CN102973135A - Protective energy-saving cover for cooking pressure cooker - Google Patents

Protective energy-saving cover for cooking pressure cookerDownload PDFInfo

- Publication number

- CN102973135A CN102973135ACN201110260477XACN201110260477ACN102973135ACN 102973135 ACN102973135 ACN 102973135ACN 201110260477X ACN201110260477X ACN 201110260477XACN 201110260477 ACN201110260477 ACN 201110260477ACN 102973135 ACN102973135 ACN 102973135A

- Authority

- CN

- China

- Prior art keywords

- cover

- pressure cooker

- shell

- saving

- pot cover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J27/00—Cooking-vessels

- A47J27/08—Pressure-cookers; Lids or locking devices specially adapted therefor

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J27/00—Cooking-vessels

- A47J27/08—Pressure-cookers; Lids or locking devices specially adapted therefor

- A47J27/09—Safety devices

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J36/00—Parts, details or accessories of cooking-vessels

- A47J36/36—Shields or jackets for cooking utensils minimising the radiation of heat, fastened or movably mounted

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J36/00—Parts, details or accessories of cooking-vessels

- A47J36/38—Parts, details or accessories of cooking-vessels for withdrawing or condensing cooking vapors from cooking utensils

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Cookers (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种煮食高压锅防护节能罩。The invention relates to a protective energy-saving cover for a cooking pressure cooker.

背景技术Background technique

公众日常在燃气灶或电磁炉上所使用的煮食高压锅(下文称:高压锅或普通高压锅)大多由铝合金或不锈钢材料制成,给人们的生活带来许多便利,相对于自动电高压锅,普通高压锅在煮食过程中能够随时随意进行火力调控,有其一定的使用优势。但是,普通高压锅的金属表面外露面积大,特别是高压锅的锅盖,除了一小部分被锅盖的手柄覆盖外,金属外表大部分外露,在煮食过程中,外露的锅盖表面处于相对高温状态,并因其表面温度高,当人体不小心触碰其上,易被烫痛或烫伤;更为明显的不足是,在高压锅煮食过程中,无论采用燃气灶还是电磁炉,高温的高压锅的锅盖总是处于向外散热状态,又因其表面温度高,外露面积大,散失的热量多,特别是在环境温度较低的冬季,锅盖与周围环境的温差大,散热更快,损失的热量更多,既不利于煮食时的节能,也不利于高压锅在停止煮食加热后的保温。Most of the cooking pressure cookers used by the public on gas stoves or induction cookers (hereinafter referred to as: pressure cookers or ordinary pressure cookers) are mostly made of aluminum alloy or stainless steel, which brings many conveniences to people's lives. Compared with automatic electric pressure cookers, ordinary pressure cookers In the cooking process, the firepower can be adjusted at any time at will, which has certain advantages in use. However, the metal surface of ordinary pressure cooker has a large exposed area, especially the pot lid of the pressure cooker. Except for a small part covered by the handle of the pot cover, most of the metal surface is exposed. During the cooking process, the exposed pot cover surface is at a relatively high temperature. state, and because of its high surface temperature, when the human body accidentally touches it, it is easy to be scalded or scalded; the more obvious disadvantage is that in the process of cooking in a pressure cooker, no matter whether a gas stove or an induction cooker is used, the temperature of the high-temperature pressure cooker The lid of the pot is always in a state of radiating heat outward, and because of its high surface temperature, large exposed area, and a lot of heat loss, especially in winter when the ambient temperature is low, the temperature difference between the lid and the surrounding environment is large, and the heat dissipation is faster and the loss The heat of the pressure cooker is more, which is not conducive to the energy saving when cooking, and is also not conducive to the heat preservation of the pressure cooker after the heating of the pressure cooker is stopped.

发明内容Contents of the invention

本发明的目的在于提供一种煮食高压锅防护节能罩,普通高压锅采用本发明的防护节能罩,使人体避免触碰在煮食中的高压锅锅盖表面,具有更完善的安全防护作用,并具有更理想的节能和保温效果。The purpose of the present invention is to provide a protective energy-saving cover for cooking pressure cooker. Ordinary pressure cooker adopts the protective energy-saving cover of the present invention to prevent the human body from touching the surface of the cover of the pressure cooker during cooking, which has a more complete safety protection effect and has More ideal energy saving and heat preservation effect.

本发明的目的是这样实现的,所述的煮食高压锅防护节能罩,其特征在于:包括套装于高压锅锅盖上的用于覆盖其外表面的壳罩,所述壳罩为由非金属材料制成的一整体构造;The object of the present invention is achieved in this way. The protective energy-saving cover for the cooking pressure cooker is characterized in that: it includes a shell cover set on the cover of the pressure cooker for covering its outer surface, and the cover is made of non-metallic material made as a unitary structure;

所述壳罩上设有用于避让限压阀阀帽的阀位孔,所述阀位孔与阀帽的周侧之间具有适宜的排汽空隙,所述阀位孔具有完整的侧壁,其下端面密合于锅盖外表面的对应位置上;The shell is provided with a valve position hole for avoiding the bonnet of the pressure limiting valve. There is a suitable exhaust space between the valve position hole and the circumference of the bonnet. The valve position hole has a complete side wall. Its lower end surface is closely attached to the corresponding position on the outer surface of the pot cover;

所述壳罩上设有用于避让盖手柄的让位槽,所述让位槽具有完整的侧壁,其下端面密合于锅盖及盖手柄外表面的对应位置上;The cover is provided with a relief groove for avoiding the handle of the cover, the relief groove has a complete side wall, and its lower end surface is closely attached to the corresponding position of the outer surface of the pot lid and the lid handle;

根据锅盖上的具体结构,所述壳罩上还设有用于避让锅盖上的其它安全构件的让位孔槽,以使套设在锅盖上的壳罩不影响该安全构件的正常使用,且该让位孔槽的下端面或内端面密合于锅盖外表面的对应位置上;According to the specific structure on the pot cover, the shell cover is also provided with a relief hole for avoiding other safety components on the pot cover, so that the shell cover set on the pot cover does not affect the normal use of the safety component , and the lower end surface or inner end surface of the relief hole is closely attached to the corresponding position on the outer surface of the pot cover;

除了为满足上述让位结构与锅盖及盖手柄的部分外表面之间密合需要而相互接触之外,所述壳罩的其余内表面与锅盖的外表面之间具有适宜的间距;In addition to meeting the mutual contact between the above-mentioned abdication structure and the part of the outer surface of the pot cover and the cover handle, there is an appropriate distance between the remaining inner surface of the shell and the outer surface of the pot cover;

所述壳罩的下部内周侧面密合于锅盖外周侧面的对应位置上,以使所述壳罩与所套合的锅盖一起共同围合而形成封闭的空腔。The inner peripheral side of the lower part of the shell is tightly fitted to the corresponding position on the outer peripheral side of the pot cover, so that the shell and the fitted pot cover together enclose together to form a closed cavity.

本发明的目的也可以是这样实现的,所述的煮食高压锅防护节能罩,其特征在于:所述阀位孔的下端部设有与所述空腔相贯通的溢出口;所述壳罩的下部内侧设有与所述空腔相贯通的泄流口,所述泄流口设置在与所述溢出口相对应的同侧位置上。The purpose of the present invention can also be achieved in the following way. The protective energy-saving cover for cooking pressure cooker is characterized in that: the lower end of the valve position hole is provided with an overflow port that communicates with the cavity; The inner side of the lower part of the body is provided with a discharge port communicating with the cavity, and the discharge port is arranged on the same side corresponding to the overflow port.

本发明的目的还可以是这样实现的,所述的煮食高压锅防护节能罩,其特征在于:所述壳罩由具有适宜机械强度及使用温度的发泡塑胶材料制成。The purpose of the present invention can also be achieved in the following way. The protective energy-saving cover for the cooking pressure cooker is characterized in that: the cover is made of foamed plastic material with suitable mechanical strength and service temperature.

煮食高压锅配设使用本发明的防护节能罩,使高温的高压锅锅盖表面得到本发明壳罩的覆盖,人体不易直接触碰到高温的高压锅锅盖表面。由于壳罩与锅盖之间的接触面较小,且两者对应的内外表面之间具有适宜的间距,能显著降低热能经该高压锅锅盖表面传导于本发明壳罩上的速度,而使壳罩的表面温度明显低于该锅盖的表面温度,即使人体触碰到本发明壳罩表面也不会被烫痛,即对人体具有良好的安全防护作用。The cooking pressure cooker is equipped with the protective energy-saving cover of the present invention, so that the surface of the high-temperature pressure cooker cover is covered by the cover of the present invention, and the human body is difficult to directly touch the surface of the high-temperature pressure cooker cover. Because the contact surface between the shell cover and the pot cover is small, and there is a suitable distance between the inner and outer surfaces corresponding to the two, the speed at which heat energy is conducted to the shell cover of the present invention through the surface of the pressure cooker pot cover can be significantly reduced, so that The surface temperature of the shell cover is obviously lower than the surface temperature of the pot cover, even if the human body touches the surface of the shell cover of the present invention, it will not be scalded, that is, it has a good safety protection effect on the human body.

本发明中的壳罩与所套用的高压锅的锅盖一起共同围合形成封闭的空腔,该封闭空腔内的空气导热系数低,使所构设的壳罩及空腔具有良好的绝热特性。因此,本发明中的壳罩能显著减慢经该高压锅锅盖表面的散热速度,而使该高压锅在煮食过程中进一步减少热量散失,有利于加快高压锅的煮食进程,缩短煮食加热时间,从而使该高压锅在煮食时具有良好的节能效果。同样,因该高压锅的锅盖得到了本发明壳罩的绝热覆盖,使该高压锅具有良好的保温性能,该高压锅在停止加热后,也能获得更长的保温时间。The shell cover in the present invention and the cover of the applied pressure cooker together form a closed cavity, and the air in the closed cavity has a low thermal conductivity, so that the constructed shell cover and cavity have good heat insulation properties . Therefore, the shell cover in the present invention can significantly slow down the heat dissipation speed through the surface of the pressure cooker lid, so that the pressure cooker can further reduce the heat loss during the cooking process, which is beneficial to speed up the cooking process of the pressure cooker and shorten the cooking heating time , so that the pressure cooker has a good energy-saving effect when cooking. Equally, because the pot cover of this pressure cooker has obtained the heat-insulation covering of shell cover of the present invention, makes this pressure cooker have good heat preservation performance, and this pressure cooker also can obtain longer heat preservation time after stopping heating.

本发明防护节能罩中的壳罩上所构设的阀位孔,阀位孔与阀帽的周侧之间具有适宜的排汽空隙,使本发明的壳罩在所配套的煮食高压锅锅盖上覆盖不会影响限压阀的正常排气,从而有效地解决了在高压锅锅盖上进行防护及节能构造设计所面临的易影响高压锅安全使用的问题,使本发明的防护节能罩在煮食高压锅上配套使用能安全地实现对人体更完善的防护作用和获得更好的节能及保温效果,从而克服了现有技术未能合理地在高压锅锅盖上进行防护及节能构造设计而使现有高压锅在煮食使用时易存在着防护功能差和节能及保温效果欠佳等不足。The valve position hole constructed on the shell cover in the protective energy-saving cover of the present invention has a suitable exhaust gap between the valve position hole and the peripheral side of the valve cap, so that the shell cover of the present invention can be used in the matching cooking pressure cooker. Covering on the cover will not affect the normal exhaust of the pressure limiting valve, thereby effectively solving the problem of easily affecting the safe use of the pressure cooker faced by the protection and energy-saving structure design on the cover of the pressure cooker. The matching use on the pressure cooker can safely realize a more perfect protection effect on the human body and obtain better energy-saving and heat preservation effects, thereby overcoming the failure of the existing technology to reasonably carry out protection and energy-saving structural design on the pressure cooker lid. There are pressure cookers that are prone to deficiencies such as poor protection function, energy saving and thermal insulation effect when cooking and using.

本发明的防护节能罩中的壳罩可采用塑胶材料模制成型,工艺简单,生产成本低,绝热性能良好,可根据高压锅锅盖结构特点定制配套,使用安全便利。本发明的防护节能罩可与设置在高压锅上的其它绝热构件配套使用,而具有更良好的防护和节能及保温效果,能给高压锅的煮食使用带来更多便利,并有利于节能减排而具有推广应用价值。The shell cover in the protective energy-saving cover of the present invention can be molded with plastic materials, the process is simple, the production cost is low, and the heat insulation performance is good. It can be customized and matched according to the structural characteristics of the pressure cooker cover, and it is safe and convenient to use. The protective energy-saving cover of the present invention can be used in conjunction with other heat insulating components arranged on the pressure cooker, and has better protection, energy saving and heat preservation effects, can bring more convenience to the cooking and use of the pressure cooker, and is conducive to energy saving and emission reduction And has the value of promotion and application.

附图说明Description of drawings

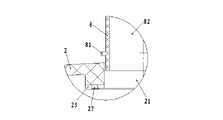

图1是本发明实施例一的构造示意图。Fig. 1 is a schematic structural diagram of

图2是图1的右视图。Fig. 2 is a right side view of Fig. 1 .

图3是图1的左剖视图。Fig. 3 is a left sectional view of Fig. 1 .

图4是图1的仰视图(局部)。Fig. 4 is a bottom view (partial) of Fig. 1 .

图5是图1的Ⅰ部放大视图。Fig. 5 is an enlarged view of part I of Fig. 1 .

图6是图3的Ⅱ部放大视图。Fig. 6 is an enlarged view of part II of Fig. 3 .

图7是本发明的壳罩与锅盖的配合关系示意图(局部)。Fig. 7 is a schematic diagram (partial) of the cooperative relationship between the shell cover and the pot cover of the present invention.

图8是图7的俯视图(局部)。FIG. 8 is a top view (partial) of FIG. 7 .

图9是本发明实施例二的构造示意图。Fig. 9 is a schematic structural diagram of

图10是图9的左剖视图。Fig. 10 is a left sectional view of Fig. 9 .

图中:锅盖1,阀帽11,帽孔12,盖手柄13,安全阀14,壳罩2,阀位孔21,让位槽22,空腔23,安全孔24,溢出口25, 泄流口26,围流槽27,隔热槽28,槽封29,罩套3,油水杯7,插耳71,插孔72,罩帽8,罩孔81,帽肩82。In the figure:

具体实施方式Detailed ways

下面结合附图和实施例对本发明进行详细说明。The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

实施例一Embodiment one

本发明实施例一的煮食高压锅防护节能罩(构造见图1至图8),其构造特点在于:包括套装于高压锅锅盖1上的用于覆盖其外表面的壳罩2;壳罩2为由具有适宜机械强度的塑胶材料制成的整体构造;The protective energy-saving cover for cooking pressure cooker according to the first embodiment of the present invention (see Figure 1 to Figure 8 for the structure), its structural feature is that it includes a

上述的壳罩2上设有用于避让限压阀阀帽11的阀位孔21,阀位孔21与阀帽11的周侧之间具有适宜的排汽空隙,阀位孔21具有完整的侧壁,其下端面密合于锅盖1外表面的对应位置上;The above-mentioned

上述的壳罩2上设有用于避让盖手柄13的让位槽22,让位槽22具有完整的侧壁,其下端面密合于锅盖1及盖手柄13外表面的对应位置上;The above-mentioned

上述的壳罩2上设有用于避让安全阀14的安全孔24,安全孔24具有完整的侧壁,其下端面密合于锅盖1外表面的对应位置上;The above-mentioned

根据锅盖1上的具体结构,壳罩2上还设有用于避让锅盖1上的其它安全构件的让位孔槽,以使套设在锅盖1上的壳罩2不影响该安全构件的正常使用,且该让位孔槽的下端面或内端面密合于锅盖1外表面的对应位置上;According to the specific structure on the

除了为满足上述让位结构与锅盖1及盖手柄13的部分外表面之间密合需要而相互接触之外,壳罩2的其余内表面与锅盖1的外表面之间具有适宜的间距;In addition to contacting each other in order to meet the need for close contact between the above-mentioned abdication structure and the part of the outer surface of the

上述的壳罩2的下部内周侧面密合于锅盖1外周侧面的对应位置上,以使壳罩2与所套合的锅盖1一起共同围合而形成封闭的空腔23。The lower inner peripheral side of the above-mentioned

本实施例中的壳罩2上所构设的阀位孔21,阀位孔21与阀帽11的周侧之间具有适宜的空隙,使从限压阀排出的汽体可以无阻碍流通,而使在锅盖1上套装壳罩2不影响高压锅在煮食加热过程中的安全使用。壳罩2与锅盖1之间的接触面较小,且壳罩2为塑胶材料制成,两者之间的传热速度慢,使壳罩2的表面温度明显低于高压锅锅盖1的表面温度,即使人体触碰到壳罩2表面也不会被烫痛,即对人体具有良好的安全防护作用。同时,壳罩2与锅盖1之间具有适宜的间距,且两者相互配合而形成封闭的空腔23,其内充满了导热系数低且不与外界对流的空气,使壳罩2具有良好的绝热性能,能显著减慢锅盖1的散热速度,有利于加快高压锅的煮食进程,缩短煮食加热时间,具有良好的节能效果。在高压锅停止加热后,壳罩2也具有更好的保温效果,使高压锅能获得更长的保温时间,减少重新加热的机会而也有利于节能。The

为使本发明防护节能罩更易于实施应用和具有更好的使用效果,在上述构造的基础上,本实施例进一步构设如下构造,其好处也随后表述。In order to make the protective energy-saving cover of the present invention easier to implement and have better use effect, on the basis of the above-mentioned structure, this embodiment further constructs the following structure, and its benefits are also described later.

进一步构造1:上述的阀位孔21的上端周沿不高于限压阀帽孔12的下沿,以使从帽孔12喷出的汽体不被阀位孔21的内壁遮挡。Further configuration 1: the upper edge of the above-mentioned

上述限定的阀位孔21与帽孔12之间的相对位置关系,可使从帽孔12中喷出的汽体免于被阀位孔21的内壁遮挡而使该汽体免于在阀位孔21中形成油水,从而能确保限压阀正常排气及高压锅的安全使用,并有利于壳罩2保持良好的绝热效果和使用方便性。The above-mentioned relative positional relationship between the

进一步构造2:上述的阀位孔21的下端部设有与空腔23相贯通的溢出口25。Further configuration 2: the lower end of the

所构设的溢出口25易于使阀位孔21中的油水集中从溢出口25流至锅盖1表面,该油水被汽化后所形成的汽体又可以从溢出口25返冒并经阀位孔21排出,以免阀位孔21中的油水出现积聚状态而影响限压阀的正常排气及高压锅的安全使用。The configured

进一步构造3:上述的壳罩2的下部内侧设有与空腔23相贯通的泄流口26,泄流口26设置在与溢出口25相对应的同侧位置上。Further configuration 3: the inner side of the lower part of the above-mentioned

当从溢出口25流至锅盖1表面上的油水未能完全被汽化,未被汽化的油水可集中从泄流口26排出,以免该油水积聚在壳罩2及空腔23内而影响壳罩2的正常使用,并使壳罩2保持良好的绝热作用和使用方便性。油水集中从泄流口26排出,也为油水的集中收集提供便利。When the oil and water flowing from the

进一步构造4:上述的阀位孔21的下端部沿周向设有与溢出口25相贯通的环形围流槽27,以使从阀位孔21中渗入于围流槽27内的油水易于集中从溢出口25所界定的锅盖1表面流入空腔23内。Further configuration 4: the lower end of the above-mentioned

当阀位孔21的下端部与锅盖1表面配合状态不够理想时,所构设的围流槽27不易使阀位孔21中的油水从任意方位渗到空腔23内而影响壳罩2的正常使用及油水的集中收集。所构设的围流槽27的形状和大小可根据O型密封圈常用的规格来设计和制作,以便在必要时可以在围流槽27中配设该规格的O型密封圈,以使空腔23的封闭状态更理想,从而使壳罩2保持良好的绝热性能和使用方便性。When the matching state between the lower end of the

进一步构造5:上述的泄流口26的出口位置上设有具有一对插耳71的油水杯7;壳罩2上设有一对与插耳71相配对的插孔72,使油水杯7挂接在壳罩2的外侧及锅盖1的下侧沿,以承接从泄流口26排出的油水。Further structure 5: the outlet position of the above-mentioned

所构设的油水杯7可承接从泄流口26排出的油水,而使该油水免于溢流至灶台上,使采用本发明防护节能罩的高压锅煮食使用更安全便利。The configured oil-

进一步构造6:上述的阀位孔21中设有由塑胶材料制成的罩帽8,罩帽8呈圆筒形,并设有用于避让阀帽11的罩孔81,罩孔81的上端为封闭状态;罩帽8设有与阀位孔21上端周沿相密合的帽肩82。Further structure 6: the above-mentioned

在高压锅停止加热而进入保温状态时,可以不必卸下阀帽11,上述所构设的罩帽8能直接套入壳罩2上的阀位孔21中,以阻断或封闭在阀位孔21位置上的散热通道,可以进一步减少高压锅内的热量散失,以增强本发明壳罩2的保温效果。在高压锅煮食加热过程中,则需要从壳罩2上卸下罩帽8。When the pressure cooker stops heating and enters the heat preservation state, it is not necessary to unload the

进一步构造7:上述的壳罩2下端部的内外周侧之间沿周向设有具有适宜深度的环形隔热槽28。Further configuration 7: An annular

所构设的隔热槽28使壳罩2的下端部的内外周侧之间具有三重隔热层,可以克服上述的壳罩2的下部内周侧面与锅盖1外周侧面之间的接触面积偏大而带来的不足,进一步提升壳罩2的绝热性能,使壳罩2的表面温升更低,并使壳罩2具有更好的防护和节能及保温效果。The

进一步构造8:上述的隔热槽28设有套封于其端口上的槽封29;槽封29由具有适宜弹性的塑胶材料制成,并与锅盖1的对应表面之间具有预设定的接触变形余量,以使其能与锅盖1的外周侧面保持密贴状态。Further structure 8: the above-mentioned

所构设的槽封29使隔热槽28成为封闭的隔热空腔,有利于提升壳罩2的绝热性能。由弹性塑胶材料制成的槽封29易与锅盖1的外周侧面保持密贴状态,可以克服上述的壳罩2的下部内周侧面与锅盖1外周侧面之间的接触或密贴状态不良而带来的不足,有利于保持壳罩2的绝热性能。The configured

本实施例一中的壳罩2采用塑胶材料制成,具有取材容易和易于大批量生产的优势。当然,本实施例中的壳罩2还可以采用具有一定绝热作用的其它非金属材料制成,如可采用陶瓷或木材经适当的工艺方法制成本发明的壳罩,同样可以实现本发明的目的。The

实施例二Embodiment two

本发明实施例二的煮食高压锅防护节能罩(构造见图9和图10)。为了使本发明防护节能罩的功能更加完善,以使之更易于实施和应用,在本发明实施例一的基础上,本发明实施例二进一步构设如下构造,其好处也随后表述。The protective energy-saving cover for the cooking pressure cooker of the second embodiment of the present invention (see Figure 9 and Figure 10 for the structure). In order to make the function of the protective energy-saving cover of the present invention more perfect and make it easier to implement and apply, on the basis of the first embodiment of the present invention, the second embodiment of the present invention further constructs the following structure, and its benefits are also described later.

进一步构造1:上述的壳罩2由具有适宜机械强度及使用温度的发泡塑胶材料制成。Further configuration 1: the above-mentioned

本实施例中的壳罩2由具有适宜机械强度及适宜最高使用温度的发泡塑胶材料制成,以求成本更低和使用更方便,并且可以获得更好的节能及保温效果。本实施例中的壳罩2优先选用发泡聚丙烯,以求本发明防护节能罩更环保和耐用,并获得理想的绝热效果,且更贴近实际需要,使本发明防护节能罩易于实施应用。The

进一步构造2:上述的壳罩2的外表面设有与其套接的罩套3;罩套3由金属薄板或塑胶材料制成,并与壳罩2相紧密套合连接或粘合成一体。Further structure 2: the outer surface of the above-mentioned

所构设的罩套3有利于保护壳罩2,以克服由发泡塑胶材料制成的壳罩2易存在的其表面易受污染且易变形破损等不足,以使壳罩2更能适应本发明防护节能罩在实际使用时对结构的耐用性及使用方便性等要求,并有利于增强壳罩2的绝热效果,而更有利于本发明防护节能罩在煮食高压锅上实施应用。由于壳罩2采用了发泡塑胶材料制成,其所配设的起保护作用的罩套3则根据不同需要可以采用塑胶材料或金属薄板制作,而若选择金属薄板制作,则优选以不锈钢薄板冲压制成。The constructed

本实施例的煮食高压锅防护节能罩具有如下特点:1.本实施例中的壳罩2上所构设的阀位孔21,解决了在高压锅锅盖1上进行防护及节能构造设计所面临的易影响高压锅安全使用的问题,使本实施例防护节能罩能在高压锅煮食过程中覆盖和安全地使用,从而实现了在高压锅煮食加热过程中对高压锅锅盖1的绝热覆盖,使人体避免触碰该锅盖的高温表面,显著减少人体被高温的高压锅表面烫痛或烫伤的机会,起到了有效的安全防护作用。同时,本实施例的壳罩2与所套合的锅盖1一起共同围合成封闭的空腔23,能显著减慢高压锅的散热速度,而使高压锅获得更理想的节能及保温效果,从而克服了现有技术未能合理地在高压锅锅盖上进行防护及节能构造设计而使现有高压锅在煮食使用时易存在着防护功能差和节能及保温效果欠佳等不足。2.本实施例中的壳罩2为一整体构造,可以采用模具制造而易获得较高的制造精度,而使壳罩2与所套合的锅盖1之间的空腔23保持更为良好的封闭状态,从而使壳罩2保持良好的绝热性能,并给其使用带来更多便利。3.煮食高压锅采用本发明的防护节能罩,若高压锅出现异常排汽状态而于阀位孔21中的锅盖1表面上形成较多油水,则该油水可经本实施例所构设的溢出口25和泄流口26排出,以免影响限压阀的正常排气,从而有效地解决了采用本实施例防护节能罩的高压锅在出现异常排汽状态下的安全使用问题, 使本实施例的壳罩2更能适应于高压锅出现异常排汽状态下的安全使用,使本实施例防护节能罩具有更强的使用适应性和安全性。4.本实施例中的壳罩2优选发泡聚丙烯材料制成,具有易于大批量生产和生产成本低及使用轻便环保等优势,而且具有理想的绝热效果,更能贴近实际需要,而使本发明防护节能罩易于实施应用。5.本实施例的防护节能罩,可根据高压锅锅盖结构特点定制配套,使用安全方便;本实施例的防护节能罩不仅可以单独与高压锅的锅盖配合使用,并可与设置在高压锅体上的其它绝热构件配套或组合使用,能给高压锅的煮食使用带来更多便利,并有利于节能减排而具有推广应用价值。The protective energy-saving cover for the cooking pressure cooker of this embodiment has the following characteristics: 1. The

Claims (10)

Translated fromChinesePriority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201610901446.0ACN106361136A (en) | 2011-09-06 | 2011-09-06 | Oil and water accumulation-free protective and energy-saving cover of cooking pressure cooker |

| CN201610904631.5ACN106388567A (en) | 2011-09-06 | 2011-09-06 | Cooking pressure cooker protecting energy-saving cover capable of being easily and tightly arranged |

| CN201610904946.XACN106361138A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of cooking pressure cooker with function of collecting oil and water |

| CN201610904939.XACN106419524A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of oil water guiding cooking pressure cooker |

| CN201110260477.XACN102973135B (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover for cooking pressure cooker |

| CN201610901461.5ACN106361137A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover efficiently applicable to cooking pressure cooker |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201110260477.XACN102973135B (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover for cooking pressure cooker |

Related Child Applications (5)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610904631.5ADivisionCN106388567A (en) | 2011-09-06 | 2011-09-06 | Cooking pressure cooker protecting energy-saving cover capable of being easily and tightly arranged |

| CN201610904939.XADivisionCN106419524A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of oil water guiding cooking pressure cooker |

| CN201610901461.5ADivisionCN106361137A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover efficiently applicable to cooking pressure cooker |

| CN201610904946.XADivisionCN106361138A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of cooking pressure cooker with function of collecting oil and water |

| CN201610901446.0ADivisionCN106361136A (en) | 2011-09-06 | 2011-09-06 | Oil and water accumulation-free protective and energy-saving cover of cooking pressure cooker |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102973135Atrue CN102973135A (en) | 2013-03-20 |

| CN102973135B CN102973135B (en) | 2016-09-07 |

Family

ID=47847699

Family Applications (6)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610901446.0APendingCN106361136A (en) | 2011-09-06 | 2011-09-06 | Oil and water accumulation-free protective and energy-saving cover of cooking pressure cooker |

| CN201110260477.XAExpired - Fee RelatedCN102973135B (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover for cooking pressure cooker |

| CN201610904939.XAPendingCN106419524A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of oil water guiding cooking pressure cooker |

| CN201610901461.5APendingCN106361137A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover efficiently applicable to cooking pressure cooker |

| CN201610904631.5APendingCN106388567A (en) | 2011-09-06 | 2011-09-06 | Cooking pressure cooker protecting energy-saving cover capable of being easily and tightly arranged |

| CN201610904946.XAPendingCN106361138A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of cooking pressure cooker with function of collecting oil and water |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610901446.0APendingCN106361136A (en) | 2011-09-06 | 2011-09-06 | Oil and water accumulation-free protective and energy-saving cover of cooking pressure cooker |

Family Applications After (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610904939.XAPendingCN106419524A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of oil water guiding cooking pressure cooker |

| CN201610901461.5APendingCN106361137A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover efficiently applicable to cooking pressure cooker |

| CN201610904631.5APendingCN106388567A (en) | 2011-09-06 | 2011-09-06 | Cooking pressure cooker protecting energy-saving cover capable of being easily and tightly arranged |

| CN201610904946.XAPendingCN106361138A (en) | 2011-09-06 | 2011-09-06 | Protective energy-saving cover of cooking pressure cooker with function of collecting oil and water |

Country Status (1)

| Country | Link |

|---|---|

| CN (6) | CN106361136A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103829789A (en)* | 2013-12-19 | 2014-06-04 | 柳州市京阳节能科技研发有限公司 | Safe and energy-saving pressure cooker lid convenient and fast to use |

| CN103829791A (en)* | 2013-12-19 | 2014-06-04 | 柳州市京阳节能科技研发有限公司 | Multipurpose high-heat energy-saving pan convenient to use |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019032876A1 (en) | 2017-08-09 | 2019-02-14 | Sharkninja Operating Llc | Cooking device and components thereof |

| USD914447S1 (en) | 2018-06-19 | 2021-03-30 | Sharkninja Operating Llc | Air diffuser |

| USD883014S1 (en) | 2018-08-09 | 2020-05-05 | Sharkninja Operating Llc | Food preparation device |

| USD883015S1 (en) | 2018-08-09 | 2020-05-05 | Sharkninja Operating Llc | Food preparation device and parts thereof |

| USD903413S1 (en) | 2018-08-09 | 2020-12-01 | Sharkninja Operating Llc | Cooking basket |

| USD934027S1 (en) | 2018-08-09 | 2021-10-26 | Sharkninja Operating Llc | Reversible cooking rack |

| WO2020176477A1 (en) | 2019-02-25 | 2020-09-03 | Sharkninja Operating Llc | Cooking system with guard |

| US11051654B2 (en) | 2019-02-25 | 2021-07-06 | Sharkninja Operating Llc | Cooking device and components thereof |

| USD918654S1 (en) | 2019-06-06 | 2021-05-11 | Sharkninja Operating Llc | Grill plate |

| USD982375S1 (en) | 2019-06-06 | 2023-04-04 | Sharkninja Operating Llc | Food preparation device |

| US11678765B2 (en) | 2020-03-30 | 2023-06-20 | Sharkninja Operating Llc | Cooking device and components thereof |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN87207771U (en)* | 1987-05-13 | 1988-06-22 | 代范伊 | Splash-proof lid for pressure cooker with double layer splash-proof |

| CN2031238U (en)* | 1988-04-30 | 1989-01-25 | 代范伊 | Jet-proof pressure cooker lid with two-layer structure |

| JPH0227915A (en)* | 1988-07-18 | 1990-01-30 | Kubota Ltd | harvester |

| CN201127508Y (en)* | 2007-08-23 | 2008-10-08 | 李钊鸿 | Pressure-limiting valve airflow fence group structure of pressure cooker |

| CN201295133Y (en)* | 2008-09-05 | 2009-08-26 | 苏权希 | Scald-proof pressure cooker cover |

| CN201798581U (en)* | 2010-09-13 | 2011-04-20 | 陆意祥 | Pot cover capable of storing water |

| CN102973136A (en)* | 2011-09-06 | 2013-03-20 | 戴梦云 | Protective energy-saving pressure cooker |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2072811U (en)* | 1990-07-12 | 1991-03-13 | 曾为至 | Energy-saving pot |

| JP3200911B2 (en)* | 1992-01-29 | 2001-08-20 | 井関農機株式会社 | Water control equipment in grain processing equipment |

| CN2301944Y (en)* | 1997-04-18 | 1998-12-30 | 劳建荣 | Energy-saving insulation electric cooker |

| KR200440495Y1 (en)* | 2006-11-27 | 2008-06-16 | 이신근 | Cookware lid with overflow protection |

| CN101485538B (en)* | 2008-01-15 | 2010-11-10 | 徐佳义 | Low-pressure quick-cooking pot with air overflow chamber and control method thereof |

| CN201528995U (en)* | 2009-09-08 | 2010-07-21 | 刘建华 | Electric pressure cooker steam liquid collecting and cooling device |

- 2011

- 2011-09-06CNCN201610901446.0Apatent/CN106361136A/enactivePending

- 2011-09-06CNCN201110260477.XApatent/CN102973135B/ennot_activeExpired - Fee Related

- 2011-09-06CNCN201610904939.XApatent/CN106419524A/enactivePending

- 2011-09-06CNCN201610901461.5Apatent/CN106361137A/enactivePending

- 2011-09-06CNCN201610904631.5Apatent/CN106388567A/enactivePending

- 2011-09-06CNCN201610904946.XApatent/CN106361138A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN87207771U (en)* | 1987-05-13 | 1988-06-22 | 代范伊 | Splash-proof lid for pressure cooker with double layer splash-proof |

| CN2031238U (en)* | 1988-04-30 | 1989-01-25 | 代范伊 | Jet-proof pressure cooker lid with two-layer structure |

| JPH0227915A (en)* | 1988-07-18 | 1990-01-30 | Kubota Ltd | harvester |

| CN201127508Y (en)* | 2007-08-23 | 2008-10-08 | 李钊鸿 | Pressure-limiting valve airflow fence group structure of pressure cooker |

| CN201295133Y (en)* | 2008-09-05 | 2009-08-26 | 苏权希 | Scald-proof pressure cooker cover |

| CN201798581U (en)* | 2010-09-13 | 2011-04-20 | 陆意祥 | Pot cover capable of storing water |

| CN102973136A (en)* | 2011-09-06 | 2013-03-20 | 戴梦云 | Protective energy-saving pressure cooker |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103829789A (en)* | 2013-12-19 | 2014-06-04 | 柳州市京阳节能科技研发有限公司 | Safe and energy-saving pressure cooker lid convenient and fast to use |

| CN103829791A (en)* | 2013-12-19 | 2014-06-04 | 柳州市京阳节能科技研发有限公司 | Multipurpose high-heat energy-saving pan convenient to use |

Also Published As

| Publication number | Publication date |

|---|---|

| CN106361136A (en) | 2017-02-01 |

| CN106361138A (en) | 2017-02-01 |

| CN106361137A (en) | 2017-02-01 |

| CN106388567A (en) | 2017-02-15 |

| CN102973135B (en) | 2016-09-07 |

| CN106419524A (en) | 2017-02-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102973135B (en) | Protective energy-saving cover for cooking pressure cooker | |

| CN102961037B (en) | Protective energy-saving cover for cooking pressure cooker | |

| CN102973136B (en) | Protective energy-saving pressure cooker | |

| CN102908048B (en) | Protective energy-saving pressure cooker | |

| CN102973133B (en) | Protective energy-saving cover for cooking pressure cooker | |

| CN204394269U (en) | Interior pot and electric cooker | |

| CN102973134B (en) | Protective energy-saving pressure cooker | |

| CN201977593U (en) | Shell of water-resisting saucepot | |

| CN102894868B (en) | Protective energy-saving cover for cooking pressure cooker | |

| CN102908049B (en) | Protective energy-saving cover for cooking pressure cooker | |

| CN203263010U (en) | Novel double-layer heat-insulation saucepan | |

| CN201510105U (en) | Novel gas heat conduction pan | |

| CN201727353U (en) | Water-boiling kettle with very high water boiling efficiency | |

| CN207202688U (en) | A kind of glass boiler | |

| CN102961036B (en) | Protection energy-saving high-pressure cooker | |

| CN201157241Y (en) | Insulation pot for electromagnetic oven | |

| CN202335695U (en) | Water cup capable of controlling temperature |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C41 | Transfer of patent application or patent right or utility model | ||

| CB03 | Change of inventor or designer information | Inventor after:Dai Mengyun Inventor after:Huang Hao Inventor before:Dai Mengyun | |

| COR | Change of bibliographic data | ||

| TA01 | Transfer of patent application right | Effective date of registration:20160603 Address after:Gulou District of Fuzhou city in Fujian province 350012 Lake Street No. 30 before Wufeng Dajing Intertek villa 104 B unit Applicant after:Huang Hao Address before:350300, 38, Rong Rong Avenue, Fuqing, Fujian, Fuzhou 903 Applicant before:Dai Mengyun | |

| C41 | Transfer of patent application or patent right or utility model | ||

| TA01 | Transfer of patent application right | Effective date of registration:20160629 Address after:350300 No. 38, Rong Rong Avenue, Yuping street, Fujian, Fuqing 903 Applicant after:Dai Yongfeng Address before:Gulou District of Fuzhou city in Fujian province 350012 Lake Street No. 30 before Wufeng Dajing Intertek villa 104 B unit Applicant before:Huang Hao | |

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20160907 Termination date:20190906 |