CN103323381A - Method for evaluating attenuation degree of porous asphalt mixture void - Google Patents

Method for evaluating attenuation degree of porous asphalt mixture voidDownload PDFInfo

- Publication number

- CN103323381A CN103323381ACN2013102314066ACN201310231406ACN103323381ACN 103323381 ACN103323381 ACN 103323381ACN 2013102314066 ACN2013102314066 ACN 2013102314066ACN 201310231406 ACN201310231406 ACN 201310231406ACN 103323381 ACN103323381 ACN 103323381A

- Authority

- CN

- China

- Prior art keywords

- test

- drainage

- asphalt mixture

- test specimen

- wheel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000010426asphaltSubstances0.000titleclaimsabstractdescription92

- 239000000203mixtureSubstances0.000titleclaimsabstractdescription60

- 239000011800void materialSubstances0.000titleclaimsabstractdescription27

- 238000000034methodMethods0.000titleabstractdescription14

- 238000012360testing methodMethods0.000claimsabstractdescription96

- 238000005096rolling processMethods0.000claimsabstractdescription11

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription65

- 238000011156evaluationMethods0.000claimsdescription9

- 239000011148porous materialSubstances0.000claimsdescription6

- 239000008393encapsulating agentSubstances0.000claims3

- 238000002513implantationMethods0.000claims1

- 230000001105regulatory effectEffects0.000claims1

- 238000009490roller compactionMethods0.000claims1

- 238000005303weighingMethods0.000claims1

- 239000003566sealing materialSubstances0.000abstractdescription11

- 230000009471actionEffects0.000abstractdescription6

- 230000007423decreaseEffects0.000description6

- 238000006073displacement reactionMethods0.000description6

- 230000009467reductionEffects0.000description6

- 238000013461designMethods0.000description5

- 239000010410layerSubstances0.000description5

- 239000002344surface layerSubstances0.000description5

- 229910000831SteelInorganic materials0.000description4

- 238000004140cleaningMethods0.000description4

- 238000010586diagramMethods0.000description4

- 238000005516engineering processMethods0.000description4

- 230000007246mechanismEffects0.000description4

- 239000010959steelSubstances0.000description4

- 239000000428dustSubstances0.000description3

- 230000008569processEffects0.000description3

- 239000005060rubberSubstances0.000description3

- 230000008859changeEffects0.000description2

- 239000011521glassSubstances0.000description2

- 238000012423maintenanceMethods0.000description2

- 238000005259measurementMethods0.000description2

- 239000003595mistSubstances0.000description2

- 239000012188paraffin waxSubstances0.000description2

- 239000000843powderSubstances0.000description2

- 238000011160researchMethods0.000description2

- 238000009825accumulationMethods0.000description1

- 238000004458analytical methodMethods0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000015572biosynthetic processEffects0.000description1

- 230000000903blocking effectEffects0.000description1

- 238000004364calculation methodMethods0.000description1

- 239000003153chemical reaction reagentSubstances0.000description1

- 238000007906compressionMethods0.000description1

- 230000006835compressionEffects0.000description1

- 230000003247decreasing effectEffects0.000description1

- 238000011161developmentMethods0.000description1

- 230000000694effectsEffects0.000description1

- 238000009472formulationMethods0.000description1

- 230000004313glareEffects0.000description1

- 239000003550markerSubstances0.000description1

- 239000000463materialSubstances0.000description1

- 239000004570mortar (masonry)Substances0.000description1

- 239000002245particleSubstances0.000description1

- 238000011084recoveryMethods0.000description1

- 238000012827research and developmentMethods0.000description1

- 238000009666routine testMethods0.000description1

- 239000002689soilSubstances0.000description1

- 238000013519translationMethods0.000description1

Images

Landscapes

- Road Paving Structures (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于道路工程技术领域,具体涉及在车辆荷载反复作用下,排水性沥青混合料空隙衰减程度的评价方法。The invention belongs to the technical field of road engineering, and in particular relates to an evaluation method for void attenuation degree of drainage asphalt mixture under repeated action of vehicle load.

背景技术Background technique

在我国已经建成的沥青路面中,面层大多采用密级配沥青混合料和骨架密实型混合料这些传统的形式。无论是空隙率4%左右的密级配沥青混合料,还是空隙率8%左右的骨架密实型混合料,都基本不透水,在雨天行车时容易产生较大的水雾和水漂,严重影响车辆行驶的安全性。另一方面,由于传统沥青路面面层的空隙率较小,车辆行驶时轮胎与路表之间容易产生较大的噪声,给道路周边居民造成严重的噪声污染。可以说,传统的沥青面层主要以保障车辆的正常通行为原则,对于车辆行驶时噪音的降低与控制、雨天行车时抗滑性能的要求都未能充分考虑。因此,传统的沥青路面型式已很难满足人们对道路安全性和舒适性日益增长的要求。In the asphalt pavement that has been built in our country, the surface layer mostly adopts the traditional forms of densely graded asphalt mixture and skeleton dense mixture. Whether it is a densely graded asphalt mixture with a porosity of about 4% or a skeleton-dense mixture with a porosity of about 8%, they are basically impervious to water, and it is easy to generate large water mist and water drift when driving in rainy days, seriously affecting vehicles. driving safety. On the other hand, due to the small porosity of the traditional asphalt pavement surface layer, large noise is likely to be generated between the tires and the road surface when the vehicle is running, causing serious noise pollution to the residents around the road. It can be said that the traditional asphalt pavement is mainly based on the principle of ensuring the normal passage of vehicles, and the requirements for noise reduction and control during driving and anti-skid performance during driving in rainy days have not been fully considered. Therefore, the traditional asphalt pavement type has been difficult to meet people's increasing requirements for road safety and comfort.

为了增加车辆行驶的安全性,提高司乘人员和道路周边居民舒适感,20世纪后期道路科技工作者研发了排水性沥青路面。排水性沥青路面采用空隙率较大(20%左右)的沥青混合料铺设路面排水层,雨水通过排水层中混合料的内部连通空隙排出路面结构。其优点主要表现在:(1)优异的排水性能使道路表面无法形成水膜,减少了行车水雾和水飘,可大大提高雨天行车的安全性;(2)由于路表大量连通空隙的存在,使轮胎与路表面的接触噪音有更大的消散空间,从而大大降低车辆行驶噪音;(3)道路表面粗糙的纹理使白天照在路面上的太阳光和夜间的灯光产生漫反射,减少眩光,提高能见度,改善行驶视线,降低车辆发生交通事故的可能性。In order to increase the safety of vehicles and improve the comfort of drivers, passengers and residents around the road, road scientists and technicians developed drainage asphalt pavement in the late 20th century. Drainage asphalt pavement uses asphalt mixture with a large void ratio (about 20%) to pave the pavement drainage layer, and the rainwater is discharged from the pavement structure through the internal interconnected gaps of the mixture in the drainage layer. Its advantages are mainly manifested in: (1) Excellent drainage performance prevents the formation of water film on the road surface, reduces driving water mist and water drift, and can greatly improve the safety of driving in rainy days; (2) Due to the existence of a large number of connected gaps on the road surface , so that the contact noise between the tire and the road surface has more space to dissipate, thereby greatly reducing the vehicle driving noise; (3) The rough texture of the road surface makes the sunlight shining on the road during the day and the light at night produce diffuse reflection, reducing glare , Improve visibility, improve driving sight, and reduce the possibility of vehicle accidents.

鉴于排水性沥青路面具有优异的排水、降噪和防止眩光功能,目前这种路面形式已经在很多国家和地区得到了初步应用。但是,在排水沥青路面应用过程中,人们逐渐发现随着使用时间的延长,一些排水性沥青路面的排水、降噪、抗滑等性能往往出现不同程度的衰减,逐步丧失了其相比于传统路面所存在的优势。对于排水性沥青路面排水、降噪等功能的衰减,世界各国的道路科技工作者普遍认为是由两个原因引起的:第一,车辆荷载重复作用下排水性沥青混合料内部空隙发生衰变;第二,灰尘、轮胎橡胶粉等堵塞混合料空隙。近年来,由灰尘和轮胎橡胶粉等堵塞空隙造成空隙率下降的问题,已经引起道路科技工作者的重视,相关的维护设备已经陆续被研发,并取得了良好的应用效果。但是,由于车辆荷载反复作用导致的孔结构衰变问题还没有得到系统研究,尤其是采用什么方法评价混合料内部空隙的衰减尚没有获得解决。In view of the excellent drainage, noise reduction and anti-glare functions of drainage asphalt pavement, this pavement form has been initially applied in many countries and regions. However, in the application process of drainage asphalt pavement, people gradually found that with the prolongation of use time, some drainage asphalt pavement's drainage, noise reduction, anti-skid and other performances tend to attenuate to varying degrees, and gradually lose its advantages compared with traditional Advantages of the road surface. For the attenuation of drainage and noise reduction functions of drainage asphalt pavement, road science and technology workers in various countries generally believe that it is caused by two reasons: first, the internal voids of drainage asphalt mixture decay under repeated vehicle loads; second, Second, dust, tire rubber powder, etc. block the gap of the mixture. In recent years, the problem of decreased porosity caused by clogging the voids with dust and tire rubber powder has attracted the attention of road science and technology workers. Related maintenance equipment has been developed one after another, and good application results have been achieved. However, the problem of the decay of the pore structure due to the repeated action of the vehicle load has not been systematically studied, especially what method to use to evaluate the decay of the internal voids of the mixture has not been resolved.

因此,设计一种排水性沥青混合料空隙衰减程度的评价方法,不仅对完善排水性沥青混合料配合比设计方法,尤其是级配设计方法具有较大的理论价值,对于延长排水性沥青路面使用寿命、降低维护成本亦具有重大的实际意义。Therefore, the design of an evaluation method for void attenuation of drainage asphalt mixture not only has great theoretical value for perfecting the design method of drainage asphalt mixture ratio, especially the gradation design method, but also has great theoretical value for extending the use of drainage asphalt pavement. Longer life and lower maintenance cost are also of great practical significance.

发明内容Contents of the invention

本发明的目的在于针对目前排水性沥青路面排水、降噪功能过快衰减的现状,提供一种测试空隙衰变程度的方法,用于排水性沥青混合料级配设计和路用性能评价过程中,起到延缓排水性沥青路面空隙衰变的作用。The purpose of the present invention is to provide a method for testing the degree of void decay in view of the current drainage asphalt pavement drainage and noise-reducing function attenuation too fast, which can be used in the process of drainage asphalt mixture gradation design and road performance evaluation. Play a role in delaying the decay of drainage asphalt pavement voids.

本发明采用的技术方案如下:The technical scheme that the present invention adopts is as follows:

排水性沥青混合料空隙衰减程度的评价方法,其特征在于包括如下步骤:The method for evaluating void attenuation degree of drainage asphalt mixture is characterized in that it includes the following steps:

1)按照待测定的集料级配和沥青用量,在实验室内碾压成型排水性沥青混合料的板式试件,在板式试件的四个侧面中,选择三个侧面,并和试件底面一起涂抹密封材料,封住三侧面和底面表面的空隙;1) According to the aggregate gradation and asphalt content to be determined, the plate-type specimen of the drainage asphalt mixture is rolled and formed in the laboratory. Among the four sides of the plate-type specimen, three sides are selected and combined with the specimen. Apply sealing material to the bottom surface together to seal the gaps on the three sides and the bottom surface;

2)以未涂抹密封材料的试件侧面作为排水侧面,把板式试件放入排水系数测试仪中,调节测试的板式试件坡度为α;关闭水箱阀门,在水箱内注入质量为a0的水,迅速打开水箱阀门,并按动计时器,当水箱内的水全部排出、且侧面排水量筒内水位不变时,记为t1秒;称得侧面排水量桶中水的质量a1;以初始排水系数表征沥青混合料的初始排水能力;2) Use the side of the test piece that has not been coated with sealing material as the drainage side, put the plate test piece into the drainage coefficient tester, adjust the slope of the test plate test piece to α; close the valve of the water tank, and inject water with a quality of a0 into the water tank , quickly open the valve of the water tank, and press the timer. When all the water in the water tank is discharged and the water level in the side displacement cylinder remains unchanged, record it as t1 seconds; weigh the mass a1 of the water in the side displacement cylinder; use the initial drainage coefficient To characterize the initial drainage capacity of asphalt mixture;

3)把板式试件放入车辙试验机内进行车辙试验,试验时,轮迹带必须与步骤2)中的排水侧面平行,试验结束后,取出板式试件,在试件上表面画出车辙试验的轮迹带,以及与轮迹带垂直相交、通过轮迹带两个端点的两条直线,沿这两条直线,把板式试件切割为三部分,取表面含有轮迹带的部分,并采用密封材料涂抹切割后形成的两个侧面;3) Put the plate-type test piece into the rutting test machine for rutting test. During the test, the wheel track belt must be parallel to the drainage side in step 2). After the test, take out the plate-type test piece and draw the rut on the upper surface of the test piece The test track strip, and two straight lines perpendicular to the track strip and passing through the two ends of the track strip, along these two straight lines, cut the plate specimen into three parts, and take the part containing the track strip on the surface, And coat the two sides formed after cutting with sealing material;

4)把含有轮迹带的试件部分放入排水系数测试仪中,试件的坡度应与步骤2)初始排水系数测试时试件采用的坡度相同,为α,按照步骤2)测试其排水系数P2,以空隙衰减指数表征排水性沥青混合料孔结构的衰变程度,n越大说明孔结构衰变的程度越严重。4) Put the part of the test piece containing the wheel track into the drainage coefficient tester. The slope of the test piece should be the same as that used in step 2) in the initial drainage coefficient test, which is α. Follow step 2) to test its drainage Coefficient P2, to exponent of void attenuation It represents the degree of decay of the pore structure of the drainage asphalt mixture, and the larger n is, the more serious the degree of pore structure decay is.

所述的排水性沥青混合料空隙衰减程度的评价方法,其特征在于步骤3)中所述的车辙试验较优条件为:试验温度为60℃,轮压为0.7MPa,轮碾速度为42次/min,试验时间1h。The evaluation method for void attenuation degree of drainage asphalt mixture is characterized in that the optimal conditions of the rutting test described in step 3) are: the test temperature is 60°C, the wheel pressure is 0.7MPa, and the wheel rolling speed is 42 times /min, test time 1h.

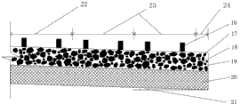

本方案采用的仪器为排水系数测试仪,由试验平台升降系统、水量收集和测量系统组成,包括水箱1、水箱阀门2、试件侧面排水收集箱3、密封垫4、侧面排水量筒5、连接头6、输水软管7、钢铰链8、底座9、试验平台10、排水滤网11、升降螺帽12、螺丝13、密封件14、内腔15,如图1所示。所述平台升降系统包括底座9以及试验平台10,所述的试验平台10与底座9的一端通过钢铰链8相连接,试验平台10与底座9的另一端通过升降螺帽12和螺丝13相连接,;所述的水量收集和测量系统包括水箱1、试件侧面排水收集箱3、输水软管7以及侧面排水量筒5,所述的水箱设置在内腔15的上端,在水箱的底部设置有水箱阀门2,所述的试件侧面排水收集箱3设置在内腔15的侧面并与侧面排水量筒5连接,在所述的水箱1与内腔15之间、内腔15与侧面排水收集箱3之间均设置有排水滤网11,所述的水箱1与水箱阀门之间设置密封垫4,所述的水箱1与排水滤网11由密封件14连接,所述的输水软管7与侧面排水收集箱3之间通过连接头6连接。The instrument used in this program is a drainage coefficient tester, which is composed of a test platform lifting system, water collection and measurement system, including

本方案技术拟定的依据:The basis for the technical formulation of this program:

本发明考虑到空隙这一混合料细观结构的测试相当繁琐,而空隙衰变这一细观结构问题在宏观上主要表现为连通空隙率的下降和排水能力的降低,因此本发明提出了以车辆荷载反复作用前后沥青混合料排水系数的变化来反映孔结构的衰变特征,并设计了空隙衰减评价方法和指标等在内的一整套技术。The present invention considers that the test of the mesoscopic structure of the mixture, such as voids, is quite cumbersome, and the mesoscopic structural problem of void decay is mainly manifested in the decrease of the connected void ratio and the reduction of drainage capacity in the macroscopic view. Therefore, the present invention proposes a vehicle The change of the drainage coefficient of the asphalt mixture before and after the repeated load is used to reflect the decay characteristics of the pore structure, and a set of technologies including the evaluation method and index of the void attenuation are designed.

1)排水性沥青路面的排水通道1) Drainage channel of drainage asphalt pavement

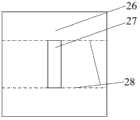

图2为高速公路半幅排水性沥青面层典型结构的示意图,包括车辆轮胎16、排水性沥青面层17、集料18、空隙19、密级配沥青层20、路面横坡21、路面超车道22、行车道23和路肩24。当排水性沥青路面处于理想工作状态下,降雨时图2所示路面结构的排水路径为:雨水降落到排水性沥青面层17表面后,会沿着排水性沥青混合料中集料18之外的空隙19渗入到排水性沥青混合料内部,然后依靠路面横坡21从排水沥青面层17内沿横向依次通过超车道22、行车道23和路肩24,并最终排出路面结构。但是,当车辆多次作用于路表后,排水性沥青路面在车轮经常作用的轮迹带上会出现进一步的压密,表现为轮迹带位置处沥青路面出现车辙等竖向永久变形。竖向永久变形的出现可能会对上述排水路径形成两方面的负面影响:第一,永久变形可能会引起排水性沥青混合料竖向的连通空隙率下降;雨水降落到路表后,不能快速甚至不能通过竖向空隙渗入到排水性沥青面层内部,导致排水沥青面层的表层出现积水,丧失排水功能;第二,永久变形可能会引起排水性沥青混合料横向的连通空隙率下降;当雨水降落到路表,并通过竖向空隙渗入到沥青混合料内部时,横向连通空隙率下降,使得雨水不能快速甚至不能通过路面横坡排出路面结构,导致排水性沥青路面丧失排水功能。Figure 2 is a schematic diagram of a typical structure of a half-width drainage asphalt pavement on an expressway, including

可见,从理论上来说车辆反复作用引起的永久变形,可能会导致排水性沥青混合料出现横向和竖向空隙的下降,使其逐步丧失排水功能。为此,须准确把握排水性沥青混合料永久变形后,其竖向和横向空隙的变化规律。It can be seen that, theoretically, the permanent deformation caused by the repeated action of the vehicle may lead to the decrease of the lateral and vertical voids of the drainage asphalt mixture, making it gradually lose its drainage function. For this reason, it is necessary to accurately grasp the change law of the vertical and transverse voids after the permanent deformation of the drainage asphalt mixture.

2)竖向排水空隙的变化规律2) Variation law of vertical drainage gap

上海市于2002年~2009年先后建成通车了浦东北路、高科东路和中环线浦东段高架,上述三条道路的某些路段均采用了排水性沥青路面,建成时竖向渗水系数均大于900ml/15s。在排水路面建成通车后一年之后,对上述路段进行现场竖向渗水系数的测试,发现渗水系数出现了较大幅度的下降,个别路段的渗水系数甚至为零。2009年10月,工程技术人员采用排水性沥青路面机能恢复车(GYPJH2000)对上述路段进行了清洗作业,经多次清洗后发现路表的竖向渗水系数有较大程度的提高,基本可以满足900ml/15s的技术要求。From 2002 to 2009, Shanghai opened to traffic North Pudong Road, Gaoke East Road and the elevated section of the Pudong section of the Central Ring Road. Some sections of the above three roads have adopted drainage asphalt pavement, and the vertical water seepage coefficient was greater than 900ml when they were completed. /15s. One year after the drainage pavement was completed and opened to traffic, the on-site vertical water seepage coefficient test was carried out on the above-mentioned road sections, and it was found that the water seepage coefficient had dropped significantly, and the water seepage coefficient of some road sections was even zero. In October 2009, engineers and technicians used a drainage asphalt pavement function recovery vehicle (GYPJH2000) to clean the above-mentioned road section. After repeated cleaning, it was found that the vertical water seepage coefficient of the road surface has been greatly improved, which can basically meet the The technical requirement of 900ml/15s.

在国外,对于竖向渗水系数一般也是认为可以恢复的,比如在排水沥青路面应用广泛的日本,开发了许多设备用于清洗排水路面的空隙,认为通过清洗作业可以较好的提升竖向渗水的能力。在丹麦,针对竖向空隙堵塞也作了大量研究,设备的开发和应用也十分活跃。In foreign countries, the vertical water seepage coefficient is generally considered to be recoverable. For example, in Japan, where drainage asphalt pavement is widely used, a lot of equipment has been developed to clean the gaps in the drainage pavement. It is believed that the vertical water seepage can be better improved through cleaning operations. ability. In Denmark, a lot of research has also been done on vertical void blocking, and the development and application of equipment is also very active.

由此可见,竖向渗水系数的降低主要由空隙堵塞造成,通过清洗空隙可以恢复竖向排水通道。也就是说,车辆的反复作用没有对竖向排水通道造成十分显著的影响,车辆荷载作用对排水性沥青路面中竖向空隙的衰减不明显。It can be seen that the reduction of the vertical water seepage coefficient is mainly caused by the clogging of the voids, and the vertical drainage channel can be restored by cleaning the voids. That is to say, the repeated action of the vehicle did not have a very significant impact on the vertical drainage channels, and the attenuation of the vertical voids in the drainage asphalt pavement by the vehicle load was not obvious.

3)横向排水空隙的变化规律3) Variation law of lateral drainage gap

在实验室内,采用轮碾法成型排水性沥青混合料OGFC-13的板式试件,在温度为60℃,接地压强为0.7MPa、0.8MPa和0.9MPa时分别进行车辙试验,并测试车辙试验30min、45min、60min后的车辙深度,结果如表1所示。In the laboratory, the plate-type specimen of the drainage asphalt mixture OGFC-13 was formed by the wheel rolling method, and the rutting test was carried out at a temperature of 60°C and a ground pressure of 0.7MPa, 0.8MPa and 0.9MPa, and the rutting test was carried out The rut depths after 30min, 45min and 60min are shown in Table 1.

表1OGFC-13的车辙深度Table 1 Rut depth of OGFC-13

从表1的数据可以看出,尽管排水性沥青混合料采用了骨架型结构,在车辆荷载的反复作用下,它仍然会出现车辙永久变形,且车辙深度随着荷载作用次数和轮胎压强的增大而增大。上述沥青混合料宏观车辙的出现,在细观结构上表现为粗集料颗粒的平移和转动、沥青砂浆的压缩、空隙的缩小。因此,可以推断在车轮荷载的反复碾压下,垂直于轮迹带方向的空隙(横向空隙)会出现衰减,且车辆碾压次数越多,衰减程度可能越大。From the data in Table 1, it can be seen that although the drainage asphalt mixture adopts a skeleton structure, it still has permanent deformation of ruts under repeated loads of vehicles, and the rut depth increases with the number of loads and tire pressure. Big and increase. The macroscopic rutting of the above-mentioned asphalt mixture is manifested in the mesoscopic structure as translation and rotation of coarse aggregate particles, compression of asphalt mortar, and shrinkage of voids. Therefore, it can be inferred that under the repeated rolling of the wheel load, the gap (transverse gap) perpendicular to the direction of the wheel track will attenuate, and the more times the vehicle is rolled, the greater the degree of attenuation may be.

通过上述分析可以看出:1)在车辆反复碾压下,路面竖向空隙不会出现较大程度的衰减;2)受车辆荷载的反复作用,路面横向空隙会出现一定程度的降低。结合图2所示的排水性沥青路面的排水原理,路面的超车道主要行驶小轿车等轴载较小、速度较快的车辆,行车道上车辙深度通常较小;道路最右侧的行车道主要行驶大客车、大货车等轴载较大、速度较慢的车辆,在行车道轮迹带位置很容易形成较深的车辙,该位置下面的排水性沥青混合料内部的横向空隙会出现衰减,对于整个路面横截面而言,右侧行车道轮迹带内部相当于排水的“瓶颈”区域,如图3所示。图中17为排水性沥青面层,20为密级配沥青层,22为路面超车道,23为行车道,24为路肩,25为横向排水的瓶颈区域。图3中空隙衰减引起的排水瓶颈区域25是影响横向排水的关键因素。Through the above analysis, it can be seen that: 1) Under the repeated rolling of vehicles, the vertical gap of the pavement will not attenuate to a large extent; 2) Under the repeated action of vehicle loads, the lateral gap of the pavement will decrease to a certain extent. Combined with the drainage principle of the drainage asphalt pavement shown in Figure 2, the overtaking lane on the pavement mainly drives cars with small axle loads and fast speeds, and the rut depth on the roadway is usually small; the roadway on the far right side mainly Vehicles with large axle loads and slow speeds such as buses and large trucks are likely to form deep ruts at the wheel mark of the roadway, and the lateral voids inside the drainage asphalt mixture below this position will attenuate. For the entire cross-section of the road surface, the inside of the wheel mark of the right roadway is equivalent to the "bottleneck" area of drainage, as shown in Figure 3. In the figure, 17 is a drainage asphalt surface layer, 20 is a densely graded asphalt layer, 22 is a road overtaking lane, 23 is a carriageway, 24 is a road shoulder, and 25 is a bottleneck area of lateral drainage. The

本发明与现有技术相比,其有益效果是:(1)现有对排水性沥青路面空隙衰减的研究,主要针对灰尘、橡胶、泥土等引起的路表竖向空隙的堵塞问题,包括竖向渗水系数的衰减,以及以竖向渗水系数恢复为目的的空隙清洗试剂和设备的研发;现有技术没有考虑到车辆反复碾压会引起排水性沥青路面横向空隙衰减这一问题,本发明弥补了现有技术的这一缺陷;(2)本发明所述的排水测试仪较好的模拟了雨水在排水性沥青路面中的实际流动状况;(3)本发明所述的空隙衰减评价方法充分考虑了公路车辆按行驶速度和重量分道通行的实际特点,以及由此引起的排水性沥青路面排水瓶颈,符合路面实际情形;(4)本发明涉及到的试验只有板式试件的轮碾成型、排水系数的测试和车辙试验,其中板式试件的成型和车辙试验为道路工程专业的常规试验,排水系数的测试操作过程简单,都易于工程技术人员掌握。Compared with the prior art, the present invention has the beneficial effects as follows: (1) The existing research on void attenuation of drainage asphalt pavement mainly aims at the blockage of vertical voids on road surface caused by dust, rubber, soil, etc., including vertical The attenuation of water seepage coefficient, and the research and development of gap cleaning reagents and equipment for the purpose of restoring vertical water seepage coefficient; the existing technology does not take into account the problem that the repeated rolling of vehicles will cause the transverse void decay of drainage asphalt pavement, and the present invention makes up for (2) The drainage tester described in the present invention has better simulated the actual flow condition of rainwater in the drainage asphalt pavement; (3) The void attenuation evaluation method described in the present invention is sufficient Considering the actual characteristics of road vehicles passing in separate lanes according to driving speed and weight, and the drainage bottleneck of the drainage asphalt pavement caused by this, it is in line with the actual situation of the road surface; , Drainage coefficient test and rutting test, among which the forming of plate specimens and rutting test are routine tests of road engineering profession, the operation process of drainage coefficient test is simple, and it is easy for engineers and technicians to master.

附图说明Description of drawings

图1为排水系数测试仪;Fig. 1 is a drainage coefficient tester;

图2为高速公路半幅排水性沥青面层典型结构的示意图;Figure 2 is a schematic diagram of a typical structure of a half-width drainage asphalt pavement on an expressway;

图3为路面空隙衰减形成的排水瓶颈区域;Figure 3 shows the drainage bottleneck area formed by the pavement void attenuation;

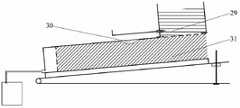

图4为车辙试验后板式试件的切割示意图;Figure 4 is a schematic diagram of the cutting of the plate specimen after the rutting test;

图5为车辙试验后混合料终了排水系数的测试示意图。Figure 5 is a schematic diagram of the final drainage coefficient test of the mixture after the rutting test.

具体实施例specific embodiment

下面结合附图,通过实施例对本发明技术方案进行详细说明,但是本发明的保护范围不局限于所述实施例。The technical solutions of the present invention will be described in detail below through examples in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the examples.

实施例:排水性沥青混合料OGFC-13空隙衰减程度的评价方法,包括如下步骤:Embodiment: The evaluation method of the void attenuation degree of drainage asphalt mixture OGFC-13 comprises the steps:

(1)排水性沥青混合料板式试件的成型(1) Forming of drainage asphalt mixture plate specimen

待评价的排水性沥青混合料OGFC-13采用的级配如表2所示,其目标空隙率为20%,该沥青混合料用于某高速公路的上面层,横坡为1.5%。按照排水性沥青混合料配合比设计方法,由析漏试验和飞散试验最终确定的OGFC-13混合料的油石比为4.9%。The gradation used in the drainage asphalt mixture OGFC-13 to be evaluated is shown in Table 2, and its target void ratio is 20%. The asphalt mixture is used for the upper layer of an expressway, and the cross slope is 1.5%. According to the design method of drainage asphalt mixture, the asphalt ratio of OGFC-13 mixture finally determined by leakage test and flying test is 4.9%.

表2排水性沥青混合料OGFC-13的级配Table 2 Gradation of drainage asphalt mixture OGFC-13

按表2所示的级配和4.9%的油石比,进行沥青混合料的拌和,把拌和后的混合料放入到车辙试验板所用的钢制模具内,采用轮碾法碾压成型沥青混合料的板式试件,试件尺寸为长300mm×宽300mm×厚50mm。在常温下存放至少24h后脱模,获得排水性沥青混合料的板式试件。According to the gradation shown in Table 2 and the asphalt ratio of 4.9%, the asphalt mixture is mixed, and the mixed mixture is put into the steel mold used for the rutting test plate, and the asphalt mixture is formed by wheel rolling. The plate-type test piece of the material, the size of the test piece is 300mm long x 300mm wide x 50mm thick. Store at room temperature for at least 24 hours and demould to obtain a plate-type test piece of drainage asphalt mixture.

选择板式试件中尺寸50mm×300mm的三个矩形侧面,采用橡皮泥涂抹于三个侧面表面,封住混合料表面的空隙;采用同样的方法,封住板式试件尺寸为300mm×300mm的一个正方形表面的空隙。密封材料可以为玻璃腻子、油灰、橡皮泥或石蜡。Select three rectangular sides with a size of 50mm×300mm in the plate-type test piece, and apply plasticine to the three side surfaces to seal the gaps on the surface of the mixture; use the same method to seal one of the plate-type test pieces with a size of 300mm×300mm Voids in square surfaces. The sealing material can be glass putty, putty, plasticine or paraffin.

(2)初始排水系数的测试(2) Test of initial drainage coefficient

把板式试件放入到图1所示的水平放置的排水系数测试仪内腔中,使未涂抹密封材料的试件侧面紧挨着排水测试仪的垂直调节机构,未涂抹密封材料的正方形表面朝上放置;转动垂直调节机构的螺帽,采用游标卡尺测量,使螺帽上升h=380×α=380×1.5%=5.7mm,其中380mm为排水系数测试仪中钢铰链与螺丝的水平距离,以确保排水测试仪的试验平台与底座之间形成的坡度与路面横坡相同,都为1.5%。Put the plate-type test piece into the inner cavity of the horizontal drainage coefficient tester shown in Figure 1, so that the side of the test piece that is not coated with sealing material is next to the vertical adjustment mechanism of the drainage tester, and the square surface that is not coated with sealing material Put it upwards; turn the nut of the vertical adjustment mechanism and measure it with a vernier caliper to make the nut rise h=380×α=380×1.5%=5.7mm, where 380mm is the horizontal distance between the steel hinge and the screw in the drainage coefficient tester, To ensure that the slope formed between the test platform of the drainage tester and the base is the same as the cross slope of the road surface, both of which are 1.5%.

在排水系数测试仪的水箱内注入质量a0为2000g的水,待水箱内的水稳定不动后,迅速打开水箱阀门,并同时按动秒表计时器;当水箱内的水全部排出、且侧面排水量筒内水位不变时,计时为t1=5s;称得侧面排水量桶中水的质量a1为1870g,计算得到的OGFC-13排水性沥青混合料初始排水系数为。Inject water with a quality of2000g into the water tank of the drainage coefficient tester. After the water in the water tank is stable, open the valve of the water tank quickly and press the stopwatch timer at the same time; when all the water in the water tank is discharged and the side When the water level in the displacement cylinder remains constant, the timing is t1 =5s; the mass a1 of the water in the side displacement cylinder is weighed to be 1870g, and the calculated initial drainage coefficient of OGFC-13 drainage asphalt mixture is .

(3)车辙试验与板式试件的切割(3) Rutting test and cutting of plate specimen

从排水系数测试仪内取出板式试件,放置于自然通风的环境中,充分晾干水分。把晾干后的试件放入车辙试验仪中,放置时必须使即将碾压的轮胎与试件的排水侧面相平行;在60℃环境中保温2h,然后在轮压为0.7MPa,轮碾速度为42次/min的条件下车辙试验,对试件进行往返的碾压,1h后停止试验,并取出排水性沥青混合料的板式试件。Take out the plate specimen from the drainage coefficient tester, place it in a naturally ventilated environment, and fully dry the water. Put the dried test piece into the rutting tester. When placing it, the tire to be rolled must be parallel to the drainage side of the test piece; keep warm at 60°C for 2 hours, and then run the wheel at a wheel pressure of 0.7MPa. For the rutting test at a speed of 42 times/min, the test piece was rolled back and forth, and the test was stopped after 1 hour, and the plate-type test piece of the drainage asphalt mixture was taken out.

把碾压过的板式试件,放在室内常温下冷却至少2h。用记号笔画出车辙试验中轮胎碾压过的痕迹(轮迹带),并沿着与轮迹带垂直的方向,画出通过轮迹带两端点的两条直线。沿着这两条直线,对板式试件进行切割,得到三部分试样,如图4所示,图中26为沥青混合料板式试件,27为轮碾后形成的轮迹带,28为切割线,取中间带有轮迹带的试样备用。对表面带有轮迹带的试样,因切割形成的两个新侧面,采用密封材料涂抹于表面,封住混合料表面的空隙,密封材料可以为玻璃腻子、油灰、橡皮泥或石蜡。Cool the rolled plate specimen at room temperature for at least 2 hours. Use a marker pen to draw the traces (wheel tracks) that the tires have run over in the rutting test, and along the direction perpendicular to the wheel tracks, draw two straight lines passing through the two ends of the wheel tracks. Along these two straight lines, the plate specimen was cut to obtain three parts of the specimen, as shown in Figure 4, in which 26 is the asphalt mixture plate specimen, 27 is the wheel track formed after wheel rolling, and 28 is the Cut the line, and take a sample with a wheel mark in the middle for use. For samples with wheel tracks on the surface, the two new sides formed by cutting should be coated with sealing material on the surface to seal the gap on the surface of the mixture. The sealing material can be glass putty, putty, plasticine or paraffin.

(4)终了排水系数的测试与空隙衰减指数的计算(4) Final drainage coefficient test and void attenuation index calculation

把试样放入到水平放置的测试仪内腔中,未涂抹密封材料的排水侧面挨着排水测试仪的垂直调节机构,转动垂直调节机构的螺帽,使试件的坡度应与步骤(2)初始排水系数测试时试件采用的坡度相同,即上升380×1.5%=5.7mm,如图5所示,图中29为水,30为试件轮迹带位置的永久变形,31为板式试件切割后的含轮迹带的试样。Put the sample into the inner cavity of the tester placed horizontally, and the drainage side not coated with sealing material is next to the vertical adjustment mechanism of the drainage tester, and turn the nut of the vertical adjustment mechanism so that the slope of the test piece should be the same as the step (2 ) The slope of the specimen used in the initial drainage coefficient test is the same, that is, an increase of 380×1.5%=5.7mm. The sample containing the wheel track after cutting the test piece.

在排水系数测试仪的水箱内注入质量a0为2000g的水,待水箱内的水稳定不动后,迅速打开水箱阀门,并同时按动秒表计时器;当水箱内的水全部排出、且侧面排水量筒内水位不变时,计时为t2=6.4s;称得侧面排水量桶中水的质量a2为1845g,计算得到的OGFC-13排水性沥青混合料终了排水系数为计算得到的OGFC-13空隙衰减指数

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2013102314066ACN103323381A (en) | 2013-06-09 | 2013-06-09 | Method for evaluating attenuation degree of porous asphalt mixture void |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2013102314066ACN103323381A (en) | 2013-06-09 | 2013-06-09 | Method for evaluating attenuation degree of porous asphalt mixture void |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103323381Atrue CN103323381A (en) | 2013-09-25 |

Family

ID=49192268

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2013102314066APendingCN103323381A (en) | 2013-06-09 | 2013-06-09 | Method for evaluating attenuation degree of porous asphalt mixture void |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103323381A (en) |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104062159A (en)* | 2014-06-26 | 2014-09-24 | 东南大学 | Porous asphalt mixture gap blocking experiment method |

| CN104655571A (en)* | 2015-03-19 | 2015-05-27 | 云南省交通规划设计研究院 | Device for simulating visibility test of drainage asphalt pavement under rainy day conditions |

| CN104807977A (en)* | 2015-05-13 | 2015-07-29 | 云南省交通规划设计研究院 | Hydrological simulation device for drainage asphalt pavement and testing method for hydrological simulation device |

| CN104931515A (en)* | 2015-06-01 | 2015-09-23 | 大连海事大学 | Internal homogeneity identification method based on the relative density of each component of asphalt mixture |

| CN105136647A (en)* | 2015-09-30 | 2015-12-09 | 河海大学 | Bituminous mixture permeability testing device and method |

| CN105445162A (en)* | 2015-11-17 | 2016-03-30 | 沈阳建筑大学 | Method for extracting indoor emulsified asphalt sand sealing layer test piece and measuring porosity |

| CN105910969A (en)* | 2016-04-07 | 2016-08-31 | 河海大学 | Method for testing blocking degree of pores in porous asphalt mixture |

| CN105954173A (en)* | 2016-06-08 | 2016-09-21 | 山西省交通科学研究院 | Macroporous asphalt mixture pore change law experimental testing device |

| CN106644887A (en)* | 2016-12-30 | 2017-05-10 | 河海大学 | Method for determining void saturation of large-void asphalt mixture in seepage state |

| CN106840997A (en)* | 2016-12-29 | 2017-06-13 | 河海大学 | The estimation device and method of big space bituminous paving horizontal infiltration flow |

| CN108982823A (en)* | 2018-08-14 | 2018-12-11 | 长沙理工大学 | Speeding-up simulation device and method in a kind of Asphalt mix for open-graded friction course drainage performance decaying behavior room |

| CN109959596A (en)* | 2019-03-18 | 2019-07-02 | 河海大学 | Test method for water permeability of double-layer asphalt mixture by attenuation effect of interlayer interface |

| CN110082196A (en)* | 2019-04-28 | 2019-08-02 | 中路高科(北京)公路技术有限公司 | A kind of porous asphalt pavement disperses the detection method of disease |

| CN110231267A (en)* | 2019-03-28 | 2019-09-13 | 广州珠江黄埔大桥建设有限公司 | A kind of device and method of indoor test drainage type asphalt drainage performance |

| CN110763607A (en)* | 2019-11-12 | 2020-02-07 | 云南省交通规划设计研究院有限公司 | A kind of asphalt mixture water permeability tester and water permeability coefficient calculation method |

| CN111693439A (en)* | 2020-07-20 | 2020-09-22 | 江西省交通科学研究院 | Drainage capability testing device and evaluation method for drainage asphalt concrete |

| CN112084566A (en)* | 2020-09-21 | 2020-12-15 | 南京林业大学 | Analysis method for attenuation law of pore structure of double-layer drainage asphalt pavement |

| CN112525740A (en)* | 2020-07-20 | 2021-03-19 | 宝丰县公路管理局 | Rut test device and double-wheel dynamic stability calculation method |

| CN113462172A (en)* | 2021-05-14 | 2021-10-01 | 河海大学 | Performance improving method for SBS (styrene butadiene styrene) modified asphalt stored on site |

| CN114910399A (en)* | 2022-04-06 | 2022-08-16 | 景德镇新越沥青有限公司 | Testing method based on pore change of macroporous asphalt mixture |

| CN115656488A (en)* | 2022-10-09 | 2023-01-31 | 广西交科集团有限公司 | Method for evaluating durability of drainage asphalt pavement under four-field coupling effect |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002250002A (en)* | 2001-02-23 | 2002-09-06 | Nikken Kk | Water permeability testing device for drainage pavement |

| CN201965079U (en)* | 2011-01-12 | 2011-09-07 | 长安大学 | Multi-gradient seepage tester |

| CN102445397A (en)* | 2011-10-14 | 2012-05-09 | 河海大学 | Rut testing device for asphalt mixture of mountain roads and method thereof |

| CN102507410A (en)* | 2011-10-14 | 2012-06-20 | 河海大学 | Device and method for simultaneously testing water seepage and drainage capacities of asphalt mixture |

| CN102519873A (en)* | 2011-12-26 | 2012-06-27 | 同济大学 | Method for evaluating durability of steel bridge deck pavement waterproof bonding system |

| CN103033453A (en)* | 2012-09-26 | 2013-04-10 | 天津市市政工程研究院 | Method for measuring voidage of asphalt concrete pavement core |

- 2013

- 2013-06-09CNCN2013102314066Apatent/CN103323381A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002250002A (en)* | 2001-02-23 | 2002-09-06 | Nikken Kk | Water permeability testing device for drainage pavement |

| CN201965079U (en)* | 2011-01-12 | 2011-09-07 | 长安大学 | Multi-gradient seepage tester |

| CN102445397A (en)* | 2011-10-14 | 2012-05-09 | 河海大学 | Rut testing device for asphalt mixture of mountain roads and method thereof |

| CN102507410A (en)* | 2011-10-14 | 2012-06-20 | 河海大学 | Device and method for simultaneously testing water seepage and drainage capacities of asphalt mixture |

| CN102519873A (en)* | 2011-12-26 | 2012-06-27 | 同济大学 | Method for evaluating durability of steel bridge deck pavement waterproof bonding system |

| CN103033453A (en)* | 2012-09-26 | 2013-04-10 | 天津市市政工程研究院 | Method for measuring voidage of asphalt concrete pavement core |

Cited By (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104062159A (en)* | 2014-06-26 | 2014-09-24 | 东南大学 | Porous asphalt mixture gap blocking experiment method |

| CN104655571A (en)* | 2015-03-19 | 2015-05-27 | 云南省交通规划设计研究院 | Device for simulating visibility test of drainage asphalt pavement under rainy day conditions |

| CN104655571B (en)* | 2015-03-19 | 2017-04-05 | 云南省交通规划设计研究院 | Porous asphalt pavement visibility test device under the conditions of a kind of simulation rainy day |

| CN104807977A (en)* | 2015-05-13 | 2015-07-29 | 云南省交通规划设计研究院 | Hydrological simulation device for drainage asphalt pavement and testing method for hydrological simulation device |

| CN104931515A (en)* | 2015-06-01 | 2015-09-23 | 大连海事大学 | Internal homogeneity identification method based on the relative density of each component of asphalt mixture |

| CN105136647A (en)* | 2015-09-30 | 2015-12-09 | 河海大学 | Bituminous mixture permeability testing device and method |

| CN105445162B (en)* | 2015-11-17 | 2018-09-14 | 沈阳建筑大学 | The extraction of indoor emulsified asphalt sand seal layer test specimen and the measurement method of voidage |

| CN105445162A (en)* | 2015-11-17 | 2016-03-30 | 沈阳建筑大学 | Method for extracting indoor emulsified asphalt sand sealing layer test piece and measuring porosity |

| CN105910969A (en)* | 2016-04-07 | 2016-08-31 | 河海大学 | Method for testing blocking degree of pores in porous asphalt mixture |

| CN105954173B (en)* | 2016-06-08 | 2019-10-08 | 山西省交通科学研究院 | Porous asphalt hole changing rule experiment test device |

| CN105954173A (en)* | 2016-06-08 | 2016-09-21 | 山西省交通科学研究院 | Macroporous asphalt mixture pore change law experimental testing device |

| CN106840997B (en)* | 2016-12-29 | 2019-08-20 | 河海大学 | Apparatus and method for estimating lateral seepage flow rate of asphalt pavement with large voids |

| CN106840997A (en)* | 2016-12-29 | 2017-06-13 | 河海大学 | The estimation device and method of big space bituminous paving horizontal infiltration flow |

| CN106644887A (en)* | 2016-12-30 | 2017-05-10 | 河海大学 | Method for determining void saturation of large-void asphalt mixture in seepage state |

| CN106644887B (en)* | 2016-12-30 | 2019-04-16 | 河海大学 | The determination method of Asphalt mix for open-graded friction course gap saturation degree under seepage state |

| CN108982823A (en)* | 2018-08-14 | 2018-12-11 | 长沙理工大学 | Speeding-up simulation device and method in a kind of Asphalt mix for open-graded friction course drainage performance decaying behavior room |

| CN109959596A (en)* | 2019-03-18 | 2019-07-02 | 河海大学 | Test method for water permeability of double-layer asphalt mixture by attenuation effect of interlayer interface |

| CN109959596B (en)* | 2019-03-18 | 2021-05-11 | 河海大学 | Test method for water permeability of double-layer asphalt mixture by attenuation effect of interlayer interface |

| CN110231267A (en)* | 2019-03-28 | 2019-09-13 | 广州珠江黄埔大桥建设有限公司 | A kind of device and method of indoor test drainage type asphalt drainage performance |

| CN110082196A (en)* | 2019-04-28 | 2019-08-02 | 中路高科(北京)公路技术有限公司 | A kind of porous asphalt pavement disperses the detection method of disease |

| CN110763607A (en)* | 2019-11-12 | 2020-02-07 | 云南省交通规划设计研究院有限公司 | A kind of asphalt mixture water permeability tester and water permeability coefficient calculation method |

| CN111693439A (en)* | 2020-07-20 | 2020-09-22 | 江西省交通科学研究院 | Drainage capability testing device and evaluation method for drainage asphalt concrete |

| CN112525740A (en)* | 2020-07-20 | 2021-03-19 | 宝丰县公路管理局 | Rut test device and double-wheel dynamic stability calculation method |

| CN112084566A (en)* | 2020-09-21 | 2020-12-15 | 南京林业大学 | Analysis method for attenuation law of pore structure of double-layer drainage asphalt pavement |

| CN113462172A (en)* | 2021-05-14 | 2021-10-01 | 河海大学 | Performance improving method for SBS (styrene butadiene styrene) modified asphalt stored on site |

| CN114910399A (en)* | 2022-04-06 | 2022-08-16 | 景德镇新越沥青有限公司 | Testing method based on pore change of macroporous asphalt mixture |

| CN115656488A (en)* | 2022-10-09 | 2023-01-31 | 广西交科集团有限公司 | Method for evaluating durability of drainage asphalt pavement under four-field coupling effect |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103323381A (en) | Method for evaluating attenuation degree of porous asphalt mixture void | |

| CN106525689B (en) | A water seepage meter for measuring the multidirectional permeability coefficient of pavement structures with large voids and its measuring method | |

| CN105136647A (en) | Bituminous mixture permeability testing device and method | |

| CN110188323B (en) | Water surface rate value range measuring and calculating method suitable for urban water ecological protection | |

| CN102507410A (en) | Device and method for simultaneously testing water seepage and drainage capacities of asphalt mixture | |

| CN109682744B (en) | Test device and method for evaluating permeable asphalt pavement gap evolution rule | |

| CN107476158A (en) | Areas formerly flooded by the Huanghe River high liquid limit clay embankment Con trolling index determines method and compaction technology | |

| Liu | Asphalt pavement preventive maintenance technology overview | |

| CN104062159B (en) | A kind of porous asphalt mixture gap blocks test method | |

| KR20100109753A (en) | Low noise paving mixture to improve the aggregate gradation | |

| CN111243685A (en) | A kind of design method of permeable asphalt concrete mixture mix ratio | |

| Yang et al. | Comparative analysis of performance of porous asphalt pavement and SMA pavement based on deck pavement structure | |

| Kowalski et al. | Identification of laboratory technique to optimize Superpave HMA surface friction characteristics | |

| CN111304994A (en) | Semi-flexible functional composite structure recovery layer applied to asphalt pavement maintenance | |

| CN106644887A (en) | Method for determining void saturation of large-void asphalt mixture in seepage state | |

| Gallaway et al. | Macro-texture, friction, cross slope and wheel track depression measurements on 41 typical Texas highway pavements | |

| CN103215872A (en) | Novel stone-exposed road surface construction method | |

| CN112084692A (en) | Dynamic water pressure change rule analysis method for double-layer drainage asphalt pavement | |

| CN211292483U (en) | Testing arrangement of bituminous mixture marshall test piece permeability | |

| CN204162964U (en) | A kind of combined type drainage pavement structure being applicable to area of heavy rainfull | |

| CN105910969A (en) | Method for testing blocking degree of pores in porous asphalt mixture | |

| CN113417182A (en) | Asphalt pavement paving method capable of reducing air bubbles for highway engineering | |

| Xie et al. | Research on skid resistance performance of long downhill tunnels in mountainous expressways | |

| Zhang et al. | Skid-resistance and noise-reducing characteristics of exposed-aggregate cement concrete pavement | |

| Pang | Research on the Moisture Damage Occurred on the Asphalt Pavement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C12 | Rejection of a patent application after its publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20130925 |