CN107200372B - Seawater desalination system and method - Google Patents

Seawater desalination system and methodDownload PDFInfo

- Publication number

- CN107200372B CN107200372BCN201710482067.7ACN201710482067ACN107200372BCN 107200372 BCN107200372 BCN 107200372BCN 201710482067 ACN201710482067 ACN 201710482067ACN 107200372 BCN107200372 BCN 107200372B

- Authority

- CN

- China

- Prior art keywords

- cold

- waste heat

- heat

- evaporator

- seawater

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000013535sea waterSubstances0.000titleclaimsabstractdescription65

- 238000010612desalination reactionMethods0.000titleclaimsabstractdescription32

- 238000000034methodMethods0.000titleclaimsabstractdescription30

- 239000002918waste heatSubstances0.000claimsabstractdescription45

- 238000005338heat storageMethods0.000claimsabstractdescription43

- 238000003860storageMethods0.000claimsabstractdescription34

- 238000005057refrigerationMethods0.000claimsabstractdescription30

- 239000013505freshwaterSubstances0.000claimsabstractdescription16

- 238000005292vacuum distillationMethods0.000claimsabstractdescription16

- 238000001704evaporationMethods0.000claimsabstractdescription9

- 239000003507refrigerantSubstances0.000claimsdescription33

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription22

- 230000000694effectsEffects0.000claimsdescription5

- 239000012530fluidSubstances0.000claimsdescription5

- 238000009792diffusion processMethods0.000claimsdescription4

- 239000007788liquidSubstances0.000claimsdescription3

- 238000004821distillationMethods0.000claimsdescription2

- 239000002994raw materialSubstances0.000claimsdescription2

- 238000009825accumulationMethods0.000claims6

- 238000001816coolingMethods0.000abstractdescription19

- 238000009833condensationMethods0.000abstractdescription12

- 230000005494condensationEffects0.000abstractdescription12

- 239000002440industrial wasteSubstances0.000abstractdescription12

- 230000008020evaporationEffects0.000abstractdescription7

- 238000003912environmental pollutionMethods0.000abstractdescription3

- 238000004519manufacturing processMethods0.000description8

- 239000000498cooling waterSubstances0.000description6

- 229910004298SiO 2Inorganic materials0.000description4

- 238000005516engineering processMethods0.000description4

- 239000011232storage materialSubstances0.000description4

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description3

- 229910052802copperInorganic materials0.000description3

- 239000010949copperSubstances0.000description3

- 230000007423decreaseEffects0.000description3

- 239000006260foamSubstances0.000description3

- 238000010586diagramMethods0.000description2

- 238000005265energy consumptionMethods0.000description2

- 238000004146energy storageMethods0.000description2

- 238000009776industrial productionMethods0.000description2

- 239000002699waste materialSubstances0.000description2

- 229920000742CottonPolymers0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000007547defectEffects0.000description1

- 239000003651drinking waterSubstances0.000description1

- 235000020188drinking waterNutrition0.000description1

- 230000007613environmental effectEffects0.000description1

- 239000007789gasSubstances0.000description1

- 238000010438heat treatmentMethods0.000description1

- 238000002347injectionMethods0.000description1

- 239000007924injectionSubstances0.000description1

- 238000009413insulationMethods0.000description1

- 239000012528membraneSubstances0.000description1

- 238000004321preservationMethods0.000description1

- 238000005086pumpingMethods0.000description1

- 230000005855radiationEffects0.000description1

- 150000003839saltsChemical class0.000description1

- 239000000243solutionSubstances0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/02—Treatment of water, waste water, or sewage by heating

- C02F1/04—Treatment of water, waste water, or sewage by heating by distillation or evaporation

- C02F1/14—Treatment of water, waste water, or sewage by heating by distillation or evaporation using solar energy

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2103/00—Nature of the water, waste water, sewage or sludge to be treated

- C02F2103/08—Seawater, e.g. for desalination

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A20/00—Water conservation; Efficient water supply; Efficient water use

- Y02A20/124—Water desalination

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A20/00—Water conservation; Efficient water supply; Efficient water use

- Y02A20/124—Water desalination

- Y02A20/138—Water desalination using renewable energy

- Y02A20/142—Solar thermal; Photovoltaics

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A20/00—Water conservation; Efficient water supply; Efficient water use

- Y02A20/20—Controlling water pollution; Waste water treatment

- Y02A20/208—Off-grid powered water treatment

- Y02A20/212—Solar-powered wastewater sewage treatment, e.g. spray evaporation

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Hydrology & Water Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Heat Treatment Of Water, Waste Water Or Sewage (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及海水淡化技术领域,具体涉及一种海水淡化系统与方法。The invention relates to the technical field of seawater desalination, in particular to a seawater desalination system and method.

背景技术Background technique

海水淡化即利用海水脱盐生产淡水,是实现水资源利用的开源增量技术,可以增加淡水总量,且不受时空和气候影响,可以保障沿海居民饮用水和工业锅炉补水等稳定供水。由于海水淡化过程耗能较大,如何充分利用各种能量,降低能耗、提高产水效率是海水淡化技术的重点。太阳能作为一种可再生的能源,辐射强度非常大,既可免费使用,又无需生产、运输,而且对环境没有任何污染;工业生产中,废热温度一般能达到70-120℃,其中废热中蕴含大量的热量,所以将太阳能和工业废热结合起来运用于海水淡化过程不仅能减缓能源压力,环境危机,也能减缓地域性缺水问题。Seawater desalination is the use of seawater desalination to produce fresh water. It is an open-source incremental technology to realize the utilization of water resources. It can increase the total amount of fresh water without being affected by time, space and climate, and can ensure a stable water supply such as drinking water for coastal residents and industrial boiler replenishment. Since the seawater desalination process consumes a lot of energy, how to make full use of various energy, reduce energy consumption and improve water production efficiency is the focus of seawater desalination technology. As a renewable energy source, solar energy has a very large radiation intensity, which can be used free of charge without production and transportation, and does not cause any pollution to the environment; in industrial production, the temperature of waste heat can generally reach 70-120 ° C, which contains Therefore, the combination of solar energy and industrial waste heat in the desalination process can not only alleviate the energy pressure and environmental crisis, but also alleviate the regional water shortage problem.

目前所用的主流海水淡化方法有热法海水淡化和膜法海水淡化,其中热法海水淡化因其可以利用低品位的热能,如太阳能、工业废热等,而被广泛地运用。然而,太阳能具有能量密度低、日照间歇性的缺点导致海水淡化效率低下,这制约着其在海水淡化方面的应用。在太阳能海水淡化系统中,蒸汽凝结时需要大量的冷量,通常情况都是选用海水作为冷却水,由于蒸汽凝结时释放的是潜热,而冷却蒸汽是利用海水的显热变化来满足冷负荷需要,我们需要大量的冷却水来满足蒸汽液化时冷量的需求,而为了保证产水率,冷却水泵功率是按最大蒸汽产量所需冷却水进行配备。太阳能存在能量密度低、日照间歇性和不稳定性等缺点,致使太阳能海水淡化装置中蒸汽产量并不稳定,从而造成了不必要的冷量和功耗浪费。并且,在夏季的时候,海水的温度较高,选用海水作为蒸汽凝结的冷却水会使蒸汽冷凝速度降低,从而导致产水率降低;而在工业生产中工业废热利用率较低下甚至通常未加以回收利用直接排放到环境中,不仅造成能源浪费,还污染环境,所以很有必要将这部分工业废热回收利用,用于提供海水蒸发所需的热量,既可以降低海水淡化成本,又可以提高能源的利用效率,减少环境污染。The mainstream seawater desalination methods currently used include thermal seawater desalination and membrane seawater desalination. Among them, thermal seawater desalination is widely used because it can utilize low-grade thermal energy, such as solar energy and industrial waste heat. However, solar energy has the disadvantages of low energy density and intermittent sunlight, resulting in low desalination efficiency, which restricts its application in desalination. In the solar seawater desalination system, a large amount of cooling is required when steam condenses. Usually, seawater is used as cooling water, because the latent heat is released when steam condenses, and cooling steam uses the sensible heat change of seawater to meet the cooling load needs. , we need a large amount of cooling water to meet the cooling demand of steam liquefaction, and in order to ensure the water production rate, the cooling water pump power is equipped according to the cooling water required for the maximum steam production. Solar energy has the disadvantages of low energy density, intermittent and unstable sunlight, etc., resulting in unstable steam production in solar desalination plants, resulting in unnecessary waste of cooling capacity and power consumption. In addition, in summer, the temperature of seawater is high, and the use of seawater as the cooling water for steam condensation will reduce the steam condensation rate, resulting in a decrease in the water production rate; while in industrial production, the utilization rate of industrial waste heat is low or even usually not used. It is recycled and directly discharged into the environment, which not only causes energy waste, but also pollutes the environment. Therefore, it is necessary to recycle this part of industrial waste heat to provide the heat required for seawater evaporation, which can not only reduce the cost of seawater desalination, but also improve the Energy efficiency and reduce environmental pollution.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提供一种海水淡化系统与方法,以克服现有技术的缺陷,本发明将工业废热用于海水的蒸发过程,利用太阳能进行喷射制冷为海水蒸汽凝结提供冷负荷,解决了太阳能海水淡化装置中蒸汽凝结所需冷负荷的动态匹配问题,降低了海水淡化的成本,还可以充分利用工业废热,提高能源利用效率,减少环境污染。The purpose of the present invention is to provide a seawater desalination system and method to overcome the defects of the prior art. The present invention uses industrial waste heat for the evaporation process of seawater, and uses solar energy to perform jet refrigeration to provide cooling load for the condensation of seawater vapor, which solves the problem of solar energy. The dynamic matching of the cooling load required for steam condensation in the seawater desalination device reduces the cost of seawater desalination, and can also make full use of industrial waste heat, improve energy utilization efficiency, and reduce environmental pollution.

为达到上述目的,本发明采用如下技术方案:To achieve the above object, the present invention adopts the following technical solutions:

一种海水淡化系统,包括:A seawater desalination system, comprising:

集热单元:用于将太阳能收集储存;Heat collection unit: used to collect and store solar energy;

制冷单元:利用集热单元储存的热量产生冷量;Refrigeration unit: use the heat stored in the heat collection unit to generate cooling capacity;

蓄冷单元:用于将制冷单元产生的冷量储存;Cold storage unit: used to store the cold energy generated by the refrigeration unit;

废热储存单元:用于将电厂废弃的热量收集储存;Waste heat storage unit: used to collect and store waste heat from power plants;

低温蒸馏单元:利用废热储存单元储存的热量将海水蒸发产生蒸汽,然后利用蓄冷单元储存的冷量将蒸汽凝结为淡水。Low temperature distillation unit: Use the heat stored in the waste heat storage unit to evaporate seawater to generate steam, and then use the cold energy stored in the cold storage unit to condense the steam into fresh water.

进一步地,集热单元包括太阳能集热器,太阳能集热器的两端通过连接管连接至发生器,发生器中设有制冷剂,所述制冷剂能够通过吸收太阳能集热器的热量产生高温高压制冷剂蒸汽,且连接管上设有循环水泵。Further, the heat collecting unit includes a solar heat collector, both ends of the solar heat collector are connected to the generator through connecting pipes, and a refrigerant is arranged in the generator, and the refrigerant can generate high temperature by absorbing the heat of the solar heat collector. High-pressure refrigerant vapor, and a circulating water pump is installed on the connecting pipe.

进一步地,制冷单元包括连接在发生器出口端的双级射流泵,双级射流泵的出口端连接有冷凝器,冷凝器的出口端分别通过节流阀和增压泵连接至蒸发器和发生器,蒸发器的制冷剂出口连接至双级射流泵的一级吸口;Further, the refrigeration unit includes a dual-stage jet pump connected to the outlet end of the generator, the outlet end of the dual-stage jet pump is connected with a condenser, and the outlet end of the condenser is respectively connected to the evaporator and the generator through a throttle valve and a booster pump. , the refrigerant outlet of the evaporator is connected to the first-stage suction port of the two-stage jet pump;

蓄冷单元包括蓄冷管和蓄冷器,蒸发器的冷量出口通过蓄冷管连接至蓄冷器。The cool storage unit includes a cool storage tube and a cool storage device, and the cold outlet of the evaporator is connected to the cool storage device through the cool storage tube.

进一步地,蓄冷管中设有纳米流体介质SiO2。Further, a nano-fluid medium SiO2 is arranged in the regenerator tube.

进一步地,低温蒸馏单元包括板式冷凝器和板式蒸发器,海水通过海水泵依次连接至板式蒸发器和板式冷凝器,然后通过淡水泵抽出,且板式冷凝器通过循环管路连接至蓄冷器,板式蒸发器连接至废热储存单元,且板式蒸发器与双级射流泵的二级吸口连接。Further, the low-temperature distillation unit includes a plate condenser and a plate evaporator, the seawater is sequentially connected to the plate evaporator and the plate condenser through a sea water pump, and then pumped out through a fresh water pump, and the plate condenser is connected to the regenerator through a circulation pipeline. The evaporator is connected to the waste heat storage unit, and the plate evaporator is connected to the secondary suction of the two-stage jet pump.

进一步地,废热储存单元包括废热储罐,废热储罐通过泵连接至板式蒸发器。Further, the waste heat storage unit includes a waste heat storage tank, and the waste heat storage tank is connected to the plate evaporator through a pump.

一种海水淡化方法,采用上述的海水淡化系统,包括以下步骤:A seawater desalination method, using the above-mentioned seawater desalination system, comprises the following steps:

步骤一:集热:太阳能集热器将太阳能收集在其内部,连接管内的循环介质通过循环水泵的增压作用将太阳能传递给发生器中制冷剂,为发生器产生高温高压的制冷剂蒸汽提供热能;Step 1: Collecting heat: The solar collector collects the solar energy inside, and the circulating medium in the connecting pipe transfers the solar energy to the refrigerant in the generator through the pressurization of the circulating water pump, which provides the high temperature and high pressure refrigerant vapor generated by the generator. thermal energy;

步骤二:制冷:发生器中产生的高温高压的制冷剂蒸汽进入双级射流泵中,由于双级射流泵的射流紊动扩散作用,在一级吸口处产生负压而将蒸发器内的低温低压的气态制冷剂卷吸入双级射流泵内,两股制冷剂进行动量和能量的交换后进入冷凝器内进行放热,制冷剂温度降低并由气态变成液态,然后制冷剂再经节流阀降压后进入蒸发器进行吸热而产生冷量;Step 2: Refrigeration: The high-temperature and high-pressure refrigerant vapor generated in the generator enters the double-stage jet pump. Due to the turbulent diffusion of the jet flow of the double-stage jet pump, negative pressure is generated at the first-stage suction port to reduce the low temperature in the evaporator. The low-pressure gaseous refrigerant is drawn into the two-stage jet pump, and the two refrigerants exchange momentum and energy and then enter the condenser to release heat. The temperature of the refrigerant decreases and changes from gas to liquid, and then the refrigerant is throttled. After the valve is depressurized, it enters the evaporator to absorb heat and generate cold energy;

步骤三:蓄冷:蓄冷管将制冷过程中蒸发器内产生的冷量储存在蓄冷器内;Step 3: Cold storage: the cold storage tube stores the cold energy generated in the evaporator during the refrigeration process in the cold storage device;

步骤四:废热储存:废热储罐将电厂废弃的热量储存在其内部,通过流动介质水将热量传递给板式蒸发器;Step 4: Waste heat storage: The waste heat storage tank stores the waste heat of the power plant in its interior, and transfers the heat to the plate evaporator through the flowing medium water;

步骤五:低温蒸馏:双级射流泵的二级吸口处产生负压而卷吸板式蒸发器内空气,使板式蒸发器保持真空度;原料海水经海水泵的抽吸作用进入板式蒸发器内,吸收废热储存过程中废热储罐中的热量,在真空环境下而变成蒸汽;而后进入板式冷凝器内,吸收蓄冷过程中蓄冷器内储存的冷量,蒸汽凝结成淡水而被淡水泵抽出。Step 5: Low temperature distillation: negative pressure is generated at the secondary suction port of the two-stage jet pump to entrain the air in the plate evaporator, so that the plate evaporator can maintain the vacuum degree; the raw seawater enters the plate evaporator through the suction of the seawater pump, It absorbs the heat in the waste heat storage tank during the waste heat storage process, and turns into steam in a vacuum environment; then enters the plate condenser to absorb the cold energy stored in the regenerator during the cold storage process, and the steam condenses into fresh water and is pumped out by the fresh water pump.

与现有技术相比,本发明具有以下有益的技术效果:Compared with the prior art, the present invention has the following beneficial technical effects:

本发明通过集热单元将太阳能收集储存,然后制冷单元利用集热单元储存的热量作为驱动热源用于制冷而产生冷量,然后通过蓄冷单元将冷量储存,同时利用废热储存单元将电厂废弃的热量收集储存,最后利用废热储存单元储存的热量将海水蒸发产生蒸汽,然后利用蓄冷单元储存的冷量将蒸汽凝结为淡水,结构简单,运行稳定可靠,易于操作,另外,与现有海水淡化系统中利用电能加热使海水蒸发相比,本发明对驱动热源品位要求低,使用工业废热作为海水蒸发的热源,对于节约能源和保护环境都有重要意义,并且与太阳能海水淡化系统中选用海水作为蒸汽凝结时的冷却水相比,本发明使用太阳能进行喷射制冷产生冷量用于海水蒸汽的凝结,冷负荷稳定使系统产水率高,能够降低海水淡化成本。In the invention, the solar energy is collected and stored by the heat collecting unit, and then the refrigeration unit uses the heat stored in the heat collecting unit as a driving heat source for cooling to generate cold energy, and then the cold energy is stored by the cold storage unit, and at the same time, the waste heat storage unit is used to store the waste heat from the power plant. The heat is collected and stored, and finally the heat stored in the waste heat storage unit is used to evaporate the seawater to generate steam, and then the cold energy stored in the cold storage unit is used to condense the steam into fresh water. The structure is simple, the operation is stable and reliable, and it is easy to operate. Compared with the use of electric energy heating to evaporate seawater, the present invention has lower requirements on the quality of the driving heat source, and the use of industrial waste heat as the heat source for seawater evaporation is of great significance for saving energy and protecting the environment. Compared with the cooling water during condensation, the present invention uses solar energy to perform jet refrigeration to generate cold energy for condensation of seawater vapor, and the cooling load is stable, so that the water production rate of the system is high, and the cost of seawater desalination can be reduced.

进一步地,本发明除了增压泵、循环泵无运动部件,所以系统使用寿命长。Further, the present invention has no moving parts except the booster pump and the circulating pump, so the service life of the system is long.

进一步地,本发明利用相变蓄热技术将太阳能储存起来,在夜间或者当太阳光照不足时,可以将热能释放,保证制冷单元冷量的稳定输出;利用纳米流体相变蓄冷技术将制冷单元中产生的冷量储存在蓄冷器中,这可以为蒸汽凝结过程提供稳定的冷负荷,从而得到稳定的产水率。Further, the present invention uses the phase change heat storage technology to store solar energy, and at night or when the sunlight is insufficient, the heat energy can be released to ensure the stable output of the cooling capacity of the refrigeration unit; the nano-fluid phase change heat storage technology is used to store the energy in the refrigeration unit. The generated cold energy is stored in the regenerator, which can provide a stable cooling load for the steam condensation process, resulting in a stable water production rate.

进一步地,本发明中制冷单元中的双级射流泵,由于其两级抽吸作用一方面可以使蒸发器中的制冷剂增压,达到喷射制冷的目的;另一方面可以将板式蒸发器内抽真空,使海水在较低的温度下蒸发,从而减小了海水蒸发所需的热负荷,降低了系统的能耗。Further, the two-stage jet pump in the refrigeration unit of the present invention can pressurize the refrigerant in the evaporator on the one hand due to its two-stage suction effect, so as to achieve the purpose of jet refrigeration; Vacuuming makes the seawater evaporate at a lower temperature, thereby reducing the heat load required for seawater evaporation and reducing the energy consumption of the system.

附图说明Description of drawings

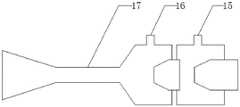

图1为本发明海水淡化系统示意图;Fig. 1 is the schematic diagram of the seawater desalination system of the present invention;

图2为本发明双级射流泵结构示意图。FIG. 2 is a schematic structural diagram of the two-stage jet pump of the present invention.

图中,1.废热储罐,2.泵,3.板式冷凝器,4.淡水泵,5.蓄冷器,6.冷凝器,7.节流阀,8.增压泵,9.蒸发器,10.蓄冷管,11.连接管,12.太阳能集热器,13.循环水泵,14.发生器,15.一级吸口,16.二级吸口,17.双级射流泵, 18.抽真空管路,19.海水泵,20.板式蒸发器。In the figure, 1. Waste heat storage tank, 2. Pump, 3. Plate condenser, 4. Fresh water pump, 5. Regenerator, 6. Condenser, 7. Throttle valve, 8. Booster pump, 9. Evaporator , 10. Cool storage pipe, 11. Connecting pipe, 12. Solar collector, 13. Circulating water pump, 14. Generator, 15. Primary suction port, 16. Secondary suction port, 17. Double-stage jet pump, 18. Pumping Vacuum line, 19. Sea water pump, 20. Plate evaporator.

具体实施方式Detailed ways

下面结合附图对本发明作进一步详细描述:Below in conjunction with accompanying drawing, the present invention is described in further detail:

本发明的海水淡化系统,如图1所示,包括五个单元,分别是集热单元、制冷单元、蓄冷单元、低温蒸馏单元、工业废热储存单元。The seawater desalination system of the present invention, as shown in FIG. 1 , includes five units, which are a heat collection unit, a refrigeration unit, a cold storage unit, a low-temperature distillation unit, and an industrial waste heat storage unit.

集热单元包括太阳能集热器12、连接管11、循环水泵13等,太阳能集热器12与循环水泵13之间用管段连接,管内循环流动的介质为水。在太阳能集热器12的底部填充有相变蓄热材料泡沫铜,用于太阳能的储存,在夜间或者太阳光照强度不高时将储存的太阳能释放为喷射制冷提供驱动热源。The heat collecting unit includes a

制冷单元包括发生器14、冷凝器6、蒸发器9、节流阀7、双级射流泵 17、增压泵8等,发生器14与集热单元中的太阳能集热器12、循环水泵13 之间通过连接管11连接,连接管11中的循环介质将热能传递给发生器14;双级射流泵17的二级吸口16与低温蒸馏单元中的板式蒸发器20连接,用于抽真空用,使板式蒸发器20内保持一定的真空度;双级射流泵17的一级吸口15与蒸发器9连接,双级射流泵17出口与冷凝器6连接,冷凝器6与节流阀7连接;从而蒸发器9、冷凝器6、节流阀7以及双级射流泵17形成了一个制冷循环,为低温多馏单元的蒸汽凝结过程提供冷量;The refrigeration unit includes a

蓄冷单元包括蓄冷器5、蓄冷管10等,蓄冷器5一侧通过蓄冷管9与制冷单元中的蒸发器9连接,蓄冷管9中填充的是相变蓄冷材料纳米流体SiO2,用于储存制冷单元蒸发器9中产生的冷量;蓄冷器5另一侧通过管段与低温蒸馏单元中的板式冷凝器3连接,管段中的循环介质为水;The cold storage unit includes a

低温蒸馏单元包括板式蒸发器20、板式冷凝器3等,板式蒸发器20与工业废热储存单元中的废热储罐1连接,板式冷凝器3与蓄冷器5连接;The low-temperature distillation unit includes a

工业废热储存单元包括废热储罐1、泵2等,废热储罐1与低温蒸馏单元的板式蒸发器20连接,为其提供热源将海水蒸发。The industrial waste heat storage unit includes a waste heat storage tank 1, a

其中,废热储存单元中的废热储罐1是用来收集储存电厂产生的废热,为海水淡化过程中海水的蒸发提供热源,废热储罐1的外壁需要裹一层保温棉用于保温;低温蒸馏单元中的板式蒸发器20的作用是使海水蒸发产水蒸汽,使海水与海水中的盐分离。板式冷凝器3的作用是使板式蒸发器20中产生的蒸汽凝结成淡水;制冷单元中的发生器14的作用是提高制冷剂的温度和压力,即从发生器出来后的制冷剂变成了高温高压的制冷剂;蒸发器9为低温蒸馏单元产生冷量,双级射流泵17一方面将板式蒸发器20内抽成真空,使海水在较低温度下蒸发,另一方面将蒸发器9内的制冷剂增压,达到喷射制冷的目的,蓄冷单元中的蓄冷器5的作用是将制冷单元中蒸发器9产生的冷量储存起来,用于低温蒸馏单元中蒸汽的凝结,蓄冷管10内流动的是纳米流体SiO2,集热单元中的太阳能集热器12的作用是将太阳能收集储存起来,为发生器14中制冷剂蒸汽的产生提供热量,太阳能集热器12底部还填充有相变蓄热材料泡沫铜,用于太阳能的储存。Among them, the waste heat storage tank 1 in the waste heat storage unit is used to collect and store the waste heat generated by the power plant, and provide a heat source for the evaporation of seawater in the process of seawater desalination. The outer wall of the waste heat storage tank 1 needs to be wrapped with a layer of insulation cotton for heat preservation; The function of the

下面对本发明的操作过程做详细描述:The operation process of the present invention is described in detail below:

第一,集热过程:太阳能集热器12将太阳能收集在其内部,并且相变蓄热材料泡沫铜将太阳能储存在起来;连接管11内的循环介质通过循环水泵 13的增压作用将太阳能传递给发生器14,为发生器14产生蒸汽提供热能。First, the heat collection process: the

第二,制冷过程:发生器14中产生的高温高压的制冷剂蒸汽进入双级射流泵17中,由于双级射流泵17的射流紊动扩散作用,在一级吸口15处产生负压而将蒸发器9内的低温低压的气态制冷剂卷吸入双级射流泵17内,两股制冷剂进行动量和能量的交换后进入冷凝器6内进行放热,制冷剂温度降低并由气态变成液态,制冷剂再经节流阀7降压后进入蒸发器9进行吸热而产生冷量。在这个循环过程中,发生器14与双级射流泵17相当于压缩机的作用,与冷凝器6、节流阀7、蒸发器9构成制冷循环的四大件。Second, the refrigeration process: the high-temperature and high-pressure refrigerant vapor generated in the

第三,蓄冷过程:蓄冷管10内流动的纳米流体介质SiO2将制冷过程中蒸发器9内产生的冷量储存在蓄冷器5内,为低温蒸馏过程蒸汽的凝结提供冷负荷。Third, the cold storage process: the nano-fluid medium SiO2 flowing in the

第四,废热储存过程:废热储罐1将电厂废弃的热量储存在其内部,通过流动介质水将热量传递给板式蒸发器20,为低温蒸馏过程海水的蒸发提供热源。Fourth, the waste heat storage process: the waste heat storage tank 1 stores the waste heat of the power plant in its interior, transfers the heat to the

第五,低温蒸馏过程:由于双级射流泵17的射流紊动扩散作用,二级吸口16处产生负压而卷吸板式蒸发器20内空气,使板式蒸发器20保持一定的真空度;原料海水经海水泵19的抽吸作用进入板式蒸发器20内,吸收废热储存过程中废热储罐1中的热量,在真空环境下而变成蒸汽;而后进入板式冷凝器3内,吸收蓄冷过程中蓄冷器5内储存的冷量,蒸汽凝结成淡水而被淡水泵4抽出。Fifth, the low-temperature distillation process: due to the jet turbulent diffusion effect of the two-

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710482067.7ACN107200372B (en) | 2017-06-22 | 2017-06-22 | Seawater desalination system and method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201710482067.7ACN107200372B (en) | 2017-06-22 | 2017-06-22 | Seawater desalination system and method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107200372A CN107200372A (en) | 2017-09-26 |

| CN107200372Btrue CN107200372B (en) | 2020-10-09 |

Family

ID=59906959

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201710482067.7AActiveCN107200372B (en) | 2017-06-22 | 2017-06-22 | Seawater desalination system and method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN107200372B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108408804B (en)* | 2017-11-23 | 2024-08-16 | 中石化石油工程技术服务有限公司 | Integrated equipment for desalting brine and preparing dry steam |

| CN110332086A (en)* | 2019-05-22 | 2019-10-15 | 大连海水淡化工程研究中心有限公司 | A kind of solar energy optical-thermal water-electricity cogeneration technique |

| CN111115733B (en)* | 2020-01-17 | 2024-03-29 | 大连海事大学 | Ship sea water desalination system based on injection-compression heat pump technology |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103993920A (en)* | 2014-05-27 | 2014-08-20 | 鄂尔多斯大规模储能技术研究所 | Island energy supply system with cold energy |

| CN105576943A (en)* | 2014-10-13 | 2016-05-11 | 国家电网公司 | High-voltage DC converter valve heat recycling system and realizing method thereof |

| CN106698565A (en)* | 2016-07-11 | 2017-05-24 | 杨昌智 | Solar-heat pump sea water desalination device |

| CN106745426A (en)* | 2017-01-25 | 2017-05-31 | 广州中国科学院先进技术研究所 | Based on nano-fluid phase change cold-storage and Driven by Solar Energy seawater desalination system and technique |

- 2017

- 2017-06-22CNCN201710482067.7Apatent/CN107200372B/enactiveActive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103993920A (en)* | 2014-05-27 | 2014-08-20 | 鄂尔多斯大规模储能技术研究所 | Island energy supply system with cold energy |

| CN105576943A (en)* | 2014-10-13 | 2016-05-11 | 国家电网公司 | High-voltage DC converter valve heat recycling system and realizing method thereof |

| CN106698565A (en)* | 2016-07-11 | 2017-05-24 | 杨昌智 | Solar-heat pump sea water desalination device |

| CN106745426A (en)* | 2017-01-25 | 2017-05-31 | 广州中国科学院先进技术研究所 | Based on nano-fluid phase change cold-storage and Driven by Solar Energy seawater desalination system and technique |

Also Published As

| Publication number | Publication date |

|---|---|

| CN107200372A (en) | 2017-09-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103968574B (en) | A kind of high efficiency energy storage type Solar Heat Pump Heating System method of round-the-clock running | |

| CN103245085B (en) | A kind of accumulating type solar oscillating heat pipe heat pump heat distribution system and method thereof | |

| CN201811485U (en) | Solar Working Fluid Energy Storage Continuous Refrigeration Device | |

| CN112503782A (en) | Oil field waste heat recovery system and method applying solar energy and lithium bromide heat pump | |

| CN101556095A (en) | Low-grade energy driving and mechanical work driving combined heat pump or refrigerating system | |

| CN101571330A (en) | Multifunctional frost-free solar-assisted heat pump system | |

| CN107200372B (en) | Seawater desalination system and method | |

| CN103090582B (en) | The absorption energy storage equipment of a kind of boosting type three-phase | |

| CN101619908A (en) | Energy storage refrigeration method using solar thermal energy driving | |

| CN113587187A (en) | Flue gas waste heat recycling system and method | |

| CN202254475U (en) | Absorption type chemical energy storage device including crystallization | |

| CN201706772U (en) | Solar single/double effect lithium bromide absorption type refrigerating unit formed by effective heat exchanger | |

| CN105972858A (en) | System and method for supplying energy and storing energy by utilizing waste heat of air compressor | |

| CN205783976U (en) | The refrigeration system that a kind of solar energy absorption type refrigeration is compound with absorption type refrigerating | |

| CN101235995A (en) | New Heat Pipe Solar Air Conditioning System | |

| CN201973952U (en) | Lithium bromide absorption evaporative condensation water chiller | |

| CN205048782U (en) | Compression and integrative unit of absorption formula dual intensity source combination cold -storage refrigeration | |

| CN207539872U (en) | Energy supply system | |

| CN203190713U (en) | Pressurization type three-phase absorption energy storage device | |

| CN103256848B (en) | Self-warming type thermochemical heat accumulating device and application | |

| CN212252557U (en) | A steam generation system coupled with solar energy and heat pump | |

| CN111911990A (en) | A long-distance absorption cooling and heating system based on solution energy storage | |

| CN109282397B (en) | Novel energy storage air conditioner and method based on air compression refrigeration cycle | |

| CN110762947A (en) | An air cooling device in a low pressure air separation system | |

| CN101975487B (en) | Diffusion absorption refrigeration and hot water system applying solar energy |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |