CN103112651A - External fixed plug - Google Patents

External fixed plugDownload PDFInfo

- Publication number

- CN103112651A CN103112651ACN2011103629948ACN201110362994ACN103112651ACN 103112651 ACN103112651 ACN 103112651ACN 2011103629948 ACN2011103629948 ACN 2011103629948ACN 201110362994 ACN201110362994 ACN 201110362994ACN 103112651 ACN103112651 ACN 103112651A

- Authority

- CN

- China

- Prior art keywords

- cork

- adapter plate

- joint portion

- fixed plug

- knock hole

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000463materialSubstances0.000claimsabstractdescription27

- 239000007799corkSubstances0.000claimsdescription58

- 238000000926separation methodMethods0.000claimsdescription6

- 230000000694effectsEffects0.000abstractdescription10

- 239000012611container materialSubstances0.000description6

- 230000008878couplingEffects0.000description5

- 238000010168coupling processMethods0.000description5

- 238000005859coupling reactionMethods0.000description5

- 239000011521glassSubstances0.000description5

- 239000004033plasticSubstances0.000description5

- 229920003023plasticPolymers0.000description5

- 229910052573porcelainInorganic materials0.000description5

- 239000004677NylonSubstances0.000description3

- 238000000034methodMethods0.000description3

- 229920001778nylonPolymers0.000description3

- 229920002725thermoplastic elastomerPolymers0.000description3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000description2

- 239000000853adhesiveSubstances0.000description2

- 230000001070adhesive effectEffects0.000description2

- 239000000741silica gelSubstances0.000description2

- 229910002027silica gelInorganic materials0.000description2

- 238000001816coolingMethods0.000description1

- 229920001971elastomerPolymers0.000description1

- 238000005516engineering processMethods0.000description1

- 238000010304firingMethods0.000description1

- 238000004519manufacturing processMethods0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 239000002699waste materialSubstances0.000description1

Images

Landscapes

- Closures For Containers (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种外接式固定塞,尤其是涉及一种可以直接与一盖体结合、用以将容器的开口封闭的固定塞。The invention relates to an external fixed plug, in particular to a fixed plug which can be directly combined with a cover to close the opening of a container.

背景技术Background technique

如图1所示,图1是一种公知的固定塞9,其由一本体91与一塞体92结合,本体91与塞体92之间有较为牢固的结合,本体91上设置有凸出环911和缺槽912,而塞体92则设置有相对应的嵌槽921与肋条922,通过塞体92的可张闭弹性,使该固定塞9可以塞入在容器的口部,塞体92通常为公知的橡胶或发泡塑料等。As shown in Figure 1, Figure 1 is a known

已知瓶、罐、坛、瓮等容器,利用玻璃、陶、瓷等材料制造,因此该本体91通常会以与容器相同的玻璃、陶、瓷等材料制成。在制造该容器时,该容器的口部内径常因烧制及冷却温度、时间而有不同的收缩比率,对于玻璃材料制造的容器,其口部内径约有±0.5mm的公差,对于陶、瓷等材料制造的容器,其口部内径约有±1.0mm的公差。而该塞体92由于在现有技术下,其直径较被容易控制,因此,该塞体92直径通常被制造成大于该容器口部内径之上差直径,使该固定塞9的塞体92可以成较紧密的塞入在该容器的口部。Containers such as known bottles, jars, altars, and urns are made of materials such as glass, pottery, and porcelain, so the

只有当欲将该固定塞9由容器的口部取出时,该塞体92与容器的口部形成干涩状态下,若仅靠该塞体92的可压缩变形弹性,欲将该固定塞9从容器的口部取出,变得困难与不容易,以致于该塞体92与本体91间会形成脱落。Only when the

因此,业界于是有以PE、ABS、NYLON等塑料材料先射制成型该本体91后,再将该本体91置入于成型塞体92的模具内,将热塑性橡胶一体成型在该本体91的外表面,由于该本体91的外表面系设置有凸出的环等结合部911,因此该塞体92的内环面即可以依该本体91的结合部911形成一体结合。Therefore, in the industry, there are plastic materials such as PE, ABS, NYLON, etc. to inject and mold the

该一体成型的固定塞,虽然较前述以组装方式所形成的固定塞具有较为牢固的结合效果。但由于该本体若以PE、ABS、NYLON等塑料材料制成,且该固定塞9使用在容器时,由于该本体91的塑料材料与由玻璃、陶、瓷等材料制成的容器不一致,因此,该固定塞9的使用就受到限制。Although the integrally formed fixing plug has a firmer bonding effect than the aforementioned fixing plug formed in an assembled manner. But if this body is made of plastic materials such as PE, ABS, NYLON, and when this

于是有些人制成一无帽头的本体,由该本体以黏着剂黏合在一与容器相同材料制成的盖,如此该盖与容器的材料可以相同,使该容器有较佳的外观。但利用黏着剂黏合该本体与盖,经过一段时间之后,由该容器上欲取出该盖时,该盖与本体之间极易形成断损,进而造成使用者之不便。So some people make a body without a cap, and the body is bonded to a cover made of the same material as the container with an adhesive, so that the cover and the container can be made of the same material, so that the container has a better appearance. However, if the body and the cover are bonded with an adhesive, after a period of time, when the cover is to be taken out from the container, breakage is easily formed between the cover and the body, which causes inconvenience to the user.

发明内容Contents of the invention

本发明的目的是为了提供一种外接式固定塞,该外接式固定塞可以牢固地与容器材料相同的盖体结合在一起,以避免该固定塞与盖体形成脱落者。The purpose of the present invention is to provide an external fixed plug, which can be firmly combined with the cover of the same container material, so as to prevent the fixed plug from falling off from the cover.

本发明的另一目的是为了提供一种外接式固定塞,由于该固定塞可以与容器材料相同的盖体结合在一起,如此该外接式固定塞可具有较佳的外观形状。Another object of the present invention is to provide an external fixed plug. Since the fixed plug can be combined with the lid of the same container material, the external fixed plug can have a better appearance shape.

为了达到本发明的发明目的,本发明的外接式固定塞,所述外接式固定塞包括:一个本体,所述本体包含有一个固定板,在所述固定板上设置有一个定位孔,在所述固定板的一表面的定位孔周边各设置有一个延伸部,每个延伸部朝向所述定位孔的内壁面,在所述内壁面设置有一个第一结合部;以及一个软塞,所述软塞由可变形材料制成,所述软塞结合在所述本体的外壁面。In order to achieve the purpose of the present invention, the external fixed plug of the present invention, the external fixed plug includes: a body, the body contains a fixed plate, a positioning hole is arranged on the fixed plate, and Each of the positioning holes on one surface of the fixing plate is provided with an extension, each extension faces the inner wall of the positioning hole, and a first joint is arranged on the inner wall; and a cork, the The cork is made of deformable material, and the cork is combined with the outer wall of the body.

优选地,所述软塞与所述本体一体成型。Preferably, the cork is integrally formed with the body.

优选地,所述本体的数个延伸部外壁面各设置有凸条,所述软塞的内壁面设置有环槽,所述环槽与所述凸条相对应结合。Preferably, each of the outer walls of the extensions of the body is provided with a raised line, and the inner wall of the cork is provided with an annular groove, and the annular groove is correspondingly combined with the raised line.

优选地,所述本体的数个延伸部外壁面各设置有凹槽,所述软塞的内壁面设置有凸条,所述凹槽与所述凸条相对应结合。所述本体的凹槽直接形成为凸出在内壁面的第一结合部。Preferably, grooves are provided on the outer walls of several extension parts of the body, convex lines are provided on the inner wall of the cork, and the grooves are combined with the convex lines correspondingly. The groove of the body is directly formed as the first joint portion protruding from the inner wall surface.

优选地,数个延伸部的相邻部位形成有不连接的一个分离部。Preferably, adjacent parts of several extension parts are formed with a separate part which is not connected.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端连接于一个封闭板。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions are connected to a closing plate.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端形成未连接的开放端。数个延伸部的开放端以一个封闭板封闭。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions form unconnected open ends. The open ends of several extensions are closed with a closing plate.

本发明还提供了另一外接式固定塞,所述外接式固定塞包括:一个本体,所述本体包含有一个固定板,在所述固定板上设置有一个定位孔,形成所述定位孔的所述固定板的周边至少设置有一个第一结合部,所述固定板的一表面的定位孔周边各设置有一个延伸部;以及一个软塞,所述软塞由可变形材料制成,所述软塞结合在所述本体的外壁面。The present invention also provides another external fixing plug, which includes: a body, the body includes a fixing plate, and a positioning hole is arranged on the fixing plate, forming the positioning hole The periphery of the fixed plate is provided with at least one first joint portion, and the periphery of the positioning holes on one surface of the fixed plate is respectively provided with an extension portion; and a cork, the cork is made of a deformable material, so The cork is combined with the outer wall of the body.

优选地,所述软塞与所述本体一体成型。Preferably, the cork is integrally formed with the body.

优选地,所述本体的数个延伸部外壁面各设置有凸条,所述软塞的内壁面设置有环槽,所述环槽与所述凸条相对应结合。Preferably, each of the outer walls of the extensions of the body is provided with a raised line, and the inner wall of the cork is provided with an annular groove, and the annular groove is correspondingly combined with the raised line.

优选地,所述本体的数个延伸部外壁面各设置有凹槽,所述软塞的内壁面设置有凸条,所述凹槽与所述凸条相对应结合。所述本体的凹槽直接形成为凸出在内壁面的第一结合部。Preferably, grooves are provided on the outer walls of several extension parts of the body, convex lines are provided on the inner wall of the cork, and the grooves are combined with the convex lines correspondingly. The groove of the body is directly formed as the first joint portion protruding from the inner wall surface.

优选地,数个延伸部的相邻部位形成有不连接的一个分离部。Preferably, adjacent parts of several extension parts are formed with a separate part which is not connected.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端连接于一个封闭板。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions are connected to a closing plate.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端形成未连接的开放端。数个延伸部的开放端以一个封闭板封闭。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions form unconnected open ends. The open ends of several extensions are closed with a closing plate.

优选地,所述本体的柱杆与定位孔的断面形状,形成相吻合的非正圆形状。优选地,所述本体的第一结合部为凸出的钩体,所述盖体的第二结合部为一环设于柱杆外周的槽。优选地,所述第一结合部一端连接在该固定板,所述第一结合部的另一端形成开放端,且朝向该定位孔方向凸出。Preferably, the cross-sectional shape of the pole of the body and the positioning hole forms a non-circular shape that matches. Preferably, the first joint part of the body is a protruding hook, and the second joint part of the cover is a groove provided around the outer periphery of the pole. Preferably, one end of the first coupling part is connected to the fixing plate, and the other end of the first coupling part forms an open end and protrudes toward the positioning hole.

此外,本发明还提供了一外接式固定塞,所述外接式固定塞包括:所述外接式固定塞包括:一个本体,所述本体包含有一个固定板,在所述固定板上设置有一个定位孔,在所述固定板的一表面的定位孔周边各设置有一个延伸部,每个延伸部朝向所述定位孔的内壁面,在所述内壁面设置有一个第一结合部;一个软塞,所述软塞由可变形材料制成,所述软塞结合在所述本体的外壁面;以及一个盖体,所述盖体具有一个内表面,所述内表面设置有一个柱杆,所述柱杆设置有第二结合部,所述第二结合部能够与所述本体的第一结合部相结合。In addition, the present invention also provides an external fixed plug, the external fixed plug includes: the external fixed plug includes: a body, the body includes a fixed plate, and a fixed plate is arranged on the fixed plate The positioning hole is provided with an extension part on the periphery of the positioning hole on a surface of the fixing plate, and each extension part faces the inner wall surface of the positioning hole, and a first joint part is arranged on the inner wall surface; a soft a plug, the cork is made of deformable material, the cork is combined with the outer wall of the body; and a cover, the cover has an inner surface, and the inner surface is provided with a post, The post is provided with a second combining portion, and the second combining portion can be combined with the first combining portion of the body.

优选地,所述软塞与所述本体一体成型。Preferably, the cork is integrally formed with the body.

优选地,所述本体的数个延伸部外壁面各设置有凸条,所述软塞的内壁面设置有环槽,所述环槽与所述凸条相对应结合。Preferably, each of the outer walls of the extensions of the body is provided with a raised line, and the inner wall of the cork is provided with an annular groove, and the annular groove is correspondingly combined with the raised line.

优选地,所述本体的数个延伸部外壁面各设置有凹槽,所述软塞的内壁面设置有凸条,所述凹槽与所述凸条相对应结合。所述本体的凹槽直接形成为凸出在内壁面的第一结合部。Preferably, grooves are provided on the outer walls of several extension parts of the body, convex lines are provided on the inner wall of the cork, and the grooves are combined with the convex lines correspondingly. The groove of the body is directly formed as the first joint portion protruding from the inner wall surface.

优选地,数个延伸部的相邻部位形成有不连接的一个分离部。Preferably, adjacent parts of several extension parts are formed with a separate part which is not connected.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端连接于一个封闭板。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions are connected to a closing plate.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端形成未连接的开放端。数个延伸部的开放端以一个封闭板封闭。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions form unconnected open ends. The open ends of several extensions are closed with a closing plate.

再有,本发明还提供了一外接式固定塞,所述外接式固定塞包括:一个本体,所述本体包含有一个固定板,在所述固定板上设置有一个定位孔,形成该定位孔的该固定板周边至少设置有一个第一结合部,所述固定板的一表面的定位孔周边各设置有一个延伸部;一个软塞,由可变形材料制成,所述软塞结合在所述本体的外壁面;以及一个盖体,所述盖体具有一个内表面,所述内表面设置有一个柱杆,所述柱杆设置有第二结合部,所述第二结合部能够与所述本体的第一结合部相结合。Moreover, the present invention also provides an externally connected fixing plug, which includes: a body, the body includes a fixing plate, and a positioning hole is arranged on the fixing plate to form the positioning hole The periphery of the fixing plate is provided with at least one first joint portion, and the periphery of the positioning holes on one surface of the fixing plate is respectively provided with an extension portion; a cork is made of deformable material, and the cork is bonded to the The outer wall surface of the body; and a cover, the cover has an inner surface, the inner surface is provided with a pole, the pole is provided with a second joint part, and the second joint part can be connected with the combined with the first joint portion of the body.

优选地,所述软塞与所述本体一体成型。Preferably, the cork is integrally formed with the body.

优选地,所述本体的数个延伸部外壁面各设置有凸条,所述软塞的内壁面设置有环槽,所述环槽与所述凸条相对应结合。Preferably, each of the outer walls of the extensions of the body is provided with a raised line, and the inner wall of the cork is provided with an annular groove, and the annular groove is correspondingly combined with the raised line.

优选地,所述本体的数个延伸部外壁面各设置有凹槽,所述软塞的内壁面设置有凸条,所述凹槽与所述凸条相对应结合。所述本体的凹槽直接形成为凸出在内壁面的第一结合部。Preferably, grooves are provided on the outer walls of several extension parts of the body, convex lines are provided on the inner wall of the cork, and the grooves are combined with the convex lines correspondingly. The groove of the body is directly formed as the first joint portion protruding from the inner wall surface.

优选地,数个延伸部的相邻部位形成有不连接的一个分离部。Preferably, adjacent parts of several extension parts are formed with a separate part which is not connected.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端连接于一个封闭板。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions are connected to a closing plate.

优选地,数个延伸部的第一端与固定板连接,数个延伸部的第二端形成未连接的开放端。数个延伸部的开放端以一个封闭板封闭。Preferably, the first ends of the several extensions are connected to the fixing plate, and the second ends of the several extensions form unconnected open ends. The open ends of several extensions are closed with a closing plate.

优选地,所述本体的柱杆与定位孔的断面形状,形成相吻合的非正圆形状。优选地,所述本体的第一结合部为凸出的钩体,所述盖体的第二结合部为一环设于柱杆外周的槽。优选地,所述第一结合部一端连接在该固定板,所述第一结合部的另一端形成开放端,且朝向该定位孔方向凸出。Preferably, the cross-sectional shape of the pole of the body and the positioning hole forms a non-circular shape that matches. Preferably, the first joint part of the body is a protruding hook, and the second joint part of the cover is a groove provided around the outer periphery of the pole. Preferably, one end of the first coupling part is connected to the fixing plate, and the other end of the first coupling part forms an open end and protrudes toward the positioning hole.

由此,本发明的外接式固定塞可以方便、牢固地与容器材料相同的盖体结合,如此,本发明具有可以防止该固定塞与盖体脱落效果之功效。本发明的外接式固定塞,由于该固定塞可以与容器材料相同的盖体结合,如此本发明的固定塞具有较佳外观效果的功效。Thus, the external fixing plug of the present invention can be conveniently and firmly combined with the cover of the same container material, so that the present invention has the effect of preventing the fixing plug and the cover from falling off. The external fixed plug of the present invention can be combined with the cover body of the same container material, so the fixed plug of the present invention has the effect of better appearance effect.

附图说明Description of drawings

图1表示公知的固定塞构造分解立体图。FIG. 1 shows an exploded perspective view of a known fixing plug structure.

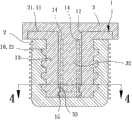

图2表示本发明的第一实施例分解立体图。Fig. 2 shows an exploded perspective view of the first embodiment of the present invention.

图3表示本发明的第一实施例组合剖面图。Fig. 3 shows an assembled sectional view of the first embodiment of the present invention.

图4表示沿图3的4-4线剖面图。Fig. 4 shows a sectional view along line 4-4 of Fig. 3 .

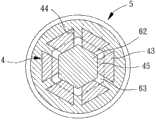

图5表示本发明的第二实施例分解立体图。Fig. 5 shows an exploded perspective view of a second embodiment of the present invention.

图6表示本发明的第二实施例组合剖面图。Fig. 6 shows an assembled sectional view of a second embodiment of the present invention.

图7表示沿图6的7-7线剖面图。Fig. 7 shows a sectional view along line 7-7 of Fig. 6 .

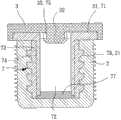

图8表示本发明的第三实施例分解立体图。Fig. 8 shows an exploded perspective view of a third embodiment of the present invention.

图9表示本发明的第三实施例未结合时的剖面图。Fig. 9 shows a sectional view of the third embodiment of the present invention when it is not combined.

图10表示沿图9的10-10线视图。Figure 10 shows a view along line 10-10 of Figure 9 .

图11表示本发明的第三实施例结合过程的剖面图。Fig. 11 shows a cross-sectional view of the bonding process of the third embodiment of the present invention.

图12表示本发明的第三实施例结合时的剖面图。Fig. 12 shows a cross-sectional view of the third embodiment of the present invention when combined.

主要附图标记说明:Explanation of main reference signs:

本发明部分:1本体、11固定板、12定位孔、13延伸部、14分离部、15第一结合部、16凸条、2软塞、21环槽、3盖体、31内表面、32柱杆、33第二结合部、4本体、41固定板、42定位孔、43延伸部、44分离部、45第一结合部、46凹槽、47连接部、48间距、49封闭板、5软塞、51凸条、6盖体、61内表面、62柱杆、63第二结合部、7本体、71固定板、72定位孔、73延伸部、74分离部、75第一结合部、76凹槽、77封闭板;Parts of the present invention: 1 body, 11 fixing plate, 12 positioning hole, 13 extension part, 14 separation part, 15 first joint part, 16 convex strip, 2 soft plug, 21 ring groove, 3 cover body, 31 inner surface, 32 Column rod, 33 second joint part, 4 body, 41 fixed plate, 42 positioning hole, 43 extension part, 44 separation part, 45 first joint part, 46 groove, 47 connection part, 48 distance, 49 closed plate, 5 Soft plug, 51 convex strip, 6 cover body, 61 inner surface, 62 column rod, 63 second joint part, 7 body, 71 fixing plate, 72 positioning hole, 73 extension part, 74 separation part, 75 first joint part, 76 grooves, 77 closed plates;

公知部分:9固定塞、91本体、911凸出环、912缺槽、92塞体、921嵌槽、922肋条。Known parts: 9 fixed plug, 91 body, 911 protruding ring, 912 missing groove, 92 plug body, 921 embedded groove, 922 rib.

具体实施方式Detailed ways

为使贵审查员能进一步了解本发明的结构、特征及其它目的,现结合所附较佳实施例附以附图详细说明如下,本附图所说明的实施例仅用于说明本发明的技术方案,并非限定本发明。其中相同组件将以相同的附图标记加以说明。In order to enable your examiners to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now attached in detail with the accompanying drawings as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technology of the present invention scheme, not to limit the present invention. The same components will be described with the same reference numerals.

如图2所示,图2表示本发明的外接式固定塞第一较佳实施例,该外接式固定塞由一本体1和一软塞2所构成,该软塞2可以与本体1结合为一固定塞,该固定塞可供一盖体3结合。As shown in Figure 2, Figure 2 shows the first preferred embodiment of the external fixed plug of the present invention, the external fixed plug is composed of a

该本体1由PE、ABS、NYLON等塑料材料制成,该本体1在一固定板11上设置有一定位孔12,该定位孔12可以为各种几何形状,其可以为圆形、三角形、方形、多边形等各种形状,其较佳为非正圆的形状,在本实施例中是以四边形予以说明,该固定板11由其一表面的定位孔12周边各设置有一延伸部13,数个延伸部13相邻部位较佳地形成不连接的形态,使得各个延伸部13之间形成有一分离部14,以使该各延伸部13可以作径向扩张。在数个延伸部13朝向该定位孔12的内壁面至少设置有一第一结合部15,该第一结合部15可以为凸出的钩体,在本实施例中,数个延伸部13的内壁面各设置有该第一结合部15。数个延伸部13另外还有一外壁面,该外壁面可以供软塞2结合,该外壁面可以设置有凸条16,使该软塞2可以成为较为牢固地结合。The

该软塞2可以由热塑性橡胶、硅胶等可变形材料经由模具成型为一筒形状,该软塞2可以结合在本体1的外壁面以形成一瓶塞,在本实施例当中,该软塞2可以与本体1一体成型为一固定塞。为了使该软塞2与本体1可形成较为牢固地结合,该筒形状的软塞2内壁面还可以设置有环槽21,该环槽21可以与本体1的凸条16相对应结合,使该软塞2与本体1的结合更为牢固。The

该盖体3可以由玻璃、陶、瓷等与容器相同材料所制成,该盖体3可供已相结合的软塞2与本体1再结合以形成一固定塞。该盖体3具有一内表面31,该内表面31对应于本体1的固定板11,且在该盖体3的内表面31设置有一柱杆32,该柱杆32竖立在该内表面31。该柱杆32设置有第二结合部33,该第二结合部33可以与本体1的第一结合部15相结合,在本实施例中,该第二结合部33为一环设于柱杆32外周的槽,该本体1的第一结合部15为凸出的钩,由该第二结合部33可以与第一结合部15相结合。该柱杆32的外壁面与定位孔12的内壁面的断面形状,较佳系形成相吻合的非正圆形状,使该柱杆32结合在定位孔12后,该柱杆32与定位孔12之间无法作相对的旋转,在本实施例中,该柱杆32的外壁面与定位孔12的内壁面的断面形状形成四边形。The

如图3、4所示,图3、4表示本发明第一实施例的组合情形,该软塞2被结合在本体1以形成一固定塞,在本实施例中,该软塞2与本体1一体成型为一固定塞,且该固定塞还可以供盖体3结合,即该盖体3由其柱杆32结合在本体1的定位孔12,如此,该盖体3与该固定塞的结合可以更为方便,且不会有脱落的可能。As shown in Figures 3 and 4, Figures 3 and 4 represent the combined situation of the first embodiment of the present invention, the

如5图所示,图5表示本发明的外接式固定塞第二实施例,由一本体4褐一软塞5所构成,该软塞5可以与本体4结合为一固定塞,该瓶塞可供一盖体6结合。As shown in Figure 5, Figure 5 shows the second embodiment of the external fixed plug of the present invention, which is composed of a

该本体4与第一实施例所揭示的内容大致相同,该本体4有一固定板41和一定位孔42,在该固定板41的一表面的定位孔42周边各设置有数个延伸部43,在本实施例中,数个延伸部43为六片,数个延伸部43相邻部位较佳形成不连接的形态,使各个延伸部43之间形成有一分离部44,以使数个延伸部43可以作径向扩张。数个延伸部43第一端固定在固定板41,数个延伸部43第二端相连接于一封闭板49,以使数个延伸部43第二端形成封闭端。在数个延伸部43所形成该定位孔42的内壁面,可以在至少其一延伸部43设置有一第一结合部45,或如图所示,设置在各个延伸部43的内壁面。数个延伸部43的外壁面可以供软塞5结合,该外壁面可以设凹槽46,使该软塞5可以成为较为牢固地结合,该凹槽46较佳与内壁面的第一结合部45相对应,且较佳由该缩径的凹槽46直接形成为凸出在该内壁面的第一结合部45。再者,在数个延伸部43相邻的分离部44接近顶段部位,可以设置有相连接的连接部47,该连接部47与固定板41顶表面形成一间距48。The

该软塞5与第一实施例所揭示的内容大致相同,可以由热塑性橡胶、硅胶等可变形材料经由模具成型为一筒形状,该软塞5可以结合在本体4的外壁面以形成一瓶塞,该软塞5与本体4一体成型为该固定塞较佳。该筒形状的软塞5成型时,该软塞5的内壁面可以形成凸条51及凸出部52,该凸条51与本体4的凹槽46相对应结合,该凸出部52延伸入该本体4之间距48,使该软塞5与本体4的结合更为牢固。The

该盖体6与第一实施例的内容大致相同,由该内表面61对应于本体4的固定板41,该盖体6内表面61的柱杆62设置有第二结合部63,该第二结合部63可以与本体4的第一结合部45相结合,在本实施例中,该柱杆62的外壁面与定位孔42的内壁面形成相同的六边形状,使该柱杆62结合在定位孔42后,该柱杆62与定位孔42之间无法作相对的旋转。The content of the

如图6、7所示,图6、7表示本发明第二实施例的组合使用情形,本实施例所揭示的软塞5与本体4相结合后,同可以供盖体6结合。As shown in Figures 6 and 7, Figures 6 and 7 show the combined use of the second embodiment of the present invention. After the

如图8所示,图8表示本发明的外接式固定塞第三实施例,由一本体7及一软塞2所构成,该软塞2可以与本体7结合为一固定塞,该固定塞可供一盖体3结合。As shown in Figure 8, Figure 8 shows the third embodiment of the external fixed plug of the present invention, which is composed of a

该软塞2及盖体3与第一实施例所揭示的内容大致相同,该软塞2系可以结合在本体7的外壁面以形成一固定塞,该软塞2内壁面亦可以设置环槽21,该环槽21与本体7的凸条76相对应结合,使该软塞2与本体1的结合更为牢固。The

该盖体3与第一实施例的内容大致相同,由该内表面31对应于本体7的固定板71,在本实施例中,该盖体3内表面31的柱杆32仅有较小长度。该盖体3同样设置有第二结合部33,该第二结合部33可以与本体7的第一结合部75相结合,且该柱杆32结合在定位孔72后,该柱杆32与定位孔72之间无法作相对的旋转。The content of the

该本体7同由一固定板71上设有置一定位孔72,该固定板71由其一表面的定位孔72周边各设数个延伸部73,数个延伸部73之间形成有一分离部74,形成该定位孔72的该固定板71周边,至少设置有一第一结合部75,该第一结合部75一端连接在该固定板71,该第一结合部75的另一端形成开放端,且朝向该定位孔72方向凸出。数个延伸部73外壁面可以供软塞2结合,该外壁面可以设凸条76,使该软塞2可以成为较为牢固地结合。The

另外,该本体7所设数个延伸部73的第一端连接在固定板71,数个延伸部43第二端形成开放端,数个延伸部43的第二端还可以被一封闭板77封闭,如此,当该软塞2与本体7一体成型时,可以避免成型该软塞2的材料进入数个延伸部43之间,以避免成型该软塞2材料的浪费。In addition, the first ends of

如图9所示,图9表示本发明的外接式固定塞与盖体3还未结合时的剖面图,此时,该软塞2与本体7形成一体成型的结合,该本体7的数个第一结合部75形成凸出在该定位孔72(如图10所示)。As shown in Figure 9, Figure 9 shows a cross-sectional view of the external fixed plug of the present invention when it is not combined with the

如图10所示,当该盖体3欲与外接式固定塞结合时,可以利用该盖体3的柱杆32顶推该本体7的数个第一结合部75,使数个第一结合部75形成退缩,以使该盖体3的第二结合部33可以与本体7的第一结合部75相结合(如图12所示)。As shown in Figure 10, when the

由此,本发明的外接式固定塞可以方便、牢固地与容器材料相同的盖体结合,如此,本发明具有可以防止该固定塞与盖体脱落效果之功效。本发明的外接式固定塞,由于该固定塞可以与容器材料相同的盖体结合,如此本发明的固定塞具有较佳外观效果的功效。Thus, the external fixing plug of the present invention can be conveniently and firmly combined with the cover of the same container material, so that the present invention has the effect of preventing the fixing plug and the cover from falling off. The external fixed plug of the present invention can be combined with the cover body of the same container material, so the fixed plug of the present invention has the effect of better appearance effect.

需要声明的是,上述发明内容及具体实施方式意在证明本发明所提供技术方案的实际应用,不应解释为对本发明保护范围的限定。本领域技术人员在本发明的精神和原理内,当可作各种修改、等同替换、或改进。本发明的保护范围以所附权利要求书为准。It should be declared that the above summary of the invention and specific implementation methods are intended to prove the practical application of the technical solutions provided by the present invention, and should not be interpreted as limiting the protection scope of the present invention. Those skilled in the art may make various modifications, equivalent replacements, or improvements within the spirit and principles of the present invention. The protection scope of the present invention shall be determined by the appended claims.

Claims (15)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011103629948ACN103112651A (en) | 2011-11-16 | 2011-11-16 | External fixed plug |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011103629948ACN103112651A (en) | 2011-11-16 | 2011-11-16 | External fixed plug |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103112651Atrue CN103112651A (en) | 2013-05-22 |

Family

ID=48411053

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011103629948APendingCN103112651A (en) | 2011-11-16 | 2011-11-16 | External fixed plug |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103112651A (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD860716S1 (en) | 2017-03-27 | 2019-09-24 | Yeti Coolers, Llc | Container lid |

| USD871133S1 (en) | 2018-10-17 | 2019-12-31 | Yeti Coolers, Llc | Lid |

| USD876905S1 (en) | 2015-11-20 | 2020-03-03 | Yeti Coolers, Llc | Jug |

| USD883738S1 (en) | 2018-10-17 | 2020-05-12 | Yeti Coolers, Llc | Lid |

| USD883737S1 (en) | 2018-10-17 | 2020-05-12 | Yeti Coolers, Llc | Lid |

| USD896572S1 (en) | 2018-08-20 | 2020-09-22 | Yeti Coolers, Llc | Container lid |

| USD897151S1 (en) | 2018-10-17 | 2020-09-29 | Yeti Coolers, Llc | Lid |

| US10926925B2 (en) | 2015-08-14 | 2021-02-23 | Yeti Coolers, Llc | Container with magnetic cap |

| US10959553B2 (en) | 2016-10-17 | 2021-03-30 | Yeti Coolers, Llc | Container and method of forming a container |

| US10959552B2 (en) | 2016-10-17 | 2021-03-30 | Yeti Coolers, Llc | Container and method of forming a container |

| US11021314B2 (en) | 2016-10-17 | 2021-06-01 | Yeti Coolers, Llc | Container and method of forming a container |

| US11034505B2 (en) | 2016-10-17 | 2021-06-15 | Yeti Coolers, Llc | Container and method of forming a container |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2021259A (en)* | 1934-04-11 | 1935-11-19 | Champion Foundry & Machine Co | Bottle closure |

| US3638821A (en)* | 1970-04-01 | 1972-02-01 | Angelo Guala Di Piergiocomo & | Closure for bottles and similar containers |

| CN1337915A (en)* | 2000-10-31 | 2002-02-27 | 黄旭隆 | cork |

| CN1494505A (en)* | 2001-04-11 | 2004-05-05 | ˨�ֶ�ƿ������˾ | bottle stopper |

| CN2808783Y (en)* | 2005-07-15 | 2006-08-23 | 林明峰 | Flow-adjustable bottle stopper |

- 2011

- 2011-11-16CNCN2011103629948Apatent/CN103112651A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2021259A (en)* | 1934-04-11 | 1935-11-19 | Champion Foundry & Machine Co | Bottle closure |

| US3638821A (en)* | 1970-04-01 | 1972-02-01 | Angelo Guala Di Piergiocomo & | Closure for bottles and similar containers |

| CN1337915A (en)* | 2000-10-31 | 2002-02-27 | 黄旭隆 | cork |

| CN1494505A (en)* | 2001-04-11 | 2004-05-05 | ˨�ֶ�ƿ������˾ | bottle stopper |

| CN2808783Y (en)* | 2005-07-15 | 2006-08-23 | 林明峰 | Flow-adjustable bottle stopper |

Cited By (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10926925B2 (en) | 2015-08-14 | 2021-02-23 | Yeti Coolers, Llc | Container with magnetic cap |

| US12227340B2 (en) | 2015-08-14 | 2025-02-18 | Yeti Coolers, Llc | Container with magnetic cap |

| US11794960B2 (en) | 2015-08-14 | 2023-10-24 | Yeti Coolers, Llc | Container with magnetic cap |

| US11273961B2 (en) | 2015-08-14 | 2022-03-15 | Yeti Coolers, Llc | Container with magnetic cap |

| USD899871S1 (en) | 2015-11-20 | 2020-10-27 | Yeti Coolers, Llc | Jug |

| USD960660S1 (en) | 2015-11-20 | 2022-08-16 | Yeti Coolers, Llc | Jug |

| USD1039919S1 (en) | 2015-11-20 | 2024-08-27 | Yeti Coolers, Llc | Jug |

| USD1018214S1 (en) | 2015-11-20 | 2024-03-19 | Yeti Coolers, Llc | Jug |

| USD876905S1 (en) | 2015-11-20 | 2020-03-03 | Yeti Coolers, Llc | Jug |

| US10959553B2 (en) | 2016-10-17 | 2021-03-30 | Yeti Coolers, Llc | Container and method of forming a container |

| US11814235B2 (en) | 2016-10-17 | 2023-11-14 | Yeti Coolers, Llc | Container and method of forming a container |

| US12269666B2 (en) | 2016-10-17 | 2025-04-08 | Yeti Coolers, Llc | Container and method of forming a container |

| US10959552B2 (en) | 2016-10-17 | 2021-03-30 | Yeti Coolers, Llc | Container and method of forming a container |

| US11021314B2 (en) | 2016-10-17 | 2021-06-01 | Yeti Coolers, Llc | Container and method of forming a container |

| US11034505B2 (en) | 2016-10-17 | 2021-06-15 | Yeti Coolers, Llc | Container and method of forming a container |

| US11930944B2 (en) | 2016-10-17 | 2024-03-19 | Yeti Coolers, Llc | Container and method of forming a container |

| US11840365B2 (en) | 2016-10-17 | 2023-12-12 | Yeti Coolers, Llc | Container and method of forming a container |

| US11503932B2 (en) | 2016-10-17 | 2022-11-22 | Yeti Coolers, Llc | Container and method of forming a container |

| US11524833B2 (en) | 2016-10-17 | 2022-12-13 | Yeti Coolers, Llc | Container and method of forming a container |

| USD860716S1 (en) | 2017-03-27 | 2019-09-24 | Yeti Coolers, Llc | Container lid |

| USD988789S1 (en) | 2018-08-20 | 2023-06-13 | Yeti Coolers, Llc | Container lid |

| USD913746S1 (en) | 2018-08-20 | 2021-03-23 | Yeti Coolers, Llc | Container lid |

| USD913745S1 (en) | 2018-08-20 | 2021-03-23 | Yeti Coolers, Llc | Container lid |

| USD1061140S1 (en) | 2018-08-20 | 2025-02-11 | Yeti Coolers, Llc | Container lid |

| USD896572S1 (en) | 2018-08-20 | 2020-09-22 | Yeti Coolers, Llc | Container lid |

| USD883737S1 (en) | 2018-10-17 | 2020-05-12 | Yeti Coolers, Llc | Lid |

| USD883738S1 (en) | 2018-10-17 | 2020-05-12 | Yeti Coolers, Llc | Lid |

| USD935268S1 (en) | 2018-10-17 | 2021-11-09 | Yeti Coolers, Llc | Lid |

| USD897151S1 (en) | 2018-10-17 | 2020-09-29 | Yeti Coolers, Llc | Lid |

| USD1046619S1 (en) | 2018-10-17 | 2024-10-15 | Yeti Coolers, Llc | Lid |

| USD871133S1 (en) | 2018-10-17 | 2019-12-31 | Yeti Coolers, Llc | Lid |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103112651A (en) | External fixed plug | |

| US20190225378A1 (en) | Container with grip | |

| US20140319158A1 (en) | Container Insulator | |

| MY168339A (en) | Preform and plastic bottle | |

| TW200422087A (en) | Toy maraca | |

| JP4618579B2 (en) | Double container and molding method | |

| CN205256943U (en) | Container lid with concatenation function | |

| CN202032207U (en) | Universal pipe joint | |

| CN205087350U (en) | Can splice container lid with axial splicing mechanism | |

| CN202924046U (en) | container cap | |

| CN205261095U (en) | Fast connecting device | |

| CN108033135B (en) | Commercial lamp protection device | |

| WO2015054876A1 (en) | Decorative lamp | |

| CN202302466U (en) | Quick Fitting | |

| CN111556717B (en) | Cosmetic container system for manufacturing cosmetic containers using the same | |

| CN103508061B (en) | snap-on container stopper | |

| TWM467623U (en) | Container plug and cork structure thereof | |

| JP6923786B2 (en) | Storage container | |

| KR101676399B1 (en) | Double bottle | |

| TW201318927A (en) | Outer-connected fixing stopper | |

| JP3185665U (en) | Opener | |

| JP2005047563A (en) | Double container and method for molding it | |

| CN214597199U (en) | Rotary top tip and toy top | |

| CN211168076U (en) | Upside down fixed plastic case | |

| CN103508063A (en) | External expansion container plug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C05 | Deemed withdrawal (patent law before 1993) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20130522 |