CN106461523B - Electronic cigarette performance testing device and testing method - Google Patents

Electronic cigarette performance testing device and testing methodDownload PDFInfo

- Publication number

- CN106461523B CN106461523BCN201480078961.2ACN201480078961ACN106461523BCN 106461523 BCN106461523 BCN 106461523BCN 201480078961 ACN201480078961 ACN 201480078961ACN 106461523 BCN106461523 BCN 106461523B

- Authority

- CN

- China

- Prior art keywords

- electronic cigarette

- negative pressure

- control module

- air inlet

- pressure value

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N7/00—Analysing materials by measuring the pressure or volume of a gas or vapour

Landscapes

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及电子烟性能测试技术领域,尤其涉及电子烟性能测试装置及测试方法。The invention relates to the technical field of electronic cigarette performance testing, in particular to an electronic cigarette performance testing device and a testing method.

背景技术Background technique

电子烟作为香烟的替代,对其性能的评价主要集中在以下几个发明:1)灵敏度性能,表现为吸烟者在吸烟中开启点燃电子烟所需要的力度;2)通气和憋气性能,表现为吸烟者在吸烟过程中吸气的轻重,具体为吸烟者在吸电子烟时感觉吸气顺畅与否,一般而言,好的电子烟吸气比较顺畅,与吸真烟的感觉比较接近;3)烟雾量,每口吸到的烟雾量是否足够,一般来说,好的电子烟烟雾量感觉更大一些;4)电池寿命,一般来说电池用的时间越长的,电子烟性能越好;5)雾化器寿命,质量较差的电子烟产品雾化器非常容易损坏,雾化器的寿命越长,电子烟的性能越好;5)烟弹的容量,一般来说指烟弹容量大的,电子烟的性能越好。As a substitute for cigarettes, the performance evaluation of electronic cigarettes mainly focuses on the following inventions: 1) Sensitivity performance, which is expressed as the strength required by the smoker to open and ignite the electronic cigarette during smoking; 2) Ventilation and breath holding performance, which is expressed as The weight of the smoker’s inhalation during smoking, specifically, is whether the smoker feels that the inhalation is smooth when smoking the e-cigarette. Generally speaking, a good e-cigarette inhales more smoothly, which is closer to the feeling of smoking a real cigarette; 3 ) The amount of smoke, whether the amount of smoke inhaled by each puff is enough, generally speaking, the smoke volume of a good electronic cigarette feels larger; 4) Battery life, generally speaking, the longer the battery is used, the better the performance of the electronic cigarette ;5) The life of the atomizer, the atomizer of poor quality electronic cigarette products is very easy to damage, the longer the life of the atomizer, the better the performance of the electronic cigarette; 5) The capacity of the cartridge, generally refers to the cartridge The larger the capacity, the better the performance of the electronic cigarette.

现有技术中,电子烟的性能测试,如通气性能、烟雾流通性能、雾化性能等都是采用人工口吸来进行测试的。这种测试的方式工作慢,效率低,而且浪费人力,增加成本,延长研发周期,而且存在太多的人为因素,测试结果不准确,不卫生。In the prior art, the performance tests of electronic cigarettes, such as ventilation performance, smoke circulation performance, atomization performance, etc., are all tested by artificial mouth inhalation. This method of testing is slow, inefficient, and wastes manpower, increases costs, prolongs the development cycle, and there are too many human factors, the test results are inaccurate and unhygienic.

发明内容Contents of the invention

鉴于上述缺陷,本发明提供了一种能准确、高效地检测电子烟的性能的电子烟性能测试装置及测试方法。In view of the above defects, the present invention provides an electronic cigarette performance testing device and testing method that can accurately and efficiently test the performance of electronic cigarettes.

本发明提供一种电子烟性能测试装置,包括套筒及插设在所述套筒内的活塞,所述活塞与所述套筒围成烟雾收集腔,所述套筒还具有与所述烟雾收集腔连通的进气口,所述进气口通过进气管与电子烟的烟嘴连通,所述活塞用于对所述电子烟抽气以模拟吸烟动作;The invention provides an electronic cigarette performance testing device, which includes a sleeve and a piston inserted in the sleeve, the piston and the sleeve form a smoke collection chamber, and the sleeve also has a The air inlet connected to the collection cavity, the air inlet communicates with the mouthpiece of the electronic cigarette through the air inlet pipe, and the piston is used to draw air from the electronic cigarette to simulate smoking action;

所述进气口中具有进气单向阀,所述进气单向阀用于防止所抽入套筒内的气体逸出;There is an air intake one-way valve in the air inlet, and the air intake one-way valve is used to prevent the gas drawn into the sleeve from escaping;

所述电子烟性能测试装置还包括控制模块以及与所述控制模块电连接的驱动机构和负压检测仪;其中,The electronic cigarette performance testing device also includes a control module, a driving mechanism and a negative pressure detector electrically connected to the control module; wherein,

所述驱动机构用于驱动所述活塞运动以实现抽气;The drive mechanism is used to drive the piston to move to achieve air extraction;

所述负压检测仪通过进气分管与所述进气管相连通,用于感应所述进气管中的负压值,并将所述负压值发送给所述控制模块;The negative pressure detector communicates with the intake pipe through the intake branch pipe, and is used to sense the negative pressure value in the intake pipe and send the negative pressure value to the control module;

所述控制模块用于控制所述驱动机构的启闭并根据所述负压值判断所述电子烟的通气性能。The control module is used for controlling the opening and closing of the driving mechanism and judging the ventilation performance of the electronic cigarette according to the negative pressure value.

上述的电子烟性能测试装置中,所述套筒还开设有与所述烟雾收集腔连通的出气口,所述出气口通过出气管与外部连通;所述出气口中具有出气单向阀,用于防止所述外部的气体流入所述烟雾收集腔中。In the above-mentioned electronic cigarette performance testing device, the sleeve is also provided with an air outlet communicating with the smoke collection cavity, and the air outlet communicates with the outside through an air outlet pipe; the air outlet has an air outlet check valve for Prevent the external air from flowing into the smoke collection cavity.

上述的电子烟性能测试装置中,所述控制模块还用于控制所述驱动机构驱动所述活塞排出所抽入的气体以判断所述电子烟的雾化性能。In the above electronic cigarette performance testing device, the control module is further used to control the driving mechanism to drive the piston to discharge the sucked gas so as to judge the atomization performance of the electronic cigarette.

上述的电子烟性能测试装置中,还包括与所述控制模块电连接的报警装置,所述报警装置用于根据所述控制模块的判断结果发出警报。The above electronic cigarette performance testing device further includes an alarm device electrically connected to the control module, and the alarm device is configured to issue an alarm according to the judgment result of the control module.

上述的电子烟性能测试装置中,还包括用于夹持所述电子烟的夹持装置。The above electronic cigarette performance testing device further includes a clamping device for clamping the electronic cigarette.

上述的电子烟性能测试装置中,所述夹持装置包括固定座以及位于所述固定座上用于容纳所述电子烟的烟嘴的弹性容置件,所述弹性容置件与所述进气管相连通。In the above electronic cigarette performance testing device, the clamping device includes a fixed seat and an elastic container located on the fixed seat for accommodating the mouthpiece of the electronic cigarette, and the elastic container is connected to the air intake pipe connected.

上述的电子烟性能测试装置中,还包括内中空的箱体,所述活塞、控制模块、驱动机构以及夹持装置均位于所述箱体中,所述报警装置固定在所述箱体的外壁上。The above electronic cigarette performance testing device also includes a hollow box, the piston, control module, driving mechanism and clamping device are all located in the box, and the alarm device is fixed on the outer wall of the box superior.

上述的电子烟性能测试装置中,所述驱动机构包括气缸和用于控制所述气缸进气或出气的电磁阀。In the above electronic cigarette performance testing device, the driving mechanism includes a cylinder and a solenoid valve for controlling air intake or output from the cylinder.

上述的电子烟性能测试装置中,所述驱动机构包括电机以及连接在所述电机与所述活塞之间的传动机构。In the above electronic cigarette performance testing device, the driving mechanism includes a motor and a transmission mechanism connected between the motor and the piston.

上述的电子烟性能测试装置中,所述传动机构为丝杆滑台机构。In the above electronic cigarette performance testing device, the transmission mechanism is a screw slide mechanism.

本发明还提供一种电子烟性能测试方法,包括以下步骤:The present invention also provides a method for testing the performance of an electronic cigarette, comprising the following steps:

S1、控制模块控制驱动机构驱动活塞对电子烟进行抽气以模拟吸烟动作;S1. The control module controls the driving mechanism to drive the piston to extract air from the electronic cigarette to simulate smoking action;

S2、负压检测仪检测抽气时进气管中的负压值,并将检测到的负压值发送给S2. The negative pressure detector detects the negative pressure value in the intake pipe when pumping air, and sends the detected negative pressure value to

控制模块;control module;

S3、控制模块对检测到的负压值进行判断以确定所述电子烟的通气性能。S3. The control module judges the detected negative pressure value to determine the ventilation performance of the electronic cigarette.

上述的电子烟性能测试方法,所述步骤S3包括以下步骤:In the above electronic cigarette performance testing method, the step S3 includes the following steps:

在所述控制模块中预设负压值范围;Presetting the range of negative pressure values in the control module;

判断所述检测到的负压值是否处于所述预设的负压值范围内;如是,则所述电子烟的通气性能良好;反之,则所述电子烟的通气性能不好。Judging whether the detected negative pressure value is within the preset negative pressure value range; if yes, the ventilation performance of the electronic cigarette is good; otherwise, the ventilation performance of the electronic cigarette is not good.

上述的电子烟性能测试方法,还包括:The above-mentioned e-cigarette performance test method also includes:

S4、当所述检测到的负压值未处于所述预设的负压值范围内,所述控制模块S4. When the detected negative pressure value is not within the preset negative pressure value range, the control module

控制报警装置发出警报。The control alarm device sends out an alarm.

上述的电子烟测试方法中,还包括以下步骤:In the above electronic cigarette test method, the following steps are also included:

所述控制模块控制驱动机构驱动活塞运动以排出所抽入的气体;The control module controls the driving mechanism to drive the piston to move to discharge the drawn gas;

根据排出的所述气体的颜色判断所述电子烟的雾化性能;judging the atomization performance of the electronic cigarette according to the color of the discharged gas;

当排出的所述气体呈白色时,所述电子烟的雾化性能良好。When the discharged gas is white, the atomization performance of the electronic cigarette is good.

实施本发明的电子烟性能测试装置的有益效果在于:在依据本发明的电子烟性能测试装置及方法中,通过设置负压检测仪对抽烟时电子烟的负压值进行检测,并通过控制模块对检测到的负压值进行判断,从而直接用试验数据表征电子烟的通气性能,因此测试结果准确、工作效率高;而且该测试装置及方法对于所有的电子烟而言具有重复性,因此可用于批量测试电子烟。另外,还根据电子烟性能测试装置中排出的烟雾的颜色判断电子烟的雾化性能。The beneficial effect of implementing the electronic cigarette performance testing device of the present invention is that in the electronic cigarette performance testing device and method according to the present invention, the negative pressure value of the electronic cigarette when smoking is detected by setting a negative pressure detector, and the negative pressure value of the electronic cigarette is detected by the control module Judging the detected negative pressure value, so as to directly use the test data to characterize the ventilation performance of the electronic cigarette, so the test result is accurate and the work efficiency is high; and the test device and method are repeatable for all electronic cigarettes, so it can be used for mass testing of e-cigarettes. In addition, the atomization performance of the electronic cigarette is also judged according to the color of the smoke discharged from the electronic cigarette performance testing device.

附图说明Description of drawings

下面将结合附图及实施例对本发明作进一步说明,附图中;The present invention will be further described below in conjunction with accompanying drawing and embodiment, in accompanying drawing;

图1为本发明的电子烟性能测试装置的工作原理框图;Fig. 1 is a working principle block diagram of the electronic cigarette performance testing device of the present invention;

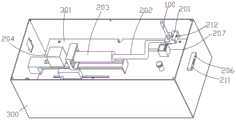

图2为本发明的电子烟性能测试装置的结构示意图;Fig. 2 is a schematic structural diagram of the electronic cigarette performance testing device of the present invention;

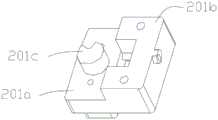

图3为图2所示的夹持装置的结构示意图。FIG. 3 is a schematic structural diagram of the clamping device shown in FIG. 2 .

具体实施方式Detailed ways

在依据本发明的电子烟性能测试装置及方法中,通过设置负压检测仪对抽烟时电子烟的负压值进行检测,并通过控制模块对检测到的负压值进行判断,从而直接用试验数据表征电子烟的通气性能,因此测试结果准确且公正;而且该测试装置及方法对于所有的电子烟而言具有重复性,因此可用于批量测试电子烟。另外,还根据电子烟性能测试装置中排出的烟雾的颜色判断电子烟的雾化性能。In the electronic cigarette performance testing device and method according to the present invention, the negative pressure value of the electronic cigarette when smoking is detected by setting a negative pressure detector, and the detected negative pressure value is judged by the control module, so as to directly use the test The data represent the ventilation performance of the electronic cigarette, so the test result is accurate and fair; and the test device and method are repeatable for all electronic cigarettes, so they can be used for batch testing of electronic cigarettes. In addition, the atomization performance of the electronic cigarette is also judged according to the color of the smoke discharged from the electronic cigarette performance testing device.

参考图1和图2中提供的电子烟性能测试装置,用于对电子烟100的通气性能、雾化性能等进行测试。该电子烟性能测试装置包括感应开关、夹持装置201、负压检测仪207、套筒203、活塞(未标示)、驱动机构204、控制模块205、报警装置206、箱体300。Referring to the electronic cigarette performance testing device provided in FIG. 1 and FIG. 2 , it is used to test the ventilation performance and atomization performance of the

在本实施例中,箱体300大致呈内中空的长方体状,箱体300中安装有承载板301,感应开关、夹持装置201、负压检测仪207、套筒203、活塞、驱动机构204、控制模块205均容纳在箱体300内部,并固定安装在承载板301上。报警装置206安装在箱体300的外壁上,以便于测试过程中很快地发现报警信息。In this embodiment, the

电子烟100安装在夹持装置201中。活塞插设在套筒203内,并与套筒203围成烟雾收集腔。The

套筒203还具有与烟雾收集腔连通的进气口和出气口。进气口通过进气管202与电子烟100的烟嘴连通,套筒203用于对电子烟100抽气以模拟吸烟动作。其中,进气口中具有进气单向阀209,用于防止所抽入套筒203内的气体逸出;出气口通过出气管210与外部连通,出气口中具有出气单向阀208,用于使烟雾收集腔中的气体经出气管210排出并防止外部的气体进入烟雾收集腔中。The

驱动机构204与活塞连接,并与控制模块205电连接。驱动机构204用于根据控制模块205的指令驱动活塞运动以实现抽气或排气。在一实施例中,驱动机构204包括市面可售的气缸和用于控制气缸进气或出气的电磁阀,其中气缸的活塞插设在套筒203中实现抽气或排气的动作。The

在另一实施例中,参考图3,驱动机构204包括电机和传动机构。在本实施例中,传动机构为市面可售的丝杆滑台模组。丝杆滑台模组将电机工作时的旋转运动通过传动机构转换成活塞的直线运动,从而推动活塞运动以实现抽气或排气的动作。在本实施例中,电机的驱动轴与丝杆的一端螺纹连接,并在电机启动后,通过丝杆将电机的旋转运动转化为直线运动,丝杆的另一端与滑台上的滑块的一端固定连接,从而带动滑块运动;滑块的另一端与活塞固定连接,进而带动活塞运动。在该装置中设计此种传动机构可以实现该装置的各个结构之间连接紧凑,使得该装置的结构紧凑。In another embodiment, referring to FIG. 3 , the

负压检测仪207为市面可售的负压检测器,其通过分管与进气管202相连通,并与控制模块205电连接,用于检测进气管202中的负压值,并将负压值发送给控制模块205。The

控制模块205中预设有负压值的用于判断检测的负压值是否正常的预设范围,其用于控制驱动机构204的启闭并根据负压值判断电子烟的通气性能。The

报警装置206与控制模块205电连接,当控制模块205判断出电子烟100的通气性能较差时发出指令控制报警装置206发出警报以提示用户。The

在本实施例中,感应开关与控制模块205电连接,用于检测夹持装置201上是否插置有待检测的电子烟100。该感应开关包括安装在夹持装置201上的感应探头212和安装在箱体300的外壁上的传感器调节阀211。在本实施例中,感应开关为感光开关,感应探头为光纤感应探头(也称为光纤传感器),当夹持装置201上插置有电子烟100时,感应探头212感应到光的变化,从而发出信号至控制模块205,控制模块205控制驱动机构204运动以对电子烟100进行抽气。In this embodiment, the inductive switch is electrically connected to the

夹持装置201固定安装在承载板301上,包括用于插置电子烟100的固定座201a和用于安装感应探头212的安装座201b。固定座201a与安装座201b分别为两块相互垂直设置的平板。固定座201a的一面与承载板301固定连接,固定座201a的另一面用于固定电子烟100的、由硅胶制成的弹性容置件201c。采用硅胶可以使烟嘴与弹性容置件201c之间贴合地更紧密,从而防止烟雾泄露出去。The

进一步,详细地说明该电子烟性能测试装置的测试方法。Further, the test method of the electronic cigarette performance test device is described in detail.

测试方法包括以下步骤:The test method includes the following steps:

感应开关检测到电子烟100插置在夹持装置201上时,发出信号给控制模块205;When the sensor switch detects that the

控制模块205控制驱动机构204驱动活塞对电子烟100进行抽气以模拟吸烟动作;The

负压检测仪207检测抽气时进气管202中的负压值,并将检测到的负压值发送给控制模块205;

控制模块205对检测到的负压值进行判断以确定电子烟的通气性能,具体地,在控制模块205中预设正常的负压值范围;判断检测到的负压值是否处于预设的负压值范围内;如是,则电子烟100的通气性能良好;反之,则电子烟100的通气性能不好,即可能出现憋气、漏气等情况。The

当控制模块205判断出电子烟100的性能不好(即负压值未处于预设的负压值范围内)时,控制报警装置206发出警报,以提醒用户。When the

当通气性能检测完成后,控制模块205控制驱动机构204往反方向运动从而推动活塞运动以排出套筒203内收集到的烟雾,并将烟雾从出气口处排出。用户根据排出的烟雾的颜色对电子烟的雾化性能进行判断,当排出的烟雾呈白色时,则表明排出的烟雾量大,电子烟的雾化性能良好;反之,则电子烟的雾化性能不好。After the breathability test is completed, the

应当理解的是,对本领域普通技术人员来说,可以根据上述说明加以改进或变换,而所有这些改进和变换都应属于本发明所附权利要求的保护范围。It should be understood that those skilled in the art can make improvements or changes based on the above description, and all these improvements and changes should belong to the protection scope of the appended claims of the present invention.

Claims (9)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/CN2014/078773WO2015180089A1 (en) | 2014-05-29 | 2014-05-29 | Electronic cigarette performance test apparatus and test method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN106461523A CN106461523A (en) | 2017-02-22 |

| CN106461523Btrue CN106461523B (en) | 2019-10-15 |

Family

ID=54697870

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201480078961.2AExpired - Fee RelatedCN106461523B (en) | 2014-05-29 | 2014-05-29 | Electronic cigarette performance testing device and testing method |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN106461523B (en) |

| WO (1) | WO2015180089A1 (en) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20160345631A1 (en) | 2005-07-19 | 2016-12-01 | James Monsees | Portable devices for generating an inhalable vapor |

| US10279934B2 (en) | 2013-03-15 | 2019-05-07 | Juul Labs, Inc. | Fillable vaporizer cartridge and method of filling |

| US10039321B2 (en) | 2013-11-12 | 2018-08-07 | Vmr Products Llc | Vaporizer |

| US20160366947A1 (en) | 2013-12-23 | 2016-12-22 | James Monsees | Vaporizer apparatus |

| US10076139B2 (en) | 2013-12-23 | 2018-09-18 | Juul Labs, Inc. | Vaporizer apparatus |

| DE202014011260U1 (en) | 2013-12-23 | 2018-11-13 | Juul Labs Uk Holdco Limited | Systems for an evaporation device |

| US10159282B2 (en) | 2013-12-23 | 2018-12-25 | Juul Labs, Inc. | Cartridge for use with a vaporizer device |

| USD825102S1 (en) | 2016-07-28 | 2018-08-07 | Juul Labs, Inc. | Vaporizer device with cartridge |

| US10058129B2 (en) | 2013-12-23 | 2018-08-28 | Juul Labs, Inc. | Vaporization device systems and methods |

| USD842536S1 (en) | 2016-07-28 | 2019-03-05 | Juul Labs, Inc. | Vaporizer cartridge |

| MX394125B (en) | 2014-12-05 | 2025-03-24 | Juul Labs Inc | CALIBRATED DOSE CONTROL |

| EP3413960B1 (en) | 2016-02-11 | 2021-03-31 | Juul Labs, Inc. | Fillable vaporizer cartridge and method of filling |

| CO2018009342A2 (en) | 2016-02-11 | 2018-09-20 | Juul Labs Inc | Secure fixing cartridges for vaporizing devices |

| US10405582B2 (en) | 2016-03-10 | 2019-09-10 | Pax Labs, Inc. | Vaporization device with lip sensing |

| USD849996S1 (en) | 2016-06-16 | 2019-05-28 | Pax Labs, Inc. | Vaporizer cartridge |

| USD836541S1 (en) | 2016-06-23 | 2018-12-25 | Pax Labs, Inc. | Charging device |

| USD851830S1 (en) | 2016-06-23 | 2019-06-18 | Pax Labs, Inc. | Combined vaporizer tamp and pick tool |

| CN107167557A (en)* | 2017-04-25 | 2017-09-15 | 广东中烟工业有限责任公司 | One kind visualization flue gas suction experimental provision and its application process |

| USD887632S1 (en) | 2017-09-14 | 2020-06-16 | Pax Labs, Inc. | Vaporizer cartridge |

| CN111296893A (en)* | 2018-12-10 | 2020-06-19 | 尉关兴 | A display device for the functions and use effects of electronic cigarettes |

| CN109596975B (en)* | 2018-12-24 | 2021-03-30 | 深圳瀚星翔科技有限公司 | Electronic cigarette circuit board detection system and method |

| CN111616423B (en)* | 2020-06-15 | 2024-11-12 | 深圳市智立方自动化设备股份有限公司 | Electronic cigarette ventilation flow performance testing device |

| CN115399504A (en)* | 2021-05-27 | 2022-11-29 | 湖南中烟工业有限责任公司 | Fixing device for testing electronic smoke core and its use method |

| CN113433096A (en)* | 2021-06-24 | 2021-09-24 | 青岛颐中科技有限公司 | Heating cigarette flue gas transmittance detection device |

| CN115219287A (en)* | 2022-07-26 | 2022-10-21 | 深圳市艾瑞斯电子有限公司 | Sampling air extraction device and method for electronic cigarette atomized aerosol test |

| CN116138507A (en)* | 2022-08-19 | 2023-05-23 | 北京慧荣和科技有限公司 | Electronic cigarette smoking machine with smoke trapping function |

| CN117882891A (en)* | 2024-03-04 | 2024-04-16 | 太仓强兴福达科技有限公司 | Electronic cigarette atomization core detection equipment for electronic cigarette production |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002171954A (en)* | 2000-12-11 | 2002-06-18 | Rikku:Kk | Cigarette smoke generator |

| CN102419297A (en)* | 2011-08-18 | 2012-04-18 | 中国烟草总公司郑州烟草研究院 | Piston-type constant-flow controllable airflow source pressure measuring device |

| CN103416843A (en)* | 2013-08-03 | 2013-12-04 | 中烟摩迪(江门)纸业有限公司 | Smoking machine |

| CN103512827A (en)* | 2012-06-29 | 2014-01-15 | 刘秋明 | Electronic cigarette performance testing device and electronic cigarette performance testing method |

| CN204008396U (en)* | 2014-05-29 | 2014-12-10 | 惠州市吉瑞科技有限公司 | Electronic cigarette performance testing device |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2011409A1 (en)* | 2007-07-04 | 2009-01-07 | Philip Morris Products S.A. | Resistance-to-draw measuring device |

| CN202372423U (en)* | 2011-12-20 | 2012-08-08 | 浙江中烟工业有限责任公司 | Standard draw resistance measuring device |

| CN202994655U (en)* | 2013-01-14 | 2013-06-12 | 安徽中烟工业有限责任公司 | Device for measuring smoking easy degree of cigarettes |

| CN103091280A (en)* | 2013-01-14 | 2013-05-08 | 安徽中烟工业有限责任公司 | Determination method for suction easiness degree of cigarette |

- 2014

- 2014-05-29CNCN201480078961.2Apatent/CN106461523B/ennot_activeExpired - Fee Related

- 2014-05-29WOPCT/CN2014/078773patent/WO2015180089A1/enactiveApplication Filing

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002171954A (en)* | 2000-12-11 | 2002-06-18 | Rikku:Kk | Cigarette smoke generator |

| CN102419297A (en)* | 2011-08-18 | 2012-04-18 | 中国烟草总公司郑州烟草研究院 | Piston-type constant-flow controllable airflow source pressure measuring device |

| CN103512827A (en)* | 2012-06-29 | 2014-01-15 | 刘秋明 | Electronic cigarette performance testing device and electronic cigarette performance testing method |

| CN103416843A (en)* | 2013-08-03 | 2013-12-04 | 中烟摩迪(江门)纸业有限公司 | Smoking machine |

| CN204008396U (en)* | 2014-05-29 | 2014-12-10 | 惠州市吉瑞科技有限公司 | Electronic cigarette performance testing device |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015180089A1 (en) | 2015-12-03 |

| CN106461523A (en) | 2017-02-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN106461523B (en) | Electronic cigarette performance testing device and testing method | |

| CN204008396U (en) | Electronic cigarette performance testing device | |

| CN103512827B (en) | Electronic cigarette performance testing device and method | |

| CN101788447B (en) | Cigarette smoke aerosol real-time testing system | |

| CN216484577U (en) | Smog volume concentration detection equipment | |

| CN110051035A (en) | A kind of cigarette annular perforating device based on tobacco density | |

| CN108548910B (en) | A kind of detection method of water content of deep dewatered sludge | |

| CN110893018B (en) | Heating member management method and device | |

| CN110025038B (en) | Annular perforating device of running water formula cigarette | |

| CN105004581A (en) | Method for measuring puff-by-puff carbon monoxide in cigarette mainstream smoke | |

| CN212807766U (en) | Portable gas, dust and smoke dust sampling instrument calibration device | |

| CN203616233U (en) | Device for evaluating filter efficiency of PM2.5 mask in real atmosphere environment | |

| CN205757198U (en) | Electronic cigarette | |

| CN209148646U (en) | A kind of device detecting indoor cabinet content of formaldehyde | |

| CN204789596U (en) | Multi -functional alcohol detector | |

| CN208795563U (en) | A portable manual cigarette smoke collection device | |

| CN219306052U (en) | Air flow detection device for air flow sensor test | |

| CN218960081U (en) | Air pressure adjustable air flow sensor testing device | |

| CN108844953A (en) | A kind of indoor harmful gas automatic detection device | |

| CN209656647U (en) | An environmental protection building material formaldehyde detection equipment | |

| CN207075549U (en) | A kind of cigarette igniting aspirator | |

| CN206949537U (en) | The simulation use device of electronic cigarette | |

| CN115918994A (en) | Cigarette smoke trapping device | |

| CN116807088B (en) | Airflow detection device and test method for airflow sensor testing | |

| CN211785438U (en) | Evaluation device for cigarette side-stream smoke |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20191015 Termination date:20200529 | |

| CF01 | Termination of patent right due to non-payment of annual fee |