromechanical Surgical Device with Signal Relay Arrangement", now US Patent Application Publication 2014/0246474;

-名称为“Multiple Processor Motor Control for Modular SurgicalInstruments”的美国专利申请序列号13/782,460,现为美国专利申请公布2014/0246478;- US Patent Application Serial No. 13/782,460 entitled "Multiple Processor Motor Control for Modular Surgical Instruments", now US Patent Application Publication 2014/0246478;

-名称为“Joystick Switch Assemblies For Surgical Instruments”的美国专利申请序列号13/782,358,现为美国专利申请公布2014/0246477;- US Patent Application Serial No. 13/782,358 entitled "Joystick Switch Assemblies For Surgical Instruments", now US Patent Application Publication 2014/0246477;

-名称为“Sensor Straightened End Effector During Removal ThroughTrocar”的美国专利申请序列号13/782,481,现为美国专利申请公布2014/0246479;- US Patent Application Serial No. 13/782,481 entitled "Sensor Straightened End Effector During Removal ThroughTrocar", now US Patent Application Publication 2014/0246479;

-名称为“Control Methods for Surgical Instruments with RemovableImplement Portions”的美国专利申请序列号13/782,518,现为美国专利申请公布2014/0246475;- US Patent Application Serial No. 13/782,518 entitled "Control Methods for Surgical Instruments with RemovableImplement Portions", now US Patent Application Publication 2014/0246475;

-名称为“Rotary Powered Surgical Instruments With Multiple Degrees ofFreedom”的美国专利申请序列号13/782,375,现为美国专利申请公布2014/0246473;以及- US Patent Application Serial No. 13/782,375 entitled "Rotary Powered Surgical Instruments With Multiple Degrees of Freedom", now US Patent Application Publication 2014/0246473; and

-名称为“SURGICAL INSTRUMENT SOFT STOP”的美国专利申请序列号13/782,536,现为美国专利申请公布2014/0246476。- US Patent Application Serial No. 13/782,536 entitled "SURGICAL INSTRUMENT SOFT STOP", now US Patent Application Publication 2014/0246476.

本申请的申请人还拥有下面识别的美国专利申请,这些申请于2013年3月14日提交,各自以引用方式全文并入本文:The applicant of the present application also owns the following identified US patent applications, which were filed on March 14, 2013, each of which is hereby incorporated by reference in its entirety:

-名称为“ARTICULATABLE SURGICAL INSTRUMENT COMPRISING A FIRING DRIVE”的美国专利申请序列号13/803,097,现为美国专利申请公布2014/0263542;- US Patent Application Serial No. 13/803,097 entitled "ARTICULATABLE SURGICAL INSTRUMENT COMPRISING A FIRING DRIVE", now US Patent Application Publication 2014/0263542;

-名称为“CONTROL ARRANGEMENTS FOR A DRIVE MEMBER OF A SURGICALINSTRUMENT”的美国专利申请序列号13/803,193,现为美国专利申请公布2014/0263537;- US Patent Application Serial No. 13/803,193 entitled "CONTROL ARRANGEMENTS FOR A DRIVE MEMBER OF A SURGICALINSTRUMENT", now US Patent Application Publication 2014/0263537;

-名称为“INTERCHANGEABLE SHAFT ASSEMBLIES FOR USE WITH A SURGICALINSTRUMENT”的美国专利申请序列号13/803,053,现为美国专利申请公布2014/0263564;- US Patent Application Serial No. 13/803,053 entitled "INTERCHANGEABLE SHAFT ASSEMBLIES FOR USE WITH A SURGICALINSTRUMENT", now US Patent Application Publication 2014/0263564;

-名称为“ARTICULATABLE SURGICAL INSTRUMENT COMPRISING AN ARTICULATIONLOCK”的美国专利申请序列号13/803,086,现为美国专利申请公布2014/0263541;- US Patent Application Serial No. 13/803,086 entitled "ARTICULATABLE SURGICAL INSTRUMENT COMPRISING AN ARTICULATION LOCK", now US Patent Application Publication 2014/0263541;

-名称为“SENSOR ARRANGEMENTS FOR ABSOLUTE POSITIONING SYSTEM FORSURGICAL INSTRUMENTS”的美国专利申请序列号13/803,210,现为美国专利申请公布2014/0263538;- US Patent Application Serial No. 13/803,210 entitled "SENSOR ARRANGEMENTS FOR ABSOLUTE POSITIONING SYSTEM FORSURGICAL INSTRUMENTS", now US Patent Application Publication 2014/0263538;

-名称为“MULTI-FUNCTION MOTOR FOR A SURGICAL INSTRUMENT”的美国专利申请序列号13/803,148,现为美国专利申请公布2014/0263554;- US Patent Application Serial No. 13/803,148 entitled "MULTI-FUNCTION MOTOR FOR A SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0263554;

-名称为“DRIVE SYSTEM LOCKOUT ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS”的美国专利申请序列号13/803,066,现为美国专利申请公布2014/0263565;- US Patent Application Serial No. 13/803,066 entitled "DRIVE SYSTEM LOCKOUT ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS", now US Patent Application Publication 2014/0263565;

-名称为“ARTICULATION CONTROL SYSTEM FOR ARTICULATABLE SURGICALINSTRUMENTS”的美国专利申请序列号13/803,117,现为美国专利申请公布2014/0263553;- US Patent Application Serial No. 13/803,117 entitled "ARTICULATION CONTROL SYSTEM FOR ARTICULATABLE SURGICALINSTRUMENTS", now US Patent Application Publication 2014/0263553;

-名称为“DRIVE TRAIN CONTROL ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS”的美国专利申请序列号13/803,130,现为美国专利申请公布2014/0263543;以及- US Patent Application Serial No. 13/803,130 entitled "DRIVE TRAIN CONTROL ARRANGEMENTS FOR MODULAR SURGICALINSTRUMENTS", now US Patent Application Publication 2014/0263543; and

-名称为“METHOD AND SYSTEM FOR OPERATING A SURGICAL INSTRUMENT”的美国专利申请序列号13/803,159,现为美国专利申请公布2014/0277017。- US Patent Application Serial No. 13/803,159 entitled "METHOD AND SYSTEM FOR OPERATING A SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0277017.

本申请的申请人还拥有2014年3月7日提交并且全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent application filed on March 7, 2014 and incorporated herein by reference in its entirety:

-名称为“CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS”的美国专利申请序列号14/200,111,现为美国专利申请公布2014/0263539。- US Patent Application Serial No. 14/200,111 entitled "CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS", now US Patent Application Publication 2014/0263539.

本申请的申请人还拥有2014年3月26日提交并且各自全文以引用方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on March 26, 2014 and each of which is hereby incorporated by reference in its entirety:

-名称为“POWER MANAGEMENT CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS”的美国专利申请序列号14/226,106,现为美国专利申请公布2015/0272582;- US Patent Application Serial No. 14/226,106 entitled "POWER MANAGEMENT CONTROL SYSTEMS FOR SURGICAL INSTRUMENTS", now US Patent Application Publication 2015/0272582;

-名称为“STERILIZATION VERIFICATION CIRCUIT”的美国专利申请序列号14/226,099,现为美国专利申请公布2015/0272581;- US Patent Application Serial No. 14/226,099 entitled "STERILIZATION VERIFICATION CIRCUIT", now US Patent Application Publication 2015/0272581;

-名称为“VERIFICATION OF NUMBER OF BATTERY EXCHANGES/PROCEDURE COUNT”的美国专利申请序列号14/226,094,现为美国专利申请公布2015/0272580;- US Patent Application Serial No. 14/226,094 entitled "VERIFICATION OF NUMBER OF BATTERY EXCHANGES/PROCEDURE COUNT", now US Patent Application Publication 2015/0272580;

-名称为“POWER MANAGEMENT THROUGH SLEEP OPTIONS OF SEGMENTED CIRCUITAND WAKE UP CONTROL”的美国专利申请序列号14/226,117,现为美国专利申请公布2015/0272574;- US Patent Application Serial No. 14/226,117 entitled "POWER MANAGEMENT THROUGH SLEEP OPTIONS OF SEGMENTED CIRCUITAND WAKE UP CONTROL", now US Patent Application Publication 2015/0272574;

-名称为“MODULAR POWERED SURGICAL INSTRUMENT WITH DETACHABLE SHAFTASSEMBLIES”的美国专利申请序列号14/226,075,现为美国专利申请公布2015/0272579;- US Patent Application Serial No. 14/226,075 entitled "MODULAR POWERED SURGICAL INSTRUMENT WITH DETACHABLE SHAFTASSEMBLIES", now US Patent Application Publication 2015/0272579;

-名称为“FEEDBACK ALGORITHMS FOR MANUAL BAILOUT SYSTEMS FOR SURGICALINSTRUMENTS”的美国专利申请序列号14/226,093,现为美国专利申请公布2015/0272569;- US Patent Application Serial No. 14/226,093 entitled "FEEDBACK ALGORITHMS FOR MANUAL BAILOUT SYSTEMS FOR SURGICALINSTRUMENTS", now US Patent Application Publication 2015/0272569;

-名称为“SURGICAL INSTRUMENT UTILIZING SENSOR ADAPTATION”的美国专利申请序列号14/226,116,现为美国专利申请公布2015/0272571;- US Patent Application Serial No. 14/226,116 entitled "SURGICAL INSTRUMENT UTILIZING SENSOR ADAPTATION", now US Patent Application Publication 2015/0272571;

-名称为“SURGICAL INSTRUMENT CONTROL CIRCUIT HAVING A SAFETYPROCESSOR”的美国专利申请序列号14/226,071,现为美国专利申请公布2015/0272578;- US Patent Application Serial No. 14/226,071 entitled "SURGICAL INSTRUMENT CONTROL CIRCUIT HAVING A SAFETYPROCESSOR", now US Patent Application Publication 2015/0272578;

-名称为“SURGICAL INSTRUMENT COMPRISING INTERACTIVE SYSTEMS”的美国专利申请序列号14/226,097,现为美国专利申请公布2015/0272570;- US Patent Application Serial No. 14/226,097 entitled "SURGICAL INSTRUMENT COMPRISING INTERACTIVE SYSTEMS", now US Patent Application Publication 2015/0272570;

-名称为“INTERFACE SYSTEMS FOR USE WITH SURGICAL INSTRUMENTS”的美国专利申请序列号14/226,126,现为美国专利申请公布2015/0272572;- US Patent Application Serial No. 14/226,126 entitled "INTERFACE SYSTEMS FOR USE WITH SURGICAL INSTRUMENTS", now US Patent Application Publication 2015/0272572;

-名称为“MODULAR SURGICAL INSTRUMENT SYSTEM”的美国专利申请序列号14/226,133,现为美国专利申请公布2015/0272557;- US Patent Application Serial No. 14/226,133 entitled "MODULAR SURGICAL INSTRUMENT SYSTEM", now US Patent Application Publication 2015/0272557;

-名称为“SYSTEMS AND METHODS FOR CONTROLLING A SEGMENTED CIRCUIT”的美国专利申请序列号14/226,081,现为美国专利申请公布2015/0277471;- US Patent Application Serial No. 14/226,081 entitled "SYSTEMS AND METHODS FOR CONTROLLING A SEGMENTED CIRCUIT", now US Patent Application Publication 2015/0277471;

-名称为“POWER MANAGEMENT THROUGH SEGMENTED CIRCUIT AND VARIABLEVOLTAGE PROTECTION”的美国专利申请序列号14/226,076,现为美国专利申请公布2015/0280424;- US Patent Application Serial No. 14/226,076 entitled "POWER MANAGEMENT THROUGH SEGMENTED CIRCUIT AND VARIABLEVOLTAGE PROTECTION", now US Patent Application Publication 2015/0280424;

-名称为“SURGICAL STAPLING INSTRUMENT SYSTEM”的美国专利申请序列号14/226,111,现为美国专利申请公布2015/0272583;以及- US Patent Application Serial No. 14/226,111 entitled "SURGICAL STAPLING INSTRUMENT SYSTEM", now US Patent Application Publication 2015/0272583; and

-名称为“SURGICAL INSTRUMENT COMPRISING A ROTATABLE SHAFT”的美国专利申请序列号14/226,125,现为美国专利申请公布2015/0280384。- US Patent Application Serial No. 14/226,125 entitled "SURGICAL INSTRUMENT COMPRISING A ROTATABLE SHAFT", now US Patent Application Publication 2015/0280384.

本申请的申请人还拥有2014年9月5日提交并且全文各自以引用的方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on September 5, 2014 and each of which is hereby incorporated by reference in its entirety:

-名称为“用于电动医疗设备的电路和传感器(CIRCUITRY AND SENSORS FORPOWERED MEDICAL DEVICE)”的美国专利申请序列号14/479,103,现为美国专利申请公布号2016/0066912;- US Patent Application Serial No. 14/479,103 entitled "CIRCUITRY AND SENSORS FORPOWERED MEDICAL DEVICE", now US Patent Application Publication No. 2016/0066912;

-名称为“具有集成传感器以量化组织压缩的附属物(ADJUNCT WITH INTEGRATEDSENSORS TO QUANTIFY TISSUE COMPRESSION)”美国专利申请序列号14/479,119,现为美国专利申请公开号2016/0066914;- US Patent Application Serial No. 14/479,119 entitled "ADJUNCT WITH INTEGRATEDSENSORS TO QUANTIFY TISSUE COMPRESSION", now US Patent Application Publication No. 2016/0066914;

-名称为“基于部件评估的监测设备降级(MONITORING DEVICE DEGRADATIONBASED ON COMPONENT EVALUATION)”的美国专利申请序列号14/478,908,现在为美国专利申请公布号2016/0066910;- US Patent Application Serial No. 14/478,908 entitled "MONITORING DEVICE DEGRADATIONBASED ON COMPONENT EVALUATION", now US Patent Application Publication No. 2016/0066910;

-名称为“具有影响第二传感器输出或判读的一个传感器的多个传感器(MULTIPLESENSORS WITH ONE SENSOR AFFECTING A SECOND SENSOR'S OUTPUT ORINTERPRETATION)”的美国专利申请序列号14/478,895,现在为美国专利申请公布号2016/0066909;- US Patent Application Serial No. 14/478,895 entitled "MULTIPLESENSORS WITH ONE SENSOR AFFECTING A SECOND SENSOR'S OUTPUT ORINTERPRETATION", now US Patent Application Publication No. 2016 /0066909;

-名称为“使用霍尔磁铁检测极性检测误装载仓(USE OF POLARITY OF HALLMAGNET DETECTION TO DETECT MISLOADED CARTRIDGE)”的美国专利申请序列号14/479,110,现在为美国专利申请公布号2016/0066915;- US Patent Application Serial No. 14/479,110 entitled "USE OF POLARITY OF HALLMAGNET DETECTION TO DETECT MISLOADED CARTRIDGE", now US Patent Application Publication No. 2016/0066915;

-名称为“智能仓唤醒操作和数据保留(SMART CARTRIDGE WAKE UP OPERATIONAND DATA RETENTION)”的美国专利申请序列号14/479,098,现在为美国专利申请公布号2016/0066911;- US Patent Application Serial No. 14/479,098 entitled "SMART CARTRIDGE WAKE UP OPERATION AND DATA RETENTION", now US Patent Application Publication No. 2016/0066911;

-名称为“用于电动医疗设备的多马达控制(MULTIPLE MOTOR CONTROL FORPOWERED MEDICAL DEVICE)”美国专利申请序列号14/479,115,现在为美国专利申请公布号2016/0066916;以及- US Patent Application Serial No. 14/479,115 entitled "MULTIPLE MOTOR CONTROL FORPOWERED MEDICAL DEVICE", now US Patent Application Publication No. 2016/0066916; and

-名称为“组织参数稳定的局部显示(LOCAL DISPLAY OF TISSUE PARAMETERSTABILIZATION)”的美国专利申请序列号14/479,108,现在是美国专利申请公开号2016/0066913。- US Patent Application Serial No. 14/479,108 entitled "LOCAL DISPLAY OF TISSUE PARAMETERSTABILIZATION", now US Patent Application Publication No. 2016/0066913.

本申请的申请人还拥有2014年4月9日提交并且全文各自以引用的方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on April 9, 2014 and each of which is hereby incorporated by reference in its entirety:

-名称为“MOTOR DRIVEN SURGICAL INSTRUMENTS WITH LOCKABLE DUAL DRIVESHAFTS”的美国专利申请序列号14/248,590,现为美国专利申请公布2014/0305987;- US Patent Application Serial No. 14/248,590 entitled "MOTOR DRIVEN SURGICAL INSTRUMENTS WITH LOCKABLE DUAL DRIVESHAFTS", now US Patent Application Publication 2014/0305987;

-名称为“SURGICAL INSTRUMENT COMPRISING A CLOSING DRIVE AND A FIRINGDRIVE OPERATED FROM THE SAME ROTATABLE OUTPUT”的美国专利申请序列号14/248,581,现为美国专利申请公布2014/0305989;- US Patent Application Serial No. 14/248,581 entitled "SURGICAL INSTRUMENT COMPRISING A CLOSING DRIVE AND A FIRINGDRIVE OPERATED FROM THE SAME ROTATABLE OUTPUT", now US Patent Application Publication 2014/0305989;

-名称为“SURGICAL INSTRUMENT SHAFT INCLUDING SWITCHES FOR CONTROLLINGTHE OPERATION OF THE SURGICAL INSTRUMENT”的美国专利申请序列号14/248,595,现为美国专利申请公布2014/0305988;- US Patent Application Serial No. 14/248,595 entitled "SURGICAL INSTRUMENT SHAFT INCLUDING SWITCHES FOR CONTROLLINGTHE OPERATION OF THE SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0305988;

-名称为“POWERED LINEAR SURGICAL STAPLER”的美国专利申请序列号14/248,588,现为美国专利申请公布2014/0309666;- US Patent Application Serial No. 14/248,588 entitled "POWERED LINEAR SURGICAL STAPLER", now US Patent Application Publication 2014/0309666;

-名称为“TRANSMISSION ARRANGEMENT FOR A SURGICAL INSTRUMENT”的美国专利申请序列号14/248,591,现为美国专利申请公布2014/0305991;- US Patent Application Serial No. 14/248,591 entitled "TRANSMISSION ARRANGEMENT FOR A SURGICAL INSTRUMENT", now US Patent Application Publication 2014/0305991;

-名称为“MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH ALIGNMENTFEATURES FOR ALIGNING ROTARY DRIVE SHAFTS WITH SURGICAL END EFFECTOR SHAFTS”的美国专利申请序列号14/248,584,现为美国专利申请公布2014/0305994;- US Patent Application Serial No. 14/248,584 entitled "MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH ALIGNMENTFEATURES FOR ALIGNING ROTARY DRIVE SHAFTS WITH SURGICAL END EFFECTOR SHAFTS", now US Patent Application Publication 2014/0305994;

-名称为“POWERED SURGICAL STAPLER”的美国专利申请序列号14/248,587,现为美国专利申请公布2014/0309665;- US Patent Application Serial No. 14/248,587 entitled "POWERED SURGICAL STAPLER", now US Patent Application Publication 2014/0309665;

-名称为“DRIVE SYSTEM DECOUPLING ARRANGEMENT FOR A SURGICALINSTRUMENT”的美国专利申请序列号14/248,586,现为美国专利申请公布2014/0305990;以及- US Patent Application Serial No. 14/248,586 entitled "DRIVE SYSTEM DECOUPLING ARRANGEMENT FOR A SURGICALINSTRUMENT", now US Patent Application Publication 2014/0305990; and

-名称为“MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH STATUSINDICATION ARRANGEMENTS”的美国专利申请序列号14/248,607,现为美国专利申请公布2014/0305992。- US Patent Application Serial No. 14/248,607 entitled "MODULAR MOTOR DRIVEN SURGICAL INSTRUMENTS WITH STATUSINDICATION ARRANGEMENTS", now US Patent Application Publication 2014/0305992.

本申请的申请人还拥有2013年4月16日提交并且全文各自以引用的方式并入本文的以下专利申请:The applicant of the present application also owns the following patent applications filed on April 16, 2013 and each of which is hereby incorporated by reference in its entirety:

-名称为“SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR”的美国临时专利申请序列号61/812,365;- US Provisional Patent Application Serial No. 61/812,365 entitled "SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR";

-名称为“LINEAR CUTTER WITH POWER”的美国临时专利申请序列号61/812,376;- US Provisional Patent Application Serial No. 61/812,376 entitled "LINEAR CUTTER WITH POWER";

-名称为“LINEAR CUTTER WITH MOTOR AND PISTOL GRIP”的美国临时专利申请序列号61/812,382;- US Provisional Patent Application Serial No. 61/812,382 entitled "LINEAR CUTTER WITH MOTOR AND PISTOL GRIP";

-名称为“SURGICAL INSTRUMENT HANDLE WITH MULTIPLE ACTUATION MOTORS ANDMOTOR CONTROL”的美国临时专利申请序列号61/812,385;以及- U.S. Provisional Patent Application Serial No. 61/812,385 entitled "SURGICAL INSTRUMENT HANDLE WITH MULTIPLE ACTUATION MOTORS ANDMOTOR CONTROL"; and

-名称为“SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR”的美国临时专利申请序列号61/812,372。- US Provisional Patent Application Serial No. 61/812,372 entitled "SURGICAL INSTRUMENT WITH MULTIPLE FUNCTIONS PERFORMED BY ASINGLE MOTOR".

本文列出了许多具体细节,以提供对说明书中所述和附图中所示的实施方案的整体结构、功能、制造和用途的透彻理解。没有详细描述熟知的操作、部件和元件,以免使说明书中描述的实施方案模糊不清。读者将会理解,本文所述和所示的实施方案为非限制性示例,从而可认识到,本文所公开的特定结构和功能细节可为代表性和例示性的。在不脱离权利要求的范围的情况下,可对这些实施方案进行变型和改变。Numerous specific details are set forth herein in order to provide a thorough understanding of the general structure, function, manufacture, and use of the embodiments described in the specification and shown in the accompanying drawings. Well-known operations, components and elements have not been described in detail so as not to obscure the embodiments described in the specification. The reader will understand that the embodiments described and illustrated herein are by way of non-limiting example, so that the specific structural and functional details disclosed herein may be representative and illustrative, and may be appreciated. Variations and changes may be made to these embodiments without departing from the scope of the claims.

术语“包括(comprise)”(以及“包括(comprise)”的任何形式,诸如“包括(comprises)”和“包括(comprising)”)、“具有(have)”(以及“具有(have)”的任何形式,诸如“具有(has)”和“具有(having)”)、“包含(include)”(以及“包含(include)”的任何形式,诸如“包含(includes)”和“包含(including)”)、以及“含有(contain)”(以及“含有(contain)”的任何形式,诸如“含有(contains)”和“含有(containing)”)为开放式系动词。因此,“包括”、“具有”、“包含”或“含有”一个或多个元件的外科系统、装置、或设备具有这些一个或多个元件,但不限于仅具有这些一个或多个元件。同样,“包括”、“具有”、“包含”或“含有”一个或多个特征的系统、装置、或设备的元件具有那些一个或多个特征,但不限于仅具有那些一个或多个特征。The term "comprise" (and any form of "comprise" such as "comprises" and "comprising"), "have" (and "have" any form, such as "has" and "having"), "include" (and any form of "include", such as "includes" and "including" "), and "contain" (and any form of "contain" such as "contains" and "containing") are open-ended copulas. Thus, a surgical system, device, or device that "comprises," "has," "comprises," or "contains" one or more elements has those one or more elements, but is not limited to having only those one or more elements. Likewise, an element of a system, apparatus, or device that "comprises," "has," "includes," or "contains" one or more features has those one or more features, but is not limited to having only those one or more features .

术语“近侧”和“远侧”在本文中是相对于操纵外科器械的柄部部分的临床医生来使用的。术语“近侧”是指最靠近临床医生的部分,术语“远侧”是指远离临床医生定位的部分。还应当理解,为简洁和清楚起见,本文可结合附图使用诸如“竖直”、“水平”、“上”和“下”等空间术语。然而,外科器械在许多方向和位置中使用,并且这些术语并非限制性的和/或绝对的。The terms "proximal" and "distal" are used herein with respect to a clinician manipulating the handle portion of a surgical instrument. The term "proximal" refers to the portion closest to the clinician, and the term "distal" refers to the portion located away from the clinician. It should also be understood that, for brevity and clarity, spatial terms such as "vertical," "horizontal," "upper," and "lower" may be used herein in connection with the drawings. However, surgical instruments are used in many orientations and positions, and these terms are not intended to be limiting and/or absolute.

提供各种示例性装置和方法以用于执行腹腔镜式和微创外科手术操作。然而,读者将容易理解,本文所公开的各种方法和装置可用于多种外科手术和应用中,包括例如与开放式外科手术结合。继续参阅本具体实施方式,读者将进一步理解,本文所公开的各种器械能够以任何方式插入体内,诸如通过自然腔道、通过形成于组织中的切口或穿刺孔等。器械的工作部分或端部执行器部分可直接插入患者体内或者可通过具有工作通道的进入装置插入,外科器械的端部执行器和细长轴可通过所述工作通道推进。Various exemplary devices and methods are provided for performing laparoscopic and minimally invasive surgical procedures. However, the reader will readily appreciate that the various methods and devices disclosed herein can be used in a variety of surgical procedures and applications, including, for example, in conjunction with open surgery. With continued reference to this detailed description, the reader will further appreciate that the various instruments disclosed herein can be inserted into the body in any manner, such as through a natural orifice, through an incision or puncture hole formed in tissue, and the like. The working or end effector portion of the instrument can be inserted directly into the patient or through an access device having a working channel through which the end effector and elongated shaft of the surgical instrument can be advanced.

外科缝合系统可包括轴和从轴延伸的端部执行器。端部执行器包括第一钳口和第二钳口。第一钳口包括钉仓。钉仓能够插入到第一钳口中并且能够从第一钳口移除;然而,设想到其中钉仓不能够从第一钳口移除或至少能够易于从第一钳口替换的其他实施方案。第二钳口包括被构造成能够使从钉仓射出的钉变形的砧座。第二钳口能够相对于第一钳口围绕闭合轴线枢转;然而,可设想到其中第一钳口能够相对于第二钳口枢转的其它实施方案。外科缝合系统还包括被构造成能够允许端部执行器相对于轴旋转或进行关节运动的关节运动接头。端部执行器能够围绕延伸穿过关节运动接头的关节运动轴线旋转。设想了不包括关节运动接头的其它实施方案。The surgical stapling system can include a shaft and an end effector extending from the shaft. The end effector includes a first jaw and a second jaw. The first jaw includes a staple cartridge. The staple cartridge is insertable into and removable from the first jaw; however, other embodiments are contemplated in which the staple cartridge cannot be removed from the first jaw, or at least easily replaceable from the first jaw. The second jaw includes an anvil configured to deform staples ejected from the staple cartridge. The second jaw is pivotable relative to the first jaw about the closing axis; however, other embodiments are envisioned in which the first jaw is pivotable relative to the second jaw. The surgical stapling system also includes an articulation joint configured to allow rotation or articulation of the end effector relative to the shaft. The end effector is rotatable about an articulation axis extending through the articulation joint. Other embodiments are contemplated that do not include articulation joints.

钉仓包括仓体。仓体包括近侧端部、远侧端部和在近侧端部与远侧端部之间延伸的平台。在使用中,钉仓定位在待缝合的组织的第一侧上,并且砧座定位在组织的第二侧上。砧座朝向钉仓运动以将组织压缩并夹持抵靠平台。然后,可移除地储存在仓体中的钉可部署到组织中。仓体包括限定于其中的钉腔,其中钉可移除地储存在钉腔中。钉腔被布置成六纵向排。三排钉腔定位在纵向狭槽的第一侧上且三排钉腔定位在纵向狭槽的第二侧上。钉腔和钉的其它构造也是可以的。The staple cartridge includes a cartridge body. The cartridge body includes a proximal end, a distal end, and a platform extending between the proximal and distal ends. In use, the staple cartridge is positioned on a first side of tissue to be stapled, and the anvil is positioned on a second side of tissue. The anvil moves toward the staple cartridge to compress and clamp the tissue against the platform. The staples, which are removably stored in the cartridge body, can then be deployed into tissue. The cartridge body includes staple cavities defined therein, wherein the staples are removably stored in the staple cavities. The nail cavities are arranged in six longitudinal rows. Three rows of staple cavities are positioned on a first side of the longitudinal slot and three rows of staple cavities are positioned on a second side of the longitudinal slot. Other configurations of staple cavities and staples are also possible.

钉由仓体中的钉驱动器支撑。驱动器能够在第一或非击发位置和第二或击发位置之间运动,以从钉仓射出钉。驱动器通过保持器保留在仓体中,保持器围绕仓体的底部延伸并且包括被构造成能够抓持仓体以及将保持器保持至仓体的弹性构件。驱动器能够通过滑动件在其非击发位置和击发位置之间运动。滑动件能够在与近侧端部相邻的近侧位置和与远侧端部相邻的远侧位置之间运动。滑动件包括多个斜坡表面,该斜坡表面被构造成能够朝向砧座在驱动器下方滑动以及提升驱动器,并且钉在驱动器上受到支撑。The staples are supported by staple drivers in the cartridge body. The driver is movable between a first or non-fired position and a second or fired position to fire staples from the staple cartridge. The driver is retained in the cartridge body by a retainer that extends around the bottom of the cartridge body and includes a resilient member configured to grip and retain the retainer to the cartridge body. The driver is movable between its unfired and fired positions by means of a slide. The slider is movable between a proximal position adjacent the proximal end and a distal position adjacent the distal end. The slider includes a plurality of ramp surfaces configured to slide under the driver toward the anvil and to lift the driver, and the staples are supported on the driver.

除上述以外,滑动件还可通过击发构件朝远侧运动。击发构件被构造成能够接触滑动件并朝向远侧端部推动滑动件。限定于仓体中的纵向狭槽被构造成能够接纳击发构件。砧座还包括被构造成能够接纳击发构件的狭槽。击发构件还包括接合第一钳口的第一凸轮和接合第二钳口的第二凸轮。在击发构件朝远侧推进时,第一凸轮和第二凸轮可控制钉仓的平台和砧座之间的距离或组织间隙。击发构件还包括被构造成能够切入在钉仓和砧座中间捕集的组织的刀。希望刀定位成至少部分接近斜坡表面,使得钉先于刀被射出。In addition to the above, the slider can also be moved distally by the firing member. The firing member is configured to contact the slider and urge the slider toward the distal end. A longitudinal slot defined in the cartridge body is configured to receive a firing member. The anvil also includes a slot configured to receive the firing member. The firing member also includes a first cam engaging the first jaw and a second cam engaging the second jaw. The first and second cams may control the distance or tissue clearance between the platform of the staple cartridge and the anvil as the firing member is advanced distally. The firing member also includes a knife configured to cut through tissue captured between the staple cartridge and the anvil. It is desirable for the knife to be positioned at least partially proximate the ramp surface so that the nails are fired ahead of the knife.

本文描述的某些外科缝合和切割端部执行器包括细长通道,该细长通道被构造成可移除地接收钉仓,该钉仓具有存储在钉仓中的外科钉。钉仓包括可移动地支撑在钉仓的仓主体内的射出器或驱动器,射出器或驱动器各自被构造成在其上支撑一个或多个钉。钉支撑驱动器在仓主体内布置成纵向排,其位于仓主体中限定的纵向延伸狭槽的每侧上。该狭槽被构造成可移动地容纳击发构件,该击发构件可在其上具有组织切割边缘,该组织切割边缘用于切割已经夹紧在砧座和钉仓之间的组织。当驱动器与仓主体通过滑动件接触时,驱动器被迫使在仓主体中向上,即,朝向仓主体的平台,该滑动件被构造成由击发构件纵向地驱动通过仓主体。滑动件可移动地支撑在仓中,并且包括多个成角度的或楔形的凸轮,其对应于仓主体内的钉驱动器的行。在未击发的或“新的”钉仓中,滑动件定位在每个线中最靠近钉驱动器或在钉驱动器最近侧的起始位置。在击发冲程期间,击发构件向远侧推进滑动件,以从仓主体射出钉。一旦钉仓至少部分地被击发,即从仓主体射出,击发构件就缩回到开始或未击发位置,并且滑动件保持在现在用完的钉仓的远侧。一旦击发构件已经返回到开始或未击发位置,就可将用完的钉仓从端部执行器的通道移除。Certain surgical stapling and cutting end effectors described herein include an elongated channel configured to removably receive a staple cartridge having surgical staples stored in the staple cartridge. The staple cartridge includes an ejector or driver movably supported within a cartridge body of the staple cartridge, the ejector or driver each being configured to support one or more staples thereon. The staple support drivers are arranged within the cartridge body in longitudinal rows on each side of longitudinally extending slots defined in the cartridge body. The slot is configured to movably receive a firing member, which may have a tissue cutting edge thereon for cutting tissue that has been clamped between the anvil and the staple cartridge. The driver is forced upward in the cartridge body, ie, towards the platform of the cartridge body, when the driver is in contact with the cartridge body through a slide configured to be driven longitudinally through the cartridge body by the firing member. The slider is movably supported in the cartridge and includes a plurality of angled or wedge-shaped cams that correspond to the rows of staple drivers within the cartridge body. In an unfired or "new" staple cartridge, the slider is positioned in each wire at the starting position closest to the staple driver or on the proximal-most side of the staple driver. During the firing stroke, the firing member advances the slider distally to fire the staples from the cartridge body. Once the staple cartridge is at least partially fired, ie, fired from the cartridge body, the firing member is retracted to the start or unfired position, and the slider remains distal to the now spent staple cartridge. Once the firing member has returned to the starting or unfired position, the spent staple cartridge can be removed from the channel of the end effector.

除上述之外,图1中示出了外科器械系统10。外科器械系统10包括柄部14和轴组件200,轴组件200可移除地可附接到柄部14。轴组件200包括端部执行器300,端部执行器300包括仓通道302和能够相对于仓通道302移动的砧座306。钉仓304可移除地定位在仓通道302中。In addition to the above,

此类切割和缝合端部执行器安装到细长轴组件的远侧端部,细长轴组件可操作地支撑各种驱动轴和部件,该驱动轴和部件被构造成将各种控制运动施加到端部执行器。在各种情况下,轴组件可包括关节运动接头,或者当关节运动动作被施加到端部执行器时,可以其它方式被构造成便于端部执行器相对于细长轴的一部分进行关节运动。轴组件联接到支撑各种驱动系统的壳体,所述系统在细长轴组件中可操作地与各种组件对接。在某些布置中,壳体可包括手持壳体或柄部。在其它布置中,壳体可包括机器人或自动外科系统的一部分。壳体的各种驱动系统可被构造成将轴向驱动运动、旋转驱动运动和/或轴向驱动运动和旋转驱动运动的组合施加到细长轴组件。在手持式布置中,轴向运动可由一个或多个手动致动的手动曲柄产生和/或由一个或多个电动马达产生。机器人系统可采用电动马达和/或其它自动驱动布置,其被构造成产生并向细长轴组件施加必要的控制运动,并且在一些情况下,最终向端部执行器中的击发构件施加必要的控制运动。Such cutting and stapling end effectors are mounted to the distal end of an elongated shaft assembly operatively supporting various drive shafts and components configured to impart various control motions to the end effector. In various cases, the shaft assembly may include an articulation joint, or may be otherwise configured to facilitate articulation of the end effector relative to a portion of the elongated shaft when an articulation action is applied to the end effector. The shaft assembly is coupled to a housing that supports various drive systems that operably interface with the various components in the elongated shaft assembly. In some arrangements, the housing may include a handheld housing or handle. In other arrangements, the housing may include part of a robotic or automated surgical system. The various drive systems of the housing may be configured to impart axial drive motion, rotational drive motion, and/or a combination of axial and rotational drive motion to the elongated shaft assembly. In a hand-held arrangement, the axial movement may be produced by one or more manually actuated hand cranks and/or by one or more electric motors. The robotic system may employ electric motors and/or other automated drive arrangements configured to generate and apply the necessary control motion to the elongated shaft assembly and, in some cases, ultimately to the firing member in the end effector. Control movement.

对于需要旋转控制运动的外科端部执行器,细长轴组件可包括“近侧”旋转驱动轴部分,其由对应的马达或支撑在壳体中的其它旋转运动源旋转。近侧旋转驱动轴被构造成将旋转控制运动施加到端部执行器驱动轴,该端部执行器驱动轴支撑在端部执行器中。在此类布置中,击发构件与端部执行器驱动轴对接,使得击发构件可被纵向推进通过端部执行器,然后返回到未击发位置。For surgical end effectors requiring rotationally controlled motion, the elongated shaft assembly may include a "proximal" rotational drive shaft portion that is rotated by a corresponding motor or other source of rotational motion supported in the housing. The proximal rotational drive shaft is configured to apply rotational control motion to an end effector drive shaft supported in the end effector. In such arrangements, the firing member interfaces with the end effector drive shaft such that the firing member can be advanced longitudinally through the end effector and then returned to the unfired position.

当使用被构造成切割和缝合组织的外科器械时,应采取措施以确保在致动外科器械的击发驱动系统之前已将未用完的外科钉仓正确地安装在外科器械的端部执行器中。例如,如果临床医生无意中致动了击发驱动系统的组织切割构件而没有首先在端部执行器中安装未用完的钉仓,则组织切割构件可以在不缝合组织的情况下切断组织。如果临床医生无意中将部分用完的钉仓安装到端部执行器中,也会出现类似的问题。当在先前手术中或手术的先前步骤中使用钉仓时,可以产生部分用完的钉仓,然后在钉中的全部从其中射出之前从端部执行器移除。如果要在外科器械中重复使用此种部分用完的仓,则组织切割构件可在组织中产生比施加到组织的钉线更长的切口。因此,当使用被构造成切割和缝合组织的外科端部执行器时,期望外科端部执行器被构造成防止组织切割构件的致动,除非未用完的“新的”钉仓已正确安装在端部执行器中。When using a surgical instrument configured to cut and staple tissue, steps should be taken to ensure that an unused surgical staple cartridge has been properly installed in the surgical instrument's end effector prior to actuating the surgical instrument's firing drive system . For example, if a clinician inadvertently actuates the tissue-cutting member of the firing drive system without first installing an unused cartridge in the end effector, the tissue-cutting member may sever tissue without stapling the tissue. A similar problem can arise if a clinician inadvertently installs a partially used cartridge into an end effector. When a staple cartridge is used in a previous procedure or in a previous step of a procedure, a partially used staple cartridge can be created and then removed from the end effector before all of the staples are ejected therefrom. If such a partially used cartridge is to be reused in a surgical instrument, the tissue cutting member can create a longer incision in the tissue than the staple line applied to the tissue. Therefore, when using a surgical end effector configured to cut and staple tissue, it is desirable that the surgical end effector be configured to prevent actuation of the tissue cutting member unless an unused "new" staple cartridge has been properly installed in the end effector.

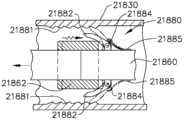

图2和图3示出了可解决此类问题的外科切割和缝合端部执行器20000的部分。如在图2和图3中可以看到的,端部执行器20000包括旋转端部执行器驱动轴20010。虽然未示出,但是旋转端部执行器驱动轴20010可旋转地支撑在细长通道内,该细长通道被构造成在细长通道中可移除地支撑外科钉仓。旋转端部执行器驱动轴20010被构造成从近侧旋转驱动轴接收旋转驱动运动,该近侧旋转驱动轴附接到通道或以其它方式可操作地与旋转端部执行器驱动轴20010对接。旋转控制运动可通过对应的驱动布置施加到近侧旋转驱动轴,该驱动布置可包括由机器人控制系统或其它(一个或多个)旋转控制运动源手动致动或控制的一个或多个马达。在另选布置中,可手动产生旋转控制运动。仍然参考图2和图3,外科端部执行器20000包括击发组件20020,该击发组件20020被构造用于在通道内纵向行进。在所示实施方案中,击发组件20020包括上部击发主体20022,该上部击发主体20022具有远侧击发耳状物20024和近侧击发耳状物20026。在远侧击发耳状物20024中具有无螺纹孔(未示出),该无螺纹孔被构造成接收穿过其中的旋转端部执行器驱动轴20010。近侧击发耳状物20026与远侧击发耳状物20024间隔开,以在近侧击发耳状物和远侧击发耳状物之间限定螺母腔体20028。近侧击发耳状物20026具有穿过其中的无螺纹孔20027,该无螺纹孔20027被构造成接收穿过其中的旋转端部执行器驱动轴20010。2 and 3 illustrate portions of a surgical cutting and stapling