CN103282059A - Method for disinfecting air in an air channel - Google Patents

Method for disinfecting air in an air channelDownload PDFInfo

- Publication number

- CN103282059A CN103282059ACN201080069291XACN201080069291ACN103282059ACN 103282059 ACN103282059 ACN 103282059ACN 201080069291X ACN201080069291X ACN 201080069291XACN 201080069291 ACN201080069291 ACN 201080069291ACN 103282059 ACN103282059 ACN 103282059A

- Authority

- CN

- China

- Prior art keywords

- air

- disinfectant

- feed path

- disinfecting

- air feed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription20

- 230000000249desinfective effectEffects0.000titleclaimsabstractdescription12

- 239000000645desinfectantSubstances0.000claimsabstractdescription36

- 239000002245particleSubstances0.000claimsabstractdescription22

- 239000012530fluidSubstances0.000claimsabstractdescription8

- 231100000252nontoxicToxicity0.000claimsabstractdescription7

- 230000003000nontoxic effectEffects0.000claimsabstractdescription7

- 239000007921spraySubstances0.000claimsabstract5

- 238000002347injectionMethods0.000claimsdescription28

- 239000007924injectionSubstances0.000claimsdescription28

- 238000004659sterilization and disinfectionMethods0.000claimsdescription7

- KRKNYBCHXYNGOX-UHFFFAOYSA-Ncitric acidChemical compoundOC(=O)CC(O)(C(O)=O)CC(O)=OKRKNYBCHXYNGOX-UHFFFAOYSA-N0.000claimsdescription6

- 238000009826distributionMethods0.000claimsdescription6

- CIWBSHSKHKDKBQ-JLAZNSOCSA-NAscorbic acidChemical compoundOC[C@H](O)[C@H]1OC(=O)C(O)=C1OCIWBSHSKHKDKBQ-JLAZNSOCSA-N0.000claimsdescription4

- 238000004378air conditioningMethods0.000claimsdescription4

- JVTAAEKCZFNVCJ-UHFFFAOYSA-Nlactic acidChemical compoundCC(O)C(O)=OJVTAAEKCZFNVCJ-UHFFFAOYSA-N0.000claimsdescription4

- 230000003115biocidal effectEffects0.000claimsdescription3

- 239000003139biocideSubstances0.000claimsdescription3

- ZZZCUOFIHGPKAK-UHFFFAOYSA-ND-erythro-ascorbic acidNatural productsOCC1OC(=O)C(O)=C1OZZZCUOFIHGPKAK-UHFFFAOYSA-N0.000claimsdescription2

- 229930003268Vitamin CNatural products0.000claimsdescription2

- 239000004310lactic acidSubstances0.000claimsdescription2

- 235000014655lactic acidNutrition0.000claimsdescription2

- 230000001954sterilising effectEffects0.000claimsdescription2

- 235000019154vitamin CNutrition0.000claimsdescription2

- 239000011718vitamin CSubstances0.000claimsdescription2

- 239000004531microgranuleSubstances0.000claims7

- 238000005452bendingMethods0.000claims2

- 239000000306componentSubstances0.000claims1

- 238000012423maintenanceMethods0.000claims1

- 238000005507sprayingMethods0.000abstractdescription6

- 241000894006BacteriaSpecies0.000description4

- 230000008021depositionEffects0.000description3

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description3

- 241000195493CryptophytaSpecies0.000description2

- 241000233866FungiSpecies0.000description2

- 230000001133accelerationEffects0.000description2

- 230000015572biosynthetic processEffects0.000description2

- 238000010586diagramMethods0.000description2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description1

- CBENFWSGALASAD-UHFFFAOYSA-NOzoneChemical compound[O-][O+]=OCBENFWSGALASAD-UHFFFAOYSA-N0.000description1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-NPhenolChemical compoundOC1=CC=CC=C1ISWSIDIOOBJBQZ-UHFFFAOYSA-N0.000description1

- 230000035508accumulationEffects0.000description1

- 238000009825accumulationMethods0.000description1

- 235000015165citric acidNutrition0.000description1

- 230000007423decreaseEffects0.000description1

- 230000000694effectsEffects0.000description1

- 230000036541healthEffects0.000description1

- QSHDDOUJBYECFT-UHFFFAOYSA-NmercuryChemical compound[Hg]QSHDDOUJBYECFT-UHFFFAOYSA-N0.000description1

- 229910052753mercuryInorganic materials0.000description1

- 244000005700microbiomeSpecies0.000description1

- 239000003595mistSubstances0.000description1

- 230000005180public healthEffects0.000description1

- 238000005086pumpingMethods0.000description1

- 238000011012sanitizationMethods0.000description1

- 239000000126substanceSubstances0.000description1

- 238000009827uniform distributionMethods0.000description1

- 238000009736wettingMethods0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L9/00—Disinfection, sterilisation or deodorisation of air

- A61L9/14—Disinfection, sterilisation or deodorisation of air using sprayed or atomised substances including air-liquid contact processes

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L9/00—Disinfection, sterilisation or deodorisation of air

- A61L9/16—Disinfection, sterilisation or deodorisation of air using physical phenomena

- A61L9/22—Ionisation

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H3/00—Other air-treating devices

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F3/00—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems

- F24F3/12—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling

- F24F3/16—Air-conditioning systems in which conditioned primary air is supplied from one or more central stations to distributing units in the rooms or spaces where it may receive secondary treatment; Apparatus specially designed for such systems characterised by the treatment of the air otherwise than by heating and cooling by purification, e.g. by filtering; by sterilisation; by ozonisation

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F8/00—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying

- F24F8/20—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying by sterilisation

- F24F8/24—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying by sterilisation using sterilising media

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2209/00—Aspects relating to disinfection, sterilisation or deodorisation of air

- A61L2209/10—Apparatus features

- A61L2209/16—Connections to a HVAC unit

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2209/00—Aspects relating to disinfection, sterilisation or deodorisation of air

- A61L2209/20—Method-related aspects

- A61L2209/21—Use of chemical compounds for treating air or the like

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2221/00—Details or features not otherwise provided for

- F24F2221/22—Cleaning ducts or apparatus

- F24F2221/225—Cleaning ducts or apparatus using a liquid

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A50/00—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE in human health protection, e.g. against extreme weather

- Y02A50/20—Air quality improvement or preservation, e.g. vehicle emission control or emission reduction by using catalytic converters

Landscapes

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Animal Behavior & Ethology (AREA)

- Veterinary Medicine (AREA)

- Public Health (AREA)

- General Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Epidemiology (AREA)

- Disinfection, Sterilisation Or Deodorisation Of Air (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

- Central Air Conditioning (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明公开了一种在空气供给通道中用无毒的消毒剂对空气流的空气进行消毒的方法,所述空气供给通道特别是空调系统的空气供给通道。The invention discloses a method for disinfecting the air of an air stream with a non-toxic disinfectant in an air supply channel, in particular an air supply channel of an air conditioning system.

背景技术Background technique

在最接近的现有技术EP0615603中公开了用于对空调的空气供给通道中的空气进行消毒的方法和装置。借助于喷注装置,无毒消毒剂迎着空气流被喷射到空气供给通道中。In the closest prior art EP0615603 a method and a device for sanitizing the air in the air supply channel of an air conditioner are disclosed. By means of the injection device, the non-toxic disinfectant is injected into the air supply channel against the air flow.

所使用的无毒消毒剂可以杀死真菌、藻类、细菌和类似的生物,并且不仅在空气流本身中有效,而且,因为其附着在空气供给通道的内壁上,可以长时间地对附着在在内壁上的细菌起作用,使细菌不再进入空气流中。The non-toxic disinfectant used kills fungi, algae, bacteria and similar organisms and is effective not only in the air stream itself, but also, because it adheres to the inner walls of the air supply channel, for a long time against the The bacteria on the inner wall work so that the bacteria can no longer enter the air stream.

所公开的方法描述了在喷注装置的区域内对空气的消毒。消毒剂的微粒一方面可以沿空气流方向注入到空气供给通道中,另一方面,微粒通过电离装置电离。迎着空气流的喷射导致在喷嘴的周围形成云,在此微粒的一部分在喷射装置附近被甩向空气供给通道的临近的内壁,并优选堆积在那里。The disclosed method describes the disinfection of the air in the region of the injection device. Particles of the disinfectant can be injected into the air supply channel in the direction of the air flow on the one hand and, on the other hand, the particles are ionized by the ionization device. The spraying against the air flow leads to the formation of a cloud around the nozzle, where a part of the particles is thrown in the vicinity of the spraying device towards the adjacent inner wall of the air supply channel and preferably accumulates there.

通过借助电离装置附加地电离微粒,使注入的微粒带电,由于空气供给通道接地,使微粒向空气供给通道的内壁的方向迅速消散。由此经电离的微粒在出来后不久就在喷嘴区域内沉积在空气供给通道的内壁上,而不再在空气供给通道内流动。因此,在喷注装置的区域内发生在局部局限于喷射位置的空气消毒。与之相关的是微粒在喷注装置附近的沉积受干扰。局部消毒的空气在喷注装置附近被消毒后在空气供给通道中循环且不被进一步消毒,因为微粒被限于空气供给通道范围内。By additionally ionizing the particles by means of the ionization device, the injected particles are charged, and due to the grounding of the air supply channel, the particles dissipate rapidly in the direction of the inner wall of the air supply channel. As a result, the ionized particles deposit on the inner wall of the air supply channel in the region of the nozzle shortly after exiting, and no longer flow in the air supply channel. A locally localized disinfection of the air at the spraying point thus takes place in the area of the spraying device. Associated with this is a disturbance in the deposition of the particles in the vicinity of the injection device. After the locally sterilized air has been sterilized in the vicinity of the injection device, it circulates in the air supply channel and is not further sterilized, since the particles are confined within the air supply channel.

所取得的结果仅在最初和在新设备的情形是令人满意的。经过一定的时间后在空气供给通道中与喷注装置相距不同的距离处形成受扰动的沉积,而这也可以是菌群。The results obtained are satisfactory only initially and in the case of new equipment. Disturbed deposits, which can also be colonies of bacteria, form after a certain time in the air supply channel at different distances from the injection device.

发明内容Contents of the invention

本发明的目的是,提供在空气供给通道中用无毒的消毒剂对空气流的空气进行消毒的方法和装置,该方法和装置能够实现消毒剂微粒几乎在空气供给通道的整个长度延伸上的分布、实现消毒剂微粒尽可能均匀地分布在空气供给通道的内壁上。The object of the present invention is to provide a method and a device for disinfecting the air of an air stream with a non-toxic disinfectant in an air supply channel, which method and device enable the disinfection of particles of the disinfectant almost over the entire length of the air supply channel. Distribution, achieving as uniform a distribution of the disinfectant particles as possible on the inner wall of the air supply channel.

本发明的目的以及附加的避免在喷嘴区域内壁上的干扰的局部堆积由本发明的设备和本发明的方法实现。注入导致消毒剂在空气中结合(Verbindung)以及其随后在通道内壁上的沉积。The object of the invention and the additional avoidance of disturbing local accumulations on the inner wall in the region of the nozzle are achieved by the device according to the invention and the method according to the invention. The injection leads to airborne binding (Verbindung) of the disinfectant and its subsequent deposition on the inner walls of the channel.

在优选的实施例中,所注入的消毒剂具有保持的(retensiv)特性,这使得消毒剂在整个通道中分布,因而能够实现对所有内壁的消毒。In a preferred embodiment, the injected disinfectant has retensiv properties, which allow distribution of the disinfectant throughout the channel, thus enabling disinfection of all inner walls.

在所进行的测试的结果中,空气在通道中比消毒剂微粒移动的速度快几倍(约5-6倍),消毒剂微粒由于其惯性附着在通道内壁上、再被空气流夹带并重新附着在其它位置。这个过程可以重复进行,其能实现对通道内壁的足够完全的润湿和灭菌。In the results of the tests carried out, the air moves in the channel several times faster (about 5-6 times) than the disinfectant particles, which due to their inertia adhere to the inner walls of the channel, are entrained by the air flow and re- attached to other locations. This process can be repeated, which achieves a sufficiently complete wetting and sterilization of the inner walls of the channel.

由于电离或空气分子的静电荷,涉及到了所有微生物。另一方面,要避免形成臭氧,由于臭氧破坏消毒剂或其组份。All microorganisms are involved due to ionization or electrostatic charge of air molecules. On the other hand, the formation of ozone is to be avoided since it destroys the disinfectant or its components.

附图说明Description of drawings

在下面将参照附图描述本发明的优选实施例。Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

图1示出了空气供给通道的示意图。Figure 1 shows a schematic diagram of the air supply channel.

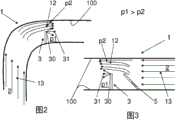

图2示出了弯曲的空气供给通道的截面的示意图,以及Figure 2 shows a schematic diagram of a section of a curved air supply channel, and

图3示出了笔直的空气供给通道的示意图,该空气供给通道具有用于操纵空气流的挡板。Figure 3 shows a schematic view of a straight air supply channel with baffles for manipulating the air flow.

其中,附图标记说明如下:Wherein, the reference signs are explained as follows:

1 空气供给通道1 air supply channel

100 内壁100 inner wall

2 空气流(箭头)2 Air flow (arrows)

3 喷注装置3 Injection device

30 喷嘴30 nozzles

31 喷注方向(箭头)31 Injection direction (arrow)

4 流传感器4 flow sensor

5 挡板5 baffles

7 电线7 wires

8 控制装置8 control device

9 管道9 pipes

10 泵10 pumps

11 容器11 containers

12 缩窄部12 constriction

13 最大横截面面积。13 Maximum cross-sectional area.

具体实施方式Detailed ways

图1示出了空气供给通道1的一部分,其中,空气流2用箭头2表示。流传感器4和喷注装置3在流动方向2上依次嵌入在空气供给通道1,喷注装置3具有用于使消毒剂雾化和喷射消毒剂的至少一个喷嘴30。在空气供给通道1的进一步延伸中,可以提供在这里未示出的、其它喷注装置3。这里描述的方法和装置尤其可以应用于空调系统中。FIG. 1 shows a part of an

这些元件通过电线7与控制装置8相连接。具有至少一个喷嘴30的喷注装置3与管道9连接,管道9引导至泵10,泵10将溶解在水中的消毒剂从容器11泵送到至少一个喷嘴30。当空气流2减小到低于某一阈值时,流传感器4可以关停泵10。此外,泵送操作可被调整到与空气流通量相匹配。These elements are connected to a

由至少一个喷嘴30生成的消毒剂气雾由大小约为50μm的微粒组成,其在空气流2的方向上沿喷注方向(31)喷注。通过在空气供给通道1内在空气流2的方向上的这种喷注,在微粒沉积在内壁100上之前,微粒可继续通过空气供给通道1、最好通过整个空气供给通道1被输送,微粒在内壁100上施展更长时间的消毒作用。The disinfectant mist generated by the at least one

在流体加速后面的区域、在较低的流速但较高的压力占主导的位置进行喷注是有利的。It is advantageous to inject in the region behind fluid acceleration, where lower flow rates but higher pressures prevail.

图1中喷注装置3被设置成使空气流2的一部分被遮蔽,从而在缩窄部12中导致较高的流速。如从文丘里(Venturi)管已知的,在空气供给通道1的缩窄部12与具有最大的横截面面积的区域13之间压力差占主导。In FIG. 1 the

在缩窄部12的区域,消毒剂通过喷嘴30被雾化喷注,从而微粒由于高流速而随空气流被夹带经过大的距离。高流速阻止了微粒迅速吸附在空气供给通道1的内壁100上。In the region of the

图2中所示的空气供给通道1的弯曲部导致流体加速,其中在弯曲部的较窄半径的一侧,在弯曲部的出口区域,较高压力p1占主导。在缩窄部12在较大半径的一侧的压力p2小于压力p1,且相应的空气流2的高流速在这一位置上出现。高流速携带被雾化的消毒剂微粒,由此使得在远离喷注装置3的区域内也能达到所希望的消毒剂分布。通过喷注装置3在缩窄部12的区域的这种设置确保了微粒在吸附在内壁100上之前大致均匀地分布在空气供给通道1中。The bend of the

在进一步的实施例中,使用设置在空气供给通道1的横截面内的挡板5,该实施例能够实现消毒剂在空气供给通道1的整个长度上沉积。这在图3中示意性地示出。挡板5在空气供给通道1中形成一缩窄部12,并迫使空气流2朝向通过缩窄部12的方向,在此也导致pl与p2之间出现压力差。在挡板5后喷注通过至少一个喷嘴30的朝向流体下游进行,从而使雾化的消毒剂沉积在空气供给通道1的广大的范围内。本实施方式中,挡板5也可以省略。In a further embodiment, using

若要加湿空气,则可以在空气供给通道中合适的位置上使水蒸发,水的量借助于湿度传感器由控制装置8控制。优选地,添加同一种消毒剂到水中,以防止引入真菌或藻类等。If the air is to be humidified, water can be evaporated at suitable points in the air supply channel, the amount of which is controlled by the

由于空气流从空气供给通道1最终达到工作或生活空间,该消毒剂应满足严格的健康控制要求。它不应该包含汞、苯酚、或类似的物质并且不应含酒精。Since the air flow from the

举例来说,可使用包括乳酸、维生素C和柠檬酸的生物杀灭剂产品,作为优选的用于本发明的方法和装置的消毒剂,所述生物杀灭剂产品可依申请人的商标“OLLOSTAT”而获得。这种消毒剂由瑞士联邦公共卫生部批准作为消毒剂使用。By way of example, biocide products including lactic acid, vitamin C and citric acid, available under the applicant's trademark " OLLOSTAT". This disinfectant is approved for use as a disinfectant by the Swiss Federal Ministry of Public Health.

Claims (10)

- One kind in air feed path (1) with the air method of disinfecting of nontoxic disinfectant to air flow (2), this air feed path (1) is the air feed path of air conditioning system particularly,It is characterized in that,Make described disinfectant be atomized into microgranule and also pass through at least one nozzle (30) of injection device (3) along the described microgranule of injection direction (31) spray, wherein said injection direction (31) is approximately equal to the direction of described air flow (2), and the Particle Distribution of described disinfectant can make described microgranule be adsorbed on the inwall (100) in the whole length of described air feed path (1) subsequently in described air flow (2) thus.

- One kind in air feed path (1) with the air method of disinfecting of nontoxic disinfectant to air flow (2), this air feed path (1) is the air feed path of air conditioning system particularly, wherein, make air ionization in described passage, at least make described airborne sterilization microgranule charged, and make described conduit wall remain on earth potential, thereby described charged corpuscle is deposited on the described conduit wall more quicklyIt is characterized in that,Make described disinfectant be atomized into microgranule and also spray described microgranule by at least one nozzle (30) of injection device (3) along injection direction (31), wherein said injection direction (31) is approximately equal to the direction of described air flow (2), and the Particle Distribution of described disinfectant makes described microgranule be deposited on the inwall (100) in the whole length of described air feed path (1) subsequently in described air flow (2) thus.

- 3. the method for disinfecting air according to claim 1 is characterized in that, the disinfectant injected shows as maintenance.

- 4. according to the method for each described disinfecting air in the claim 1 to 3, it is characterized in that, described injection occurs in the zone of narrowing portion (12) back, thereby fluid is accelerated, wherein, the pressure (p1) after described fluid accelerates is greater than the pressure (p2) in described narrowing portion (12) zone.

- 5. according to the method for claim 3 or 4 described disinfecting airs, it is characterized in that, realize in the described air feed path (1) that by described injection device (3) is arranged on described fluid accelerates.

- 6. according to the method for claim 3 or 4 described disinfecting airs, it is characterized in that, realize that by the bending section of described air feed path (1) described fluid accelerates, wherein, described injection device (3) is arranged on the less side of radius in the exit region of bending section.

- 7. according to the method for claim 3 or 4 described disinfecting airs, it is characterized in that described fluid accelerates to realize by the baffle plate (5) that is arranged in the described air feed path (1).

- 8. according to each described method in the aforementioned claim, it is characterized in that adopt the biocide product as disinfectant, described biocide product especially comprises lactic acid component, vitamin C and citric acid component.

- 9. be used for the device according to each described method disinfecting air of aforementioned claim, it is characterized in that, at described injection device (3) at least one nozzle (30) is set, provides disinfectant from container (11) for described injection device (3) by pipeline (9) and pump (10).

- 10. device according to claim 9 is characterized in that, controls, changes atomizing and the emitted dose of described disinfectant via electric wire (7) by control device (8).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2010/064255WO2012041362A1 (en) | 2010-09-27 | 2010-09-27 | Method for disinfecting air in air ducts |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103282059Atrue CN103282059A (en) | 2013-09-04 |

Family

ID=43127691

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201080069291XAPendingCN103282059A (en) | 2010-09-27 | 2010-09-27 | Method for disinfecting air in an air channel |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20130255285A1 (en) |

| EP (1) | EP2621547A1 (en) |

| JP (1) | JP5693735B2 (en) |

| CN (1) | CN103282059A (en) |

| AU (1) | AU2010361376A1 (en) |

| CA (1) | CA2812625A1 (en) |

| RU (1) | RU2013119370A (en) |

| WO (1) | WO2012041362A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106739967A (en)* | 2016-11-24 | 2017-05-31 | 谢馥伊 | A kind of air-conditioning device that human-body safety type thimerosal is sprayed with air-supply passage |

| CN107735184A (en)* | 2015-05-28 | 2018-02-23 | 首尔大学校产学协办团 | Ultrafine spray device |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2991436B1 (en)* | 2012-05-31 | 2016-10-14 | Stephane Jacky Boiral | APPARATUS FOR CONDITIONING THE AIR OF A ROOM OR CLOSED ENCLOSURE |

| US10758948B1 (en)* | 2019-04-01 | 2020-09-01 | William Edmund Harris | Apparatus and methods for cleaning and remediating environmental air handling apparatus |

| IT201700064157A1 (en)* | 2017-06-09 | 2018-12-09 | Dropsa Spa | Device and method of sanitizing an environment |

| IT201700064091A1 (en)* | 2017-06-09 | 2018-12-09 | Dropsa Spa | Device and method of sanitizing an environment |

| EP3929499A1 (en)* | 2020-06-25 | 2021-12-29 | TakeAir BV | System for injecting beneficial micro-organisms into an indoor environment |

| US12270572B2 (en)* | 2020-08-25 | 2025-04-08 | Regal Beloit America, Inc. | Systems and methods for controlling indoor air quality with a fluid moving apparatus |

| IT202100028973A1 (en)* | 2021-11-16 | 2023-05-16 | Ras Group Srl | SANITIZATION SYSTEM FOR AERAULIC SYSTEMS |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5648046A (en)* | 1992-04-28 | 1997-07-15 | Desostar Holland Bvio | Method and a system for disinfecting air in air conditioning ducts |

| CN1444999A (en)* | 2003-05-07 | 2003-10-01 | 李一平 | Large atomised disinfection passage |

| US7638114B1 (en)* | 1999-07-07 | 2009-12-29 | Schuer Joerg Peter | Method for disinfecting the air |

| US20100219259A1 (en)* | 2009-02-27 | 2010-09-02 | Mario Starcic | Hvac disinfection and aromatization system |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3503704A (en)* | 1966-10-03 | 1970-03-31 | Alvin M Marks | Method and apparatus for suppressing fumes with charged aerosols |

| JPH0385180A (en)* | 1989-08-15 | 1991-04-10 | Jerome H Remerson | Face mask |

| EP0687869A3 (en)* | 1994-06-13 | 1998-01-07 | CEPTER LTD., Switzerland | Process and device for eradicating pests from air |

| JP3501926B2 (en)* | 1997-09-19 | 2004-03-02 | プリマハム株式会社 | Meat processing method |

| JP2000257933A (en)* | 1999-03-10 | 2000-09-22 | Giken Kogyo Kk | Exhaust duct with deodorizing function |

| AU777167B2 (en)* | 1999-04-23 | 2004-10-07 | Battelle Memorial Institute | Directionally controlled EHD aerosol sprayer |

| JP2003047938A (en)* | 2001-08-08 | 2003-02-18 | Eiwa Kogyo:Kk | Garbage treatment machine |

| JP2003147694A (en)* | 2001-11-12 | 2003-05-21 | Nakadoi Riken Kk | Method for producing hazardous substance-eliminating material for food and daily necessities by mixing vitamin to paper or nonwoven fabric |

| JP4697625B2 (en)* | 2004-10-12 | 2011-06-08 | 俊介 細川 | Sterilization deodorization device |

| JP4966169B2 (en)* | 2007-11-21 | 2012-07-04 | パナソニック株式会社 | Blower |

| JP4915961B2 (en)* | 2008-05-27 | 2012-04-11 | パナソニック株式会社 | Air cleaner |

- 2010

- 2010-09-27AUAU2010361376Apatent/AU2010361376A1/ennot_activeAbandoned

- 2010-09-27RURU2013119370/15Apatent/RU2013119370A/ennot_activeApplication Discontinuation

- 2010-09-27EPEP10757771.0Apatent/EP2621547A1/ennot_activeWithdrawn

- 2010-09-27CNCN201080069291XApatent/CN103282059A/enactivePending

- 2010-09-27JPJP2013530582Apatent/JP5693735B2/ennot_activeExpired - Fee Related

- 2010-09-27CACA2812625Apatent/CA2812625A1/ennot_activeAbandoned

- 2010-09-27WOPCT/EP2010/064255patent/WO2012041362A1/enactiveApplication Filing

- 2010-09-27USUS13/876,206patent/US20130255285A1/ennot_activeAbandoned

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5648046A (en)* | 1992-04-28 | 1997-07-15 | Desostar Holland Bvio | Method and a system for disinfecting air in air conditioning ducts |

| US7638114B1 (en)* | 1999-07-07 | 2009-12-29 | Schuer Joerg Peter | Method for disinfecting the air |

| CN1444999A (en)* | 2003-05-07 | 2003-10-01 | 李一平 | Large atomised disinfection passage |

| US20100219259A1 (en)* | 2009-02-27 | 2010-09-02 | Mario Starcic | Hvac disinfection and aromatization system |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107735184A (en)* | 2015-05-28 | 2018-02-23 | 首尔大学校产学协办团 | Ultrafine spray device |

| CN107735184B (en)* | 2015-05-28 | 2020-08-18 | 首尔大学校产学协办团 | Super-fine particle spraying device |

| CN106739967A (en)* | 2016-11-24 | 2017-05-31 | 谢馥伊 | A kind of air-conditioning device that human-body safety type thimerosal is sprayed with air-supply passage |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013540008A (en) | 2013-10-31 |

| CA2812625A1 (en) | 2012-04-05 |

| US20130255285A1 (en) | 2013-10-03 |

| EP2621547A1 (en) | 2013-08-07 |

| JP5693735B2 (en) | 2015-04-01 |

| RU2013119370A (en) | 2014-11-10 |

| WO2012041362A1 (en) | 2012-04-05 |

| AU2010361376A1 (en) | 2013-04-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103282059A (en) | Method for disinfecting air in an air channel | |

| JP3357056B2 (en) | Method and apparatus for sterilizing air in air conditioning duct | |

| RU2623779C2 (en) | Method and plant for electrostatic painting | |

| US11135328B2 (en) | Apparatus for disinfecting an enclosed space | |

| EP2303340B1 (en) | Microaerosol-based decontamination method | |

| CN105025934A (en) | Main body and system comprising multiple nozzles for cleaning an object, in particular a medical product, and method for producing such a main body | |

| US20170246336A1 (en) | Device and method for diffusing a dry mist | |

| CN1871073A (en) | Device for atomizing a liquid composition | |

| EP2785467A1 (en) | Atomisation device | |

| JP2000051330A (en) | Method and device for sterilizing and deodorizing barn | |

| US9131704B2 (en) | Carbon dioxide based method and system for the humane mass culling of poultry and sterilization of rearing sheds | |

| KR20210001365U (en) | Decontamination system for space and surface with scrubbing device | |

| KR101834661B1 (en) | Spray device having spray nozzles installed in a air blast duct for spraying liquid chemical and spray apparatus using the same | |

| JP2005071899A (en) | Ultrasonic atomization type dust-free ionizer, and ultrasonic atomization type static elimination or dust elimination system | |

| CN102123741A (en) | Nebulizer manifold | |

| JP2005078980A (en) | Static eliminator | |

| CN111432852A (en) | Air purifier device | |

| WO2022139584A1 (en) | Method and device for purifying polluted air using dry and wet electrostatic treatment | |

| RU185062U1 (en) | Device for aerosol spraying liquids | |

| US12419980B2 (en) | Droplet bandpass filter | |

| CN100554799C (en) | Fogging device for maximum contamination removal | |

| US11602573B2 (en) | Cleaning system by means of artificial mist | |

| CN107899049A (en) | One kind disinfection water injection system | |

| CN213374078U (en) | Luggage article sterilizing device and security inspection system with same | |

| RU87626U1 (en) | AEROSOLATION DEVICE |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20130904 |