CN109249617B - 3D droplet printer and method for preparing suspension droplets by using same - Google Patents

3D droplet printer and method for preparing suspension droplets by using sameDownload PDFInfo

- Publication number

- CN109249617B CN109249617BCN201811168233.7ACN201811168233ACN109249617BCN 109249617 BCN109249617 BCN 109249617BCN 201811168233 ACN201811168233 ACN 201811168233ACN 109249617 BCN109249617 BCN 109249617B

- Authority

- CN

- China

- Prior art keywords

- oil phase

- printing

- droplets

- axis

- nozzle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000725suspensionSubstances0.000titleclaimsdescription8

- 238000000034methodMethods0.000titleabstractdescription21

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription25

- 238000007639printingMethods0.000claimsdescription41

- 238000002360preparation methodMethods0.000claimsdescription16

- 239000000463materialSubstances0.000claimsdescription10

- 238000010008shearingMethods0.000claimsdescription9

- GVJHHUAWPYXKBD-UHFFFAOYSA-N(±)-α-TocopherolChemical compoundOC1=C(C)C(C)=C2OC(CCCC(C)CCCC(C)CCCC(C)C)(C)CCC2=C1CGVJHHUAWPYXKBD-UHFFFAOYSA-N0.000claimsdescription4

- 239000007788liquidSubstances0.000claimsdescription4

- 239000000126substanceSubstances0.000claimsdescription4

- 230000002572peristaltic effectEffects0.000claimsdescription3

- NIXOWILDQLNWCW-UHFFFAOYSA-NAcrylic acidChemical compoundOC(=O)C=CNIXOWILDQLNWCW-UHFFFAOYSA-N0.000claimsdescription2

- 229920002125Sokalan®Polymers0.000claimsdescription2

- 229930003427Vitamin ENatural products0.000claimsdescription2

- 229960001631carbomerDrugs0.000claimsdescription2

- 210000000085cashmereAnatomy0.000claimsdescription2

- 150000002148estersChemical class0.000claimsdescription2

- WIGCFUFOHFEKBI-UHFFFAOYSA-Ngamma-tocopherolNatural productsCC(C)CCCC(C)CCCC(C)CCCC1CCC2C(C)C(O)C(C)C(C)C2O1WIGCFUFOHFEKBI-UHFFFAOYSA-N0.000claimsdescription2

- 239000000203mixtureSubstances0.000claimsdescription2

- 229940046009vitamin EDrugs0.000claimsdescription2

- 235000019165vitamin ENutrition0.000claimsdescription2

- 239000011709vitamin ESubstances0.000claimsdescription2

- 229920001285xanthan gumPolymers0.000claimsdescription2

- 229940082509xanthan gumDrugs0.000claimsdescription2

- 235000010493xanthan gumNutrition0.000claimsdescription2

- 239000000230xanthan gumSubstances0.000claimsdescription2

- 238000005516engineering processMethods0.000abstractdescription12

- 2380000101463D printingMethods0.000abstractdescription8

- 239000000017hydrogelSubstances0.000abstractdescription6

- 230000008093supporting effectEffects0.000abstract1

- 239000012071phaseSubstances0.000description39

- 239000002245particleSubstances0.000description8

- 239000006185dispersionSubstances0.000description4

- 239000002537cosmeticSubstances0.000description3

- 230000008021depositionEffects0.000description3

- 238000013461designMethods0.000description3

- 238000005191phase separationMethods0.000description3

- 230000009286beneficial effectEffects0.000description2

- 238000011161developmentMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 239000004530micro-emulsionSubstances0.000description2

- 239000000178monomerSubstances0.000description2

- UIVPNOBLHXUKDX-UHFFFAOYSA-N3,5,5-trimethylhexyl 3,5,5-trimethylhexanoateChemical compoundCC(C)(C)CC(C)CCOC(=O)CC(C)CC(C)(C)CUIVPNOBLHXUKDX-UHFFFAOYSA-N0.000description1

- 239000008346aqueous phaseSubstances0.000description1

- 239000007864aqueous solutionSubstances0.000description1

- 229940049638carbomer homopolymer type cDrugs0.000description1

- 229940043234carbomer-940Drugs0.000description1

- 230000007812deficiencyEffects0.000description1

- 239000003814drugSubstances0.000description1

- 229940100554isononyl isononanoateDrugs0.000description1

- 239000004005microsphereSubstances0.000description1

- 238000005457optimizationMethods0.000description1

- 238000012545processingMethods0.000description1

- 239000000243solutionSubstances0.000description1

- 230000004382visual functionEffects0.000description1

- 238000012800visualizationMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/20—Apparatus for additive manufacturing; Details thereof or accessories therefor

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y30/00—Apparatus for additive manufacturing; Details thereof or accessories therefor

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Optics & Photonics (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及微乳液领域,具体涉及一种利用3D液滴打印机制备悬浮液滴的方法。The invention relates to the field of microemulsion, in particular to a method for preparing suspended droplets by using a 3D droplet printer.

背景技术Background technique

悬浮液滴是一种油性液滴长期稳定悬浮在水相之中的微乳液,其中油相可包含各种油性成分,可广泛应用于新型材料加工,开发新产品应用于化妆品、医药、食品等领域。传统通过剪切方法制备的悬浮液滴体系,存在多个问题。首先通过剪切方法制备的体系,无法对分散过程进行准确控制,易形成相分离,导致油相在水相中的比例较低,难以提高。其次通过剪切方法制备的体系,其液滴粒径不一、分散不均、位置无序,限制其在开发新材料和设计新产品中的应用,本发明采用3D液滴打印技术,能够对液滴大小和位置进行精准控制,制备特定结构的悬浮液滴体系,对材料和产品进行精准设计,增强功能可视化效果,扩大其应用范围。Suspended droplet is a microemulsion in which oily droplets are stably suspended in the water phase for a long time. The oily phase can contain various oily components. It can be widely used in the processing of new materials and the development of new products for cosmetics, medicine, food, etc. field. There are several problems in the traditional suspension droplet system prepared by shearing method. First of all, the system prepared by the shearing method cannot accurately control the dispersion process, and it is easy to form phase separation, resulting in a low proportion of oil phase in the water phase, which is difficult to increase. Secondly, the system prepared by the shearing method has different particle sizes, uneven dispersion and disordered positions of the droplets, which limit its application in the development of new materials and the design of new products. The present invention adopts the 3D droplet printing technology, which can Precise control of droplet size and position, preparation of suspended droplet systems with specific structures, precise design of materials and products, enhanced functional visualization, and expanded application scope.

在本发明中利用一种以数字模型文件为基础,通过逐层打印的方式来构造物体的熔融沉积式3D打印技术。3D打印技术可以将复杂的三维模型转化为一系列简单的二维制造,因而可以在不用模具的情况下可以生成任意复杂的模型。In the present invention, a fused deposition 3D printing technology for constructing objects by layer-by-layer printing based on a digital model file is utilized. 3D printing technology can transform complex three-dimensional models into a series of simple two-dimensional manufacturing, so arbitrarily complex models can be generated without molds.

本发明把传统熔融沉积式3D打印机的耗材进给机构改造为控制液体流量的压力控制机构,如注射泵或者蠕动泵,将液体通过打印喷头在水凝胶中打印出粒径均一的液滴。与通过剪切方法制备悬浮液滴相比,3D打印机制备悬浮微液滴能精确控制油性液滴在三维空间的位置,通过油性液滴的特定排列优化油相和水相的比例,另外控制每个液滴在三维空间位置可以打印出特定形状的三维模型,拓展了该技术在各个领域中的应用。The present invention transforms the consumables feeding mechanism of the traditional fused deposition type 3D printer into a pressure control mechanism for controlling the liquid flow, such as a syringe pump or a peristaltic pump, and prints droplets with uniform particle size in the hydrogel through the printing nozzle. Compared with the preparation of suspended droplets by the shearing method, the preparation of suspended microdroplets by 3D printers can precisely control the position of oily droplets in three-dimensional space, optimize the ratio of oil phase and water phase through the specific arrangement of oily droplets, and control each oily droplet. Each droplet can print a three-dimensional model of a specific shape in a three-dimensional space position, which expands the application of this technology in various fields.

发明内容SUMMARY OF THE INVENTION

针对现有技术的不足,本发明提供一种基于3D打印技术制备悬浮液滴的方法,解决了传统的以微流控技术制备悬浮液滴难以提高油相占比的难题,该方法简便易行并可获得大小均一、位置可控的液滴,并可根据具体需求制备由液滴组成的特定形状的三维模型,该技术在化妆品、工艺品等领域中具有广泛的应用前景。In view of the deficiencies of the prior art, the present invention provides a method for preparing suspension droplets based on 3D printing technology, which solves the problem that it is difficult to increase the proportion of oil in the traditional preparation of suspension droplets by microfluidic technology, and the method is simple and easy to implement And droplets of uniform size and controllable position can be obtained, and three-dimensional models of specific shapes composed of droplets can be prepared according to specific requirements. This technology has broad application prospects in the fields of cosmetics and handicrafts.

为实现上述目的,本发明提供如下解决方案:To achieve the above object, the present invention provides the following solutions:

本发明首先公开了一种制备悬浮液滴的3D打印机,包括三维移动打印系统,所述的三维移动打印系统包括Z轴升降平台、X轴移动机构、Y轴移动机构和打印喷头,X轴移动机构、Y轴移动机构用于带动所述打印喷头实现XY平面内的移动;所述的Z轴升降平台用于实现待打印区域与打印喷头之间Z轴方向距离的调节;所述的3D打印机还包括压力控制机构和导管;所述的压力控制机构通过导管与打印喷头相连。The invention firstly discloses a 3D printer for preparing suspended droplets, including a three-dimensional mobile printing system. The three-dimensional mobile printing system includes a Z-axis lifting platform, an X-axis moving mechanism, a Y-axis moving mechanism and a printing nozzle. The X-axis moving The mechanism and the Y-axis moving mechanism are used to drive the printing nozzles to move in the XY plane; the Z-axis lifting platform is used to adjust the Z-axis distance between the area to be printed and the printing nozzles; the 3D printer It also includes a pressure control mechanism and a conduit; the pressure control mechanism is connected with the printing nozzle through the conduit.

本发明以水平面为XY平面,Z方向为垂直与所述水平面的方向,且以水平向右为X轴正方向,水平向前为Y轴正方向,竖直向上为Z轴正方向。In the present invention, the horizontal plane is the XY plane, the Z direction is the direction perpendicular to the horizontal plane, and the horizontal rightward is the positive direction of the X axis, the horizontal forward is the positive direction of the Y axis, and the vertical upward is the positive direction of the Z axis.

优选的,所述的压力控制机构为注射泵或蠕动泵。Preferably, the pressure control mechanism is a syringe pump or a peristaltic pump.

优选的,所述的3D打印机还包括用于容纳水相的箱体;所述的箱体设置在Z轴升降平台,由Z轴升降平台调节所述箱体在Z轴方向的高度;所述箱体位于打印喷头下方。Preferably, the 3D printer further includes a box body for accommodating the water phase; the box body is arranged on the Z-axis lifting platform, and the height of the box body in the Z-axis direction is adjusted by the Z-axis lifting platform; the The box is located under the print nozzle.

本发明还公开了一种所述3D打印机的悬浮液滴制备方法,包括以下步骤:The invention also discloses a method for preparing suspension droplets of the 3D printer, comprising the following steps:

1)将具有剪切变稀的材料溶解到水中,得到透明的水凝胶状液体作为水相,选取一种或多种油性物质混合作为油相;1) dissolving the shear-thinning material into water, obtaining a transparent hydrogel-like liquid as the water phase, and selecting one or more oily substances to mix as the oil phase;

2)将水相放置在Z轴升降平台上,压力控制机构用于提供动力将油相通过打印喷头挤出;2) Place the water phase on the Z-axis lifting platform, and the pressure control mechanism is used to provide power to extrude the oil phase through the printing nozzle;

3)通过X轴移动机构、Y轴移动机构带动打印喷头在XY平面内的移动,通过Z轴升降平台实现待打印区域与打印喷头之间Z轴方向距离的调节,从而控制3D打印机上的打印喷头的运动轨迹,控制压力控制机构的工作状态,从而剪切油相得到分散到水相中的液滴。3) The movement of the printing nozzle in the XY plane is driven by the X-axis moving mechanism and the Y-axis moving mechanism, and the Z-axis distance between the area to be printed and the printing nozzle is adjusted through the Z-axis lifting platform, thereby controlling the printing on the 3D printer. The movement trajectory of the nozzle controls the working state of the pressure control mechanism, thereby shearing the oil phase to obtain droplets dispersed into the water phase.

优选的,所述的剪切变稀材料可以为卡波姆或黄原胶。Preferably, the shear thinning material may be carbomer or xanthan gum.

优选的,所述的打印喷头是一个细长型的空心圆柱,一端与导管相连,另一端作为喷嘴。Preferably, the printing nozzle is an elongated hollow cylinder, one end of which is connected to a conduit, and the other end is used as a nozzle.

优选的,所述的打印喷头运动轨迹是打印喷头移动到水相中一个位置时先停顿,然后压力控制机构挤出定量的油相体积,等待定量的油相体积全部挤出后再移动到下一个位置。Preferably, the movement trajectory of the printing nozzle is that when the printing nozzle moves to a position in the water phase, it first pauses, and then the pressure control mechanism extrudes a quantitative oil phase volume, and then moves to the bottom after the quantitative oil phase volume is fully extruded. a location.

优选的,所述的油性物质可以为蚕丝油、羊绒酯或维生素E中的一种或者几种混合。Preferably, the oily substance can be one or a mixture of silk oil, cashmere ester or vitamin E.

本发明还公开了通过控制打印喷头的移动轨迹得到由微液滴组成的特定形状的三维模型。The invention also discloses that a three-dimensional model of a specific shape composed of micro droplets can be obtained by controlling the movement track of the printing nozzle.

本发明还公开了根据所述的3D液滴打印机及其制备悬浮液滴,所述的液滴可以被精确控制其粒径大小和空间位置,采用特定的液滴空间排布方式可以最大优化水相和油相的配比。另外采用以数字模型文件为基础3D打印技术,可以根据需求制备出由液滴组成的特定形状的三维模型。The invention also discloses the 3D droplet printer and its preparation of suspended droplets. The droplets can be precisely controlled in particle size and spatial position, and a specific droplet spatial arrangement can maximize the optimization of water droplets. The ratio of phase and oil phase. In addition, using the 3D printing technology based on digital model files, a 3D model of a specific shape composed of droplets can be prepared according to requirements.

本发明的有益效果如下:The beneficial effects of the present invention are as follows:

(1)本发明提出一种基于3D液滴打印机制备悬浮微液滴体系,该方法简便易行,微液滴粒径均一可控,可对体系进行精准设计和控制。(1) The present invention proposes a suspension micro-droplet system based on a 3D droplet printer. The method is simple and easy to implement, the particle size of the micro-droplets is uniform and controllable, and the system can be precisely designed and controlled.

(2)本发明采用3D打印技术,是以数字模型文件为基础,可以根据需求制备出由液滴组成的具有特定三维形状的悬浮微液滴体系。传统通过剪切方法制备的体系,其液滴粒径不一、分散不均、位置无序、易形成相分离。3D液滴打印技术能够对液滴大小和位置进行精准控制,制备特定结构的悬浮液滴体系,在实际生产中具有广泛的应用前景。(2) The present invention adopts 3D printing technology, which is based on a digital model file, and can prepare a suspended microdroplet system composed of droplets with a specific three-dimensional shape according to requirements. The traditional system prepared by shearing method has different droplet size, uneven dispersion, disordered position, and easy to form phase separation. 3D droplet printing technology can precisely control the size and position of droplets and prepare suspended droplet systems with specific structures, which has broad application prospects in actual production.

(3)传统通过剪切方法制备的体系,无法对分散过程进行准确控制,易形成相分离,导致油相在水相中的比例较低,难以提高。本发明提出3D打印制备悬浮微液滴体系,通过精确控制每个液滴位置实现液滴的最优排列,可大幅度提高油相在悬浮微液滴体系中的比例,最高可达74%。(3) The traditional system prepared by shearing method cannot accurately control the dispersion process, and is easy to form phase separation, resulting in a low proportion of oil phase in the water phase, which is difficult to increase. The invention proposes 3D printing to prepare a suspended micro-droplet system, and by precisely controlling the position of each droplet to achieve the optimal arrangement of the droplets, the proportion of the oil phase in the suspended micro-droplet system can be greatly increased, up to 74%.

(4)本发明采用3D液滴打印可以精准控制微液滴大小,优化油相与水相的比例,打印出由油相液滴组成的具有特定形状的三维模型。通过选取相应油相可以开发和设计相应材料产品,例如采用蚕丝油等对皮肤有益的油相,可开发和设计功能可视化的化妆品。再例如采用可聚合油相单体,通过3D液滴打印设计密堆积结构,将油相单体聚合形成颗粒,颗粒间相互连接,可得到由颗粒组成的材料模型。(4) The present invention adopts 3D droplet printing to precisely control the size of microdroplets, optimize the ratio of oil phase to water phase, and print a three-dimensional model composed of oil phase droplets with a specific shape. By selecting the corresponding oil phase, the corresponding material products can be developed and designed, for example, by using the oil phase that is beneficial to the skin such as silk oil, cosmetics with visual functions can be developed and designed. Another example is to use polymerizable oil phase monomers, design a close-packed structure through 3D droplet printing, polymerize the oil phase monomers to form particles, and connect the particles to each other to obtain a material model composed of particles.

附图说明Description of drawings

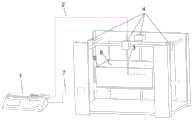

图1为利用改装后的3D打印机制备悬浮微液滴。Figure 1 shows the preparation of suspended microdroplets using a modified 3D printer.

图2为制备由悬浮微液滴组成的以简单立方排列的液滴模型。Figure 2 is a model for preparing droplets in a simple cubic arrangement consisting of suspended microdroplets.

图中:1、注射泵,2、导管,3、打印喷头,4、步进电机,5、容器,6、水相溶液、7串行接口线。In the picture: 1. Syringe pump, 2. Catheter, 3. Printing nozzle, 4. Stepper motor, 5. Container, 6. Aqueous solution, 7. Serial interface line.

图3为制备有悬浮微液滴组成的球形和倒映四角锥型的液滴模型。FIG. 3 is a model for preparing spherical and reflected quadrangular pyramids composed of suspended microdroplets.

具体实施方式Detailed ways

参照附图1,采用本发明的方法制备步骤如下:With reference to accompanying drawing 1, adopt the method preparation step of the present invention as follows:

下面结合附图1和实施例对本发明做进一步说明。The present invention will be further described below with reference to Figure 1 and the embodiments.

本发明提供了一种3D打印机及其在水凝胶中制备悬浮液滴的方法,通过3D打印机来控制液滴的粒径大小和空间位置,如图1所示,该3D打印机由注射泵1、导管2、打印喷头3、步进电机4、容器5组成。3D打印是一种以数字模型文件为基础的技术,通过数字模型文件可以控制打印机三维运动系统和注射泵的推进量。将打印喷头浸没到水凝胶中。打印喷头移动到某个位置时,停顿几秒,然后注射泵进给定量的油相体积,油相在打印喷头处形成微球,等待定量油相全部被挤出,然后再移动打印喷头,在剪切力的作用下,得到悬浮在水凝胶中的液滴。The present invention provides a 3D printer and a method for preparing suspended droplets in hydrogel. The particle size and spatial position of the droplets are controlled by the 3D printer. As shown in FIG. 1 , the 3D printer consists of a syringe pump 1 ,

下面举实施例说明本发明,但本发明并不限于下述的实施例。The present invention is described below with reference to examples, but the present invention is not limited to the following examples.

实施例1:制备由液滴组成的圆柱体。Example 1: Preparation of cylinders composed of droplets.

采用本发明的方法制备悬浮液滴,具体步骤如下:Adopt the method of the present invention to prepare suspension droplets, and the concrete steps are as follows:

(1)将传统的熔融沉积式3D打印机的控制耗材进给的电路通过串行接口连接到注射泵控制系统上。选取内径为0.33mm、外径0.63mm、长度为15mm的针头作为打印喷头,打印喷头与注射泵通过PE管连接输送油相液体。(1) Connect the circuit of the traditional fused deposition 3D printer to control the feeding of consumables to the syringe pump control system through the serial interface. A needle with an inner diameter of 0.33 mm, an outer diameter of 0.63 mm, and a length of 15 mm was selected as the printing nozzle, and the printing nozzle was connected with the syringe pump to transport the oil phase liquid through the PE pipe.

(2)将卡波姆940溶解到水中,调节pH到7。得到澄清的水凝胶作为水相。选用异壬酸异壬酯作为油相。(2) Dissolve Carbomer 940 in water to adjust pH to 7. A clear hydrogel was obtained as the aqueous phase. Isononyl isononanoate was selected as the oil phase.

(3)用菌种瓶盛放水相,然后将菌种瓶放置在Z轴平台上。(3) Use a strain bottle to hold the water phase, and then place the strain bottle on the Z-axis platform.

(4)通过编写数字模型文件控制3D打印机工作进程,得到由油相液滴组成的三维圆柱体模型。(4) Control the working process of the 3D printer by writing a digital model file, and obtain a three-dimensional cylinder model composed of oil phase droplets.

实施例2:制备由液滴组成的具有特定三维形状的悬浮微液滴体系。Example 2: Preparation of a suspended microdroplet system composed of droplets with a specific three-dimensional shape.

(1)如实施例1所示,搭建3D液滴打印机,准备油相和水相材料,将水相放入烧杯中,然后将烧杯放置在Z轴平台上。(1) As shown in Example 1, build a 3D droplet printer, prepare oil phase and water phase materials, put the water phase into a beaker, and then place the beaker on the Z-axis platform.

(2)通过编写数字模型文件控制3D打印机工作进程,得到由油相液滴组成的三维球形模型和倒映四角锥模型(如图3所示)。(2) Control the working process of the 3D printer by writing a digital model file, and obtain a three-dimensional spherical model and a reflected quadrangular pyramid model composed of oil-phase droplets (as shown in Figure 3).

Claims (7)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811168233.7ACN109249617B (en) | 2018-10-08 | 2018-10-08 | 3D droplet printer and method for preparing suspension droplets by using same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811168233.7ACN109249617B (en) | 2018-10-08 | 2018-10-08 | 3D droplet printer and method for preparing suspension droplets by using same |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109249617A CN109249617A (en) | 2019-01-22 |

| CN109249617Btrue CN109249617B (en) | 2020-11-17 |

Family

ID=65045410

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811168233.7AActiveCN109249617B (en) | 2018-10-08 | 2018-10-08 | 3D droplet printer and method for preparing suspension droplets by using same |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109249617B (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111171341B (en)* | 2019-12-31 | 2021-05-07 | 浙江大学 | A Janus droplet with structural color based on 3D droplet printing and its preparation method |

| CN113524674B (en)* | 2021-07-07 | 2022-12-13 | 清华大学深圳国际研究生院 | Device and method for preparing three-dimensional patterned multi-material hydrogel heterostructure |

| CN113524660B (en)* | 2021-08-10 | 2022-12-13 | 烟台液秀生物科技有限公司 | High-throughput array type 3D liquid drop printing method |

| CN115042427B (en)* | 2022-06-23 | 2023-07-11 | 浙江大学 | 3D liquid printing method for high-throughput preparation of heavy metal isotope label combinations |

| CN117464993B (en)* | 2023-10-18 | 2024-06-14 | 浙江大学 | Device and method for 3D printing gradient pore macroporous gelatin through multi-nozzle array |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103635252A (en)* | 2011-03-08 | 2014-03-12 | 卡普苏姆公司 | Method of forming droplets of a first phase dispersed in a second phase substantially immiscible with the first phase |

| WO2017081040A1 (en)* | 2015-11-09 | 2017-05-18 | University College Dublin, National University Of Ireland, Dublin | A method, system and device for three dimensional additive manufacturing in a liquid phase |

| WO2017210298A1 (en)* | 2016-05-31 | 2017-12-07 | Northwestern University | Method for the fabrication of three-dimensional objects and apparatus for same |

| CN107803504A (en)* | 2016-09-09 | 2018-03-16 | 北京梦之墨科技有限公司 | A kind of suspension printing-forming method of liquid metal three-dimensional macro structure |

| CN108357101A (en)* | 2018-04-08 | 2018-08-03 | 浙江大学 | A kind of environment-friendly type powder 3D printer |

- 2018

- 2018-10-08CNCN201811168233.7Apatent/CN109249617B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103635252A (en)* | 2011-03-08 | 2014-03-12 | 卡普苏姆公司 | Method of forming droplets of a first phase dispersed in a second phase substantially immiscible with the first phase |

| WO2017081040A1 (en)* | 2015-11-09 | 2017-05-18 | University College Dublin, National University Of Ireland, Dublin | A method, system and device for three dimensional additive manufacturing in a liquid phase |

| WO2017210298A1 (en)* | 2016-05-31 | 2017-12-07 | Northwestern University | Method for the fabrication of three-dimensional objects and apparatus for same |

| CN107803504A (en)* | 2016-09-09 | 2018-03-16 | 北京梦之墨科技有限公司 | A kind of suspension printing-forming method of liquid metal three-dimensional macro structure |

| CN108357101A (en)* | 2018-04-08 | 2018-08-03 | 浙江大学 | A kind of environment-friendly type powder 3D printer |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109249617A (en) | 2019-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109249617B (en) | 3D droplet printer and method for preparing suspension droplets by using same | |

| US10974442B2 (en) | Set-up and method of electrohydrodynamic jet 3D printing based on resultant effect of electric field and thermal field | |

| CN106984490B (en) | The device for discharging fixed and method of fluent material | |

| US20190224670A1 (en) | Microfluidic chip and control method thereof, droplet generation device, and microsphere preparation device | |

| CN108656524B (en) | Electric field driven micro-nano 3D printing device integrated with spray head and working method thereof | |

| CN104494151B (en) | A kind of hydraulic pressure for biological 3D printing extrudes feeding system and method | |

| CN108456457B (en) | 3D direct writing zirconia ceramic ink | |

| CN103655005B (en) | A kind of 3D printing equipment of three-dimensional biological structure and Method of printing | |

| CN104815709A (en) | Method and device for micro-droplet production | |

| CN107414080B (en) | Liquid metal 3D prints shower nozzle device and is equipped with device's 3D printer | |

| Shen et al. | A robust ink deposition system for binder jetting and material jetting | |

| CN105413772B (en) | Single multi- component drop preparation facilities and its control method based on integrated micro-channels | |

| CN113524660B (en) | High-throughput array type 3D liquid drop printing method | |

| Zhu et al. | On-demand generation of double emulsions based on interface shearing for controlled ultrasound activation | |

| CN110743634A (en) | A microfluidic device | |

| JP2022538387A (en) | Method and system for feedstock monitoring in additive manufacturing | |

| WO2020236167A1 (en) | Powdered build material distribution | |

| Deng et al. | Amoeboid soft robot based on multi-material composite 3D printing technology | |

| CN109985557A (en) | Environmental Protective Water-paint preparation system, preparation process and its component proportion | |

| CN207240853U (en) | A kind of barrel and the high storing parallel arm 3D printer of nozzle separate type | |

| CN215203468U (en) | 3D printing spray head structure with controllable extrusion flow and for multiple materials | |

| Persembe et al. | Binder-jetting 3D printer capable of voxel-based control over deposited ink volume, adaptive layer thickness, and selective multi-pass printing | |

| CN206690542U (en) | Multi-material 3D printer | |

| CN106926445A (en) | A kind of work of fine arts 3D printer support system | |

| CN203901485U (en) | Three-dimensional clay printer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |