CN109071325B - Sealing unit with transparent laser welded area - Google Patents

Sealing unit with transparent laser welded areaDownload PDFInfo

- Publication number

- CN109071325B CN109071325BCN201780016429.1ACN201780016429ACN109071325BCN 109071325 BCN109071325 BCN 109071325BCN 201780016429 ACN201780016429 ACN 201780016429ACN 109071325 BCN109071325 BCN 109071325B

- Authority

- CN

- China

- Prior art keywords

- substrate

- glass

- laser

- inorganic film

- stress

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Joining Of Glass To Other Materials (AREA)

Abstract

Description

Translated fromChinese相关申请的交叉引用CROSS-REFERENCE TO RELATED APPLICATIONS

本申请要求以下专利申请的优先权权益:2016年3月10日提交的题为“SealedDevices Comprising Transparent Laser Weld Regions”[《包含透明激光焊接区域的密封装置》]的第15/066704号美国专利申请;2014年5月7日提交的题为“Laser WeldingTransparent Glass Sheets Using Low Melting Glass Or Thin Absorbing Films”[《使用低熔点玻璃或薄吸收膜对透明玻璃片进行激光焊接》]的第14/271,797号美国专利申请,该美国专利申请要求以下美国临时申请的优先权权益:2013年5月10日提交的题为“LaserWelding Transparent Glass Sheet Using Low Melting Glass Film”[《使用低熔点玻璃膜对透明玻璃片进行激光焊接》]的第61/822,048号美国临时申请;2013年10月4日提交的题为“Laser Welding Transparent Glass Sheets Using Ultraviolet Absorbing Film”[《使用紫外吸收膜对透明玻璃片进行激光焊接》]的第61/886,928号美国临时申请;和2013年5月31日提交的题为“Laser Sealing Using Low Melting Temperature Glass forHermetic Devices”[《使用低熔化温度玻璃对气密性装置进行激光密封》]的第61/829,379号美国临时申请,本文以上述每件申请的内容为基础,并将其通过引用的方式全文纳入本文。This application claims the benefit of priority to the following patent application: US Patent Application No. 15/066704, filed March 10, 2016, entitled "SealedDevices Comprising Transparent Laser Weld Regions" ; No. 14/271,797, "Laser Welding Transparent Glass Sheets Using Low Melting Glass Or Thin Absorbing Films", filed May 7, 2014 U.S. Patent Application, which claims the priority benefit of the following U.S. Provisional Application: "LaserWelding Transparent Glass Sheet Using Low Melting Glass Film", filed May 10, 2013 U.S. Provisional Application No. 61/822,048; "Laser Welding Transparent Glass Sheets Using Ultraviolet Absorbing Film", filed Oct. 4, 2013 ["Laser Welding Transparent Glass Sheets Using Ultraviolet Absorbing Film"] ] of U.S. Provisional Application No. 61/886,928; and "Laser Sealing Using Low Melting Temperature Glass for Hermetic Devices", filed May 31, 2013 US Provisional Application No. 61/829,379 of , which is hereby incorporated by reference in its entirety, is based on the contents of each of the aforementioned applications.

技术领域technical field

本公开一般涉及密封装置以及包含所述密封装置的电子部件和显示部件,更具体而言,涉及包含透明焊接区域的密封玻璃装置。The present disclosure generally relates to sealing devices and electronic and display components including the same, and more particularly, to sealing glass devices that include transparent solder regions.

背景技术Background technique

许多现代装置要求密封环境来进行操作,并且其中许多是需要电偏置的“有源”装置。显示器,例如需要透光性和光偏置的有机发光二极管(OLED),由于使用电子注入材料需要绝对气密性,因此是高要求的应用。除此以外,这些材料一般会在几秒内在大气中分解,因此相应的装置应长时间保持真空或惰性气氛。另外,由于待包封的有机材料的温度敏感性高,因此气密性密封应在近环境温度下进行。Many modern devices require a sealed environment to operate, and many of these are "active" devices that require electrical biasing. Displays, such as Organic Light Emitting Diodes (OLEDs) which require light transmission and light biasing, are demanding applications due to the use of electron injection materials requiring absolute hermeticity. In addition to this, these materials generally decompose in the atmosphere within seconds, so corresponding devices should be kept in vacuum or inert atmosphere for long periods of time. Additionally, due to the high temperature sensitivity of the organic material to be encapsulated, hermetic sealing should be performed at near ambient temperature.

基于玻璃料的密封剂包括例如研磨到粒径通常在约2至150微米范围内的玻璃材料。对于玻璃料密封应用来说,通常将玻璃料材料与粒径相近的负CTE材料混合,并且使用有机溶剂或粘合剂将得到的混合物掺混到糊料中。示例性的负CTE无机填料包括堇青石颗粒(例如Mg2Al3[AlSi5O18])、硅酸钡、β-锂霞石、钒酸锆(ZrV2O7)或钨酸锆(ZrW2O8),将它们添加到玻璃料中来形成糊料以降低基材与玻璃料之间的热膨胀系数错配。溶剂用于调整合并的粉末和有机粘合剂糊料的流变粘度,并且这些溶剂需适于受控的分配目的。为了使两个基材结合,可以通过旋涂或丝网印刷将玻璃料层施涂到一个或两个基材的密封表面上。经过玻璃料涂覆的基材初始在相对较低的温度下经受有机烧尽步骤(例如,在250℃下进行30分钟),以去除有机载体。然后,沿着相应的密封表面,对待结合的两个基材进行组装/匹配,并将该对基材放入晶片结合器中。在明确限定的温度和压力下执行热压缩循环,由此熔化玻璃料以形成紧凑的玻璃密封件。除去某些含铅组合物外,玻璃料材料的玻璃化转变温度通常大于450℃,因此需要在高温下加工以形成阻挡层。这样的高温密封工艺对温度敏感型工件来说可能是不利的。另外,为了减小通常的基材与玻璃料之间的热膨胀系数错配,使用负CTE无机填料,这些负CTE无机填料将被包含到结合接头中,并导致基于玻璃料的阻挡层基本上不透明。基于上述,期望在低温下形成透明且气密的玻璃-玻璃密封件、玻璃-金属密封件、玻璃-陶瓷密封件及其他密封件。Glass frit-based encapsulants include, for example, glass materials ground to particle sizes typically in the range of about 2 to 150 microns. For frit sealing applications, the frit material is typically mixed with a negative CTE material of similar particle size, and the resulting mixture is blended into a paste using an organic solvent or binder. Exemplary negative CTE inorganic fillers include cordierite particles (eg, Mg2 Al3 [AlSi5 O18 ]), barium silicate, beta-eucryptite, zirconium vanadate (ZrV2 O7 ), or zirconium tungstate (ZrW2 O8 ), which are added to the glass frit to form a paste to reduce the thermal expansion coefficient mismatch between the substrate and the glass frit. Solvents are used to adjust the rheological viscosity of the combined powder and organic binder paste, and these solvents need to be suitable for controlled dispensing purposes. To bond the two substrates, a frit layer can be applied to the sealing surfaces of one or both substrates by spin coating or screen printing. The frit-coated substrate is initially subjected to an organic burnout step at a relatively low temperature (eg, at 250°C for 30 minutes) to remove the organic vehicle. Then, along the respective sealing surfaces, the two substrates to be bonded are assembled/matched, and the pair of substrates is placed in the wafer bonder. A thermal compression cycle is performed at well-defined temperatures and pressures, thereby melting the frit to form a compact glass seal. With the exception of certain lead-containing compositions, glass frit materials typically have glass transition temperatures greater than 450°C and therefore require processing at elevated temperatures to form the barrier layer. Such a high temperature sealing process can be disadvantageous for temperature sensitive workpieces. Additionally, in order to reduce the thermal expansion coefficient mismatch between the usual substrate and glass frit, negative CTE inorganic fillers are used, which will be incorporated into the bond joint and result in a substantially opaque glass frit based barrier layer . Based on the above, it is desirable to form transparent and hermetic glass-glass seals, glass-metal seals, glass-ceramic seals, and other seals at low temperatures.

虽然常规的玻璃基材激光焊接可使用超大功率激光装置,但是这种在近激光烧蚀下的操作常常损坏玻璃基材并得到质量较差的气密性密封件。再者,这种常规方法使得到的装置的不透明度增加,并且还提供了低质量的密封件。While conventional laser welding of glass substrates can use ultra-high power laser devices, this operation under near-laser ablation often damages the glass substrate and results in poor quality hermetic seals. Again, this conventional approach results in increased opacity of the resulting device and also provides a low quality seal.

在一些情况中,密封件可能不是光学透明的,例如可能是着色的。在用于对光进行发射、透射、转换、提取、漫射和/或散射的密封封装件的情形中,这些缺陷尤为不利。例如,不透明的密封件可以阻挡光透射,而光学不透明的密封件可能在光通过密封区域时使光发生不期望的畸变。由于这些原因,通常围绕基材外周施涂密封剂,例如施涂在围绕待密封物体的框架中,或者仅在边缘处施涂,即使封装件中未密封物体。尽管如此,在一些构造中,边缘处的材料仍可使光发生不期望的畸变或使光透射减小。In some cases, the seal may not be optically clear, eg, may be colored. These defects are particularly disadvantageous in the context of hermetic packages used to emit, transmit, convert, extract, diffuse and/or scatter light. For example, opaque seals can block light transmission, while optically opaque seals can undesirably distort light as it passes through the sealed area. For these reasons, sealants are typically applied around the periphery of the substrate, for example in a frame around the object to be sealed, or only at the edges, even if the object is not sealed in the package. Nonetheless, in some configurations, the material at the edges can undesirably distort the light or reduce light transmission.

因此,有利的是,提供对基材进行激光密封的方法,该方法除了其他优点之外,还可以增加密封件的透明度、强度和/或气密性,降低制造成本和/或复杂性,并且/或者提高生产率和/或产率。还会有利的是,提供用于显示器和其他电子装置的密封装置,其可使光透射性得到改进和/或使畸变减少。得到的密封装置自身可用作显示器或其他电子装置中的部件,或者可用于保护各种电子器件和其他部件,例如发光结构或颜色转换元件,例如激光二极管(LD)、LED、OLED和/或QD。Accordingly, it would be advantageous to provide a method of laser sealing a substrate that, among other advantages, increases the transparency, strength and/or air tightness of the seal, reduces manufacturing cost and/or complexity, and /or increase productivity and/or productivity. It would also be advantageous to provide sealing arrangements for displays and other electronic devices that would result in improved light transmission and/or reduced distortion. The resulting encapsulated device can itself be used as a component in displays or other electronic devices, or can be used to protect various electronic devices and other components, such as light emitting structures or color conversion elements such as laser diodes (LDs), LEDs, OLEDs and/or QD.

发明内容SUMMARY OF THE INVENTION

本公开的实施方式一般涉及气密性阻挡层,更具体地,涉及使用吸收薄膜来密封固体结构的方法和组合物。本公开的实施方式提供了使用薄膜作为界面引发剂,对玻璃片和其他材料片进行激光焊接或密封的方法,所述薄膜在密封过程中具有吸收特性。根据一些实施方式,示例性的激光焊接条件可适于在导电性界面膜上进行焊接,并且导电性的下降可忽略不计。因此,所述实施方式可用于形成有源装置(例如OLED或其他装置)的气密性封装件,并且能够广泛、大批量地制造合适的玻璃或半导体封装件。应注意的是,术语密封、结合、接合和焊接在本公开中可互换使用并且是互换使用的。这种用法不应当限制本文所附的权利要求书的范围。还应注意的是,在本公开中,当术语玻璃和无机涉及对名词膜进行修饰时,它们可互换使用,并且这种用法不应当限制本文所附的权利要求书的范围。Embodiments of the present disclosure relate generally to hermetic barriers and, more particularly, to methods and compositions for sealing solid structures using absorbent films. Embodiments of the present disclosure provide methods for laser welding or sealing sheets of glass and other materials using thin films as interfacial initiators, the films having absorbing properties during the sealing process. According to some embodiments, exemplary laser welding conditions may be suitable for welding on conductive interface films with negligible drop in conductivity. Thus, the described embodiments can be used to form hermetic packages for active devices, such as OLEDs or other devices, and enable the wide-scale, high-volume manufacture of suitable glass or semiconductor packages. It should be noted that the terms sealing, bonding, joining and welding are used interchangeably and interchangeably in this disclosure. Such usage should not limit the scope of the claims appended hereto. It should also be noted that in this disclosure, when the terms glass and inorganic refer to modifications to the noun membrane, they are used interchangeably, and such usage should not limit the scope of the claims appended hereto.

本公开的实施方式提供了一种激光密封方法,例如激光焊接、漫射焊接等,所述方法可在两个玻璃之间的界面处提供吸收膜。在稳定状态中,吸收可以大于或高达约70%,或者可以小于或低至约10%。小于或低至10%的吸收依赖于在入射激光波长下,在玻璃基材中的色心形成并结合示例性的激光吸收膜,而该色心形成是由于外在色心(例如杂质或掺杂剂)或玻璃固有的内在色心所致。膜的一些非限制性实例包括Tg<600℃的SnO2、ZnO、TiO2、ITO、UV吸收玻璃膜,以及低熔点玻璃(LMG)或低液相线温度(LLT)膜(无玻璃化转变温度的材料),它们可用于玻璃基材的界面处。例如,LLT材料可以包括但不限于陶瓷、玻璃陶瓷和玻璃材料。例如,LLT玻璃可包括锡氟磷酸盐玻璃、掺钨的锡氟磷酸盐玻璃、硫属化合物玻璃、亚碲酸盐玻璃、硼酸盐玻璃和磷酸盐玻璃。在另一个非限制性实施方式中,密封材料可以为含Sn2+的无机氧化物材料,例如,SnO、SnO+P2O5和SnO+BPO4。其他非限制性实例可以包括吸收峰在>800nm波长处的近红外(NIR)吸收玻璃膜。使用这些材料的焊接可提供可见光透射,并且具有足够的UV或NIR吸收来引发温和的稳态扩散焊接。这些材料还可提供具有局部密封温度,并且该温度适于进行扩散焊接的透明激光焊接件。这种扩散焊接使相应的玻璃基材进行低功率和低温激光焊接,并且可以以有效且快速的焊接速度产生优异的透明焊接件。根据本公开的实施方式所述的示例性激光焊接工艺还可依赖于色心形成后的玻璃的光诱导吸收特性,以包括温度诱导吸收。Embodiments of the present disclosure provide a laser sealing method, such as laser welding, diffusion welding, etc., that can provide an absorbing film at the interface between two glasses. In a steady state, the absorption may be greater than or as high as about 70%, or may be less than or as low as about 10%. Absorption of less than or as low as 10% depends on the formation of color centers in the glass substrate at the incident laser wavelength due to extrinsic color centers (e.g. impurities or doping) in combination with exemplary laser absorbing films. impurities) or the inherent color center of glass. Some non-limiting examples of films include SnO2, ZnO, TiO2, ITO, UV absorbing glass films with Tg < 600°C, and low melting glass (LMG) or low liquidus temperature (LLT) films (no glass transition temperature). material), they can be used at the interface of glass substrates. For example, LLT materials may include, but are not limited to, ceramics, glass ceramics, and glass materials. For example, LLT glasses may include tin fluorophosphate glasses, tungsten-doped tin fluorophosphate glasses, chalcogenide glasses, tellurite glasses, borate glasses, and phosphate glasses. In another non-limiting embodiment, the sealing material may be a Sn2+ containing inorganic oxide material, eg, SnO, SnO+P2 O5 and SnO+BPO4 . Other non-limiting examples may include near-infrared (NIR) absorbing glass films with absorption peaks at >800 nm wavelengths. Welding with these materials provides visible light transmission with sufficient UV or NIR absorption to induce mild steady-state diffusion welding. These materials can also provide transparent laser welds with local sealing temperatures suitable for diffusion welding. This diffusion welding enables low-power and low-temperature laser welding of the corresponding glass substrates and can produce excellent transparent welds at efficient and fast welding speeds. Exemplary laser welding processes according to embodiments of the present disclosure may also rely on the light-induced absorption properties of the glass after color center formation to include temperature-induced absorption.

本文描述了使用低熔点无机(LMG)材料或紫外吸收(UVA)或红外吸收(IRA)材料的界面薄膜,利用激光将各透明玻璃片焊接在一起以引发密封的现象。在示例性实施方式中,描述了实现强结合形成的三个标准:(1)示例性的LMG或UVA或IRA膜可在透明度窗口(例如约420nm至约750nm)以外的入射波长下充分吸收,以将足够的热传播到玻璃基材中,并且玻璃基材可因此表现出(2)温度诱导的吸收和(3)在入射波长下形成瞬态色心。测量表明形成了热压缩扩散焊接机制,其定性地导致形成极强的结合。本文还描述了与焊接工艺相关的温度事件的演变以及激光焊接中色心形成过程的明显普遍性。还论述了LMG或UVA材料与Eagle材料之间的CTE错配不相关性以及热循环到600℃后的焊后强度增强情况。还论述了关于通过使用导热板将厚度不同的各玻璃片焊接在一起的实施方式。因此,本文所述的实施方式可具备形成具有无源和有源装置的气密性封装件的能力,其可包括与使用LMG或UVA界面材料相关的激光密封属性。示例性的属性包括但不限于在可见光谱中的透明、强、薄、高的透射性、“绿色”组成、LMG或UVA膜与玻璃基材之间的CTE错配不相关性,以及低熔化温度。This paper describes the use of low melting point inorganic (LMG) materials or interfacial films of ultraviolet absorbing (UVA) or infrared absorbing (IRA) materials to laser weld together transparent glass sheets to induce sealing. In exemplary embodiments, three criteria for achieving strong bond formation are described: (1) the exemplary LMG or UVA or IRA film can absorb sufficiently at incident wavelengths outside the transparency window (eg, about 420 nm to about 750 nm), to transmit sufficient heat into the glass substrate, and the glass substrate may thus exhibit (2) temperature-induced absorption and (3) the formation of transient color centers at the incident wavelength. Measurements indicate the formation of a thermocompression diffusion welding mechanism, which qualitatively leads to the formation of extremely strong bonds. The paper also describes the evolution of temperature events associated with the welding process and the apparent prevalence of color center formation processes in laser welding. Also discusses LMG or UVA materials and Eagle Independence of CTE mismatch between materials and post-weld strength enhancement after thermal cycling to 600°C. Embodiments are also discussed regarding the use of thermally conductive plates to weld together glass sheets of different thicknesses. Thus, the embodiments described herein may have the capability to form hermetic packages with passive and active devices, which may include laser sealing properties associated with the use of LMG or UVA interface materials. Exemplary properties include, but are not limited to, transparency in the visible spectrum, strong, thin, high transmission, "green" composition, CTE mismatch independence between LMG or UVA films and glass substrates, and low melting temperature.

本公开的另外的实施方式提供了具有低温结合形成和“直接玻璃密封”的激光密封方法,其中,可在入射波长下将透明玻璃密封到吸光玻璃(absorbing glass),从而形成在可见波长400-700nm下的不透明密封件。在示例性实施方式中,两块玻璃在入射激光波长下以及在可见波长范围中均是透明的或几乎是透明的。得到的密封件在可见波长范围中也是透明的,其对照明应用来说是吸引人的,因为在密封位置处不吸收光,因此不会产生与密封相关的热堆积。另外,由于可将膜施加在整个盖板玻璃上方,因此无需精确分配密封用玻璃糊料来进行密封操作,从而为装置制造商提供了很大的自由度来改变他们的密封图案而不需要对密封区域进行特殊的图案化或加工。在其他实施方式中,还可在玻璃区域的某些点上进行密封以形成用于机械稳定性的非气密性结合。此外,可在弯曲的共型表面上进行所述密封。Additional embodiments of the present disclosure provide laser sealing methods with low temperature bond formation and "direct glass sealing", wherein transparent glass can be sealed to absorbing glass at incident wavelengths, thereby forming 400- Opaque seal at 700nm. In an exemplary embodiment, both glasses are transparent or nearly transparent at the incident laser wavelength and in the visible wavelength range. The resulting seal is also transparent in the visible wavelength range, which is attractive for lighting applications because no light is absorbed at the location of the seal and thus no seal-related heat build-up occurs. Additionally, since the film can be applied over the entire cover glass, there is no need to precisely dispense the sealing glass paste for the sealing operation, giving device manufacturers a great deal of freedom to change their sealing pattern without the need for The sealing area is specially patterned or machined. In other embodiments, sealing may also be performed at certain points in the glass area to form a non-hermetic bond for mechanical stability. Furthermore, the sealing can be performed on curved conformal surfaces.

本公开的实施方式提供了低熔化温度材料,其可以用于将玻璃片激光焊接在一起,这涉及焊接任意的玻璃而不考虑玻璃的CTE差异。另外的实施方式可提供玻璃基材的对称焊接(即,厚玻璃与厚玻璃的焊接),例如Eagle与Eagle的焊接、Lotus与Lotus的焊接等。一些实施方式可使用导热板来提供玻璃基材的不对称焊接(即,薄玻璃与厚玻璃的焊接),例如Willow与Eagle的焊接、Eagle与Lotus的焊接(即,薄玻璃与薄玻璃的焊接)、Eagle与熔合二氧化硅的焊接、Willow与Willow的焊接、熔合二氧化硅与熔合二氧化硅的焊接等。其他实施方式可提供不同基材的焊接(玻璃与陶瓷、玻璃与金属等),并且可提供透明和/或半透明焊接线。一些实施方式可对薄的、不可渗透的、“绿色”材料进行焊接,并且可在CTE差异大的两种基材或材料之间提供强的焊接。Embodiments of the present disclosure provide low melting temperature materials that can be used to laser weld glass sheets together, which involves welding arbitrary glasses regardless of the CTE differences of the glasses. Additional embodiments may provide for symmetrical welding of glass substrates (ie, thick glass to thick glass welding), such as Eagle to Eagle welding, Lotus to Lotus welding, and the like. Some embodiments may use thermally conductive plates to provide asymmetric welding of glass substrates (ie, welding of thin glass to thick glass), such as Willow and Eagle welding, Eagle and Lotus welding (ie, thin glass to thin glass welding), Eagle and fused silica welding, Willow and Willow welding, fused silica and fused silica welding, etc. Other embodiments may provide welding of different substrates (glass to ceramic, glass to metal, etc.) and may provide transparent and/or translucent welding lines. Some embodiments can weld thin, impermeable, "green" materials and can provide strong welds between two substrates or materials with large differences in CTE.

实施方式还提供了用于将玻璃封装件激光焊接在一起的材料,从而能够对对氧和湿气侵袭所导致的降解敏感的无源和有源装置进行长久气密操作。示例性的LMG或其他吸收薄膜密封件在将各结合表面组装后可以利用激光吸收被热活化,并且可以具有更高的制造效率,因为密封每个工作装置的速率由热活化和结合形成决定,而不是由通过在真空或惰性气体组装线中的在线(inline)薄膜沉积对装置进行封装的速率决定。在UV或NIR-IR密封件中的示例性的LMG、LLT及其他吸收薄膜还能够对大片多重装置进行密封,随后刻划或切成各个装置(单个化),并且由于机械完整性高,因此单个化的产率可以较高。Embodiments also provide materials for laser welding glass packages together, enabling long-term hermetic operation of passive and active devices that are sensitive to degradation due to oxygen and moisture aggression. Exemplary LMG or other absorptive film seals can be thermally activated using laser absorption after the individual bonding surfaces are assembled, and can have higher manufacturing efficiencies because the rate at which each working device is sealed is determined by thermal activation and bond formation, Rather, it is determined by the rate at which the device is packaged by inline thin film deposition in a vacuum or inert gas assembly line. Exemplary LMG, LLT, and other absorbing films in UV or NIR-IR seals also enable sealing of large sheets of multiple devices, subsequent scoring or dicing of individual devices (singulated), and due to high mechanical integrity, The yield of singulation can be higher.

在一些实施方式中,结合工件的方法包括在第一基材表面的上方形成无机膜;将待受保护的工件布置在第一基材与第二基材之间,其中,使所述膜与第二基材接触;以及通过利用具有预定波长的激光辐射对膜进行局部加热而将工件结合在第一基材与第二基材之间。无机膜、第一基材或第二基材在约420nm至约750nm下可具有透射性。In some embodiments, the method of bonding workpieces includes forming an inorganic film over a surface of a first substrate; disposing the workpiece to be protected between the first substrate and the second substrate, wherein the film is caused to contacting the second substrate; and bonding the workpiece between the first substrate and the second substrate by locally heating the film with laser radiation having a predetermined wavelength. The inorganic film, the first substrate, or the second substrate may have transmittance at about 420 nm to about 750 nm.

在其他实施方式中,提供了一种结合装置,其包括在第一基材表面上方形成的无机膜,以及在第一基材与第二基材之间的受保护的装置,其中,无机膜与第二基材接触。在这样的实施方式中,所述装置包括通过用具有预定波长的激光辐射来局部加热无机膜而在第一基材与第二基材之间形成的结合,其根据第一或第二基材中的杂质组成变化而变化,并且根据无机膜的组成变化而变化。另外,无机膜、第一基材或第二基材在约420nm至约750nm下可具有透射性。In other embodiments, a bonding device is provided that includes an inorganic film formed over a surface of a first substrate, and a protected device between the first substrate and the second substrate, wherein the inorganic film in contact with the second substrate. In such embodiments, the device includes a bond formed between the first substrate and the second substrate by locally heating the inorganic film with laser radiation having a predetermined wavelength, depending on whether the first or second substrate The impurity composition in the film changes, and it changes according to the composition change of the inorganic film. In addition, the inorganic film, the first substrate, or the second substrate may have transmittance at about 420 nm to about 750 nm.

在另外的实施方式中,提供了一种对装置进行保护的方法,所述方法包括在第一基材的第一部分表面上方形成无机膜层;将待受保护的装置布置在第一基材与第二基材之间,其中使密封层与第二基材接触;以及使用激光辐射局部加热无机膜层和第一及第二基材以使密封层和基材熔化而在各基材之间形成密封。第一基材可包括玻璃或玻璃陶瓷,而第二基材可包括玻璃、金属、玻璃陶瓷或陶瓷。In further embodiments, a method of protecting a device is provided, the method comprising forming an inorganic film layer over a first portion of a surface of a first substrate; disposing the device to be protected on the first substrate and the between the second substrates, wherein the sealing layer is brought into contact with the second substrate; and the inorganic film layer and the first and second substrates are locally heated using laser radiation to melt the sealing layer and the substrates between the substrates form a seal. The first substrate may comprise glass or glass-ceramic, and the second substrate may comprise glass, metal, glass-ceramic or ceramic.

在各个实施方式中,本公开还涉及密封装置,其包括在第一基材表面上方形成的无机膜;与无机膜接触的第二基材;和焊接区域,所述焊接区域包括在第一基材和第二基材之间形成的结合,并且该焊接区域从第一基材中的第一深度延伸到第二基材中的第二深度。根据另外的实施方式,无机膜包括至少一种无机膜元素,并且第一基材和第二基材中的一种或两种包括至少一种无机基材元素。在另外的实施方式中,在焊接区域中的第一或第二基材的第一无机膜元素浓度高于焊接区域外的第一或第二基材的第二无机膜元素浓度。根据另外的实施方式,在焊接区域中的第一基材元素浓度高于焊接区域外的无机膜的第二基材元素浓度。在另外的实施方式中,可以在第二基材表面上方形成第二无机膜。In various embodiments, the present disclosure also relates to a sealing device that includes an inorganic film formed over a surface of a first substrate; a second substrate in contact with the inorganic film; and a welding region, the welding region comprising a surface of the first substrate A bond is formed between the material and the second substrate, and the welded region extends from a first depth in the first substrate to a second depth in the second substrate. According to further embodiments, the inorganic film includes at least one inorganic film element, and one or both of the first substrate and the second substrate include at least one inorganic substrate element. In further embodiments, the concentration of the first inorganic film element of the first or second substrate in the weld zone is higher than the concentration of the second inorganic film element of the first or second substrate outside the weld zone. According to further embodiments, the concentration of the first substrate element in the weld zone is higher than the second substrate element concentration of the inorganic film outside the weld zone. In further embodiments, a second inorganic film may be formed over the surface of the second substrate.

在一些实施方式中,无机膜和任选地第一或第二基材中的至少一种在约420nm至约750nm范围内的波长下具有透射性。在另外的实施方式中,第一基材、第二基材和无机膜中的每一种在约420nm至约750nm范围内的波长下均可以具有透射性。在其他实施方式中,焊接区域可以是透明的。第一基材或第二基材中的一者或二者可以选自玻璃或玻璃陶瓷,例如钠钙硅酸盐玻璃、硅铝酸盐玻璃、碱金属硅铝酸盐玻璃、硼硅酸盐玻璃、碱金属硼硅酸盐玻璃、铝硼硅酸盐玻璃、碱金属铝硼硅酸盐玻璃和碱土金属铝硼硅酸盐玻璃。根据某些实施方式,第一基材或第二基材可以包括聚合物、陶瓷或金属。In some embodiments, at least one of the inorganic film and optionally the first or second substrate is transmissive at wavelengths in the range of about 420 nm to about 750 nm. In further embodiments, each of the first substrate, the second substrate, and the inorganic film may be transmissive at wavelengths in the range of about 420 nm to about 750 nm. In other embodiments, the weld area may be transparent. One or both of the first substrate or the second substrate may be selected from glass or glass ceramics, such as soda lime silicate glass, aluminosilicate glass, alkali metal aluminosilicate glass, borosilicate glass Glass, alkali metal borosilicate glass, aluminoborosilicate glass, alkali metal aluminoborosilicate glass and alkaline earth metal aluminoborosilicate glass. According to certain embodiments, the first substrate or the second substrate may comprise polymers, ceramics or metals.

无机膜可以具有包含以下物质的组合物:20-100摩尔%SnO;0-50摩尔%SnF2;和0-30摩尔%P2O5或B2O3。无机膜还可以具有包含以下物质的组合物:10-80摩尔%B2O3;5-60摩尔%Bi2O3;和0-70摩尔%ZnO。根据各个实施方式,无机膜的厚度可在约0.1微米至约10微米的范围内。在另外的实施方式中,焊接区域的厚度可以在约0.3微米至约14微米的范围内。The inorganic film may have a composition comprising: 20-100 mol %SnO ; 0-50 mol %SnF2; and 0-30 mol %P2O5 orB2O3 .The inorganic film may also have a composition comprising: 10-80 mol% B2O3; 5-60 mol%Bi2O3; and 0-70 mol% ZnO. According to various embodiments, the thickness of the inorganic film may range from about 0.1 microns to about 10 microns. In further embodiments, the thickness of the weld region may be in the range of about 0.3 microns to about 14 microns.

在一些实施方式中,密封装置还可包括至少包围焊接区域的应力区域,其中,应力区域中的第一应力大于应力区域外的第二应力。例如,第一应力可在大于约1MPa至约25MPa的范围内。在另外的实施方式中,第一应力相对于第二应力的比值在约1.1:1至约25:1的范围内。根据某些实施方式,应力区域的厚度可在约20微米至约500微米的范围内。In some embodiments, the sealing device may further include a stress region surrounding at least the weld region, wherein the first stress in the stress region is greater than the second stress outside the stress region. For example, the first stress may be in the range of greater than about 1 MPa to about 25 MPa. In further embodiments, the ratio of the first stress to the second stress is in the range of about 1.1:1 to about 25:1. According to certain embodiments, the thickness of the stressed region may range from about 20 microns to about 500 microns.

本文还公开了密封装置,其包括在第一基材表面上方形成的无机膜;与无机膜接触的第二基材;以及焊接区域,所述焊接区域包括在第一基材与第二基材之间形成的结合。根据另外的实施方式,第一基材和第二基材中的一种或两种包括至少一种无机基材元素。在另外的实施方式中,焊接区域相比于焊接区域外的一部分无机膜富含所述至少一种无机基材元素。本文还公开了密封装置,其包括在第一基材表面上方形成的无机膜;与无机膜接触的第二基材;以及焊接区域,所述焊接区域包括在第一基材与第二基材之间形成的结合。根据另外的实施方式,无机膜包括至少一种无机膜元素。在另外的实施方式中,第一或第二基材包括在焊接区域中的第一部分和在焊接区域外的第二部分。根据另外的实施方式,相比于第二部分,第一部分富含所述至少一种无机膜元素。在另外的实施方式中,可以在第二基材表面上方形成第二无机膜。Also disclosed herein is a sealing device comprising an inorganic film formed over the surface of the first substrate; a second substrate in contact with the inorganic film; and a welding region comprising the first substrate and the second substrate combination formed between. According to further embodiments, one or both of the first substrate and the second substrate comprise at least one inorganic substrate element. In further embodiments, the weld area is enriched with the at least one inorganic substrate element compared to a portion of the inorganic film outside the weld area. Also disclosed herein is a sealing device comprising an inorganic film formed over the surface of the first substrate; a second substrate in contact with the inorganic film; and a welding region comprising the first substrate and the second substrate combination formed between. According to further embodiments, the inorganic film includes at least one inorganic film element. In further embodiments, the first or second substrate includes a first portion in the weld zone and a second portion outside the weld zone. According to a further embodiment, the first part is enriched in the at least one inorganic membrane element compared to the second part. In further embodiments, a second inorganic film may be formed over the surface of the second substrate.

在以下的详细描述中提出了要求保护的主题的另外的特征和优点,其中的部分特征和优点对本领域的技术人员而言根据所作描述即容易理解,或者通过实施包括以下具体实施方式、权利要求书以及附图在内的本文所述的要求保护的主题而被认识。Additional features and advantages of the claimed subject matter are set forth in the following detailed description, some of which are readily apparent to those skilled in the art from the description, or by practice including the following detailed description, claims The claimed subject matter described herein, including the book and drawings, is recognized.

应当理解的是,前面的一般性描述和以下的具体实施方式都描述了本公开的实施方式且都旨在提供用于理解所要求保护的主题的性质和特性的总体评述或框架。所包含的附图供进一步理解本公开,附图被结合在本说明书中并构成说明书的一部分。附图例示了各个实施方式,且与说明书一起用于解释所要求保护的主题的原理和操作。It is to be understood that both the foregoing general description and the following detailed description describe embodiments of the present disclosure and are both intended to provide a general overview or framework for understanding the nature and character of the claimed subject matter. The accompanying drawings are included to provide a further understanding of the present disclosure, and are incorporated in and constitute a part of this specification. The drawings illustrate various embodiments, and together with the description serve to explain the principles and operation of the claimed subject matter.

附图说明Description of drawings

出于说明的目的提供了这些附图,应当理解的是,本文公开和论述的实施方式不限于所示的布置和机构。These figures are provided for illustrative purposes, it being understood that the embodiments disclosed and discussed herein are not limited to the arrangements and instrumentalities shown.

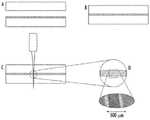

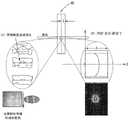

图1是根据本公开的一个实施方式所述的激光焊接的一个示例性过程图。FIG. 1 is an exemplary process diagram of laser welding according to an embodiment of the present disclosure.

图2是例示了通过一个实施方式的激光密封形成气密性密封装置的示意图。FIG. 2 is a schematic diagram illustrating the formation of a hermetic sealing device by laser sealing of one embodiment.

图3为本主题的另一个实施方式的图。Figure 3 is a diagram of another embodiment of the subject matter.

图4是用于估计激光焊接结合区的物理范围的实验布置示意图。Figure 4 is a schematic diagram of the experimental setup used to estimate the physical extent of the laser welded bond area.

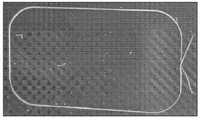

图5是断裂样品的显微图像。Figure 5 is a microscopic image of a fractured sample.

图6是根据本公开的一些实施方式所述的建模方案示意图。6 is a schematic diagram of a modeling scheme according to some embodiments of the present disclosure.

图7是根据本公开的实施方式所述的另一个建模方案。FIG. 7 is another modeling scheme according to an embodiment of the present disclosure.

图8是通过Eagle 0.7mm玻璃基材的355nm激光透射率(%T)用于%T相对于时间测量的实验布置图。8 is a graph of the experimental setup for %T versus time measurement of 355 nm laser transmittance (%T) through Eagle 0.7 mm glass substrates.

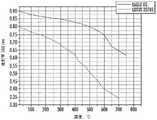

图9是根据本公开的一个实施方式所述的图。FIG. 9 is a diagram according to one embodiment of the present disclosure.

图10是分析了在玻璃界面处,从LMG膜层进入到Eagle玻璃基材中的扩散的一系列图。Figure 10 is an analysis of the entry from the LMG layer to the Eagle at the glass interface. A series of graphs of diffusion in a glass substrate.

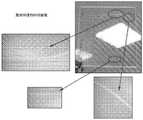

图11是在不同厚度的玻璃片之间的激光焊接性能的示意图。Figure 11 is a graphical representation of laser welding performance between glass sheets of different thicknesses.

图12是估算在ITO引线(leads)上方的激光焊接范围的实验示意图。Figure 12 is a schematic diagram of an experiment to estimate the extent of laser welding over ITO leads.

图13提供了在ITO图案化膜上方形成的激光密封线的照片。Figure 13 provides a photograph of a laser seal line formed over an ITO patterned film.

图14是在图案化膜上方形成的另外的激光密封线的照片。Figure 14 is a photograph of an additional laser seal line formed over the patterned film.

图15是根据一些实施方式所述的另一种方法的简化图。15 is a simplified diagram of another method according to some embodiments.

图16是一些实施方式的两层激光加热表面吸收模型。16 is a two-layer laser-heated surface absorption model of some embodiments.

图17是一些实施方式的一系列温度变化图。Figure 17 is a series of temperature change graphs for some embodiments.

图18是针对一些实施方式的,在扫掠激光的停留时间内沉积的一系列平均能量图。Figure 18 is a series of plots of average energy deposited over the dwell time of the swept laser for some embodiments.

图19是在用IR辐射源加热期间,在355nm下的Eagle和Lotus玻璃透射性图。Figure 19 is the Eagle at 355nm during heating with an IR radiation source and Lotus Glass transmittance map.

图20是一些实施方式在加热期间在355nm下的玻璃透射性图。Figure 20 is a graph of glass transmittance at 355 nm during heating for some embodiments.

图21是一些实施方式在UV辐射期间和之后,对膜和基材的透射性的影响图。Figure 21 is a graph of the effect of some embodiments on the transmittance of films and substrates during and after UV radiation.

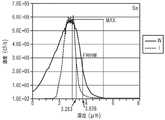

图22是一些实施方式的吸收相对于波长的图。Figure 22 is a graph of absorption versus wavelength for some embodiments.

图23是在Eagle玻璃上的示例性低熔点玻璃膜的激光密封或结合线照片。Figure 23 is in Eagle Photo of a laser seal or bond line of an exemplary low melting point glass film on glass.

图24是在Eagle玻璃上的示例性低熔点玻璃膜的交叉激光密封线照片。Figure 24 is in Eagle Cross-laser seal line photo of an exemplary low melting point glass film on glass.

图25是一些实施方式在激光焊接时观察到的界面接触几何范围示意图。25 is a schematic illustration of the geometric range of interfacial contact observed during laser welding for some embodiments.

图26是在施加的恒定压力P外下,在对界面间隙区域进行激光焊接期间,相对接触区域Ac/A0的演变示意图。Figure 26 is a schematic diagram of the evolution of the relative contact areaAc /A0 during laser welding of the interfacial gap area underan applied constant pressure P.

图27例示了使用通常的激光焊接条件在一个实施方式的激光扫掠区域上方的轮廓仪迹线。Figure 27 illustrates a profiler trace over the laser swept region of one embodiment using typical laser welding conditions.

图28是提供了针对一些实施方式估算的焊接速率比较情况的一系列图。28 is a series of graphs that provide a comparison of estimated weld rates for some embodiments.

图29是一些实施方式的偏振测量和图像的示意图。Figure 29 is a schematic diagram of polarization measurements and images of some embodiments.

图30是根据示例性焊接线提供应力位置的图。30 is a diagram of providing stress locations according to an exemplary weld line.

图31是根据一些实施方式所述的经过激光焊接的钠钙玻璃的一系列照片。31 is a series of photographs of laser welded soda lime glass according to some embodiments.

图32是一些实施方式的示意图。Figure 32 is a schematic diagram of some embodiments.

图33-34是一些实施方式中的焊接线的照片。33-34 are photographs of weld lines in some embodiments.

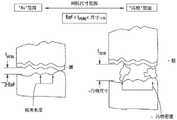

图35A是包含两个基材和无机膜的制品的侧视图。Figure 35A is a side view of an article comprising two substrates and an inorganic film.

图35B是经受一种示例性密封工艺的一种制品的顶视图。35B is a top view of an article undergoing an exemplary sealing process.

图35C是根据本公开的各个实施方式所述的密封装置的截面图。35C is a cross-sectional view of a sealing device according to various embodiments of the present disclosure.

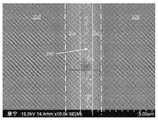

图36A-36B是分别是在激光密封之前和之后的密封界面的SEM图像。36A-36B are SEM images of the sealed interface before and after laser sealing, respectively.

图37例示了用于元素分析的经过焊接的制品和示例性区域。Figure 37 illustrates welded articles and exemplary regions for elemental analysis.

图38A-38C例示了在密封制品的焊接区域和非焊接区域中的元素深度分布(F、P、Sn)的各个图。38A-38C illustrate various graphs of elemental depth distribution (F, P, Sn) in welded and non-welded areas of a sealed article.

图39A-39C例示了在密封制品的焊接区域和非焊接区域中的元素深度分布(Al、B、Si)的各个图。39A-39C illustrate various graphs of elemental depth distribution (Al, B, Si) in welded and non-welded regions of a sealed article.

图40例示了根据本公开的各个实施方式,密封装置的应力分布随着深度变化而变化的各个图。40 illustrates various graphs of stress distribution of a sealing arrangement as a function of depth, according to various embodiments of the present disclosure.

虽然本说明书可包括许多特定情况,但这些不构成本公开的范围的限制,而是描述对于具体的实施方式特定的特征。Although this specification may contain many specific situations, these should not be construed as limitations on the scope of the disclosure but rather as descriptions of features specific to particular implementations.

具体实施方式Detailed ways

参考附图描述了密封方法和密封装置的各个实施方式,其中为了便于理解,相同元件以相同的附图标记给出。Various embodiments of the sealing method and sealing device are described with reference to the accompanying drawings, wherein like elements are given like reference numerals for ease of understanding.

还应理解,除非另外说明,否则,术语例如“顶部”、“底部”、“向外”、“向内”等是为了方便起见的用语,不应视为限制性用语。此外,每当将一个组描述为包含一组元素和它们的组合中的至少一种时,所述组可以单个元素或相互组合的形式包含任何数量的这些所列元素,或者主要由任何数量的这些所列元素组成,或者由任何数量的这些所列元素组成。It should also be understood that unless stated otherwise, terms such as "top," "bottom," "outward," "inward," etc. are terms of convenience and should not be regarded as limiting. Furthermore, whenever a group is described as containing at least one of a group of elements and combinations thereof, the group can contain any number of those listed elements, either individually or in combination with one another, or consist essentially of any number of elements consists of, or consists of, any number of, these listed elements.

类似地,每当将一个组描述为由一组元素中的至少一个元素或它们的组合组成时,所述组可以单个元素或相互组合的形式由任何数量的这些所列元素组成。除非另有说明,否则,所列举的数值范围同时包括所述范围的上限和下限。除非另外说明,否则,本文所用的不定冠词“一个”和“一种”及其相应的定冠词“该/所述”表示“至少一(个/种)”,或者“一(个/种)或多(个/种)”。Similarly, whenever a group is described as consisting of at least one of the group of elements, or a combination thereof, the group can consist of any number of the listed elements, either individually or in combination with one another. Unless otherwise indicated, recited numerical ranges include both the upper and lower limits of the stated range. Unless stated otherwise, the indefinite articles "a" and "an" and their corresponding definite articles "the/the" as used herein mean "at least one", or "an" species) or multiple (one/species)”.

本领域的技术人员能够认识到,可以对所述实施方式做出许多改变,同时仍能获得本发明的有益效果。还应显而易见的是,本公开的期望益处中的一部分可以通过选择一些所述特征而不利用其他特征来获得。因此,本领域技术人员应认识到,许多更改和修改都是可能的,在某些情况下甚至是希望的,并且是本公开的一部分。因此,提供以下描述作为对本公开原理的说明而不构成对本公开的限制。Those skilled in the art will recognize that many changes can be made to the described embodiments while still obtaining the benefits of the present invention. It should also be apparent that some of the desired benefits of the present disclosure may be obtained by selecting some of the described features without utilizing other features. Accordingly, those skilled in the art will recognize that many changes and modifications are possible, and in some cases even desirable, and are a part of this disclosure. Accordingly, the following description is provided as an illustration of the principles of the present disclosure and is not intended to limit the disclosure.

本领域技术人员应理解,在不偏离本发明的精神和范围的情况下,可对本文所述的示例性实施方式进行许多修改。因此,本发明的描述并非意在受限于所给出的实例,也不应理解为受限于所给出的实例,而应被赋予由所附权利要求书及其等同体提供的全部保护范围。此外,可以利用本公开的一些特性而不相应地利用其他特性。因此,前面提供对示例性或说明性实施方式的描述的目的在于说明本公开的原理而不是对其加以限制,并且可包括其修改形式和变换形式。Those skilled in the art will appreciate that many modifications to the exemplary embodiments described herein can be made without departing from the spirit and scope of the invention. Therefore, the description of the present invention is not intended to be, and should not be construed as limited by, the examples given, but should be accorded the full protection afforded by the appended claims and their equivalents scope. Furthermore, some of the features of the present disclosure may be utilized without a corresponding utilization of other features. Thus, the foregoing description of exemplary or illustrative embodiments is provided for the purpose of illustrating the principles of the present disclosure, not to limit it, and may include modifications and variations thereof.

图1是根据本公开的一些实施方式所述的激光焊接的一个示例性过程图。参考图1,该图提供了使用合适的UV激光将两片Eagle(EXG)玻璃片或基材激光焊接在一起的过程。虽然例示及描述的是两片EXG玻璃片,但是本文所附的权利要求书不应限于此,因为可使用本公开的实施方式对任何类型和组成的玻璃基材进行激光焊接。也就是说,本文所述的方法能够适用于钠钙玻璃、强化及未强化玻璃、硅铝酸盐玻璃等。FIG. 1 is an exemplary process diagram of laser welding according to some embodiments of the present disclosure. Referring to Figure 1, this figure provides the (EXG) The process of laser welding together glass sheets or substrates. Although two sheets of EXG glass are illustrated and described, the claims appended hereto should not be so limited, as embodiments of the present disclosure may be used to laser weld glass substrates of any type and composition. That is, the methods described herein can be applied to soda lime glass, strengthened and unstrengthened glass, aluminosilicate glass, and the like.

图35A类似地描述了堆叠件100的侧视图,其包括具有第一表面115的第一基材110和具有第二表面125的第二基材120。可以在第一玻璃基材110与第二基材120之间设置无机膜130,以形成密封界面135。在本文中,密封界面135是指第一基材110的第一表面115和第二基材120的第二表面125之间的与无机膜130接触的点,例如,待通过焊接或密封结合的各表面的相遇处。FIG. 35A similarly depicts a side view of

在一些实施方式中,可在全部、基本上全部或一部分的第一表面115和/或第二表面125上方形成无机膜130。虽然在图35A中未示出,但是在第一表面115或第二表面125上可提供装置、层或其他元件,并且其可与无机膜130接触(例如邻接或由无机膜130覆盖),或者在其他实施方式中,可将无机膜130布置在装置、层或元件周围(例如作为围绕装置外周的框架或其他构造设置)。在另外的实施方式中,第一和第二基材110、120中的一者或两者可包含一个或多个其中可放置装置或元件的腔体(未示出)。In some embodiments,

继续参考图1,该图提供了将两个玻璃基材激光焊接在一起的一系列示例性步骤,由此可使一个或两个基材涂覆有低熔点玻璃(LMG)或紫外吸收(UVA)膜材料或NIR吸收(IRA)膜材料。在步骤A至B中,可将顶部玻璃基材压制到涂覆有示例性UVA、IRA或LMG膜的另一个基材上。应注意的是,本文所述的许多实验和实例可能涉及特定类型的无机膜(例如LMG、UVA等)。但是这不应限制本文所附的权利要求书的范围,因为许多类型的无机膜均适用于所述的焊接工艺。在步骤C中,可将激光引导到两片玻璃片的界面处,并且适当选择参数以引发如步骤D例示的焊接工艺。发现焊接尺寸略小于入射光束的尺寸(约500μm)。With continued reference to Figure 1, an exemplary series of steps for laser welding two glass substrates together, whereby one or both substrates can be coated with low melting glass (LMG) or ultraviolet absorbing (UVA) ) membrane material or NIR absorbing (IRA) membrane material. In steps A to B, the top glass substrate can be pressed onto another substrate coated with an exemplary UVA, IRA or LMG film. It should be noted that many of the experiments and examples described herein may involve specific types of inorganic films (eg, LMG, UVA, etc.). However, this should not limit the scope of the claims appended hereto, as many types of inorganic films are suitable for the described welding process. In step C, the laser can be directed at the interface of the two glass sheets, and the parameters appropriately selected to initiate the welding process as exemplified in step D. The weld size was found to be slightly smaller than the size of the incident beam (about 500 μm).

图2是例示了通过一个实施方式的激光密封形成气密性密封装置的示意图。参考图2,在初始步骤中,可沿着第一平坦玻璃基材302的密封表面形成包含低熔化温度(即低Tg)玻璃的图案化玻璃层380。玻璃层380可经由物理汽相沉积来沉积,例如通过来自溅射靶180的溅射进行沉积。在一个实施方式中,该玻璃层可沿着外周密封表面形成,该外周密封表面经过调整而与第二玻璃或其他材料基材304的密封表面接合。在例示的实施方式中,当使第一和第二基材采用匹配构造时,它们与玻璃层配合以限定含有待受保护的工件330的内部体积342。在示出了组件的分解图像的例示实例中,第二基材包括工件330位于其中的凹陷部分。FIG. 2 is a schematic diagram illustrating the formation of a hermetic sealing device by laser sealing of one embodiment. Referring to FIG. 2, in an initial step, a patterned

在一个替代性实施方式中,作为形成图案化玻璃层的替代,可在第一基材和/或第二基材的基本上全部的表面上方形成密封(低熔化温度)玻璃的覆盖层(blanket layer)。可如上所述组装包含第一基材/密封玻璃层/第二基材的组装结构,并可使用激光器来局部限定两个基材之间的密封界面。In an alternative embodiment, instead of forming a patterned glass layer, a blanket layer of sealing (low melting temperature) glass may be formed over substantially the entire surface of the first substrate and/or the second substrate layer). The assembled structure comprising the first substrate/sealing glass layer/second substrate can be assembled as described above, and a laser can be used to locally define the sealing interface between the two substrates.

在非限制性实施方式中,无机膜可以沉积在第一基材的表面以及第二基材的表面上,并且可以使这些膜接触以形成密封界面。认为在密封界面中的两个表面上包含无机膜可以使第一基材与第二基材之间具有更强的结合。通过包含两个膜(例如第一和第二无机膜),可以在两个表面上同时开始界面基材加热,而不是在一侧(例如无机膜沉积在其上的基材)上开始加热再散布到第二侧(例如与无机膜接触的基材)。另外,可以需要更少的能量来诱导基材和膜的粘弹性膨胀或溶胀,这可以使得在焊接区域中具有更少的残余应力。可以通过这种残余应力的减小来改进结合强度,否则可能导致内聚破坏。在这样的实施方式中,第一无机膜的厚度可以与第二无机膜的厚度相同或不同。在另外的实施方式中,第一和第二无机膜的合并总厚度可以近似本文限定的单个无机膜的厚度,例如在约100nm至约10微米的范围内。In a non-limiting embodiment, an inorganic film can be deposited on the surface of the first substrate and the surface of the second substrate, and the films can be brought into contact to form a sealed interface. It is believed that the inclusion of an inorganic film on both surfaces in the sealing interface can result in a stronger bond between the first substrate and the second substrate. By including two films (eg, the first and second inorganic films), the interface substrate heating can be initiated simultaneously on both surfaces, rather than starting on one side (eg, the substrate on which the inorganic film is deposited) and then heating Spread to the second side (eg the substrate in contact with the inorganic film). Additionally, less energy may be required to induce viscoelastic expansion or swelling of the substrate and film, which may result in less residual stress in the weld zone. Bond strength can be improved by this reduction in residual stress, which might otherwise lead to cohesive failure. In such embodiments, the thickness of the first inorganic film may be the same or different from the thickness of the second inorganic film. In further embodiments, the combined total thickness of the first and second inorganic films may approximate the thickness of a single inorganic film as defined herein, eg, in the range of about 100 nm to about 10 microns.

来自激光器500的聚焦激光束501可用于局部熔化低熔化温度玻璃和相邻的玻璃基材材料以形成密封界面。在一种方法中,激光可通过第一基材302聚焦并随后在密封表面上平移(扫描)以局部加热玻璃密封材料。为了影响玻璃层的局部熔化,该玻璃层可优选在激光加工波长下吸收。玻璃基材在激光加工波长下可以是初始透明的(例如至少透明50%、70%、80%或90%)。A

激光器500可具有影响密封的任何合适输出。示例性的激光器可以为UV激光器,例如但不限于355nm激光器,其处于常见显示器玻璃的透明范围中。合适的激光功率可在约1W至约10W的范围内。密封区域的宽度可以与激光光斑尺寸成比例,其可以是约0.06至2mm,例如0.06、0.1、0.2、0.5、1、1.5或2mm。激光器的平移速率(即密封速率)可以在约1mm/秒至400mm/秒或者甚至是约1mm/秒至1m/秒或更大的范围内,例如1、2、5、10、20、50、100、200或400mm/秒、600mm/秒、800mm/秒、1m/秒。激光光斑尺寸(直径)可以是约0.02至2mm。

参考图35B,可以对堆叠件100进行密封,例如使用引导到并聚焦在密封界面上、密封界面下方或密封界面上方的激光500,使得界面上的束斑直径D可以小于约2mm。例如,束斑直径可以小于约1mm,例如小于约500微米、小于约400微米、小于约300微米、或小于约200微米、小于约100微米、小于50微米、或小于20微米,包括其间的所有范围和子范围。在一些实施方式中,束斑直径D可以在约20微米至约500微米的范围内,例如约50微米至约250微米、约75微米至约200微米或约100微米至约150微米,包括其间的所有范围和子范围。Referring to Figure 35B, the

利用任何预定路径,激光500可以相对于基材进行扫描或平移,或者基材可以相对于激光平移(如箭头所示),以产生任何图案,例如正方形、矩形、圆形、卵形或任意其他合适的图案或形状,从而例如气密性或非气密性地密封装置中的一个或多个腔体。激光束(或基材)沿着界面移动的平移速度Vs可以根据应用变化并且可以取决于例如第一和第二基材的组成和/或聚焦构造以及/或者激光功率、频率和/或波长。在某些实施方式中,激光的平移速度可以在约1mm/s(毫米/秒)至约1000mm/s的范围内,例如,约10mm/s至约500mm/s、或约50mm/s至约700mm/s,例如大于约100mm/s、大于约200mm/s、大于约300mm/s、大于约400mm/s、大于约500mm/s或大于约600mm/s,包括其间的所有范围和子范围。Using any predetermined path, the

激光在单个焊接点上花费的平均时间量也被称为“停留时间”,其可以与束斑直径D和平移速度Vs相关,例如,停留时间=(D/Vs)。例如,示例性的停留时间可在约1微秒(ms)至约10ms的范围内,例如约2ms至约9ms、约3ms至约8ms、约4ms至约7ms、或约5ms至约6ms,包括其间的所有范围和子范围。The average amount of time the laser spends on a single weld spot is also referred to as the "dwell time", which can be related to the beam spot diameter D and translation velocityVs , eg, dwell time=(D/Vs ). For example, exemplary dwell times may be in the range of about 1 microsecond (ms) to about 10 ms, such as about 2 ms to about 9 ms, about 3 ms to about 8 ms, about 4 ms to about 7 ms, or about 5 ms to about 6 ms, including All scopes and subscopes in between.

激光束在密封界面处的平移速度Vs和束斑直径D可以影响激光焊接的强度、图案和/或形态。另外,脉冲激光的重复频率(rp)或连续波(CW)激光的调制速率(rm)可影响得到的激光焊接线。在某些实施方式中,脉冲激光可以某一平移速度Vs工作,根据下式(1),该平移速度Vs大于密封界面处激光束的束斑直径D乘以激光束的重复频率(rp)的乘积,所述式(1)为:The translational velocityVs and beam spot diameter D of the laser beam at the sealing interface can affect the strength, pattern and/or morphology of the laser weld. Additionally, the repetition rate (rp ) of the pulsed laser or the modulation rate (rm ) of the continuous wave (CW) laser can affect the resulting laser weld line. In some embodiments, the pulsed laser can operate at a translationspeed Vs that is greater than the beam spot diameter D of the laser beam at the sealing interface multiplied by the repetition frequency of the laser beam (r, according to the following equation (1)p ), the formula (1) is:

Vs/(D*rp)>1 (1)Vs /(D*rp )>1 (1)

类似地,调制CW激光可以某一平移速度Vs工作,根据下式(1’),该平移速度Vs大于密封界面处激光束的束斑直径D乘以激光束的调制速率(rm)的乘积,所述式(1’)为:Similarly, the modulated CW laser can work with a certain translationvelocity Vs , which is greater than the beam spot diameter D of the laser beam at the sealing interface multiplied by the modulation rate (rm ) of the laser beam according to the following equation (1') The product of , the formula (1') is:

Vs/(D*rm)>1 (1’)Vs /(D*rm )>1 (1')

当然,对于给定的平移速度,还可改变束斑直径、重复频率和/或调制速度以满足式(1)或(1’)。在这些参数下工作的激光可产生包含各个“点”的非重叠激光焊接。例如,各激光脉冲之间的时间(1/rp或1/rm)可以大于停留时间(D/Vs)。在一些实施方式中,Vs/(D*rp)或Vs/(D*rm)可在约1.05至约10的范围内,例如约1.1至约8、约1.2至约7、约1.3至约6、约1.4至约5、约1.5至约4、约1.6至约3、约1.7至约2或约1.8至约1.9,包括其间的所有范围和子范围。例如,根据本公开的各个实施方式,这种焊接图案可以用于形成非气密性密封件。Of course, for a given translation speed, the beam spot diameter, repetition frequency, and/or modulation speed can also be varied to satisfy equation (1) or (1'). A laser operating at these parameters can produce non-overlapping laser welds containing individual "dots". For example, the time between laser pulses (1/rp or 1/ rm) may be greater than the dwell time (D/Vs ). In some embodiments,Vs /(D*rp ) orVs/ (D*rm) may be in the range of about 1.05 to about 10, eg, about 1.1 to about 8, about 1.2 to about 7, about 1.3 to about 6, about 1.4 to about 5, about 1.5 to about 4, about 1.6 to about 3, about 1.7 to about 2, or about 1.8 to about 1.9, including all ranges and subranges therebetween. For example, according to various embodiments of the present disclosure, such weld patterns may be used to form non-hermetic seals.

在其他实施方式中,脉冲激光可以某一平移速度Vs工作,根据下式(2),该平移速度Vs小于或等于束斑直径D乘以重复频率(rp)的乘积,所述式(2)为:In other embodiments, the pulsed laser may operate at a translationspeed Vs that is less than or equal to the product of the beam spot diameter D times the repetition frequency (rp ) according to the following formula (2), the formula (2) is:

Vs/(D*rp)≤1 (2)Vs /(D*rp )≤1 (2)

类似地,调制CW激光可以某一平移速度Vs工作,根据下式(2’),该平移速度Vs小于或等于密封界面处激光束的束斑直径D乘以激光束的调制速度(rm)的乘积,所述式(2’)为:Similarly, the modulated CW laser can work with a certain translation speed Vs , which is less than or equal to the beam spot diameter D of the laser beam at the sealing interface multiplied by the modulationspeed of the laser beam (rm ), the formula (2') is:

Vs/(D*rm)≤1 (2’)Vs /(D*rm )≤1 (2')

当然,对于给定的平移速度,还可改变束斑直径、重复频率和/或调制速率以满足式(2)或(2’)。在所述参数下工作可形成包含连续“点”的重叠激光焊接,该连续点可接近连续线(例如当rm或rp增加到无穷大时)。例如,各激光脉冲之间的时间(1/rp或1/rm)可以小于或等于停留时间(D/Vs)。在一些实施方式中,Vs/(D*rp)或V/(D*rm)可在约0.01至约1的范围内,例如约0.05至约0.9、约0.1至约0.8、约0.2至约0.7、约0.3至约0.6或约0.4至约0.5,包括其间的所有范围和子范围。例如,根据本公开的各个实施方式,这些焊接图案可以用于形成气密性密封件。Of course, for a given translation velocity, the beam spot diameter, repetition frequency, and/or modulation rate can also be varied to satisfy equations (2) or (2'). Working under the parameters described can result in overlapping laser welds containing continuous "dots" that can approach a continuous line (eg, asrm orrp increases to infinity). For example, the time between laser pulses (1/rp or 1/ rm) may be less than or equal to the dwell time (D/Vs ). In some embodiments,Vs /(D*rp ) or V/ (D*rm) may be in the range of about 0.01 to about 1, eg, about 0.05 to about 0.9, about 0.1 to about 0.8, about 0.2 to about 0.7, about 0.3 to about 0.6, or about 0.4 to about 0.5, including all ranges and subranges therebetween. For example, according to various embodiments of the present disclosure, these weld patterns may be used to form a hermetic seal.

合适的玻璃基材在密封期间表现出显著的诱导吸收。在一些实施方式中,第一基材302可以是透明玻璃板,例如康宁股份有限公司以Eagle的商品名制造和销售的那些或其他玻璃。或者,第一基材302可以是任何的透明玻璃板,例如由以下公司制造和销售的那些:旭硝子玻璃株式会社(Asahi Glass Co.)(如AN100玻璃)、日本电气玻璃公司(Nippon Electric Glass Co.)(如OA-100玻璃或OA-21玻璃)或者康宁精密材料公司(Corning Precision Materials)。第二基材304可以是与第一玻璃基材相同的玻璃材料,或者第二基材304可以是不透明基材,例如但不限于陶瓷基材或金属基材。示例性的玻璃基材的热膨胀系数可以小于约150x10-7/℃,例如小于50x10-7/℃、20x10-7/℃或10x10-7/℃。当然,在其他实施方式中,第一基材302可以是图案化或连续形式的陶瓷、ITO、金属或其他材料基材。Suitable glass substrates exhibit significant induced absorption during sealing. In some embodiments, the

图3为本主题的另一个实施方式的图。参考图3,左上图例示了可用于对两个Eagle(EXG)玻璃基材进行激光焊接的一些示例性参数。可随着时间监控透射率(%T),并且在左下图中例示了三种不同的激光功率下的透射率。在较低激光功率曲线(最右边的曲线)中易于观察到LMG、IRA或UVA膜熔化的开始,其为“拐点”一样的拐折,随后是玻璃基材的迅速吸收和加热,这是由于玻璃的高的局部温度超过了Eagle的应变点所致。在较高的激光功率下可消除拐折(最左边的曲线)并且可诱导从LMG、IRA或UVA吸收到玻璃熔合的无缝过渡。示例性的激光焊接可包括沿着待结合的界面边界扫掠该区。右下角所示的列表中描述了三个条件并在下文进行具体描述,例如,在入射波长下低熔点膜吸收/熔化,在玻璃中形成色心和/或在一些实施方式中在玻璃中发生温度诱导的吸收。单独的膜的吸收已经足够了,而不会影响色心形成或者甚至是温度吸收效果。应注意,图3中标示的事件顺序应不限制本文所附的权利要求书的范围或表示列出的其他事件的相对重要性。Figure 3 is a diagram of another embodiment of the subject matter. Referring to Figure 3, the upper left diagram illustrates the (EXG) Some exemplary parameters for laser welding of glass substrates. Transmission (%T) can be monitored over time and is illustrated in the lower left graph at three different laser powers. The onset of melting of the LMG, IRA or UVA film is easily observed in the lower laser power curve (the rightmost curve) as a "knee"-like inflection followed by rapid absorption and heating of the glass substrate due to The high local temperature of the glass exceeds that of the Eagle caused by the strain point. At higher laser power the inflection (leftmost curve) can be eliminated and a seamless transition from LMG, IRA or UVA absorption to glass fusion can be induced. Exemplary laser welding may include sweeping the region along the boundary of the interface to be bonded. Three conditions are described in the list shown in the lower right corner and described in detail below, eg, absorption/melting of low melting point films at incident wavelengths, formation of color centers in glass and/or occurrence of in glass in some embodiments temperature-induced absorption. The absorption of the film alone is sufficient without affecting the color center formation or even the temperature absorption effect. It should be noted that the order of events identified in Figure 3 should not limit the scope of the claims appended hereto or represent the relative importance of other listed events.

在一些实施方式中,起始事件可以是低熔点玻璃(例如LMG或UVA)膜的UV激光吸收。这可以是基于薄膜在355nm下比Eagle具有更大的吸收,以及基于图3的熔化曲线。考虑图3的左上部分例示的实验布置,所述激光为Spectra Physics HIPPO 355nm,其以30kHz产生8-10ns脉冲,平均功率高至6.5瓦特。将激光束聚焦成500微米直径的束腰,监视透射的光束并进行取样,得到不同激光功率(5.0W、5.5W、6.0W)的透射百分比(%T)随着时间的图。图3的左下部分示出了这些图。在较低激光功率下(底部和中间曲线),在图3中易于观察到UVA、IRA或LMG膜熔化的开始,其为拐点一样的拐折,随后是玻璃基材的迅速吸收和加热,这是由于玻璃的高的局部温度超过了Eagle的应变点所致。正进行焊接的玻璃部分可能未熔化而仅是软化,因此当它们与适度施加的力紧密接触时,它们变得柔曲。该性质可以类似于固相扩散结合,尤其是就能够在基材的熔化温度的50-80%之间下形成强结合而言。固相结合的双折射的光学截面图例示了正在被焊接的两个部分之间的明显的界面线(例如参见图4)。In some embodiments, the initiating event may be UV laser absorption of a low melting glass (eg, LMG or UVA) film. This can be based on thin films at 355nm than Eagle with greater absorption, and melting curves based on Figure 3. Considering the experimental setup illustrated in the upper left part of Figure 3, the laser is a Spectra Physics HIPPO 355nm which produces 8-10ns pulses at 30kHz with average powers up to 6.5 watts. The laser beam was focused to a 500 micron diameter beam waist, and the transmitted beam was monitored and sampled to obtain a plot of percent transmission (%T) versus time for different laser powers (5.0W, 5.5W, 6.0W). These figures are shown in the lower left part of FIG. 3 . At lower laser powers (bottom and middle curves), the onset of melting of UVA, IRA or LMG films is easily observed in Figure 3, which is an inflection point like inflection, followed by rapid absorption and heating of the glass substrate, which is due to the high local temperature of the glass exceeding the Eagle caused by the strain point. The parts of the glass being welded may not melt but only soften, so when they are brought into intimate contact with moderately applied forces, they become flexed. This property may be similar to solid state diffusion bonding, especially in terms of being able to form strong bonds between 50-80% of the melting temperature of the substrate. An optical cross-sectional view of solid-phase bound birefringence illustrates a distinct interface line between the two parts being welded (see, eg, Figure 4).

另一个实施方式包括用355nm脉冲激光进行的焊接,从而以1MHz、2MHz或5MHz重复频率产生一系列1ns脉冲。当将无机膜上的光束聚焦成直径在0.02mm至0.15mm之间的光斑并且焊接速度在50mm/s至400mm/s的范围内时,形成了约60μm至约200μm的无缺陷的结合线。所需的激光功率可在约1W至约10W的范围内。Another embodiment includes welding with a 355 nm pulsed laser to generate a series of 1 ns pulses at a repetition rate of 1 MHz, 2 MHz, or 5 MHz. When the light beam on the inorganic film was focused into a spot with a diameter between 0.02 mm and 0.15 mm and the welding speed was in the range of 50 mm/s to 400 mm/s, defect-free bond lines of about 60 μm to about 200 μm were formed. The required laser power may range from about 1W to about 10W.

参考图4,该图例示了用于估计激光焊接结合区的物理范围的实验布置。继续参考图4,如前所述激光焊接两片Eagle片,将其安装在玻璃夹层结构中并用金刚石锯切割。这例示于图4的左图中。将得到的截面安装在偏振计中以测量由局部应力区域产生的光学双折射。这在图4的右图中示出。在该右图中较亮的区域表示更大的应力。如图4的右图所示,结合区域表现出具有约50微米的物理范围。另外,虽然未出现任何的基底或基材玻璃熔化,但是在两个玻璃基材之间形成的结合却非常强。例如,双折射图像截面的中心中的图示出了固相结合区域延伸深入到Eagle基材中(50微米),这表明了高的密封强度。激光焊接将包括沿着待结合的界面边界扫掠该区。Referring to Figure 4, this figure illustrates an experimental setup for estimating the physical extent of a laser welded bond. Continuing to refer to Figure 4, two pieces of Eagle are laser welded as previously described pieces, mounted in a glass sandwich and cut with a diamond saw. This example is shown in the left panel of FIG. 4 . The resulting sections were mounted in a polarimeter to measure the optical birefringence resulting from the localized stress region. This is shown in the right panel of FIG. 4 . Brighter areas in the right graph indicate greater stress. As shown in the right panel of Figure 4, the bonding area appears to have a physical extent of about 50 microns. Additionally, although no base or substrate glass melting occurred, the bond formed between the two glass substrates was very strong. For example, the figure in the center of the birefringence image section shows that the solid phase bound region extends deep into the Eagle in the substrate (50 microns), which indicates a high seal strength. Laser welding will involve sweeping the region along the boundary of the interface to be bonded.

图5是断裂样品的显微图像。参考图5,所示的断裂样品的三维共聚焦显微图像说明本公开的实施方式的密封强度足够地强,使得通过撕开下面的基材(例如Eagle基材)材料深达44μm才发生失效(即内聚破坏)。样品未进行过退火。图5还例示了经受剃须刀片裂纹打开技术的未退火的激光焊接实施方式的断裂样品。进行一系列三维共聚焦测量,并且在图5的右侧示出代表性实例。这些共聚焦图像的一个特征显示出界面密封强度可以足够地强,使得在大部分基材材料内的失效发生在例如,在所述情况中远离界面深达44μm,并在其他实验中深达约200μm。在另外的实验中,偏振计测量显示了新形成的激光焊接(与图5中研究的条件相同)中产生的残余应力,将新形成的激光焊接在600℃下退火1小时,得到的牢固结合通过偏振测量表现出没有可测量的应力。试图破坏这种结合,结果导致除焊接基材的密封线外,其余地方均破裂。Figure 5 is a microscopic image of a fractured sample. Referring to Figure 5, the three-dimensional confocal microscopic image of the fractured sample shown illustrates that the seal strength of embodiments of the present disclosure is sufficiently strong that by tearing apart the underlying substrate (eg, Eagle Substrate) materials up to 44 μm deep before failure (ie, cohesive failure). The samples were not annealed. Figure 5 also illustrates a fractured sample of an unannealed laser welded embodiment subjected to a razor blade crack opening technique. A series of three-dimensional confocal measurements were performed and a representative example is shown on the right side of Figure 5. One feature of these confocal images shows that the interface seal strength can be strong enough that failure within most substrate materials occurs, for example, as deep as 44 μm away from the interface in the described case, and as deep as approx. 200μm. In additional experiments, polarimeter measurements revealed residual stresses developed in newly formed laser welds (same conditions as studied in Figure 5), which were annealed at 600°C for 1 hour, resulting in strong bonds No measurable stress was shown by polarization measurements. Attempts to break this bond resulted in cracks in all but the sealing line where the substrate was welded.

如在图3中注意到的,使用本公开的实施方式,利用示例性的低熔点膜或在入射波长下吸收/熔化的另一种膜,在膜和玻璃中形成色心以及在膜和玻璃中发生温度诱导的吸收可实现强的、气密性的透明结合。关于第一个判据,例如低熔点玻璃吸收事件,具有足够高的每单位面积功率的玻璃-LMG/UVA-玻璃结构的激光照射可以在溅射的薄膜LMG/UVA界面中引发吸收,从而引起熔化。图3左下角的底部曲线中易于观察到这一情况。底部曲线的第一斜坡跟踪LMG/UVA熔化过程约15秒,此时发生另一个过程,这一过程是相应基材中的玻璃-激光相互作用(即,色心形成)。在约17秒后,该中间向下曲线的大曲率能够表明由于玻璃中形成色心而发生了大的吸收。这些色心一般可根据基材中的元素杂质含量变化而变化,所述元素杂质例如As、Fe、Ga、K、Mn、Na、P、Sb、Ti、Zn、Sn等。透射曲线越弯曲,则形成的色心越多。这是在图3中提到的第二个判据。LMG/UVA膜的熔点可以为,但不限于约450℃,但是基于使用替代的涂覆有铝的EXG玻璃基材在类似的激光焊接条件下所进行的激光照射实验的观察情况,界面温度可能高于660℃。在该实验中,铝熔化(熔化温度:660℃),并且使用经过校准的热成像摄像机(FLIR摄像机)测量到使用激光焊接条件的表面温度为约250℃。As noted in FIG. 3 , using embodiments of the present disclosure, color centers are formed in films and glasses using an exemplary low melting point film or another film that absorbs/melts at incident wavelengths and in films and glasses. The temperature-induced absorption that occurs in the medium enables a strong, gas-tight transparent bond. Regarding the first criterion, such as low melting glass absorption events, laser irradiation of glass-LMG/UVA-glass structures with sufficiently high power per unit area can induce absorption in the sputtered thin-film LMG/UVA interface, thereby causing melt. This is easily observed in the bottom curve in the lower left corner of Figure 3. The first slope of the bottom curve traces the LMG/UVA melting process for about 15 seconds, at which point another process occurs, which is the glass-laser interaction (ie, color center formation) in the corresponding substrate. After about 17 seconds, the large curvature of the middle downward curve can indicate a large absorption due to the formation of color centers in the glass. These color centers can generally vary depending on the content of elemental impurities in the substrate, such as As, Fe, Ga, K, Mn, Na, P, Sb, Ti, Zn, Sn, and the like. The more curved the transmission curve, the more color centers are formed. This is the second criterion mentioned in Figure 3. The melting point of the LMG/UVA film may be, but is not limited to, about 450°C, but based on observations from laser irradiation experiments using an alternative aluminum-coated EXG glass substrate under similar laser welding conditions, the interface temperature may be higher than 660°C. In this experiment, aluminum was melted (melting temperature: 660°C), and the surface temperature using laser welding conditions was measured to be about 250°C using a calibrated thermal imaging camera (FLIR camera).

图6是根据本公开的一些实施方式所述的建模方案示意图。参考图6,利用LMG/UVA和EXG材料的热传输特性来模拟355nm激光以0.8–3kW/cm2撞击包含1μm薄无机膜+700μmEXG的两层堆叠件。在模型中未考虑无机薄膜(例如,LMG、IRA、UVA膜等)中的相变。继续参考图6,瞬态热分布的估计表明可获得大于660℃的界面温度。无论是否达到了高于660℃的确切的界面温度,热熔化的LMG/UVA界面膜的存在通过将能带隙转移到较低能量而增加了玻璃基材中的吸收。这些带隙改变一般应理解为是由于基材晶格的热膨胀所致,其与电子能的改变有关,以及与由于电子-光子相互作用引起的带能量直接重整化有关。图3的右下角示出了熔合二氧化硅中的这一性质的图。净效果是热的LMG/UVA膜通过降低带隙而在界面附近的EXG基材中促使了更多的吸收,这进而从内部转换过程产生了更多的热量,甚至使带隙进一步降低。这一过程可以统称为热诱导吸收,其表示图3指示的第三个判据。当然,在这些实施方式中可以使用其他无机膜,并且这些实例不应限制所附权利要求书的范围。6 is a schematic diagram of a modeling scheme according to some embodiments of the present disclosure. Referring to Figure 6, the thermal transport properties of LMG/UVA and EXG materials were used to simulate a 355 nm laser striking atwo -layer stack containing 1 μm thin inorganic film + 700 μm EXG at 0.8–3 kW/cm. Phase transitions in inorganic thin films (eg, LMG, IRA, UVA films, etc.) are not considered in the model. With continued reference to Figure 6, an estimate of the transient thermal distribution indicates that an interface temperature greater than 660°C can be obtained. Whether or not the exact interfacial temperature above 660°C is reached, the presence of the thermally melted LMG/UVA interfacial film increases absorption in the glass substrate by shifting the energy bandgap to lower energies. These bandgap changes are generally understood to be due to thermal expansion of the substrate lattice, which is related to changes in electron energy, as well as to direct renormalization of the band energy due to electron-photon interactions. A graph of this property in fused silica is shown in the lower right corner of FIG. 3 . The net effect is that the hot LMG/UVA film induces more absorption in the EXG substrate near the interface by lowering the bandgap, which in turn generates more heat from the internal conversion process and even lowers the bandgap further. This process can be collectively referred to as thermally induced absorption, which represents the third criterion indicated in FIG. 3 . Of course, other inorganic membranes may be used in these embodiments, and these examples should not limit the scope of the appended claims.

如上所述,色心形成在本公开实施方式的激光焊接形成中起到重要作用。使用图8所示的实验布置在图7中例示了在非多光子条件下对基本色心形成过程建模以基于三能级图(three level diagram)导出拟合函数。图7是根据本公开的实施方式所述的另一个建模方案。在图7的左图中,玻璃的三个电子带态吸收355nm光子,在基态ng[t]、导带ne[t]和色心ncc[t]中累积或消耗布居数(population)。应注意的是,单头箭头表示激光吸收,而双头箭头表示受激吸收和发射。在图7的右图中,提供了速率方程,其预测电子能级布居的平滑单调累积和消耗,而系统的相干驱动部分表现出相同布居的快速振荡图7的右图的最下行提供了三个能级的初始条件。图8是通过Eagle 0.7mm玻璃基材的355nm激光透射率(%T)用于%T相对于时间测量的实验布置图。参考图8,特征封装(diagnosticpackaging)可以在通过熔合二氧化硅窗口和Eagle玻璃片之后测量UV脉冲的积分能量和时间波形,其中平均功率为约5至6W。As described above, color center formation plays an important role in the laser welding formation of embodiments of the present disclosure. Modeling the fundamental color center formation process under non-multiphoton conditions to derive a fitting function based on a three level diagram is exemplified in FIG. 7 using the experimental arrangement shown in FIG. 8 . FIG. 7 is another modeling scheme according to an embodiment of the present disclosure. In the left panel of Figure 7, the three electronic bandstates of the glass absorb355 nm photons, accumulating ordepleting the population ( population). It should be noted that single-headed arrows indicate laser absorption, while double-headed arrows indicate stimulated absorption and emission. In the right panel of Figure 7, rate equations are provided that predict smooth monotonic accumulation and depletion of the electron energy level population, while the coherently driven part of the system exhibits fast oscillations of the same population The bottom row of the right panel of Figure 7 provides the initial conditions for the three energy levels. 8 is a graph of the experimental setup for %T versus time measurement of 355 nm laser transmittance (%T) through Eagle 0.7 mm glass substrates. Referring to Figure 8, diagnostic packaging can be performed by fusing silica windows and Eagle The integrated energy and time waveforms of the UV pulses were measured after the glass sheet, with an average power of about 5 to 6 W.

下面的方程(1)描述了实验可观察到的吸光度(Abs)与时间的关系,例如,与透射率(trans)对时间数据的关系有关:(1≈Abs+Trans)。解可以是上升和衰减指数的总和,但可以简化为以下表达式:Equation (1) below describes the experimentally observable absorbance (Abs) versus time, eg, transmittance (trans) versus time data: (1≈Abs+Trans). The solution can be the sum of the rising and decaying exponents, but can be simplified to the following expression:

其中α表示线性吸收系数(cm-1),I表示激光通量(光子/cm2·秒),σg表示基态吸收截面(cm2),σesa(σ激发)表示激发态吸收截面(cm2),σcc表示色心(color-enter)吸收截面(cm2),kec表示瞬态色心率,并且kf表示荧光衰减率。参考方程(1)和图8,可观察到色心形成在本公开实施方式中的作用。图9是根据本公开的一个实施方式所述的图。参考图9,对于某些非限制性激光-玻璃相互作用参数,在存在色心形成的情况下提供等式(1)的图(图示的弧线),以及在不存在色心形成的情况下提供等式(1)的图(图示的直线),所述激光-玻璃相互作用参数为α=0.01cm-1,I=4.6·10-21光子/cm2·秒,σg=1.20·10-17cm2,σesa=1.21·10-17cm2,σcc=2.20·10-13cm2,kec≈kf≈1.0·107秒-1。设置σcc=0,可以进行线性相关。然后通过以下关系:%透射率=100-%吸光度的关系得到%透射率。如图9所例示,由此可见,使用合理选择的参数值,简单地将色心形成项归零(即,设置σcc=0)将弧线变换为直线。实验用激光焊接玻璃基材通常表现出这种曲率,所述玻璃基材包括但不限于EagleLotusWillow、以及Willow与Willow、Willow与Lotus和Willow与Eagle的组合。where α represents the linear absorption coefficient (cm-1 ), I represents the laser flux (photons/cm2 ·sec), σg represents the ground-state absorption cross-section (cm2 ), and σesa (σexcitation ) represents the excited-state absorption cross-section (cm 2 ). ), σcc represents the color-enter absorption cross section (cm2 ), kec represents the transient color heart rate, and kf represents the fluorescence decay rate. Referring to equation (1) and FIG. 8, the role of color center formation in embodiments of the present disclosure can be observed. FIG. 9 is a diagram according to one embodiment of the present disclosure. Referring to Figure 9, for some non-limiting laser-glass interaction parameters, a plot of equation (1) (illustrated arc) is provided in the presence of color center formation, and in the absence of color center formation A plot of equation (1) (illustrated line) is provided below with the laser-glass interaction parameters α = 0.01 cm−1 , I = 4.6·10−21 photons/cm2 ·sec, σg = 1.20 · 10−17 cm2 , σesa =1.21·10−17 cm2 , σcc =2.20·10−13 cm2 , kec ≈kf≈1.0·107 sec−1 . Setting σcc =0, a linear correlation can be performed. The % transmittance is then obtained by the relationship: % transmittance = 100-% absorbance. As illustrated in Figure 9, it can be seen that, using reasonably chosen parameter values, simply zeroing the color center forming term (ie, setting σcc =0) transforms the arc into a straight line. This curvature is typically exhibited by experimental laser-welded glass substrates, including but not limited to Eagle Lotus Willow, and a combination of Willow and Willow, Willow and Lotus, and Willow and Eagle.

图10提供了分析在玻璃界面处,从示例性LMG膜层进入到Eagle玻璃基材中的扩散的图。参考图10,利用TOF-SIMS分析在合适的激光焊接条件下,在玻璃界面处从LMG膜层可能进入到Eagle玻璃基材的扩散,所述LMG膜层具有示例性的非限制性组成(38%SnO、40%SnF2、20%P2O5、2%Nb2O5)并且厚度为约0.8μm。在原始界面上方(a、b)和经过激光焊接的界面上方(c,d)的F和Sn线扫描表明离开界面的扩散程度很小,而氟从界面迁移大约0.5微米,平均而言,锡没有显著移动。因此,虽然图10似乎表明缺少显著的LMG材料扩散到示例性基材中,但是对无机膜与基材之间的互混程度进行进一步的努力研究和量化确认了各种无机膜元素迁移到了基材中,并且基材元素进入到了无机膜中(例如参见图38A-38C和39A-39C,下文有更详细地论述)。Figure 10 provides analysis at the glass interface from an exemplary LMG film layer into Eagle Diagram of diffusion in a glass substrate. Referring to Figure 10, using TOF-SIMS analysis, under suitable laser welding conditions, it is possible to enter the Eagle from the LMG film layer at the glass interface Diffusion of glass substrates, the LMG film layer has an exemplary, non-limiting composition (38% SnO, 40%SnF2 , 20%P2O5 ,2 %Nb2O5) and a thickness of about 0.8 [mu]m. Line scans of F and Sn above the pristine interface (a, b) and above the laser welded interface (c, d) show little diffusion away from the interface, while fluorine migrates from the interface by about 0.5 microns, and on average, tin No significant movement. Thus, while Figure 10 appears to indicate a lack of significant LMG material diffusion into the exemplary substrates, further efforts to investigate and quantify the degree of intermixing between the inorganic film and the substrate confirmed that various inorganic film elements migrated to the substrate. and the substrate elements into the inorganic film (see, eg, FIGS. 38A-38C and 39A-39C, discussed in more detail below).

图35C示出了密封装置200的截面图(例如沿着图35B中的线C截取)。如图所示,可以在密封之后形成焊接区域250,该焊接区域从第一基材210中的第一深度d1延伸到第二基材220中的第二深度d2。不希望囿于理论,认为焊接区域250可以表示组成与第一和第二基材210、220中的任一者和/或无机膜230不相同的区域。例如,由于基材和/或膜的粘弹性膨胀或溶胀,来自每层的各种元素可以从它们各自的各个层迁移出并进入到焊接区域250中,如关于图38A-C更详细地讨论的。例如,无机膜230可以包括一种或多种无机膜元素,例如F、P、Sn、B、Bi、Zn、Ti、W、Ce、Nb、Pb、Fe、Va、Cr、Mn、Mg或Ge,它们可以存在或不存在于第一和/或第二基材210、220中。同样地,第一和/或第二基材210、220可以包括一种或多种无机基材元素,例如Al、B、Si、Na、Li、K、Mg、Ca或Ba,它们可以存在或不存在于无机膜230中。这些膜和基材元素的迁移和混合可以产生化学组成与各个层不同的焊接区域。Figure 35C shows a cross-sectional view of the sealing device 200 (eg, taken along line C in Figure 35B). As shown, a

例如,在一些实施方式中,在激光密封期间,基材和/或无机膜可能由于吸收激光能而膨胀和变形,并且由于这种吸收而产生局部加热。热膨胀可以使一种或多种无机膜和基材元素迁移(不同于扩散),从而形成化学组成与各个部件不同的焊接区域250,所述化学组成例如来自第一基材210、无机膜230和/或第二基材220的元素混合物。焊接区域250可以存在于密封装置的焊接部分W中,例如,激光束入射在密封界面上的地方,从而在两个基材之间形成结合。焊接部分W可以构成连续的单条线,或者在其他实施方式中,一个或多个焊接部分W可以被非焊接部分I分开(例如,如图35C所示)。For example, in some embodiments, during laser sealing, the substrate and/or inorganic film may expand and deform due to absorption of laser energy and localized heating due to this absorption. Thermal expansion can migrate (as opposed to diffusion) one or more of the inorganic film and substrate elements to form a

根据各个实施方式,无机膜和基材元素迁移进和迁移出密封界面可以产生厚度tW大于无机膜的初始厚度的焊接区域250。例如,一个或多个膜元素可以在任一侧上从无机膜迁移到深度d1或d2,从而形成厚度tW=ti+d1+d2的焊接区域250,其中ti是无机膜厚度(未标记)。在该区域中,焊接区域的化学组成可以与无机膜和第一或第二基材不同,例如,由于一种或多种膜元素迁移到基材中和/或一种或多种基材元素迁移到无机膜中所致。根据各个实施方式,深度d1和d2可以相同或不同,并且例如,可以为约0.1μm至约2μm,例如约0.2μm至约1.8μm、约0.3μm至约1.6μm、约0.4μm至约1.5μm、约0.5μm至约1.4μm、约0.6μm至约1.2μm、或约0.8μm至约1μm,包括其间的所有范围和子范围。焊接区域250的厚度tW可以类似地变化,这取决于无机膜130的初始厚度以及膜和/或基材元素的迁移程度(例如,d1和d2的量值)。示例性的焊接厚度tW可包括但不限于0.3μm至约14μm,例如约0.5μm至约12μm、约0.8μm至约10μm、约1μm至约8μm、约2μm至约7μm、约3μm至约6μm或约4μm至约5μm,包括其间的所有范围和子范围。According to various embodiments, migration of the inorganic film and substrate elements into and out of the sealing interface can result in a

在一些实施方式中,焊接区域250的化学组成可以与非焊接部分I中的无机膜230和/或第一或第二基材210、220的化学组成不同。例如,焊接区域250可以具有第一无机基材元素浓度,其大于非焊接部分I中(例如参见区域Ii)无机膜230中的第二无机基材元素浓度。在其他实施方式中,焊接区域250可以具有第一无机膜元素浓度,其大于非焊接部分I中(例如参见区域S1i和S2i)的第一和/或第二基材210、220中的第二无机膜元素浓度。根据另外的实施方式,焊接区域250可以具有第一无机膜元素浓度,其大于焊接部分W中,但落在焊接区域250外(例如参见区域S1和S2)的第一和/或第二基材210、220中的第三无机膜元素浓度。在另外的实施方式中,焊接区域250中的第一和/或第二基材的一部分(例如参见区域S1W和S2W)可以具有第四无机膜元素浓度,其大于非焊接的I和/或焊接的W部分中(例如参见区域S1i和S2i和/或S1和S2)的第一和/或第二基材中的第二和/或第三无机膜元素浓度。In some embodiments, the chemical composition of the

图36A-B是分别是在激光焊接之前和之后的密封界面的SEM图像。在所示的实施方式中,第一和第二基材210、220包括EAGLE玻璃,并且无机膜230包括LMG。在图36A中(焊接前),无机膜230的厚度为1.05μm,而在图36B中(焊接后),焊接区域250的厚度为2.80μm。在图36B中明显看到基材和膜的粘弹性膨胀或溶胀,以及这些层的互混而形成焊接区域250。焊接区域中(例如参见区域S1W和S2W)的第一和/或第二基材的部分的化学组成可以与图36A(焊接前)中的基材210、220的不同。例如,来自膜230的一种或多种无机膜元素可以迁移到焊接区域250中的基材中。类似地,焊接区域250的化学组成可以与图36A(焊接前)中的无机膜230中的化学组成不同。例如,来自基材210和/或220的一种或多种无机基材元素可以迁移到焊接区域250中。36A-B are SEM images of the sealed interface before and after laser welding, respectively. In the embodiment shown, the first and

例如,取决于所用的材料和激光加工参数,上述区域各自之间的浓度差异可独自变化,并且在一些实施方式中,可在约5摩尔%至约80摩尔%的范围内,例如约10摩尔%至约75摩尔%、约15摩尔%至约70摩尔%、约20摩尔%至约65摩尔%、约25摩尔%至约60摩尔%、约30摩尔%至约55摩尔%、约35摩尔%至约50摩尔%、或约40摩尔%至约45摩尔%,包括其间的所有范围和子范围。在一些实施方式中,第一膜元素浓度可以比第二膜元素浓度高至少约5摩尔%(例如高至少约10、20、30、40、50、60、70或80摩尔%),并且/或者第一基材元素浓度可以比第二基材元素浓度高至少约30摩尔%(例如高至少约40、50、60、70或80摩尔%)。可以以本领域已知的各种方式测量这种组成差异,举例而言,例如二次离子束质谱(SIMS)、元素探针显微镜分析(EPMA)和过渡电子显微技术(TEM)。For example, depending on the materials used and laser processing parameters, the difference in concentration between each of the above regions can vary independently, and in some embodiments can range from about 5 mol % to about 80 mol %, such as about 10 mol % % to about 75 mol %, about 15 mol % to about 70 mol %, about 20 mol % to about 65 mol %, about 25 mol % to about 60 mol %, about 30 mol % to about 55 mol %, about 35 mol % % to about 50 mol %, or about 40 mol % to about 45 mol %, including all ranges and subranges therebetween. In some embodiments, the first film element concentration may be at least about 5 mole percent higher (eg, at least about 10, 20, 30, 40, 50, 60, 70, or 80 mole percent higher) than the second film element concentration, and/ Alternatively, the first substrate element concentration may be at least about 30 mole percent higher (eg, at least about 40, 50, 60, 70, or 80 mole percent higher) than the second substrate element concentration. Such compositional differences can be measured in various ways known in the art, such as, for example, secondary ion beam mass spectrometry (SIMS), elemental probe microscopy (EPMA), and transitional electron microscopy (TEM).

在密封期间或之后,还可以在装置中形成应力区域或热影响区域(HAZ)260,该应力区域从第一基材210中的第三深度d3延伸到第二基材220中的第四深度d4。如图35C所示,应力区域260可以涵盖或包括焊接区域250以及周围的区域(例如,区域S1S和S2S)。由此,焊接区域250外的第一和/或第二基材的部分仍然可以落入应力区域260内,无论是在装置的焊接的W部分还是非焊接的I部分中。在一些实施方式中,应力区域260的厚度tS可在几十微米至几百微米的范围内,例如,约20μm至约500μm,例如约30μm至约400μm、约40μm至约300μm、约50μm至约200μm、约60μm至约150μm、约70μm至约120μm、或者约80μm至约100μm,包括其间的所有范围和子范围。根据另外的实施方式,深度d3和d4可以相同或不同。During or after sealing, a stress zone or heat affected zone (HAZ) 260 may also be formed in the device, the stress zone extending from a third depth d3 in the

不希望囿于理论,但认为区域260中的残余应力可能因在焊接区域中或附近有激光暴露,使得基材迅速加热和冷却而存在。虽然激光可以在密封界面处聚焦于特定束斑直径,但是来自激光的热量可以散发并影响更大部分的密封装置,该更大部分延伸超过焊接区域250,例如,大到焊接区域外几十或几百微米。例如,取决于焊接温度和激光的停留时间,应力区域的尺寸可以变化。但是,即使是在高的平移速度下(例如停留时间<2-3ms),热扩散(1.4x10-6m2/s)可导致应力区大到几十微米。可以影响应力区的其他因素可包括由于玻璃基材中的色心吸收和/或玻璃的UV边缘位移而导致的基材的直接加热。Without wishing to be bound by theory, it is believed that residual stress in

在一些实施方式中,区域260中的应力可以与区域260外的密封装置中的应力不同。例如,区域260中(例如参见区域S1S)的一部分第一基材210可以具有第一应力,其大于区域260外(例如参见区域S1)的第一基材210中的第二应力。在其他实施方式中,区域260中(例如参见区域S2S)的一部分第二基材220可以具有第三应力,其大于区域260外(例如参见区域S2)的第二基材220中的第四应力。虽然在图36A-36B的SEM图像中不易见到具有可变应力的这些区域,但是每个区域的应力可使用下述任意方法进行定量和比较。In some embodiments, the stress in the

例如,取决于所用的材料和激光加工参数,上述区域各自之间的应力差异可独立变化,并且在一些实施方式中可在约1MPa至约25MPa或更高的范围内,例如约2MPa至约20MPa、约3MPa至约15MPa、约4MPa至约10MPa、约5MPa至约8MPa、或约6MPa至约7MPa,包括其间的所有范围和子范围。根据另外的实施方式,区域260中的应力相对于区域260外的应力的比值可以在约1.1:1至约25:1的范围内,例如约1.2:1至约20:1、约1.3:1至约15:1、约1.4:1至约10:1、约1.5:1至约9:1、约1.6:1至约8:1、约1.7:1至约7:1、约1.8:1至约6:1、约1.9:1至约5:1、约2:1至约4:1、或约2.5:1至约3:1,包括其间的所有范围和子范围。For example, depending on the material used and the laser processing parameters, the stress difference between each of the above regions can vary independently, and in some embodiments can range from about 1 MPa to about 25 MPa or higher, such as about 2 MPa to about 20 MPa , about 3 MPa to about 15 MPa, about 4 MPa to about 10 MPa, about 5 MPa to about 8 MPa, or about 6 MPa to about 7 MPa, including all ranges and subranges therebetween. According to further embodiments, the ratio of the stress in the

这些区域中的应力可通过各种技术来测量和/或估算,包括但不限于应力双折射(应力测试)、拉曼光谱法(假想温度和应力的变化)、布里渊(Brilluoin)光谱法(假想温度和应力的变化)、折射率测量(由于假想温度和应力引起的折射率变化)、偏振显微技术和/或热容量测量。根据各个实施方式,如果需要,在密封后,可以使密封装置进行一步或多步随后的退火步骤以降低和/或估算区域260中的应力。Stress in these regions can be measured and/or estimated by a variety of techniques including, but not limited to, stress birefringence (stress testing), Raman spectroscopy (change in hypothetical temperature and stress), Brilluoin spectroscopy (change in hypothetical temperature and stress), refractive index measurement (change in refractive index due to hypothetical temperature and stress), polarization microscopy and/or heat capacity measurement. According to various embodiments, after sealing, the sealing device may be subjected to one or more subsequent annealing steps to reduce and/or estimate stress in

虽然基于界面各材料之间明显大的CTE错配——CTE870CHM=18ppm/℃相比于CTEEXG=3.1ppm/℃,可能预计本公开实施方式中使用的可移动的原子物质具有显著更大的扩散,但是并没有观察到剥离。相反,反复循环高达600℃的温度似乎消除了任何残余应力,从而产生更强的结合。得到的无机薄膜足够地薄,使得由于各个玻璃基材的CTE错配导致的剥离力远小于结合力。这符合来自粘合膜沉积应力的层压结构复合应力与膜厚度的立方成比例的知识。Although based on the significantly larger CTE mismatch between the materials at the interface - CTE870CHM = 18 ppm/°C compared to CTEEXG = 3.1 ppm/°C, it may be expected that the mobile atomic species used in embodiments of the present disclosure have significantly larger diffusion, but no peeling was observed. Conversely, repeated cycling of temperatures up to 600°C appears to remove any residual stress, resulting in a stronger bond. The resulting inorganic films are thin enough that the peel force due to the CTE mismatch of the individual glass substrates is much smaller than the bond force. This is consistent with the knowledge that the composite stress of the laminate structure from the deposition stress of the adhesive film is proportional to the cube of the film thickness.

图11是在不同厚度的玻璃片之间的激光焊接性能的示意图。参考图11,发现将超薄Willow玻璃(0.1mm)焊接到Eagle玻璃(0.7mm),即“不对称”的情况,可得到质量差的焊接。在“对称的”Eagle与Eagle情况中(图11的左侧),沿着玻璃界面扫掠热的热区以进行优异的焊接。在每个示图下方例示了相应的温度分布。然而,当使用不同厚度的玻璃片时,出现了不对称的热区,在一些情况下,例如当焊接Willow与Eagle时,会导致质量差的焊接(图11的中间示图)。然而,示例性实施方式可提供这种不对称焊接问题的解决方案,其在图11的右侧示出,其中使用导热板可以消散任何热并冷却薄玻璃片以有效地恢复热的热区而形成牢固的焊接结合。因此,本文所述的一些实施方式可利用导热板的用处来对厚度不同的玻璃片进行激光焊接。Figure 11 is a graphical representation of laser welding performance between glass sheets of different thicknesses. Referring to Figure 11, it was found that the ultra-thin Willow glass (0.1mm) was soldered to the Eagle Glass (0.7mm), the "asymmetric" case, can give poor quality welds. In the "symmetric" Eagle and Eagle case (left side of Figure 11), the hot hot zone is swept along the glass interface for excellent welding. The corresponding temperature distributions are illustrated below each graph. However, when glass sheets of different thicknesses were used, asymmetrical hot zones appeared, which in some cases, such as when welding Willow and Eagle, resulted in poor quality welds (middle panel of Figure 11). However, exemplary embodiments may provide a solution to this asymmetric welding problem, shown on the right side of Figure 11, where the use of thermally conductive plates can dissipate any heat and cool the thin glass sheet to effectively restore the hot hot zone while Forms a strong welded bond. Accordingly, some embodiments described herein may utilize the use of thermally conductive plates to laser weld glass sheets of varying thicknesses.