CN103700903A - Battery heating and charging device of hybrid electric vehicle and control method of device - Google Patents

Battery heating and charging device of hybrid electric vehicle and control method of deviceDownload PDFInfo

- Publication number

- CN103700903A CN103700903ACN201310724680.7ACN201310724680ACN103700903ACN 103700903 ACN103700903 ACN 103700903ACN 201310724680 ACN201310724680 ACN 201310724680ACN 103700903 ACN103700903 ACN 103700903A

- Authority

- CN

- China

- Prior art keywords

- battery

- heat exchanger

- charge

- controller

- state

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/48—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte

- H01M10/486—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte for measuring temperature

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/48—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于新能源汽车领域,尤其是一种混合动力汽车电池加热和充电装置及其控制方法。The invention belongs to the field of new energy vehicles, in particular to a battery heating and charging device for a hybrid vehicle and a control method thereof.

背景技术Background technique

混合动力汽车一般由一个内燃机结合一个或多个电池和电机来形成混合动力驱动系统。内燃机消耗燃料,将燃料的化学能转换成动能和热能,动能用于驱动车辆行驶,热能往往以废气等形式耗散至周围环境。电池负责向电机供电,将电能转化为动能驱动车辆行驶。电池的性能会受到温度的影响,当电池的周围环境温度或者电池温度低于预定温度值,如-8℃,电池的性能会显著下降,从而影响混动动力系统的性能,如:能量回收、起/停功能。当车辆处于纯电动状态时,蓄电池温度以及电荷状态的降低还会对整车动力性造成影响。为了提升电池性能,一些插电式混合动力系统可以让车辆接入外接充电装置充电,同时利用电阻型加热器加热电池,然而在许多地方如车站、机场或者商业停车场,往往没有外接充电装置,而且目前绝大部分的混合动力系统不具备外界充电功能。此外,还有一些驾驶员会通过让发动机怠速空转来让车辆其他部件升温,但对于电池尤其是锂电池而言,其温度往往不会随着发动机的运行而增加。因此如果能够利用车辆本身的热能来确保电池温度和电荷状态始终处于理想状态,将对混合动力汽车整车性能的提高具有十分重要的意义。A hybrid electric vehicle generally consists of an internal combustion engine combined with one or more batteries and electric motors to form a hybrid drive system. The internal combustion engine consumes fuel and converts the chemical energy of the fuel into kinetic energy and heat energy. The kinetic energy is used to drive the vehicle, and the heat energy is often dissipated to the surrounding environment in the form of exhaust gas. The battery is responsible for supplying power to the motor, which converts electrical energy into kinetic energy to drive the vehicle. The performance of the battery will be affected by the temperature. When the ambient temperature of the battery or the temperature of the battery is lower than a predetermined temperature value, such as -8°C, the performance of the battery will drop significantly, thereby affecting the performance of the hybrid power system, such as: energy recovery, Start/stop function. When the vehicle is in a purely electric state, the decrease in battery temperature and state of charge will also affect the power of the vehicle. In order to improve battery performance, some plug-in hybrid systems allow the vehicle to be connected to an external charging device for charging, and at the same time use a resistance heater to heat the battery. However, in many places such as stations, airports or commercial parking lots, there are often no external charging devices. Moreover, the vast majority of hybrid power systems do not have an external charging function. In addition, some drivers will let other parts of the vehicle heat up by idling the engine, but for batteries, especially lithium batteries, their temperature often does not increase with the operation of the engine. Therefore, if the thermal energy of the vehicle itself can be used to ensure that the battery temperature and state of charge are always in an ideal state, it will be of great significance to improve the performance of the hybrid vehicle.

发明内容Contents of the invention

针对现有技术中存在不足,本发明提供了一种混合动力汽车电池加热和充电装置及其控制方法,利用车辆排放出的废气中的热能给电池加热和/或者充电,使电池温度和电荷状态一直处于理想状态,保证电池的高性能,提升混合动力汽车整车性能。Aiming at the deficiencies in the prior art, the present invention provides a hybrid electric vehicle battery heating and charging device and its control method, which uses the heat energy in the exhaust gas emitted by the vehicle to heat and/or charge the battery, so that the battery temperature and charge state It has been in an ideal state to ensure the high performance of the battery and improve the performance of the hybrid vehicle.

本发明是通过以下技术手段实现上述技术目的的。The present invention achieves the above-mentioned technical purpose through the following technical means.

混合动力汽车电池加热和充电装置,包括废气热量回收装置、热能传递回路、第一热交换器、第二热交换器、热电装置、电池盖板、温度传感器、电荷状态指示器、控制器,所述废气热量回收装置包括设置在废气管上并与排气管相通的分支气管、设置在分支气管上的废气热交换器、设置废气管与分支气管之间的第一分流阀,所述热能传递回路包括与废气交换器的出口相连的第一管路、与废气交换器的进口相连的第二管路,所述第一管路分别与第一热交换器、第二热交换器的入口相连,所述第二管路分别与第一热交换器、第二热交换器的出口相连,所述第一管路上设置有循环泵和第二分流阀,第二分流阀设置在第一管路的分支处;所述第一热交换器通过传热管与电池盖板连接,所述电池盖板包裹在电池外部,所述第二热交换器通过导热材料与热电装置连接,热电装置通过导线与电池连接;温度传感器、电荷状态指示器安装在电池上、并分别与控制器连接,所述控制器还与第一分流阀、第二分流阀连接。Battery heating and charging devices for hybrid electric vehicles, including exhaust heat recovery devices, heat energy transfer circuits, first heat exchangers, second heat exchangers, thermoelectric devices, battery covers, temperature sensors, charge status indicators, controllers, all The waste gas heat recovery device includes a branch air pipe arranged on the waste gas pipe and communicated with the exhaust pipe, an exhaust gas heat exchanger arranged on the branch air pipe, and a first diverter valve arranged between the waste gas pipe and the branch air pipe. The circuit includes a first pipeline connected to the outlet of the exhaust gas exchanger, a second pipeline connected to the inlet of the exhaust gas exchanger, and the first pipeline is connected to the inlets of the first heat exchanger and the second heat exchanger respectively , the second pipeline is connected to the outlet of the first heat exchanger and the second heat exchanger respectively, a circulation pump and a second diverter valve are arranged on the first pipeline, and the second diverter valve is arranged on the first pipeline at the branch; the first heat exchanger is connected to the battery cover through the heat transfer tube, and the battery cover is wrapped around the battery; the second heat exchanger is connected to the thermoelectric device through a heat-conducting material, and the thermoelectric device is connected through a wire It is connected with the battery; the temperature sensor and the charge state indicator are installed on the battery and connected with the controller respectively, and the controller is also connected with the first diverter valve and the second diverter valve.

优选地,所述电池盖板由导热材料制成。Preferably, the battery cover is made of thermally conductive material.

混合动力汽车电池加热和充电装置的控制方法,其特征在于,包括以下步骤:A control method for a battery heating and charging device of a hybrid electric vehicle is characterized in that it comprises the following steps:

(1)温度传感器和电荷状态指示器实时监测电池的温度和电荷状态,并将电池的实时温度和电荷状态信号传输到控制器;(1) The temperature sensor and charge state indicator monitor the temperature and charge state of the battery in real time, and transmit the real-time temperature and charge state signals of the battery to the controller;

(2)控制器根据电池的实时温度、电荷状态信号分别与电池的最高温度预设值、电荷状态预设值进行比较,当电池的实时温度低于最高温度预定值或者电荷状态低于电荷状态预定值时,控制器控制第一分流阀将废气分流至分支气管,废气热交换器将废气中的热量转移至传热流体中;否则,控制器控制第一分流阀将废气直接导入排气管排至车外;(2) The controller compares the battery's real-time temperature and charge state signals with the battery's maximum temperature preset value and charge state preset value respectively. When the real-time temperature of the battery is lower than the maximum temperature preset value or the charge state is lower than the charge state When the predetermined value is reached, the controller controls the first diverter valve to divert the exhaust gas to the branch air pipe, and the exhaust gas heat exchanger transfers the heat in the exhaust gas to the heat transfer fluid; otherwise, the controller controls the first diverter valve to direct the exhaust gas into the exhaust pipe out of the vehicle;

(3)控制器进一步判断电池的实时温度是否低于电池的最低温度预定值,若是,控制器控制第二分流阀仅导通第一管路与第一热交换器;若不是,则控制器进一步判断电池的实时温度是否介于电池的最低温度预定值与最高温度预定值之间,若不是,控制器控制第二分流阀仅导通第一管路与第二热交换器;若是,则控制器进一步判断电池的实时电池电荷状态是否大于电荷状态预设值,若是,控制器控制第二分流阀仅导通第一管路与第一热交换器;若不是,控制器控制第二分流阀同时导通第一管路与第一热交换器、第二热交换器。(3) The controller further judges whether the real-time temperature of the battery is lower than the minimum temperature preset value of the battery. If so, the controller controls the second diverter valve to only conduct the first pipeline and the first heat exchanger; if not, the controller Further judge whether the real-time temperature of the battery is between the minimum temperature preset value and the maximum temperature preset value of the battery, if not, the controller controls the second diverter valve to only conduct the first pipeline and the second heat exchanger; if so, then The controller further judges whether the real-time battery state of charge of the battery is greater than the preset value of the state of charge. If so, the controller controls the second diverter valve to only connect the first pipeline and the first heat exchanger; if not, the controller controls the second diverter valve The valve is connected to the first pipeline, the first heat exchanger and the second heat exchanger at the same time.

本发明在车辆排气系统上增设废气热量回收装置,将废气中的热能通过热能传递回路转移至第一热交换器和第二热交换器,第一热交换器可以利用热能给电池加热,第二热交换器可以和热电装置配合利用热能给电池充电,从而实现利用车辆排放出的废气中的热能给电池加热和/或充电。In the present invention, an exhaust gas heat recovery device is added to the exhaust system of the vehicle, and the heat energy in the exhaust gas is transferred to the first heat exchanger and the second heat exchanger through the heat energy transfer circuit. The first heat exchanger can use heat energy to heat the battery. The second heat exchanger can cooperate with the thermoelectric device to use heat energy to charge the battery, so that the heat energy in the exhaust gas emitted by the vehicle can be used to heat and/or charge the battery.

通过安装在电池上的温度传感器和电荷状态指示器实时监测电池的温度和电荷状态,控制器根据电池的温度和电荷状态、以及根据电池的具体参数确定的最低温度预定值、最高温度预定值和电荷状态预定值,通过对第一分流阀和第二分流阀的控制,来控制所述混合动力汽车电池加热和充电装置的运行,确定是否给电池加热或者充电。The temperature and charge state of the battery are monitored in real time through the temperature sensor and charge state indicator installed on the battery. The controller determines the minimum temperature preset value, maximum temperature preset value and The predetermined charge state value is used to control the operation of the battery heating and charging device of the hybrid electric vehicle through the control of the first diverter valve and the second diverter valve, and determine whether to heat or charge the battery.

只要电池温度低于最高温度预定值或者电荷状态低于电荷状态预定值时,废气热量回收装置就处于工作状态,回收废气中的热能,否则,废气热量回收装置不工作,废气直接导入排气管排至车外。当电池温度低于最低温度预定值时,此时无论电池电荷状态如何,所有热能全部用于给电池加热,因为温度低时,电池的性能会很差,即使充电,效率也很低;当电池温度处于最低温度预定值和最高温度预定值之间时,若电荷状态高于电荷状态预定值,则热能全部用于给电池加热,若电荷状态低于电荷状态预定值,则热能一部分用于给电池加热,另一部分用于给电池充电;当电池温度达到最高温度预定值时,此时停止给电池加热,热能全部用于给电池充电。As long as the battery temperature is lower than the maximum temperature preset value or the charge state is lower than the charge state preset value, the exhaust gas heat recovery device is in the working state to recover the heat energy in the exhaust gas, otherwise, the exhaust gas heat recovery device does not work, and the exhaust gas is directly directed into the exhaust pipe out of the car. When the battery temperature is lower than the minimum temperature preset value, all heat energy is used to heat the battery regardless of the battery charge state at this time, because when the temperature is low, the performance of the battery will be very poor, even if it is charged, the efficiency is very low; when the battery When the temperature is between the minimum temperature preset value and the maximum temperature preset value, if the state of charge is higher than the predetermined value of the state of charge, all the heat energy is used to heat the battery; if the state of charge is lower than the predetermined value of the state of charge, part of the heat energy is used for heating The battery is heated, and the other part is used to charge the battery; when the battery temperature reaches the maximum temperature preset value, the heating of the battery is stopped at this time, and all the heat energy is used to charge the battery.

本发明具有如下优点:The present invention has the following advantages:

(1)完全利用车辆排放出的废气中的热能给电池加热和/或充电,充分利用能源。(1) Fully use the heat energy in the exhaust gas emitted by the vehicle to heat and/or charge the battery, making full use of energy.

(2)确保电池温度和电荷状态始终处于理想状态,保证电池处于高性能状态,从而提升混合动力汽车整车性能。(2) Ensure that the battery temperature and charge state are always in an ideal state, and ensure that the battery is in a high-performance state, thereby improving the performance of the hybrid vehicle.

附图说明Description of drawings

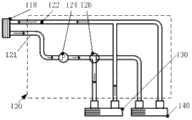

图1为本发明所述混合动力汽车电池加热和充电装置的结构图。Fig. 1 is a structural diagram of a battery heating and charging device for a hybrid electric vehicle according to the present invention.

图2为本发明所述混合动力汽车电池加热和充电控制方法的流程图。Fig. 2 is a flow chart of the method for controlling heating and charging of a battery of a hybrid electric vehicle according to the present invention.

图3为所述混合动力汽车电池加热和充电装置仅为电池加热的局部状态图。Fig. 3 is a partial state diagram of the hybrid vehicle battery heating and charging device only heating the battery.

图4为所述混合动力汽车电池加热和充电装置仅为电池充电的局部状态图。Fig. 4 is a partial state diagram of the hybrid vehicle battery heating and charging device only charging the battery.

图5为所述混合动力汽车电池加热和充电装置同时为电池加热、充电的局部状态图。Fig. 5 is a partial state diagram of the hybrid electric vehicle battery heating and charging device simultaneously heating and charging the battery.

附图标记说明如下:The reference signs are explained as follows:

110-废气热量回收装置,112-废气管,114-第一分流阀,116-排气管,117-分支气管,118-废气热交换器,120-热能传递回路,121-第一管路,122-第二管路,124-循环泵,126-第二分流阀,130-第一热交换器,140-第二热交换器,145-热电装置,150-导线,160-电池盖板,170-电池,180-温度传感器,190-电荷状态指示器,200-传热管,210-控制器。110-Exhaust gas heat recovery device, 112-Exhaust gas pipe, 114-First diverter valve, 116-Exhaust pipe, 117-Branch air pipe, 118-Exhaust gas heat exchanger, 120-Heat energy transfer circuit, 121-First pipeline, 122-second pipeline, 124-circulation pump, 126-second diverter valve, 130-first heat exchanger, 140-second heat exchanger, 145-thermoelectric device, 150-wire, 160-battery cover, 170-battery, 180-temperature sensor, 190-charge status indicator, 200-heat transfer tube, 210-controller.

具体实施方式Detailed ways

下面结合附图以及具体实施例对本发明作进一步的说明,但本发明的保护范围并不限于此。The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

如图1所示,本发明所述的混合动力汽车电池加热和充电装置,包括废气热量回收装置110、热能传递回路120、第一热交换器130、第二热交换器140、热电装置145、电池盖板160、温度传感器180、电荷状态指示器190、控制器210。所述废气热量回收装置110包括设置在废气管112上并与排气管116相通的分支气管117,设置在分支气管117上的废气热交换器118,设置废气管112与分支气管117之间的第一分流阀114。第一分流阀114用于控制废气的走向,当第一分流阀114导通废气管112与排气管116时,废气直接排出;当第一分流阀114导通废气管112与分支气管117时,废气流经废气热交换器118,废气热交换器118将废气中的热能转移至热能传递回路120中的传热流体中的传热流体吸收。用于加热电池170和/或为电池170充电。所述热能传递回路120中有传热流体,包括与废气交换器的出口相连的第一管路121,与废气交换器的进口相连的第二管路122。所述第一管路121分别与第一热交换器130、第二热交换器140的入口相连,所述第二管路122分别与第一热交换器130、第二热交换器140的出口相连,所述第一管路121上设置有循环泵124和第二分流阀126。第二分流阀126设置在第一管路121的分支处,用于控制传热流体为第一热交换器130和/或第二热交换器140供热。所述第一热交换器130通过传热管200与电池盖板160连接,所述电池盖板160为导热材料制成的,包裹在电池170外部,所述第二热交换器140通过导热材料与热电装置145连接,热电装置145通过导线150与电池170连接。当第二分流阀126仅导通第一管路121与第一热交换器130时,传热流体中的热能仅用于加热电池盖板160,为电池170加热;当第二分流阀126仅导通第一管路121与第二热交换器140时,第二热交换器140将流经的传热流体中的热能转移至热电装置145,热电装置145吸收热能利用温差产生电能,电能以电流的形式通过导线150输入电池170,对电池170充电;当第二分流阀126同时导通第一热交换器130和第二热交换器140时,传热流体中的热能同时用于电池170加热、充电。温度传感器180、电荷状态指示器190安装在电池170上,并且分别与控制器210连接。温度传感器180用于监测电池170的温度,电荷状态指示器190用于确定电池170的电荷状态。温度传感器180、电荷状态指示器190分别用于实时监测电池170的温度、电池170电荷状态,并将监测结果传递给控制器210。所述控制器210还与第一分流阀114、第二分流阀126连接。控制器210根据温度传感器180、电荷状态指示器190实时监测的电池170的温度、电池170的电荷状态,通过对第一分流阀114、第二分流阀126的控制实现对整个混合动力汽车电池加热和充电装置工作的控制。As shown in Figure 1, the battery heating and charging device for a hybrid electric vehicle according to the present invention includes an exhaust gas

具体的,本发明所述混合动力汽车电池加热和充电装置的控制方法为:Specifically, the control method of the hybrid electric vehicle battery heating and charging device of the present invention is as follows:

首先,温度传感器180和电荷状态指示器190实时监测电池170的温度和电荷状态,并将电池170的实时温度和电荷状态信号传输到控制器210。Firstly, the

然后,控制器210根据电池170的实时温度、电荷状态信号分别与电池170的最高温度预设值、电荷状态预设值进行比较,当电池170的实时温度低于最高温度预定值或者电荷状态低于电荷状态预定值时,控制器210控制第一分流阀114将废气分流至分支气管117,废气热交换器118将废气中的热量转移至传热流体中;否则,控制器210控制第一分流阀114将废气直接导入排气管116排至车外。Then, the

最后,控制器210进一步判断电池170的实时温度是否低于电池170的最低温度预定值,若是,控制器210控制第二分流阀126仅导通第一管路121与第一热交换器130,如图3所示,传热流体中的热能仅用于加热电池盖板160,为电池170加热,使电池170升温,温度保持正常;若不是,则控制器210进一步判断电池170的实时温度是否介于电池170的最低温度预定值与最高温度预定值之间。当电池170的实时温度不介于电池170的最低温度预定值与最高温度预定值之间时,控制器210控制第二分流阀126仅导通第一管路121与第二热交换器140,如图5所示,第二热交换器140将流经的传热流体中的热能转移至热电装置145,热电装置145吸收热能利用温差产生电能,电能以电流的形式通过导线150输入电池170,对电池170充电,使电荷状态保持正常;当电池170的实时温度介于电池170的最低温度预定值与最高温度预定值之间时,则控制器210进一步判断电池170的实时电池170电荷状态是否大于电荷状态预设值。若电池170的实时电池170电荷状态大于电荷状态预设值,控制器210控制第二分流阀126仅导通第一管路121与第一热交换器130,如图3所示,传热流体中的热能仅用于加热电池盖板160,为电池170加热;若电池170的实时电池电荷状态不大于电荷状态预设值,控制器210控制第二分流阀126同时导通第一管路121与第一热交换器130、第二热交换器140,如图5所示,传热流体中的热能同时用于电池170加热、充电,使电池170的温度和电荷状态最终达到正常水平。Finally, the

本发明利用混合动力车辆废气中的热能来确保电池170的温度和电荷状态始终处于理想状态,保证电池170的高性能,从而提升了混合动力汽车整车性能。The present invention utilizes the heat energy in the exhaust gas of the hybrid electric vehicle to ensure that the temperature and charge state of the

上述实施例为本发明的优选的实施方式,但发明并不限于上述实施方式,在不背离本发明的实质内容的情况下,本领域技术人员能够做出的任何显而易见的改进、替换或变型均属于本发明的保护范围。The above-mentioned embodiment is a preferred implementation of the present invention, but the invention is not limited to the above-mentioned implementation, and any obvious improvement, replacement or modification that can be made by those skilled in the art without departing from the essence of the present invention is acceptable. Belong to the protection scope of the present invention.

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310724680.7ACN103700903B (en) | 2013-12-24 | 2013-12-24 | Hybrid power automobile battery heating and charging device and control method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310724680.7ACN103700903B (en) | 2013-12-24 | 2013-12-24 | Hybrid power automobile battery heating and charging device and control method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN103700903Atrue CN103700903A (en) | 2014-04-02 |

| CN103700903B CN103700903B (en) | 2016-04-06 |

Family

ID=50362357

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310724680.7AExpired - Fee RelatedCN103700903B (en) | 2013-12-24 | 2013-12-24 | Hybrid power automobile battery heating and charging device and control method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103700903B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107425231A (en)* | 2016-04-27 | 2017-12-01 | 福特全球技术公司 | Traction battery thermal management algorithm and system |

| CN110137628A (en)* | 2019-05-06 | 2019-08-16 | 奇瑞商用车(安徽)有限公司 | A kind of power battery self-heating system and its heating means |

| CN111725587A (en)* | 2019-03-20 | 2020-09-29 | 上海汽车集团股份有限公司 | Temperature regulating system of power battery and control method thereof |

| CN115295925A (en)* | 2022-09-30 | 2022-11-04 | 小米汽车科技有限公司 | Method and device for heating battery, battery assembly, storage medium and vehicle |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101537787A (en)* | 2009-04-17 | 2009-09-23 | 北京工业大学 | Battery heating and comprehensive utilization device of hybrid power electric automobile |

| CN203674344U (en)* | 2013-12-24 | 2014-06-25 | 江苏大学 | Hybrid power vehicle battery heating and charging device |

- 2013

- 2013-12-24CNCN201310724680.7Apatent/CN103700903B/ennot_activeExpired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101537787A (en)* | 2009-04-17 | 2009-09-23 | 北京工业大学 | Battery heating and comprehensive utilization device of hybrid power electric automobile |

| CN203674344U (en)* | 2013-12-24 | 2014-06-25 | 江苏大学 | Hybrid power vehicle battery heating and charging device |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107425231A (en)* | 2016-04-27 | 2017-12-01 | 福特全球技术公司 | Traction battery thermal management algorithm and system |

| CN107425231B (en)* | 2016-04-27 | 2022-08-16 | 福特全球技术公司 | Traction battery thermal management method and system |

| CN111725587A (en)* | 2019-03-20 | 2020-09-29 | 上海汽车集团股份有限公司 | Temperature regulating system of power battery and control method thereof |

| CN111725587B (en)* | 2019-03-20 | 2021-05-18 | 上海汽车集团股份有限公司 | Temperature adjusting system of power battery and control method thereof |

| CN110137628A (en)* | 2019-05-06 | 2019-08-16 | 奇瑞商用车(安徽)有限公司 | A kind of power battery self-heating system and its heating means |

| CN110137628B (en)* | 2019-05-06 | 2021-11-23 | 奇瑞商用车(安徽)有限公司 | Self-heating system and heating method for power battery |

| CN115295925A (en)* | 2022-09-30 | 2022-11-04 | 小米汽车科技有限公司 | Method and device for heating battery, battery assembly, storage medium and vehicle |

| CN115295925B (en)* | 2022-09-30 | 2023-02-21 | 小米汽车科技有限公司 | Method and device for heating battery, battery assembly, storage medium and vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103700903B (en) | 2016-04-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202076386U (en) | Battery temperature management system and automobile | |

| CN106828022B (en) | Pure electric vehicles thermal management system and air conditioning system | |

| CN103612570B (en) | A kind of Pure electric vehicle thermal management control system and control method thereof | |

| CN102529642B (en) | Control method of air-conditioner heating system for extended range electric vehicle | |

| CN101962000B (en) | Heating system of power battery of pure electric automobile and control method thereof | |

| WO2018113750A1 (en) | Fuel cell system and fuel cell vehicle | |

| CN202839901U (en) | Power battery thermal management system | |

| CN106541814B (en) | 4 wheel driven wheel hub drives pure electric automobile power assembly temperature integrated regulation and control system | |

| CN102774251A (en) | Air-conditioning control device for electric vehicle | |

| CN105932366B (en) | Control method, temperature control gateway and the temperature control system of the temperature of battery system | |

| CN103972607A (en) | Electric vehicle thermal management system | |

| KR20110054140A (en) | Air-conditioning device and method using battery charging control of electric vehicle | |

| JP2013119259A (en) | On-board battery temperature regulator | |

| US9261093B2 (en) | Heater and pump performance diagnostic for a hybrid battery thermal system | |

| CN206134866U (en) | A BMS safety management system device for medium and low-speed new energy electric vehicles | |

| CN106848496A (en) | A kind of fuel cell tramcar residual neat recovering system based on thermo-electric generation | |

| CN202138214U (en) | Cooling circulation system of electrocar | |

| CN103700903B (en) | Hybrid power automobile battery heating and charging device and control method thereof | |

| CN106099256A (en) | A kind of electric motor car energy storage type heat management system | |

| CN203674344U (en) | Hybrid power vehicle battery heating and charging device | |

| CN117360285A (en) | Charging method | |

| CN117227534A (en) | Electric vehicle | |

| CN203995645U (en) | A kind of multi-functional tail gas heat energy recovering device of hybrid vehicle | |

| CN101791970A (en) | System and method for cooling vehicle-mounted charger | |

| CN205185831U (en) | Electric automobile and power battery heating system thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20160406 Termination date:20161224 |