CN102885783A - Nanometer medicament microspheres - Google Patents

Nanometer medicament microspheresDownload PDFInfo

- Publication number

- CN102885783A CN102885783ACN2012103615776ACN201210361577ACN102885783ACN 102885783 ACN102885783 ACN 102885783ACN 2012103615776 ACN2012103615776 ACN 2012103615776ACN 201210361577 ACN201210361577 ACN 201210361577ACN 102885783 ACN102885783 ACN 102885783A

- Authority

- CN

- China

- Prior art keywords

- drug

- microspheres

- nano

- nanoparticles

- oil

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000004005microsphereSubstances0.000titleclaimsabstractdescription349

- 239000003814drugSubstances0.000titleclaimsabstractdescription321

- 229940079593drugDrugs0.000claimsabstractdescription259

- 239000002105nanoparticleSubstances0.000claimsabstractdescription214

- 239000000725suspensionSubstances0.000claimsabstractdescription103

- 238000002360preparation methodMethods0.000claimsabstractdescription62

- 239000000839emulsionSubstances0.000claimsabstractdescription44

- 239000000546pharmaceutical excipientSubstances0.000claimsabstractdescription40

- 229940124531pharmaceutical excipientDrugs0.000claimsabstractdescription37

- 229920000642polymerPolymers0.000claimsabstractdescription33

- 239000007900aqueous suspensionSubstances0.000claimsabstractdescription24

- 239000004094surface-active agentSubstances0.000claimsabstractdescription22

- 239000003960organic solventSubstances0.000claimsabstractdescription10

- 239000011259mixed solutionSubstances0.000claimsabstractdescription6

- 229920001223polyethylene glycolPolymers0.000claimsdescription90

- 239000002202Polyethylene glycolSubstances0.000claimsdescription89

- YMWUJEATGCHHMB-UHFFFAOYSA-NDichloromethaneChemical compoundClCClYMWUJEATGCHHMB-UHFFFAOYSA-N0.000claimsdescription87

- 239000003921oilSubstances0.000claimsdescription80

- AOJJSUZBOXZQNB-TZSSRYMLSA-NDoxorubicinChemical compoundO([C@H]1C[C@@](O)(CC=2C(O)=C3C(=O)C=4C=CC=C(C=4C(=O)C3=C(O)C=21)OC)C(=O)CO)[C@H]1C[C@H](N)[C@H](O)[C@H](C)O1AOJJSUZBOXZQNB-TZSSRYMLSA-N0.000claimsdescription78

- QFJCIRLUMZQUOT-HPLJOQBZSA-NsirolimusChemical compoundC1C[C@@H](O)[C@H](OC)C[C@@H]1C[C@@H](C)[C@H]1OC(=O)[C@@H]2CCCCN2C(=O)C(=O)[C@](O)(O2)[C@H](C)CC[C@H]2C[C@H](OC)/C(C)=C/C=C/C=C/[C@@H](C)C[C@@H](C)C(=O)[C@H](OC)[C@H](O)/C(C)=C/[C@@H](C)C(=O)C1QFJCIRLUMZQUOT-HPLJOQBZSA-N0.000claimsdescription62

- 229960002930sirolimusDrugs0.000claimsdescription60

- ZAHRKKWIAAJSAO-UHFFFAOYSA-NrapamycinNatural productsCOCC(O)C(=C/C(C)C(=O)CC(OC(=O)C1CCCCN1C(=O)C(=O)C2(O)OC(CC(OC)C(=CC=CC=CC(C)CC(C)C(=O)C)C)CCC2C)C(C)CC3CCC(O)C(C3)OC)CZAHRKKWIAAJSAO-UHFFFAOYSA-N0.000claimsdescription59

- AQHHHDLHHXJYJD-UHFFFAOYSA-NpropranololChemical compoundC1=CC=C2C(OCC(O)CNC(C)C)=CC=CC2=C1AQHHHDLHHXJYJD-UHFFFAOYSA-N0.000claimsdescription54

- 239000007864aqueous solutionSubstances0.000claimsdescription51

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000claimsdescription41

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription38

- 229960004679doxorubicinDrugs0.000claimsdescription34

- 108010051696Growth HormoneProteins0.000claimsdescription32

- 102000018997Growth HormoneHuman genes0.000claimsdescription32

- 238000011282treatmentMethods0.000claimsdescription32

- 102000003951ErythropoietinHuman genes0.000claimsdescription31

- 108090000394ErythropoietinProteins0.000claimsdescription31

- 229940105423erythropoietinDrugs0.000claimsdescription31

- OXCMYAYHXIHQOA-UHFFFAOYSA-Npotassium;[2-butyl-5-chloro-3-[[4-[2-(1,2,4-triaza-3-azanidacyclopenta-1,4-dien-5-yl)phenyl]phenyl]methyl]imidazol-4-yl]methanolChemical compound[K+].CCCCC1=NC(Cl)=C(CO)N1CC1=CC=C(C=2C(=CC=CC=2)C2=N[N-]N=N2)C=C1OXCMYAYHXIHQOA-UHFFFAOYSA-N0.000claimsdescription31

- WEVYAHXRMPXWCK-UHFFFAOYSA-NAcetonitrileChemical compoundCC#NWEVYAHXRMPXWCK-UHFFFAOYSA-N0.000claimsdescription28

- 229910052588hydroxylapatiteInorganic materials0.000claimsdescription28

- XYJRXVWERLGGKC-UHFFFAOYSA-Dpentacalcium;hydroxide;triphosphateChemical compound[OH-].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=OXYJRXVWERLGGKC-UHFFFAOYSA-D0.000claimsdescription28

- 229960003712propranololDrugs0.000claimsdescription27

- 102000014150InterferonsHuman genes0.000claimsdescription26

- 108010050904InterferonsProteins0.000claimsdescription26

- 239000000122growth hormoneSubstances0.000claimsdescription26

- 229940079322interferonDrugs0.000claimsdescription26

- 239000002245particleSubstances0.000claimsdescription26

- 239000004632polycaprolactoneSubstances0.000claimsdescription26

- 229920001610polycaprolactonePolymers0.000claimsdescription26

- 238000002347injectionMethods0.000claimsdescription25

- 239000007924injectionSubstances0.000claimsdescription25

- 239000000203mixtureSubstances0.000claimsdescription24

- GWEVSGVZZGPLCZ-UHFFFAOYSA-NTitan oxideChemical compoundO=[Ti]=OGWEVSGVZZGPLCZ-UHFFFAOYSA-N0.000claimsdescription22

- 229940126586small molecule drugDrugs0.000claimsdescription21

- XEKOWRVHYACXOJ-UHFFFAOYSA-NEthyl acetateChemical compoundCCOC(C)=OXEKOWRVHYACXOJ-UHFFFAOYSA-N0.000claimsdescription18

- 238000003756stirringMethods0.000claimsdescription18

- 108090000623proteins and genesProteins0.000claimsdescription17

- XOFYZVNMUHMLCC-ZPOLXVRWSA-NprednisoneChemical compoundO=C1C=C[C@]2(C)[C@H]3C(=O)C[C@](C)([C@@](CC4)(O)C(=O)CO)[C@@H]4[C@@H]3CCC2=C1XOFYZVNMUHMLCC-ZPOLXVRWSA-N0.000claimsdescription16

- 229960004618prednisoneDrugs0.000claimsdescription16

- 206010028980NeoplasmDiseases0.000claimsdescription15

- -1pibosufanChemical compound0.000claimsdescription15

- FOIXSVOLVBLSDH-UHFFFAOYSA-NSilver ionChemical compound[Ag+]FOIXSVOLVBLSDH-UHFFFAOYSA-N0.000claimsdescription14

- NOESYZHRGYRDHS-UHFFFAOYSA-NinsulinChemical compoundN1C(=O)C(NC(=O)C(CCC(N)=O)NC(=O)C(CCC(O)=O)NC(=O)C(C(C)C)NC(=O)C(NC(=O)CN)C(C)CC)CSSCC(C(NC(CO)C(=O)NC(CC(C)C)C(=O)NC(CC=2C=CC(O)=CC=2)C(=O)NC(CCC(N)=O)C(=O)NC(CC(C)C)C(=O)NC(CCC(O)=O)C(=O)NC(CC(N)=O)C(=O)NC(CC=2C=CC(O)=CC=2)C(=O)NC(CSSCC(NC(=O)C(C(C)C)NC(=O)C(CC(C)C)NC(=O)C(CC=2C=CC(O)=CC=2)NC(=O)C(CC(C)C)NC(=O)C(C)NC(=O)C(CCC(O)=O)NC(=O)C(C(C)C)NC(=O)C(CC(C)C)NC(=O)C(CC=2NC=NC=2)NC(=O)C(CO)NC(=O)CNC2=O)C(=O)NCC(=O)NC(CCC(O)=O)C(=O)NC(CCCNC(N)=N)C(=O)NCC(=O)NC(CC=3C=CC=CC=3)C(=O)NC(CC=3C=CC=CC=3)C(=O)NC(CC=3C=CC(O)=CC=3)C(=O)NC(C(C)O)C(=O)N3C(CCC3)C(=O)NC(CCCCN)C(=O)NC(C)C(O)=O)C(=O)NC(CC(N)=O)C(O)=O)=O)NC(=O)C(C(C)CC)NC(=O)C(CO)NC(=O)C(C(C)O)NC(=O)C1CSSCC2NC(=O)C(CC(C)C)NC(=O)C(NC(=O)C(CCC(N)=O)NC(=O)C(CC(N)=O)NC(=O)C(NC(=O)C(N)CC=1C=CC=CC=1)C(C)C)CC1=CN=CN1NOESYZHRGYRDHS-UHFFFAOYSA-N0.000claimsdescription14

- 102000004169proteins and genesHuman genes0.000claimsdescription14

- 239000004372Polyvinyl alcoholSubstances0.000claimsdescription13

- 229920002451polyvinyl alcoholPolymers0.000claimsdescription13

- 229920002307DextranPolymers0.000claimsdescription12

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000claimsdescription11

- 239000006228supernatantSubstances0.000claimsdescription11

- 239000004408titanium dioxideSubstances0.000claimsdescription11

- 238000012546transferMethods0.000claimsdescription11

- IMNFDUFMRHMDMM-UHFFFAOYSA-NN-HeptaneChemical compoundCCCCCCCIMNFDUFMRHMDMM-UHFFFAOYSA-N0.000claimsdescription10

- RVGRUAULSDPKGF-UHFFFAOYSA-NPoloxamerChemical compoundC1CO1.CC1CO1RVGRUAULSDPKGF-UHFFFAOYSA-N0.000claimsdescription10

- 229960000502poloxamerDrugs0.000claimsdescription10

- 229920001983poloxamerPolymers0.000claimsdescription10

- 239000004626polylactic acidSubstances0.000claimsdescription10

- 239000003102growth factorSubstances0.000claimsdescription9

- 201000011066hemangiomaDiseases0.000claimsdescription9

- 229920000136polysorbatePolymers0.000claimsdescription9

- HEDRZPFGACZZDS-UHFFFAOYSA-NChloroformChemical compoundClC(Cl)ClHEDRZPFGACZZDS-UHFFFAOYSA-N0.000claimsdescription8

- 102000004877InsulinHuman genes0.000claimsdescription7

- 108090001061InsulinProteins0.000claimsdescription7

- 229940125396insulinDrugs0.000claimsdescription7

- VTYYLEPIZMXCLO-UHFFFAOYSA-LCalcium carbonateChemical compound[Ca+2].[O-]C([O-])=OVTYYLEPIZMXCLO-UHFFFAOYSA-L0.000claimsdescription6

- CMSMOCZEIVJLDB-UHFFFAOYSA-NCyclophosphamideChemical compoundClCCN(CCCl)P1(=O)NCCCO1CMSMOCZEIVJLDB-UHFFFAOYSA-N0.000claimsdescription6

- 239000001856Ethyl celluloseSubstances0.000claimsdescription6

- NKANXQFJJICGDU-QPLCGJKRSA-NTamoxifenChemical compoundC=1C=CC=CC=1C(/CC)=C(C=1C=CC(OCCN(C)C)=CC=1)/C1=CC=CC=C1NKANXQFJJICGDU-QPLCGJKRSA-N0.000claimsdescription6

- RJURFGZVJUQBHK-UHFFFAOYSA-Nactinomycin DNatural productsCC1OC(=O)C(C(C)C)N(C)C(=O)CN(C)C(=O)C2CCCN2C(=O)C(C(C)C)NC(=O)C1NC(=O)C1=C(N)C(=O)C(C)=C2OC(C(C)=CC=C3C(=O)NC4C(=O)NC(C(N5CCCC5C(=O)N(C)CC(=O)N(C)C(C(C)C)C(=O)OC4C)=O)C(C)C)=C3N=C21RJURFGZVJUQBHK-UHFFFAOYSA-N0.000claimsdescription6

- 210000000988bone and boneAnatomy0.000claimsdescription6

- 229940044683chemotherapy drugDrugs0.000claimsdescription6

- 229960004397cyclophosphamideDrugs0.000claimsdescription6

- 235000019325ethyl celluloseNutrition0.000claimsdescription6

- 229920001249ethyl cellulosePolymers0.000claimsdescription6

- UQSXHKLRYXJYBZ-UHFFFAOYSA-Niron oxideInorganic materials[Fe]=OUQSXHKLRYXJYBZ-UHFFFAOYSA-N0.000claimsdescription6

- 229960005486vaccineDrugs0.000claimsdescription6

- PMATZTZNYRCHOR-CGLBZJNRSA-NCyclosporin AChemical compoundCC[C@@H]1NC(=O)[C@H]([C@H](O)[C@H](C)C\C=C\C)N(C)C(=O)[C@H](C(C)C)N(C)C(=O)[C@H](CC(C)C)N(C)C(=O)[C@H](CC(C)C)N(C)C(=O)[C@@H](C)NC(=O)[C@H](C)NC(=O)[C@H](CC(C)C)N(C)C(=O)[C@H](C(C)C)NC(=O)[C@H](CC(C)C)N(C)C(=O)CN(C)C1=OPMATZTZNYRCHOR-CGLBZJNRSA-N0.000claimsdescription5

- 108010036949CyclosporineProteins0.000claimsdescription5

- ZZSNKZQZMQGXPY-UHFFFAOYSA-NEthyl celluloseChemical compoundCCOCC1OC(OC)C(OCC)C(OCC)C1OC1C(O)C(O)C(OC)C(CO)O1ZZSNKZQZMQGXPY-UHFFFAOYSA-N0.000claimsdescription5

- 230000003115biocidal effectEffects0.000claimsdescription5

- TWNQGVIAIRXVLR-UHFFFAOYSA-Noxo(oxoalumanyloxy)alumaneChemical compoundO=[Al]O[Al]=OTWNQGVIAIRXVLR-UHFFFAOYSA-N0.000claimsdescription5

- 229950008882polysorbateDrugs0.000claimsdescription5

- 229920000036polyvinylpyrrolidonePolymers0.000claimsdescription5

- 239000001267polyvinylpyrrolidoneSubstances0.000claimsdescription5

- 235000013855polyvinylpyrrolidoneNutrition0.000claimsdescription5

- DLGOEMSEDOSKAD-UHFFFAOYSA-NCarmustineChemical compoundClCCNC(=O)N(N=O)CCClDLGOEMSEDOSKAD-UHFFFAOYSA-N0.000claimsdescription4

- 108010041308Endothelial Growth FactorsProteins0.000claimsdescription4

- 108050007372Fibroblast Growth FactorProteins0.000claimsdescription4

- 102000018233Fibroblast Growth FactorHuman genes0.000claimsdescription4

- 102000004457Granulocyte-Macrophage Colony-Stimulating FactorHuman genes0.000claimsdescription4

- 108010017213Granulocyte-Macrophage Colony-Stimulating FactorProteins0.000claimsdescription4

- 108010025020Nerve Growth FactorProteins0.000claimsdescription4

- 102000015336Nerve Growth FactorHuman genes0.000claimsdescription4

- 108010079337Tissue Polypeptide AntigenProteins0.000claimsdescription4

- 108010073929Vascular Endothelial Growth Factor AProteins0.000claimsdescription4

- 102000005789Vascular Endothelial Growth FactorsHuman genes0.000claimsdescription4

- 108010019530Vascular Endothelial Growth FactorsProteins0.000claimsdescription4

- HVYWMOMLDIMFJA-DPAQBDIFSA-NcholesterolChemical compoundC1C=C2C[C@@H](O)CC[C@]2(C)[C@@H]2[C@@H]1[C@@H]1CC[C@H]([C@H](C)CCCC(C)C)[C@@]1(C)CC2HVYWMOMLDIMFJA-DPAQBDIFSA-N0.000claimsdescription4

- 229940126864fibroblast growth factorDrugs0.000claimsdescription4

- 229940053128nerve growth factorDrugs0.000claimsdescription4

- 229920000747poly(lactic acid)Polymers0.000claimsdescription4

- STQGQHZAVUOBTE-UHFFFAOYSA-N7-Cyan-hept-2t-en-4,6-diinsaeureNatural productsC1=2C(O)=C3C(=O)C=4C(OC)=CC=CC=4C(=O)C3=C(O)C=2CC(O)(C(C)=O)CC1OC1CC(N)C(O)C(C)O1STQGQHZAVUOBTE-UHFFFAOYSA-N0.000claimsdescription3

- GSDSWSVVBLHKDQ-UHFFFAOYSA-N9-fluoro-3-methyl-10-(4-methylpiperazin-1-yl)-7-oxo-2,3-dihydro-7H-[1,4]oxazino[2,3,4-ij]quinoline-6-carboxylic acidChemical compoundFC1=CC(C(C(C(O)=O)=C2)=O)=C3N2C(C)COC3=C1N1CCN(C)CC1GSDSWSVVBLHKDQ-UHFFFAOYSA-N0.000claimsdescription3

- 108010006654BleomycinProteins0.000claimsdescription3

- KLWPJMFMVPTNCC-UHFFFAOYSA-NCamptothecinNatural productsCCC1(O)C(=O)OCC2=C1C=C3C4Nc5ccccc5C=C4CN3C2=OKLWPJMFMVPTNCC-UHFFFAOYSA-N0.000claimsdescription3

- 108010092160DactinomycinProteins0.000claimsdescription3

- 108010076282Factor IXProteins0.000claimsdescription3

- 108010054218Factor VIIIProteins0.000claimsdescription3

- 102000001690Factor VIIIHuman genes0.000claimsdescription3

- GHASVSINZRGABV-UHFFFAOYSA-NFluorouracilChemical compoundFC1=CNC(=O)NC1=OGHASVSINZRGABV-UHFFFAOYSA-N0.000claimsdescription3

- 101000746367Homo sapiens Granulocyte colony-stimulating factorProteins0.000claimsdescription3

- FBOZXECLQNJBKD-ZDUSSCGKSA-NL-methotrexateChemical compoundC=1N=C2N=C(N)N=C(N)C2=NC=1CN(C)C1=CC=C(C(=O)N[C@@H](CCC(O)=O)C(O)=O)C=C1FBOZXECLQNJBKD-ZDUSSCGKSA-N0.000claimsdescription3

- GSDSWSVVBLHKDQ-JTQLQIEISA-NLevofloxacinChemical compoundC([C@@H](N1C2=C(C(C(C(O)=O)=C1)=O)C=C1F)C)OC2=C1N1CCN(C)CC1GSDSWSVVBLHKDQ-JTQLQIEISA-N0.000claimsdescription3

- 229930192392MitomycinNatural products0.000claimsdescription3

- NWIBSHFKIJFRCO-WUDYKRTCSA-NMytomycinChemical compoundC1N2C(C(C(C)=C(N)C3=O)=O)=C3[C@@H](COC(N)=O)[C@@]2(OC)[C@@H]2[C@H]1N2NWIBSHFKIJFRCO-WUDYKRTCSA-N0.000claimsdescription3

- ZDZOTLJHXYCWBA-VCVYQWHSSA-NN-debenzoyl-N-(tert-butoxycarbonyl)-10-deacetyltaxolChemical compoundO([C@H]1[C@H]2[C@@](C([C@H](O)C3=C(C)[C@@H](OC(=O)[C@H](O)[C@@H](NC(=O)OC(C)(C)C)C=4C=CC=CC=4)C[C@]1(O)C3(C)C)=O)(C)[C@@H](O)C[C@H]1OC[C@]12OC(=O)C)C(=O)C1=CC=CC=C1ZDZOTLJHXYCWBA-VCVYQWHSSA-N0.000claimsdescription3

- 229930012538PaclitaxelNatural products0.000claimsdescription3

- 239000004793PolystyreneSubstances0.000claimsdescription3

- 108010009583Transforming Growth FactorsProteins0.000claimsdescription3

- 102000009618Transforming Growth FactorsHuman genes0.000claimsdescription3

- JXLYSJRDGCGARV-WWYNWVTFSA-NVinblastineNatural productsO=C(O[C@H]1[C@](O)(C(=O)OC)[C@@H]2N(C)c3c(cc(c(OC)c3)[C@]3(C(=O)OC)c4[nH]c5c(c4CCN4C[C@](O)(CC)C[C@H](C3)C4)cccc5)[C@@]32[C@H]2[C@@]1(CC)C=CCN2CC3)CJXLYSJRDGCGARV-WWYNWVTFSA-N0.000claimsdescription3

- RJURFGZVJUQBHK-IIXSONLDSA-Nactinomycin DChemical compoundC[C@H]1OC(=O)[C@H](C(C)C)N(C)C(=O)CN(C)C(=O)[C@@H]2CCCN2C(=O)[C@@H](C(C)C)NC(=O)[C@H]1NC(=O)C1=C(N)C(=O)C(C)=C2OC(C(C)=CC=C3C(=O)N[C@@H]4C(=O)N[C@@H](C(N5CCC[C@H]5C(=O)N(C)CC(=O)N(C)[C@@H](C(C)C)C(=O)O[C@@H]4C)=O)C(C)C)=C3N=C21RJURFGZVJUQBHK-IIXSONLDSA-N0.000claimsdescription3

- 230000000692anti-sense effectEffects0.000claimsdescription3

- VSRXQHXAPYXROS-UHFFFAOYSA-Nazanide;cyclobutane-1,1-dicarboxylic acid;platinum(2+)Chemical compound[NH2-].[NH2-].[Pt+2].OC(=O)C1(C(O)=O)CCC1VSRXQHXAPYXROS-UHFFFAOYSA-N0.000claimsdescription3

- 229960001561bleomycinDrugs0.000claimsdescription3

- OYVAGSVQBOHSSS-UAPAGMARSA-Obleomycin A2Chemical compoundN([C@H](C(=O)N[C@H](C)[C@@H](O)[C@H](C)C(=O)N[C@@H]([C@H](O)C)C(=O)NCCC=1SC=C(N=1)C=1SC=C(N=1)C(=O)NCCC[S+](C)C)[C@@H](O[C@H]1[C@H]([C@@H](O)[C@H](O)[C@H](CO)O1)O[C@@H]1[C@H]([C@@H](OC(N)=O)[C@H](O)[C@@H](CO)O1)O)C=1N=CNC=1)C(=O)C1=NC([C@H](CC(N)=O)NC[C@H](N)C(N)=O)=NC(N)=C1COYVAGSVQBOHSSS-UAPAGMARSA-O0.000claimsdescription3

- 229910000019calcium carbonateInorganic materials0.000claimsdescription3

- 239000001506calcium phosphateSubstances0.000claimsdescription3

- 229910000389calcium phosphateInorganic materials0.000claimsdescription3

- 235000011010calcium phosphatesNutrition0.000claimsdescription3

- VSJKWCGYPAHWDS-FQEVSTJZSA-NcamptothecinChemical compoundC1=CC=C2C=C(CN3C4=CC5=C(C3=O)COC(=O)[C@]5(O)CC)C4=NC2=C1VSJKWCGYPAHWDS-FQEVSTJZSA-N0.000claimsdescription3

- 229940127093camptothecinDrugs0.000claimsdescription3

- 229960004562carboplatinDrugs0.000claimsdescription3

- 229960005243carmustineDrugs0.000claimsdescription3

- 229960001265ciclosporinDrugs0.000claimsdescription3

- DQLATGHUWYMOKM-UHFFFAOYSA-LcisplatinChemical compoundN[Pt](N)(Cl)ClDQLATGHUWYMOKM-UHFFFAOYSA-L0.000claimsdescription3

- 229960004316cisplatinDrugs0.000claimsdescription3

- 229940105774coagulation factor ixDrugs0.000claimsdescription3

- 229940105778coagulation factor viiiDrugs0.000claimsdescription3

- 229930182912cyclosporinNatural products0.000claimsdescription3

- 229960000640dactinomycinDrugs0.000claimsdescription3

- STQGQHZAVUOBTE-VGBVRHCVSA-NdaunorubicinChemical compoundO([C@H]1C[C@@](O)(CC=2C(O)=C3C(=O)C=4C=CC=C(C=4C(=O)C3=C(O)C=21)OC)C(C)=O)[C@H]1C[C@H](N)[C@H](O)[C@H](C)O1STQGQHZAVUOBTE-VGBVRHCVSA-N0.000claimsdescription3

- 229960000975daunorubicinDrugs0.000claimsdescription3

- VSJKWCGYPAHWDS-UHFFFAOYSA-Ndl-camptothecinNatural productsC1=CC=C2C=C(CN3C4=CC5=C(C3=O)COC(=O)C5(O)CC)C4=NC2=C1VSJKWCGYPAHWDS-UHFFFAOYSA-N0.000claimsdescription3

- 229960003668docetaxelDrugs0.000claimsdescription3

- WHWZLSFABNNENI-UHFFFAOYSA-NepinastineChemical compoundC1C2=CC=CC=C2C2CN=C(N)N2C2=CC=CC=C21WHWZLSFABNNENI-UHFFFAOYSA-N0.000claimsdescription3

- 229960002548epinastine hydrochlorideDrugs0.000claimsdescription3

- VJJPUSNTGOMMGY-MRVIYFEKSA-NetoposideChemical compoundCOC1=C(O)C(OC)=CC([C@@H]2C3=CC=4OCOC=4C=C3[C@@H](O[C@H]3[C@@H]([C@@H](O)[C@@H]4O[C@H](C)OC[C@H]4O3)O)[C@@H]3[C@@H]2C(OC3)=O)=C1VJJPUSNTGOMMGY-MRVIYFEKSA-N0.000claimsdescription3

- 229960005420etoposideDrugs0.000claimsdescription3

- 229960002949fluorouracilDrugs0.000claimsdescription3

- 229960002074flutamideDrugs0.000claimsdescription3

- MKXKFYHWDHIYRV-UHFFFAOYSA-NflutamideChemical compoundCC(C)C(=O)NC1=CC=C([N+]([O-])=O)C(C(F)(F)F)=C1MKXKFYHWDHIYRV-UHFFFAOYSA-N0.000claimsdescription3

- 230000002068genetic effectEffects0.000claimsdescription3

- PCHJSUWPFVWCPO-UHFFFAOYSA-NgoldChemical compound[Au]PCHJSUWPFVWCPO-UHFFFAOYSA-N0.000claimsdescription3

- 239000010931goldSubstances0.000claimsdescription3

- 229910052737goldInorganic materials0.000claimsdescription3

- 229910017053inorganic saltInorganic materials0.000claimsdescription3

- 229960003376levofloxacinDrugs0.000claimsdescription3

- 239000002502liposomeSubstances0.000claimsdescription3

- ZLNQQNXFFQJAID-UHFFFAOYSA-Lmagnesium carbonateChemical compound[Mg+2].[O-]C([O-])=OZLNQQNXFFQJAID-UHFFFAOYSA-L0.000claimsdescription3

- 239000001095magnesium carbonateSubstances0.000claimsdescription3

- 229910000021magnesium carbonateInorganic materials0.000claimsdescription3

- VTHJTEIRLNZDEV-UHFFFAOYSA-Lmagnesium dihydroxideChemical compound[OH-].[OH-].[Mg+2]VTHJTEIRLNZDEV-UHFFFAOYSA-L0.000claimsdescription3

- 239000000347magnesium hydroxideSubstances0.000claimsdescription3

- 229910001862magnesium hydroxideInorganic materials0.000claimsdescription3

- 229960000485methotrexateDrugs0.000claimsdescription3

- 229960004857mitomycinDrugs0.000claimsdescription3

- 230000000921morphogenic effectEffects0.000claimsdescription3

- 108020004707nucleic acidsProteins0.000claimsdescription3

- 102000039446nucleic acidsHuman genes0.000claimsdescription3

- 150000007523nucleic acidsChemical class0.000claimsdescription3

- 239000002773nucleotideSubstances0.000claimsdescription3

- 125000003729nucleotide groupChemical group0.000claimsdescription3

- 229960001699ofloxacinDrugs0.000claimsdescription3

- 229960001592paclitaxelDrugs0.000claimsdescription3

- 229920002223polystyrenePolymers0.000claimsdescription3

- 150000003384small moleculesChemical class0.000claimsdescription3

- 239000000126substanceSubstances0.000claimsdescription3

- 229960001603tamoxifenDrugs0.000claimsdescription3

- RCINICONZNJXQF-MZXODVADSA-NtaxolChemical compoundO([C@@H]1[C@@]2(C[C@@H](C(C)=C(C2(C)C)[C@H](C([C@]2(C)[C@@H](O)C[C@H]3OC[C@]3([C@H]21)OC(C)=O)=O)OC(=O)C)OC(=O)[C@H](O)[C@@H](NC(=O)C=1C=CC=CC=1)C=1C=CC=CC=1)O)C(=O)C1=CC=CC=C1RCINICONZNJXQF-MZXODVADSA-N0.000claimsdescription3

- QORWJWZARLRLPR-UHFFFAOYSA-Htricalcium bis(phosphate)Chemical compound[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=OQORWJWZARLRLPR-UHFFFAOYSA-H0.000claimsdescription3

- VBEQCZHXXJYVRD-GACYYNSASA-NuroantheloneChemical compoundC([C@@H](C(=O)N[C@H](C(=O)N[C@@H](CS)C(=O)N[C@@H](CC(N)=O)C(=O)N[C@@H](CS)C(=O)N[C@H](C(=O)N[C@@H]([C@@H](C)CC)C(=O)NCC(=O)N[C@@H](CC=1C=CC(O)=CC=1)C(=O)N[C@@H](CO)C(=O)NCC(=O)N[C@@H](CC(O)=O)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CS)C(=O)N[C@@H](CCC(N)=O)C(=O)N[C@@H]([C@@H](C)O)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CC(O)=O)C(=O)N[C@@H](CC(C)C)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CC=1C2=CC=CC=C2NC=1)C(=O)N[C@@H](CC=1C2=CC=CC=C2NC=1)C(=O)N[C@@H](CCC(O)=O)C(=O)N[C@@H](CC(C)C)C(=O)N[C@@H](CCCNC(N)=N)C(O)=O)C(C)C)[C@@H](C)O)NC(=O)[C@H](CO)NC(=O)[C@H](CC(O)=O)NC(=O)[C@H](CC(C)C)NC(=O)[C@H](CO)NC(=O)[C@H](CCC(O)=O)NC(=O)[C@@H](NC(=O)[C@H](CC=1NC=NC=1)NC(=O)[C@H](CCSC)NC(=O)[C@H](CS)NC(=O)[C@@H](NC(=O)CNC(=O)CNC(=O)[C@H](CC(N)=O)NC(=O)[C@H](CC(C)C)NC(=O)[C@H](CS)NC(=O)[C@H](CC=1C=CC(O)=CC=1)NC(=O)CNC(=O)[C@H](CC(O)=O)NC(=O)[C@H](CC=1C=CC(O)=CC=1)NC(=O)[C@H](CO)NC(=O)[C@H](CO)NC(=O)[C@H]1N(CCC1)C(=O)[C@H](CS)NC(=O)CNC(=O)[C@H]1N(CCC1)C(=O)[C@H](CC=1C=CC(O)=CC=1)NC(=O)[C@H](CO)NC(=O)[C@@H](N)CC(N)=O)C(C)C)[C@@H](C)CC)C1=CC=C(O)C=C1VBEQCZHXXJYVRD-GACYYNSASA-N0.000claimsdescription3

- 229960003048vinblastineDrugs0.000claimsdescription3

- JXLYSJRDGCGARV-XQKSVPLYSA-NvincaleukoblastineChemical compoundC([C@@H](C[C@]1(C(=O)OC)C=2C(=CC3=C([C@]45[C@H]([C@@]([C@H](OC(C)=O)[C@]6(CC)C=CCN([C@H]56)CC4)(O)C(=O)OC)N3C)C=2)OC)C[C@@](C2)(O)CC)N2CCC2=C1NC1=CC=CC=C21JXLYSJRDGCGARV-XQKSVPLYSA-N0.000claimsdescription3

- OGWKCGZFUXNPDA-XQKSVPLYSA-NvincristineChemical compoundC([N@]1C[C@@H](C[C@]2(C(=O)OC)C=3C(=CC4=C([C@]56[C@H]([C@@]([C@H](OC(C)=O)[C@]7(CC)C=CCN([C@H]67)CC5)(O)C(=O)OC)N4C=O)C=3)OC)C[C@@](C1)(O)CC)CC1=C2NC2=CC=CC=C12OGWKCGZFUXNPDA-XQKSVPLYSA-N0.000claimsdescription3

- 229960004528vincristineDrugs0.000claimsdescription3

- OGWKCGZFUXNPDA-UHFFFAOYSA-NvincristineNatural productsC1C(CC)(O)CC(CC2(C(=O)OC)C=3C(=CC4=C(C56C(C(C(OC(C)=O)C7(CC)C=CCN(C67)CC5)(O)C(=O)OC)N4C=O)C=3)OC)CN1CCC1=C2NC2=CC=CC=C12OGWKCGZFUXNPDA-UHFFFAOYSA-N0.000claimsdescription3

- 238000005406washingMethods0.000claimsdescription3

- FVLVBPDQNARYJU-XAHDHGMMSA-NC[C@H]1CCC(CC1)NC(=O)N(CCCl)N=OChemical compoundC[C@H]1CCC(CC1)NC(=O)N(CCCl)N=OFVLVBPDQNARYJU-XAHDHGMMSA-N0.000claimsdescription2

- 101800003838Epidermal growth factorProteins0.000claimsdescription2

- 102400001368Epidermal growth factorHuman genes0.000claimsdescription2

- 229940009456adriamycinDrugs0.000claimsdescription2

- 235000012000cholesterolNutrition0.000claimsdescription2

- 229940116977epidermal growth factorDrugs0.000claimsdescription2

- 238000004108freeze dryingMethods0.000claimsdescription2

- 229960003440semustineDrugs0.000claimsdescription2

- 239000002246antineoplastic agentSubstances0.000claims2

- NDLPOXTZKUMGOV-UHFFFAOYSA-Noxo(oxoferriooxy)iron hydrateChemical compoundO.O=[Fe]O[Fe]=ONDLPOXTZKUMGOV-UHFFFAOYSA-N0.000claims2

- 102100022641Coagulation factor IXHuman genes0.000claims1

- 229920000954PolyglycolidePolymers0.000claims1

- 229960004667ethyl celluloseDrugs0.000claims1

- 239000004633polyglycolic acidSubstances0.000claims1

- 229910052814silicon oxideInorganic materials0.000claims1

- 238000000034methodMethods0.000abstractdescription75

- 238000005538encapsulationMethods0.000abstractdescription56

- 239000000463materialSubstances0.000abstractdescription52

- 230000002209hydrophobic effectEffects0.000abstractdescription34

- 206010061218InflammationDiseases0.000abstractdescription21

- 230000004054inflammatory processEffects0.000abstractdescription21

- 230000021164cell adhesionEffects0.000abstractdescription19

- 150000004965peroxy acidsChemical class0.000abstractdescription17

- 238000004945emulsificationMethods0.000abstractdescription8

- 238000013270controlled releaseMethods0.000abstractdescription5

- 238000005119centrifugationMethods0.000abstractdescription3

- 239000002861polymer materialSubstances0.000abstractdescription2

- 239000000243solutionSubstances0.000description39

- FAPWRFPIFSIZLT-UHFFFAOYSA-MSodium chlorideChemical compound[Na+].[Cl-]FAPWRFPIFSIZLT-UHFFFAOYSA-M0.000description30

- 108010017080Granulocyte Colony-Stimulating FactorProteins0.000description27

- 102000004269Granulocyte Colony-Stimulating FactorHuman genes0.000description27

- 239000002253acidSubstances0.000description24

- 238000000338in vitroMethods0.000description24

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical groupCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description23

- 239000000377silicon dioxideSubstances0.000description20

- 230000000694effectsEffects0.000description18

- 238000004364calculation methodMethods0.000description17

- 201000010099diseaseDiseases0.000description17

- 208000037265diseases, disorders, signs and symptomsDiseases0.000description17

- 230000000844anti-bacterial effectEffects0.000description16

- 235000002639sodium chlorideNutrition0.000description16

- 239000011780sodium chlorideSubstances0.000description15

- SPSXSWRZQFPVTJ-ZQQKUFEYSA-Nhepatitis b vaccineChemical compoundC([C@H](NC(=O)[C@H]([C@@H](C)O)NC(=O)[C@H]([C@@H](C)O)NC(=O)[C@H](CO)NC(=O)[C@H](CC(N)=O)NC(=O)[C@H](CC=1C2=CC=CC=C2NC=1)NC(=O)[C@H](CCC(N)=O)NC(=O)[C@@H](N)CCSC)C(=O)N[C@@H](CC1N=CN=C1)C(=O)N[C@@H](CCC(N)=O)C(=O)N[C@@H]([C@@H](C)O)C(=O)N[C@@H](CC(C)C)C(=O)N[C@@H](CCC(N)=O)C(=O)N[C@@H](CC(O)=O)C(=O)N1[C@@H](CCC1)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](C(C)C)C(=O)OC(=O)CNC(=O)CNC(=O)[C@H](C)NC(=O)[C@H]1N(CCC1)C(=O)[C@H](CC=1C=CC=CC=1)NC(=O)[C@H](CC=1C=CC(O)=CC=1)NC(=O)[C@H](CC(C)C)NC(=O)CNC(=O)[C@@H](N)CCCNC(N)=N)C1=CC=CC=C1SPSXSWRZQFPVTJ-ZQQKUFEYSA-N0.000description13

- 229940124736hepatitis-B vaccineDrugs0.000description13

- 238000011866long-term treatmentMethods0.000description13

- 235000018102proteinsNutrition0.000description12

- 230000001093anti-cancerEffects0.000description10

- 238000002474experimental methodMethods0.000description10

- 238000005297material degradation processMethods0.000description10

- 238000012360testing methodMethods0.000description10

- 230000003285pharmacodynamic effectEffects0.000description9

- 230000008569processEffects0.000description9

- WCUXLLCKKVVCTQ-UHFFFAOYSA-MPotassium chlorideChemical compound[Cl-].[K+]WCUXLLCKKVVCTQ-UHFFFAOYSA-M0.000description8

- 208000007502anemiaDiseases0.000description8

- 210000001519tissueAnatomy0.000description6

- 230000000699topical effectEffects0.000description6

- ZAMOUSCENKQFHK-UHFFFAOYSA-NChlorine atomChemical compound[Cl]ZAMOUSCENKQFHK-UHFFFAOYSA-N0.000description5

- PEDCQBHIVMGVHV-UHFFFAOYSA-NGlycerineChemical compoundOCC(O)COPEDCQBHIVMGVHV-UHFFFAOYSA-N0.000description5

- 239000000460chlorineSubstances0.000description5

- 229910052801chlorineInorganic materials0.000description5

- 230000009467reductionEffects0.000description5

- XBBVURRQGJPTHH-UHFFFAOYSA-N2-hydroxyacetic acid;2-hydroxypropanoic acidChemical compoundOCC(O)=O.CC(O)C(O)=OXBBVURRQGJPTHH-UHFFFAOYSA-N0.000description4

- 208000005189EmbolismDiseases0.000description4

- DHMQDGOQFOQNFH-UHFFFAOYSA-NGlycineChemical compoundNCC(O)=ODHMQDGOQFOQNFH-UHFFFAOYSA-N0.000description4

- 238000001727in vivoMethods0.000description4

- 239000012053oil suspensionSubstances0.000description4

- 239000001103potassium chlorideSubstances0.000description4

- 235000011164potassium chlorideNutrition0.000description4

- 230000002792vascularEffects0.000description4

- 206010016654FibrosisDiseases0.000description3

- 229920003171Poly (ethylene oxide)Polymers0.000description3

- 230000002708enhancing effectEffects0.000description3

- 230000004761fibrosisEffects0.000description3

- 230000005661hydrophobic surfaceEffects0.000description3

- 108091032973(ribonucleotides)n+mProteins0.000description2

- AOJJSUZBOXZQNB-VTZDEGQISA-N4'-epidoxorubicinChemical compoundO([C@H]1C[C@@](O)(CC=2C(O)=C3C(=O)C=4C=CC=C(C=4C(=O)C3=C(O)C=21)OC)C(=O)CO)[C@H]1C[C@H](N)[C@@H](O)[C@H](C)O1AOJJSUZBOXZQNB-VTZDEGQISA-N0.000description2

- 108091003079Bovine Serum AlbuminProteins0.000description2

- VEXZGXHMUGYJMC-UHFFFAOYSA-MChloride anionChemical compound[Cl-]VEXZGXHMUGYJMC-UHFFFAOYSA-M0.000description2

- 102000013831Coagulation factor IXHuman genes0.000description2

- 229930105110Cyclosporin ANatural products0.000description2

- FBPFZTCFMRRESA-FSIIMWSLSA-ND-GlucitolNatural productsOC[C@H](O)[C@H](O)[C@@H](O)[C@H](O)COFBPFZTCFMRRESA-FSIIMWSLSA-N0.000description2

- HTIJFSOGRVMCQR-UHFFFAOYSA-NEpirubicinNatural productsCOc1cccc2C(=O)c3c(O)c4CC(O)(CC(OC5CC(N)C(=O)C(C)O5)c4c(O)c3C(=O)c12)C(=O)COHTIJFSOGRVMCQR-UHFFFAOYSA-N0.000description2

- 239000004471GlycineSubstances0.000description2

- DGAQECJNVWCQMB-PUAWFVPOSA-MIlexoside XXIXChemical compoundC[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+]DGAQECJNVWCQMB-PUAWFVPOSA-M0.000description2

- XEEYBQQBJWHFJM-UHFFFAOYSA-NIronChemical compound[Fe]XEEYBQQBJWHFJM-UHFFFAOYSA-N0.000description2

- 241001465754MetazoaSpecies0.000description2

- 239000004698PolyethyleneSubstances0.000description2

- DNIAPMSPPWPWGF-UHFFFAOYSA-NPropylene glycolChemical compoundCC(O)CODNIAPMSPPWPWGF-UHFFFAOYSA-N0.000description2

- 208000001647Renal InsufficiencyDiseases0.000description2

- BQCADISMDOOEFD-UHFFFAOYSA-NSilverChemical compound[Ag]BQCADISMDOOEFD-UHFFFAOYSA-N0.000description2

- CDBYLPFSWZWCQE-UHFFFAOYSA-LSodium CarbonateChemical compound[Na+].[Na+].[O-]C([O-])=OCDBYLPFSWZWCQE-UHFFFAOYSA-L0.000description2

- 239000003242anti bacterial agentSubstances0.000description2

- 230000000840anti-viral effectEffects0.000description2

- 229940088710antibiotic agentDrugs0.000description2

- 229940098773bovine serum albuminDrugs0.000description2

- 208000001969capillary hemangiomaDiseases0.000description2

- 230000015556catabolic processEffects0.000description2

- 239000001913celluloseSubstances0.000description2

- 229920002678cellulosePolymers0.000description2

- 238000012512characterization methodMethods0.000description2

- 238000006731degradation reactionMethods0.000description2

- WBKFWQBXFREOFH-UHFFFAOYSA-Ndichloromethane;ethyl acetateChemical compoundClCCl.CCOC(C)=OWBKFWQBXFREOFH-UHFFFAOYSA-N0.000description2

- 239000006185dispersionSubstances0.000description2

- 239000002552dosage formSubstances0.000description2

- 229960001904epirubicinDrugs0.000description2

- 235000011187glycerolNutrition0.000description2

- 208000006454hepatitisDiseases0.000description2

- 231100000283hepatitisToxicity0.000description2

- 201000006370kidney failureDiseases0.000description2

- 201000002364leukopeniaDiseases0.000description2

- 231100001022leukopeniaToxicity0.000description2

- 230000007774longtermEffects0.000description2

- 239000003094microcapsuleSubstances0.000description2

- 238000001000micrographMethods0.000description2

- 229920000573polyethylenePolymers0.000description2

- FGIUAXJPYTZDNR-UHFFFAOYSA-Npotassium nitrateChemical compound[K+].[O-][N+]([O-])=OFGIUAXJPYTZDNR-UHFFFAOYSA-N0.000description2

- 239000000843powderSubstances0.000description2

- 235000012239silicon dioxideNutrition0.000description2

- 229910052709silverInorganic materials0.000description2

- 239000004332silverSubstances0.000description2

- 239000011734sodiumSubstances0.000description2

- 229910052708sodiumInorganic materials0.000description2

- 239000000600sorbitolSubstances0.000description2

- 235000010356sorbitolNutrition0.000description2

- 238000005507sprayingMethods0.000description2

- 239000010414supernatant solutionSubstances0.000description2

- 239000013589supplementSubstances0.000description2

- 238000013268sustained releaseMethods0.000description2

- 239000012730sustained-release formSubstances0.000description2

- 238000002604ultrasonographyMethods0.000description2

- HDTRYLNUVZCQOY-UHFFFAOYSA-Nα-D-glucopyranosyl-α-D-glucopyranosideNatural productsOC1C(O)C(O)C(CO)OC1OC1C(O)C(O)C(O)C(CO)O1HDTRYLNUVZCQOY-UHFFFAOYSA-N0.000description1

- 102000040650(ribonucleotides)n+mHuman genes0.000description1

- IXPNQXFRVYWDDI-UHFFFAOYSA-N1-methyl-2,4-dioxo-1,3-diazinane-5-carboximidamideChemical compoundCN1CC(C(N)=N)C(=O)NC1=OIXPNQXFRVYWDDI-UHFFFAOYSA-N0.000description1

- OWEGMIWEEQEYGQ-UHFFFAOYSA-N100676-05-9Natural productsOC1C(O)C(O)C(CO)OC1OCC1C(O)C(O)C(O)C(OC2C(OC(O)C(O)C2O)CO)O1OWEGMIWEEQEYGQ-UHFFFAOYSA-N0.000description1

- GUBGYTABKSRVRQ-XLOQQCSPSA-NAlpha-LactoseChemical compoundO[C@@H]1[C@@H](O)[C@@H](O)[C@@H](CO)O[C@H]1O[C@@H]1[C@@H](CO)O[C@H](O)[C@H](O)[C@H]1OGUBGYTABKSRVRQ-XLOQQCSPSA-N0.000description1

- 239000004475ArginineSubstances0.000description1

- 229920001661ChitosanPolymers0.000description1

- 229920000858CyclodextrinPolymers0.000description1

- FBPFZTCFMRRESA-KVTDHHQDSA-ND-MannitolChemical compoundOC[C@@H](O)[C@@H](O)[C@H](O)[C@H](O)COFBPFZTCFMRRESA-KVTDHHQDSA-N0.000description1

- FBPFZTCFMRRESA-JGWLITMVSA-ND-glucitolChemical compoundOC[C@H](O)[C@@H](O)[C@H](O)[C@H](O)COFBPFZTCFMRRESA-JGWLITMVSA-N0.000description1

- 206010013883DwarfismDiseases0.000description1

- 239000004386ErythritolSubstances0.000description1

- UNXHWFMMPAWVPI-UHFFFAOYSA-NErythritolNatural productsOCC(O)C(O)COUNXHWFMMPAWVPI-UHFFFAOYSA-N0.000description1

- IMROMDMJAWUWLK-UHFFFAOYSA-NEthenolChemical compoundOC=CIMROMDMJAWUWLK-UHFFFAOYSA-N0.000description1

- WQZGKKKJIJFFOK-GASJEMHNSA-NGlucoseNatural productsOC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1OWQZGKKKJIJFFOK-GASJEMHNSA-N0.000description1

- WHUUTDBJXJRKMK-UHFFFAOYSA-NGlutamic acidNatural productsOC(=O)C(N)CCC(O)=OWHUUTDBJXJRKMK-UHFFFAOYSA-N0.000description1

- XEUCQOBUZPQUMQ-UHFFFAOYSA-NGlycoloneChemical compoundCOC1=C(CC=C(C)C)C(=O)NC2=C1C=CC=C2OCXEUCQOBUZPQUMQ-UHFFFAOYSA-N0.000description1

- UWIULCYKVGIOPW-UHFFFAOYSA-NGlycoloneNatural productsCCOC1=C(CC=CC)C(=O)N(C)c2c(O)cccc12UWIULCYKVGIOPW-UHFFFAOYSA-N0.000description1

- ODKSFYDXXFIFQN-BYPYZUCNSA-PL-argininium(2+)Chemical compoundNC(=[NH2+])NCCC[C@H]([NH3+])C(O)=OODKSFYDXXFIFQN-BYPYZUCNSA-P0.000description1

- WHUUTDBJXJRKMK-VKHMYHEASA-NL-glutamic acidChemical compoundOC(=O)[C@@H](N)CCC(O)=OWHUUTDBJXJRKMK-VKHMYHEASA-N0.000description1

- HNDVDQJCIGZPNO-YFKPBYRVSA-NL-histidineChemical compoundOC(=O)[C@@H](N)CC1=CN=CN1HNDVDQJCIGZPNO-YFKPBYRVSA-N0.000description1

- KDXKERNSBIXSRK-YFKPBYRVSA-NL-lysineChemical compoundNCCCC[C@H](N)C(O)=OKDXKERNSBIXSRK-YFKPBYRVSA-N0.000description1

- GUBGYTABKSRVRQ-QKKXKWKRSA-NLactoseNatural productsOC[C@H]1O[C@@H](O[C@H]2[C@H](O)[C@@H](O)C(O)O[C@@H]2CO)[C@H](O)[C@@H](O)[C@H]1OGUBGYTABKSRVRQ-QKKXKWKRSA-N0.000description1

- KDXKERNSBIXSRK-UHFFFAOYSA-NLysineNatural productsNCCCCC(N)C(O)=OKDXKERNSBIXSRK-UHFFFAOYSA-N0.000description1

- 239000004472LysineSubstances0.000description1

- GUBGYTABKSRVRQ-PICCSMPSSA-NMaltoseNatural productsO[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@@H](CO)OC(O)[C@H](O)[C@H]1OGUBGYTABKSRVRQ-PICCSMPSSA-N0.000description1

- 229930195725MannitolNatural products0.000description1

- WHNWPMSKXPGLAX-UHFFFAOYSA-NN-Vinyl-2-pyrrolidoneChemical compoundC=CN1CCCC1=OWHNWPMSKXPGLAX-UHFFFAOYSA-N0.000description1

- 229920001007Nylon 4Polymers0.000description1

- DMGNFLJBACZMRM-UHFFFAOYSA-NO[P]Chemical compoundO[P]DMGNFLJBACZMRM-UHFFFAOYSA-N0.000description1

- 235000008331Pinus X rigitaedaNutrition0.000description1

- 235000011613Pinus brutiaNutrition0.000description1

- 241000018646Pinus brutiaSpecies0.000description1

- 229920002472StarchPolymers0.000description1

- 229930006000SucroseNatural products0.000description1

- CZMRCDWAGMRECN-UGDNZRGBSA-NSucroseChemical compoundO[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1CZMRCDWAGMRECN-UGDNZRGBSA-N0.000description1

- 102000004887Transforming Growth Factor betaHuman genes0.000description1

- 108090001012Transforming Growth Factor betaProteins0.000description1

- HDTRYLNUVZCQOY-WSWWMNSNSA-NTrehaloseNatural productsO[C@@H]1[C@@H](O)[C@@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1HDTRYLNUVZCQOY-WSWWMNSNSA-N0.000description1

- 241000700605VirusesSpecies0.000description1

- 239000002671adjuvantSubstances0.000description1

- 230000002776aggregationEffects0.000description1

- 238000004220aggregationMethods0.000description1

- 230000032683agingEffects0.000description1

- HDTRYLNUVZCQOY-LIZSDCNHSA-Nalpha,alpha-trehaloseChemical compoundO[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1HDTRYLNUVZCQOY-LIZSDCNHSA-N0.000description1

- 235000001014amino acidNutrition0.000description1

- ODKSFYDXXFIFQN-UHFFFAOYSA-NarginineNatural productsOC(=O)C(N)CCCNC(N)=NODKSFYDXXFIFQN-UHFFFAOYSA-N0.000description1

- 230000009286beneficial effectEffects0.000description1

- WQZGKKKJIJFFOK-VFUOTHLCSA-Nbeta-D-glucoseChemical compoundOC[C@H]1O[C@@H](O)[C@H](O)[C@@H](O)[C@@H]1OWQZGKKKJIJFFOK-VFUOTHLCSA-N0.000description1

- GUBGYTABKSRVRQ-QUYVBRFLSA-Nbeta-maltoseChemical compoundOC[C@H]1O[C@H](O[C@H]2[C@H](O)[C@@H](O)[C@H](O)O[C@@H]2CO)[C@H](O)[C@@H](O)[C@@H]1OGUBGYTABKSRVRQ-QUYVBRFLSA-N0.000description1

- 210000004204blood vesselAnatomy0.000description1

- 159000000007calcium saltsChemical class0.000description1

- 210000004027cellAnatomy0.000description1

- 230000008859changeEffects0.000description1

- 150000001875compoundsChemical class0.000description1

- 150000001879copperChemical class0.000description1

- 230000007547defectEffects0.000description1

- 230000007812deficiencyEffects0.000description1

- 150000002009diolsChemical class0.000description1

- 238000007876drug discoveryMethods0.000description1

- 230000000857drug effectEffects0.000description1

- 230000010102embolizationEffects0.000description1

- 230000001804emulsifying effectEffects0.000description1

- UNXHWFMMPAWVPI-ZXZARUISSA-NerythritolChemical compoundOC[C@H](O)[C@H](O)COUNXHWFMMPAWVPI-ZXZARUISSA-N0.000description1

- 235000019414erythritolNutrition0.000description1

- 229940009714erythritolDrugs0.000description1

- IDGUHHHQCWSQLU-UHFFFAOYSA-Nethanol;hydrateChemical compoundO.CCOIDGUHHHQCWSQLU-UHFFFAOYSA-N0.000description1

- 239000008103glucoseSubstances0.000description1

- 239000004220glutamic acidSubstances0.000description1

- 235000013922glutamic acidNutrition0.000description1

- 150000004676glycansChemical class0.000description1

- 229960005150glycerolDrugs0.000description1

- 239000008187granular materialSubstances0.000description1

- 208000002672hepatitis BDiseases0.000description1

- HNDVDQJCIGZPNO-UHFFFAOYSA-NhistidineNatural productsOC(=O)C(N)CC1=CN=CN1HNDVDQJCIGZPNO-UHFFFAOYSA-N0.000description1

- 238000011835investigationMethods0.000description1

- 229910052742ironInorganic materials0.000description1

- 239000008101lactoseSubstances0.000description1

- 230000003902lesionEffects0.000description1

- 229920002521macromoleculePolymers0.000description1

- 159000000003magnesium saltsChemical class0.000description1

- 239000000594mannitolSubstances0.000description1

- 235000010355mannitolNutrition0.000description1

- 229960001855mannitolDrugs0.000description1

- 230000007721medicinal effectEffects0.000description1

- 235000013336milkNutrition0.000description1

- 239000008267milkSubstances0.000description1

- 210000004080milkAnatomy0.000description1

- 150000002751molybdenumChemical class0.000description1

- 229940031182nanoparticles iron oxideDrugs0.000description1

- NUKCGLDCWQXYOQ-UHFFFAOYSA-NpiposulfanChemical compoundCS(=O)(=O)OCCC(=O)N1CCN(C(=O)CCOS(C)(=O)=O)CC1NUKCGLDCWQXYOQ-UHFFFAOYSA-N0.000description1

- 229950001100piposulfanDrugs0.000description1

- 229920001282polysaccharidePolymers0.000description1

- 239000005017polysaccharideSubstances0.000description1

- 239000004323potassium nitrateSubstances0.000description1

- 235000010333potassium nitrateNutrition0.000description1

- 229960005205prednisoloneDrugs0.000description1

- OIGNJSKKLXVSLS-VWUMJDOOSA-NprednisoloneChemical compoundO=C1C=C[C@]2(C)[C@H]3[C@@H](O)C[C@](C)([C@@](CC4)(O)C(=O)CO)[C@@H]4[C@@H]3CCC2=C1OIGNJSKKLXVSLS-VWUMJDOOSA-N0.000description1

- 230000002265preventionEffects0.000description1

- 230000001737promoting effectEffects0.000description1

- 229960004063propylene glycolDrugs0.000description1

- 239000002994raw materialSubstances0.000description1

- 230000001105regulatory effectEffects0.000description1

- 150000003839saltsChemical class0.000description1

- HFHDHCJBZVLPGP-UHFFFAOYSA-Nschardinger α-dextrinChemical compoundO1C(C(C2O)O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC(C(O)C2O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC2C(O)C(O)C1OC2COHFHDHCJBZVLPGP-UHFFFAOYSA-N0.000description1

- 239000000661sodium alginateSubstances0.000description1

- 235000010413sodium alginateNutrition0.000description1

- 229940005550sodium alginateDrugs0.000description1

- 229910000029sodium carbonateInorganic materials0.000description1

- 235000017550sodium carbonateNutrition0.000description1

- 239000002904solventSubstances0.000description1

- 229960002920sorbitolDrugs0.000description1

- 239000008107starchSubstances0.000description1

- 235000019698starchNutrition0.000description1

- 239000005720sucroseSubstances0.000description1

- 235000000346sugarNutrition0.000description1

- 150000008163sugarsChemical class0.000description1

- ZRKFYGHZFMAOKI-QMGMOQQFSA-NtgfbetaChemical compoundC([C@H](NC(=O)[C@H](C(C)C)NC(=O)CNC(=O)[C@H](CCC(O)=O)NC(=O)[C@H](CCCNC(N)=N)NC(=O)[C@H](CC(N)=O)NC(=O)[C@H](CC(C)C)NC(=O)[C@H]([C@@H](C)O)NC(=O)[C@H](CCC(O)=O)NC(=O)[C@H]([C@@H](C)O)NC(=O)[C@H](CC(C)C)NC(=O)CNC(=O)[C@H](C)NC(=O)[C@H](CO)NC(=O)[C@H](CCC(N)=O)NC(=O)[C@@H](NC(=O)[C@H](C)NC(=O)[C@H](C)NC(=O)[C@@H](NC(=O)[C@H](CC(C)C)NC(=O)[C@@H](N)CCSC)C(C)C)[C@@H](C)CC)C(=O)N[C@@H]([C@@H](C)O)C(=O)N[C@@H](C(C)C)C(=O)N[C@@H](CC=1C=CC=CC=1)C(=O)N[C@@H](C)C(=O)N1[C@@H](CCC1)C(=O)N[C@@H]([C@@H](C)O)C(=O)N[C@@H](CC(N)=O)C(=O)N[C@@H](CCC(O)=O)C(=O)N[C@@H](C)C(=O)N[C@@H](CC=1C=CC=CC=1)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](C)C(=O)N[C@@H](CC(C)C)C(=O)N1[C@@H](CCC1)C(=O)N1[C@@H](CCC1)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CCC(O)=O)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CO)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CC(C)C)C(=O)N[C@@H](CC(C)C)C(O)=O)C1=CC=C(O)C=C1ZRKFYGHZFMAOKI-QMGMOQQFSA-N0.000description1

- 230000001225therapeutic effectEffects0.000description1

- 231100000331toxicToxicity0.000description1

- 230000002588toxic effectEffects0.000description1

- 231100000419toxicityToxicity0.000description1

- 230000001988toxicityEffects0.000description1

- 230000009466transformationEffects0.000description1

- 229910052721tungstenInorganic materials0.000description1

- 238000002525ultrasonicationMethods0.000description1

- 229940124931vaccine adjuvantDrugs0.000description1

- 239000012646vaccine adjuvantSubstances0.000description1

- 230000004584weight gainEffects0.000description1

- 235000019786weight gainNutrition0.000description1

- 150000003751zincChemical class0.000description1

Images

Landscapes

- Medicinal Preparation (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及药物微球制剂,具体地说,是一种纳米颗粒混悬液包油-油包纳米药物(N/O/N)微球,属于制药技术领域。The invention relates to drug microsphere preparations, in particular to nanoparticle suspension oil-in-oil nano drug (N/O/N) microspheres, belonging to the technical field of pharmacy.

背景技术Background technique

制药行业从药物发现,到临床的应用,最后一个环节是药物制剂。其中有一部分药物需要长期给药才能治愈,还有一部分需要靶向等局部给药。要达到这些目的,原料药必须要制备成相应的剂型。例如需要长期给药但在体内的半衰期短的药物,宜制备成缓释或控释剂型;对于一些肿瘤的治疗,需要一些药物靶向于病灶,例如靶向于肿瘤血管的栓塞微球制剂等。In the pharmaceutical industry, from drug discovery to clinical application, the last link is drug preparation. Some of the drugs need long-term administration to be cured, and some of them need targeted and other local administration. To achieve these goals, raw materials must be prepared into corresponding dosage forms. For example, drugs that require long-term administration but have a short half-life in the body should be prepared as sustained-release or controlled-release dosage forms; for the treatment of some tumors, some drugs need to be targeted to the lesion, such as embolization microsphere preparations that target tumor blood vessels, etc. .

关于微球制剂的制备方法,Shi等 [Double walled POE/PLGA microspheres: encapsulation of water-soluble and water-insoluble proteins and their release properties,Journal of Controlled Release,89 (2003):167–177] 利用W/O/W方法把牛血清白蛋白(BSA)和环孢霉素A(CyA)包封在POE/PLGA壳-核微球里,该方法利用最常见的W/O/W复乳法来制备双层微球,而该复乳的油水界面是公认的蛋白杀手,容易导致水溶性的蛋白在该界面聚集,同样致使包封率不高,存在不完全释放和突释等缺陷。Morita等 [Protein encapsulation into biodegradable microspheres by a novel S/O/W emulsion method using poly(ethylene glycol) as a protein micronization adjuvant,Journal of Controlled Release,69 (2000):435-444] 用聚乙二醇(PEG)作为蛋白微粉化的赋形剂,即表面活性剂,然后用水包油-油包固体的方法把蛋白微囊包在生物可降解的微球里,该文献虽然利用新的S/O/W 乳化法制备载蛋白微球,但只是改变了表面活性剂,将以前报道较多的聚乙烯醇(PVA)改为聚乙二醇(PEG),这种改变仍不能克服包封率低,疏水性表面易引起局部微囊化及炎症的缺点。Regarding the preparation method of microsphere preparations, Shi et al. [Double walled POE/PLGA microspheres: encapsulation of water-soluble and water-insoluble proteins and their release properties, Journal of Controlled Release, 89 (2003): 167–177] using W/ The O/W method encapsulates bovine serum albumin (BSA) and cyclosporine A (CyA) in POE/PLGA shell-core microspheres, which is prepared by the most common W/O/W double emulsion method Double-layer microspheres, and the oil-water interface of the double emulsion is a recognized protein killer, which easily leads to the aggregation of water-soluble proteins at the interface, which also leads to low encapsulation efficiency, and defects such as incomplete release and burst release. [Protein encapsulation into biodegradable microspheres by a novel S/O/W emulsion method using poly(ethylene glycol) as a protein micronization adjuvant, Journal of Controlled Release, 69 (2000): 435-444] by Morita et al. PEG) is used as the excipient of protein micronization, that is, surfactant, and then protein microcapsules are encapsulated in biodegradable microspheres by the method of oil-in-water-solid-in-oil. Although this document uses the new S/O/ The W emulsification method prepared protein-loaded microspheres, but only changed the surfactant, and changed the previously reported polyvinyl alcohol (PVA) to polyethylene glycol (PEG). This change still cannot overcome the low encapsulation efficiency. The hydrophobic surface is prone to the disadvantages of local microencapsulation and inflammation.

用常规的S/O、S/O/W和S/O/O方法制备的微球,由于表面疏水,容易导致体内组织微囊化及炎症等副作用,且药物突释易造成药物本身的毒副作用。关于纳米颗粒混悬液包油-油包纳米药物(N/O/N)微球,目前还未见报道。Microspheres prepared by conventional S/O, S/O/W and S/O/O methods are likely to cause side effects such as microencapsulation of tissues in the body and inflammation due to the hydrophobic surface, and the sudden release of the drug is likely to cause the toxicity of the drug itself. side effect. There is no report about nanoparticle suspension oil-in-oil nanomedicine (N/O/N) microspheres.

发明内容Contents of the invention

本发明的目的是针对现有技术中的不足,提供一种纳米颗粒混悬液包油-油包纳米药物(N/O/N)微球,以解决现有技术中微球制剂包封率低,不完全释放和突释,疏水性表面会引起局部微囊化及炎症的缺点。The purpose of the present invention is to address the deficiencies in the prior art, to provide a nanoparticle suspension oil-in-oil nano-drug (N/O/N) microspheres to solve the encapsulation efficiency of microsphere preparations in the prior art Low, incomplete release and burst release, hydrophobic surface can cause disadvantages of local microencapsulation and inflammation.

为实现上述目的,本发明采取的技术方案是:For realizing above-mentioned object, the technical scheme that the present invention takes is:

一种纳米药物微球,所述微球的表面自组装有一层纳米颗粒,微球中药物的重量百分比为0.01%-40%,纳米颗粒的重量百分比为0.01%-96%,聚合物的重量百分比为3.65%-99.98%,药用辅料的重量百分比为0%-30%,微球的粒径为1-500 μm。A nanomedicine microsphere, the surface of the microsphere is self-assembled with a layer of nanoparticles, the weight percentage of the drug in the microsphere is 0.01%-40%, the weight percentage of the nanoparticle is 0.01%-96%, and the weight percentage of the polymer is The percentage is 3.65%-99.98%, the weight percentage of pharmaceutical excipients is 0%-30%, and the particle size of the microspheres is 1-500 μm.

所述的药物包括小分子药物和大分子药物,所述的小分子药物为化学药物,可选自肿瘤化疗类药物、治疗血管瘤的药物或抗生素类药物中的一种,所述的大分子药物为生物大分子药物,可选自蛋白大分子药物、疫苗、抗体、核酸或脂质体药物中的一种或几种,所述的药用辅料为注射用药用辅料,所述微球的粒径为10-100 μm。The drugs include small molecule drugs and macromolecular drugs, and the small molecule drugs are chemical drugs, which can be selected from tumor chemotherapy drugs, drugs for treating hemangioma or antibiotic drugs, and the macromolecule drugs The drug is a biological macromolecular drug, which can be selected from one or more of protein macromolecular drugs, vaccines, antibodies, nucleic acid or liposome drugs. The pharmaceutical excipients are injection drug excipients, and the microspheres The particle size is 10-100 μm.

所述的肿瘤化疗类药物选自阿霉素、环磷酰胺、更生霉素、博莱霉素、柔红霉素、表阿霉素、丝裂霉素、甲氨蝶呤、氟尿嘧啶、卡铂、卡莫司汀、司莫司汀、顺铂、依托泊苷、喜树碱及其衍生物、苯芥胆甾醇、紫杉醇及其衍生物、多西紫杉醇及其衍生物、长春碱、长春新碱、它莫西芬、哌泊舒凡、环磷酰胺或氟他胺及其衍生物中的一种,所述的治疗血管瘤的药物选自泼尼松、普萘洛尔或雷帕霉素中的一种,所述的抗生素类药物选自环孢素、左氧氟沙星、氧氟沙星或盐酸依匹斯汀中的一种。The tumor chemotherapy drugs are selected from doxorubicin, cyclophosphamide, dactinomycin, bleomycin, daunorubicin, epirubicin, mitomycin, methotrexate, fluorouracil, carboplatin , Carmustine, Semustine, Cisplatin, Etoposide, Camptothecin and Its Derivatives, Cholesterol, Paclitaxel and Its Derivatives, Docetaxel and Its Derivatives, Vinblastine, Vincristine Alkaline, tamoxifen, piposulfan, cyclophosphamide or flutamide and its derivatives, the drug for treating hemangioma is selected from prednisone, propranolol or rapamycin A kind of in antibiotics, described antibiotic drug is selected from the one in cyclosporine, levofloxacin, ofloxacin or epinastine hydrochloride.

所述的生物大分子药物选自促红细胞生成素、重组人粒细胞集落刺激因子、粒细胞-巨噬细胞集落刺激因子、疫苗、干扰素、生长激素、胰岛素、表皮生长因子、成纤维细胞生长因子、转化生长因子、胰岛素生长因子、血管内皮细胞生长因子、血小板生长因子、内皮生长因子、神经生长因子、骨衍生性生长因子、骨形成蛋白、组织多肽抗原、抗体、凝血因子VIII、凝血因子IX、遗传因子、反义核苷酸、小分子RNA或基因中的一种或几种。The biomacromolecular drug is selected from the group consisting of erythropoietin, recombinant human granulocyte colony-stimulating factor, granulocyte-macrophage colony-stimulating factor, vaccine, interferon, growth hormone, insulin, epidermal growth factor, fibroblast growth factor factor, transforming growth factor, insulin growth factor, vascular endothelial growth factor, platelet growth factor, endothelial growth factor, nerve growth factor, bone-derived growth factor, bone morphogenic protein, tissue polypeptide antigen, antibody, coagulation factor VIII, coagulation factor IX. One or more of genetic factors, antisense nucleotides, small molecule RNAs or genes.

所述的纳米颗粒为有机纳米颗粒或无机纳米颗粒,可选自聚苯乙烯纳米颗粒、交联葡聚糖纳米颗粒、二氧化硅纳米颗粒、二氧化钛纳米颗粒、羟基磷灰石纳米颗粒、四氧化三铁纳米颗粒、三氧化二铁颗粒、金纳米颗粒、三氧化二铝纳米颗粒、碳酸钙纳米颗粒、磷酸钙纳米颗粒、碳酸镁纳米颗粒、氢氧化镁纳米颗粒或银纳米颗粒中的一种或几种。The nanoparticles are organic nanoparticles or inorganic nanoparticles, which can be selected from polystyrene nanoparticles, cross-linked dextran nanoparticles, silica nanoparticles, titanium dioxide nanoparticles, hydroxyapatite nanoparticles, One of iron nanoparticles, iron oxide particles, gold nanoparticles, aluminum oxide nanoparticles, calcium carbonate nanoparticles, calcium phosphate nanoparticles, magnesium carbonate nanoparticles, magnesium hydroxide nanoparticles or silver nanoparticles or several.

所述的聚合物选自聚己内酯、聚乳酸、聚乳酸-羟基乙酸、聚乳酸-聚乙二醇、聚羟基乙酸-聚乳酸-聚乙二醇或聚己内酯-聚乙二醇中的一种或几种。The polymer is selected from polycaprolactone, polylactic acid, polylactic acid-glycolic acid, polylactic acid-polyethylene glycol, polyglycolic acid-polylactic acid-polyethylene glycol or polycaprolactone-polyethylene glycol one or more of them.

所述的微球采用以下步骤制备而成:The microspheres are prepared by the following steps:

(1)将药物和药用辅料制备成纳米药物,所述药物在纳米药物中的重量百分比为0.1%-90%,药用辅料在纳米药物中的重量百分比为0%-20 %;(1) Prepare the drug and pharmaceutical excipients into nano-medicines, the weight percentage of the drug in the nano-medicine is 0.1%-90%, and the weight percentage of the pharmaceutical excipients in the nano-medicine is 0%-20%;

(2)将步骤(1)制备的纳米药物按照1:1-1:10的重量比分散在重量百分比浓度为0.5%-80%聚合物的有机溶剂混合溶液中,形成均匀的混悬液,即油包纳米药物混悬液;(2) Dispersing the nanomedicine prepared in step (1) in a weight ratio of 1:1-1:10 in an organic solvent mixed solution with a weight percent concentration of 0.5%-80% polymer to form a uniform suspension, That is, nano-drug suspension in oil;

(3)将步骤(2)形成的油包纳米药物混悬液加入到含重量百分比为1%-80%纳米颗粒的水混悬液或含重量百分比为1%-80%纳米颗粒和重量百分比为0.5%-5%表面活性剂的水混悬液中,进行乳化,形成纳米颗粒混悬液包油-油包纳米药物复乳;(3) Adding the nano-drug suspension in oil formed in step (2) to an aqueous suspension containing 1%-80% by weight nanoparticles or 1%-80% by weight nanoparticles and a weight percent It is emulsified in an aqueous suspension of 0.5%-5% surfactant to form nanoparticle suspension oil-in-oil nano-drug re-emulsion;

(4)将所述纳米颗粒混悬液包油-油包纳米药物复乳转移到含重量百分比为1%-10%无机盐的水溶液中固化1-4小时;(4) Transferring the oil-in-oil-in-oil nano-drug double emulsion of the nanoparticle suspension to an aqueous solution containing 1%-10% by weight of inorganic salt and solidifying for 1-4 hours;

(5)将步骤(4)所得样品进行离心,收集微球,并洗涤所得微球,之后冻干,得到表面自组装有纳米颗粒且内部含有纳米药物的微球。(5) Centrifuge the sample obtained in step (4), collect the microspheres, wash the obtained microspheres, and then freeze-dry to obtain microspheres with nanoparticle self-assembled on the surface and nanomedicine inside.

步骤(1)中所述的纳米药物的制备包括以下步骤:The preparation of the nanomedicine described in step (1) includes the following steps:

将药物和药用辅料溶解在水中,然后加入多孔纳米颗粒,搅拌使得药物和药用辅料充分吸附在多孔纳米颗粒里,离心去除上清液,再充分洗涤,然后冻干形成纳米药物;或Dissolving the drug and pharmaceutical excipients in water, then adding porous nanoparticles, stirring to make the drug and pharmaceutical excipients fully adsorbed in the porous nanoparticles, centrifuging to remove the supernatant, then fully washing, and then freeze-drying to form nano-medicines; or

将药物和药用辅料溶解在水中形成药物水溶液,然后将药物水溶液转移到聚乙二醇水溶液中,充分混匀后于冰箱中预冻,之后冻干,再用二氯甲烷溶解聚乙二醇并离心除去聚乙二醇得到纳米药物。Dissolve the drug and pharmaceutical excipients in water to form an aqueous solution of the drug, then transfer the aqueous solution of the drug to an aqueous solution of polyethylene glycol, mix well, pre-freeze in the refrigerator, and then freeze-dry, then dissolve the polyethylene glycol with dichloromethane And centrifuged to remove polyethylene glycol to obtain nano-medicine.

步骤(2)中所述的有机溶剂混合溶液中还添加有重量百分比为0.1%-20%的聚乙二醇或泊洛沙姆,所述的聚合物重量百分比浓度为5%-30%,所述的有机溶剂选自二氯甲烷、乙酸乙酯、乙腈、庚烷、氯仿或丙酮中的一种或几种。0.1%-20% by weight of polyethylene glycol or poloxamer is also added to the organic solvent mixed solution described in step (2), and the weight percentage concentration of the polymer is 5%-30%, The organic solvent is selected from one or more of dichloromethane, ethyl acetate, acetonitrile, heptane, chloroform or acetone.

步骤(3)中所述的纳米颗粒重量百分比浓度为20%-70%,所述的表面活性剂选自聚乙烯醇、聚乙二醇、聚乙烯吡咯烷酮、泊洛沙姆、聚山梨醇、乙基纤维素或吐温中的一种或几种。The weight percentage concentration of nanoparticles described in step (3) is 20%-70%, and the surfactant is selected from polyvinyl alcohol, polyethylene glycol, polyvinylpyrrolidone, poloxamer, polysorbate, One or more of ethyl cellulose or Tween.

本发明的有益效果在于:The beneficial effects of the present invention are:

1、本发明选择了合适的聚合物材料和制备微球的方法,制备的微球包封率高达80%以上,并且这种表面自组装有一层纳米颗粒的微球具有增强细胞黏附的作用,以及减少局部过酸和疏水材料引起的炎症及微囊化的作用。1. The present invention selects a suitable polymer material and a method for preparing microspheres, and the encapsulation rate of the prepared microspheres is as high as 80%, and the microspheres with a layer of nanoparticles self-assembled on the surface have the effect of enhancing cell adhesion, As well as reducing inflammation and microencapsulation caused by topical peracids and hydrophobic materials.

2、采用本发明方法制备的微球,其粒径大小可以根据不同需要从1 μm到500 μm进行调控,且制备过程不污染环境。2. The particle size of the microspheres prepared by the method of the present invention can be regulated from 1 μm to 500 μm according to different needs, and the preparation process does not pollute the environment.

3、本发明方法制备的微球,大大降低了药物突释,药物几乎完全释放,可以达到零级释放,释放的纳米药物可以局部高效被病变细胞摄取,从而减少药物本身的毒副作用,同时可以使药物在整个制备过程和治疗过程中保持高活性即不失活。3. The microspheres prepared by the method of the present invention greatly reduce the drug burst release, the drug is almost completely released, and can achieve zero-order release. The released nano-medicine can be locally and efficiently taken up by diseased cells, thereby reducing the toxic and side effects of the drug itself, and at the same time can Keep the drug highly active, that is, not inactivated, during the entire preparation process and treatment process.

4、采用本发明方法制成的微球制剂,其微粒表面光滑圆整,颗粒规整无粘连,其冻干粉剂为白色细腻、疏松的粉体,不会塌陷、不粘连,再分散性良好,可以运用到各种药物缓释或控释微球的制备及疫苗的佐剂制备中。4. The microsphere preparation made by the method of the present invention has a smooth and round surface, regular particles without adhesion, and its freeze-dried powder is a white fine and loose powder, which does not collapse or adhere, and has good redispersibility. It can be applied to the preparation of slow-release or controlled-release microspheres of various drugs and the preparation of vaccine adjuvants.

附图说明Description of drawings

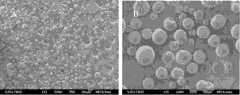

附图1是本发明实施例1制备所得微球的扫描电镜(SEM)照片。Figure 1 is a scanning electron microscope (SEM) photo of the microspheres prepared in Example 1 of the present invention.

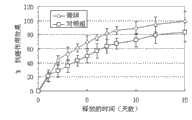

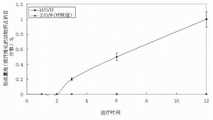

附图2是本发明实施例1制备所得微球的体外释放曲线。Accompanying

附图3是本发明实施例1制备所得微球的抗菌作用效果曲线。Accompanying

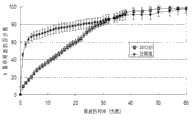

附图4是本发明实施例1制备所得微球的抗癌作用效果曲线。Accompanying

附图5是本发明实施例1制备所得微球与用S/O/W方法制备微球的体内组织相容性扫描电镜(SEM)照片。Figure 5 is a scanning electron microscope (SEM) photograph of the in vivo histocompatibility of the microspheres prepared in Example 1 of the present invention and the microspheres prepared by the S/O/W method.

附图6是本发明实施例3制备所得微球的扫描电镜(SEM)照片。Figure 6 is a scanning electron microscope (SEM) photo of the microspheres prepared in Example 3 of the present invention.

附图7是本发明实施例3制备所得微球的体外释放曲线。Accompanying drawing 7 is the in vitro release curve of the microspheres prepared in Example 3 of the present invention.

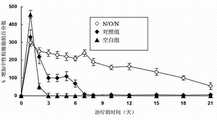

附图8是本发明实施例3制备所得微球的药效作用曲线。Accompanying

附图9是本发明实施例3制备所得微球与用S/O/W方法制备微球的体内组织相容性情况。Figure 9 shows the in vivo histocompatibility of the microspheres prepared in Example 3 of the present invention and the microspheres prepared by the S/O/W method.

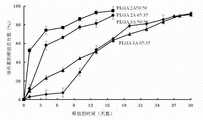

附图10是本发明实施例5制备所得微球的体外释放曲线。Accompanying

附图11是本发明实施例5制备所得微球的药效作用曲线。Accompanying drawing 11 is the pharmacodynamic action curve of the microspheres prepared in Example 5 of the present invention.

附图12是本发明实施例7制备所得微球的药效作用曲线。Accompanying

附图13是本发明实施例9制备所得微球的药效作用曲线。Accompanying drawing 13 is the pharmacodynamic action curve of the microspheres prepared in Example 9 of the present invention.

附图14是本发明实施例13制备所得微球的药效作用曲线。Accompanying drawing 14 is the pharmacodynamic action curve of the microspheres prepared in Example 13 of the present invention.

附图15是本发明实施例15制备所得微球的药效作用曲线。Accompanying

具体实施方式Detailed ways

下面结合具体实施例并参照附图对本发明作详细说明。The present invention will be described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

应该理解,这些实施例仅用于说明本发明,而不用于限定本发明的保护范围。在实际应用中本领域技术人员根据本发明做出的改进和调整,仍属于本发明的保护范围。It should be understood that these examples are only used to illustrate the present invention, not to limit the protection scope of the present invention. Improvements and adjustments made by those skilled in the art according to the present invention in practical applications still belong to the protection scope of the present invention.

一种纳米颗粒混悬液包油-油包纳米药物制备的微球,所述微球的粒径为1-500 μm,较佳地为10-100 μm,其表面组装有一层纳米颗粒;其中所述微球中,药物的重量百分比为0.01%-40%,纳米颗粒的重量百分比为0.01%-96%,聚合物的重量百分比为3.65%-99.98%,药用辅料的重量百分比为0%-30%。A microsphere prepared by oil-in-nanoparticle suspension-oil-in-nanomedicine, the particle size of the microsphere is 1-500 μm, preferably 10-100 μm, and a layer of nanoparticles is assembled on its surface; wherein In the microspheres, the weight percentage of the drug is 0.01%-40%, the weight percentage of the nanoparticles is 0.01%-96%, the weight percentage of the polymer is 3.65%-99.98%, and the weight percentage of the pharmaceutical excipient is 0% -30%.

需要说明的是,本发明技术方案中,所述的小分子药物为化学药物,可以是肿瘤化疗类药物、治疗血管瘤的药物或抗生素类药物中的一种,其中肿瘤化疗类药物选自阿霉素、环磷酰胺、更生霉素、博莱霉素、柔红霉素、表阿霉素、丝裂霉素、甲氨蝶呤、氟尿嘧啶、卡铂、卡莫司汀(BCNU)、司莫司汀、顺铂、依托泊苷、喜树碱及其衍生物、苯芥胆甾醇、紫杉醇及其衍生物、多西紫杉醇及其衍生物、长春碱、长春新碱、它莫西芬、哌泊舒凡、环磷酰胺或氟他胺及其衍生物等中的一种;治疗血管瘤的药物选自泼尼松、普萘洛尔或雷帕霉素等中的一种;抗生素类药物选自环孢素、左氧氟沙星、氧氟沙星或盐酸依匹斯汀等中的一种。It should be noted that, in the technical solution of the present invention, the small molecule drug is a chemical drug, which may be one of tumor chemotherapy drugs, hemangioma treatment drugs or antibiotic drugs, wherein the tumor chemotherapy drugs are selected from Cyclophosphamide, dactinomycin, bleomycin, daunorubicin, epirubicin, mitomycin, methotrexate, fluorouracil, carboplatin, carmustine (BCNU), Mustin, cisplatin, etoposide, camptothecin and its derivatives, phenesinate, paclitaxel and its derivatives, docetaxel and its derivatives, vinblastine, vincristine, tamoxifen, One of pibosufan, cyclophosphamide or flutamide and its derivatives; the drug for treating hemangioma is selected from one of prednisone, propranolol or rapamycin; antibiotics The drug is selected from one of cyclosporine, levofloxacin, ofloxacin or epinastine hydrochloride and the like.

所述的大分子药物为生物大分子药物,选自蛋白大分子药物、疫苗、抗体、核酸或脂质体药物中的一种或几种,具体指选自促红细胞生成素(EPO)、重组人粒细胞集落刺激因子(G-CSF)、粒细胞-巨噬细胞集落刺激因子(GM-CSF)、疫苗、干扰素(IFN)、生长激素(GH)、胰岛素(Insulin)、表皮生长因子(EGF)、成纤维细胞生长因子(FGF)、转化生长因子(TGF-β)、胰岛素生长因子(IGF)、血管内皮细胞生长因子(VEGF)、血小板生长因子(PDGF)、内皮生长因子(EGF)、神经生长因子(NGF)、骨衍生性生长因子(BDGF)、骨形成蛋白(BMP)、组织多肽抗原(TPA)、抗体(Antibody)、凝血因子VIII、凝血因子IX、遗传因子、反义核苷酸(anti-RNA)、小分子RNA或基因(DNA)等中的一种或几种。The macromolecular drug is a biomacromolecular drug, selected from one or more of protein macromolecular drugs, vaccines, antibodies, nucleic acid or liposome drugs, specifically selected from erythropoietin (EPO), recombinant Human granulocyte colony-stimulating factor (G-CSF), granulocyte-macrophage colony-stimulating factor (GM-CSF), vaccine, interferon (IFN), growth hormone (GH), insulin (Insulin), epidermal growth factor ( EGF), Fibroblast Growth Factor (FGF), Transforming Growth Factor (TGF-β), Insulin Growth Factor (IGF), Vascular Endothelial Growth Factor (VEGF), Platelet Growth Factor (PDGF), Endothelial Growth Factor (EGF) , nerve growth factor (NGF), bone-derived growth factor (BDGF), bone morphogenic protein (BMP), tissue polypeptide antigen (TPA), antibody (Antibody), coagulation factor VIII, coagulation factor IX, genetic factors, antisense nuclear One or more of nucleotide (anti-RNA), small molecule RNA or gene (DNA).

所述的药用辅料为注射用药用辅料,可以是小糖类(如蔗糖、海藻糖、葡萄糖、麦芽糖或乳糖等)、多羟基类化合物(如甘露醇、山梨醇、甘油、1,2-丙二醇、赤鲜糖醇、聚乙二醇、聚乙烯醇、聚环氧乙烷或聚吡咯烷酮等)、多糖类化合物(如葡聚糖、海藻酸钠、壳聚糖、淀粉、纤维素或环糊精等)、氨基酸化合物(如甘氨酸、赖氨酸、精氨酸、谷氨酸或组氨酸等)或无机盐类物质(如锌盐、钙盐、铜盐、镁盐或钼盐等)中的一种或任意组合。The pharmaceutical excipients are excipients for injection, which can be small sugars (such as sucrose, trehalose, glucose, maltose or lactose, etc.), polyhydroxy compounds (such as mannitol, sorbitol, glycerin, 1,2- Propylene glycol, erythritol, polyethylene glycol, polyvinyl alcohol, polyethylene oxide or polypyrrolidone, etc.), polysaccharides (such as dextran, sodium alginate, chitosan, starch, cellulose or Cyclodextrin, etc.), amino acid compounds (such as glycine, lysine, arginine, glutamic acid or histidine, etc.) or inorganic salts (such as zinc salts, calcium salts, copper salts, magnesium salts or molybdenum salts etc.), or any combination of them.

所述的聚合物选自聚己内酯(PCL)、聚乳酸(PLA)、聚乳酸-羟基乙酸(PLGA)、聚乳酸-聚乙二醇(PLA-PEG)、聚羟基乙酸-聚乳酸-聚乙二醇(PLGA-PEG)或聚己内酯-聚乙二醇(PCL-PEG)中的一种或几种。The polymer is selected from polycaprolactone (PCL), polylactic acid (PLA), polylactic acid-glycolic acid (PLGA), polylactic acid-polyethylene glycol (PLA-PEG), polyglycolic acid-polylactic acid- One or more of polyethylene glycol (PLGA-PEG) or polycaprolactone-polyethylene glycol (PCL-PEG).

制备微球的步骤(2)中,所述的聚合物有机溶剂混合溶液中还添加有重量百分比为0.1%-20%的聚乙二醇(PEG)或泊洛沙姆(Poloxamer)。In the step (2) of preparing the microspheres, polyethylene glycol (PEG) or poloxamer (Poloxamer) is added in a weight percentage of 0.1%-20% to the polymer-organic solvent mixed solution.

所述的有机溶剂选自二氯甲烷、乙酸乙酯、乙腈、庚烷、氯仿或丙酮中的一种或几种,其中以二氯甲烷、乙酸乙酯或乙腈中的一种或几种有机溶剂为佳。Described organic solvent is selected from one or more in methylene chloride, ethyl acetate, acetonitrile, heptane, chloroform or acetone, wherein with one or more organic solvents in methylene chloride, ethyl acetate or acetonitrile Solvents are preferred.

所述的纳米颗粒为有机纳米颗粒或无机纳米颗粒,具体指选自聚苯乙烯纳米颗粒、交联葡聚糖纳米颗粒、二氧化硅纳米颗粒、二氧化钛纳米颗粒、羟基磷灰石纳米颗粒、四氧化三铁纳米颗粒、三氧化二铁颗粒、金纳米颗粒、三氧化二铝纳米颗粒、碳酸钙纳米颗粒、磷酸钙纳米颗粒、碳酸镁纳米颗粒、氢氧化镁纳米颗粒或银纳米颗粒等中的一种或多种。The nanoparticles are organic nanoparticles or inorganic nanoparticles, specifically selected from polystyrene nanoparticles, cross-linked dextran nanoparticles, silicon dioxide nanoparticles, titanium dioxide nanoparticles, hydroxyapatite nanoparticles, four Iron oxide nanoparticles, iron oxide particles, gold nanoparticles, aluminum oxide nanoparticles, calcium carbonate nanoparticles, calcium phosphate nanoparticles, magnesium carbonate nanoparticles, magnesium hydroxide nanoparticles or silver nanoparticles, etc. one or more.

制备微球的步骤(3)中,所述的表面活性剂选自聚乙烯醇(PVA)、聚乙二醇(PEG)、聚乙烯吡咯烷酮(PVP)、泊洛沙姆(Poloxamer)、聚山梨醇、乙基纤维素(EC)或吐温中的一种或几种。In the step (3) of preparing microspheres, the surfactant is selected from polyvinyl alcohol (PVA), polyethylene glycol (PEG), polyvinylpyrrolidone (PVP), Poloxamer, polysorbate One or more of alcohol, ethyl cellulose (EC) or Tween.

制备微球的步骤(2)中,所述的分散方式可选择乳化、涡旋或超声等,分散时间优选为1-5分钟。In the step (2) of preparing microspheres, the dispersion method can be selected from emulsification, vortex or ultrasound, etc., and the dispersion time is preferably 1-5 minutes.

制备微球的步骤(3)中,所述的加入方式可选择滴加、一次性加入、喷雾方式加入或倒入等;所述的乳化方式可选择乳化、涡旋或超声等,乳化时间为0.1-5分钟。In the step (3) of preparing microspheres, the adding method can be selected dropwise, one-time adding, spraying or pouring, etc.; the emulsifying method can be selected from emulsification, vortex or ultrasonic, etc., and the emulsification time is 0.1-5 minutes.

制备微球的步骤(4)中,所述的无机盐可选自氯化钠、氯化钾、硝酸钾或碳酸钠等;所述的转移方式可为滴加、一次性加入、喷雾方式加入或倒入等。In the step (4) of preparing microspheres, the inorganic salt can be selected from sodium chloride, potassium chloride, potassium nitrate or sodium carbonate, etc.; the transfer method can be dropwise, one-time addition, or spraying or pour etc.

制备微球的步骤(5)中,洗涤时可采用水、乙醇或乙醇-水混合液洗涤3-5次。In the step (5) of preparing the microspheres, water, ethanol or ethanol-water mixture may be used for washing for 3-5 times.

实施例1 载有小分子药物阿霉素微球的制备(一)Example 1 Preparation of microspheres loaded with small molecule drug doxorubicin (1)

阿霉素具有抗菌作用和抗癌作用,载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球的制备,包括如下步骤:Doxorubicin has antibacterial and anticancer effects. The preparation of polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nano-medicine includes the following steps:

(1)取20 mg阿霉素溶解到0.5 ml的水中,然后和多孔二氧化硅纳米颗粒20 mg搅拌24小时,使得阿霉素充分吸附在多孔的二氧化硅纳米颗粒里,离心去除上清液,再充分洗涤3次,然后冻干形成阿霉素纳米药物;(1) Dissolve 20 mg of doxorubicin in 0.5 ml of water, then stir with 20 mg of porous silica nanoparticles for 24 hours, so that doxorubicin is fully adsorbed in the porous silica nanoparticles, and centrifuge to remove the supernatant solution, fully washed 3 times, and then freeze-dried to form adriamycin nano-medicine;

(2)把上述阿霉素纳米药物和浓度为20%(w/w)的PLGA的二氯甲烷溶液按照重量比1:9混合并超声5分钟形成均匀的混悬液,即油包阿霉素纳米药物(N/O)混悬液;(2) Mix the above-mentioned doxorubicin nanomedicine with 20% (w/w) PLGA in dichloromethane solution at a weight ratio of 1:9 and sonicate for 5 minutes to form a uniform suspension, that is, doxorubicin in oil Suspension of element nano drug (N/O);

(3)把步骤(2)所得油包阿霉素纳米药物(N/O)混悬液滴加到50 ml浓度为10%(w/w)的银纳米颗粒水混悬液中,搅拌5分钟形成纳米颗粒混悬液包油-油包阿霉素纳米药物(N/O/N)复乳;(3) Add the doxorubicin in oil nano drug (N/O) suspension obtained in step (2) dropwise to 50 ml of silver nanoparticle aqueous suspension with a concentration of 10% (w/w), and stir for 5 Form nanoparticle suspension oil-in-oil-in-oil doxorubicin nano-drug (N/O/N) double emulsion in minutes;

(4)把步骤(3)所得的纳米颗粒混悬液包油-油包阿霉素纳米药物(N/O/N)复乳滴加到1000 ml浓度为5%(w/w)的氯化钠水溶液中固化2小时;(4) Add the nanoparticle suspension oil-in-oil-in-oil doxorubicin nanodrug (N/O/N) double emulsion obtained in step (3) dropwise to 1000 ml of chlorine with a concentration of 5% (w/w). Solidified in sodium chloride aqueous solution for 2 hours;

(5)把步骤(4)所得样品进行离心,收集微球,并用水洗涤3次,冻干后得到载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球。(5) Centrifuge the sample obtained in step (4), collect the microspheres, wash with water three times, and freeze-dry to obtain polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nano-medicine.

本实施例所制得的微球中,药物的重量百分比为0.35%,纳米颗粒的重量百分比为96%,聚合物的重量百分比为3.65%,药用辅料的重量百分比为0%。In the microspheres prepared in this example, the weight percentage of the drug is 0.35%, the weight percentage of the nanoparticles is 96%, the weight percentage of the polymer is 3.65%, and the weight percentage of the pharmaceutical excipient is 0%.

对本实施例制备的载有阿霉素的聚乳酸-羟基乙酸(PLGA)微球进行形貌表征、释放曲线测试、抗菌测试、抗癌测试及在体内组织相容性测试,并将其抗菌性、抗癌性及组织相容性与用S/O/W方法(详见:李志平,李云富,张振亚,刘燕,曲燕燕,梅兴国,干扰素A-2b缓释微球的制备及影响因素考察,军事医学科学院院刊,2007,31(5):451-455)制备的微球进行对比,其中抗癌作用的测试条件为:一次给药,总剂量与对照组水溶液组每天一次的共15天的总剂量相同;组织相容性测试中,以微球注射部位出现纤维化的时间为标准计算时间。The polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin prepared in this example were subjected to morphology characterization, release curve test, antibacterial test, anticancer test and in vivo histocompatibility test, and their antibacterial properties , anticancer and histocompatibility and S/O/W method (see: Li Zhiping, Li Yunfu, Zhang Zhenya, Liu Yan, Qu Yanyan, Mei Xingguo, Preparation and influence of interferon A-2b sustained-release microspheres Factor investigation, Journal of the Academy of Military Medical Sciences, 2007, 31(5): 451-455) prepared microspheres were compared, wherein the test conditions for anticancer effect were: once-administered, the total dose was the same as that of the control group aqueous solution group once a day The total dose is the same for a total of 15 days; in the histocompatibility test, the time of fibrosis at the microsphere injection site is used as the standard calculation time.

图1是本实施例中载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球的扫描电镜(SEM)照片,其中,A为微球的扫描电镜图,B为微球的表面放大图,从图中可以看出,所制备的微球形态好,其表面自组装有一层银纳米颗粒,粒径在1-50 μm。图2是本实施例中载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球的体外释放曲线,从图中可以看出,所制备的微球几乎达到100%的药物释放率,突释非常小,几乎完全释放,基本可以达到零级释放,其体外释放性能符合要求。微球中阿霉素相对于其原始投加量的包封率为92.0%(计算方法为:实际包封在微球的药/投入的药量×100%=药物的包封率)。图3是本实施例中载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球的抗菌作用曲线,所制备微球的抗菌效果从图中看,其抗菌作用比对照组的好。图4是本实施例中载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球的抗癌作用曲线,所制备微球的抗癌作用效果比对照组的好,本实施例制备的微球约为100%,而对照组仅为80%。图5是本实施例中载有阿霉素纳米药物的聚乳酸-羟基乙酸(PLGA)微球的相容性扫描电镜(SEM)照片,可看出用S/O/W方法制备的微球(图5A)在治疗后的3-6个月出现纤维化组织;而本实施例用N/O/N方法制备的微球(图5B)在治疗一年后也没有纤维组织的出现,即注射部位的微囊化不出现,从而克服了微囊化的产生。Figure 1 is a scanning electron microscope (SEM) photo of polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nanomedicine in this example, where A is the scanning electron microscope image of the microsphere, and B is the surface of the microsphere Enlarged picture, it can be seen from the picture that the prepared microspheres have a good shape, and a layer of silver nanoparticles is self-assembled on the surface, with a particle size of 1-50 μm. Figure 2 is the in vitro release curve of polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nano-medicine in this example. It can be seen from the figure that the prepared microspheres almost reach 100% drug release rate , the burst release is very small, almost completely released, and can basically reach zero-order release, and its in vitro release performance meets the requirements. The encapsulation rate of doxorubicin in the microspheres relative to its original dosage is 92.0% (the calculation method is: the drug actually encapsulated in the microspheres / the amount of the drug input × 100% = the encapsulation rate of the drug). Figure 3 is the antibacterial effect curve of polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nano-medicine in this example, the antibacterial effect of the prepared microspheres can be seen from the figure, and its antibacterial effect is better than that of the control group . Figure 4 is the anti-cancer effect curve of polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nano-medicine in this example. The anti-cancer effect of the prepared microspheres is better than that of the control group. The microspheres are about 100%, while the control group is only 80%. Figure 5 is a compatibility scanning electron microscope (SEM) photo of polylactic-glycolic acid (PLGA) microspheres loaded with doxorubicin nanomedicine in this example, it can be seen that the microspheres prepared by the S/O/W method (Figure 5A) Fibrous tissue appeared 3-6 months after treatment; while the microspheres prepared by the N/O/N method in this example (Figure 5B) did not appear fibrous tissue after one year of treatment, that is Microencapsulation at the injection site does not occur, thereby overcoming the occurrence of microencapsulation.

以本实施例方法制备的小分子药物微球可以用于需要长期治疗的疾病,尤其是需要局部治疗的疾病如肿瘤的血管栓塞等。这种方法制备的微球包封率高,可以达到80%以上,且这种表面具有纳米颗粒的微球,由于表面亲水性材料的组织相容性比疏水性材料的好,具有增强细胞黏附、减少局部过酸和疏水材料引起的炎症及微囊化的作用。The small molecule drug microspheres prepared by the method of this example can be used for diseases requiring long-term treatment, especially for diseases requiring local treatment such as tumor vascular embolism. The encapsulation rate of the microspheres prepared by this method is high, which can reach more than 80%, and the microspheres with nanoparticles on the surface, because the histocompatibility of the surface hydrophilic material is better than that of the hydrophobic material, it has the ability to enhance cell Adhesion, reduction of inflammation caused by topical peracids and hydrophobic materials, and microencapsulation.

实施例2 载有小分子药物阿霉素微球的制备(二)Example 2 Preparation of microspheres loaded with small molecule drug doxorubicin (2)

载有阿霉素纳米药物的聚己内酯(PCL)微球的制备,包括如下步骤:The preparation of polycaprolactone (PCL) microspheres loaded with doxorubicin nanomedicine comprises the following steps:

(1)取20 mg阿霉素溶解到0.5 ml的水中,然后和多孔二氧化钛纳米颗粒20 mg搅拌24小时,使得阿霉素充分吸附在多孔的二氧化钛纳米颗粒里,离心去除上清液,再充分洗涤3次,然后冻干形成阿霉素纳米药物;(1) Dissolve 20 mg of doxorubicin in 0.5 ml of water, and then stir with 20 mg of porous titanium dioxide nanoparticles for 24 hours, so that the doxorubicin is fully adsorbed in the porous titanium dioxide nanoparticles, centrifuge to remove the supernatant, and then fully Washed 3 times, then freeze-dried to form doxorubicin nanomedicine;

(2)把上述阿霉素纳米药物和浓度为0.5%(w/w)的PCL的乙酸乙酯溶液按照重量比1:10混合并超声5分钟形成均匀的混悬液,即油包阿霉素纳米药物(N/O)混悬液;(2) Mix the above-mentioned doxorubicin nanomedicine with the ethyl acetate solution of PCL with a concentration of 0.5% (w/w) according to the weight ratio of 1:10 and ultrasonicate for 5 minutes to form a uniform suspension, that is, doxorubicin in oil Suspension of element nano drug (N/O);

(3)把步骤(2)所得油包阿霉素纳米药物(N/O)混悬液滴加到50 ml含10%(w/w)银纳米颗粒和1%(w/w)聚乙烯醇(PVA)表面活性剂的水混悬液中,搅拌5分钟形成纳米颗粒混悬液包油-油包阿霉素纳米药物(N/O/N)复乳;(3) Add the doxorubicin in oil nano-drug (N/O) suspension obtained in step (2) dropwise to 50 ml containing 10% (w/w) silver nanoparticles and 1% (w/w) polyethylene In the aqueous suspension of alcohol (PVA) surfactant, stir for 5 minutes to form nanoparticle suspension oil-in-oil-in-oil doxorubicin nano drug (N/O/N) double emulsion;

(4)把步骤(3)所得的纳米颗粒混悬液包油-油包阿霉素纳米药物(N/O/N)复乳滴加到1000 ml浓度为1%(w/w)的氯化钾水溶液中固化3小时;(4) Add the oil-in-oil-in-oil doxorubicin nano-drug (N/O/N) double emulsion of the nanoparticle suspension obtained in step (3) to 1000 ml of chlorine with a concentration of 1% (w/w) dropwise. Solidified in potassium chloride aqueous solution for 3 hours;

(5)把步骤(4)所得样品进行离心,收集微球,并用水洗涤3次,冻干后得到载有阿霉素纳米药物的聚己内酯(PCL)微球。(5) Centrifuge the sample obtained in step (4), collect the microspheres, wash with water three times, and freeze-dry to obtain polycaprolactone (PCL) microspheres loaded with doxorubicin nanomedicine.

本实施例所得的微球中,药物的重量百分比为0.47%,纳米颗粒的重量百分比为83%,聚合物的重量百分比为16.53%,药用辅料的重量百分比为0%。In the microspheres obtained in this example, the weight percentage of the drug is 0.47%, the weight percentage of the nanoparticles is 83%, the weight percentage of the polymer is 16.53%, and the weight percentage of the pharmaceutical excipient is 0%.

本实施例中载有阿霉素纳米药物的聚己内酯(PCL)微球形态好,其表面自组装有一层银纳米颗粒,粒径在10-100 μm。微球的药物体外释放率几乎达到100%,突释非常小,几乎完全释放,基本可以达到零级释放,其体外释放性能符合要求。微球中阿霉素相对于其原始投加量的包封率为93.5%(计算方法为:实际包封在微球的药/投入的药量×100%=药物的包封率)。所制备微球的抗菌、抗癌效果较好,另外,采用N/O/N方法制备的微球在治疗一年后也没有纤维组织的出现,即注射部位的微囊化不出现,从而克服了微囊化的产生。In this example, the polycaprolactone (PCL) microspheres loaded with doxorubicin nano-medicine have a good shape, and a layer of silver nanoparticles is self-assembled on the surface, with a particle size of 10-100 μm. The in vitro drug release rate of the microspheres is almost 100%, the burst release is very small, almost completely released, and can basically achieve zero-order release, and its in vitro release performance meets the requirements. The encapsulation rate of doxorubicin in the microspheres relative to its original dosage is 93.5% (the calculation method is: the drug actually encapsulated in the microspheres / the amount of the drug input × 100% = the encapsulation rate of the drug). The prepared microspheres have good antibacterial and anticancer effects. In addition, the microspheres prepared by the N/O/N method have no fibrous tissue after one year of treatment, that is, microencapsulation at the injection site does not appear, thereby overcoming generation of microencapsulation.

实施例3 载有大分子药物生长激素微球的制备(一)Example 3 Preparation of Microspheres Loaded with Macromolecular Drug Growth Hormone (1)