CN108511662B - Multilayer lithium ion battery diaphragm material and preparation method thereof - Google Patents

Multilayer lithium ion battery diaphragm material and preparation method thereofDownload PDFInfo

- Publication number

- CN108511662B CN108511662BCN201810222569.0ACN201810222569ACN108511662BCN 108511662 BCN108511662 BCN 108511662BCN 201810222569 ACN201810222569 ACN 201810222569ACN 108511662 BCN108511662 BCN 108511662B

- Authority

- CN

- China

- Prior art keywords

- attapulgite

- parts

- polymethyl methacrylate

- propylene

- preparation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000463materialSubstances0.000titleclaimsabstractdescription55

- 229910001416lithium ionInorganic materials0.000titleclaimsabstractdescription45

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription45

- HBBGRARXTFLTSG-UHFFFAOYSA-NLithium ionChemical compound[Li+]HBBGRARXTFLTSG-UHFFFAOYSA-N0.000titleclaimsabstractdescription44

- 229920005989resinPolymers0.000claimsabstractdescription90

- 239000011347resinSubstances0.000claimsabstractdescription90

- 229920003229poly(methyl methacrylate)Polymers0.000claimsabstractdescription62

- 239000004926polymethyl methacrylateSubstances0.000claimsabstractdescription62

- 229960000892attapulgiteDrugs0.000claimsabstractdescription60

- 229910052625palygorskiteInorganic materials0.000claimsabstractdescription60

- 238000001125extrusionMethods0.000claimsabstractdescription40

- 125000000391vinyl groupChemical group[H]C([*])=C([H])[H]0.000claimsabstractdescription33

- 229920002554vinyl polymerPolymers0.000claimsabstractdescription33

- QQONPFPTGQHPMA-UHFFFAOYSA-NpropyleneNatural productsCC=CQQONPFPTGQHPMA-UHFFFAOYSA-N0.000claimsabstractdescription32

- 125000004805propylene groupChemical group[H]C([H])([H])C([H])([*:1])C([H])([H])[*:2]0.000claimsabstractdescription32

- 238000002145thermally induced phase separationMethods0.000claimsabstractdescription23

- 239000002994raw materialSubstances0.000claimsabstractdescription18

- VVQNEPGJFQJSBK-UHFFFAOYSA-NMethyl methacrylateChemical compoundCOC(=O)C(C)=CVVQNEPGJFQJSBK-UHFFFAOYSA-N0.000claimsabstractdescription14

- 239000004743PolypropyleneSubstances0.000claimsdescription76

- 229920001155polypropylenePolymers0.000claimsdescription76

- 239000010410layerSubstances0.000claimsdescription63

- 239000004594Masterbatch (MB)Substances0.000claimsdescription45

- -1polyethylenePolymers0.000claimsdescription43

- 239000004698PolyethyleneSubstances0.000claimsdescription41

- 229920000573polyethylenePolymers0.000claimsdescription41

- XEKOWRVHYACXOJ-UHFFFAOYSA-NEthyl acetateChemical compoundCCOC(C)=OXEKOWRVHYACXOJ-UHFFFAOYSA-N0.000claimsdescription39

- 238000006243chemical reactionMethods0.000claimsdescription27

- 239000003085diluting agentSubstances0.000claimsdescription20

- 239000000047productSubstances0.000claimsdescription20

- RTZKZFJDLAIYFH-UHFFFAOYSA-NDiethyl etherChemical compoundCCOCCRTZKZFJDLAIYFH-UHFFFAOYSA-N0.000claimsdescription19

- 239000000203mixtureSubstances0.000claimsdescription15

- VEXZGXHMUGYJMC-UHFFFAOYSA-NHydrochloric acidChemical compoundClVEXZGXHMUGYJMC-UHFFFAOYSA-N0.000claimsdescription14

- WYURNTSHIVDZCO-UHFFFAOYSA-NTetrahydrofuranChemical compoundC1CCOC1WYURNTSHIVDZCO-UHFFFAOYSA-N0.000claimsdescription14

- 229920001577copolymerPolymers0.000claimsdescription12

- 239000003208petroleumSubstances0.000claimsdescription11

- 238000005119centrifugationMethods0.000claimsdescription10

- 239000002131composite materialSubstances0.000claimsdescription10

- 239000003795chemical substances by applicationSubstances0.000claimsdescription9

- 239000012188paraffin waxSubstances0.000claimsdescription9

- 239000007787solidSubstances0.000claimsdescription9

- 238000003756stirringMethods0.000claimsdescription9

- USIUVYZYUHIAEV-UHFFFAOYSA-Ndiphenyl etherChemical compoundC=1C=CC=CC=1OC1=CC=CC=C1USIUVYZYUHIAEV-UHFFFAOYSA-N0.000claimsdescription8

- 238000005191phase separationMethods0.000claimsdescription8

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription8

- WYTZZXDRDKSJID-UHFFFAOYSA-N(3-aminopropyl)triethoxysilaneChemical compoundCCO[Si](OCC)(OCC)CCCNWYTZZXDRDKSJID-UHFFFAOYSA-N0.000claimsdescription7

- LMDZBCPBFSXMTL-UHFFFAOYSA-N1-ethyl-3-(3-dimethylaminopropyl)carbodiimideChemical compoundCCN=C=NCCCN(C)CLMDZBCPBFSXMTL-UHFFFAOYSA-N0.000claimsdescription7

- HEDRZPFGACZZDS-UHFFFAOYSA-NChloroformChemical compoundClC(Cl)ClHEDRZPFGACZZDS-UHFFFAOYSA-N0.000claimsdescription7

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription7

- 239000002253acidSubstances0.000claimsdescription7

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000claimsdescription7

- 238000001816coolingMethods0.000claimsdescription7

- 239000000155meltSubstances0.000claimsdescription7

- PSHKMPUSSFXUIA-UHFFFAOYSA-Nn,n-dimethylpyridin-2-amineChemical compoundCN(C)C1=CC=CC=N1PSHKMPUSSFXUIA-UHFFFAOYSA-N0.000claimsdescription7

- 239000001301oxygenSubstances0.000claimsdescription7

- 229910052760oxygenInorganic materials0.000claimsdescription7

- YLQBMQCUIZJEEH-UHFFFAOYSA-NtetrahydrofuranNatural productsC=1C=COC=1YLQBMQCUIZJEEH-UHFFFAOYSA-N0.000claimsdescription7

- CTQNGGLPUBDAKN-UHFFFAOYSA-NO-XyleneChemical compoundCC1=CC=CC=C1CCTQNGGLPUBDAKN-UHFFFAOYSA-N0.000claimsdescription6

- 239000003054catalystSubstances0.000claimsdescription6

- 239000008096xyleneSubstances0.000claimsdescription6

- 229910052799carbonInorganic materials0.000claimsdescription5

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000claimsdescription4

- 229940057995liquid paraffinDrugs0.000claimsdescription4

- VLKZOEOYAKHREP-UHFFFAOYSA-Nn-HexaneChemical compoundCCCCCCVLKZOEOYAKHREP-UHFFFAOYSA-N0.000claimsdescription4

- 230000007935neutral effectEffects0.000claimsdescription4

- 239000002356single layerSubstances0.000claimsdescription4

- 239000004925Acrylic resinSubstances0.000claimsdescription3

- 229920000178Acrylic resinPolymers0.000claimsdescription3

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000claimsdescription3

- 238000000605extractionMethods0.000claimsdescription3

- VGGSQFUCUMXWEO-UHFFFAOYSA-NEtheneChemical compoundC=CVGGSQFUCUMXWEO-UHFFFAOYSA-N0.000claimsdescription2

- 239000005977EthyleneSubstances0.000claimsdescription2

- 239000013067intermediate productSubstances0.000claimsdescription2

- 238000000926separation methodMethods0.000claimsdescription2

- 235000012424soybean oilNutrition0.000claimsdescription2

- 239000003549soybean oilSubstances0.000claimsdescription2

- 238000001291vacuum dryingMethods0.000claimsdescription2

- 102100027573ATP synthase subunit alpha, mitochondrialHuman genes0.000claims1

- 101000936262Homo sapiens ATP synthase subunit alpha, mitochondrialProteins0.000claims1

- 101000936965Homo sapiens ATP synthase-coupling factor 6, mitochondrialProteins0.000claims1

- 229960000935dehydrated alcoholDrugs0.000claims1

- 229910001873dinitrogenInorganic materials0.000claims1

- 238000000034methodMethods0.000abstractdescription33

- 239000011148porous materialSubstances0.000abstractdescription10

- 230000008569processEffects0.000abstractdescription10

- 239000002861polymer materialSubstances0.000abstractdescription4

- 239000012528membraneSubstances0.000description31

- 239000003792electrolyteSubstances0.000description26

- QTBSBXVTEAMEQO-UHFFFAOYSA-NAcetic acidChemical compoundCC(O)=OQTBSBXVTEAMEQO-UHFFFAOYSA-N0.000description24

- 229920013716polyethylene resinPolymers0.000description24

- 239000007788liquidSubstances0.000description13

- 238000005516engineering processMethods0.000description9

- 239000005038ethylene vinyl acetateSubstances0.000description9

- 229920001200poly(ethylene-vinyl acetate)Polymers0.000description9

- 229920000642polymerPolymers0.000description9

- 238000010521absorption reactionMethods0.000description7

- 230000014759maintenance of locationEffects0.000description7

- LRHPLDYGYMQRHN-UHFFFAOYSA-NN-ButanolChemical compoundCCCCOLRHPLDYGYMQRHN-UHFFFAOYSA-N0.000description6

- 230000008901benefitEffects0.000description6

- 229920000098polyolefinPolymers0.000description6

- 239000003153chemical reaction reagentSubstances0.000description5

- 238000001035dryingMethods0.000description5

- 238000004519manufacturing processMethods0.000description5

- 239000011159matrix materialSubstances0.000description5

- 238000002844meltingMethods0.000description5

- 230000008018meltingEffects0.000description5

- 239000000126substanceSubstances0.000description5

- 238000005406washingMethods0.000description5

- 230000009286beneficial effectEffects0.000description4

- 238000011161developmentMethods0.000description4

- 230000018109developmental processEffects0.000description4

- IEJIGPNLZYLLBP-UHFFFAOYSA-Ndimethyl carbonateChemical compoundCOC(=O)OCIEJIGPNLZYLLBP-UHFFFAOYSA-N0.000description4

- 230000000694effectsEffects0.000description4

- 125000004494ethyl ester groupChemical group0.000description4

- 238000004502linear sweep voltammetryMethods0.000description4

- 238000013508migrationMethods0.000description4

- 230000005012migrationEffects0.000description4

- 239000000178monomerSubstances0.000description4

- 239000000725suspensionSubstances0.000description4

- 238000012360testing methodMethods0.000description4

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000description3

- 230000008859changeEffects0.000description3

- 229960001701chloroformDrugs0.000description3

- 229910052744lithiumInorganic materials0.000description3

- 239000007800oxidant agentSubstances0.000description3

- 239000002689soilSubstances0.000description3

- XKRFYHLGVUSROY-UHFFFAOYSA-NArgonChemical compound[Ar]XKRFYHLGVUSROY-UHFFFAOYSA-N0.000description2

- OMPJBNCRMGITSC-UHFFFAOYSA-NBenzoylperoxideChemical compoundC=1C=CC=CC=1C(=O)OOC(=O)C1=CC=CC=C1OMPJBNCRMGITSC-UHFFFAOYSA-N0.000description2

- BVKZGUZCCUSVTD-UHFFFAOYSA-LCarbonateChemical compound[O-]C([O-])=OBVKZGUZCCUSVTD-UHFFFAOYSA-L0.000description2

- KMTRUDSVKNLOMY-UHFFFAOYSA-NEthylene carbonateChemical compoundO=C1OCCO1KMTRUDSVKNLOMY-UHFFFAOYSA-N0.000description2

- XTXRWKRVRITETP-UHFFFAOYSA-NVinyl acetateChemical compoundCC(=O)OC=CXTXRWKRVRITETP-UHFFFAOYSA-N0.000description2

- 125000003118aryl groupChemical group0.000description2

- 235000019400benzoyl peroxideNutrition0.000description2

- 230000015572biosynthetic processEffects0.000description2

- 238000004364calculation methodMethods0.000description2

- 125000002915carbonyl groupChemical group[*:2]C([*:1])=O0.000description2

- 238000013329compoundingMethods0.000description2

- 239000013078crystalSubstances0.000description2

- 238000010586diagramMethods0.000description2

- VYFYYTLLBUKUHU-UHFFFAOYSA-NdopamineChemical compoundNCCC1=CC=C(O)C(O)=C1VYFYYTLLBUKUHU-UHFFFAOYSA-N0.000description2

- 238000000157electrochemical-induced impedance spectroscopyMethods0.000description2

- 230000007613environmental effectEffects0.000description2

- 238000004880explosionMethods0.000description2

- 238000010438heat treatmentMethods0.000description2

- 238000007731hot pressingMethods0.000description2

- 125000002887hydroxy groupChemical group[H]O*0.000description2

- 238000007654immersionMethods0.000description2

- 239000013385inorganic frameworkSubstances0.000description2

- 150000002500ionsChemical class0.000description2

- 238000005259measurementMethods0.000description2

- 238000002156mixingMethods0.000description2

- 239000003607modifierSubstances0.000description2

- 239000002086nanomaterialSubstances0.000description2

- 230000001590oxidative effectEffects0.000description2

- 238000012545processingMethods0.000description2

- 238000012712reversible addition−fragmentation chain-transfer polymerizationMethods0.000description2

- 238000012552reviewMethods0.000description2

- 238000001338self-assemblyMethods0.000description2

- 239000002904solventSubstances0.000description2

- 229910001220stainless steelInorganic materials0.000description2

- 239000010935stainless steelSubstances0.000description2

- 150000003512tertiary aminesChemical group0.000description2

- 238000010998test methodMethods0.000description2

- 101710141544Allatotropin-related peptideProteins0.000description1

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description1

- OIFBSDVPJOWBCH-UHFFFAOYSA-NDiethyl carbonateChemical compoundCCOC(=O)OCCOIFBSDVPJOWBCH-UHFFFAOYSA-N0.000description1

- 230000009471actionEffects0.000description1

- HZVVJJIYJKGMFL-UHFFFAOYSA-NalmasilateChemical compoundO.[Mg+2].[Al+3].[Al+3].O[Si](O)=O.O[Si](O)=OHZVVJJIYJKGMFL-UHFFFAOYSA-N0.000description1

- 229910001579aluminosilicate mineralInorganic materials0.000description1

- 239000010405anode materialSubstances0.000description1

- 229910052786argonInorganic materials0.000description1

- 238000010560atom transfer radical polymerization reactionMethods0.000description1

- BVKZGUZCCUSVTD-UHFFFAOYSA-Ncarbonic acidChemical compoundOC(O)=OBVKZGUZCCUSVTD-UHFFFAOYSA-N0.000description1

- 238000005266castingMethods0.000description1

- 230000003197catalytic effectEffects0.000description1

- 239000010406cathode materialSubstances0.000description1

- 238000005524ceramic coatingMethods0.000description1

- 239000004927claySubstances0.000description1

- 239000011247coating layerSubstances0.000description1

- 230000008602contractionEffects0.000description1

- 238000003869coulometryMethods0.000description1

- 238000004132cross linkingMethods0.000description1

- 230000007547defectEffects0.000description1

- 238000013461designMethods0.000description1

- 230000004069differentiationEffects0.000description1

- 239000006185dispersionSubstances0.000description1

- 229960003638dopamineDrugs0.000description1

- 238000000840electrochemical analysisMethods0.000description1

- 238000002848electrochemical methodMethods0.000description1

- 238000006056electrooxidation reactionMethods0.000description1

- 238000003912environmental pollutionMethods0.000description1

- 238000002474experimental methodMethods0.000description1

- 239000000446fuelSubstances0.000description1

- 229920001002functional polymerPolymers0.000description1

- 239000007789gasSubstances0.000description1

- 239000010439graphiteSubstances0.000description1

- 229910002804graphiteInorganic materials0.000description1

- 229920001903high density polyethylenePolymers0.000description1

- 239000004700high-density polyethyleneSubstances0.000description1

- 238000001453impedance spectrumMethods0.000description1

- 230000006872improvementEffects0.000description1

- 229910052809inorganic oxideInorganic materials0.000description1

- 230000037427ion transportEffects0.000description1

- 229910052751metalInorganic materials0.000description1

- 239000002184metalSubstances0.000description1

- 239000004005microsphereSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 238000002715modification methodMethods0.000description1

- 239000002048multi walled nanotubeSubstances0.000description1

- 239000002105nanoparticleSubstances0.000description1

- 239000002073nanorodSubstances0.000description1

- 239000007773negative electrode materialSubstances0.000description1

- 229910052757nitrogenInorganic materials0.000description1

- 230000003287optical effectEffects0.000description1

- 238000000879optical micrographMethods0.000description1

- 229920000620organic polymerPolymers0.000description1

- 229920003023plasticPolymers0.000description1

- 239000004033plasticSubstances0.000description1

- 239000005518polymer electrolyteSubstances0.000description1

- 238000010094polymer processingMethods0.000description1

- 230000009024positive feedback mechanismEffects0.000description1

- 238000004313potentiometryMethods0.000description1

- 238000010526radical polymerization reactionMethods0.000description1

- 238000011084recoveryMethods0.000description1

- 238000011160researchMethods0.000description1

- 230000035939shockEffects0.000description1

- 230000005476size effectEffects0.000description1

- 238000002791soakingMethods0.000description1

- 238000001179sorption measurementMethods0.000description1

- 230000003068static effectEffects0.000description1

- 238000003860storageMethods0.000description1

- 238000003786synthesis reactionMethods0.000description1

- 238000009864tensile testMethods0.000description1

- 230000005641tunnelingEffects0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/403—Manufacturing processes of separators, membranes or diaphragms

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

- H01M10/0525—Rocking-chair batteries, i.e. batteries with lithium insertion or intercalation in both electrodes; Lithium-ion batteries

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/411—Organic material

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/40—Separators; Membranes; Diaphragms; Spacing elements inside cells

- H01M50/409—Separators, membranes or diaphragms characterised by the material

- H01M50/449—Separators, membranes or diaphragms characterised by the material having a layered structure

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Cell Separators (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于高分子材料技术领域,具体涉及一种锂离子电池隔膜材料及其制备方法。The invention belongs to the technical field of polymer materials, and particularly relates to a lithium ion battery separator material and a preparation method thereof.

背景技术Background technique

经济全球化的快速发展将带来能源的加倍消耗,面对环境污染和资源枯竭两大亟待解决的问题,新型、高效、清洁的可再生的能源的发展非常必要,绿色能源成为将来发展的重中之重。电化学能源是一种高效洁净的能量转换与储存技术,主要包括燃料电池、二次化学电源和超级电容器等。在这其中,锂离子电池(LIB)以其工作电压高、能量密度高、循环寿命长及环境友好等优点受到科研界和产业界的瞩目,目前广泛应用于MP3、手机、笔记本电脑等电子数码产品 (Arora P, Zhang Z. Battery separators. Chemical Reviews,2004, 104(10): 4419-4462)。在充电过程中,锂离子在两个电极之间往返脱嵌,锂离子电池隔膜在电池的安全及电化学性能方面起着至关重要的作用。特别是由于LIBs中可燃电解质以及氧化剂的存在,使得电池在使用过程中存在发生火灾和爆炸的隐患:锂离子电池在短路,过充电及高温热冲击等极端环境条件下,会引发电极与电解液之间的放热化学反应,这将引起电池内部压力与温度的急剧增高 (Joho F, Novák P, Spahr M E. Safetyaspects of graphite negative electrode materials for lithium-ion batteries.Journal of The Electrochemical Society, 2002, 149(8): A1020)。温度的升高又将加速上述反应,并通过危险的正反馈机制迅速释放热量,这将导致电池热失控,火灾甚至爆炸。因此,为了推动锂离子电池在上述高能量密度新兴领域中的应用,仍需要进一步提高其安全稳定性 (Ji W, Jiang B, Ai F, et al. Temperature-responsive microspheres-coated separator for thermal shutdown protection of lithium ion batteries.RSC Adv, 2015, 5(1): 172-176)。使用具有热关断功能的电池隔膜是防止锂离子电池(LIBs)使用过程中出现灾难性热故障的有效方法。从锂离子电池的安全性能考虑,隔膜应当具有较低的闭孔温度和较高的热收缩变形温度,即较宽的安全温度窗口。目前市场上使用的聚乙烯和聚丙烯单层电池隔膜的闭孔温度与热收缩变形温度接近,无法保证锂离子电池的使用安全性。为提高锂离子电池的使用安全性,研究人员提出了开发聚丙烯(PP)/聚乙烯(PE)双层或PP/PE/PP三层复合微孔膜作为电池隔膜材料 (Tabatabaei S H, Carreau PJ, Ajji A. Microporous membranes obtained from PP/HDPE multilayer films bystretching. Journal of Membrane Science, 2009, 345(1-2): 148-159)。以期利用聚乙烯的低熔点获得较低的闭孔温度,聚丙烯的高熔点获得较高的热收缩变形温度 (Shi C,Zhang P, Chen L, et al. Effect of a thin ceramic-coating layer on thermal andelectrochemical properties of polyethylene separator for lithium-ionbatteries. Journal of Power Sources, 2014, 270:547-553)。目前制备多层复合微孔膜的方法是先在不同流延条件下分别制备出PE和PP 流延基膜并分别进行热处理,随后进行热压复合,接着在一定条件下对复合膜实施拉伸作用使其形成微孔。该制造过程工艺路线比较复杂,且设备投入多,生产效率较低 (Deimede V, Elmasides C. Separators forlithium-ion batteries: A Review on the Production Processes and RecentDevelopments. Energy Technology, 2015, 3(5): 453-468)。另一方面,目前商业化多层隔膜的缺点还在于,经过多次拉伸所制备的多孔薄膜存在残余应力,因其形状记忆的特性,在遇到高温的情况下极易发生大幅度的收缩,从而导致较差的热尺寸稳定性。为改善目前商业化多层聚烯烃隔膜热稳定性较差的问题,研究人员致力于通过各种改性方法降低隔膜的热收缩。例如,在隔膜表面涂覆具有优异热稳定性的有机聚合物/无机氧化物等,但这种工艺过程较复杂,难以批量化生产,大大提高了隔膜成本。因此寻找可以优化聚烯烃隔膜的热稳定性与热关闭性能,同时又不牺牲其优良的微孔结构、电化学性能和低成本的新方法是至关重要的。The rapid development of economic globalization will bring about double consumption of energy. Facing the two urgent problems of environmental pollution and resource depletion, the development of new, high-efficiency, clean and renewable energy is very necessary, and green energy will become the key to future development. The heaviest. Electrochemical energy is an efficient and clean energy conversion and storage technology, mainly including fuel cells, secondary chemical power sources, and supercapacitors. Among them, lithium-ion batteries (LIB) have attracted the attention of scientific research and industrial circles due to their high operating voltage, high energy density, long cycle life and environmental friendliness. Product (Arora P, Zhang Z. Battery separators. Chemical Reviews, 2004, 104(10): 4419-4462). During the charging process, lithium ions are deintercalated back and forth between the two electrodes, and the lithium ion battery separator plays a crucial role in the safety and electrochemical performance of the battery. Especially due to the existence of flammable electrolytes and oxidants in LIBs, there are hidden dangers of fire and explosion during the use of batteries: lithium-ion batteries will cause electrodes and electrolytes under extreme environmental conditions such as short circuit, overcharge and high temperature thermal shock. The exothermic chemical reaction between the two will cause a sharp increase in the internal pressure and temperature of the battery (Joho F, Novák P, Spahr M E. Safetyaspects of graphite negative electrode materials for lithium-ion batteries. Journal of The Electrochemical Society, 2002, 149(8): A1020). The increase in temperature will in turn accelerate the above reaction and rapidly release heat through a dangerous positive feedback mechanism, which will lead to thermal runaway of the battery, fire or even explosion. Therefore, in order to promote the application of lithium-ion batteries in the above-mentioned emerging fields of high energy density, it is still necessary to further improve their safety and stability (Ji W, Jiang B, Ai F, et al. Temperature-responsive microspheres-coated separator for thermal shutdown protection of lithium ion batteries. RSC Adv, 2015, 5(1): 172-176). The use of battery separators with thermal shutdown is an effective way to prevent catastrophic thermal failures during the use of lithium-ion batteries (LIBs). Considering the safety performance of lithium-ion batteries, the separator should have a lower closed cell temperature and a higher thermal shrinkage deformation temperature, that is, a wider safe temperature window. The closed-cell temperature of polyethylene and polypropylene single-layer battery separators currently on the market is close to the thermal shrinkage deformation temperature, which cannot guarantee the safety of lithium-ion batteries. In order to improve the safety of lithium-ion batteries, researchers proposed to develop polypropylene (PP)/polyethylene (PE) double-layer or PP/PE/PP triple-layer composite microporous membranes as battery separator materials (Tabatabaei S H, Carreau PJ). , Ajji A. Microporous membranes obtained from PP/HDPE multilayer films by stretching. Journal of Membrane Science, 2009, 345(1-2): 148-159). In order to use the low melting point of polyethylene to obtain a lower closed cell temperature, and the high melting point of polypropylene to obtain a higher thermal shrinkage deformation temperature (Shi C, Zhang P, Chen L, et al. Effect of a thin ceramic-coating layer on thermal andelectrochemical properties of polyethylene separator for lithium-ionbatteries. Journal of Power Sources, 2014, 270:547-553). The current method for preparing multi-layer composite microporous membranes is to first prepare PE and PP cast base membranes under different casting conditions and heat treatment respectively, then perform hot pressing compounding, and then stretch the composite membrane under certain conditions. action to form micropores. The manufacturing process has a complex process route, and requires a lot of equipment, resulting in low production efficiency (Deimede V, Elmasides C. Separators for lithium-ion batteries: A Review on the Production Processes and Recent Developments. Energy Technology, 2015, 3(5): 453 -468). On the other hand, the disadvantage of the current commercial multi-layer diaphragm is that the porous film prepared by repeated stretching has residual stress, and due to its shape memory characteristics, it is prone to large shrinkage in the case of high temperature. , resulting in poor thermal dimensional stability. In order to improve the problem of poor thermal stability of the current commercial multi-layer polyolefin separators, researchers have devoted themselves to reducing the thermal shrinkage of the separators through various modification methods. For example, organic polymers/inorganic oxides with excellent thermal stability are coated on the surface of the separator, but this process is complicated and difficult to mass-produce, which greatly increases the cost of the separator. Therefore, it is crucial to find new methods that can optimize the thermal stability and thermal shutdown properties of polyolefin separators without sacrificing their excellent microporous structure, electrochemical performance, and low cost.

微层共挤出是一种先进的聚合物加工技术,它能够高效连续地生产出具有多层结构的聚合物材料 (Cheng J F, Pu H T. Influences of matrix viscosity onalignment of multi-walled carbon nanotubes in one-dimensional confined space.European Polymer Journal, 2017, 89: 431-439)。热致相分离是目前广泛应用于商业化电池隔膜生产中的制造工艺,工作的原理是基于聚合物在高温下与稀释剂混溶,而在低温下两者发生分离,由TIPS法制备的隔膜具有良好的可控性和孔结构的均匀性 (Shi J L,Fang L F, Li H, et al. Improved thermal and electrochemical performances ofPMMA modified PE separator skeleton prepared via dopamine-initiated ATRP forlithium ion batteries. Journal of Membrane Science, 2013, 437:160-168)。在本发明中提出了一种通过微层共挤出和热致相分离相结合来制备多层隔膜的方法,以期结合两种方法的优点,一方面具有热致相分离方法自身具备的孔结构均匀可控的优点,另一方面微层共挤出技术大大简化了多层隔膜的制备工艺,避免了传统制备方法繁琐的过程,可以高效地大规模制备多层锂离子电池隔膜。Microlayer coextrusion is an advanced polymer processing technology that can efficiently and continuously produce polymer materials with multilayer structures (Cheng J F, Pu H T. Influences of matrix viscosity on alignment of multi-walled carbon nanotubes in one-dimensional confined space. European Polymer Journal, 2017, 89: 431-439). Thermally induced phase separation is a manufacturing process widely used in the production of commercial battery separators. It has good controllability and uniformity of pore structure (Shi J L,Fang L F, Li H, et al. Improved thermal and electrochemical performances of PMMA modified PE separator skeleton prepared via dopamine-initiated ATRP forlithium ion batteries. Journal of Membrane Science, 2013, 437:160-168). In the present invention, a method for preparing a multi-layer membrane by combining microlayer co-extrusion and thermally induced phase separation is proposed, in order to combine the advantages of the two methods, on the one hand, it has the pore structure possessed by the thermally induced phase separation method itself The advantages of uniformity and controllability, on the other hand, the micro-layer co-extrusion technology greatly simplifies the preparation process of the multi-layer separator, avoids the cumbersome process of the traditional preparation method, and can efficiently prepare the multi-layer lithium-ion battery separator on a large scale.

另外,非极性的聚烯烃基微孔隔膜与极性的锂离子电池电解液的亲和性较差,并且当温度高于聚烯烃基聚合物的熔点时,隔膜的机械性能急速下降,限制了锂离子电池性能的进一步提高。为了克服这些缺点,进一步提高隔膜的热稳定性与电池性能,本发明中,在乙烯基树脂/丙烯基树脂锂离子电池隔膜的基础上,添加了无机组分凹凸棒土。凹凸棒土(ATP)是一种晶质水合镁铝硅酸盐矿物,具有独特的层链状结构特征以及优异的热稳定性,是天然一维纳米材料且资源丰富价格低廉。其特殊的纤维状晶体结构和单晶内部丰富的纳米孔道赋予其优良的吸附性、催化性、流变性等特殊性能,凹凸棒土的应用前景十分广阔,被誉为万能黏土、万土之王,其产品已进入以新材料和新能源为代表的高新技术产业。另外,凹凸棒土表面含大量极性羟基,较适合于极性体系使用。但目前的问题在于,在纳米尺度下,宏观量子隧道效应、量子尺寸效应及表面/界面效应使得纳米粒子具有极高的表面能,在聚合物基体中很容易发生团聚,从而无法发挥凹凸棒土特殊的纳米性能 (Yang H,Pu H, Gong F. Preparation of poly(methyl methacrylate)-grafted attapulgite bysurface-initiated radical polymerization. Journal of Applied Polymer Science,2014, 131(22): 41062)。因此有必要对其进行表面改性,以提高其分散性能,同时使得改性后的材料适用于锂离子电池隔膜体系。聚甲基丙烯酸甲酯(PMMA)是一种性价比较高的可塑性高分子材料,具有与电解液的主要成分碳酸酯溶剂(碳酸乙烯酯EC,碳酸二甲酯DMC,碳酸二乙酯DEC)结构相似的化学结构(羰基) (Evans J, Vincent C A, Bruce P G.Electrochemical measurement of transference numbers in polymer electrolytes.Polymer, 1987, 28(13): 2324-2328),对电解液具有较强的亲和性;同时其无定形结构有利于增强离子传导以及界面稳定性。因此,本发明选取甲基丙烯酸甲酯(MMA)对凹凸棒进行改性,设计合成了一种带有还原性芳叔胺基团的表面改性剂,通过一步自组装法接枝到凹凸棒土表面,再结合过氧化二苯甲酰作为氧化剂,在游离RAFT试剂存在下进行MMA的RAFT聚合。将制备出的凹凸棒土-聚甲基丙烯酸甲酯杂化材料(ATPM)与乙烯基树脂/丙烯基树脂共混,利用热致相分离和微层共挤出相结合的方法制备出多层锂离子电池隔膜材料,并探究其物理及电化学性能,以及ATPM对上述性能的影响。In addition, the non-polar polyolefin-based microporous separator has poor affinity with the polar lithium-ion battery electrolyte, and when the temperature is higher than the melting point of the polyolefin-based polymer, the mechanical properties of the separator drop rapidly, limiting the The performance of lithium-ion batteries is further improved. In order to overcome these shortcomings and further improve the thermal stability and battery performance of the separator, in the present invention, an inorganic component attapulgite is added on the basis of the vinyl resin/propylene-based resin lithium ion battery separator. Attapulgite (ATP) is a crystalline hydrated magnesium-aluminosilicate mineral with unique layer-chain structure characteristics and excellent thermal stability. It is a natural one-dimensional nanomaterial with abundant resources and low price. Its special fibrous crystal structure and abundant nano-pores inside the single crystal endow it with excellent adsorption, catalytic, rheological and other special properties. Attapulgite has a very broad application prospect and is known as the universal clay and the king of all soils. , its products have entered the high-tech industry represented by new materials and new energy. In addition, the surface of attapulgite contains a large number of polar hydroxyl groups, which is more suitable for polar systems. But the current problem is that at the nanoscale, the macroscopic quantum tunneling effect, quantum size effect and surface/interface effect make the nanoparticles have extremely high surface energy, and it is easy to agglomerate in the polymer matrix, so that the attapulgite can not be used. Special nano-performance (Yang H, Pu H, Gong F. Preparation of poly(methyl methacrylate)-grafted attapulgite by surface-initiated radical polymerization. Journal of Applied Polymer Science, 2014, 131(22): 41062). Therefore, it is necessary to modify its surface to improve its dispersion properties, and at the same time make the modified material suitable for lithium-ion battery separator system. Polymethyl methacrylate (PMMA) is a cost-effective plastic polymer material, which has a structure with the main components of the electrolyte, carbonate solvents (ethylene carbonate EC, dimethyl carbonate DMC, diethyl carbonate DEC) Similar chemical structure (carbonyl group) (Evans J, Vincent C A, Bruce P G. Electrochemical measurement of transference numbers in polymer electrolytes. Polymer, 1987, 28(13): 2324-2328), with strong affinity for electrolytes At the same time, its amorphous structure is beneficial to enhance ion conduction and interface stability. Therefore, the present invention selects methyl methacrylate (MMA) to modify the attapulgite, designs and synthesizes a surface modifier with a reducing aromatic tertiary amine group, and grafts it to the attapulgite through a one-step self-assembly method On the soil surface, combined with dibenzoyl peroxide as an oxidant, the RAFT polymerization of MMA was carried out in the presence of free RAFT reagent. The prepared attapulgite-polymethyl methacrylate hybrid material (ATPM) was blended with vinyl resin/propylene-based resin, and multi-layers were prepared by a combination of thermal-induced phase separation and microlayer co-extrusion. Li-ion battery separator materials, and explore their physical and electrochemical properties, as well as the effect of ATPM on the above properties.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提出一种优异热稳定性性,并且制备工艺简单、原料成本低廉,可以大规模生产的多层锂离子电池隔膜材料及其制备方法。The purpose of the present invention is to provide a multi-layer lithium ion battery separator material with excellent thermal stability, simple preparation process and low cost of raw materials, which can be mass-produced and a preparation method thereof.

本发明提出的具有优异热稳定性的多层锂离子电池隔膜材料,由凹凸棒土(ATP)经甲基丙烯酸甲酯(MMA)改性而得到的凹凸棒土-聚甲基丙烯酸甲酯杂化材料(ATPM)与乙烯基树脂、丙烯基树脂共混而得到,记为乙烯基树脂/丙烯基树脂-聚甲基丙烯酸甲酯改性的凹凸棒多层隔膜;本发明中,首先选取甲基丙烯酸甲酯(MMA)对凹凸棒(ATP)进行改性;包括合成一种带有还原性芳叔胺基团的表面改性剂,通过一步自组装法接枝到凹凸棒土表面,再结合过氧化二苯甲酰作为氧化剂,在游离RAFT试剂存在下进行MMA的RAFT聚合;然后将制备的凹凸棒土-聚甲基丙烯酸甲酯杂化材料与乙烯基树脂/丙烯基树脂共混;最后利用热致相分离和微层共挤出相结合的方法制备出多层锂离子电池隔膜。制备出的隔膜具有交替层状结构,孔结构丰富,具有优异的热稳定性能及电化学性能。The multi-layer lithium ion battery separator material with excellent thermal stability proposed in the present invention is an attapulgite-polymethyl methacrylate hybrid obtained by modifying attapulgite (ATP) with methyl methacrylate (MMA). It is obtained by blending the chemical material (ATPM) with vinyl resin and propylene-based resin, which is denoted as vinyl resin/propylene-based resin-polymethyl methacrylate modified attapulgite multilayer diaphragm; The modification of attapulgite (ATP) by methyl methacrylate (MMA) includes the synthesis of a surface modifier with a reducing aromatic tertiary amine group, which is grafted to the surface of attapulgite through a one-step self-assembly method, and then Combined with dibenzoyl peroxide as an oxidant, RAFT polymerization of MMA was carried out in the presence of free RAFT reagent; then the prepared attapulgite-polymethyl methacrylate hybrid material was blended with vinyl resin/propylene-based resin; Finally, a multi-layer lithium-ion battery separator was prepared by a combination of thermally induced phase separation and microlayer co-extrusion. The prepared separator has an alternating layered structure, rich pore structure, and excellent thermal stability and electrochemical performance.

本发明提供的乙烯基树脂/丙烯基树脂-聚甲基丙烯酸甲酯改性的凹凸棒多层膜材料的制备方法,具体步骤如下:The preparation method of the attapulgite multilayer film material modified by vinyl resin/propylene-based resin-polymethyl methacrylate provided by the present invention, the specific steps are as follows:

(1)凹凸棒土-聚甲基丙烯酸甲酯杂化材料(即聚甲基丙烯酸甲酯改性的凹凸棒材料)的制备(1) Preparation of attapulgite-polymethyl methacrylate hybrid material (ie, polymethyl methacrylate modified attapulgite material)

将凹凸棒土在1 mol L-1的盐酸中搅拌反应2-8 h后静置10-14 h,过滤后洗至中性,烘干粉碎后称取1-3份分散在二甲苯中,超声0.5-2 h;加入1-3份3-氨丙基三乙氧基硅烷,升温至60-100 ℃,恒温搅拌反应5-8 h,产物抽滤洗涤干燥,粉碎后过200目筛,得中间产物,记为ATP-APTES;The attapulgite was stirred and reacted in 1 mol L-1 of hydrochloric acid for 2-8 h, then stood for 10-14 h, filtered, washed until neutral, dried and pulverized, weighed 1-3 parts and dispersed in xylene. Ultrasonic for 0.5-2 h; add 1-3 parts of 3-aminopropyltriethoxysilane, heat up to 60-100 °C, stir at constant temperature for 5-8 h, the product is filtered, washed and dried, pulverized and passed through a 200-mesh sieve, The intermediate product is obtained, denoted as ATP-APTES;

称取1-5 份偶氮二氰基戊酸溶于乙酸乙酯,加入1-5份 1-(3-二甲基氨基丙基)-3-乙基碳二亚胺作缩合剂,N2保护下搅拌反应0.5-1 h;再加入3-6份二甲氨基吡啶作催化剂,静置0.5-2 h, 记为反应体系A;Weigh 1-5 parts of azodicyanovaleric acid and dissolve it in ethyl acetate, add 1-5 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide as a condensing agent, N2 Under the protection, stir the reaction for 0.5-1 h; then add 3-6 parts of dimethylaminopyridine as a catalyst, let it stand for 0.5-2 h, and record it as reaction system A;

另称取1-3份ATP-APTES分散于乙酸乙酯中,搅拌反应1-3 h,分四至六次 (时间间隔为0.3至0.6 h 加入到反应体系A中搅拌反应,加入完毕后反应10-20 h;反应结束后经离心、洗涤、干燥,得干燥产物;In addition, 1-3 parts of ATP-APTES were weighed and dispersed in ethyl acetate, stirred and reacted for 1-3 h, divided into four to six times (the time interval was 0.3 to 0.6 h, added to the reaction system A and stirred for reaction, and after the addition was completed, the reaction was performed for 10 -20 h; after the reaction, centrifugation, washing and drying were performed to obtain a dry product;

称取1-2份上述干燥产物与15-30份甲基丙烯酸甲酯单体在60-100 ℃搅拌反应6-10 h,反应前通20-40 min氮气以除尽氧气,离心分离后用四氢呋喃洗涤2-5次, 40-60 ℃真空干燥,即得凹凸棒土-聚甲基丙烯酸甲酯杂化材料,记为ATPM;Weigh 1-2 parts of the above-mentioned dried product and 15-30 parts of methyl methacrylate monomer, stir and react at 60-100 °C for 6-10 h, pass nitrogen for 20-40 min before the reaction to remove oxygen, and use Washed with tetrahydrofuran for 2-5 times, and vacuum-dried at 40-60 °C to obtain attapulgite-polymethyl methacrylate hybrid material, denoted as ATPM;

所述各组分的份额均以质量计,下同;The proportion of each component is by mass, the same below;

(2)乙烯基树脂、丙烯基树脂母料的制备(2) Preparation of vinyl resin and acrylic resin masterbatch

在微层共挤出之前,将稀释剂及凹凸棒土-聚甲基丙烯酸甲酯杂化材料分别预分散在乙烯基树脂及丙烯基树脂中,上述组分预先混合后,放入双螺杆挤出机中制备出乙烯基树脂的母料及丙烯基树脂的母料;Before the microlayer co-extrusion, the diluent and attapulgite-polymethyl methacrylate hybrid material were pre-dispersed in vinyl resin and propylene-based resin respectively. After the above components were pre-mixed, they were put into twin-screw extrusion The masterbatch of vinyl resin and the masterbatch of propylene-based resin are prepared from the machine;

乙烯基树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of vinyl resin is calculated as:

乙烯基树脂 40-100份,40-100 parts of vinyl resin,

稀释剂 30-200份,Thinner 30-200 parts,

凹凸棒土-聚甲基丙烯酸甲酯杂化材料 0-10份,优选1-10份;Attapulgite-polymethyl methacrylate hybrid material 0-10 parts, preferably 1-10 parts;

丙烯基树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of propylene-based resin is calculated as:

丙烯基树脂 40-100份,40-100 parts of acrylic resin,

稀释剂 30-200份,Thinner 30-200 parts,

凹凸棒土-聚甲基丙烯酸甲酯杂化材料 0-10份,优选1-10份;Attapulgite-polymethyl methacrylate hybrid material 0-10 parts, preferably 1-10 parts;

(3)多层隔膜材料的制备(3) Preparation of multilayer diaphragm materials

采用双组分微层共挤出成型设备,第一进料口加入步骤(2)得到的乙烯基树脂母料,第二进料口加入步骤(2)得到的丙烯基树脂母料,调节转速为5-20 rpm,温度为80-180℃,在微层共挤出设备的基础单元-层倍增器中,层状复合材料被垂直切片,水平展开并依次重组,熔体经过n个层倍增器后可以产生具有2n+1层结构的材料;微层共挤出之后,立即将挤出的多层薄膜浸入10℃-30℃的水浴中进行冷却,从而引发热诱导相分离,由相分离形成的两相结构即为隔膜多孔结构的原型;然后将上述多层薄膜浸入萃取剂中超声5-10 h,以萃取出隔膜中的稀释剂后形成多孔结构;最后在40℃-70℃条件下真空干燥10-20 h,即得所需的乙烯基树脂/丙烯基树脂/聚甲基丙烯酸甲酯改性的凹凸棒多层膜材料。Two-component microlayer co-extrusion molding equipment is used, the vinyl resin masterbatch obtained in step (2) is added to the first feed port, the propylene-based resin masterbatch obtained in step (2) is added to the second feed port, and the rotational speed is adjusted. At a temperature of 5-20 rpm and a temperature of 80-180 °C, in the basic unit of the microlayer co-extrusion equipment - the layer multiplier, the layered composite is sliced vertically, spread out horizontally and recombined in sequence, and the melt is multiplied by n layers After microlayer co- extrusion, the extruded multilayer film was immediately immersed in a water bath at 10°C-30°C for cooling, thereby triggering thermally induced phase separation, which resulted from phase separation. The two-phase structure formed by separation is the prototype of the porous structure of the diaphragm; then the above-mentioned multilayer film is immersed in the extractant and ultrasonicated for 5-10 h to extract the diluent in the diaphragm to form a porous structure; finally, the porous structure is formed at 40℃-70℃ Under vacuum drying conditions for 10-20 h, the desired attapulgite multilayer film material modified with vinyl resin/propylene-based resin/polymethyl methacrylate is obtained.

本发明中,制备的多层膜具有交替层状结构,层数为4-512层,隔膜总厚度为10-40µm,多孔膜表面平整连续、厚度均匀且具备优良的机械强度;膜的总厚度及单层厚度可以通过调节层数及成膜模具出口厚度进行控制。In the present invention, the prepared multilayer film has an alternate layered structure, the number of layers is 4-512 layers, the total thickness of the diaphragm is 10-40 µm, the surface of the porous film is smooth and continuous, the thickness is uniform and has excellent mechanical strength; the total thickness of the film is And the thickness of the single layer can be controlled by adjusting the number of layers and the thickness of the exit of the film forming die.

本发明中,所述的乙烯基树脂为聚乙烯或乙烯的共聚物,丙烯基树脂为聚丙烯或丙烯的共聚物。In the present invention, the vinyl resin is a copolymer of polyethylene or ethylene, and the propylene-based resin is a copolymer of polypropylene or propylene.

本发明中,所用的稀释剂为固体石蜡、二苯醚、大豆油或液体石蜡中的一种。In the present invention, the used diluent is one of solid paraffin, diphenyl ether, soybean oil or liquid paraffin.

本发明中,所用的萃取剂为石油醚、正己烷、三氯甲烷、丙酮或无水乙醇中的一种。In the present invention, the used extraction agent is one of petroleum ether, n-hexane, chloroform, acetone or absolute ethanol.

本发明制备的多层膜中,加入了聚甲基丙烯酸甲酯改性的凹凸棒,使得膜具有更为优异的热稳定性能及电化学性能,可用作锂离子电池的隔膜材料。In the multi-layer film prepared by the invention, polymethyl methacrylate modified attapulgite rods are added, so that the film has more excellent thermal stability performance and electrochemical performance, and can be used as a diaphragm material for lithium ion batteries.

对制备出的多层膜进行孔结构及电化学等测试,结果表明ATPM的棒状结构贯穿于孔洞之间,形成连续的三维网络,同时也保持着乙烯基树脂/丙烯基树脂隔膜丰富的多孔结构。ATPM的加入提高了隔膜表面对电解液的浸润性,浸润性的提高将导致隔膜对电解液的吸液率保液率及离子电导率的提高,从而提升隔膜的电化学性能。另外,由于凹凸棒本身具有高温稳定性,且在隔膜内形成相互联接的三维网络,起到无机骨架的作用,因此大大提高了隔膜的热稳定性,温度升至180℃仍能保持优异的热尺寸稳定性。上述优点使得本发明多层隔膜在高安全性能锂离子电池方面具有广阔的应用前景。The pore structure and electrochemical tests of the prepared multilayer film show that the rod-like structure of ATPM runs through the pores, forming a continuous three-dimensional network, while maintaining the abundant porous structure of the vinyl resin/propylene resin separator. . The addition of ATPM improves the wettability of the diaphragm surface to the electrolyte, and the increase in wettability will lead to an increase in the liquid absorption rate and ionic conductivity of the diaphragm to the electrolyte, thereby improving the electrochemical performance of the diaphragm. In addition, because the attapulgite itself has high temperature stability, and forms an interconnected three-dimensional network in the diaphragm, which acts as an inorganic framework, thus greatly improving the thermal stability of the diaphragm, and the temperature can still be maintained at 180 ° C. Excellent thermal stability Dimensional stability. The above advantages make the multi-layer separator of the present invention have broad application prospects in the aspect of high safety performance lithium ion batteries.

本发明独创性的结合了微层共挤出技术与热致相分离方法,制备出具有丰富孔结构的多层乙烯基树脂/丙烯基树脂隔膜,并创造性地在加入聚甲基丙烯酸甲酯改性的凹凸棒,进一步增强隔膜的热稳定性能及电化学性能,制备工艺简单易行,加工成本低,具有非常强的可设计性,在多孔材料、微层共挤出领域、电池隔膜领域及功能高分子领域有广阔的应用前景和使用价值。The invention creatively combines the micro-layer co-extrusion technology and the thermally induced phase separation method to prepare a multi-layer vinyl resin/propylene-based resin diaphragm with rich pore structure, and creatively adds polymethyl methacrylate to modify the membrane. It can further enhance the thermal stability and electrochemical performance of the separator, the preparation process is simple and feasible, the processing cost is low, and it has very strong designability. The field of functional polymers has broad application prospects and use value.

本发明具体优点如下:The specific advantages of the present invention are as follows:

(1)本发明容易做到向聚合物基体内添加其他材料的要求。如本发明中选择的聚合物基体为乙烯基树脂及丙烯基树脂,添加的材料为聚甲基丙烯酸甲酯改性的凹凸棒,聚合物基体与添加的材料这两种组分混合均匀,且两组分比例可按实际需求做调整。(1) The present invention easily fulfills the requirement of adding other materials into the polymer matrix. For example, the polymer matrix selected in the present invention is vinyl resin and propylene-based resin, the added material is attapulgite modified by polymethyl methacrylate, the two components of the polymer matrix and the added material are mixed evenly, and The ratio of the two components can be adjusted according to actual needs.

(2)本发明采用双组分微层共挤出成型设备,制备了具有交替层状结构的乙烯基树脂/丙烯基树脂隔膜,采用流道结构合理的层倍增模具,分层效率高。可以通过改变层倍增模具的数目灵活地调节制备出的隔膜的层数。制备出的隔膜厚度均匀,表面平整连续且具备很高的机械强度,层与层之间界限分明且层厚均匀,改善了目前商业化多层隔膜的制备方法的繁琐过程(单层干法拉伸后进行热压复合)。(2) The present invention adopts a two-component microlayer co-extrusion molding equipment to prepare a vinyl resin/propylene-based resin diaphragm with an alternating layered structure, and adopts a layer multiplication die with a reasonable flow channel structure, and the layering efficiency is high. The number of layers of the prepared separator can be flexibly adjusted by changing the number of layer multiplying molds. The prepared diaphragm has uniform thickness, smooth and continuous surface, high mechanical strength, clear boundaries between layers and uniform layer thickness, which improves the tedious process of the current commercial multi-layer diaphragm preparation method (single-layer dry Farad). Hot-pressing compounding after stretching).

(3)本发明创造性地提出将微层共挤出与热致相分离相结合来制备多层隔膜的方法,这种方法的显著优势在于,一方面具有热致相分离方法自身具备的孔结构均匀可控的优点,另一方面微层共挤出技术大大简化了多层隔膜的制备工艺,可以高效地大规模制备多层锂离子电池隔膜。另外,多孔结构的形成是基于热致相分离的方法,避免了传统隔膜制备方法中常采用的拉伸过程,这有利于提高隔膜的热尺寸稳定性。(3) The present invention creatively proposes a method for preparing a multi-layer diaphragm by combining microlayer co-extrusion with thermally induced phase separation. The significant advantage of this method lies in that, on the one hand, it has the pore structure possessed by the thermally induced phase separation method itself. The advantages of uniformity and controllability, on the other hand, the micro-layer co-extrusion technology greatly simplifies the preparation process of the multi-layer separator, and can efficiently prepare the multi-layer lithium-ion battery separator on a large scale. In addition, the formation of the porous structure is based on the method of thermally induced phase separation, which avoids the stretching process commonly used in traditional separator preparation methods, which is beneficial to improve the thermal dimensional stability of the separator.

(4)由于非极性的聚烯烃基隔膜与极性的锂离子电池电解液的亲和性较差,并且当温度高于聚烯烃基聚合物的熔点时,隔膜的机械性能急速下降,限制了锂离子电池性能的进一步提高。本发明通过添加聚甲基丙烯酸甲酯改性的凹凸棒来改善上述缺陷。由于凹凸棒土具有独特的层链状结构特征以及优异的热稳定性,可以提高隔膜的热稳定性。另外,凹凸棒土表面含大量极性羟基,较适合于极性体系使用,聚甲基丙烯酸甲酯也具有与电解液的主要成分碳酸酯溶剂(碳酸乙烯酯EC,碳酸二甲酯DMC,碳酸二乙酯DEC)结构相似的化学结构(羰基),因此对电解液具有较强的亲和性,从而提高隔膜的电化学性能。(4) Since the non-polar polyolefin-based separator has poor affinity with the polar lithium-ion battery electrolyte, and when the temperature is higher than the melting point of the polyolefin-based polymer, the mechanical properties of the separator drop rapidly, limiting the The performance of lithium-ion batteries is further improved. The present invention improves the above-mentioned defects by adding polymethyl methacrylate-modified attapulgite rods. Because attapulgite has unique layer-chain structure characteristics and excellent thermal stability, the thermal stability of the separator can be improved. In addition, the surface of attapulgite contains a lot of polar hydroxyl groups, which is more suitable for use in polar systems. Polymethyl methacrylate also has carbonate solvents (ethylene carbonate EC, dimethyl carbonate DMC, carbonic acid, etc. Diethyl ester (DEC) has a similar chemical structure (carbonyl group), so it has a strong affinity for the electrolyte, thereby improving the electrochemical performance of the separator.

附图说明Description of drawings

图1为微层共挤出系统、热致相分离方法相结合制备乙烯基树脂/丙烯基树脂(聚甲基丙烯酸甲酯改性凹凸棒)多层隔膜的原理图。Figure 1 is a schematic diagram of the combination of a microlayer co-extrusion system and a thermally induced phase separation method to prepare a vinyl resin/propylene-based resin (polymethyl methacrylate modified attapulgite) multilayer separator.

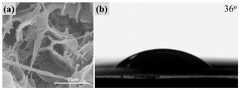

图2中,(a)为添加0%的聚甲基丙烯酸甲酯改性凹凸棒(ATPM)时,隔膜MC-TIPS PP/PE/ATPM (0%)断面的扫描电镜照片; (b)为电解液在隔膜MC-TIPS PP/PE/ATPM (0%)表面的接触角;(c)为电解液在商业化多层电池隔膜Celgard® 2325表面的接触角。In Fig. 2, (a) is the scanning electron microscope photo of the cross section of the separator MC-TIPS PP/PE/ATPM (0%) when 0% polymethyl methacrylate modified attapulgite (ATPM) is added; (b) is Contact angle of electrolyte on the surface of separator MC-TIPS PP/PE/ATPM (0%); (c) is the contact angle of electrolyte on the surface of commercial multilayer

图3中,(a)为添加6%的ATPM时,隔膜隔膜MC-TIPS PP/PE/ATPM (6%)断面的扫描电镜照片; (b)为电解液在隔膜MC-TIPS PP/PE/ATPM (6%)表面的接触角。In Figure 3, (a) is the scanning electron microscope photo of the cross-section of the separator MC-TIPS PP/PE/ATPM (6%) when 6% ATPM is added; (b) is the electrolyte in the separator MC-TIPS PP/PE/ Contact angle of ATPM (6%) surface.

图4中,(a)为添加9%的ATPM时,隔膜MC-TIPS PP/PE/ATPM (9%)断面的扫描电镜照片、; (b)为电解液在隔膜MC-TIPS PP/PE/ATPM (9%)表面的接触角。In Figure 4, (a) is the scanning electron microscope photo of the cross section of the separator MC-TIPS PP/PE/ATPM (9%) when 9% ATPM is added; (b) is the electrolyte in the separator MC-TIPS PP/PE/ Contact angle of ATPM (9%) surface.

图5中,(a)为添加0%和9%的ATPM时,隔膜MC-TIPS PP/PE/ATPM (0%)和隔膜MC-TIPS PP/PE/ATPM (9%)的拉伸应力-应变曲线;(b)为隔膜MC-TIPS PP/PE/ATPM (9%)断面多层结构的光学显微镜照片。In Fig. 5, (a) is the tensile stress of separator MC-TIPS PP/PE/ATPM (0%) and separator MC-TIPS PP/PE/ATPM (9%) with 0% and 9% ATPM added - Strain curve; (b) is the optical microscope image of the multi-layer structure of the membrane MC-TIPS PP/PE/ATPM (9%).

图6中,(a)为热收缩率随温度的变化曲线:Celgard® 2325, 隔膜MC-TIPS PP/PE/ATPM (0%),隔膜MC-TIPS PP/PE/ATPM (9%); (b) 不同温度下热处理0.5 h后,隔膜的热收缩情况:Celgard® 2325; 隔膜MC-TIPS PP/PE/ATPM (0%),隔膜MC-TIPS PP/PE/ATPM(9%)。In Figure 6, (a) is the change curve of thermal shrinkage with temperature:

图7为装配不同隔膜纽扣电池的(a)计时电量曲线与(b)线性扫描伏安曲线图:Celgard® 2325; 隔膜MC-TIPS PP/PE/ATPM (0%),隔膜MC-TIPS PP/PE/ATPM (9%)。Figure 7 shows (a) chronometric charge curves and (b) linear sweep voltammetry curves of button cells with different separators:

表1为 隔膜的基本物理参数:Celgard® 2325,隔膜MC-TIPS PP/PE/ATPM (0%),隔膜MC-TIPS PP/PE/ATPM (6%),隔膜MC-TIPS PP/PE/ATPM (9%)。Table 1 shows the basic physical parameters of the diaphragm:

具体实施方式Detailed ways

以下实施例是仅为更进一步具体说明本发明,在不违反本发明的主旨下,本发明应不限于以下实例具体明示的内容。The following examples are only for further detailed description of the present invention, and the present invention should not be limited to the specific and explicit contents of the following examples without violating the gist of the present invention.

所用原料如下:The raw materials used are as follows:

聚乙烯树脂(2426K),台湾奇美化工有限公司;Polyethylene resin (2426K), Taiwan Chi Mei Chemical Co., Ltd.;

聚丙烯树脂(K8303),中国石油天然气股份有限公司;Polypropylene resin (K8303), China National Petroleum Corporation;

乙烯-醋酸乙烯酯共聚物(醋酸乙烯酯12 wt. %),美国杜邦公司;Ethylene-vinyl acetate copolymer (

乙烯-丙烯共聚物(货号P0071705),美国陶氏公司;Ethylene-propylene copolymer (Cat. No. P0071705), Dow, USA;

凹凸棒土(200目),江苏玖川纳米材料有限公司;Attapulgite (200 mesh), Jiangsu Jiuchuan Nanomaterials Co., Ltd.;

甲基丙烯酸甲酯(化学纯),上海凌风化学试剂有限公司;Methyl methacrylate (chemically pure), Shanghai Lingfeng Chemical Reagent Co., Ltd.;

3-氨丙基三乙氧基硅烷(分析纯),国药集团化学试剂有限公司;3-Aminopropyltriethoxysilane (analytical grade), Sinopharm Chemical Reagent Co., Ltd.;

乙酸乙酯(化学纯),阿拉丁试剂(上海)有限公司;Ethyl acetate (chemically pure), Aladdin Reagent (Shanghai) Co., Ltd.;

偶氮二氰基戊酸(分析纯),阿拉丁试剂(上海)有限公司;Azodicyanovaleric acid (analytical grade), Aladdin Reagent (Shanghai) Co., Ltd.;

1-(3-二甲基氨基丙基)-3-乙基碳二亚胺(95%),上海安耐吉化学有限公司;1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide (95%), Shanghai Anaiji Chemical Co., Ltd.;

二甲氨基吡啶(分析纯),阿拉丁试剂(上海)有限公司;Dimethylaminopyridine (analytical grade), Aladdin Reagent (Shanghai) Co., Ltd.;

四氢呋喃(化学纯),上海凌风化学试剂有限公司;Tetrahydrofuran (chemically pure), Shanghai Lingfeng Chemical Reagent Co., Ltd.;

盐酸,国药集团化学试剂有限公司;Hydrochloric acid, Sinopharm Chemical Reagent Co., Ltd.;

固体石蜡(66#),中国石油天然气股份有限公司;Solid paraffin (66#), China National Petroleum Corporation;

二苯醚(化学纯),国药集团化学试剂有限公司;Diphenyl ether (chemically pure), Sinopharm Chemical Reagent Co., Ltd.;

液体石蜡(化学纯),国药集团化学试剂有限公司;Liquid paraffin (chemically pure), Sinopharm Chemical Reagent Co., Ltd.;

石油醚(化学纯),国药集团化学试剂有限公司;Petroleum ether (chemically pure), Sinopharm Chemical Reagent Co., Ltd.;

无水乙醇(99.8%),上海凌风化学试剂有限公司;Anhydrous ethanol (99.8%), Shanghai Lingfeng Chemical Reagent Co., Ltd.;

三氯甲烷(分析纯),国药集团化学试剂有限公司;Trichloromethane (analytical grade), Sinopharm Chemical Reagent Co., Ltd.;

锂离子电池电解液,深圳天合科技有限公司;Lithium-ion battery electrolyte, Shenzhen Tianhe Technology Co., Ltd.;

商业电池隔膜(Celgard® 2325),深圳天合科技有限公司。Commercial battery separator (Celgard® 2325), Shenzhen Tianhe Technology Co., Ltd.

实施例1:以固体石蜡为稀释剂,石油醚为萃取剂,微层共挤出技术与热致相分离方法制备聚乙烯/聚丙烯多层多孔隔膜。具体步骤如下:Example 1: Polyethylene/polypropylene multilayer porous membrane was prepared by using solid paraffin as diluent, petroleum ether as extractant, microlayer co-extrusion technology and thermally induced phase separation method. Specific steps are as follows:

(1)聚乙烯/聚丙烯母料的制备(1) Preparation of polyethylene/polypropylene masterbatch

在微层共挤出之前,将固体石蜡预分散在聚乙烯树脂及聚丙烯树脂中,上述组分预先混合后,放入双螺杆挤出机中制备出聚乙烯树脂及聚丙烯树脂的母料。Before the co-extrusion of the microlayer, the solid paraffin is pre-dispersed in the polyethylene resin and the polypropylene resin. After the above components are pre-mixed, they are put into a twin-screw extruder to prepare the master batch of the polyethylene resin and the polypropylene resin. .

聚乙烯树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of polyethylene resin is calculated as:

聚乙烯树脂 45份,45 parts of polyethylene resin,

固体石蜡 55份。55 parts of solid paraffin.

聚丙烯树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of polypropylene resin is calculated as:

聚丙烯树脂 45份,45 parts of polypropylene resin,

固体石蜡 55份。55 parts of solid paraffin.

(2)聚乙烯树脂/聚丙烯树脂多层多孔隔膜的制备(2) Preparation of polyethylene resin/polypropylene resin multilayer porous membrane

采用双组分微层共挤出成型设备,第一进料口加入步骤(2)得到的聚乙烯树脂母料,第二进料口加入步骤(2)得到的聚丙烯树脂母料,调节转速为10 rpm,温度为140℃,在微层共挤出设备的基础单元-层倍增器中,层状复合材料被垂直切片,水平展开并依次重组,熔体经过1个层倍增器后可以产生具有4层结构的材料。微层共挤出之后,立即将挤出的多层薄膜浸入20℃的水浴中以进行冷却从而引发热诱导相分离,由相分离形成的两相结构即为隔膜多孔结构的原型。随后将上述多层薄膜浸入石油醚中超声8 h,以萃取出隔膜中的稀释剂后形成多孔结构。随后在60℃条件下真空干燥15 h,制备出的隔膜简称为MC-TIPSPP/PE/ATPM (0%)。Two-component microlayer co-extrusion molding equipment is used, the polyethylene resin masterbatch obtained in step (2) is added to the first feeding port, the polypropylene resin masterbatch obtained in step (2) is added to the second feeding port, and the rotational speed is adjusted. At 10 rpm and a temperature of 140 °C, in the basic unit of the microlayer coextrusion equipment - the layer multiplier, the layered composite material is sliced vertically, horizontally unrolled and recombined sequentially, and the melt can be produced after passing through 1 layer multiplier. A material with a 4-layer structure. Immediately after the coextrusion of the microlayers, the extruded multilayer films were immersed in a water bath at 20 °C for cooling to induce thermally induced phase separation, and the two-phase structure formed by the phase separation was the prototype of the porous structure of the membrane. Then, the above-mentioned multilayer films were immersed in petroleum ether for 8 h to be sonicated to extract the diluent in the separator to form a porous structure. Then vacuum-dried at 60 °C for 15 h, and the prepared membrane was abbreviated as MC-TIPSPP/PE/ATPM (0%).

图1为双组分微层共挤出系统、热致相分离相结合制备多孔隔膜的原理图。实施例1中制备出的多孔隔膜断面的扫描电子显微镜照片如图2(a)所示。由图中可以看出,隔膜具有丰富的多孔结构。Figure 1 is a schematic diagram of the two-component microlayer co-extrusion system combined with thermally induced phase separation to prepare a porous membrane. The scanning electron microscope photograph of the cross-section of the porous separator prepared in Example 1 is shown in Fig. 2(a). It can be seen from the figure that the separator has a rich porous structure.

采用上海方瑞仪器有限公司的JCY系列动态/静态接触角仪测试隔膜对电解液的浸润性能。实验中将隔膜平铺放置,利用接触角测试仪将等量电解液从相同的高度滴在隔膜的表面,立即拍下液滴在隔膜表面状态的图片,而后运用相应软件分析图片,测得接触角度数。图2(b)和图2(c)分别为实施例1中制备出的隔膜与商业化锂离子电池隔膜与电解液之间的接触角,分别为50°和55°。JCY series dynamic/static contact angle meter of Shanghai Fangrui Instrument Co., Ltd. was used to test the wettability of the diaphragm to the electrolyte. In the experiment, the diaphragm was laid flat, and the contact angle tester was used to drop the same amount of electrolyte on the surface of the diaphragm from the same height, and immediately take a picture of the state of the droplet on the surface of the diaphragm, and then use the corresponding software to analyze the picture and measure the contact angle. number of angles. Figure 2(b) and Figure 2(c) show the contact angles between the separator prepared in Example 1 and the separator of a commercial lithium-ion battery and the electrolyte, which are 50° and 55°, respectively.

多孔隔膜的孔隙率(ε)通过正丁醇浸泡法进行测定,分别测量隔膜的原质量(W0)以及在正丁醇中浸泡2 h后的隔膜质量(W),ε使用下式进行计算,The porosity (ε) of the porous separator was measured by the n-butanol immersion method, and the original mass (W0 ) of the separator and the quality of the separator after soaking in n-butanol for 2 h (W) were measured respectively, and ε was calculated using the following formula ,

(1) (1)

其中 为正丁醇的密度, V0 是隔膜的几何体积。where is the density of n-butanol andV0 is the geometric volume of the diaphragm.

电解液吸液率(EU)由吸收电解液前后隔膜的重量变化来确定,The electrolyte absorption rate (EU) is determined by the weight change of the diaphragm before and after absorbing the electrolyte,

(2) (2)

其中Wb 与 Wa 分别为浸泡电解液前后隔膜的质量。电解液的保液率(ER)测定方法为,将浸泡后的隔膜置于密闭容器中,48 h后,采用与EU相同的计算方法测定其保液率。EU及ER测试中,样品测量5次取平均值。where Wb and Wa are the mass of the separator before and after immersion in the electrolyte, respectively. The liquid retention rate (ER) of the electrolyte was determined by placing the soaked diaphragm in a closed container, and after 48 h, the liquid retention rate was determined by the same calculation method as that of the EU. In the EU and ER tests, the samples were measured 5 times and averaged.

使用CHI 604C电化学工作站(CH Instruments Inc)来测定隔膜的电化学性能。在装有氩气的手套箱(Lab 2000,Etelux)中,保证水和氧含量低于0.1 ppm的情况下,将隔膜夹在阳极和阴极材料之间装配成2025型纽扣电池。在离子电导率的测试过程中,将隔膜夹在两个不锈钢电极(SS)间组装成纽扣电池,通过电化学阻抗谱(EIS)测量离子电导率。在开路电位条件下,在1 Hz至105 Hz的频率范围内记录阻抗谱,其中AC振幅为5 mV。离子电导率(σ)的计算公式为:The electrochemical performance of the separator was determined using a CHI 604C electrochemical workstation (CH Instruments Inc). A 2025 coin cell was assembled with the separator sandwiched between the anode and cathode materials in a glove box (Lab 2000, Etelux) filled with argon gas to ensure that the water and oxygen contents were below 0.1 ppm. During the measurement of ionic conductivity, a coin cell was assembled by sandwiching the separator between two stainless steel electrodes (SS), and the ionic conductivity was measured by electrochemical impedance spectroscopy (EIS). Impedance spectra were recorded in the frequency range from 1 Hz to 105 Hz with an AC amplitude of 5 mV under open circuit potential conditions. The formula for calculating ionic conductivity (σ) is:

(3) (3)

其中Rb为体积阻抗,d和A分别是隔膜和电极之间的厚度以及接触面积。 隔膜的电化学稳定性通过线性扫描电位法(LSV)测量,扫描速率为5 mV s-1,电压范围为2 V至7 V,分别使用不锈钢电极和金属锂作为工作电极和对电极。锂离子迁移数通过计时电量法测量,阶跃电势为10 mV,测试时将隔膜夹在两个金属锂电极之间装配成纽扣电池。where Rb is the bulk impedance, and d and A are the thickness and contact area between the separator and electrode, respectively. The electrochemical stability of the separator was measured by linear scanning potentiometric method (LSV) with a scan rate of 5 mV s-1 and a voltage range of 2 V to 7 V, using stainless steel electrodes and metallic lithium as the working and counter electrodes, respectively. The lithium ion migration number was measured by the chronocoulometric method with a step potential of 10 mV. During the test, the separator was sandwiched between two metal lithium electrodes to form a coin cell battery.

上述实验结果经过计算后,总结在表1中,可以看出,实施例1中制备出的多层隔膜各项性能均优于商业化锂离子电池隔膜,满足锂离子电池的技术指标要求。After the above experimental results are calculated and summarized in Table 1, it can be seen that the performance of the multilayer separator prepared in Example 1 is superior to that of the commercial lithium-ion battery separator and meets the technical index requirements of the lithium-ion battery.

实施例2:以固体石蜡为稀释剂,石油醚为萃取剂,微层共挤出技术与热致相分离方法制备聚乙烯/聚丙烯(6% 聚甲基丙烯酸甲酯改性凹凸棒)多层多孔隔膜。具体步骤如下:Example 2: Polyethylene/polypropylene (6% polymethylmethacrylate modified attapulgite) was prepared by using solid paraffin as diluent, petroleum ether as extractant, microlayer co-extrusion technology and thermally induced phase separation method. layered porous membrane. Specific steps are as follows:

(1)聚甲基丙烯酸甲酯改性凹凸棒的制备(1) Preparation of polymethyl methacrylate modified attapulgite

将凹凸棒土在1 mol L-1的盐酸中搅拌反应3 h后静置12 h,过滤后洗至中性,烘干粉碎后称取1份分散在二甲苯中,超声震荡1 h,加入1份3-氨丙基三乙氧基硅烷,升温至80℃恒温搅拌反应6 h,产物抽滤洗涤干燥,粉碎后过200目筛,产物记为ATP-APTES。称取1份ATP-APTES分散于乙酸乙酯中,超声震荡2 h;称取3份偶氮二氰基戊酸溶于乙酸乙酯,将此溶液置于250 mL三口烧瓶中,加入3份 1-(3-二甲基氨基丙基)-3-乙基碳二亚胺作缩合剂,N2保护下搅拌反应1 h,加入5份二甲氨基吡啶作催化剂,将ATP-APTES的乙酸乙酯悬浮液分五次加入到烧瓶中,加入完毕后反应进行15 h。经离心洗涤干燥后,称取1份上述产物加入到100 mL三口烧瓶中,再加入15份单体甲基丙烯酸甲酯,超声震荡5 min,通N2 30 min除尽氧气,80℃下磁力搅拌进行反应8 h,离心分离后用四氢呋喃洗涤3次,50℃条件下真空干燥,即得凹凸棒土-聚甲基丙烯酸甲酯杂化材料,记为ATPM。The attapulgite was stirred and reacted in 1 mol L-1 of hydrochloric acid for 3 h, then left to stand for 12 h, filtered, washed to neutrality, dried and pulverized, weighed and dispersed in xylene, ultrasonically oscillated for 1 h, added 1 part of 3-aminopropyltriethoxysilane was heated to 80°C under constant temperature stirring for 6 hours, the product was filtered, washed and dried, pulverized and passed through a 200-mesh sieve, and the product was recorded as ATP-APTES.

(2)聚乙烯树脂/聚丙烯树脂(ATPM)母料的制备(2) Preparation of polyethylene resin/polypropylene resin (ATPM) masterbatch

在微层共挤出之前,将稀释剂及凹凸棒土-聚甲基丙烯酸甲酯杂化材料预分散在聚乙烯树脂及聚丙烯树脂中,上述组分预先混合后,放入双螺杆挤出机中制备出聚乙烯树脂的母料及聚丙烯树脂的母料。Before microlayer co-extrusion, diluent and attapulgite-polymethyl methacrylate hybrid material are pre-dispersed in polyethylene resin and polypropylene resin. After pre-mixing the above components, they are put into twin-screw extrusion. The masterbatch of polyethylene resin and the masterbatch of polypropylene resin are prepared in the machine.

聚乙烯树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of polyethylene resin is calculated as:

聚乙烯树脂 45份,45 parts of polyethylene resin,

稀释剂 55份,Thinner 55 parts,

聚甲基丙烯酸甲酯改性的凹凸棒 6份。6 parts of attapulgite modified with polymethyl methacrylate.

聚丙烯树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of polypropylene resin is calculated as:

聚丙烯树脂 45份,45 parts of polypropylene resin,

稀释剂 55份,Thinner 55 parts,

聚甲基丙烯酸甲酯改性的凹凸棒 6份。6 parts of attapulgite modified with polymethyl methacrylate.

(3)聚乙烯树脂/聚丙烯树脂(ATPM)多层多孔隔膜的制备(3) Preparation of polyethylene resin/polypropylene resin (ATPM) multilayer porous membrane

采用双组分微层共挤出成型设备,第一进料口加入步骤(2)得到的聚乙烯树脂母料,第二进料口加入步骤(2)得到的聚丙烯树脂母料,调节转速为10 rpm,温度为160℃,在微层共挤出设备的基础单元-层倍增器中,层状复合材料被垂直切片,水平展开并依次重组,熔体经过1个层倍增器后可以产生具有4层结构的材料。微层共挤出之后,立即将挤出的多层薄膜浸入20℃的水浴中以进行冷却从而引发热诱导相分离,由相分离形成的两相结构即为隔膜多孔结构的原型。随后将上述多层薄膜浸入石油醚中超声8 h,以萃取出隔膜中的稀释剂后形成多孔结构。随后在60℃条件下真空干燥1 h,制备出的隔膜简称为MC-TIPSPP/PE/ATPM (6%)。接触角、吸液率、保液率及离子电导率等测试方法同实施例1中所述。Two-component microlayer co-extrusion molding equipment is used, the polyethylene resin masterbatch obtained in step (2) is added to the first feeding port, the polypropylene resin masterbatch obtained in step (2) is added to the second feeding port, and the rotational speed is adjusted. At 10 rpm, the temperature is 160 °C, in the basic unit of the microlayer coextrusion equipment - the layer multiplier, the layered composite is sliced vertically, horizontally unrolled and recombined sequentially, the melt can be produced after passing through 1 layer multiplier. A material with a 4-layer structure. Immediately after the coextrusion of the microlayers, the extruded multilayer films were immersed in a water bath at 20 °C for cooling to induce thermally induced phase separation, and the two-phase structure formed by the phase separation was the prototype of the porous structure of the membrane. Then, the above-mentioned multilayer films were immersed in petroleum ether for 8 h to be sonicated to extract the diluent in the separator to form a porous structure. Then vacuum-dried at 60 °C for 1 h, and the prepared membrane was abbreviated as MC-TIPSPP/PE/ATPM (6%). Test methods such as contact angle, liquid absorption rate, liquid retention rate and ionic conductivity are the same as those described in Example 1.

实施例2中制备出的多孔隔膜断面的扫描电子显微镜照片如图3(a)所示。由图中可以看出,隔膜具有丰富的多孔结构,并且在多孔结构中可以观察到一维纳米棒状结构,即为聚甲基丙烯酸甲酯改性后的凹凸棒土。实施例2中制备出的隔膜与商业化锂离子电池隔膜与电解液之间的接触角如图3(b)所示,为36°。如表1所示,吸液率、保液率及离子电导率等各项性能在实施例1制备出的隔膜的基础上有了进一步的提高,这是由于聚甲基丙烯酸甲酯改性凹凸棒土的加入提高了隔膜与电解液的浸润性,从而提高了其电化学性能,满足锂离子电池的技术指标要求。The scanning electron microscope photograph of the cross-section of the porous separator prepared in Example 2 is shown in Figure 3(a). It can be seen from the figure that the separator has abundant porous structure, and one-dimensional nanorod-like structure can be observed in the porous structure, that is, attapulgite modified by polymethyl methacrylate. The contact angle between the separator prepared in Example 2 and the separator of a commercial lithium-ion battery and the electrolyte is shown in Fig. 3(b), which is 36°. As shown in Table 1, various properties such as liquid absorption rate, liquid retention rate and ionic conductivity have been further improved on the basis of the diaphragm prepared in Example 1, which is due to the polymethyl methacrylate modified unevenness The addition of stick soil improves the wettability of the separator and the electrolyte, thereby improving its electrochemical performance and meeting the technical index requirements of lithium-ion batteries.

实施例3:以固体石蜡为稀释剂,石油醚为萃取剂,微层共挤出技术与热致相分离方法制备聚乙烯/聚丙烯(9% 聚甲基丙烯酸甲酯改性凹凸棒)多层多孔隔膜。具体步骤如下:Example 3: Polyethylene/polypropylene (9% polymethylmethacrylate modified attapulgite) was prepared by using solid paraffin as diluent, petroleum ether as extractant, microlayer co-extrusion technology and thermally induced phase separation method. layered porous membrane. Specific steps are as follows:

(1)聚甲基丙烯酸甲酯改性凹凸棒的制备(1) Preparation of polymethyl methacrylate modified attapulgite

将凹凸棒土在1 mol L-1的盐酸中搅拌反应8 h后静置12 h,过滤后洗至中性,烘干粉碎后称取2份分散在二甲苯中,超声震荡1 h,加入2份3-氨丙基三乙氧基硅烷,升温至80℃恒温搅拌反应6 h,产物抽滤洗涤干燥,粉碎后过200目筛,产物记为ATP-APTES。称取2份ATP-APTES分散于乙酸乙酯中,超声震荡3 h;称取5份偶氮二氰基戊酸溶于乙酸乙酯,将此溶液置于250 mL三口烧瓶中,加入5份1-(3-二甲基氨基丙基)-3-乙基碳二亚胺作缩合剂,N2保护下搅拌反应1 h,加入6份二甲氨基吡啶作催化剂,将ATP-APTES的乙酸乙酯悬浮液分五次加入到烧瓶中,加入完毕后反应进行20 h。经离心洗涤干燥后,称取2份上述产物加入到100 mL三口烧瓶中,再加入28份单体甲基丙烯酸甲酯,超声震荡5 min,通N2 30 min除尽氧气,80℃下磁力搅拌进行反应10 h,离心分离后用四氢呋喃洗涤5次,50℃条件下真空干燥,即得凹凸棒土-聚甲基丙烯酸甲酯杂化材料,记为ATPM。The attapulgite was stirred and reacted in 1 mol L-1 of hydrochloric acid for 8 h, then left to stand for 12 h, filtered, washed until neutral, dried and pulverized, weighed and dispersed in xylene, ultrasonically oscillated for 1 h, and added 2 parts of 3-aminopropyltriethoxysilane were heated to 80°C and stirred at a constant temperature for 6 h. The product was filtered, washed and dried, pulverized and passed through a 200-mesh sieve, and the product was recorded as ATP-APTES. Weigh 2 parts of ATP-APTES and disperse them in ethyl acetate, and ultrasonically shake for 3 h; weigh 5 parts of azodicyanovaleric acid and dissolve in ethyl acetate, put this solution in a 250 mL three-necked flask, and add 5 parts of it 1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide was used as the condensing agent, and the reaction was stirred for 1 h under the protection ofN2 , and 6 parts of dimethylaminopyridine was added as a catalyst, and the acetic acid of ATP-APTES was mixed with acetic acid. The ethyl ester suspension was added to the flask five times, and the reaction was carried out for 20 h after the addition. After centrifugation, washing and drying, 2 parts of the above product were weighed and added to a 100 mL three-necked flask, and then 28 parts of monomer methyl methacrylate were added, ultrasonically oscillated for 5 min, and N2 was used for 30 min to remove oxygen. The reaction was stirred for 10 h, washed with tetrahydrofuran for 5 times after centrifugation, and vacuum-dried at 50 °C to obtain the attapulgite-polymethyl methacrylate hybrid material, denoted as ATPM.

(2)聚乙烯树脂/聚丙烯树脂(ATPM)母料的制备(2) Preparation of polyethylene resin/polypropylene resin (ATPM) masterbatch

在微层共挤出之前,将稀释剂及凹凸棒土-聚甲基丙烯酸甲酯杂化材料分别预分散在聚乙烯树脂及聚丙烯树脂中,上述组分预先混合后,放入双螺杆挤出机中制备出聚乙烯树脂及聚丙烯树脂的母料。Before the microlayer co-extrusion, the diluent and the attapulgite-polymethyl methacrylate hybrid material were pre-dispersed in polyethylene resin and polypropylene resin respectively. After the above components were pre-mixed, put into twin-screw extrusion The master batch of polyethylene resin and polypropylene resin is prepared from the machine.

聚乙烯树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of polyethylene resin is calculated as:

聚乙烯树脂 45份,45 parts of polyethylene resin,

稀释剂 55份,Thinner 55 parts,

聚甲基丙烯酸甲酯改性的凹凸棒 9份。9 parts of attapulgite modified with polymethyl methacrylate.

聚丙烯树脂的母料的原料组成以质量份数计为:The raw material composition of the master batch of polypropylene resin is calculated as:

聚丙烯树脂 45份,45 parts of polypropylene resin,

稀释剂 55份,Thinner 55 parts,

聚甲基丙烯酸甲酯改性的凹凸棒 9份。9 parts of attapulgite modified with polymethyl methacrylate.

(3)聚乙烯树脂/聚丙烯树脂(ATPM)多层多孔隔膜的制备(3) Preparation of polyethylene resin/polypropylene resin (ATPM) multilayer porous membrane

采用双组分微层共挤出成型设备,第一进料口加入步骤(2)得到的聚乙烯树脂母料,第二进料口加入步骤(2)得到的聚丙烯树脂母料,调节转速为17 rpm,温度为165℃,在微层共挤出设备的基础单元-层倍增器中,层状复合材料被垂直切片,水平展开并依次重组,熔体经过1个层倍增器后可以产生具有4层结构的材料。微层共挤出之后,立即将挤出的多层薄膜浸入20℃的水浴中以进行冷却从而引发热诱导相分离,由相分离形成的两相结构即为隔膜多孔结构的原型。随后将上述多层薄膜浸入石油醚中超声7 h,以萃取出隔膜中的稀释剂后形成多孔结构。随后在60℃条件下真空干燥15 h,制备出的隔膜简称为MC-TIPSPP/PE/ATPM (9%)。接触角、吸液率、保液率及离子电导率等测试方法同实施例1中所述。Two-component microlayer co-extrusion molding equipment is used, the polyethylene resin masterbatch obtained in step (2) is added to the first feeding port, the polypropylene resin masterbatch obtained in step (2) is added to the second feeding port, and the rotational speed is adjusted. At 17 rpm and a temperature of 165 °C, in the basic unit of the microlayer co-extrusion equipment - the layer multiplier, the layered composite is sliced vertically, horizontally unrolled and recombined sequentially, and the melt can be produced after passing through 1 layer multiplier. A material with a 4-layer structure. Immediately after the coextrusion of the microlayers, the extruded multilayer films were immersed in a water bath at 20 °C for cooling to induce thermally induced phase separation, and the two-phase structure formed by the phase separation was the prototype of the porous structure of the membrane. Then, the above-mentioned multilayer films were immersed in petroleum ether for 7 h to be sonicated to extract the diluent in the separator to form a porous structure. Then vacuum-dried at 60 °C for 15 h, and the prepared membrane was abbreviated as MC-TIPSPP/PE/ATPM (9%). Test methods such as contact angle, liquid absorption rate, liquid retention rate and ionic conductivity are the same as those described in Example 1.

实施例3中制备出的多孔隔膜断面的扫描电子显微镜照片如图4(a)所示。由图中可以看出,隔膜具有丰富的多孔结构,并且在多孔结构中可以观察到一维纳米棒状结构,即为聚甲基丙烯酸甲酯改性后的凹凸棒土。实施例2中制备出的隔膜与商业化锂离子电池隔膜与电解液之间的接触角如图4(b)所示,为28°。如表1所示,吸液率、保液率及离子电导率等各项性能在实施例1与实施例2制备出的隔膜的基础上有了更多的提高,这是由于随着聚甲基丙烯酸甲酯改性凹凸棒土含量的提高,隔膜与电解液的浸润性进一步提高,从而提高了其电化学性能,满足锂离子电池的技术指标要求。The scanning electron microscope photograph of the cross-section of the porous separator prepared in Example 3 is shown in Fig. 4(a). It can be seen from the figure that the separator has abundant porous structure, and one-dimensional nanorod-like structure can be observed in the porous structure, that is, attapulgite modified by polymethyl methacrylate. The contact angle between the separator prepared in Example 2 and the separator of a commercial lithium-ion battery and the electrolyte is shown in Fig. 4(b), which is 28°. As shown in Table 1, various properties such as liquid absorption rate, liquid retention rate and ionic conductivity are more improved on the basis of the diaphragms prepared in Example 1 and Example 2. The increase in the content of attapulgite modified by methyl methacrylate further improves the wettability of the separator and the electrolyte, thereby improving its electrochemical performance and meeting the technical index requirements of lithium-ion batteries.

隔膜的机械性能对于电池的安全性能有重要的作用,对实施例1与实施例3所制备出的隔膜进行力学拉伸测试所得的应力-应变曲线如图5(a)所示,可以看出,实施例3制备出的隔膜具有更高的拉伸强度,这是因为聚甲基丙烯酸甲酯改性凹凸棒土是一维线性纳米结构,它的加入会在原多孔结构的基础上搭建起三维网络结构,纳米棒直接互相接触连接,当受到外力作用时,可以通过网络结构交联点将应力分散到其它链段上,从而提高隔膜的拉伸强度。实施例3制备出的隔膜横截面的多层结构可以通过光学显微镜观察到,如图5(b)所示。交替的聚丙烯层(较亮的层)和聚乙烯层(较暗的层,为便于区分,PE层中混入暗色系的色母粒)清晰可见。所有的层沿共挤出的方向平行且连续,层与层间厚度均匀。The mechanical properties of the separator play an important role in the safety performance of the battery. The stress-strain curves obtained by the mechanical tensile test of the separators prepared in Example 1 and Example 3 are shown in Figure 5(a). It can be seen that , the separator prepared in Example 3 has higher tensile strength, because the polymethyl methacrylate modified attapulgite is a one-dimensional linear nanostructure, and its addition will build a three-dimensional structure on the basis of the original porous structure In the network structure, the nanorods are directly connected to each other. When subjected to external force, the stress can be dispersed to other segments through the cross-linking points of the network structure, thereby improving the tensile strength of the separator. The multilayer structure of the cross-section of the diaphragm prepared in Example 3 can be observed by an optical microscope, as shown in Fig. 5(b). Alternating layers of polypropylene (lighter layers) and polyethylene layers (darker layers, PE layers mixed with dark-colored masterbatches for ease of differentiation) are clearly visible. All layers are parallel and continuous along the direction of co-extrusion, and the thickness between layers is uniform.

隔膜的热尺寸稳定性是高功率电池对隔膜的重要性能要求,本实施例中通过测试不同温度处理0.5 h后隔膜的尺寸变化来对此性能进行表征,结果如图6所示。从图6(a)中可以看出,当温度升至100℃ 以上时,商业化的Celgard® 2325隔膜很容易失去热尺寸稳定性而发生收缩。作为对比,实施例1中制备出的隔膜显示出了更好的热稳定性,在160℃之前都没有发生明显的热收缩现象,160℃以上由于达到PP的熔点而失去完整性,发生较明显的收缩。相比之下,在同样的测试条件下,实施例3制备出的隔膜表现出了优异的热稳定性能,在180℃内都能够表现出较高的稳定性,几乎没有明显的收缩情况,这是由于加入的凹凸棒本身具有高温热稳定性,并且有着独特的一维结构从而在隔膜内形成相互联接的三维网络,在隔膜中起到的无机骨架的作用,因此大大提高了隔膜的热稳定性。图6(b)为三种隔膜在30℃,100℃,110℃ 120℃, 140℃,160℃及180℃ 处理0.5 h后的数码照片,可以看出商业化隔膜的热收缩主要发生在拉伸方向,在垂直拉伸的方向收缩率很小。这是由于在商业化锂电隔膜的制备过程中,伴随着多次的拉伸过程已形成微孔结构,因此在高温情况下容易在拉伸方向出现形状恢复行为,从而导致当温度到达100℃ 以上时会发生显著的热收缩。而用发明的制备过程中不包含拉伸的过程,故热稳定性能显著提高,这将有利于电池安全性能的提升。The thermal dimensional stability of the separator is an important performance requirement for the separator for high-power batteries. In this example, the dimensional change of the separator after being treated at different temperatures for 0.5 h was tested to characterize the performance. The results are shown in Figure 6. As can be seen in Figure 6(a), the

采用计时电量法测量隔膜工作过程中的锂离子迁移数(t+),通过计时电量法测定前后,最终电流值和初始电流值的比值来计算,所得到的曲线及计算结果如图7(a)所示。Celgard® 2325, MC-TIPS PP/PE/ATPM (0%)和MC-TIPS PP/PE/ATPM (9%)三种隔膜的锂离子迁移数分别为0.287,0.481及0.496。这是由于采用本发明方法制备出的多孔隔膜含有大量的亚微米级开孔结构可作为锂离子传输的通道。凹凸棒的加入提高了隔膜对电解液的浸润性,也有利于锂离子迁移数的增高。图7(b)是三种隔膜的线性扫描伏安曲线(LSV曲线),其中较明显的电流密度增加的起点所对应的电压值代表隔膜电化学氧化稳定的极限。浸泡了电解液的Celgard® 隔膜相对于Li+/Li的阳极稳定性在4.53 V之前都表现良好,即电化学稳定性窗口在4.53V以内。作为对比,MC-TIPS PP/PE/ATPM(0%)和MC-TIPS PP/PE/ATPM(9%)隔膜的电化学稳定性窗口分别延伸至5.21 V和5.59 V,这意味着更优异的电化学性能。The chronocoulometric method was used to measure the lithium ion migration number (t+ ) during the working process of the diaphragm, and the ratio of the final current value to the initial current value before and after the measurement by the chrono-coulometric method was used to calculate the obtained curve and calculation results as shown in Figure 7 (a ) shown. The lithium ion migration numbers of

实施例4: 以二苯醚为稀释剂,乙醇为萃取剂,微层共挤出与热致相分离方法制备乙烯-醋酸乙烯酯共聚物/聚丙烯(3% 聚甲基丙烯酸甲酯改性凹凸棒)多层多孔隔膜。具体步骤如下:Example 4: Preparation of ethylene-vinyl acetate copolymer/polypropylene (3% polymethyl methacrylate modified by microlayer co-extrusion and thermally induced phase separation with diphenyl ether as diluent and ethanol as extractant) Attapulgite) multilayer porous membrane. Specific steps are as follows:

(1)聚甲基丙烯酸甲酯改性凹凸棒的制备(1) Preparation of polymethyl methacrylate modified attapulgite