CN103149086A - Device and method for measuring toughness damage evolution in process of metal uniaxial tension - Google Patents

Device and method for measuring toughness damage evolution in process of metal uniaxial tensionDownload PDFInfo

- Publication number

- CN103149086A CN103149086ACN2013100126128ACN201310012612ACN103149086ACN 103149086 ACN103149086 ACN 103149086ACN 2013100126128 ACN2013100126128 ACN 2013100126128ACN 201310012612 ACN201310012612 ACN 201310012612ACN 103149086 ACN103149086 ACN 103149086A

- Authority

- CN

- China

- Prior art keywords

- strain

- resistance

- sample

- tensile sample

- tensile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription101

- 239000002184metalSubstances0.000titleclaimsabstractdescription22

- 239000000463materialSubstances0.000claimsdescription25

- 238000005259measurementMethods0.000claimsdescription19

- 239000007921spraySubstances0.000claimsdescription7

- 238000009864tensile testMethods0.000claimsdescription5

- 239000003292glueSubstances0.000claimsdescription4

- 238000006073displacement reactionMethods0.000claimsdescription2

- 239000003973paintSubstances0.000claimsdescription2

- 238000012360testing methodMethods0.000description11

- 238000010586diagramMethods0.000description9

- 239000007769metal materialSubstances0.000description5

- 238000012545processingMethods0.000description3

- 238000010276constructionMethods0.000description2

- 238000002360preparation methodMethods0.000description2

- 238000003672processing methodMethods0.000description2

- 238000005070samplingMethods0.000description2

- 229920001651CyanoacrylatePolymers0.000description1

- 239000004830Super GlueSubstances0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000005540biological transmissionEffects0.000description1

- 238000012937correctionMethods0.000description1

- 125000004122cyclic groupChemical group0.000description1

- 230000007547defectEffects0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000000691measurement methodMethods0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

Images

Landscapes

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及金属材料在塑性应变过程中的损伤演化技术领域,特别涉及一种测量金属单向拉伸中韧性损伤演化的装置及方法。 The invention relates to the technical field of damage evolution of metal materials in the process of plastic strain, in particular to a device and method for measuring ductile damage evolution in metal uniaxial stretching. the

背景技术Background technique

如何方便准确获取金属材料在塑性应变过程中的损伤演化一直以来都是一个难题。 How to conveniently and accurately obtain the damage evolution of metal materials during the plastic strain process has always been a difficult problem. the

目前测量损伤的主要方法有:1.直接测量;2.通过弹性模量的变化间接测量;3.超声波测量;4.通过微硬度的变化间接测量;5.通过密度变化间接测量;6.通过电阻变化间接测量。其中,在测量金属塑性应变过程中的损伤中,最为常用的一种方法是通过弹性模量的变化间接测量,即对拉伸试样实施循环加载卸载,通过监测卸载过程中的弹性模量的变化间接获取金属材料在塑性应变过程中的损伤量。但该方法存在以下几个问题:1.由于应变片的测量范围有限,因此当试样塑性应变较大时,需要多次更换应变片,使得试验过程非常繁琐、耗时,而且多次人工干预可能造成测量系统不稳定;2.拉伸试样在发生颈缩后,颈缩区域处于三向应力状态,这也使得弹性模量的获取不直观,需要做校正;3.该方法通常一次只能监测试样中某一个位置的弹性模量变化。正是由于这些缺陷,限制了这种方法在损伤测量中的进一步应用。 At present, the main methods of measuring damage are: 1. Direct measurement; 2. Indirect measurement through the change of elastic modulus; 3. Ultrasonic measurement; 4. Indirect measurement through the change of microhardness; 5. Indirect measurement through density change; 6. Through Indirect measurement of resistance change. Among them, in measuring the damage in the process of metal plastic strain, the most commonly used method is to measure indirectly through the change of elastic modulus, that is, to implement cyclic loading and unloading on the tensile sample, and to monitor the change of elastic modulus during the unloading process. The change indirectly obtains the damage amount of the metal material during the plastic strain process. However, this method has the following problems: 1. Due to the limited measurement range of the strain gauge, when the plastic strain of the sample is large, the strain gauge needs to be replaced many times, which makes the test process very cumbersome and time-consuming, and many times of manual intervention It may cause instability of the measurement system; 2. After the necking of the tensile sample occurs, the necking area is in a three-dimensional stress state, which also makes the acquisition of the elastic modulus unintuitive and needs to be corrected; 3. This method usually only It can monitor the change of elastic modulus at a certain position in the sample. It is precisely because of these defects that the further application of this method in damage measurement is limited. the

DCPD(直流电势降)方法是一种在断裂力学中测量裂纹大小时经常采用的方法。该方法对试样通直流电,然后通过电势的变化测量裂纹的大小。而目前该方法在损伤测量这块很少应用。主要原因有:1.由于金属试样的电阻率通常很小,通常DCPD方法中为了获得能准确测量的电压降,通常都需要在试样上通较大的电流(5A-10A,甚至更大),大电流的通过会导致试样的温度升高,会引起材料电阻率的变化;2.由于金属塑性应变过程中,材料的长度方向伸长,而宽度或径向变小,同样会引起电阻的变化;3.塑性应变过程中,由于材料发生塑性应变会导致材料的电阻率发生变化;4.在试样单向拉伸过程中,通常损伤都是与颈缩一起产生,因此由于局部塑性应变和损伤引起的材料电阻率发生的变化耦合在一起,传统的测量方法无法在颈缩阶段将两者很好的区分开发。正是由于这些困难,使得DCPD方法在损伤测量中应用不多。 The DCPD (Direct Current Potential Drop) method is a method often used in fracture mechanics to measure crack size. This method applies direct current to the sample, and then measures the size of the crack through the change of the potential. At present, this method is rarely used in damage measurement. The main reasons are as follows: 1. Since the resistivity of the metal sample is usually very small, in order to obtain a voltage drop that can be accurately measured in the DCPD method, it is usually necessary to pass a relatively large current (5A-10A, or even greater) on the sample. ), the passing of a large current will cause the temperature of the sample to rise, which will cause the change of the material resistivity; 3. In the process of plastic strain, the resistivity of the material will change due to the plastic strain of the material; 4. In the process of unidirectional stretching of the sample, the damage is usually produced together with the necking, so due to the local Plastic strain and damage-induced changes in material resistivity are coupled together, and traditional measurement methods cannot distinguish the two well during the necking stage. It is because of these difficulties that the DCPD method is rarely used in damage measurement. the

本发明主要通过结合DIC(数字图像相关性)方法和DCPD方法测量金属板材单向拉伸过程中的损伤演化。该方法的特点是DIC方法可以获得全场及局部塑性应变,结合DCPD方法可以很好的区分由于塑性应变(包括试样形状的变化和电阻率的变化)和由于损伤而导致电阻的变化,从而测量金属塑性应变过程中的损伤变化,且该方法的测量装置比较容易实施。 The invention mainly measures the damage evolution of the metal plate during uniaxial stretching by combining the DIC (Digital Image Correlation) method and the DCPD method. The characteristic of this method is that the DIC method can obtain the full-field and local plastic strain, combined with the DCPD method, it can well distinguish the change of electrical resistance due to plastic strain (including the change of sample shape and resistivity) and damage, so that The damage change in the process of metal plastic strain is measured, and the measuring device of the method is relatively easy to implement. the

发明内容Contents of the invention

本发明的发明目的是针对现有测量金属材料在塑性应变过程中的损伤演化的技术不足,提供一种测量金属单向拉伸中韧性损伤演化的装置及方法。 The purpose of the present invention is to provide a device and method for measuring the ductile damage evolution of metal materials in uniaxial stretching in view of the existing technical deficiencies in measuring the damage evolution of metal materials in the process of plastic strain. the

为实现上述发明目的,本发明采用的技术方案为: For realizing above-mentioned purpose of the invention, the technical scheme that the present invention adopts is:

提供一种测量金属单向拉伸中韧性损伤演化的装置,包括拉伸试样、绝缘板、夹具、光源、相机、直流低电阻测试仪与电脑;拉伸试样表面喷有黑白相间的自由散斑;相机和光源置于拉伸试样的正前方,且光源置于相机和拉伸试样之间;直流低电阻测试仪通过四个独立的金属夹子夹持在拉伸试样的直臂部分;绝缘板粘在拉伸试样两端的夹持部分, 夹具夹持在粘有绝缘板的夹持部分,拉伸试验机提供的拉伸载荷通过夹具作用于拉伸试样上。Provides a device for measuring the evolution of toughness damage in metal uniaxial tension, including tensile samples, insulating plates, fixtures, light sources, cameras, DC low resistance testers and computers; the surface of the tensile samples is sprayed with black and white free Speckle; the camera and light source are placed directly in front of the tensile sample, and the light source is placed between the camera and the tensile sample; the DC low resistance tester is clamped directly on the tensile sample by four independent metal clips. Arm part; the insulating plate is glued to the clamping part at both ends of the tensile sample, the clamp is clamped on the clamping part glued to the insulating plate, and the tensile load provided by the tensile testing machine acts on the tensile sample through the clamp.

优选地,所述绝缘板通过具有抗剪切能力的胶水粘在拉伸试样两端的夹持部分。为了保证电阻测量的准确性,通过在拉伸试样夹持处粘贴绝缘板,使得直流低电阻测试仪中的电流只通过拉伸试样,从而隔离夹具和拉伸机对电阻测量的影响。 Preferably, the insulating plate is glued to the clamping parts at both ends of the tensile sample by glue with shear resistance. In order to ensure the accuracy of the resistance measurement, an insulating plate is attached to the clamp of the tensile sample so that the current in the DC low resistance tester only passes through the tensile sample, thereby isolating the influence of the clamp and the tensile machine on the resistance measurement. the

进一步地,提供一种测量金属单向拉伸中韧性损伤演化的方法,相机和直流低电阻测试仪同时记录表面喷有随机自由散斑的试样拉伸过程中的图像和电阻,通过DIC方法获得试样拉伸过程中的应变场,结合试样拉伸过程中的应变增量和电阻增量,间接获取拉伸过程中的损伤演化规律。 Further, a method for measuring the ductile damage evolution in metal uniaxial tension is provided. The camera and the DC low resistance tester simultaneously record the image and resistance of the sample with random free speckle sprayed on the surface during the stretching process, through the DIC method The strain field during the stretching process of the sample is obtained, combined with the strain increment and resistance increment during the stretching process of the sample, the damage evolution law during the stretching process is obtained indirectly. the

具体的,包括以下步骤: Specifically, the following steps are included:

1)在拉伸试样表面喷涂随机自由散斑;1) Spray random free speckle on the surface of the tensile sample;

2)拉伸试样两端的夹持部分通过具有抗剪切能力的胶水粘有绝缘板,使拉伸试样与拉伸试验机进行绝缘,以保证在拉伸过程中电阻测量的准确性;2) The clamping parts at both ends of the tensile sample are glued to the insulating plate through glue with shear resistance, so that the tensile sample is insulated from the tensile testing machine to ensure the accuracy of resistance measurement during the stretching process;

3)单向拉伸试样通过夹具夹持并以2-5mm/min(按照试验标准ASTM-E8要求)的速度进行单向拉伸,该单向拉伸是指在拉伸试样的长度方向进行拉伸,(另外两个方向分别是宽度方向和厚度方向);拉伸试样的两端通直流电,同时测量拉伸试样标距内的电势差变化;相机按照固定的时间间隔记录拉伸试样表面自由散斑形状的照片,直至拉伸试样被拉断;在单向拉伸过程中,拉伸试样的应变分为均匀应变阶段与非均匀应变阶段,非均匀应变阶段也为颈缩阶段,该阶段是在均匀应变之后且拉伸试样被拉断之前发生的;3) The unidirectional tensile sample is clamped by the fixture and uniaxially stretched at a speed of 2-5mm/min (according to the test standard ASTM-E8 requirements). The unidirectional stretch refers to the length of the tensile sample Stretch in one direction (the other two directions are the width direction and the thickness direction); the two ends of the tensile sample are connected with direct current, and the change of the potential difference within the gauge length of the tensile sample is measured at the same time; the camera records the tensile force at a fixed time interval. Photos of the free speckle shape on the surface of the stretched sample until the tensile sample is broken; in the uniaxial stretching process, the strain of the tensile sample is divided into a uniform strain stage and a non-uniform strain stage, and the non-uniform strain stage is also is the necking phase, which occurs after uniform strain and before the tensile specimen is broken;

4)采用DIC方法处理相机拍摄的照片,获取每个时间点上单向拉伸过程中的全场位移和应变;4) Use the DIC method to process the photos taken by the camera to obtain the full-field displacement and strain during the uniaxial stretching process at each time point;

5)通过前后两个时间点的全场应变的对比,获得每个时间点上全场应变所对应的应变增量;5) By comparing the full-field strain at the two time points before and after, the strain increment corresponding to the full-field strain at each time point is obtained;

6)处理直流低电阻测试仪所记录的每个时间点上的电阻和电阻增量;6) Process the resistance and resistance increment at each time point recorded by the DC low resistance tester;

7)处理单向拉伸过程中的每个时间点上的电阻增量,将电阻增量按照塑性应变增量的大小进行线性分配;7) Process the resistance increment at each time point in the uniaxial stretching process, and linearly distribute the resistance increment according to the plastic strain increment;

8)处理单向拉伸均匀应变阶段的应变和电阻,获取均匀应变时的塑性应变和电阻以及塑性应变增量和电阻增量之间的关系;8) Process the strain and resistance in the uniform strain stage of uniaxial stretching, and obtain the relationship between plastic strain and resistance and the plastic strain increment and resistance increment during uniform strain;

9)处理单向拉伸非均匀应变阶段的应变增量和电阻增量之间的关系,分离由于塑性应变和由于损伤而引起的电阻变化,并剔除由于塑性应变而导致的电阻变化,获得仅仅由于损伤而引起的电阻增量;9) Deal with the relationship between the strain increment and the resistance increment in the non-uniform strain stage of uniaxial tension, separate the resistance change due to plastic strain and damage, and remove the resistance change due to plastic strain to obtain only resistance increase due to damage;

10)根据损伤和电阻之间的关系,最终获得塑性应变与损伤量之间的关系。10) According to the relationship between damage and electrical resistance, the relationship between plastic strain and damage amount is finally obtained.

优选地,步骤1)中,首先通过在拉伸试样表面喷涂白色手喷漆作为底色,然后再喷涂一层黑色散点,从而获得黑白相间的自由散斑。 Preferably, in step 1), first spray white hand-sprayed paint on the surface of the tensile sample as the base color, and then spray a layer of black scattered spots, so as to obtain black and white free speckles. the

步骤1)中,为保证试样应变计算的准确性,所述相机的镜头固定在三脚架上,且与拉伸试样表面保持垂直;相机记录照片的时间间隔视材料的不同而不同,至少拍摄40-50次以上;以保证能完全反映整个拉伸过程中材料的塑性应变;尤其是材料开始发生不均匀应变后,要保证有足够的数据点,以保证计算损伤演化规律时的准确性。 In step 1), in order to ensure the accuracy of the sample strain calculation, the lens of the camera is fixed on a tripod and kept perpendicular to the surface of the tensile sample; the time interval for the camera to record photos varies depending on the material, at least More than 40-50 times; to ensure that the plastic strain of the material during the entire stretching process can be fully reflected; especially after the material begins to undergo uneven strain, it is necessary to ensure that there are enough data points to ensure the accuracy of the calculation of the damage evolution law. the

优选地,所述直流低电阻测试仪的精度为10-6~10-5欧姆。由于金属的电阻率比较小,因此必须要采用高精度的直流低电阻测试仪,其精度最好应达到10-6~10-5欧姆。而且所通直流电如果太大,会导致材料在拉伸过程中温度升高以及材料力学性能发生明显变化,因此所通直流电最好要小于1安培。电阻值测量频率一般在每秒10次左右。 Preferably, the accuracy of the DC low resistance tester is 10-6 ~10-5 ohms. Since the resistivity of the metal is relatively small, a high-precision DC low resistance tester must be used, and its accuracy should preferably reach 10-6 ~10-5 ohms. Moreover, if the direct current is too large, the temperature of the material will rise during the stretching process and the mechanical properties of the material will change significantly, so the direct current preferably should be less than 1 ampere. The frequency of resistance value measurement is generally about 10 times per second.

优选地,步骤3)中,所通直流电小于1安培;电阻值测量频率为每秒9-11次。 Preferably, in step 3), the direct current applied is less than 1 ampere; the resistance measurement frequency is 9-11 times per second. the

本发明相对于现有技术,具有以下有益效果: Compared with the prior art, the present invention has the following beneficial effects:

本发明通过相机和直流低电阻测试仪同时记录表面喷有随机自由散斑的试样拉伸过程中的图像和电阻,通过DIC方法获得试样拉伸过程中的应变场,结合试样拉伸过程中的应变增量和电阻增量,间接获取拉伸过程中的损伤演化规律。首先分析试样均匀应变阶段的应变增量和电阻增量之间的关系,获得材料在只发生均匀塑性应变时的应变与电阻之间的关系;其次分析试样在非均匀应变阶段,即产生颈缩后的应变增量与电阻增量之间的关系,并与均匀应变阶段的应变-电阻关系进行对比分析,从而获得拉伸过程中的损伤演化规律;本发明的测试平台比较容易搭建,测量过程简单;采用DIC方法可以测量全场应变,无需对单向拉伸过程实施复杂加载卸载控制以及中断试验过程多次更换应变片,减少由于多次人工干预试验过程而带来的误差;同时,避免了对不均匀应变或颈缩发生后的三向应力状态进行校正;克服了单纯DCPD方法无法处理非均匀应变的缺点,拓展了该方法的应用范围,使之可以用来测量金属塑性应变过程中的韧性损伤。The invention simultaneously records the image and resistance of the sample stretching process with random free speckle sprayed on the surface through the camera and the DC low resistance tester, obtains the strain field in the sample stretching process by the DIC method, and combines the sample stretching The strain increment and resistance increment during the stretching process can be used to indirectly obtain the damage evolution law during the stretching process. First, analyze the relationship between the strain increment and the resistance increment in the uniform strain stage of the sample, and obtain the relationship between the strain and the electric resistance of the material when only uniform plastic strain occurs; secondly, analyze the sample in the non-uniform strain stage, that is, the The relationship between the strain increment after necking and the resistance increment is compared and analyzed with the strain-resistance relationship in the uniform strain stage, so as to obtain the damage evolution law in the stretching process; the test platform of the present invention is relatively easy to build, The measurement process is simple; the DIC method can be used to measure the full-field strain, and there is no need to implement complex loading and unloading controls for the uniaxial tensile process and interrupt the test process to replace the strain gauges multiple times, reducing errors caused by multiple manual interventions in the test process; at the same time , avoiding the correction of the three-dimensional stress state after inhomogeneous strain or necking; overcoming the shortcoming that the simple DCPD method cannot deal with inhomogeneous strain, expanding the application range of the method, so that it can be used to measure metal plastic strain ductile damage in the process.

附图说明Description of drawings

图1是测量金属单向拉伸中韧性损伤演化的装置及原理图; Figure 1 is the device and schematic diagram for measuring the ductile damage evolution in metal uniaxial tension;

图2是被测拉伸试样示意图;Fig. 2 is the schematic diagram of tested tensile sample;

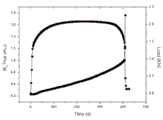

图3是SPCC材料时间-载荷曲线及时间-电阻曲线;Fig. 3 is SPCC material time-load curve and time-resistance curve;

图4是SPCC材料拉伸颈缩阶段某载荷步的应变分布图(正面);Figure 4 is the strain distribution diagram (front) of a certain load step in the tensile necking stage of the SPCC material;

图5是SPCC材料拉伸颈缩阶段某载荷步的应变分布图(侧面);Fig. 5 is the strain distribution diagram (side) of a load step in the tensile necking stage of the SPCC material;

图6是SPCC拉伸试样沿着拉伸方向的中间截面在整个拉伸过程中的应变变化;Figure 6 is the strain change of the middle section of the SPCC tensile sample along the tensile direction during the entire stretching process;

图7是SPCC拉伸标距内最大塑性应变位置的应变与材料损伤前后的电阻关系图;Figure 7 is a diagram of the relationship between the strain at the maximum plastic strain position in the SPCC tensile gauge and the resistance before and after material damage;

图8是SPCC拉伸试样标距内最大塑性应变位置的应变与损伤关系图;Figure 8 is a strain-damage relationship diagram of the maximum plastic strain position within the gauge length of the SPCC tensile specimen;

图9是SUS304材料时间-载荷曲线及时间-电阻曲线;Fig. 9 is the time-load curve and time-resistance curve of SUS304 material;

图10是SUS304材料拉伸颈缩阶段某载荷步的应变分布图(侧面);Figure 10 is the strain distribution diagram (side) of a certain load step in the tensile necking stage of the SUS304 material;

图11是SUS304拉伸试样标距内最大塑性应变位置的应变与材料损伤前后的电阻关系图;Figure 11 is a diagram of the relationship between the strain at the maximum plastic strain position within the gauge length of the SUS304 tensile sample and the resistance of the material before and after damage;

图12是SUS304拉伸试样标距内最大塑性应变位置的应变与损伤关系图。Figure 12 is a diagram of the relationship between strain and damage at the maximum plastic strain position within the gauge length of the SUS304 tensile sample.

具体实施方式Detailed ways

下面结合附图和具体实施例对本发明的发明目的作进一步详细地描述,实施例不能在此一一赘述,但本发明的实施方式并不因此限定于以下实施例。除非特别说明,本发明采用的材料和加工方法为本技术领域常规材料和加工方法。 The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments. Unless otherwise specified, the materials and processing methods used in the present invention are conventional materials and processing methods in the technical field. the

实施例1 Example 1

材料:SPCC(宝钢)Material: SPCC (Baosteel)

拉伸试样制备:按照ASTM标准小试样,通过线切割制备,几何尺寸如图2所示。Tensile sample preparation: According to the ASTM standard small sample, it is prepared by wire cutting, and the geometric dimensions are shown in Figure 2.

测试平台搭建:在图1中,在制备的拉伸试样1表面喷涂随机自由散斑,通过强力胶水在试样夹持部分粘上绝缘板2,然后通过拉伸试验机的夹具3把拉伸试样夹持住。在拉伸试样1的正面或旁边放置光源4,在正面一定距离处通过三脚架固定相机5,保证相机的镜头与拉伸试样表面垂直。直流低电阻测试仪6的四根引线分别接到拉伸试样1的直臂部分,需要注意的是这四根引线中有两根是通直流电,另外两根是测试电压降,因此通直流电的两根引线必须放在测电压降的两根引线的外面。最后,将相机5和直流低电阻测试仪6通过数据传输线接入电脑7,通过电脑7上的控制软件控制相应的拍摄参数和采样参数。为了保证拉伸在试样拉伸过程中,尤其是颈缩阶段能否有足够的数据,相机的拍摄速度可以控制在每两秒或五秒拍摄一张照片。直流低电阻测试仪的采样频率则可以控制在每秒采样两次到十次。 Test platform construction: In Figure 1, random free speckle is sprayed on the surface of the prepared

测试数据处理:在测试平台和仪器都准备好之后,就可开始拉伸试样1的单向拉伸。拉伸过程中,拉伸机记录拉伸过程中的载荷变化,拉伸试样的应变则通过相机1拍摄的图片记录,在拉伸过程中,拉伸试样标距部分的电阻变化则通过直流低电阻测试仪6记录,直到拉伸试样1被拉断。拉伸试样1和直流低电阻测试仪6所测试的数据如图3所示,分别记录了拉伸过程中载荷及电阻的变化。拉伸试样1在拉伸过程中的全场应变则通过DIC方法进行处理,其中颈缩阶段某个载荷步的全场应变分布如图4(正面)和图5(侧面)所示。以拉伸试样沿着拉伸方向的中间截面在整个拉伸过程中的应变变化如图6所示。 Test data processing: After the test platform and instruments are ready, the uniaxial stretching of the

把整个拉伸过程分成均匀拉伸阶段和非均匀拉伸阶段,在均匀拉伸阶段可以获取应变与电阻之间的关系,并认为在非均匀阶段,如果材料没有发生损伤,则这种关系仍然成立。在非均匀应变阶段,标距内由于塑性应变和损伤而引起的电阻增量按照应变增量的大小进行先行分配,由此可以获得拉伸试样标距内各点的塑性应变和电阻之间的关系。拉伸试样标距内最大塑性应变位置的应变与电阻之间的关系如图7所示。根据各点材料损伤前后电阻比值与损伤值之间的关系: ,可以进一步得到的各点随着塑性应变的增加,其损伤的变化情况,如图8所示。 Divide the entire stretching process into a uniform stretching stage and a non-uniform stretching stage. In the uniform stretching stage, the relationship between strain and resistance can be obtained, and it is considered that in the non-uniform stage, if the material is not damaged, the relationship is still established. In the non-uniform strain stage, the resistance increment caused by plastic strain and damage in the gauge length is distributed in advance according to the size of the strain increment, so that the relationship between the plastic strain and the resistance of each point in the tensile sample gauge length can be obtained Relationship. The relationship between the strain and the electrical resistance at the position of the maximum plastic strain within the gauge length of the tensile specimen is shown in Fig. 7. According to the relationship between the resistance ratio and the damage value of the material before and after damage at each point: , the change of damage of each point with the increase of plastic strain can be further obtained, as shown in Figure 8.

实施例2 Example 2

材料:SUS304(宝钢)Material: SUS304 (Baosteel)

试样制备:按照ASTM标准小试样,通过线切割制备,几何尺寸如图2所示。Sample preparation: According to the ASTM standard, small samples were prepared by wire cutting, and the geometric dimensions are shown in Figure 2.

测试平台搭建:与实施例1的步骤一致。 Test platform construction: the same as the steps in Example 1. the

测试数据处理:其数据处理的步骤和过程与实施例1相同。SUS304拉伸试样拉伸过程中的载荷及电阻的变化如图9所示。拉伸试样在拉伸过程中的颈缩阶段某个载荷步的全场应变分布如图10(侧面)所示。同样按照实施例1处理相应数据,可得到拉伸试样标距内最大塑性应变位置的应变与电阻之间的关系如图11所示。可以进一步得到各点随着塑性应变的增加,其损伤的变化情况,如图12所示。 Test data processing: the steps and process of its data processing are the same as in Example 1. The change of load and resistance during the stretching process of the SUS304 tensile sample is shown in Figure 9. The full-field strain distribution of a certain load step in the necking stage of the tensile specimen in the stretching process is shown in Fig. 10 (side). The corresponding data are also processed according to Example 1, and the relationship between the strain and the resistance at the maximum plastic strain position within the gauge length of the tensile sample can be obtained as shown in FIG. 11 . The change of damage of each point with the increase of plastic strain can be further obtained, as shown in Figure 12. the

上述实施例仅为本发明的较佳实施例,并非用来限定本发明的实施范围。即凡依本发明内容所作的均等变化与修饰,都为本发明权利要求所要求保护的范围所涵盖。 The above embodiments are only preferred embodiments of the present invention, and are not intended to limit the implementation scope of the present invention. That is, all equivalent changes and modifications made according to the content of the present invention are covered by the protection scope of the claims of the present invention. the

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310012612.8ACN103149086B (en) | 2013-01-15 | 2013-01-15 | Device and method for measuring toughness damage evolution in process of metal uniaxial tension |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310012612.8ACN103149086B (en) | 2013-01-15 | 2013-01-15 | Device and method for measuring toughness damage evolution in process of metal uniaxial tension |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN103149086Atrue CN103149086A (en) | 2013-06-12 |

| CN103149086B CN103149086B (en) | 2015-03-11 |

Family

ID=48547291

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310012612.8AExpired - Fee RelatedCN103149086B (en) | 2013-01-15 | 2013-01-15 | Device and method for measuring toughness damage evolution in process of metal uniaxial tension |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103149086B (en) |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104809362A (en)* | 2015-05-22 | 2015-07-29 | 辽宁工程技术大学 | Method for preparing speckle pattern including heterogeneous deformation based on numerical calculation |

| CN105865684A (en)* | 2016-04-06 | 2016-08-17 | 大连理工大学 | Comprehensive residual stress ultralow-temperature detection method of resin base composite material |

| CN108519381A (en)* | 2018-03-14 | 2018-09-11 | 上海交通大学 | Surface patch test method based on digital image correlation technology |

| CN108548834A (en)* | 2018-05-07 | 2018-09-18 | 湖南大学 | A kind of strain measurement method based on SEM in situ imaging systems |

| CN108593429A (en)* | 2018-06-21 | 2018-09-28 | 武汉钢铁有限公司 | Material high-speed stretch stress-strain test device and method |

| CN108760473A (en)* | 2018-07-28 | 2018-11-06 | 中国石油天然气集团有限公司 | A kind of method and experimental rig for the test of flexible composite pipe tensile property |

| CN108896388A (en)* | 2018-07-04 | 2018-11-27 | 福州大学 | A kind of power-pulse current coupling laboratory holder |

| CN110553909A (en)* | 2019-07-11 | 2019-12-10 | 华南理工大学 | offline data processing method combined with image processing |

| CN110658070A (en)* | 2019-11-18 | 2020-01-07 | 湖南沃尔丁科技有限公司 | High-speed metal sheet tensile test device driven by electromagnetic force |

| CN110987617A (en)* | 2019-12-11 | 2020-04-10 | 上海交通大学 | DIC (digital computer) measurement method for frequency conversion of tensile stress strain curve in necking stage by system |

| CN111795894A (en)* | 2020-09-08 | 2020-10-20 | 四川轻化工大学 | Non-contact method and system for measuring large deformation in uniaxial tension of polymer plastic materials |

| CN113281147A (en)* | 2021-05-08 | 2021-08-20 | 华中科技大学 | Method and device for detecting dynamic mechanical property of conductor material |

| CN113281165A (en)* | 2021-06-30 | 2021-08-20 | 燕山大学 | Limit test fixture and method for high-strength steel plate fracture in complex tension-compression path |

| CN113702162A (en)* | 2021-10-26 | 2021-11-26 | 如皋市宏茂铸钢有限公司 | Cylinder type mould steel toughness detection device |

| CN115326594A (en)* | 2022-07-28 | 2022-11-11 | 本钢板材股份有限公司 | Displacement measurement method for high-speed shearing deformation of material |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6247370B1 (en)* | 1999-01-25 | 2001-06-19 | Council Of Scientific And Industrial Research | Two dimensional stress relaxation testing device |

| JP2007078659A (en)* | 2005-09-16 | 2007-03-29 | Yamaguchi Univ | Method and apparatus for determining analysis conditions of digital image correlation method |

| CN101551350A (en)* | 2009-05-18 | 2009-10-07 | 南昌航空大学 | Method of establishing damnification self-diagnosis system for carbon fiber enhancement resin base composite material |

| CN202101900U (en)* | 2011-05-25 | 2012-01-04 | 山东大学 | DIC-based plate forming property test device |

- 2013

- 2013-01-15CNCN201310012612.8Apatent/CN103149086B/ennot_activeExpired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6247370B1 (en)* | 1999-01-25 | 2001-06-19 | Council Of Scientific And Industrial Research | Two dimensional stress relaxation testing device |

| JP2007078659A (en)* | 2005-09-16 | 2007-03-29 | Yamaguchi Univ | Method and apparatus for determining analysis conditions of digital image correlation method |

| CN101551350A (en)* | 2009-05-18 | 2009-10-07 | 南昌航空大学 | Method of establishing damnification self-diagnosis system for carbon fiber enhancement resin base composite material |

| CN202101900U (en)* | 2011-05-25 | 2012-01-04 | 山东大学 | DIC-based plate forming property test device |

Non-Patent Citations (1)

| Title |

|---|

| 陈忠等: "非接触数字图像相关应变测量的仿真与实验研究", 《测试技术学报》* |

Cited By (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104809362B (en)* | 2015-05-22 | 2018-04-06 | 辽宁工程技术大学 | It is a kind of to include heterogeneous deformation speckle pattern preparation method based on numerical computations |

| CN104809362A (en)* | 2015-05-22 | 2015-07-29 | 辽宁工程技术大学 | Method for preparing speckle pattern including heterogeneous deformation based on numerical calculation |

| CN105865684A (en)* | 2016-04-06 | 2016-08-17 | 大连理工大学 | Comprehensive residual stress ultralow-temperature detection method of resin base composite material |

| CN105865684B (en)* | 2016-04-06 | 2018-08-21 | 大连理工大学 | A kind of comprehensive residual stress low temperature detection method of polymer matrix composites |

| CN108519381A (en)* | 2018-03-14 | 2018-09-11 | 上海交通大学 | Surface patch test method based on digital image correlation technology |

| CN108548834A (en)* | 2018-05-07 | 2018-09-18 | 湖南大学 | A kind of strain measurement method based on SEM in situ imaging systems |

| CN108593429A (en)* | 2018-06-21 | 2018-09-28 | 武汉钢铁有限公司 | Material high-speed stretch stress-strain test device and method |

| CN108896388A (en)* | 2018-07-04 | 2018-11-27 | 福州大学 | A kind of power-pulse current coupling laboratory holder |

| CN108896388B (en)* | 2018-07-04 | 2024-03-12 | 福州大学 | Force-pulse current coupling action experimental clamp |

| CN108760473B (en)* | 2018-07-28 | 2020-11-06 | 中国石油天然气集团有限公司 | Method and test device for testing tensile property of flexible composite pipe |

| CN108760473A (en)* | 2018-07-28 | 2018-11-06 | 中国石油天然气集团有限公司 | A kind of method and experimental rig for the test of flexible composite pipe tensile property |

| CN110553909A (en)* | 2019-07-11 | 2019-12-10 | 华南理工大学 | offline data processing method combined with image processing |

| CN110658070A (en)* | 2019-11-18 | 2020-01-07 | 湖南沃尔丁科技有限公司 | High-speed metal sheet tensile test device driven by electromagnetic force |

| CN110658070B (en)* | 2019-11-18 | 2022-05-27 | 华瞬(深圳)智能装备有限公司 | High-speed metal sheet tensile test device driven by electromagnetic force |

| CN110987617A (en)* | 2019-12-11 | 2020-04-10 | 上海交通大学 | DIC (digital computer) measurement method for frequency conversion of tensile stress strain curve in necking stage by system |

| CN111795894A (en)* | 2020-09-08 | 2020-10-20 | 四川轻化工大学 | Non-contact method and system for measuring large deformation in uniaxial tension of polymer plastic materials |

| CN111795894B (en)* | 2020-09-08 | 2020-12-08 | 四川轻化工大学 | Non-contact method and system for measuring large deformation in uniaxial tension of polymer plastic materials |

| CN113281147A (en)* | 2021-05-08 | 2021-08-20 | 华中科技大学 | Method and device for detecting dynamic mechanical property of conductor material |

| CN113281165A (en)* | 2021-06-30 | 2021-08-20 | 燕山大学 | Limit test fixture and method for high-strength steel plate fracture in complex tension-compression path |

| CN113281165B (en)* | 2021-06-30 | 2022-09-06 | 燕山大学 | Limit test fixture and method for high-strength steel plate fracture in complex tension-compression path |

| CN113702162A (en)* | 2021-10-26 | 2021-11-26 | 如皋市宏茂铸钢有限公司 | Cylinder type mould steel toughness detection device |

| CN115326594A (en)* | 2022-07-28 | 2022-11-11 | 本钢板材股份有限公司 | Displacement measurement method for high-speed shearing deformation of material |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103149086B (en) | 2015-03-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103149086B (en) | Device and method for measuring toughness damage evolution in process of metal uniaxial tension | |

| CN110672441A (en) | Characterization method of crack tip state in fatigue crack propagation process | |

| CN107121267B (en) | Test device and test method for angle of view of lens | |

| CN110631485B (en) | A cable conductor comprehensive tester | |

| CN103245727B (en) | A kind of micro-meter scale material internal friction and modulus measurement mechanism | |

| CN111426563A (en) | 3D printing sample tensile failure performance analysis method | |

| CN105758719B (en) | A kind of homogeneous strain optical measuring device and method based on bimirror reflection | |

| CN101182994A (en) | Method for Non-Contact Measurement of Indirect Tensile Strain | |

| EP3561468A1 (en) | Stress measurement method, stress measurement device, and stress measurement system | |

| CN204405516U (en) | A kind of laminated-metal composite interface peel strength testing device | |

| CN101430352B (en) | Measuring system and method for tangential piezoelectric strain constant of piezoelectric material by quasi-static method | |

| CN113419118A (en) | Device and method for measuring piezoelectric coefficient under uniaxial depression of ferroelectric crystal | |

| CN105841926B (en) | Rapid positioning device and positioning method for optical system test | |

| CN102359908B (en) | Test control system and method used for viscous-elastic material bending fatigue test | |

| CN113720270B (en) | A method, system, device, and storage medium for online measurement of board device warpage | |

| CN204302390U (en) | A kind of strain of synchro measure small size conducing composite material and the device of resistance | |

| CN206546296U (en) | A kind of through groove fixture for micro- gauge length lamellar sample extension test | |

| CN204202571U (en) | A kind of non-contact type extensometer | |

| CN113533047B (en) | A Method for Obtaining Dynamic Tensile Stress-Strain Curves of Rocks | |

| CN103293058A (en) | Crack monitoring device and crack monitoring method | |

| CN104062735A (en) | Clamping device and clamping method for large-aperture diffraction grating | |

| CN104535944A (en) | Magneto-electric coupling dynamic microscopic observation and measurement system | |

| CN111693776A (en) | Indoor soil sample resistivity measuring device | |

| CN203117036U (en) | Device for tensile testing of small test piece made of non-metal material | |

| CN206772560U (en) | The test device of the angle of view |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20150311 | |

| CF01 | Termination of patent right due to non-payment of annual fee |