CN103489945A - Current-collecting energy-gathering netlike bypass solar cell - Google Patents

Current-collecting energy-gathering netlike bypass solar cellDownload PDFInfo

- Publication number

- CN103489945A CN103489945ACN201210194446.3ACN201210194446ACN103489945ACN 103489945 ACN103489945 ACN 103489945ACN 201210194446 ACN201210194446 ACN 201210194446ACN 103489945 ACN103489945 ACN 103489945A

- Authority

- CN

- China

- Prior art keywords

- grid lines

- solar cell

- main grid

- distributed

- lines

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000002313adhesive filmSubstances0.000claimsabstractdescription8

- 239000002184metalSubstances0.000description6

- 238000000034methodMethods0.000description3

- 238000003466weldingMethods0.000description3

- 238000010586diagramMethods0.000description2

- 230000000694effectsEffects0.000description2

- 238000004806packaging method and processMethods0.000description2

- 230000002411adverseEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000005540biological transmissionEffects0.000description1

- 230000007547defectEffects0.000description1

- 238000009792diffusion processMethods0.000description1

- 238000003475laminationMethods0.000description1

- 230000007774longtermEffects0.000description1

- 230000007246mechanismEffects0.000description1

- 238000001465metallisationMethods0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 239000004065semiconductorSubstances0.000description1

Images

Classifications

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

- H10F77/20—Electrodes

- H10F77/206—Electrodes for devices having potential barriers

- H10F77/211—Electrodes for devices having potential barriers for photovoltaic cells

- H10F77/215—Geometries of grid contacts

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02S—GENERATION OF ELECTRIC POWER BY CONVERSION OF INFRARED RADIATION, VISIBLE LIGHT OR ULTRAVIOLET LIGHT, e.g. USING PHOTOVOLTAIC [PV] MODULES

- H02S40/00—Components or accessories in combination with PV modules, not provided for in groups H02S10/00 - H02S30/00

- H02S40/30—Electrical components

- H02S40/34—Electrical components comprising specially adapted electrical connection means to be structurally associated with the PV module, e.g. junction boxes

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

- H10F77/93—Interconnections

- H10F77/933—Interconnections for devices having potential barriers

- H10F77/935—Interconnections for devices having potential barriers for photovoltaic devices or modules

- H10F77/937—Busbar structures for modules

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Photovoltaic Devices (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及光伏电池的领域,尤其是一种汇流聚能型网状旁路太阳能电池。The invention relates to the field of photovoltaic cells, in particular to a converging energy-gathering type mesh bypass solar cell.

背景技术Background technique

电池设计的一个重要方面是上电机金属栅线的设计,当单体电池的尺寸增加时,这方面就变得愈加重要了,与上电极有关的功率损失机制共有以下几种,电池顶部扩散层的横向电阻所引起的损耗;各金属线的串联电阻以及这些金属线与半导体之间的接触电阻引起的损耗;电池被这些金属栅线遮蔽所引起的损失。An important aspect of battery design is the design of the metal grid lines of the upper motor. This aspect becomes more important as the size of the single battery increases. There are several power loss mechanisms related to the upper electrode. The diffusion layer on the top of the battery The loss caused by the lateral resistance of the metal line; the loss caused by the series resistance of each metal line and the contact resistance between these metal lines and the semiconductor; the loss caused by the battery being shaded by these metal grid lines.

目前传统光伏电池电流汇流基本都是通过细栅线进行汇流到主栅线,然后通过焊接互联条,按照一定工艺路径进行焊接,再进行封装,存在高温焊接电流损失,要收集太阳能电池产生的电流,金属顶电极(或称顶部接触)是必须的,传统主栅线(在电池正面上)和外部导线直接相连,而副栅线是更细小的金属化区域,用来收集电流传输给主栅线,顶电极设计目标是通过优化电流收集来减少由于内部电阻和电池遮蔽而产生的损失,目前传统电池这样的遮蔽率一般在15%左右。电池中产生的电流一般从电池的内部垂直地流向电池的表面,然后横向通过顶部掺杂层,最后在顶层表面的接触被收集;如果有隐裂、阴影或其它遮盖物、等质量及应用缺陷,长期可能会出现热斑现象,严重时会导致整个组件实效,对整个光伏阵列的安全和效率都会存在不利影响。At present, the current confluence of traditional photovoltaic cells is basically converging to the main grid line through thin grid lines, and then through welding interconnection strips, welding according to a certain process path, and then packaging, there is a loss of high-temperature welding current, and the current generated by solar cells must be collected , the metal top electrode (or top contact) is necessary, the traditional main grid line (on the front of the battery) is directly connected to the external wire, and the sub-grid line is a finer metallization area used to collect current and transmit it to the main grid Line, the top electrode design goal is to reduce the loss due to internal resistance and battery shading by optimizing current collection. At present, the shading rate of traditional batteries is generally around 15%. The current generated in the battery generally flows vertically from the inside of the battery to the surface of the battery, and then passes through the top doped layer laterally, and finally the contact on the top layer surface is collected; if there are cracks, shadows or other coverings, and other quality and application defects , hot spots may appear in the long term, and in severe cases, it will lead to the failure of the entire module, which will have an adverse effect on the safety and efficiency of the entire photovoltaic array.

发明内容Contents of the invention

本发明要解决的技术问题是:为了克服上述中存在的问题,提供了一种汇流聚能型网状旁路太阳能电池,其设计结构合理、封装方便并且电池使用率高。The technical problem to be solved by the present invention is: in order to overcome the above-mentioned problems, a confluence and energy-gathering mesh bypass solar cell is provided, which has a reasonable design structure, convenient packaging and high battery utilization rate.

本发明解决其技术问题所采用的技术方案是:一种汇流聚能型网状旁路太阳能电池,包括太阳能电池片和粘贴在太阳能电池片上的EVA胶膜层,所述的太阳能电池片表面上分布有复数条相互交叉的副栅线,副栅线呈网状结构,所述的EVA胶膜层上分布有至少两条相互平行的主栅线,主栅线与副栅线相连接,所述的主栅线与副栅线之间夹角为40~50°。The technical solution adopted by the present invention to solve the technical problems is: a kind of confluence and energy-gathering reticular bypass solar cell, comprising a solar cell and an EVA adhesive film layer pasted on the solar cell, the surface of the solar cell There are a plurality of auxiliary grid lines intersecting with each other, and the auxiliary grid lines are in a network structure. At least two main grid lines parallel to each other are distributed on the EVA film layer, and the main grid lines are connected with the auxiliary grid lines. The above-mentioned angle between the main grid line and the auxiliary grid line is 40-50°.

为了能够使副栅线与多条主栅线相连通,能够在副栅线某处存在断线或印刷不全时,能够通过太阳能电池表面上临近的与主栅线连通的副栅线进行完成收集和传输,提高电池效率,所述的EVA胶膜层上分布有三条相互平行的主栅线。In order to connect the auxiliary grid lines with multiple main grid lines, when there is a disconnection or incomplete printing somewhere in the auxiliary grid lines, the collection can be completed through the adjacent auxiliary grid lines connected to the main grid lines on the surface of the solar cell. and transmission to improve battery efficiency, three busbar lines parallel to each other are distributed on the EVA film layer.

所述的主栅线与副栅线之间夹角为45°。The angle between the main grid line and the auxiliary grid line is 45°.

本发明的有益效果是:所述的汇流聚能型网状旁路太阳能电池,在太阳能电池片表面分布相互交叉的副栅线,能够使其具有多条路径到达主栅线,采用EVA胶膜层,在胶膜层内封装多条平行的主栅线,使其与电池片表面进行封装,使主栅线与副栅线紧密结合,有效地避免了因隐裂或遮荫而影响电流汇集。The beneficial effects of the present invention are: the converging and energy-gathering reticular bypass solar cell is distributed on the surface of the solar cell with intersecting sub-grid lines, enabling it to have multiple paths to reach the main grid line, using EVA film Layer, encapsulate multiple parallel main grid lines in the adhesive film layer, so that they are packaged with the surface of the cell, so that the main grid lines and auxiliary grid lines are closely combined, effectively avoiding the influence of current collection due to hidden cracks or shading .

附图说明Description of drawings

下面结合附图和实施例对本发明进一步说明。The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

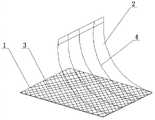

图1是本发明所述的汇流聚能型网状旁路太阳能电池的整体结构示意图。Fig. 1 is a schematic diagram of the overall structure of the confluence and energy concentrating mesh bypass solar cell according to the present invention.

附图中标记分述如下:1、太阳能电池片,2、EVA胶膜层,3、副栅线,4、主栅线。The symbols in the attached drawings are described as follows: 1. solar cells, 2. EVA film layer, 3. auxiliary grid lines, 4. main grid lines.

具体实施方式Detailed ways

现在结合附图对本发明作进一步详细的说明。这些附图均为简化的示意图,仅以示意方式说明本发明的基本结构,因此其仅显示与本发明有关的构成。The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

如图1所示的汇流聚能型网状旁路太阳能电池,包括太阳能电池片1,在太阳能电池片1上粘贴EVA胶膜层2,太阳能电池片1的表面上分布有复数条相互交叉的呈网状结构的副栅线3,EVA胶膜层2上分布有三条相互平行的主栅线4,主栅线4与副栅线3相连接,主栅线4与副栅线3之间夹角为45°。As shown in Figure 1, the converging energy-gathering mesh bypass solar cell includes a

本发明所述的汇流聚能型网状旁路太阳能电池,在太阳能电池片1表面上通过140°左右的压层工艺与材质为EVA的胶膜层2融合,通过压力的作用,使主栅线4与副栅线3紧密结合。The converging energy-gathering type mesh bypass solar cell of the present invention is fused with the

以上述依据本发明的理想实施例为启示,通过上述的说明内容,相关工作人员完全可以在不偏离本项发明技术思想的范围内,进行多样的变更以及修改。本项发明的技术性范围并不局限于说明书上的内容,必须要根据权利要求范围来确定其技术性范围。Inspired by the above-mentioned ideal embodiment according to the present invention, through the above-mentioned description content, relevant workers can make various changes and modifications within the scope of not departing from the technical idea of the present invention. The technical scope of the present invention is not limited to the content in the specification, but must be determined according to the scope of the claims.

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210194446.3ACN103489945A (en) | 2012-06-13 | 2012-06-13 | Current-collecting energy-gathering netlike bypass solar cell |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210194446.3ACN103489945A (en) | 2012-06-13 | 2012-06-13 | Current-collecting energy-gathering netlike bypass solar cell |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103489945Atrue CN103489945A (en) | 2014-01-01 |

Family

ID=49830039

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210194446.3APendingCN103489945A (en) | 2012-06-13 | 2012-06-13 | Current-collecting energy-gathering netlike bypass solar cell |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103489945A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016065934A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065937A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065944A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065953A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065943A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| CN106992220A (en)* | 2017-05-16 | 2017-07-28 | 北京汉能薄膜发电技术有限公司 | A kind of plain conductor network layer structure with electronic component |

| CN108023537A (en)* | 2017-12-27 | 2018-05-11 | 苏州携创新能源科技有限公司 | A kind of color steel tile roof photovoltaic module structure |

| CN110416326A (en)* | 2018-04-28 | 2019-11-05 | 北京铂阳顶荣光伏科技有限公司 | A kind of manufacturing method of copper indium gallium selenide solar cell assembly |

| CN113097327A (en)* | 2021-03-26 | 2021-07-09 | 福斯特(嘉兴)新材料有限公司 | Grid line glue film and solar cell module |

| CN113257937A (en)* | 2021-06-10 | 2021-08-13 | 成都晔凡科技有限公司 | Method for manufacturing a laminated assembly and laminated assembly |

- 2012

- 2012-06-13CNCN201210194446.3Apatent/CN103489945A/enactivePending

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016065934A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065937A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065944A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065953A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| WO2016065943A1 (en)* | 2014-10-31 | 2016-05-06 | Byd Company Limited | Solar cell module and manufacturing method thereof |

| CN106992220A (en)* | 2017-05-16 | 2017-07-28 | 北京汉能薄膜发电技术有限公司 | A kind of plain conductor network layer structure with electronic component |

| WO2018210284A1 (en)* | 2017-05-16 | 2018-11-22 | 北京铂阳顶荣光伏科技有限公司 | Photovoltaic device, metal wire network layered structure and manufacturing method therefor |

| CN108023537A (en)* | 2017-12-27 | 2018-05-11 | 苏州携创新能源科技有限公司 | A kind of color steel tile roof photovoltaic module structure |

| CN108023537B (en)* | 2017-12-27 | 2024-07-16 | 江苏携创新能源科技有限公司 | A photovoltaic module structure on a colored steel tile roof |

| CN110416326A (en)* | 2018-04-28 | 2019-11-05 | 北京铂阳顶荣光伏科技有限公司 | A kind of manufacturing method of copper indium gallium selenide solar cell assembly |

| CN113097327A (en)* | 2021-03-26 | 2021-07-09 | 福斯特(嘉兴)新材料有限公司 | Grid line glue film and solar cell module |

| CN113257937A (en)* | 2021-06-10 | 2021-08-13 | 成都晔凡科技有限公司 | Method for manufacturing a laminated assembly and laminated assembly |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103489945A (en) | Current-collecting energy-gathering netlike bypass solar cell | |

| CN104037265B (en) | A kind of method of HIT solar cell and electrode preparation and series connection | |

| CN201838602U (en) | Crystalline silicon solar battery with segmented grid lines | |

| CN108735831A (en) | Solar cell, solar cell string and imbrication photovoltaic module | |

| CN102709337A (en) | Back-contact solar cell, solar module using back-contact solar cell and production method of solar module | |

| CN104576781A (en) | Solar cell | |

| CN204011446U (en) | A kind of HIT solar cell | |

| CN205609550U (en) | Double -sided solar battery component | |

| CN202678326U (en) | Composite type netted bypass photovoltaic cell | |

| CN104600158A (en) | Interconnection method of crystalline silicon battery assembly | |

| WO2024174605A1 (en) | Solar photovoltaic cell | |

| CN108711582A (en) | A kind of solar cell string structure | |

| CN208444844U (en) | Solar battery sheet and solar battery for imbrication component | |

| CN102148275A (en) | Solar battery component | |

| CN204464295U (en) | a solar cell | |

| CN103489931A (en) | Combined type netted bypass photovoltaic cell | |

| CN108987510A (en) | The direct-connected solar cell module of latticed single side and preparation method | |

| CN203617305U (en) | Grid line structure of solar cell | |

| CN204991722U (en) | Solar cell | |

| CN110459618A (en) | Busbarless solar cells | |

| CN102130194A (en) | A solar cell with high transmission rate and low shading area | |

| CN103943698A (en) | Photovoltaic module with main grid lines arranged side by side | |

| CN106910783A (en) | The back electrode and battery, component, system of p-type PERC double-side solar cells | |

| CN202172072U (en) | Electrode structure at right side of solar cell | |

| CN206727078U (en) | Efficient dereliction grid cell piece solar components |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20140101 |