CN108587447B - A kind of preparation method of durable transparent superhydrophobic coating suitable for various substrates - Google Patents

A kind of preparation method of durable transparent superhydrophobic coating suitable for various substratesDownload PDFInfo

- Publication number

- CN108587447B CN108587447BCN201810209419.6ACN201810209419ACN108587447BCN 108587447 BCN108587447 BCN 108587447BCN 201810209419 ACN201810209419 ACN 201810209419ACN 108587447 BCN108587447 BCN 108587447B

- Authority

- CN

- China

- Prior art keywords

- sio

- preparation

- hydrophobic coating

- super

- transparent super

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000576coating methodMethods0.000titleclaimsabstractdescription83

- 230000003075superhydrophobic effectEffects0.000titleclaimsabstractdescription73

- 239000011248coating agentSubstances0.000titleclaimsabstractdescription72

- 239000000758substrateSubstances0.000titleclaimsabstractdescription54

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription21

- 229910004298SiO 2Inorganic materials0.000claimsabstractdescription53

- 239000002904solventSubstances0.000claimsabstractdescription44

- 239000000843powderSubstances0.000claimsabstractdescription34

- 239000002245particleSubstances0.000claimsabstractdescription24

- 239000006087Silane Coupling AgentSubstances0.000claimsabstractdescription22

- 239000002243precursorSubstances0.000claimsabstractdescription20

- 150000001335aliphatic alkanesChemical class0.000claimsabstractdescription19

- 238000000034methodMethods0.000claimsabstractdescription18

- 238000001035dryingMethods0.000claimsabstractdescription4

- VEXZGXHMUGYJMC-UHFFFAOYSA-NHydrochloric acidChemical compoundClVEXZGXHMUGYJMC-UHFFFAOYSA-N0.000claimsdescription30

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription29

- 238000003756stirringMethods0.000claimsdescription27

- 229920001296polysiloxanePolymers0.000claimsdescription23

- 239000000725suspensionSubstances0.000claimsdescription23

- 125000000217alkyl groupChemical group0.000claimsdescription20

- 239000006185dispersionSubstances0.000claimsdescription18

- IMNFDUFMRHMDMM-UHFFFAOYSA-NN-HeptaneChemical compoundCCCCCCCIMNFDUFMRHMDMM-UHFFFAOYSA-N0.000claimsdescription15

- VLKZOEOYAKHREP-UHFFFAOYSA-Nn-HexaneChemical compoundCCCCCCVLKZOEOYAKHREP-UHFFFAOYSA-N0.000claimsdescription14

- 238000005507sprayingMethods0.000claimsdescription12

- OKKJLVBELUTLKV-UHFFFAOYSA-NMethanolChemical compoundOCOKKJLVBELUTLKV-UHFFFAOYSA-N0.000claimsdescription9

- 239000007921spraySubstances0.000claimsdescription9

- KFZMGEQAYNKOFK-UHFFFAOYSA-NIsopropanolChemical compoundCC(C)OKFZMGEQAYNKOFK-UHFFFAOYSA-N0.000claimsdescription8

- BDERNNFJNOPAEC-UHFFFAOYSA-Npropan-1-olChemical compoundCCCOBDERNNFJNOPAEC-UHFFFAOYSA-N0.000claimsdescription8

- 238000001291vacuum dryingMethods0.000claimsdescription8

- 230000004048modificationEffects0.000claimsdescription4

- 238000012986modificationMethods0.000claimsdescription4

- CPUDPFPXCZDNGI-UHFFFAOYSA-Ntriethoxy(methyl)silaneChemical compoundCCO[Si](C)(OCC)OCCCPUDPFPXCZDNGI-UHFFFAOYSA-N0.000claimsdescription4

- 125000002496methyl groupChemical group[H]C([H])([H])*0.000claimsdescription3

- BFXIKLCIZHOAAZ-UHFFFAOYSA-NmethyltrimethoxysilaneChemical compoundCO[Si](C)(OC)OCBFXIKLCIZHOAAZ-UHFFFAOYSA-N0.000claimsdescription3

- 230000001476alcoholic effectEffects0.000claims1

- 229920000435poly(dimethylsiloxane)Polymers0.000abstractdescription24

- 239000004205dimethyl polysiloxaneSubstances0.000abstractdescription23

- 239000000126substanceSubstances0.000abstractdescription7

- -1polydimethylsiloxanePolymers0.000abstractdescription4

- 238000006243chemical reactionMethods0.000abstract1

- 238000009776industrial productionMethods0.000abstract1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000description28

- 235000013870dimethyl polysiloxaneNutrition0.000description23

- 238000010586diagramMethods0.000description16

- 239000000377silicon dioxideSubstances0.000description11

- 239000011521glassSubstances0.000description9

- 239000007788liquidSubstances0.000description8

- 238000001132ultrasonic dispersionMethods0.000description6

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description6

- 229910052681coesiteInorganic materials0.000description5

- 229910052906cristobaliteInorganic materials0.000description5

- 239000004576sandSubstances0.000description5

- 235000012239silicon dioxideNutrition0.000description5

- 229910052682stishoviteInorganic materials0.000description5

- 229910052905tridymiteInorganic materials0.000description5

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description4

- 238000000089atomic force micrographMethods0.000description4

- 238000002156mixingMethods0.000description4

- 239000000203mixtureSubstances0.000description4

- 239000002023woodSubstances0.000description4

- 229920000742CottonPolymers0.000description3

- 239000003795chemical substances by applicationSubstances0.000description3

- 239000010949copperSubstances0.000description3

- 229910052802copperInorganic materials0.000description3

- 125000001165hydrophobic groupChemical group0.000description3

- 125000002887hydroxy groupChemical group[H]O*0.000description3

- 239000000463materialSubstances0.000description3

- 239000002105nanoparticleSubstances0.000description3

- 238000002834transmittanceMethods0.000description3

- 238000005406washingMethods0.000description3

- WYTZZXDRDKSJID-UHFFFAOYSA-N(3-aminopropyl)triethoxysilaneChemical groupCCO[Si](OCC)(OCC)CCCNWYTZZXDRDKSJID-UHFFFAOYSA-N0.000description2

- BLRPTPMANUNPDV-UHFFFAOYSA-NSilaneChemical compound[SiH4]BLRPTPMANUNPDV-UHFFFAOYSA-N0.000description2

- 230000008878couplingEffects0.000description2

- 238000010168coupling processMethods0.000description2

- 238000005859coupling reactionMethods0.000description2

- SBRXLTRZCJVAPH-UHFFFAOYSA-Nethyl(trimethoxy)silaneChemical compoundCC[Si](OC)(OC)OCSBRXLTRZCJVAPH-UHFFFAOYSA-N0.000description2

- 239000004744fabricSubstances0.000description2

- 238000011010flushing procedureMethods0.000description2

- 230000002209hydrophobic effectEffects0.000description2

- 238000007654immersionMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 239000000123paperSubstances0.000description2

- 239000002994raw materialSubstances0.000description2

- 238000009991scouringMethods0.000description2

- 229910000077silaneInorganic materials0.000description2

- 238000002791soakingMethods0.000description2

- HQYALQRYBUJWDH-UHFFFAOYSA-Ntrimethoxy(propyl)silaneChemical compoundCCC[Si](OC)(OC)OCHQYALQRYBUJWDH-UHFFFAOYSA-N0.000description2

- CCESTPXUODXQEN-UHFFFAOYSA-N1-[diethyl(propyl)silyl]ethanamineChemical compoundNC(C)[Si](CC)(CC)CCCCCESTPXUODXQEN-UHFFFAOYSA-N0.000description1

- 230000002378acidificating effectEffects0.000description1

- 239000000853adhesiveSubstances0.000description1

- 230000001070adhesive effectEffects0.000description1

- 230000003373anti-fouling effectEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 239000003153chemical reaction reagentSubstances0.000description1

- 230000000052comparative effectEffects0.000description1

- 238000007598dipping methodMethods0.000description1

- 230000000694effectsEffects0.000description1

- 238000010292electrical insulationMethods0.000description1

- 238000001914filtrationMethods0.000description1

- 238000010438heat treatmentMethods0.000description1

- 239000001257hydrogenSubstances0.000description1

- 229910052739hydrogenInorganic materials0.000description1

- 239000003607modifierSubstances0.000description1

- 230000007935neutral effectEffects0.000description1

- 231100000252nontoxicToxicity0.000description1

- 230000003000nontoxic effectEffects0.000description1

- 230000003287optical effectEffects0.000description1

- 230000020477pH reductionEffects0.000description1

- 230000000704physical effectEffects0.000description1

- 150000003839saltsChemical class0.000description1

- 238000000926separation methodMethods0.000description1

- ABTOQLMXBSRXSM-UHFFFAOYSA-Nsilicon tetrafluorideChemical compoundF[Si](F)(F)FABTOQLMXBSRXSM-UHFFFAOYSA-N0.000description1

- 238000004528spin coatingMethods0.000description1

- 230000009967tasteless effectEffects0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D183/00—Coating compositions based on macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon, with or without sulfur, nitrogen, oxygen, or carbon only; Coating compositions based on derivatives of such polymers

- C09D183/04—Polysiloxanes

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D5/00—Coating compositions, e.g. paints, varnishes or lacquers, characterised by their physical nature or the effects produced; Filling pastes

- C09D5/18—Fireproof paints including high temperature resistant paints

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/60—Additives non-macromolecular

- C09D7/61—Additives non-macromolecular inorganic

- C09D7/62—Additives non-macromolecular inorganic modified by treatment with other compounds

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D7/00—Features of coating compositions, not provided for in group C09D5/00; Processes for incorporating ingredients in coating compositions

- C09D7/40—Additives

- C09D7/66—Additives characterised by particle size

- C09D7/67—Particle size smaller than 100 nm

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K2201/00—Specific properties of additives

- C08K2201/011—Nanostructured additives

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Materials Engineering (AREA)

- Wood Science & Technology (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Nanotechnology (AREA)

- Paints Or Removers (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及涂层制备技术领域,具体涉及一种具有一定耐久性且适应多种基底的透明超疏水涂层及其制备方法。The invention relates to the technical field of coating preparation, in particular to a transparent super-hydrophobic coating having certain durability and adapting to various substrates and a preparation method thereof.

背景技术Background technique

透明超疏水涂层作为一种功能性涂层,在微流体、防污、抗腐蚀、油水分离等方面的有巨大的应用潜力。尤其在光学汽车挡风玻璃,太阳能电池,电子设备的安全护目镜和窗户上有巨大的应用价值。As a functional coating, transparent superhydrophobic coatings have great application potential in microfluidics, antifouling, anticorrosion, oil-water separation, etc. Especially in optical car windshields, solar cells, safety goggles and windows of electronic equipment have huge application value.

二氧化硅在紫外光下稳定,制备方法简单,因此它常被以各种方式来制备超疏水涂层。从化学性质上来说,因为二氧化硅表面有大量的羟基,可以接枝各种疏水基团,所以它们的表面能可以根据所接枝的基团不同来调节;而对于物理性质,二氧化硅可以在高温下表现出优异的稳定性,其高温稳定性可以使其表面接枝不同的基团。此外当二氧化硅粒径小于100nm时,表现出高度的透明性,通过调节二氧化硅膜的厚度,甚至可以具有增透的功能。Silica is stable under UV light and has a simple preparation method, so it is often used in various ways to prepare superhydrophobic coatings. In terms of chemical properties, because there are a large number of hydroxyl groups on the surface of silica, various hydrophobic groups can be grafted, so their surface energy can be adjusted according to the grafted groups; and for physical properties, silica It can show excellent stability at high temperature, and its high temperature stability can make its surface graft different groups. In addition, when the particle size of the silica is less than 100 nm, it exhibits a high degree of transparency, and even has the function of antireflection by adjusting the thickness of the silica film.

有关透明超疏水涂层制备的专利申请较多,如公开号CN103803814A,CN103524053A,CN101362632,CN101519278,CN103553359A,CN103060773A的专利申请。然而这些方法大多采用全氟硅烷为修饰剂,在高温下成膜,耗费大量能源并且成膜过程复杂,这些方法制备的涂层热稳定性,化学稳定性差,不能满足户外环境的要求。There are many patent applications related to the preparation of transparent super-hydrophobic coatings, such as patent applications with publication numbers CN103803814A, CN103524053A, CN101362632, CN101519278, CN103553359A and CN103060773A. However, most of these methods use perfluorosilane as a modifier to form a film at high temperature, which consumes a lot of energy and has a complicated film-forming process. The coatings prepared by these methods have poor thermal stability and chemical stability, which cannot meet the requirements of outdoor environments.

超疏水涂层由于涂层与基材之间的粘附力比较差,粗糙结构非常脆弱,当表面到冲击,摩擦等机械作用很容易损坏而失去超疏水性能,另外当涂层暴露在户外时,涂层本身需要很好的耐久性,才能满足其工业化应用的要求。Due to the poor adhesion between the coating and the substrate, the superhydrophobic coating is very fragile and the rough structure is very fragile. When the surface is easily damaged by mechanical effects such as impact and friction, the superhydrophobic properties are lost. In addition, when the coating is exposed to the outdoors , the coating itself needs good durability to meet the requirements of its industrial application.

发明内容SUMMARY OF THE INVENTION

有鉴于此,本发明提供了一种制备工艺简单、生产成本低、适应各种基底的耐久性透明超疏水涂层及其制备方法,本发明通过将硅烷偶联剂修饰的SiO2与PDMS复合而制备的超疏水涂层,通过将PDMS与SiO2均匀的分散在溶剂中,使得PDMS部分包裹疏水性二氧化硅,在严苛的户外环境中,能够减少疏水基团的损失,另外PDMS的加入增强了涂层与基底的粘附力,提高了涂层的热稳定性,化学稳定性,以及机械性能稳定性,且制备的涂层的适用性广,透明度高,制备方法简单可行,大大提高了超疏水涂层的工业化应用范围。In view of this, the present invention provides a durable transparent super-hydrophobic coating with simple preparation process, low production cost, adaptable to various substrates and a preparation method thereof. The present invention combines SiO2 modified with a silane coupling agent with PDMS. The prepared superhydrophobic coating, by uniformly dispersing PDMS and SiO2 in the solvent, makes PDMS partially encapsulate hydrophobic silica, which can reduce the loss of hydrophobic groups in harsh outdoor environments. The addition enhances the adhesion between the coating and the substrate, improves the thermal stability, chemical stability, and mechanical performance stability of the coating, and the prepared coating has wide applicability, high transparency, and a simple and feasible preparation method. The industrial application range of the superhydrophobic coating is improved.

本发明第一方面提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,步骤包括:A first aspect of the present invention provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, the steps comprising:

S1、取纳米级的SiO2粒子溶于醇类溶剂中,超声分散2~8h,得到分散均匀的SiO2悬浊液;S1. Dissolve nano-scale SiO2 particles in an alcohol solvent, and ultrasonically disperse them for 2-8 hours to obtain a uniformly dispersed SiO2 suspension;

S2、取SiO2悬浊液在搅拌状态下中加入烷基链类硅烷偶联剂和盐酸溶液,超声分散搅拌2~8h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂添加体积与SiO2悬浊液体积相等;S2, take the SiO2 suspension, add the alkyl chain silane coupling agent and hydrochloric acid solution under stirring, and ultrasonically disperse and stir for 2 to 8 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling The volume of the agent added is equal to the volume of the SiO2 suspension;

S3、将前驱体溶液离心干燥,得到白色粉末,真空干燥得到具有部分甲基改性的SiO2粉末;S3, centrifugal drying the precursor solution to obtain white powder, and vacuum drying to obtain SiO powder with partial methyl modification;

S4、取步骤S3的SiO2粉末溶于烷类溶剂中,将硅酮加入到溶液中,搅拌超声2~4h得到分散液,所述硅酮的添加质量与SiO2粉末质量之比为0~0.7:0.3;S4. Dissolve the SiO2 powder in step S3 in an alkane solvent, add silicone into the solution, stir and ultrasonicate for 2-4 h to obtain a dispersion, and the ratio of the added mass of the silicone to the mass of the SiO2 powder is 0- 0.7:0.3;

S5、将所述分散液涂覆于基底,再用热空气吹干基底,多次循环,得透明超疏水涂层。S5. Coat the dispersion on the substrate, then dry the substrate with hot air, and circulate for many times to obtain a transparent super-hydrophobic coating.

本发明第二方面提供了采用上述适应多种基底的耐久性透明超疏水涂层的制备方法制备得到的涂层。The second aspect of the present invention provides a coating prepared by the above-mentioned preparation method of a durable transparent super-hydrophobic coating suitable for various substrates.

与现有技术相比,本发明的有益效果是:Compared with the prior art, the beneficial effects of the present invention are:

1.本发明制备的耐久性透明超疏水涂层,制备方法简单且成本低;1. The durable transparent super-hydrophobic coating prepared by the present invention has a simple preparation method and low cost;

2.本发明制备的耐久性透明超疏水涂层较高的透明性,其最高透过率可达80%;2. The durable transparent super-hydrophobic coating prepared by the present invention has high transparency, and its maximum transmittance can reach 80%;

3.本发明制备的耐久性透明超疏水涂层能够在低温-15℃,高温500℃仍能保持其超疏水特性;3. The durable transparent super-hydrophobic coating prepared by the present invention can still maintain its super-hydrophobic properties at a low temperature of -15°C and a high temperature of 500°C;

4.本发明制备的耐久性透明超疏水涂层在酸性,碱性,中性,盐环境中仍能保持其超疏水特性;4. The durable transparent super-hydrophobic coating prepared by the present invention can still maintain its super-hydrophobic properties in acidic, alkaline, neutral and salt environments;

5.本发明制备的耐久性透明超疏水涂层在其经过水流,砂砾冲刷下仍能保持其超疏水特性;5. The durable transparent super-hydrophobic coating prepared by the present invention can still maintain its super-hydrophobic properties under water flow and sand scouring;

6.本发明制备的耐久性透明超疏水涂层可应用于木材,纸张,铜网,玻璃等各种基材上。6. The durable transparent super-hydrophobic coating prepared by the present invention can be applied to various substrates such as wood, paper, copper mesh, and glass.

本发明工艺简单、生产成本低、涂层适应性广,能大批量工业化生产。The invention has simple process, low production cost, wide coating adaptability, and can be industrialized in large quantities.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the drawings in the following description are For some embodiments of the present invention, for those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

图1是实施例5与实例2制备的超疏水涂层的扫描图,其中,a为实施例6所得涂层的扫描图,b为实施例2所得涂层的扫描图。Fig. 1 is a scanning diagram of the superhydrophobic coatings prepared in Example 5 and Example 2, wherein a is a scanning diagram of the coating obtained in Example 6, and b is a scanning diagram of the coating obtained in Example 2.

图2是实施例5与实例2制备的超疏水涂层的原子力显微镜图;其中,a为实施例6所得涂层的原子力显微镜图,b为实施例2所得涂层的原子力显微镜图。2 is an atomic force microscope image of the superhydrophobic coatings prepared in Example 5 and Example 2; wherein, a is the atomic force microscope image of the coating obtained in Example 6, and b is the atomic force microscope image of the coating obtained in Example 2.

图3是实施例2制备的在不同基材上的透明超疏水膜图;其中,a中基材为A4纸,b中基材为木材,c中基材为玻璃,d中基材为棉布,e中基材为铜网。3 is a diagram of the transparent superhydrophobic films prepared in Example 2 on different substrates; wherein, the substrate in a is A4 paper, the substrate in b is wood, the substrate in c is glass, and the substrate in d is cotton cloth , the base material in e is copper mesh.

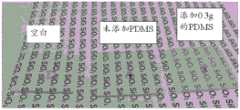

图4是实施例2与实施例5制备的超疏水涂层在载玻片上喷涂后的透明度图,图中依次为未喷涂涂层玻璃、喷涂未添加PDMS涂层玻璃、喷涂添加0.3gPDMS涂层玻璃。Fig. 4 is the transparency diagram of the super-hydrophobic coatings prepared in Example 2 and Example 5 after spraying on glass slides, the figures are sequentially unsprayed coated glass, sprayed without added PDMS coated glass, and sprayed with 0.3g PDMS coating added Glass.

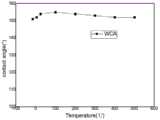

图5是实施例2制备的超疏水涂层的热稳定图。5 is a thermal stability diagram of the superhydrophobic coating prepared in Example 2.

图6是实施例2制备的超疏水涂层经酸碱溶液浸泡后,水流和沙砾冲刷后的接触角图,其中,a为未经处理时的接触角图,b为在pH=2的溶液中浸泡2h后的接触角图,c为在pH=12的溶液中浸泡2h后的接触角图,d为水流冲刷后的接触角图,e为沙砾冲刷后的接触角图。Figure 6 is a contact angle diagram of the superhydrophobic coating prepared in Example 2 after being soaked in an acid-base solution and washed with water and sand, wherein a is the contact angle diagram without treatment, and b is the solution at pH=2 Contact angle diagram after immersion in medium for 2h, c is the contact angle diagram after immersion in pH=12 solution for 2h, d is the contact angle diagram after water flushing, e is the contact angle diagram after sand and gravel flushing.

具体实施方式Detailed ways

本发明第一方面提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,步骤包括:A first aspect of the present invention provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, the steps comprising:

S1、取纳米级的SiO2粒子溶于醇类溶剂中,超声分散2~8h,得到分散均匀的SiO2悬浊液;S1. Dissolve nano-scale SiO2 particles in an alcohol solvent, and ultrasonically disperse them for 2-8 hours to obtain a uniformly dispersed SiO2 suspension;

S2、取SiO2悬浊液在搅拌状态下中加入烷基链类硅烷偶联剂和盐酸溶液,超声分散搅拌2~8h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂添加体积与SiO2悬浊液体积相等;S2, take the SiO2 suspension, add the alkyl chain silane coupling agent and hydrochloric acid solution under stirring, and ultrasonically disperse and stir for 2 to 8 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling The volume of the agent added is equal to the volume of the SiO2 suspension;

S3、将前驱体溶液离心干燥,得到白色粉末,真空干燥得到具有部分甲基改性的SiO2粉末;S3, centrifugal drying the precursor solution to obtain white powder, and vacuum drying to obtain SiO powder with partial methyl modification;

S4、取步骤S3的SiO2粉末溶于烷类溶剂中,将硅酮加入到溶液中,搅拌超声2~4h得到分散液,所述硅酮的添加质量与SiO2粉末质量之比为0~0.7:0.3;S4. Dissolve the SiO2 powder in step S3 in an alkane solvent, add silicone into the solution, stir and ultrasonicate for 2-4 h to obtain a dispersion, and the ratio of the added mass of the silicone to the mass of the SiO2 powder is 0- 0.7:0.3;

S5、将所述分散液涂覆于基底,再用热空气吹干基底,多次循环,得透明超疏水涂层。S5. Coat the dispersion on the substrate, then dry the substrate with hot air, and circulate for many times to obtain a transparent super-hydrophobic coating.

PDMS(聚二甲基硅氧烷)是一种疏水类的有机硅物料,本身具有良好的耐磨性、化学稳定性、生理惰性、电绝缘性并且无毒无味,是一种低表面能材料,其本身是无色透明的,可用于制备透明的超疏水层,本身具有一定的粘附力,能够提高涂层与基材之间的结合力。通过将PDMS和SiO2复合,则能够有效提高超疏水涂层的热稳定性,化学稳定性,机械性能稳定性,增强超疏水涂层的耐久性,扩大透明超疏水涂层的工业化应用范围。PDMS (polydimethylsiloxane) is a hydrophobic silicone material, which has good wear resistance, chemical stability, physiological inertness, electrical insulation, non-toxic and tasteless, and is a low surface energy material. , itself is colorless and transparent, and can be used to prepare a transparent superhydrophobic layer. It has a certain adhesive force and can improve the bonding force between the coating and the substrate. By combining PDMS and SiO2 , the thermal stability, chemical stability, and mechanical property stability of superhydrophobic coatings can be effectively improved, the durability of superhydrophobic coatings can be enhanced, and the industrial application scope of transparent superhydrophobic coatings can be expanded.

本发明将硅烷偶联剂修饰的SiO2与PDMS均匀的分散在溶液中,使PDMS部分包裹SiO2颗粒,减少了疏水基团的暴露,在保证超疏水的同时,增强了超疏水涂层的热稳定性,化学稳定性,SiO2表面剩余的羟基与PDMS表面的羟基以氢键接,提高了涂层的附着力,进一步提高了超疏水涂层的耐久性。In the invention, the SiO2 modified by the silane coupling agent and the PDMS are uniformly dispersed in the solution, so that the PDMS partially wraps the SiO2 particles, reduces the exposure of the hydrophobic group, and enhances the super-hydrophobic coating while ensuring the super-hydrophobicity. Thermal stability, chemical stability, hydrogen bonding between the remaining hydroxyl groupson the SiO surface and the hydroxyl groups on the PDMS surface improves the adhesion of the coating and further improves the durability of the superhydrophobic coating.

优选的,步骤S1所述纳米级的SiO2粒子为粒径大小为20nm~100nm的SiO2粒子。具体的,可以为20nm、40nm、70nm、100nm的SiO2粒子中的一种或几种按任意比例混合的混合物。Preferably, the nano-scale SiO2 particles in step S1 are SiO2 particles with a particle size of 20 nm to 100 nm. Specifically, it may be a mixture of one or more of SiO2 particles of 20 nm, 40 nm, 70 nm, and 100 nm mixed in any proportion.

更加优选的,步骤S1所述醇类溶剂为乙醇,甲醇,正丙醇或异丙醇中的一种或几种按任意比例混合的混合物;所述SiO2粒子质量与醇类溶剂体积之比为1:9~11g/mL。More preferably, the alcohol solvent described in step S1 is a mixture of one or more of ethanol, methanol, n-propanol or isopropanol in any proportion; the ratio of the SiO particle mass to the alcohol solvent volume It is 1:9~11g/mL.

优选的,步骤S2所述烷基链类硅烷偶联剂为甲基三甲氧基硅烷,乙基三甲氧基硅烷,丙基三甲氧基硅烷,甲基三乙氧基硅烷,氨丙基三乙氧基硅烷中的一种或几种按任意比例混合的混合物。Preferably, the alkyl chain silane coupling agent in step S2 is methyltrimethoxysilane, ethyltrimethoxysilane, propyltrimethoxysilane, methyltriethoxysilane, aminopropyltriethylsilane A mixture of one or more oxysilanes in any proportion.

优选的,步骤S2所述盐酸溶液为质量分数为25~28%的盐酸溶液,所述盐酸溶液的添加体积与SiO2悬浊液体积比为0.1~0.3:2。Preferably, the hydrochloric acid solution in step S2 is a hydrochloric acid solution with a mass fraction of 25-28%, and the ratio of the added volume of the hydrochloric acid solution to the volume of the SiO2 suspension is 0.1-0.3:2.

优选的,步骤S4所述硅酮为硅酮184、硅酮181中的一种或两种。硅酮为一系列不同分子量的聚二甲基硅氧烷,本发明优选硅酮型号为硅酮184,其A组分(PDMS)与B组分(固化剂)质量比为10:1。Preferably, the silicone in step S4 is one or both of silicone 184 and silicone 181 . The silicone is a series of polydimethylsiloxanes with different molecular weights. The preferred silicone type of the present invention is silicone 184, and the mass ratio of its A component (PDMS) to B component (curing agent) is 10:1.

优选的,步骤S4所述烷类溶剂为正己烷、正庚烷中一种或两种。Preferably, the alkane solvent in step S4 is one or both of n-hexane and n-heptane.

优选的,步骤S5中,所述涂覆方式选自喷涂,旋涂,浸渍提拉等,优选方式为喷涂,喷枪的喷射速度为2-4cm/s,喷涂距离为15-20cm;所述热空气温度为115~125℃。Preferably, in step S5, the coating method is selected from spraying, spin coating, dipping and pulling, etc., the preferred method is spraying, the spraying speed of the spray gun is 2-4 cm/s, and the spraying distance is 15-20 cm; The air temperature is 115 to 125°C.

本发明第二方面提供了采用上述适应多种基底的耐久性透明超疏水涂层的制备方法制备得到的涂层。The second aspect of the present invention provides a coating prepared by the above-mentioned preparation method of a durable transparent super-hydrophobic coating suitable for various substrates.

为了便于理解本发明,下文将结合说明书附图和实施例对本发明作更全面、细致地描述,但本发明的保护范围并不限于以下具体的实施例。In order to facilitate understanding of the present invention, the present invention will be described more comprehensively and in detail below with reference to the accompanying drawings and embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

除非另有定义,下文中所使用的所有专业术语与本领域技术人员通常理解的含义相同。本文中所使用的专业术语只是为了描述具体实施例的目的,并不是旨在限制本发明的保护范围。Unless otherwise defined, all technical terms used hereinafter have the same meaning as commonly understood by those skilled in the art. The technical terms used herein are only for the purpose of describing specific embodiments, and are not intended to limit the protection scope of the present invention.

除非另有特别说明,本发明中用到的各种原材料、试剂、仪器和设备等,均可通过市场购买得到或者可通过现有方法制备得到,如用到的原料硅酮184、硅酮181均为市场购买得到。Unless otherwise specified, various raw materials, reagents, instruments and equipment used in the present invention can be purchased from the market or can be prepared by existing methods, such as the raw materials used in silicone 184, silicone 181 are available in the market.

实施例1Example 1

本实施例提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,通过将纳米级的SiO2粒子与硅烷偶联剂在室温下反应,经过酸化处理,得到溶胶状前驱体溶液,经过高温烘干得到具有超疏水性质的粉末。将超疏水性质的粉末与聚二甲基硅氧烷在烷类溶剂中混合经超声分散,使PDMS部分包裹SiO2颗粒,得到分散液,涂覆基材表面后,经热处理后得到超疏水涂层。具体包括如下的步骤:This embodiment provides a method for preparing a durable transparent super-hydrophobic coating suitable for a variety of substrates. By reacting nano-scale SiO2 particles with a silane coupling agent at room temperature, and undergoing acidification treatment, a sol-like precursor is obtained The solution is dried at high temperature to obtain a powder with superhydrophobic properties. The superhydrophobic powder and polydimethylsiloxane are mixed in an alkane solvent and dispersed by ultrasonic, so that the PDMS partially encapsulates theSiO2 particles to obtain a dispersion liquid. After coating the surface of the substrate, the superhydrophobic coating is obtained after heat treatment. Floor. Specifically include the following steps:

(1)取纳米级的SiO2粒子2g溶于20ml溶剂醇中,超声分散5h,得到分散均匀的SiO2悬浊液;所述溶剂醇为乙醇、正丙醇按体积比2:1混合所得。(1) get nano-scale SiO particles2g and dissolve in 20ml solvent alcohol, ultrasonically disperse for 5h to obtain evenly dispersed SiO suspension; the solvent alcohol is obtained by mixing ethanol and n-propanol at a volume ratio of2 :1 .

(2)等量步骤(1)的SiO2悬浊液在搅拌状态下中加入2ml烷基链类硅烷偶联剂和0.1ml质量分数为28%的盐酸溶液。超声分散搅拌5h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂为甲基三甲氧基硅烷与乙基三甲氧基硅烷按体积比1:1混合所得。(2) Add 2 ml of alkyl chain silane coupling agent and 0.1 ml of hydrochloric acid solution with a mass fraction of 28% to the SiO2 suspension of step (1) under stirring. Ultrasonic dispersion and stirring were carried out for 5 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling agent was obtained by mixing methyltrimethoxysilane and ethyltrimethoxysilane in a volume ratio of 1:1.

(3)将等量步骤(2)的前驱体溶液,经过离心干燥,得到白色粉末,通过真空干燥,得到部分甲基化的SiO2粉末;(3) the precursor solution of the equal amount of step (2 ) is centrifuged and dried to obtain a white powder, and the partially methylated SiO powder is obtained by vacuum drying;

(4)取0.3g步骤(3)的SiO2粉末,溶于20ml烷类溶剂中,将0.1g硅酮184(A组份与B组份质量比10:1)加入到溶液中,搅拌超声3h,使PDMS均匀分和SiO2颗粒均匀分散在溶剂中,得到分散液;所述烷类溶剂为正己烷。(4) Take 0.3g ofSiO2 powder from step (3), dissolve it in 20ml of alkane solvent, add 0.1g of silicone 184 (component A to component B mass ratio 10:1) into the solution, stir and ultrasonically 3h, the PDMS and SiO2 particles are uniformly dispersed in the solvent to obtain a dispersion; the alkane solvent is n-hexane.

(5)将分散液喷于各种基底,再用120℃热空气吹干基底,多次循环,可得透明超疏水涂层。(5) Spray the dispersion liquid on various substrates, then dry the substrates with hot air at 120°C, and circulate for many times to obtain a transparent superhydrophobic coating.

实施例2Example 2

本实施例提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,包括如下的步骤:The present embodiment provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, comprising the following steps:

(1)取纳米级的SiO2粒子2g溶于20ml溶剂醇中,超声分散6h,得到分散均匀的SiO2悬浊液;所述溶剂醇为异丙醇。(1) Dissolve 2 g of nano-sized SiO2 particles in 20 ml of solvent alcohol, and ultrasonically disperse for 6 h to obtain a uniformly dispersed SiO2 suspension; the solvent alcohol is isopropanol.

(2)等量步骤(1)的SiO2悬浊液在搅拌状态下中加入2ml烷基链类硅烷偶联剂和0.1ml质量分数为28%的盐酸溶液。超声分散搅拌6h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂为氨丙基三乙氧基硅烷。(2) Add 2 ml of alkyl chain silane coupling agent and 0.1 ml of hydrochloric acid solution with a mass fraction of 28% to the SiO2 suspension of step (1) under stirring. Ultrasonic dispersion and stirring are carried out for 6 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling agent is aminopropyltriethoxysilane.

(3)将等量步骤(2)的前驱体溶液,经过离心干燥,得到白色粉末,通过真空干燥,得到部分甲基化的SiO2粉末;(3) the precursor solution of the equal amount of step (2 ) is centrifuged and dried to obtain a white powder, and the partially methylated SiO powder is obtained by vacuum drying;

(4)取0.3g步骤(3)的SiO2粉末,溶于20ml烷类溶剂中,将0.3g硅酮184(A组份与B组份质量比10:1)加入到溶液中,搅拌超声3h,PDMS和SiO2均匀的分散在溶剂中,得到分散液;所述烷类溶剂为正己烷。(4) Take 0.3g ofSiO2 powder from step (3), dissolve it in 20ml of alkane solvent, add 0.3g of silicone 184 (the mass ratio of component A to component B is 10:1) into the solution, stir and ultrasonically 3h, PDMS and SiO2 are uniformly dispersed in the solvent to obtain a dispersion; the alkane solvent is n-hexane.

(5)将分散液喷于各种基底,再用120℃热空气吹干基底,多次循环,可得透明超疏水涂层。(5) Spray the dispersion liquid on various substrates, then dry the substrates with hot air at 120°C, and circulate for many times to obtain a transparent superhydrophobic coating.

本实施例制备得到的超疏水涂层的扫描图如附图1所示,所得涂层的原子力显微镜图如附图2所示,超疏水涂层在载玻片上喷涂后的透明度图如附图4所示,PDMS的不同添加量在波长为550nm和800nm处的透过率对比如表1所示,超疏水涂层的热稳定图如附图5所示。The scanning diagram of the superhydrophobic coating prepared in this example is shown in Figure 1, the atomic force microscope image of the obtained coating is shown in Figure 2, and the transparency diagram of the superhydrophobic coating after spraying on the glass slide is shown in the accompanying drawing As shown in Fig. 4, the transmittance comparison of different addition amounts of PDMS at wavelengths of 550 nm and 800 nm is shown in Table 1, and the thermal stability diagram of the superhydrophobic coating is shown in Figure 5.

表1 PDMS的不同添加量在波长为550nm和800nm处的透过率对比Table 1 Comparison of transmittances of different dosages of PDMS at wavelengths of 550nm and 800nm

将本实施例所得分散液喷涂于在不同基材上,其透明超疏水膜图如附图3所示,所述基材分别为A4纸、木材、玻璃、棉布、铜网,具体的,在不同基材上的接触角如下:在A4纸上接触角为154°,在玻璃上接触角为155°,在铜网上接触角为153°,在木材上接触角为152°,在棉布上接触角为153°;喷涂工艺为:喷枪的喷射速度为2-4cm/s,喷涂距离为15-20cm。The dispersion liquid obtained in the present embodiment is sprayed on different substrates, and its transparent super-hydrophobic film is shown in accompanying drawing 3, and the substrates are respectively A4 paper, wood, glass, cotton cloth, and copper mesh. The contact angles on different substrates are as follows: 154° on A4 paper, 155° on glass, 153° on copper wire, 152° on wood, and 152° on cotton The angle is 153°; the spraying process is: the spraying speed of the spray gun is 2-4cm/s, and the spraying distance is 15-20cm.

将本实施例所得超疏水涂层经酸碱溶液浸泡后,水流和沙砾冲刷后的接触角图如附图6所示,从图6可见,未经处理时的接触角为155°,经PH=2的溶液中浸泡2h后接触角为152°,经PH=12的溶液中浸泡2h后接触角为153°,经水流冲刷后接触角为152°,经砂砾冲刷后接触角为151°。After the super-hydrophobic coating obtained in the present embodiment is soaked in acid-base solution, the contact angle diagram after water flow and sand scouring is shown in accompanying drawing 6, as can be seen from Fig. 6, the contact angle when untreated is 155 °, after pH The contact angle was 152° after soaking in the solution of pH=2 for 2h, 153° after soaking in the solution of pH=12 for 2h, 152° after washing with water, and 151° after washing with sand.

实施例3Example 3

本实施例提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,包括如下的步骤:The present embodiment provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, comprising the following steps:

(1)取纳米级的SiO2粒子2g溶于20ml溶剂醇中,超声分散3h,得到分散均匀的SiO2悬浊液;所述溶剂醇为甲醇与正丙醇混合物。(1) Dissolve 2 g of nanoscale SiO2 particles in 20 ml of solvent alcohol, and ultrasonically disperse for 3 h to obtain a uniformly dispersed SiO2 suspension; the solvent alcohol is a mixture of methanol and n-propanol.

(2)等量步骤(1)的SiO2悬浊液在搅拌状态下中加入2ml烷基链类硅烷偶联剂和0.1ml质量分数为28%的盐酸溶液。超声分散搅拌8h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂为丙基三甲氧基硅烷。(2) Add 2 ml of alkyl chain silane coupling agent and 0.1 ml of hydrochloric acid solution with a mass fraction of 28% to the SiO2 suspension of step (1) under stirring. Ultrasonic dispersion and stirring are carried out for 8 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling agent is propyltrimethoxysilane.

(3)将等量步骤(2)的前驱体溶液,经过离心干燥,得到白色粉末,通过真空干燥,得到部分甲基化的SiO2粉末;(3) the precursor solution of the equal amount of step (2 ) is centrifuged and dried to obtain a white powder, and the partially methylated SiO powder is obtained by vacuum drying;

(4)取0.3g步骤(3)的SiO2粉末,溶于20ml烷类溶剂中,取0.5g硅酮184(A组份与B组份质量比10:1)加入到溶液中,搅拌超声4h,将PDMS与SiO2均匀分散在溶剂中,得到分散液;所述烷类溶剂为正庚烷。(4) Take 0.3g ofSiO2 powder from step (3), dissolve it in 20ml of alkane solvent, take 0.5g of silicone 184 (the mass ratio of component A and component B is 10:1) and add it to the solution, stir and ultrasonically 4h, the PDMS and SiO2 are uniformly dispersed in the solvent to obtain a dispersion; the alkane solvent is n-heptane.

(5)将分散液喷于各种基底,再用120℃热空气吹干基底,多次循环,可得透明超疏水涂层。(5) Spray the dispersion liquid on various substrates, then dry the substrates with hot air at 120°C, and circulate for many times to obtain a transparent superhydrophobic coating.

实施例4Example 4

本实施例提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,包括如下的步骤:The present embodiment provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, comprising the following steps:

(1)取纳米级的SiO2粒子2g溶于20ml溶剂醇中,超声分散8h,得到分散均匀的SiO2悬浊液;所述溶剂醇为乙醇。(1) Dissolve 2 g of nano-sized SiO2 particles in 20 ml of solvent alcohol, and ultrasonically disperse for 8 h to obtain a uniformly dispersed SiO2 suspension; the solvent alcohol is ethanol.

(2)等量步骤(1)的SiO2悬浊液在搅拌状态下中加入2ml烷基链类硅烷偶联剂和0.1ml质量分数为28%的盐酸溶液。超声分散搅拌3h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂为甲基三乙氧基硅烷。(2) Add 2 ml of alkyl chain silane coupling agent and 0.1 ml of hydrochloric acid solution with a mass fraction of 28% to the SiO2 suspension of step (1) under stirring. Ultrasonic dispersion and stirring are carried out for 3 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling agent is methyltriethoxysilane.

(3)将等量步骤(2)的前驱体溶液,经过离心干燥,得到白色粉末,通过真空干燥,得到部分甲基化的SiO2粉末;(3) the precursor solution of the equal amount of step (2 ) is centrifuged and dried to obtain a white powder, and the partially methylated SiO powder is obtained by vacuum drying;

(4)取0.3g步骤(3)的超疏水粉末,溶于20ml烷类溶剂中,取0.7g硅酮184(A组份与B组份质量比10:1)加入到溶液中,搅拌超声2h,PDMS与SiO2均匀分散在溶剂中,得到分散液;所述烷类溶剂为正己烷和正庚烷按体积比1:1混合所得。(4) Take 0.3g of the superhydrophobic powder from step (3), dissolve it in 20ml of alkane solvent, take 0.7g of silicone 184 (the mass ratio of component A and component B is 10:1) and add it to the solution, stir and ultrasonically 2h, PDMS and SiO2 are uniformly dispersed in the solvent to obtain a dispersion liquid; the alkane solvent is obtained by mixing n-hexane and n-heptane in a volume ratio of 1:1.

(5)分散液喷于各种基底,再用120℃热空气吹干基底,多次循环,可得透明超疏水涂层。(5) The dispersion liquid is sprayed on various substrates, and then the substrates are dried with 120° C. hot air, and the transparent super-hydrophobic coating can be obtained after repeated cycles.

实施例5Example 5

本实施例提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,包括如下的步骤:The present embodiment provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, comprising the following steps:

(1)取纳米级的SiO2粒子2g溶于20ml溶剂醇中,超声分散5h,得到分散均匀的SiO2悬浊液;所述溶剂醇为异丙醇。(1) Dissolve 2 g of nanoscale SiO2 particles in 20 ml of solvent alcohol, and ultrasonically disperse for 5 h to obtain a uniformly dispersed SiO2 suspension; the solvent alcohol is isopropanol.

(2)等量步骤(1)的SiO2悬浊液在搅拌状态下中加入2ml烷基链类硅烷偶联剂和0.1ml质量分数为28%的盐酸溶液。超声分散搅拌5h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂为氨丙基三乙氧基硅烷。(2) Add 2 ml of alkyl chain silane coupling agent and 0.1 ml of hydrochloric acid solution with a mass fraction of 28% to the SiO2 suspension of step (1) under stirring. Ultrasonic dispersion and stirring were carried out for 5 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling agent was aminopropyltriethoxysilane.

(3)将等量步骤(2)的前驱体溶液,经过砂芯漏斗洗涤过滤,得到白色粉末,通过真空干燥,得到部分甲基化的SiO2粉末;(3) washing and filtering the same amount of the precursor solution of step (2 ) through a sand core funnel to obtain a white powder, which is dried in a vacuum to obtain a partially methylated SiO powder;

(4)取0.3g步骤(3)的SiO2粉末,溶于20ml烷类溶剂中,搅拌超声3h,得到超疏水喷剂;所述烷类溶剂为正己烷。(4) Dissolve 0.3 g of the SiO2 powder in step (3) in 20 ml of an alkane solvent, stir and ultrasonicate for 3 h to obtain a super-hydrophobic spray; the alkane solvent is n-hexane.

(5)喷剂喷于各种基底,再用120℃热空气吹干基底,多次循环,可得透明超疏水涂层。(5) Spray the spray on various substrates, then dry the substrates with hot air at 120°C, and circulate for many times to obtain a transparent super-hydrophobic coating.

为与其他实施例形成对照,本实施例作为对比例,制备步骤中PDMS含量为0。In order to form a comparison with other examples, this example is used as a comparative example, and the PDMS content in the preparation step is 0.

实施例6Example 6

本实施例提供了一种适应多种基底的耐久性透明超疏水涂层的制备方法,包括如下的步骤:The present embodiment provides a method for preparing a durable transparent superhydrophobic coating suitable for various substrates, comprising the following steps:

(1)取纳米级的SiO2粒子2g溶于20ml溶剂醇中,超声分散8h,得到分散均匀的SiO2悬浊液;所述溶剂醇为乙醇。(1) Dissolve 2 g of nano-sized SiO2 particles in 20 ml of solvent alcohol, and ultrasonically disperse for 8 h to obtain a uniformly dispersed SiO2 suspension; the solvent alcohol is ethanol.

(2)等量步骤(1)的SiO2悬浊液在搅拌状态下中加入2ml烷基链类硅烷偶联剂和0.1ml质量分数为28%的盐酸溶液。超声分散搅拌3h,得到溶胶状的前驱体溶液;所述烷基链类硅烷偶联剂为甲基三乙氧基硅烷。(2) Add 2 ml of alkyl chain silane coupling agent and 0.1 ml of hydrochloric acid solution with a mass fraction of 28% to the SiO2 suspension of step (1) under stirring. Ultrasonic dispersion and stirring are carried out for 3 hours to obtain a sol-like precursor solution; the alkyl chain silane coupling agent is methyltriethoxysilane.

(3)将等量步骤(2)的前驱体溶液,经过离心干燥,得到白色粉末,通过真空干燥,得到部分甲基化的SiO2粉末;(3) the precursor solution of the equal amount of step (2 ) is centrifuged and dried to obtain a white powder, and the partially methylated SiO powder is obtained by vacuum drying;

(4)取0.3g步骤(3)的超疏水粉末,溶于20ml烷类溶剂中,取0.7g硅酮181加入到溶液中,搅拌超声2h,PDMS与SiO2均匀分散在溶剂中,得到分散液;所述烷类溶剂为正己烷和正庚烷按体积比1:1混合所得。(4) Take 0.3g of the superhydrophobic powder from step (3), dissolve it in 20ml of alkane solvent, take 0.7g of silicone 181 and add it to the solution, stir and ultrasonicate for 2h, PDMS andSiO2 are uniformly dispersed in the solvent to obtain a dispersion The alkane solvent is obtained by mixing n-hexane and n-heptane in a volume ratio of 1:1.

(5)分散液喷于各种基底,再用120℃热空气吹干基底,多次循环,可得透明超疏水涂层。(5) The dispersion liquid is sprayed on various substrates, and then the substrates are dried with 120° C. hot air, and the transparent super-hydrophobic coating can be obtained after repeated cycles.

以上所述仅为本发明的较佳实施例,并不用以限制本发明,凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。The above are only preferred embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included in the protection of the present invention. within the range.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810209419.6ACN108587447B (en) | 2018-03-14 | 2018-03-14 | A kind of preparation method of durable transparent superhydrophobic coating suitable for various substrates |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810209419.6ACN108587447B (en) | 2018-03-14 | 2018-03-14 | A kind of preparation method of durable transparent superhydrophobic coating suitable for various substrates |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108587447A CN108587447A (en) | 2018-09-28 |

| CN108587447Btrue CN108587447B (en) | 2020-11-10 |

Family

ID=63626327

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201810209419.6AExpired - Fee RelatedCN108587447B (en) | 2018-03-14 | 2018-03-14 | A kind of preparation method of durable transparent superhydrophobic coating suitable for various substrates |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN108587447B (en) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110734700A (en)* | 2019-10-30 | 2020-01-31 | 上海交通大学 | A kind of superhydrophobic coating composite material for anti-icing and preparation method thereof |

| CN112225581B (en)* | 2020-09-28 | 2023-01-31 | 太原理工大学 | Preparation method of a durable hydrophobic anti-light aging stone cultural relics sealing coating |

| CN115704191A (en)* | 2021-08-17 | 2023-02-17 | 美盈森集团股份有限公司 | Moisture-proof coating liquid, preparation method and corrugated case |

| CN113731187B (en)* | 2021-08-27 | 2022-06-14 | 北京工业大学 | A method to improve the desalination stability of porous ceramic membranes by constructing a hydrophobic protective layer |

| CN113999553A (en)* | 2021-11-11 | 2022-02-01 | 中国矿业大学 | Fly ash-based super-hydrophobic coating and preparation method thereof |

| CN114479154A (en)* | 2022-03-01 | 2022-05-13 | 南京航空航天大学 | A kind of multifunctional durable film with hierarchical structure and preparation method thereof |

| CN114752302A (en)* | 2022-05-20 | 2022-07-15 | 深圳技术大学 | High-transparency super-hydrophobic spray coating and preparation method thereof |

| CN115156013B (en)* | 2022-07-14 | 2023-09-19 | 扬州大学 | Method for improving durability of wood coating |

| CN115651534A (en)* | 2022-11-14 | 2023-01-31 | 云南大学 | Super-hydrophobic coating, self-cleaning coating, and preparation method and application thereof |

| CN118109123A (en)* | 2022-11-29 | 2024-05-31 | 东南大学 | Super-hydrophobic nano composite slurry and application thereof in breathable super-hydrophobic coating |

| CN116200103B (en)* | 2023-02-22 | 2024-10-01 | 航天长屏科技有限公司 | Corrosion-resistant electromagnetic protective coating, preparation method and application thereof and wind power generation equipment |

| CN116396679A (en)* | 2023-03-31 | 2023-07-07 | 陕西科技大学 | Preparation method of wear-resistant superhydrophobic coating and wear-resistant superhydrophobic surface treatment method |

| CN116854380A (en)* | 2023-07-14 | 2023-10-10 | 成都理工大学 | A self-healing superhydrophobic coating and preparation method |

| CN117026634A (en)* | 2023-07-17 | 2023-11-10 | 江苏金呢工程织物股份有限公司 | Papermaking blanket preparation method and papermaking blanket |

| CN117186768A (en)* | 2023-08-23 | 2023-12-08 | 北京建筑大学 | Preparation method and application of self-repairing fluorine-free PDMS/Si-Me super-hydrophobic coating |

| CN117358556A (en)* | 2023-10-09 | 2024-01-09 | 南京林业大学 | Preparation method for preparing super-hydrophobic poplar by sand-in method, product and application |

| CN117363211B (en)* | 2023-10-27 | 2024-05-10 | 重庆大学 | A large-area anti-icing and de-icing coating with excellent durability and preparation method thereof |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101845242A (en)* | 2010-04-28 | 2010-09-29 | 四川大学 | Super-hydrophobic nano-composite coating and preparation method thereof |

| CN104073116B (en)* | 2014-07-08 | 2017-01-25 | 深圳大学 | Preparation method of super-amphiphobic coating |

| CN104231916B (en)* | 2014-09-30 | 2016-08-24 | 东南大学 | A kind of transparent hydrophobic nano coating and spraying preparation method thereof |

- 2018

- 2018-03-14CNCN201810209419.6Apatent/CN108587447B/ennot_activeExpired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN108587447A (en) | 2018-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108587447B (en) | A kind of preparation method of durable transparent superhydrophobic coating suitable for various substrates | |

| CN107384055B (en) | A kind of durable superhydrophobic coating and preparation method thereof | |

| CN101445396B (en) | Method for preparing porcelain insulator surface super-hydrophobic coating | |

| JP5680900B2 (en) | Oil-repellent coated article and method for producing the same | |

| CN103289031B (en) | High-transparency super-hydrophobicity coating material and application thereof | |

| WO2010018744A1 (en) | Ultrahydrophobic powder, structure with ultrahydrophobic surface, and processes for producing these | |

| CN113004749A (en) | Super-hydrophobic coating and preparation method and application thereof | |

| CN103359954A (en) | Preparation method of silicon dioxide super-hydrophobic thin film and super-hydrophobic material | |

| CN115368762A (en) | Hydrophobic and oleophobic coating, preparation method and application thereof | |

| Chi et al. | Highly stable self-cleaning antireflection coatings from fluoropolymer brush grafted silica nanoparticles | |

| CN111542550B (en) | Base for forming polymer brush, method for producing the base, and precursor liquid used in the method | |

| CN101649065A (en) | Method for preparing pollution preventing self-cleaning polyvinylidene fluoride (PVDF) film and product thereof | |

| JP7317203B2 (en) | SELF-HEALING OR REPEATABLE PRODUCTS, PRODUCTION METHOD AND APPLICATION THEREOF | |

| CN107128937A (en) | A kind of application in graphene oxide/silicic acid copper composite powder and preparation method thereof and super-hydrophobic coat | |

| JP2010043365A (en) | Superhydrophobic powder, structure having superhydrophobic surface using the same, and method for producing the same | |

| CN105130206A (en) | Method for preparing superhydrophobic and self-cleaning glass | |

| CN107916069A (en) | Preparation method and application with more superb hydrophobic silicones alkane polymer coating | |

| CN107903734B (en) | Preparation method of water-resistant long-acting anti-fog and anti-frost high-light-transmittance coating with self-repairing performance | |

| CN105802446A (en) | Wear-resistant and super-hydrophobic coating material and preparation method thereof | |

| CN108755111A (en) | A method of deposition silver nano-grain processability stablizes antibacterial superhydrophobic fabric | |

| CN105038338A (en) | Transparent super-hydrophobic spraying agent, and preparation method and application thereof | |

| JP2009514661A (en) | Production of coated substrates | |

| CN113122081B (en) | A transparent, high-hardness, multi-functional integrated self-healing coating and its preparation method and application | |

| CN115748237B (en) | Fluorine-free super-hydrophobic material and preparation method thereof | |

| Fu et al. | Study on surface wetting property regulation of greenhouse film and its antifogging performance |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20201110 Termination date:20210314 | |

| CF01 | Termination of patent right due to non-payment of annual fee |